Page 1

Service Manual - Scrambler 1200

XC

Introduction

Introduction

This manual is designed primarily for use by trained technicians in a properly

equipped workshop. However, it contains enough detail and basic information to

make it us eful to the owner who desires to perform his own basic maintenance and

repair work. The work can only be carried out if the owner has the necessary hand

and special service tools to complete the job.

A basic knowledge of mechanics , including the proper use of tools and workshop

procedures is necess ary in order to carry out maintenance and repair work

satis factorily. Whenever the owner has ins ufficient experience or doubts regarding his

ability to do the work, an authoris ed Trium ph dealer mus t undertake all adjus tments,

maintenance, and repair work.

In order to perform the work efficiently and to avoid costly m istakes, read the text and

thoroughly familiarise yourself with procedures before starting work.

All work should be performed with great care and in a clean working area with

adequate lighting.

Always us e the correct special service tools or equipment specified. Under no

circum stances use makeshift tools or equipm ent since the use of subs titutes may

adversely affect safe operation.

Where accurate measurements are required, they can only be made using

calibrated, precis ion ins trum ents.

For the duration of the warranty period, an authorised Triumph dealer mus t perform

all repairs and scheduled maintenance.

To maximis e the life of your motorcycle:

Accurately follow the maintenance requirem ents of the periodic maintenance

chart in the Service Manual.

Do not allow problems to develop. Inves tigate unus ual nois es and changes in

the riding characteristics of the motorcycle. Rectify all problems as soon as

pos sible (im mediately if safety related).

Use only genuine Trium ph parts as lis ted in the electronic parts catalogue (EPC).

Follow the procedures in this manual carefully and completely. Do not take short

cuts.

Keep complete records of all maintenance and repairs with dates and any new

parts installed.

Service Manual - Scrambler 1200 XC 1 of 640

Page 2

Use only approved lubricants, as specified in the Owner's Handbook, in the

maintenance of the motorcycle.

How to use this manual

To as sis t in the us e of this manual, the section title is given at the top.

Each major section starts with a contents page, listing the inform ation contained in

the section.

The individual steps com pris ing repair operations are to be followed in the sequence

in which they appear.

Adjustment and repair operations include reference to service tool numbers and the

ass ociated illustration depicts the tool.

Where us age is not obvious , the tool is shown in us e.

Adjustment and repair operations als o include reference to wear limits, relevant data,

torque figures, specialis t information and useful assem bly details .

Warnings, Cautions and Note s

Particularly im portant information is presented in the following form:

WARNING

This warning symbol identifies special instructions or procedures which, if not

correctly followed, could result in pers onal injury, or loss of life.

CAUTION

This caution symbol identifies special instructions or procedures which, if not

strictly observed, could result in damage to or des truction of equipment.

Note

This note symbol indicates points of particular interest for more efficient and

convenient operation.

Tampering with Noise Control Syste m Prohibited

Owners are warned that the law may prohibit:

The removal or rendering inoperative by any person other than for purposes of

maintenance, repair or replacement, of any device or element of design

incorporated into any new vehicle for the purpos e of nois e control prior to its sale

or delivery to the ultimate purchaser or while it is in use; and

The use of the vehicle after such device or elem ent of design has been removed

or rendered inoperative by any pers on.

Service Manual - Scrambler 1200 XC 2 of 640

Page 3

Refe re nces

References to the left hand or right hand side given in this manual are made when

viewing the motorcycle from the rear.

Operations covered in this manual do not always include reference to testing the

motorcycle after repair. It is essential that work is ins pected and tested after

completion and, if necessary, a road test of the motorcycle is carried out particularly

where safety related items are concerned.

Dimensions

The dim ensions quoted are to des ign engineering specification with service limits

where applicable.

During the period of running-in from new, certain adjus tments may vary from the

specification figures given in this manual. These will be reset by the dealer at the 500

mile/800 km service, and thereafter should be maintained at the figures specified in

this manual.

Repairs and Replace ments

Before rem oval and disas sem bly, thoroughly clean the motorcycle. Any dirt entering

the engine or other parts will work as an abras ive and shorten the life of the

motorcycle. Particular attention should be paid when installing a new part, that any

dus t or metal filings are cleared from the immediate area.

Force

Com mon sens e should dictate how much force is necess ary in assembly and

dis ass embly. If a part seem s especially difficult to remove or install, stop and

exam ine what may be causing the problem . Never lever a com ponent as this will

caus e damage both to the component itself and to the surface being levered against.

Whenever tapping to aid removal of an item is necess ary, tap lightly using a hide or

plastic faced mallet.

Edge s

Watch for sharp edges , es pecially during engine disassem bly and assembly. Protect

the hands with industrial quality gloves.

When replacement parts are required, it is es sential that only genuine Triumph parts

are us ed.

Safety features and corrosion prevention treatments em bodied in the motorcycle may

be im paired if parts other than genuine Trium ph parts are fitted. In certain territories ,

legis lation prohibits the fitting of parts not to the manufacturer's specification.

Tightening procedure

Service Manual - Scrambler 1200 XC 3 of 640

Page 4

Generally, when ins talling a part with several bolts, nuts or screws, they should all be

started in their holes and tightened to a snug fit, evenly and in a cros s pattern. This is

to avoid distortion of the part and/or gas or oil leakage. Conversely, bolts, nuts, or

screws, should all be loosened (in sequence if specified) by about a quarter of a turn

and then rem oved.

Where there is a tightening sequence specified in this Service Manual, the bolts,

nuts, or screws must be tightened in the order and by the method indicated.

Torque wrench setting figures given in this manual must be observed. The torque

tools used must be of accurate calibration.

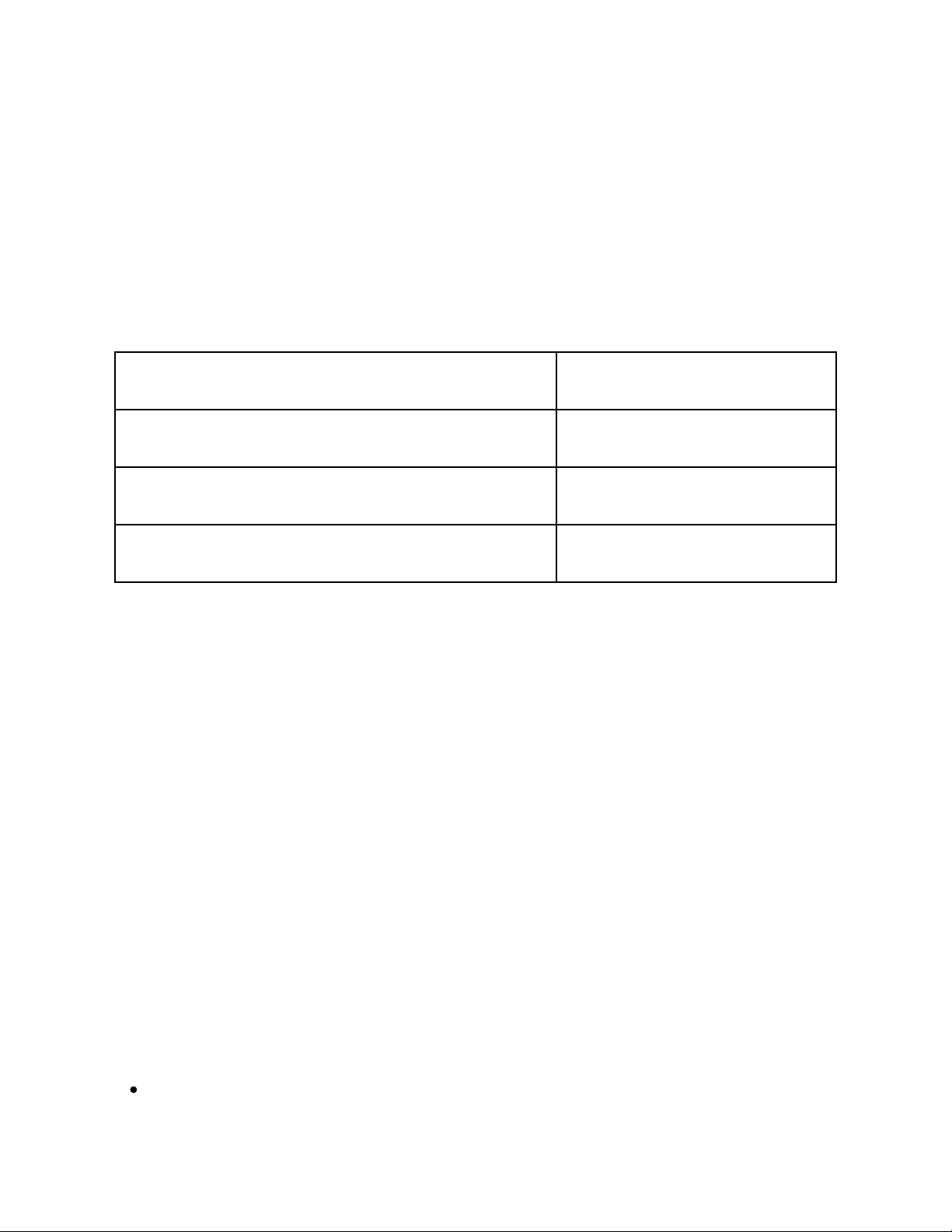

Torque Tolerance

Torque

Tolerance

0 Nm to 25 Nm

+/- 10%

26 Nm to 100 Nm

+ 10% -0%

101 Nm to 200 Nm

+10% -0%

Locking devices, where specified, must be fitted. If the efficiency of a locking device is

impaired during removal it must be renewed. This applies particularly to micro-

encaps ulated fixings which must always be replaced if disturbed. Where neces s ary,

the text in this manual will indicate where such a fixing is us ed.

