Page 1

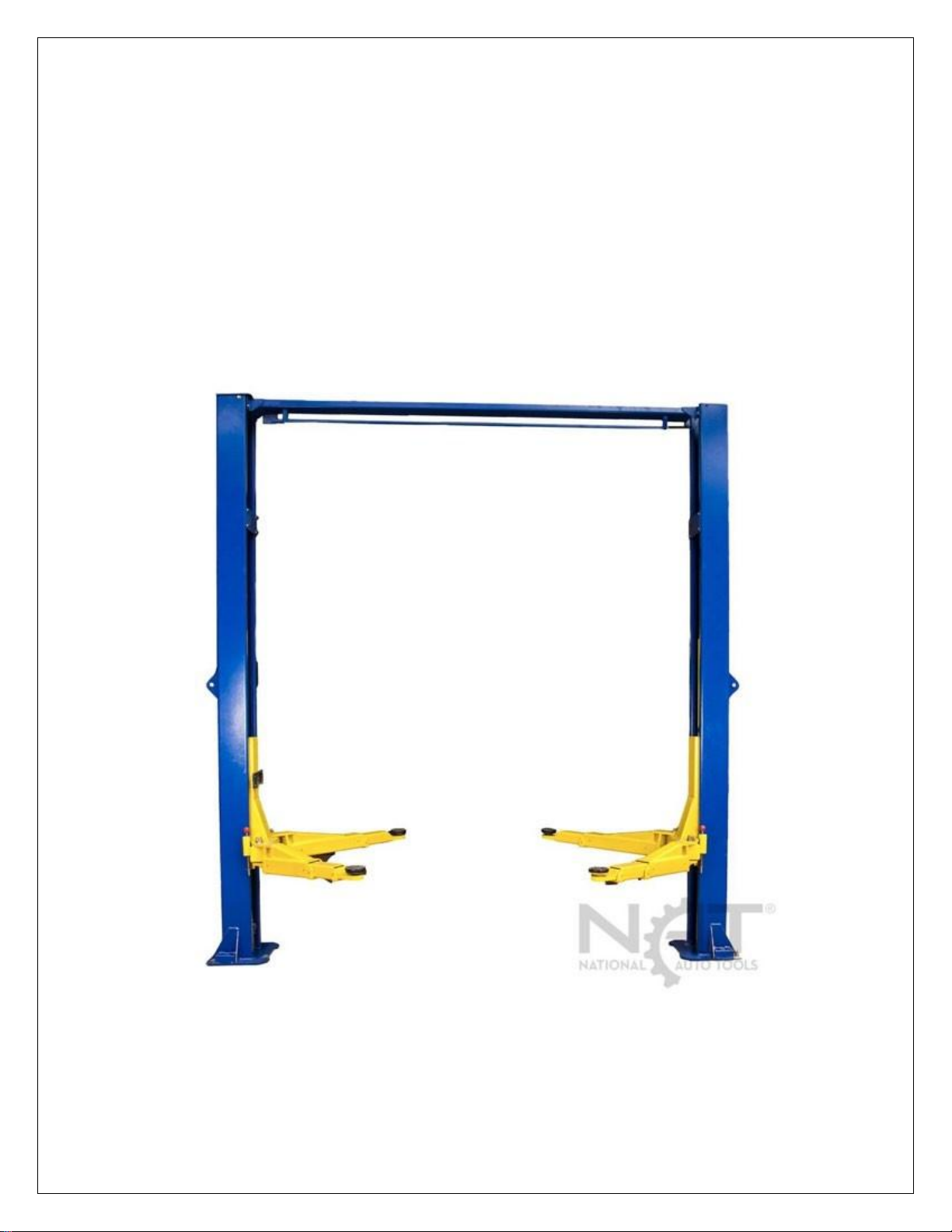

OVERHEAD TWO POST LIFT

FOR MODELS:

NTO-9A - NTO-10A - NTO-9AE

DATE INSTALLED: ____________ SERIAL NUMBER _____________

Page 1 of 20

Page 2

INTRODUCTION

You have purchased a two post 9,000 pound lift that is a great value for the price. Please

read this manual thoroughly before starting any installation. You will find information not

only in install but also safety, maintenance and troubleshooting that should also be

understood.