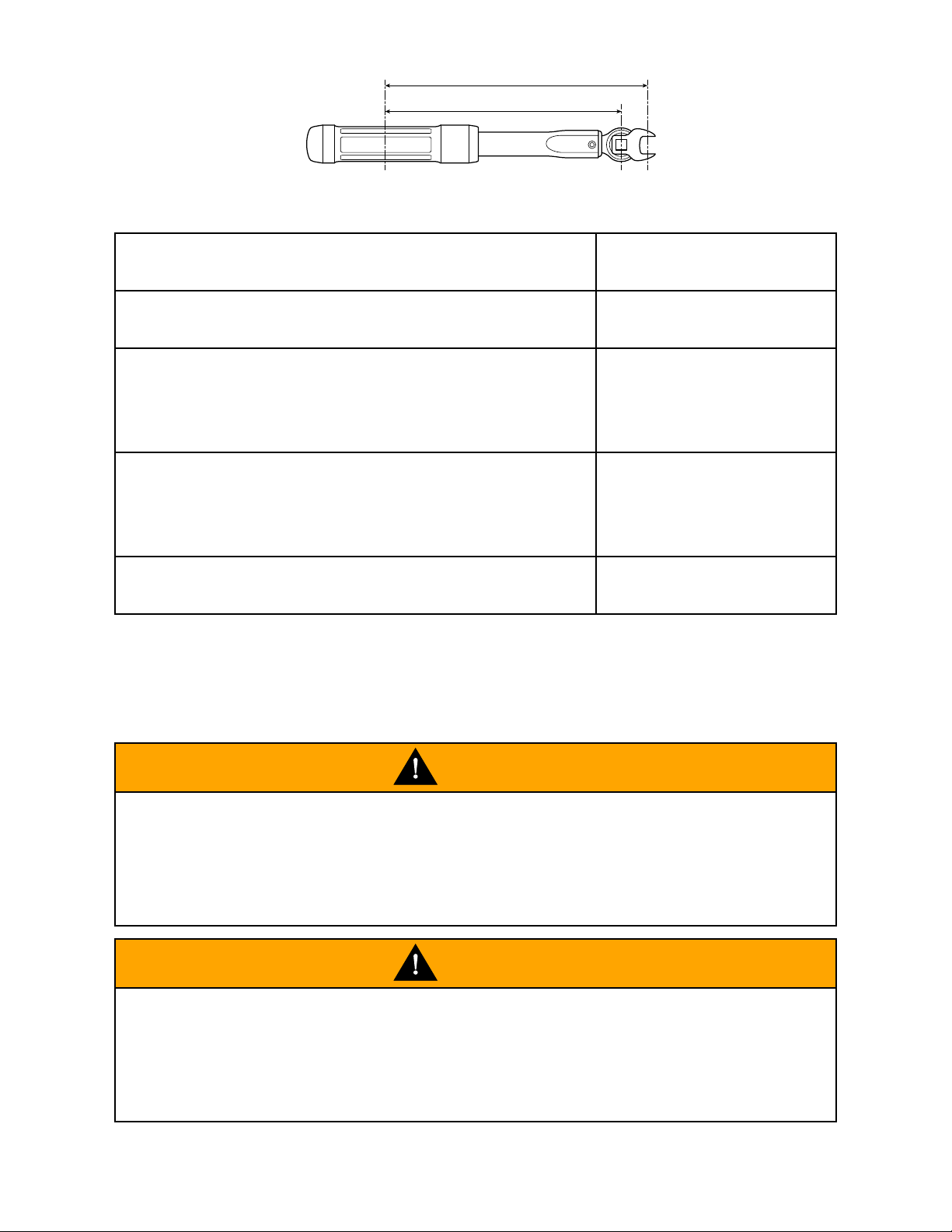

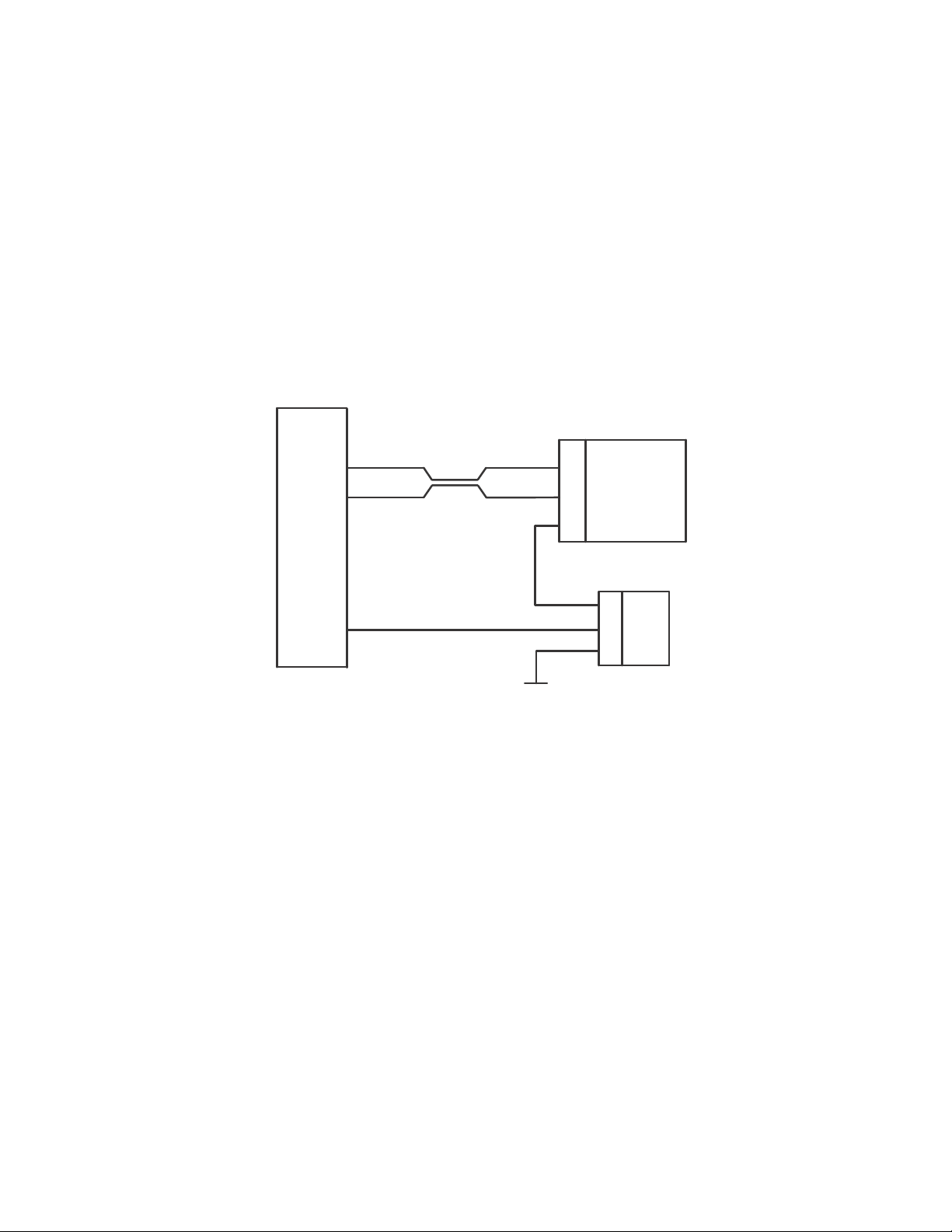

Use of Crow Foot Spanner Adapters with Torque Wrenches

The use of a crow foot spanner adapter will effectively lengthen the lever arm of a

torque wrench. The amount of torque applied to a fas tener is increas ed as the torque

wrench lever arm is extended, therefore the torque wrench setting must be adjus ted

in order to achieve the correct tightening torque.

Before tightening a fixing using a crow foot spanner adapter, measure the normal

length of the torque wrench from the centre of the drive square to the centre of the

handle (dim ens ion L1). Fit the crow foot spanner adapter to the torque wrench as

shown below. Meas ure the extended length of the torque wrench from the centre of

the crow foot spanner head to the centre of the handle (dimens ion L2).

Use the following formula to calculate the correct torque wrench setting to achieve the

required tightening torque.

Note

The example shown below is calculated using a crow foot spanner measuring

25 mm from the centre of the spanner head to the centre of the drive square.

Service Manual - Scrambler 1200 XC 4 of 640

Page 5

ciyj

L2

L1

M1 = M2 x L1 / L2

Example

M2 is the required tightening torque to be applied

90 Nm

L1 is the normal length of the torque wrench,

measured from the centre of the drive square to the

centre of the handle

300 mm

L2 is the extended length of the torque wrench,

measured from the centre of the crow foot spanner

head to the centre of the handle

325 mm

M1 is the calculated torque wrench setting

83 Nm

General Information

Ignition System Safety Precautions

WARNING

The ignition sys tem produces extrem ely high voltages . Do not touch any part of the

ignition sys tem or any cables while the engine is running.

An electric shock caus ed by contact with the ignition system may lead to illness,

injury or death.

WARNING

Wearers of surgically implanted heart pacemaker devices should not be in close

proximity to ignition circuits and or diagnos tic equipment.

The ignition sys tem and any diagnostic equipm ent may interrupt the normal

operation of such devices causing illnes s or death.

Dangerous Substance s

Service Manual - Scrambler 1200 XC 5 of 640

Page 6

WARNING

Many liquids and other substances used in motor vehicles are poisonous and

should under no circumstances be consum ed and should, as far as pos sible, be

kept from contact with the skin. Thes e subs tances am ong others include acid,

antifreeze, asbestos, brake fluid, fuel, lubricants, and various adhesives. Always

pay close attention to the instructions printed on labels and obey the instructions

contained within. These instructions are included for your safety and well-being.

NEVER DISREGARD THESE INSTRUCTIONS!

Third Party Products

WARNING

Many proprietary products, such as chemicals, solvents and cleaning agents, will

caus e damage to components if used incorrectly or inappropriately. Always follow

the manufacturer’s ins tructions printed on the product container’s labels and obey

the ins tructions given. Thes e instructions are included for your safety and well-

being.

Dam age to the motorcycle components caus ed by the incorrect or inappropriate

use of chemicals, solvents and cleaning agents may reduce the components

efficiency, resulting in los s of motorcycle control and an accident.

Fluoroe lastomers

WARNING

Fluoroelastomer material is us ed in the manufacture of various seals in Triumph

motorcycles.

In fire conditions involving temperatures greater than 315°C this material will

decompose and can then be potentially hazardous. Highly toxic and corrosive

decomposition products, including hydrogen fluoride, carbonyl fluoride, fluorinated

olefins and carbon monoxide can be generated and will be present in fumes from

fires.

In the presence of any water or humidity, hydrogen fluoride may dis solve to form

extremely corrosive liquid hydrofluoric acid.

If such conditions exist, do not touch the material and avoid all skin contact. Skin

contact with liquid or decomposition res idues can cause painful and penetrating

burns leading to perm anent, irreversible skin and tis s ue damage.

Oils

Service Manual - Scrambler 1200 XC 6 of 640

Page 7

WARNING

The engine oil may be hot to the touch. Contact with hot oil may caus e the skin to

be scalded or burned.

WARNING

Prolonged or repeated contact with engine oil can lead to skin dryness , irritation

and derm atitis. In addition, used engine oil contains potentially harmful

contam inants which can cause cancer. Wear suitable clothing and avoid skin

contact.

Health Prote ction Precautions

Avoid prolonged and repeated contact with oils , particularly used engine oils.

Wear protective clothing, including impervious gloves where practicable.

Do not put oily rags in pockets.

Overalls must be cleaned regularly. Dis card heavily soiled clothing and oil

impregnated footwear.

First aid treatment should be obtained im mediately for open cuts and wounds .

Always be aware of who your nearest First Aider is and where the medical

facilities are kept.

Use barrier creams , applying before each work period to protect the skin from the

effects of oil and greas e and to aid removal of the same after completing work.

Wash with soap and water to ensure all oil is rem oved (skin cleansers and nail

brus hes will help). Preparations containing lanolin replace the natural skin oils

which have been removed.

Do not use petrol, kerosene, dies el fuel, gas oil, thinners or solvents for cleaning

skin.

If skin disorders develop, obtain medical advice without delay.

Where practicable, degrease components prior to handling.

WARNING

Any ris k of eye injury mus t be avoided. Always wear eye protection when using a

ham mer, air line, cleaning agent or where there is ANY ris k of flying debris or

chem ical splashing.

Environmental Protection Precautions

Service Manual - Scrambler 1200 XC 7 of 640

Page 8

CAUTION

Do not pour oil on the ground, down sewers or drains, or into water courses . To

prevent pollution of water cours es etc., dis pose of us ed oil sensibly. If in doubt

contact your local authority.

Burning of used engine oil in small space heaters or boilers can be recommended

only for units of approved des ign. If in doubt, check with the appropriate local authority

and/or manufacturer of the approved appliance.

Dispos e of used oil and used filters through authorised waste dis pos al contractors,

to licensed waste disposal sites, or to the was te oil reclam ation trade. If in doubt,

contact your local authority for advice on disposal facilities.

Brakes

WARNING

Brake fluid is hygroscopic which means it will absorb mois ture from the air. Any

abs orbed moisture will greatly reduce the boiling point of the brake fluid causing a

reduction in braking efficiency.

Replace brake fluid in line with the routine maintenance schedule. A dangerous

riding condition could result if this important maintenance item is neglected!

Do not spill brake fluid onto any area of the bodywork as this will dam age any

painted or plas tic surface.

Always us e new brake fluid from a sealed container and never use fluid from an

uns ealed container or from one that has been previous ly opened.

Do not mix different brands of fluid. Check for fluid leakage around brake fittings,

seals and joints.

Check regularly for brake hos e damage.

FAILURE TO OBSERVE ANY OF THE ABOVE WARNINGS MAY REDUCE BRAKING

EFFICIENCY LEADING TO AN ACCIDENT.

WARNING

If there has been an appreciable drop in the level of the fluid in either brake fluid

reservoir, consult your authorised Triumph dealer for advice before riding.

If the brake lever or pedal feels soft when it is applied, or if the lever/pedal travel

becomes excessive, there may be air in the brake lines or the brake may be

defective.

It is dangerous to operate the motorcycle under such conditions and rem edial

action must be taken by your authorised Trium ph dealer before riding the

Service Manual - Scrambler 1200 XC 8 of 640

Page 9

WARNING

motorcycle.

Failure to take remedial action may reduce braking efficiency leading to an

accident.

WARNING

Use only DOT 4 specification brake fluid as listed in the General Information

section of this manual. The use of brake fluids other than those DOT 4 fluids listed

in the General Information section may reduce the efficiency of the braking sys tem

leading to an accident.

Failure to change the brake fluid at the interval specified in the routine

maintenance schedule may reduce braking efficiency resulting in an accident.

WARNING

Never use mineral-based greas e in any part of the braking system or in any area

where contact with the braking system is possible. Mineral-based grease will

dam age the hydraulic seals in the calipers and master cylinders.

Dam age caus ed by contact with mineral-based grease may reduce braking

efficiency resulting in an accident.

WARNING

Before installation, all internal brake components should be cleaned and

lubricated with clean new DOT 4 brake fluid.

Never use solvents, petrol (gasoline), engine oil or any other petroleum distillate

on internal brake components as this will caus e deterioration of the hydraulic

seals in the calipers and master cylinders.

A dangerous riding condition leading to loss of motorcycle control and an accident

could res ult if this warning is ignored.

Safety Instructions

Jacking and Lifting

WARNING

Always ensure that any lifting apparatus has adequate load and safety capacity for

Service Manual - Scrambler 1200 XC 9 of 640

Page 10

WARNING

the weight to be lifted. Ensure the motorcycle is well supported to prevent any

pos sibility of the machine falling prior to lifting or jacking or while repairs and

servicing are carried out.

Never rely on a single means of support when working with the motorcycle. Use

additional safety supports and straps to prevent toppling.

Do not leave tools, lifting equipment, s pilled oil, etc. in a place where they could

become a hazard to health. Always work in a clean, tidy area and put all tools away

when the work is finished.

Precautions Against Damage

Avoid spilling brake fluid or battery acid on any part of the bodywork. Was h spillages

off with water imm ediately.

Disconnect the battery earth lead before starting work, see

ELECTRICAL

PRECAUTIONS

.

Always us e the recom mended service tool where specified.

Protect exposed bearing and sealing surfaces , and screw threads from damage.

Coolant

WARNING

Coolant mixture, which is blended with antifreeze and corrosion inhibitors

contains toxic chemicals which are harmful to the hum an body. Never swallow

antifreeze, corrosion inhibitors or any of the motorcycle coolant.

WARNING

Do not remove the radiator cap when the engine is hot. When the engine is hot,

the coolant inside the radiator is hot and als o under pres s ure. Contact with the

pres surised coolant will caus e scalds and skin damage.

CAUTION

The coolant antifreeze contains a corrosion inhibitor which helps prevent dam age

to the metal surfaces ins ide the cooling system . Without this inhibitor, the coolant

would 'attack' the metals and the resulting corrosion would caus e blockages in

the cooling sys tem leading to engine overheating and damage. Always use the

correct antifreeze as specified in the Owner's Handbook. Never use a methanol

Service Manual - Scrambler 1200 XC 10 of 640

Page 11

CAUTION

bas ed antifreeze as this does not contain the required corrosion inhibition

properties.

CAUTION

Distilled water must be used with the antifreeze (see specification for antifreeze) in

the cooling sys tem.

If hard water is used in the system , it causes scale accumulation in the water

pas sages, and considerably reduces the efficiency of the cooling system .

Reduced cooling sys tem efficiency may lead to the engine overheating and engine

dam age.

Cleaning Components

A high flas hpoint solvent is recommended to reduce fire hazard.

Always follow container directions regarding the use of any solvent.

Always us e the recom mended cleaning agent or equivalent.

Do not use degreasing equipm ent for components containing items which could be

dam aged by the use of this process . Whenever pos s ible, clean components and the

area surrounding them before removal. Always observe scrupulous cleanliness

when cleaning dismantled components.

Lubrication

The majority of engine wear occurs while the engine is warming up and before all the

rubbing surfaces have an adequate lubrication film. During ass embly, oil or greas e

(whichever is more suitable) should be applied to any rubbing surface, which has

los t its lubrication film . Old grease and dirty oil should be cleaned off. This is

becaus e used lubricants will have lost som e lubrication qualities and may contain

abrasive foreign particles.

Use recomm ended lubricants. Some oils and greases in particular should be us ed

only in certain applications and may be harmful if us ed in an application for which

they are not intended. This manual makes reference to molybdenum disulphide

grease in the assem bly of certain engine and chassis parts. Always check

manufacturer recommendations before us ing such special lubricants.

Joints and Joint Faces

As sem ble joints dry unles s otherwise specified in this manual.

If gas kets and/or jointing com pound is recommended for use; remove all traces of

old jointing material prior to reassembly. Do not use a tool which will dam age the

Service Manual - Scrambler 1200 XC 11 of 640

Page 12

joint faces and smooth out any scratches or burrs on the joint faces using an oil

stone. Do not allow dirt or jointing material to enter any tapped holes.

Gaskets, O-rings

Do not reuse a gasket or O-ring once it has been in service. The mating surfaces

around the gasket should be free of foreign matter and perfectly sm ooth to avoid oil or

compress ion leaks .

Liquid Gasket, Non-permanent Locking Agent

Follow manufacturer's directions for cleaning and preparing surfaces where these

compounds will be used. Apply sparingly as excessive amounts of sealer may block

engine oil pass ages and cause serious dam age.

Prior to reas sem bly, blow through any pipes, channels or crevices with compressed

air.

WARNING

To prevent injury, always us e eye, face and ear protection when using compressed

air. Always wear protective gloves if the com pres sed air is to be directed in

proximity to the skin.

Screw Threads

Metric threads to ISO standard are used.

Dam aged nuts, bolts and screws mus t always be discarded.

Cas tellated nuts must not be loosened back to accept a split pin, except in those

recom mended cases when this forms part of an adjustment.

Do not allow oil or grease to enter blind threaded holes . The hydraulic action on

screwing in the bolt or stud could split the housing.

Always tighten a nut or bolt to the recom mended torque figure. Dam aged or corroded

threads can affect the torque reading.

Unles s specified, threaded fixings mus t always be fitted dry (no lubrication).

WARNING

Never lubricate a thread unless instructed to do so.

When a thread of a fixing is lubricated, the thread friction is reduced. When the

fixing is tightened, reduced friction will caus e over tightening and possible fixing

failure.

A fixing which fails in service could caus e component detachment leading to los s

of control and an accident.

Service Manual - Scrambler 1200 XC 12 of 640

Page 13

Locking Devices

Always release locking tabs and fit new locking was hers . Do not reuse locking tabs.

Fitting a Split Pin

Always fit new split pins of the correct size for the hole in the bolt or stud. Do not

loosen back castle nuts when fitting a split pin, except in thos e recom mended cases

when this forms part of an adjus tment.

Always fit new roll pins of an interference fit in the hole.

Circlips, Retaining Rings

Replace any circlips and retaining rings that are rem oved. Rem oval weakens and

deform s circlips causing looseness in the circlip groove. When installing circlips and

retaining rings, take care to compres s or expand them only enough to install them.

Always us e the correct replacement circlip as recommended in the Trium ph parts

catalogue.

Self-Locking Nuts

Self-locking nuts can be reus ed, provided resistance can be felt when the locking

portion passes over the thread of the bolt or stud.

DO NOT reuse self-locking nuts in critical locations, e.g. s uspens ion components.

Always us e the correct replacement self-locking nut.

Encapsulated Bolts

An encapsulated bolt can be identified by a coloured section of thread which is

treated with a locking agent.

Unles s a specified repair procedure states otherwise, encapsulated bolts cannot be

reus ed and MUST be replaced if disturbed or rem oved.

WARNING

Failure to replace an encapsulated bolt could lead to a dangerous riding

condition. Always replace encapsulated bolts.

Oil and Grease Seals

Replace any oil or grease seals that are rem oved. Removal will cause damage to an

oil seal which, if reused, would cause an oil leak.

Ensure the surface on which the new seal is to run is free of burrs or scratches.

Renew the component if the original sealing surface cannot be completely res tored.

Service Manual - Scrambler 1200 XC 13 of 640

Page 14

Protect the seal from any surface which could cause damage over which it has to

pas s when being fitted. Use a protective sleeve or tape to cover the relevant surface

and avoid touching the sealing lip.

Lubricate the sealing lips with a recom mended lubricant. This will help to prevent

dam age in initial use. On dual lipped seals, smear the area between the lips with

appropriate grease.

When pressing in a seal which has manufacturer's marks, press in with the marks

facing out.

Seals mus t be pressed into place us ing a suitable driver. Use of im proper tools will

dam age the seal.

Press

A part installed us ing a pres s or driver, such as a wheel bearing, should first be

coated with oil or grease on its outer or inner circum ference so that it will locate

smoothly.

Ball Bearing

When installing a ball bearing, the bearing race which is an interference fit should be

pus hed by a suitable driver. This prevents severe stress or dam age to the load

carrying components. Press a ball bearing until it touches the shoulder in the bore or

on the shaft.

With the sealing lip facing the lubricant, press or drift a seal to the depth of its

housing, if the housing is shouldered, or flush with the face of the housing where no

shoulder is provided.

Chassis Bearing Lubrication

Note

This information relates only to bearing lubrication. For the procedures

necessary to replace a bearing, always refer to the relevant section of this

Service Manual.

Bearings installed in engine and transmission applications are not covered by

this information. Refer to the Lubrication chapter or the relevant engine

chapter for additional information.

General

For a bearing to be serviceable for its anticipated life span it must be checked,

adjus ted and lubricated at regular intervals, as specified in the service schedules

given in the Owner’s Handbook and this Service Manual.

A correctly lubricated bearing will have a film of lubrication that separates the moving

parts, dis perses heat and protects the bearing surfaces from corrosion.

Service Manual - Scrambler 1200 XC 14 of 640

Page 15

Note

In all cases, use the lubricant recommended.

Grease the bearing, not the cavity where it is located.

A bearing that is not regularly checked and lubricated will have a reduced life

span.

New Bearings

New bearings are typically protected with an oil pres ervative to prevent corrosion etc.

during storage. This is NOT the lubrication for the bearing but DOES NOT need to be

was hed off prior to assem bly and in-service lubrication.

When lubricating a new bearing with grease the following steps should be taken:

Do not clean off the oil preservative.

1.

Grease must be forced between the roller elements and the roller cage.

2.

Rotate the bearing to ens ure that the grease is distributed over the entire

circum ference of the internal parts.

3.

Any excess grease should be smeared on the outside of the rollers .

4.

Lubrication and Checks While Servicing a Bearing

Disass emble parts as necess ary to access the bearing.

1.

Inspect the old grease covering the bearing, looking for signs of bearing damage,

i.e. flakes or specks of metal.

2.

Rem ove the old grease.

3.

Check the bearing for smooth operation and vis ually check for corros ion, dents

and flaking in the bearing race, rollers or cage. Replace if neces sary.

4.

Below/overleaf several com m on bearing types and the lubrication procedures for

each are identified:

ceon

Service Manual - Scrambler 1200 XC 15 of 640

Page 16

Sealed Bearings

Note

Sealed bearings can be identified by their integrated seals.

Sealed bearings are lubricated for life by the manufacturer.

Any attempt to change the grease in a sealed bearing will damage the

integrated seals. If the seals are damaged, dirt and water will ingress and the

life of the bearing will be greatly reduced.

ceon

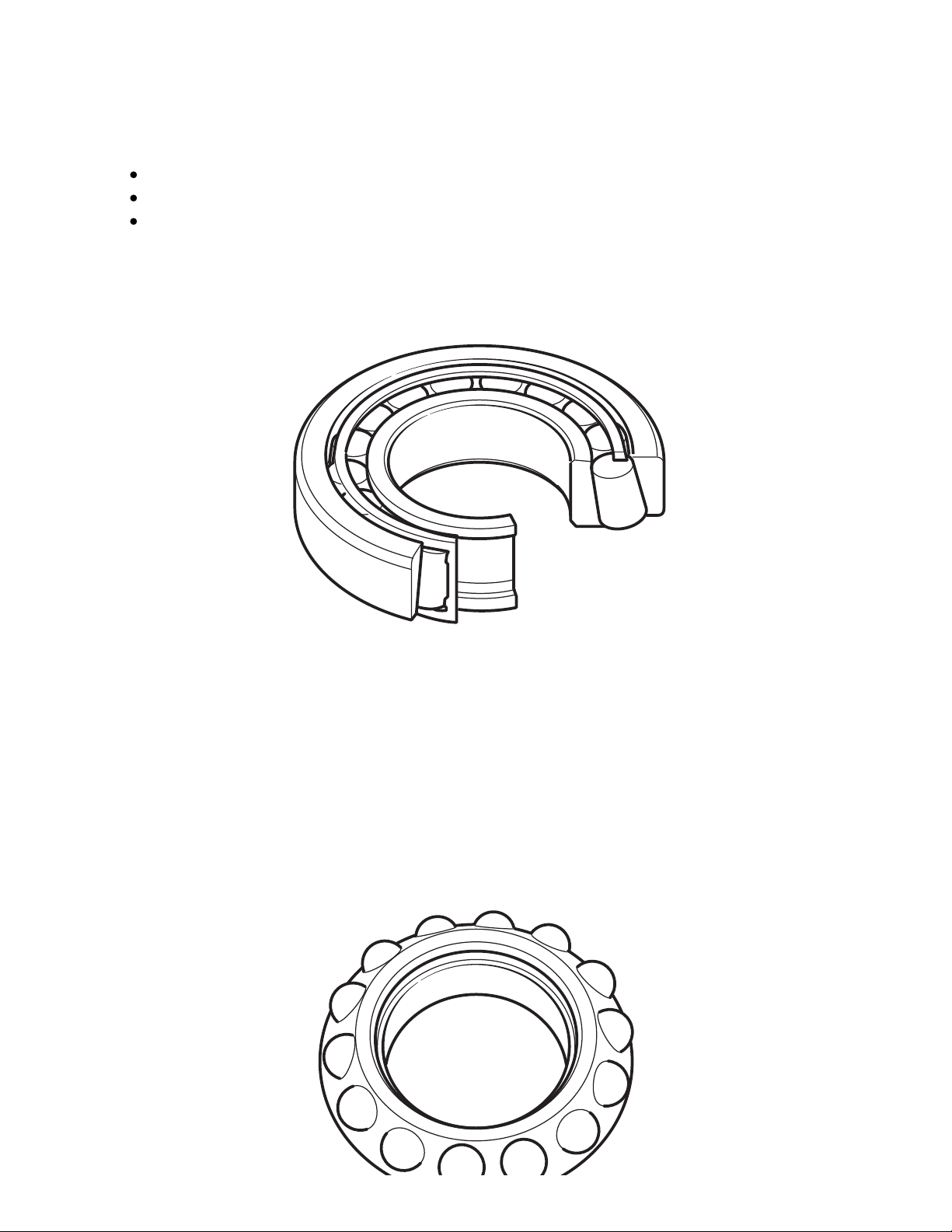

Taper Bearings

Grease must be forced between the inner race and the roller carrier.

1.

Rotate the bearing to ens ure that the grease is distributed over the entire

circum ference of the internal parts.

2.

Any excess grease should be smeared on the outside of the rollers .

3.

Service Manual - Scrambler 1200 XC 16 of 640

Page 17

ceon

Angular Contact and Ball Bearing

Grease the bearing races and the ball bearing carrier.

1.

Rotate the bearing to ens ure that the grease is distributed over the entire

circum ference of the internal parts.