If properly taken care of, this lift should be useful to you for a long time. Pay attention to

safety and maintenance as they play an important part in making your lift last a long time.

Call us if you have any questions or need any repair parts for this lift.

Thoroughly read this manual before operating the lift. Always display this manual in a

conspicuous location near the lift. Personal injury and property damage incurred due to

non-compliance this these safety instructions are not covered by warranty.

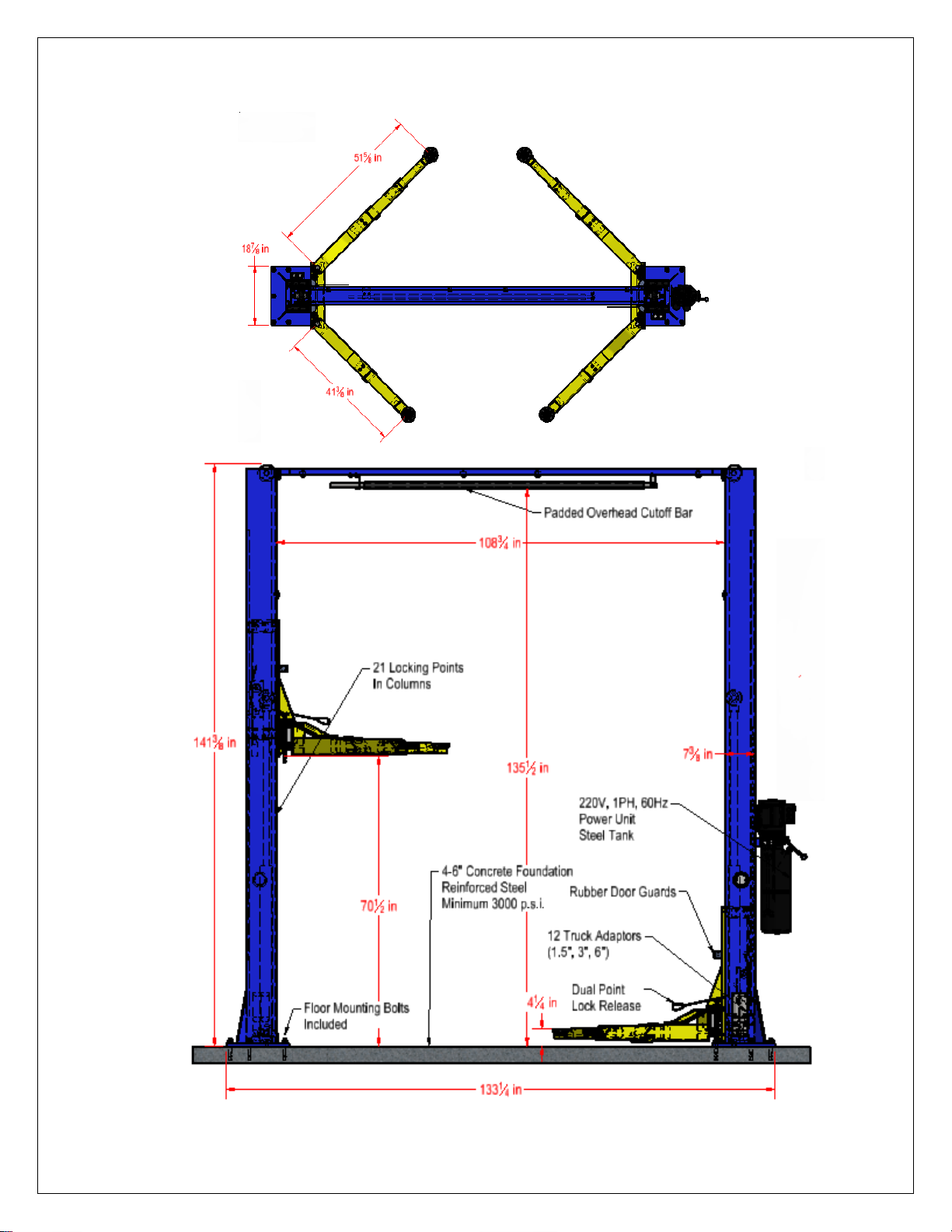

LIFT SPECIFICATIONS

9,000 Pound (NTO-9AE & NTO09A) 10,000 Pound (NTO-10A) Max Capacity

Two Post Overhead Verisymmetric

Triple Arm Length (Max 51.5”, Min 29”)

Double Arm Length (Max 41.5” Min 27”)

Rubber Door Protectors on columns

Chain Lifting – Stronger than cable used on other lifts

Hydraulic Power Unit - 220 V, 1PH, 60Hz (Standard), 3 HP

Lifting Time 40-50 Seconds

Cable Equalization

Locking Method: Dual Point Release

Electric Safety Cutoff Bar

Distance between columns: 109”

Distance to outside of columns: 124”

Drive through width at carriage: 100”

Overall width including power unit: 145”

Height Under Arm at top of Stroke: 73.5”

Height under Arm at top Lock 67”

12 Sets of Drop In Adapters (1.5”, 3”, 6”)

Height to top of pad when lift fully Lowered: 4.5”

Overall Lift Height: 142.5”

Distance outside of base plates: 133”

Shipping Weight: 1407 Pounds

Page 2 of 20

Page 3

Page 3 of 20

Page 4

BOLT BOX CONTENTS

Cable

33’7” Long

7.25” (thread and blank)

4 5/8 Thread

Cable 5/16

½ Stud Threaded

Hole for cable is 5/8 (so can’t use 3/8” Cables)

2 nuts 2 washers

TOOLS TO INSTALL

Hammer Drill

¾” Carbide Drill Bit

Various wrenches, pliers and screwdrivers

Block of Wood

Hammer

Torque Wrench

Tall Ladder

Fork Lift or other method of raising columns and toprails

Electrical connectors to connect 220 volt power unit (use Qualified Electrician)

Level

Chalk Line

Good O-ring Pliers

Grease for column

Chain oil for chains

Vacuum to clean dust from anchor holes

Rags

Allow at least 3-4 hours to set up lift.