2.

ceop

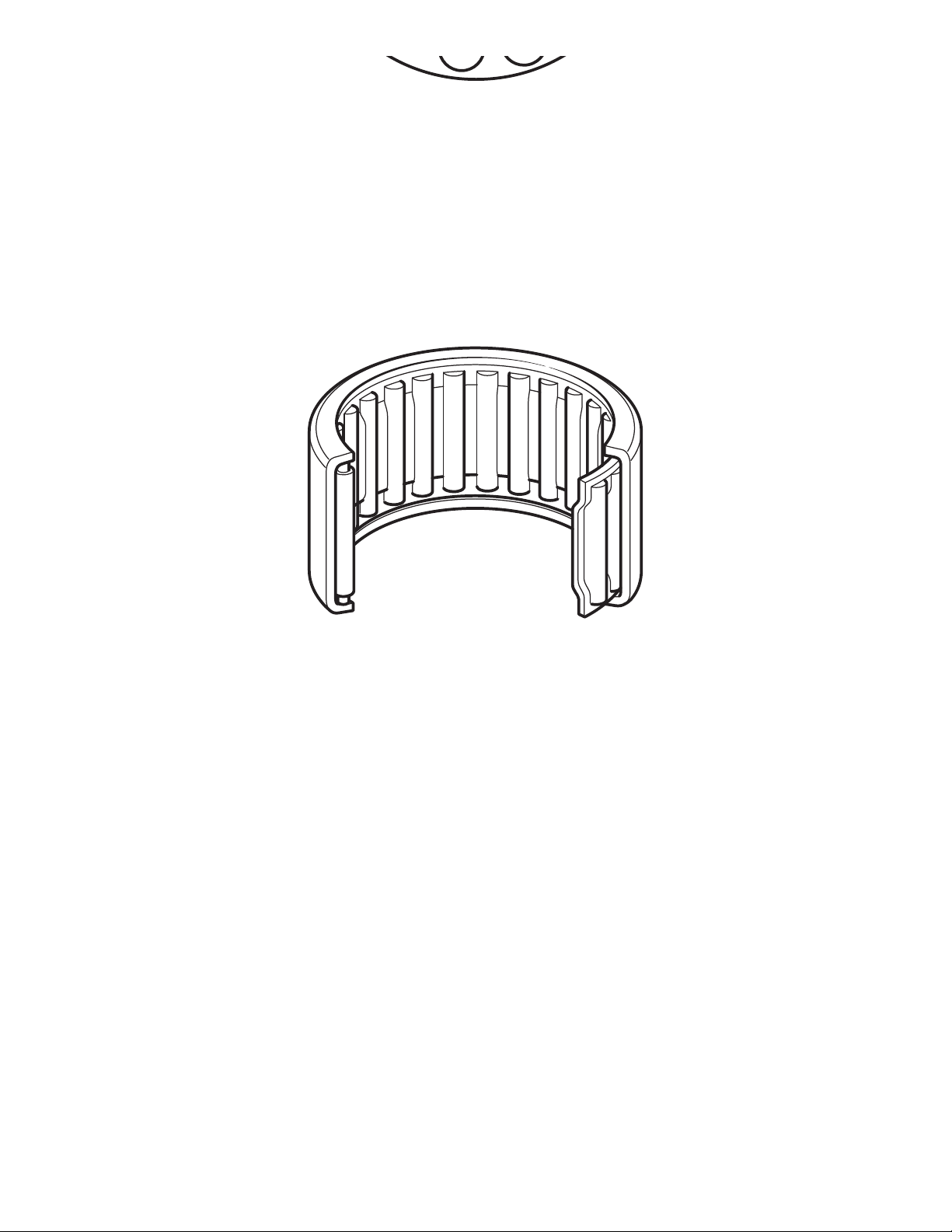

Needle Roller Bearings

Coat the needle rollers with grease.

1.

Ensure the needle rollers turn so that the grease is distributed over the entire

circum ference of the internal parts.

2.

As sem ble the parts, adjus t and check as neces sary.

3.

Metal Bushes

Disass emble the parts as necess ary to access the bus h.

1.

Rem ove the old grease.

2.

Apply fresh grease to the metal bush.

3.

Fuel Handling Precautions

General

The following information provides basic precautions which must be observed if

Service Manual - Scrambler 1200 XC 17 of 640

Page 18

petrol (gas oline) is to be handled safely. It also outlines other areas of risk which

mus t not be ignored. This inform ation is iss ued for basic guidance only and, if in

doubt, appropriate enquiries should be made to your local Fire Officer.

Petrol – Gasoline

When petrol (gasoline) evaporates it produces 150 times its own volum e in vapour

which when diluted with air becom es a readily ignitable mixture. The vapour is

heavier than air and will always fall to the lowes t level. It can readily be distributed

throughout any indoor environment by air currents, consequently, even a small

spillage of petrol (gas oline) is potentially very dangerous.

WARNING

Petrol (gasoline) is highly flam m able and can be explosive under certain

conditions. When opening the fuel tank cap always observe all the following items:

Turn the motorcycle ignition switch OFF.

Do not sm oke.

Always have a fire extinguisher containing FOAM, CO2, HALON or POWDER close

at hand when handling or draining fuel or fuel system s. Fire extinguishers must

als o be present in areas where fuel is stored.

Always disconnect the vehicle battery, negative (black) lead first, before carrying

out, dism antling or draining work on a fuel sys tem .

Whenever petrol (gasoline) is being handled, drained, stored or when fuel

systems are being dis mantled, make sure the area is well ventilated. All potential

forms of ignition must be extinguis hed or removed (this includes any appliance

with a pilot light). Any lead-lamps must be flame-proof and kept clear of any fuel

spillage.

Warning notices mus t be posted at a safe distance from the site of the work to

warn others that petrol (gasoline) is being openly handled. The notice must

ins truct the reader of the precautions which mus t be taken.

Failure to obs erve any of the above warnings may lead to a fire hazard which could

result in pers onal injury.

WARNING

No one should be permitted to repair components associated with petrol

(gas oline) without first having specialis t training on the fire hazards which may be

created by incorrect installation and repair of items associated with petrol

(gas oline).

Repairs carried out by untrained personnel could bring about a safety hazard

leading to a risk of personal injury.

Service Manual - Scrambler 1200 XC 18 of 640

Page 19

WARNING

Draining or extraction of petrol (gasoline) from a vehicle fuel tank mus t be carried

out in a well ventilated area.

The receptacle used to contain the petrol (gas oline) must be more than adequate

for the full amount of fuel to be extracted or drained. The receptacle should be

clearly marked with its contents, and placed in a safe storage area which meets

the requirements of local authority regulations.

When petrol (gasoline) has been extracted or drained from a fuel tank, the

precautions governing naked lights and ignition sources should be maintained.

Failure to obs erve any of the above warnings could bring about a safety hazard

leading to a risk of personal injury.

Fuel Tank Removal

Fuel tanks should have a 'PETROL (GASOLINE) VAPOUR' warning label attached to

them as soon as they are removed from the vehicle. In all cases, they must be stored

in a secured, marked area.

Chassis Repairs

WARNING

If the motorcycle is involved in an accident or collis ion it mus t be taken to an

authoris ed Triumph dealer for repair or inspection. Any accident can caus e

dam age to the motorcycle, which if not correctly repaired, may caus e a second

accident which may res ult in injury or death.

The frame mus t not be modified as any modification to the frame such as welding

or drilling may weaken the frame resulting in an accident.

Electrical Precautions

The following guidelines are intended to ensure the safety of the operator whils t

preventing dam age to the electrical and electronic components fitted to the

motorcycle. Where necessary, specific precautions are detailed in the relevant

sections of this manual which should be referred to prior to commencing repair

operations.

Equipm ent - Prior to commencing any test procedure on the motorcycle ens ure that

the relevant test equipment is working correctly and any harnes s or connectors are in

good condition, in particular mains leads and plugs.

WARNING

Service Manual - Scrambler 1200 XC 19 of 640

Page 20

WARNING

The ignition sys tem produces extrem ely high voltages . Do not touch any part of the

ignition sys tem or any cables while the engine is running.

An electric shock caus ed by contact with the ignition system may lead to illness,

injury or death.

WARNING

Wearers of surgically implanted heart pacemaker devices should not be in close

proximity to ignition circuits and/or diagnos tic equipment.

The ignition sys tem and any diagnostic equipm ent may interrupt the normal

operation of such devices causing illnes s or death.

WARNING

The battery contains harmful materials . Always keep children away from the

battery whether or not it is fitted in the motorcycle.

Do not jump start the battery, touch the battery cables together or reverse the

polarity of the cables as any of these actions may cause a spark which would

ignite battery gas es caus ing a risk of personal injury.

High Voltage Circuits - Whenever disconnecting live H.T. circuits always use insulated

pliers . Exercise caution when meas uring the voltage on the coil terminals while the

engine is running. High voltage spikes can occur on these terminals.

Connectors and Harness - The engine of a motorcycle is a particularly hostile

environm ent for electrical com ponents and connectors. Always ensure thes e items

are dry and oil-free before dis connecting and connecting test equipm ent. Never force

connectors apart either by us ing tools or by pulling on the wiring itself. Always ensure

locking mechanis ms are disengaged before rem oval and note the orientation to

enable correct reconnection. Ensure that any protective covers and substances are

replaced if disturbed.

Having confirmed a component to be faulty, switch off the ignition and disconnect the

battery negative (black) lead first. Rem ove the component and support the

dis connected harness. When replacing the com ponent keep oily hands away from

electrical connection areas and push connectors home until any locking mechanism

becomes fully engaged.

Battery Disconnecting

Before disconnecting the battery, switch off all electrical equipment.

Service Manual - Scrambler 1200 XC 20 of 640

Page 21

WARNING

To prevent the risk of a battery exploding and to prevent damage to electrical

components ALWAYS dis connect the battery negative (black) lead first. When

reconnecting the battery, always connect the pos itive (red) lead first, then the

negative (black) lead. Always disconnect the battery when working on any part of

the electrical system .

Failure to obs erve the above warnings may lead to electrical dam age and a fire

hazard which could cause personal injury.

Always ensure that battery leads are routed correctly and are not close to any

potential chafing points.

Disciplines

Switch off the ignition prior to making any connection or disconnection in the system.

An electrical surge can be caus ed by disconnecting 'live' connections which can

dam age electronic com ponents.

Ensure hands and work surfaces are clean and free of grease, swarf, etc. as grease

collects dirt which can cause tracking or high-resis tance contacts.

Prior to comm encing any test, and periodically during any tes t, touch a good earth to

dis charge body static. This is because some electronic components are vulnerable

to static electricity.

Electrical Wires

All the electrical wires are either single-colour or two-colour and, with only a few

exceptions , must be connected to wires of the sam e colour. On any of the two-colour

wires there is a greater am ount of one colour and a less er amount of a second

colour. A two-colour wire is identified by first the primary colour and then the

secondary colour. For example, a yellow wire with thin red stripes is referred to as a

'yellow/red' wire; it would be a 'red/yellow' wire if the colours were reversed to make

red the main colour.

Electrical Testing

For any electrical system to work, electricity must be able to flow in a complete circuit

from the power source (the battery) via the components and back to the battery. No

circuit means no electrical flow. Once the power has left the positive side of the

battery and run through the component it must then return to the battery on its

negative side (this is called earth or ground). To save on wiring, connections and

space, the negative side of the battery is connected directly to the frame or engine.

Around the frame and engine will be various other ground points to which the wiring

coming from com ponents will be connected. In the cas e of the starter motor it bolts

directly to the engine, which is bolted to the frame. Therefore the frame and engine

Service Manual - Scrambler 1200 XC 21 of 640

Page 22

als o form part of the earth return path.

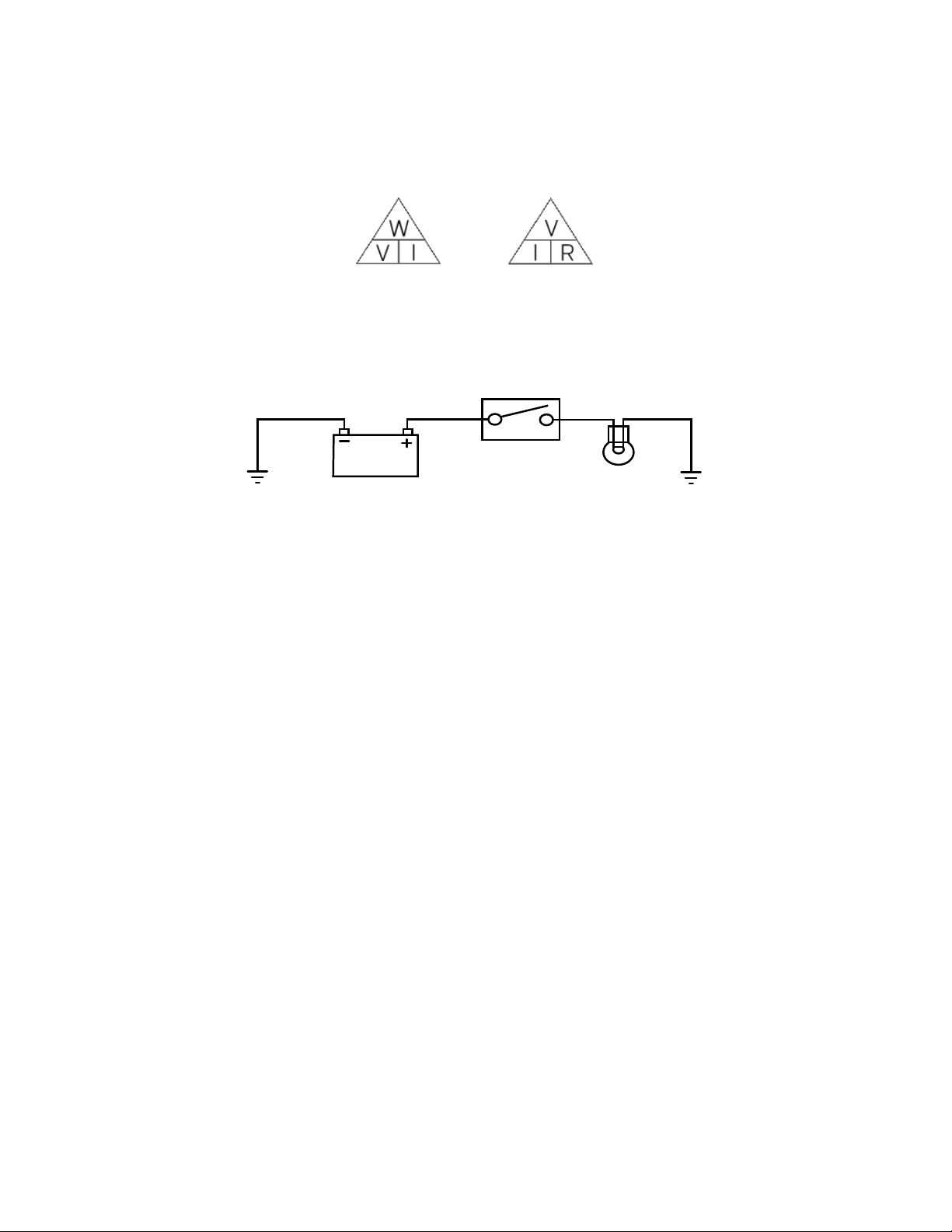

Ohm’s Law

The relationship between voltage, current and resistance is defined by Ohm’s Law.

The potential of a battery is measured in volts (V).

The flow of current in a circuit (I) is measured in amperes.

The power rating of a consumer is measured in watts (W).

The resistance (R) of a circuit is meas ured in Ohms.

Ohm’s law, for practical work can be described as -

Power is calculated by multiplying Volts x Amps -

By trans pos ing either of thes e formulae, the value of any unit can be calculated if the

other two values are known.

For example, if a battery of 12 V is connected to a bulb of 60 W:

the current flowing in the circuit can be calculated by using -

the bulb res istance can be calculated by using -

Service Manual - Scrambler 1200 XC 22 of 640

Page 23

To us e either of the following triangles, put your finger over the value you want to find.

Multiply the remaining values if side by side, or divide if one is over the other.

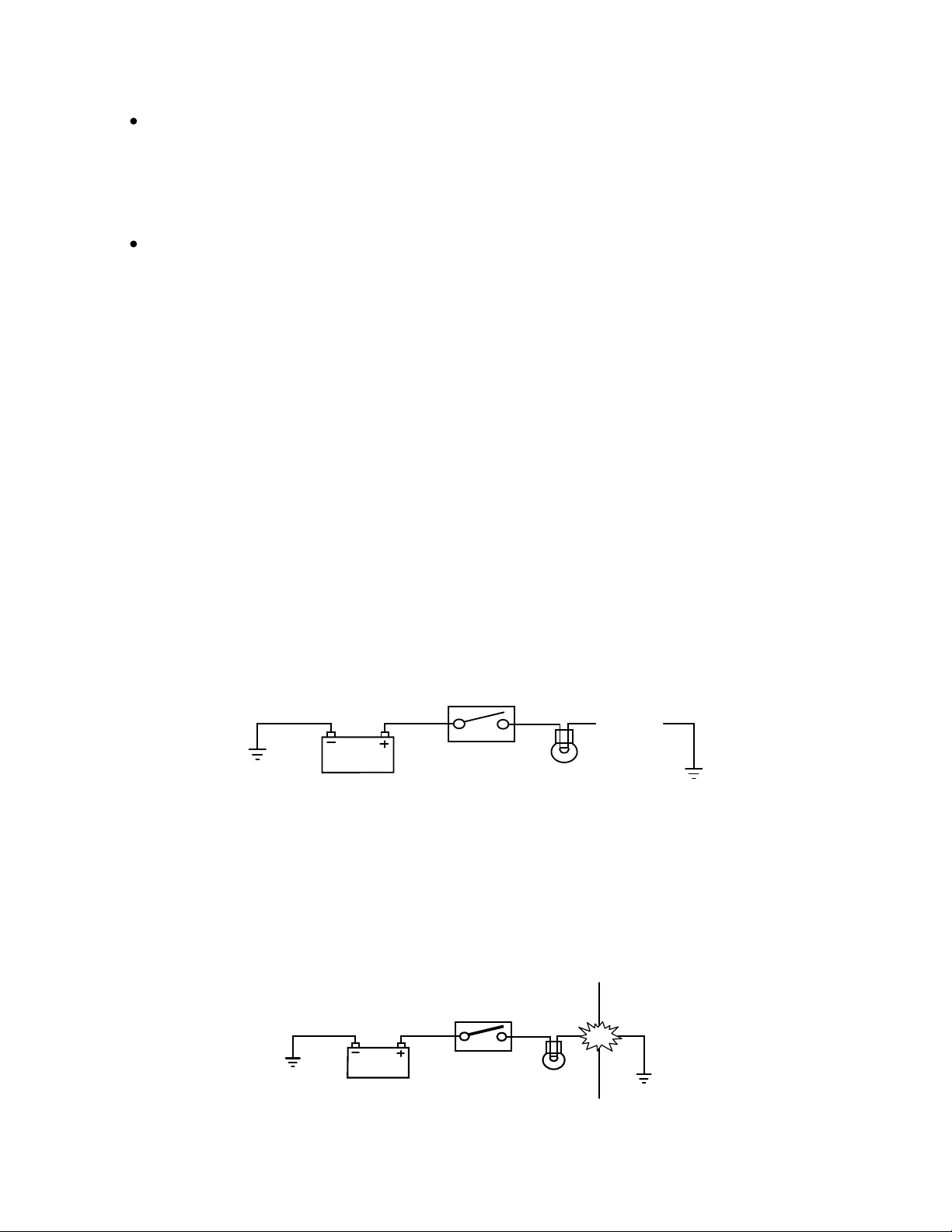

Basic Electrical Circuits

Basic Circuit Diagram

In the above circuit an electrical reservoir (the battery) is connected via a cable to a

terminal on the controlling device (the switch) whos e contacts are either open or

clos ed. The other terminal on the switch is connected via a cable to the consumer

(the bulb), and the other side of the bulb filament is connected to ground (earth) by

another cable. The ground point is us ually a part of the frame or engine, to which the

battery negative terminal is also connected.

When the switch contacts are open (as shown in the diagram), the circuit is broken

and no current flows. When the switch contacts are closed, the circuit is made and

current flows from the battery positive terminal through the switch contacts and bulb

filam ent to ground. The frame completes the circuit to the battery negative terminal

and the bulb illuminates .

Although som e circuits on the circuit diagram may at firs t seem more com plicated, it

will generally be found that they can be broken down into sections which do not differ

greatly from the basic circuit above.

Circuit Diagrams

Circuit diagram s are created to provide a 'picture' of the electrical system and to

identify the route taken by each individual wire through the system , in order to identify

which com ponents it feeds and which connectors the wire runs through. Circuit

diagrams are an essential tool for fault finding, as it is possible to locate start and

finis h points for a circuit without having to manually trace the wire through the

motorcycle itself. Circuits diagrams may look confus ing at first but when they are

studied closely they soon become logical.

Service Manual - Scrambler 1200 XC 23 of 640

Page 24

Due to the com plex circuits and the num ber of individual wires, Trium ph uses two

types of circuit diagram in its Service Manuals.

Within the manual, conventional circuit diagrams are used to show the layout of

the main circuits of the motorcycle. Thes e are: Engine managem ent/ignition,

Lighting, Starting and Charging and Auxiliary and Access ory. In thes e diagram s

no attempt is made to show the components of the system in any particular order

or pos ition in relation to the motorcycle.

At the back of the Service Manual a full colour layout circuit diagram is used to

show the main electrical com ponents in a pos ition similar to the actual position

on the motorcycle.

Both of these circuit diagrams us e sim ilar symbols to illus trate the various sys tem

components and will be accompanied by a key indicating circuit diagram

components and wiring colour codes.

Circuit diagram s als o depict the inner workings of a switch hous ing (i.e. which wire

connects to which when a switch is turned from one pos ition to another) so that a test

of that switch can be made us ing the wire term inals in the connector instead of

dis ass embling the switch itself.

Tracing Circuits

The following is a description of two types of common electrical failures , and som e of

the methods which may be used to find them .

Open Circuit

A break in an electrical circuit - current cannot flow. Us ually caused by a break in a

wire or cable or by a loose connection. Open circuits can often be intermittent, making

diagnosis difficult.

Short Circuit

A 'short cut' in an electrical circuit - current bypasses the intended circuit, either to

Service Manual - Scrambler 1200 XC 24 of 640

Page 25

ground or to another, different circuit. Often caused by failure of the cable ins ulation

due to chafing or trapping of the wire. There are two different types of short circuit -

short to ground and short to battery Voltage.

A short to ground means that the current is going to ground before it reaches the

component it is supposed to feed. These are often caus ed by chafing of the harness

to the fram e or wires trapped between a bolted com ponent, and will often blow the

fuse on that circuit.

A short to battery voltage (12 Volts) is caused by a live power supply wire contacting

an adjacent cable. Note that it is also possible for a 5 Volt sensor reference voltage to

short to an adjacent circuit, which can also cause electrical failures and DTCs

(Diagnostic Trouble Code) to be stored.

When tracing a wire that is suspect, carefully check the circuit diagram before

starting. Remember:

a wire may diverge at a splice and go off to feed other circuits. If these circuits are

working, check for wiring faults from the splice onwards .

the circuit diagram is not an accurate guide to the actual location of the parts

when fitted on the motorcycle. It is a schematic diagram of the circuits.

particularly where engine management items are concerned, the circuit is only

completed by the ECM. If the ECM is not connected, the circuit may register as

open.

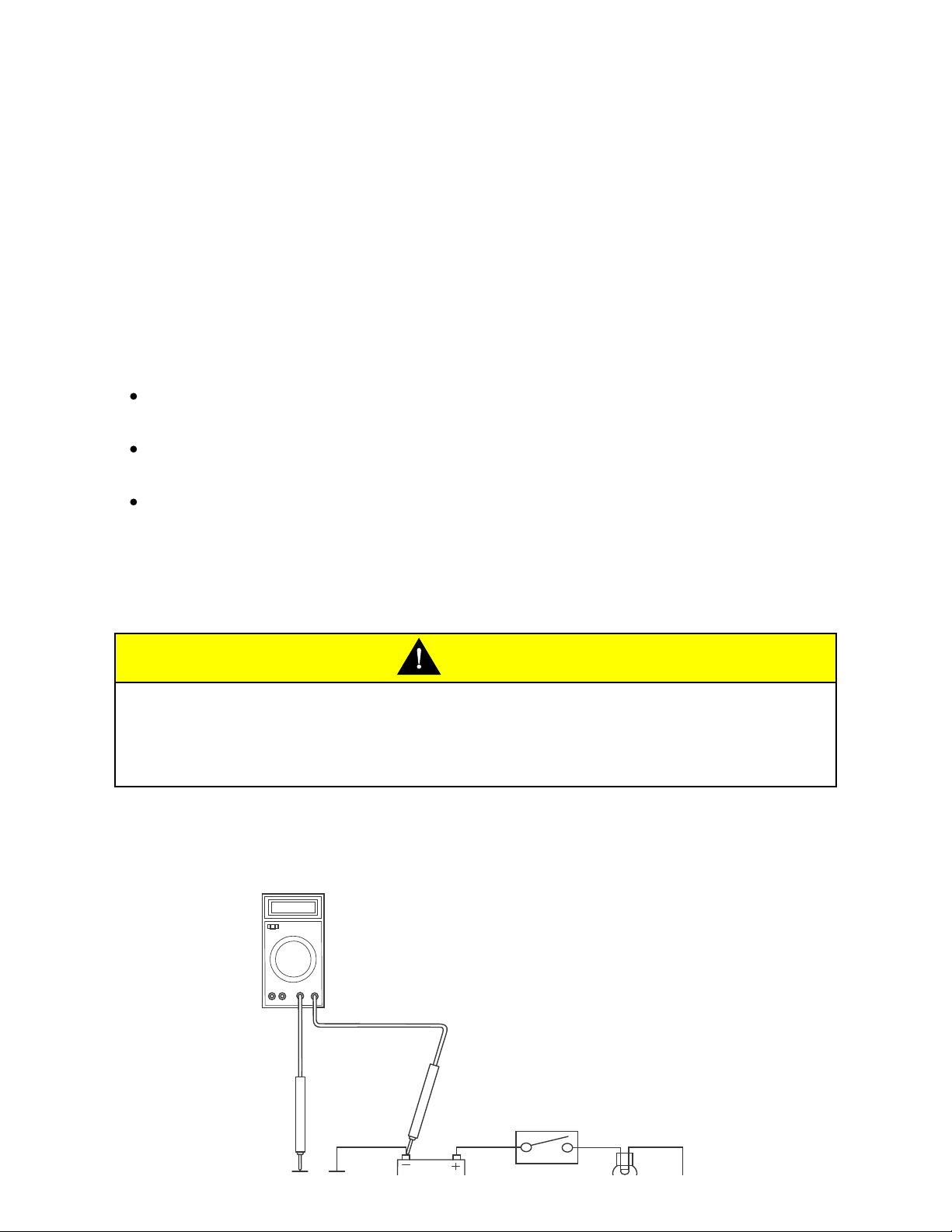

To Check Continuity:

CAUTION

Ensure the circuit being tested is switched off before measuring continuity.

Dam age to the Digital Multi Meter (DMM) may res ult from testing a 'live' circuit with

the meter set to resistance (Ω).

In the example below, the ground circuit continuity is being tested from the battery to

the frame.

Ω

0.0

Service Manual - Scrambler 1200 XC 25 of 640

Page 26

Locate each end of the wire.

Set the Digital Multi Meter (DMM) to res istance check Ohms.

Probe each end of the wire.

If there is continuity, the meter will usually bleep or regis ter the resis tance of the

cable.

A high resistance figure could indicate a dirty or corroded connection.

If there is a break in the wire, the meter will not bleep or regis ter a resis tance.

By probing the wire in various places, the position of a high resistance or break in

the wire (open circuit) can be narrowed down until it is found.

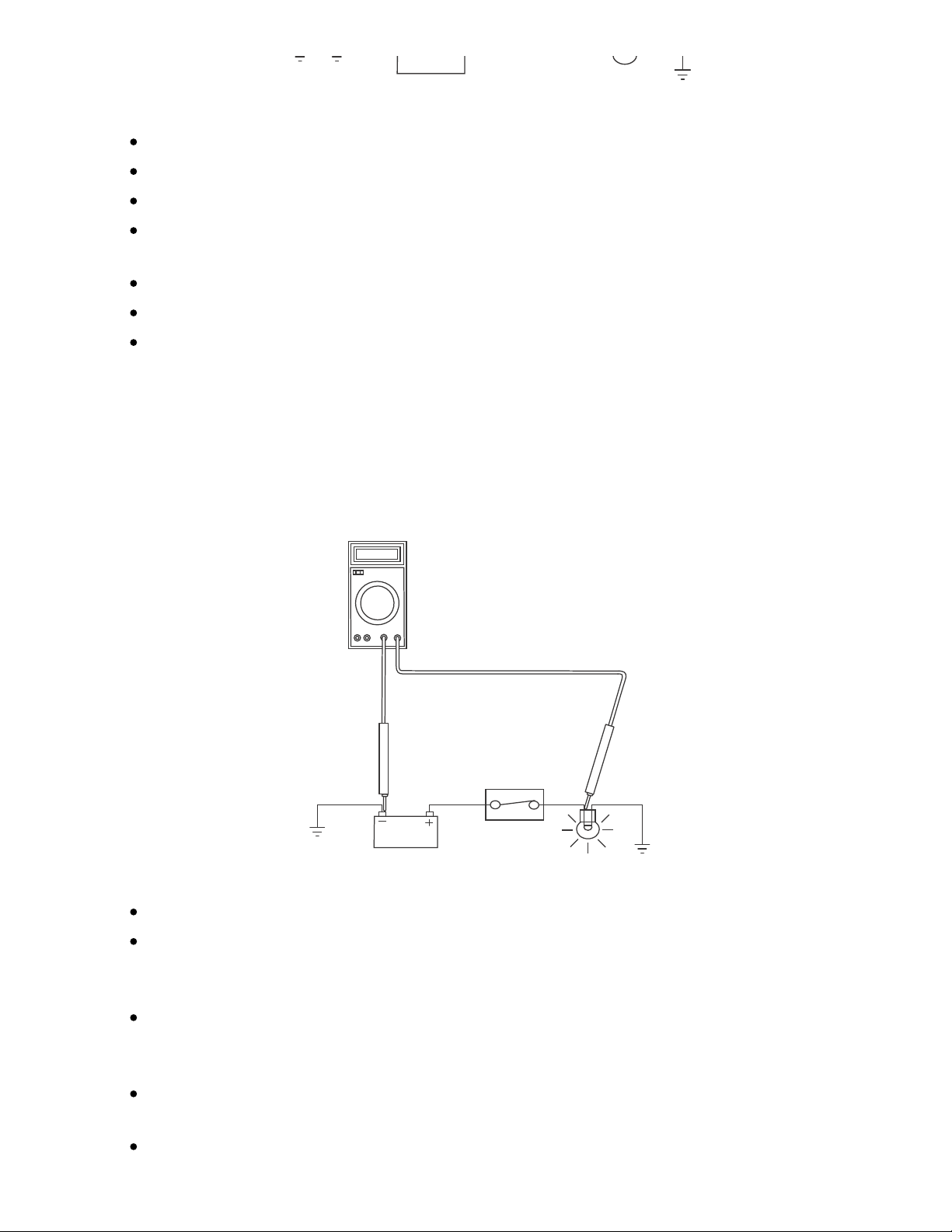

To Measure Voltage:

In the example below, the circuit voltage is being meas ured at the bulb positive (+)

terminal.

V

12.7

Turn the circuit to be tested 'ON'.

Set the Digital Multi Meter (DMM) to Voltage Check (V). Ensure the multi meter is

set to DC Volts for direct current circuits (mos t circuits) or AC Volts for alternating

current circuits (typically alternator output voltage tests).

Set the range of the DMM to the range best suited to the voltage of the circuit

being tested (typically 20 Volts for most DMMs). Refer to the DMM manufacturers

ins tructions.

Connect the black (ground) lead of the DMM to a reliable ground connection

(usually the battery or frame ground).

Locate the pos itive terminal of the wire or component to be tested.

Service Manual - Scrambler 1200 XC 26 of 640

Page 27

Connect the red (positive) lead of the DMM to the positive terminal.

Read the voltage from meter.

Splices

Splices are probably the most com m on cause of wiring faults after connectors .

Splices are made where two or more wires com e together and diverge in different

directions, usually to feed a different circuit.

To locate a splice, it is necessary to peel back the insulation and examine the splice

for its integrity. The mos t comm on fault is where one of the wires at the joint has

come adrift usually causing the circuit it feeds or grounds to becom e 'dead'.

Switches

To check a switch, set the multimeter to resistance/continuity and probe the two pins

that form a closed circuit when the switch is pus hed. If the switch is working correctly,

the resistance should register or the meter will bleep.

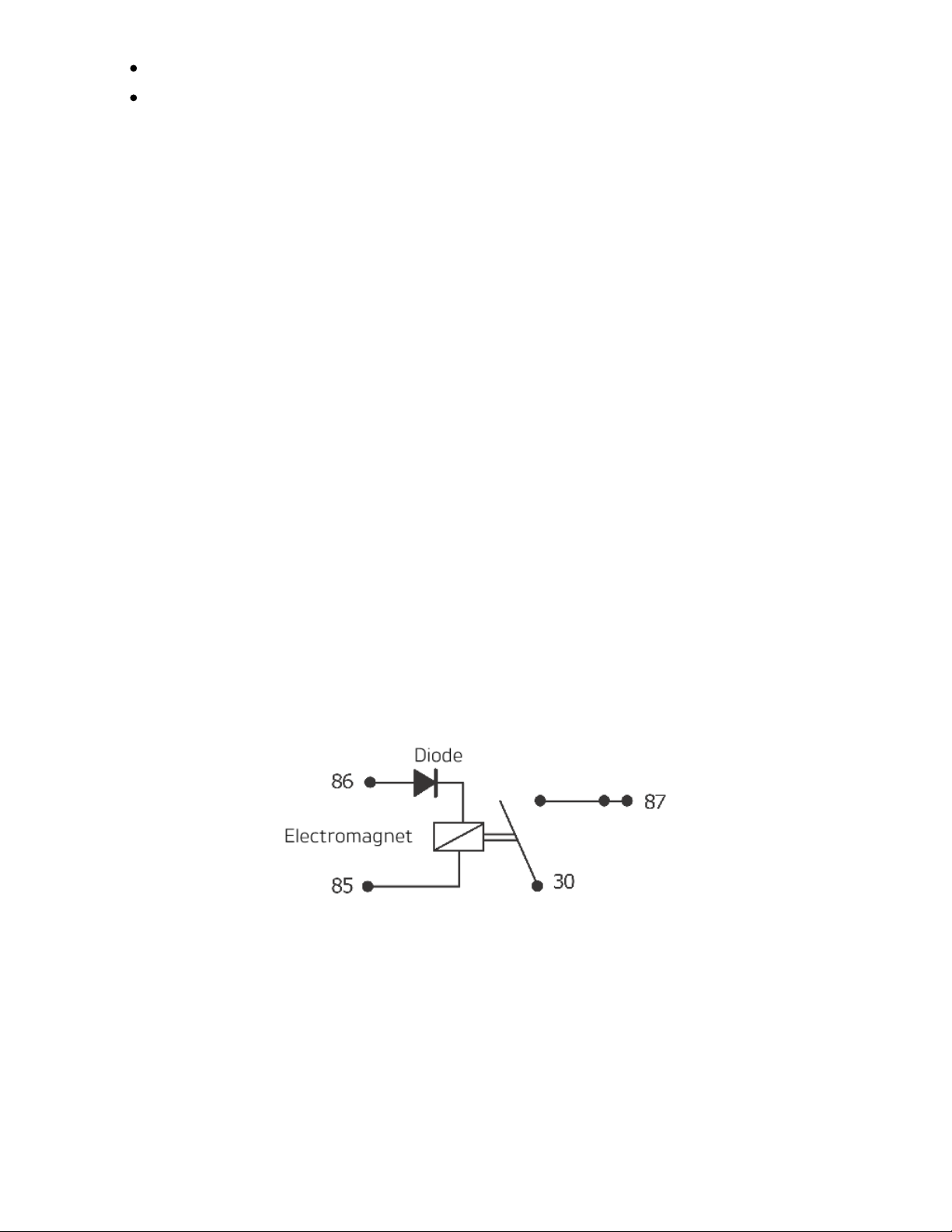

Relays

All relay cases have a circuit path engraved on them showing the circuit path across

the electromagnet and the switch. Before making any checks , first note the pin

des ignations, current paths, and whether or not there is a diode in either circuit path.

Make continuity checks across the electromagnet first, us ually from pin 86 (positive)

to pin 85 (negative). If a diode appears in the circuit use the diode check on the

multimeter (Volts scale) in the direction of current flow. If there is no diode, use the

resistance check facility. An open circuit or unus ually high resistance value indicates

a faulty relay.

To check the switch side, apply a 12 Volt supply between pins 86 and 85. With the

Service Manual - Scrambler 1200 XC 27 of 640

Page 28

supply connected, the relay should be heard to click and there should be continuity

between pins 30 and 87. An open circuit indicates a faulty relay.

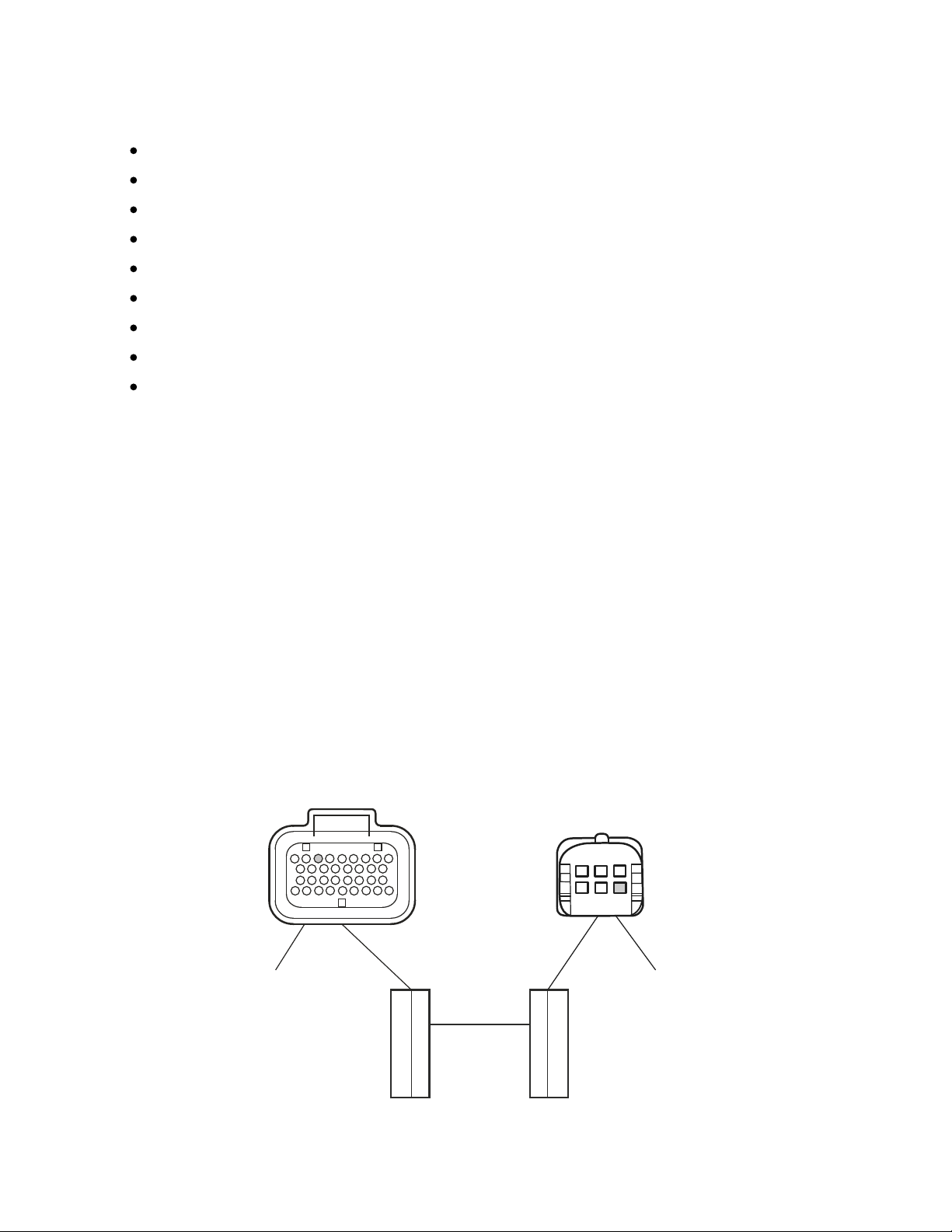

CAN (Controller Are a Networking)

CAN (som etimes called CANbus ) is a protocol for data communication between

Electronic Control Modules (ECMs). Each ECM on the network is connected by a

single pair of twisted wires (or bus) which are used for the transm iss ion of vehicle

sensor data. By us ing CAN, the overall num ber of sys tem sens ors, and the am ount of

cabling required to allow ECMs to communicate with each other is greatly reduced.

This saves cost, weight and space, and makes the sys tem more reliable, as the

physical number of wires and connections is reduced.

4

5

16

R

U

B28

B27

A34

B

KY

1

3

2

CAN works by each ECM sending out 'packets' of information (such as engine speed

or fuel consum ption inform ation) on to the network bus (note that the network must

be free of data before any ECM is allowed to transm it). This data is given a priority

according to its im portance (for example 'engine speed' may have a higher priority

than 'low fuel level'), so that even if two ECMs send data at the sam e time, high

priority information is always sent first. Lower priority data is then res ent after the high

priority data has been received by all ECMs on the network.

The receiving ECM confirms the data has been received correctly and that the data is

valid, and this information is then used by the ECM as necessary. Specific data not

required by an ECM will still be received and acknowledged as correct but then

dis regarded (for example if an ECM does not require 'clutch switch pos ition'

inform ation, this data packet would be ignored).

This allows for a very high speed system of comm unication, which is also very

reliable. Should one ECM fail or trans mit corrupted or otherwis e incorrect messages,

none of the other ECMs on the network will be affected, and after a certain time that

ECM will be prevented from trans mitting further messages until the fault is rectified.

This stops the ECM from clogging the network with incorrect data and preventing

Service Manual - Scrambler 1200 XC 28 of 640

Page 29

other messages from getting through. The fault would then be reported by a DTC

(Diagnostic Trouble Code).

Triumph currently us es CAN for comm unication between the following ECMs :

Engine ECM

Instruments

ABS ECM

Immobiliser or Chassis ECM

Diagnostic connector

Inertial Measurement Unit (if fitted)

Audio sys tem (if fitted)

Electronic steering lock (if fitted)

LED Headlights (if fitted).

LIN (Local Interconnect Network)

LIN (Local Interconnect Network) is a serial network protocol used for communication

between components in vehicles. The bus is a single master/multiple slave bus that

uses a single wire to transmit data.

By us ing LIN, the am ount of cabling required to allow components to communicate

with each other is greatly reduced. This saves cost, weight and space, and makes

the system more reliable, as the physical num ber of wires and connections is

reduced.

The ins truments us e som e of this data internally and also broadcasts it on the

CANbus (Controller Area Networking) for use on the motorcycle as necess ary.

Information (such as headlight main beam) is being requested continuously by the

Instruments, once a confirm ation of the reques t is recognised the instruments will

react accordingly.

7 4

25

34

17

9 1

10

18

26

1

1

3

4

6

2

Service Manual - Scrambler 1200 XC 29 of 640

Page 30

Instruments

1.

Switch housing (left hand side)

2.

Example

Press ing the headlight main beam button on the switch housing (left hand

handlebar) confirms to the instruments that headlight main beam is required.

The ins truments confirm the data has been received correctly and that the data is

valid.

Once confirm ed the headlight main beam is switched on.

Triumph currently us es LIN on certain models for communication between the

ins truments and the following components:

Fog light button

Heated seat

Dip beam/Daytime running lights (DRL) switch (if equipped)

Mode button

Turn signal switch

Joystick button

Horn button

High beam button

Service Tools

Serv ice Tools

Special service tools have been developed to facilitate rem oval, dis mantling and

ass embly of certain mechanical com ponents in a practical manner without causing

dam age. Some operations in this Service Manual cannot be carried out without the

aid of the relevant service tools . Where this is the case, the tools required will be

des cribed during the procedure.

Special Service Tools:

Service Manual - Scrambler 1200 XC 30 of 640

Page 31

cdgh

T3880001 - Fuel Pressure Gauge

T3880016 - Balancer Gear C-Spanner

T3880039

T3880023 - 50 mm Socket

T3880039 - Idler Gear Timing Pin

T3880041

cczb

T3880041 - Idler Gear Timing Wrench

T3880053 - Wheel Bearing Extraction Kit

Service Manual - Scrambler 1200 XC 31 of 640

Page 32

T3880057 - Triumph Diagnos tic Interface

T3880067 - Fork Spring Compressor

cczb

ccg s

T3880075 - Bearing Installer

T3880085 - Fork Piston Holder

cdoa

T3880104 - Swinging Arm Adjuster

Wrench

T3880105 - Torque Angle Gauge

Service Manual - Scrambler 1200 XC 32 of 640

Page 33

Specifications

Engine

Engine Configuration

Liquid cooled parallel twin,

270° firing angle

Arrangement

Transverse in-line

Displacem ent

1200 cc

Bore x Stroke

97.6 x 80 mm

Com pression Ratio

11.00:1

Cylinder num bering

Left to right

Firing Order

1-2

Cylinder Head and Valve s

Cylinder head

Flatnes s

tolerance

0.030 mm

Valve Head Diameter

Inlet

35.60 mm

Exhaust

29.70 mm

Valve Lift

Inlet

10.3 mm

Exhaust

9.2 mm

Valve Stem Diameter

Inlet

4.975 - 4.990 mm (standard)

4.965 mm (service limit)

Exhaust

4.970 - 4.980 mm (standard)

Service Manual - Scrambler 1200 XC 33 of 640

Page 34

4.960 mm (service limit)

Valve Guide Bore Diameter

Inlet

5.000 - 5.015 mm (standard)

5.043 mm (service limit)

Exhaust

5.000 - 5.015 mm (standard)

5.043 mm (service limit)

Valve Stem to Guide

Clearance

Inlet

0.010 - 0.040 mm (standard)

0.078 mm (service limit)

Exhaust

0.020 - 0.045 mm (standard)

0.083 mm (service limit)

Valve Seat Width (in head)

Inlet

1.000 - 1.100 mm (standard)

1.500 mm (service limit)

Exhaust

1.200 - 1.300 mm (standard)

1.700 mm (service limit)

Valve Seat Width (valve)

1.50 - 1.85 mm

Valve Seat Angle

90° inclusive

Valve Spring Length

49.9 mm

Inlet/Exhaust Valve Spring 'Load at Length'

214 N +/- 10 at 39.5 mm

Valve Clearance

Inlet

0.05 - 0.13 mm

Exhaust

0.12 - 0.22 mm

Service Manual - Scrambler 1200 XC 34 of 640

Page 35

Camshafts

Cam shaft Tim ing (at 1 mm lift)

Inlet

Open 5.0° ATDC

Close 41.0° ABDC

Duration 216°

Exhaust

Open 39.0° BBDC

Close 4.0° BTDC

Duration 215°

Cam shaft Journal Diameter

22.930 - 22.960 mm

Cam shaft Journal Clearance

0.040 - 0.091 mm (standard)

0.130 mm (service limit)

Cam shaft Journal Bore Diam eter

23.000 - 23.021 mm

Cam shaft End Float

0.05 - 0.20 mm (standard)

Cam shaft Run-out

0.015 mm (standard)

Clutch and Primary Drive

Primary Drive Type

Gear

Reduction Ratio

1.26:1 (93/74)

Clutch Type

Wet multi-plate

No. of Friction Plates

8

Steel Plate Flatnes s Limit

0.15 mm

Service Manual - Scrambler 1200 XC 35 of 640

Page 36

Friction Plate Flatnes s Limit

0.20 mm

Friction Plate Thickness (new)

2.90 - 3.10 mm

Friction Plate Thickness (service limit)

2.80 mm

Clutch Pack Height

38.00 mm + 0.34/-0.66 mm

Clutch Actuation Method

Cable

Cable Free Play (at lever)

2.0 - 3.0 mm

Piston

Cylinder Barrel Diam eter - 10 mm from the

top of the barrel

97.585 - 97.601 mm (standard)

Cylinder Barrel Diam eter - 97 mm from the

top of the barrel

97.600 - 97.615 mm (standard)

Piston Diam eter

97.570 - 97.580 mm (standard)

97.530 mm (service lim it)

Piston Ring to Groove

Clearance

Top

0.02 - 0.07 mm (standard)

0.085 mm (service limit)

Second

0.02 - 0.06 mm (standard)

0.075 mm (service limit)

Piston Ring Groove Width

Top

1.21 - 1.24 mm (standard)

Second

1.01 - 1.03 mm (standard)

Oil

2.51 - 2.53 mm (standard and

Service Manual - Scrambler 1200 XC 36 of 640

Page 37

service lim it)

Piston Ring End Gap

Top

0.183 - 0.383 mm (standard)

0.503 mm (service limit)

Second

0.353 - 0.553 mm (standard)

0.673 mm (service limit)

Oil

0.153 - 0.703 mm (standard)

0.843 mm (service limit)

Gudgeon Pin Bore Diameter In Pis ton

21.004 - 21.012 mm (standard)

21.040 mm (service lim it)

Gudgeon Pin Diameter

20.995 - 21.000 mm (standard)

20.985 mm (service lim it)

Connecting Rod Small End Diam eter

21.016 - 21.029 mm (standard)

21.039 mm (service lim it)

Connecting Rod Big End Diameter

41.000 - 41.009 mm (standard)

Connecting Rod Big End Side Clearance

0.15 - 0.30 mm (standard)

0.50 mm (service lim it)

Crankshaft

Crankshaft Big End Journal Diameter

38.000 - 37.984 mm (standard)

37.9469 mm (service limit)

Service Manual - Scrambler 1200 XC 37 of 640

Page 38

Crankshaft Big End Bearing Clearance

0.036 - 0.061 mm (standard)

0.100 mm (service limit)

Crankshaft Main Journal Diameter

43.108 - 43.092 mm (standard)

43.052 mm (service lim it)

Crankshaft Main Bearing Clearance

0.018 - 0.042 mm (standard)

0.100 mm (service limit)

Crankshaft End Float

0.05 - 0.20 mm (standard)

0.50 mm (service lim it)

Crankshaft Run-out

0.02 mm (standard)

0.035 mm (service limit)

Transmission

Type

6 Speed, Constant Mes h

Gear Ratios Primary

1.26:1 (93/74)

1st

3.50:1 (49/14)

2nd

2.50:1 (45/18)

3rd

1.85:1 (37/20)

4th

1.48:1 (37/25)

5th

1.30:1 (35/27)

6th

1.17:1 (34/29)

Service Manual - Scrambler 1200 XC 38 of 640

Page 39

Gear Selector Fork

Thickness

5.90 - 6.00 mm (standard)

5.80 mm (service lim it)

Gear Selector Groove Width

6.10 - 6.20 mm (standard)

6.30 mm (service lim it)

Gear Selector Fork to Groove

Clearance

0.1 - 0.3 mm (standard)

0.50 mm (service lim it)

Final Drive

Final Drive Type

Chain - EK525ZVX3, 110 links

Final Drive Ratio

2.75:1 (44/16)

Drive Chain Slack

See

Final Drive Chain Adjus tment

Drive Chain Lubrication

Chain spray s uitable for X-ring chains

Lubrication

Oil Capacity (including

filter, dry fill)

3.80 litres

Oil and Filter Change

3.40 litres

Oil Change only

3.20 litres

Recommended Oil

Approval Rating

API SH (or higher) and JASO MA

Viscos ity

10W/40 or 10W/50

Type

Semi or fully synthetic

Service Manual - Scrambler 1200 XC 39 of 640

Page 40

Oil Press ure (in main

gallery)

3.00 - 3.60 bar at 3,500 rpm

Oil Pump Rotor Tip

Clearance

0.15 mm (standard)

0.20 mm (service lim it)

Oil Pump Body Clearance

0.15 - 0.239 mm (standard)

0.369 mm (service limits)

Oil Pump Rotor End Float

0.04 - 0.09 mm (standard)

0.12 mm (service lim it)

Ignition System

Type

Digital electronic

Electronic Rev-Limiter

7,500 rpm

Pick up Coil Air Gap

Fixed, not adjustable

Primary Coil Resis tance

0.185 Kohm s

Ignition Coil Type

Inductive, plug top

Spark Plug Type

NGK LMAR8A-9

Spark Plug Gap

0.9 mm +0.0/-0.1 mm

Fuel System

Fuel Type

Unleaded, 91 RON (CLC or AKI octane rating

(R+M)/2 of 87 or higher)

Fuel Tank Capacity

16 litres

Service Manual - Scrambler 1200 XC 40 of 640

Page 41

Low Level Warning Light

3.25 litres

Fuel Pum p Type

Subm erged, electric

Fuel Pres sure (nominal)

3.5 bar

Purge Control Sys tem

Modulated, vacuum

Emissions Control Syste m

Type

Digital electronic

Idle Speed

1,000 rpm

Injector Type

Multi hole, solenoid operated plate valve

Throttle

Electronically controlled throttle bodies

Idle Speed Control

Electronic

Control Sensors

Atmospheric air pressure, throttle position, twist

grip pos ition, coolant temperature, crankshaft

pos ition, oxygen sensor, intake air temperature,

gear pos ition, MAP, vehicle speed (from ABS)

Catalysts

One, in the catalytic converter box

Oxygen Sens or

One per cylinder, heated, in header pipe

Evaporative Control

Activated carbon canister (certain markets only)

Cooling System

Coolant Mixture

Premixed

Antifreeze Type

Triumph HD4X Hybrid OAT coolant

Service Manual - Scrambler 1200 XC 41 of 640

Page 42

Cooling System Capacity

1.89 litres

Radiator Cap Opening

Press ure

1.2 bar

Thermostat Opening

Tem perature

88°C

Cooling Fan Switch On

Tem perature

103°C

Tem perature Gauge Sens or

Res istance

173 Ohms (+/- 10%) at 100°C

Suspension

Front Fork Travel

200 mm

Recommended Fork Oil

Grade

Showa SS47

Oil Level (spring, spring seat

and spacer removed and

fork fully compressed)

114 mm

Oil Volum e (dry fill)

602cc

Front Fork Pull Through

45.7 mm +/- 0.5 mm from lower edge of top yoke

to the top of the inner tube (not the top cap)

Fork Spring Rate

4.5 N/mm

Rear Wheel Travel

200 mm

Brakes

Front Type

Four pis ton monobloc calipers acting on twin discs

Service Manual - Scrambler 1200 XC 42 of 640

Page 43

Front Caliper Piston

Diameter

28m m

Front Disc Diameter

320mm

Front Disc Thickness

4.5mm

4.0mm

Front Disc Run-out Max.

0.25m m

Front Mas ter Cylinder

Diameter

18 mm

Recommended Fluid

DOT 4

Rear Type

Twin piston sliding caliper acting on single disc

Rear Caliper Piston

Diameter

28m m

Rear Dis c Diam eter

255mm

Rear Dis c Thickness

5.5mm

5mm

Rear Dis c Run-out Max.

0.25m m

Rear Master Cylinder

Diameter

14m m

Recommended Fluid

DOT 4

Frame

Frame Type

Tubular steel

Service Manual - Scrambler 1200 XC 43 of 640

Page 44

Rake

25.8°

Trail

121.0mm

Maximum . Payload (rider,

pas senger, luggage and

acces sories)

210 kg

Whee ls and Tyres

Front Wheel Size

MT 21 x 2.15

Front Tyre Size

90/90-21 54H

Front Tyre Pressure

2.5 bar (36 lb/ in²)

Front Wheel Rim Axial run-

out

1 mm

Front Wheel Rim Radial

Run-out

1 mm

Rear Wheel Size

MT 17 x 4.5

Rear Tyre Size

150/70R17 69V

Rear Tyre Pressure

2.9 bar (42 psi lb/ in²)

Rear Wheel Rim Axial run-

out

1 mm

Rear Wheel Rim Radial

Run-out

1 mm

Approved Tyres

A list of approved tyres specific to these models is

available from your authorised Triumph dealer, or

on the Internet at www.trium ph.co.uk.

Electrical Equipment

Service Manual - Scrambler 1200 XC 44 of 640

Page 45

Battery Type

YTZ10S

Battery Rating

12 V - 8.6 Amp. Hour

Alternator Rating

18 Amps at 1000 rpm

33 Amps at 6000 rpm

Headlight

LED

Rear Light/Brake Light

LED

Licence Plate Light

LED

Directional Indicator Lights

LED

Torque Wrench Settings

Cylinder Head

Application

Torque

(Nm)

Notes

Cam shaft cover to cylinder head

*

See

Cam shaft Cover -

Installation

Cam shaft drive chain tens ioner blade to

cylinder head

10 Nm

Fit new fixing(s) if

loosened or removed

Cam shaft drive chain tens ioner to cylinder

barrel

16 Nm

Cam shaft fram e to cylinder head

*

See

Cam shaft -

Installation

Cam shaft idler shaft bolt

10 Nm

Fit new fixing(s) if

loosened or removed

Cam shaft s procket to cams haft

*

See

Cam shaft -

Service Manual - Scrambler 1200 XC 45 of 640

Page 46

Application

Torque

(Nm)

Notes

Installation

Fit new fixing(s) if

loosened or removed

Cylinder head dry seal plug

6 Nm

Fit new fixing(s) if

loosened or removed

Cylinder head to crankcas e

*

See

Cylinder Head -

Installation

Exhaust stud to cylinder head

10 Nm

Fit new fixing(s) if

loosened or removed

Flanged plug to cylinder head

22 Nm

Fit new fixing(s) if

loosened or removed

Spark plugs

12 Nm

Service tool

T3880609 - Timing Torque

Lim iter

0.6 Nm

Clutch

Application

Torque

(Nm)

Notes

Clutch cable lower lock nut

3 Nm

Clutch centre nut

98 Nm

Fit new fixing(s) if

loosened or removed

Fit new Belleville

was her

Clutch lever clamp bolts

12 Nm

Clutch lever nut

3.4 Nm

Clutch pres s ure plate to centre

10 Nm

Service Manual - Scrambler 1200 XC 46 of 640

Page 47

Application

Torque

(Nm)

Notes

Clutch switch cover

1 Nm

Balancer, Crankshaft and Crankcase

Application

Torque

(Nm)

Notes

Breather plate to crankcase

9 Nm

Fit new fixing(s) if

loosened or removed

Connecting rod big end bolts

*

See

Connecting Rod -

Installation

Crankcas e breather pipes to crankcase

9 Nm

Fit new fixing(s) if

loosened or removed

Crankcas e to crankcase bolts

*

See

Crankcas e -

As sem bly

Dead shaft clam p pinch bolt

10 Nm

Dead shaft clam p retaining bolt

10 Nm

Fit new fixing(s) if

loosened or removed

Dead shaft preload

*

See

Balancer Shafts

Dynamic Adjustment

Dry s eal plug

23 Nm

Fit new fixing(s) if

loosened or removed

Flanged plug

10 Nm

Fit new fixing(s) if

loosened or removed

Oil filler cap

3 Nm

Plug, front balancer shaft adjuster clam p

23 Nm

Service Manual - Scrambler 1200 XC 47 of 640

Page 48

Application

Torque

(Nm)

Notes

Rear dead shaft retaining washer

12 Nm

Fit new fixing(s) if

loosened or removed

Sprag clutch housing fixings

*

Fit new fixing(s) if

loosened or removed

See

Starter Drive/Sprag

Clutch - Installation

Sprag thrust washer fixings

12 Nm

Fit new fixing(s) if

loosened or removed

Engine Covers

Application

Torque

(Nm)

Notes

Alternator cover embellisher to cover

4 Nm

Fit new fixing(s) if

loosened or removed

Alternator cover to crankcase

10 Nm

Baffle to sump

6 Nm

Cable cover to alternator cover

6 Nm

Fit new fixing(s) if

loosened or removed

Cam shaft cover

*

Cam shaft Cover -

Installation

Clutch cover embellisher to clutch cover

4 Nm

Fit new fixing(s) if

loosened or removed

Clutch cover plug

10 Nm

Clutch cover to crankcas e

*

Fit new fixing(s) if

loosened or removed

See

Clutch Cover -

Installation

Service Manual - Scrambler 1200 XC 48 of 640

Page 49

Application

Torque

(Nm)

Notes

Front sprocket cover - outer to inner

9 Nm

Front sprocket cover - inner to crankcas e

3 Nm

Sump plate

6 Nm

Fit new fixing(s) if

loosened or removed

Sump plug

25 Nm

Fit new sealing

was her(s)

Sump to crankcase

10 Nm

Transmission

Application

Torque

(Nm)

Notes

Detent arm fixing

12 Nm

Fit new fixing(s) if

loosened or removed

Detent arm spring fixing

12 Nm

Fit new fixing(s) if

loosened or removed

Detent wheel to selector drum

12 Nm

Fit new fixing(s) if

loosened or removed

Front sprocket to output shaft nut

180 Nm

Fit new fixing(s) if

loosened or removed

Gear change pedal pinch bolt

8 Nm

Input selector fork plug

22 Nm

Fit new fixing(s) if

loosened or removed

Input shaft bearing retainer

7 Nm

Fit new fixing(s) if

loosened or removed

Service Manual - Scrambler 1200 XC 49 of 640

Page 50

Application

Torque

(Nm)

Notes

Output selector shaft retainer

12 Nm

Fit new fixing(s) if

loosened or removed

Selector drum bearing retaining screw

12 Nm

Fit new fixing(s) if

loosened or removed

Starter drive flywheel

*

See

Starter Drive/Sprag

Clutch - Installation

Lubrication System

Application

Torque

(Nm)

Notes

Oil cooling jet (pis tons)

9 Nm

Fit new fixing(s) if

loosened or removed

Oil filter

10 Nm

Apply clean engine oil

to the seal(s)

Oil filter adapter

10 Nm

Fit new fixing(s) if

loosened or removed

Oil pres sure relief valve plug

10 Nm

Oil pres sure switch

15 Nm

Fit new sealing

was her(s)

Oil pum p drive chain guide fixings

7 Nm

Fit new fixing(s) if

loosened or removed

Oil pum p drive sprocket to oil pump

12 Nm

Oil pum p rotor cover to oil pump body

10 Nm

Oil pum p to crankcase

10 Nm

Fit new fixing(s) if

loosened or removed

Service Manual - Scrambler 1200 XC 50 of 640

Page 51

Application

Torque

(Nm)

Notes

Sump baffle plate to sump

6 Nm

Fuel System, Exhaust System and Airbox

Application

Torque

(Nm)

Notes

Air filter cover to airbox

1 Nm

Air intake duct clip

1.5 Nm

Air intake finisher

1.5 Nm

Fit new fixing(s) if

loosened or removed

Air intake finisher mounting

3 Nm

Fit new fixing(s) if

loosened or removed

Air temperature sensor

1.5 Nm

Airbox to frame

6 Nm

Am bient air pressure sens or

2 Nm

Crankshaft pos ition sensor

6 Nm

Fit new fixing(s) if

loosened or removed

Engine ECM bracket

4 Nm

Exhaust centre cover assem bly

6 Nm

Exhaust headers to cylinder head

*

Left Hand Header Pipe

- Installation

Exhaust Catalytic

Converter - Ins tallation

Exhaust rear cover and bracket

6 Nm

Service Manual - Scrambler 1200 XC 51 of 640

Page 52

Application

Torque

(Nm)

Notes

Exhaust silencer bracket to frame

19 Nm

Fit new fixing(s) if

loosened or removed

Fall detection switch

3 Nm

Fit new fixing(s) if

loosened or removed

Fuel hose bracket to fuel pump mounting

bracket

4 Nm

Fuel hose to fuel pump

15 Nm

Fit new sealing

was her(s)

Fuel pump baffle clamp

3 Nm

Fuel pump clamp

4 Nm

Fuel pump mounting bracket to fuel pump

plate

7 Nm

Fit new fixing(s) if

loosened or removed

Fuel pump mounting plate to fuel tank

*

Fit new sealing

was her(s)

. See

Fuel

Pump - Installation

Fuel rail to cylinder head

6 Nm

Fuel tank strap

5 Nm

Fuel tank strap boss

1.5 Nm

Fit new fixing(s) if

loosened or removed

Fuel tank to frame

8 Nm

Gear pos ition sens or

5 Nm

Fit new fixing(s) if

loosened or removed

Heatshield to exhaust silencer

6 Nm

Service Manual - Scrambler 1200 XC 52 of 640

Page 53

Application

Torque

(Nm)

Notes

Ignition coil assembly fixings

3 Nm

Fit new fixing(s) if

loosened or removed

Inlet manifold to cylinder head

9 Nm

MAP sensor

2 Nm

Oxygen sens or

25 Nm

Oxygen sens or connector bracket

3 Nm

Purge valve bracket

4 Nm

Relay bracket

1.5 Nm

Single throttle body to inlet manifold

9 Nm

Twist grip position sensor

2.5 Nm

Fit new fixing(s) if

loosened or removed

Cooling System

Application

Torque

(Nm)

Notes