SYMBOLS IN THIS MANUAL

Failure to comply with instructions could result in personal injury.

Failure to comply with instructions could result in property damage.

Important Information

Page 4 of 20

Page 5

SHIPPING AND DELIVERY

If not picked up at our location, your freight will be delivered in a semi-truck and box trailer.

Please be sure that a truck this large can access your delivery location. If the truck cannot

gain access, you will have to make other arrangements with the freight company. Your lift

could weigh from 1,200 lbs - 1,900 pounds depending on your model. You will need

assistance, or a forklift, tractor or backhoe, to remove from the delivery truck.

We can arrange for you to pick up at the nearest freight terminal with your personal trailer.

Drivers cannot help you unload the truck. You must unload the lift. Drivers are not required

to come on to your property if they think it is dangerous them, their truck or you property.

Customers are responsible for arranging any delivery appointments with the delivery

trucking company. The driver can only deliver to the address on the delivery receipt (the

driver has no authorization to change delivery address). All products must be delivered to a

physical address. Please note that we do not own or operate the delivery trucks, they are all

common carriers. Customer can arrange an appointment for delivery. Please note that the

driver will not call you when he is at the location or just before arriving. His job is to deliver,

not to call each customer.

Automotive lifts are too large for a lift gate. If you have ordered any product that can be

delivered on a pallet then you can arrange for a lift gate but that will be extra expense.

The following locations are considered to be limited access areas and may require special

equipment or special circumstances for delivery. There is an extra charge to deliver to these

and some other special areas. Customer is responsible for these extra charges..

These areas include but are not limited to:

Residence, any location that has a living residence on site

Farms

Schools

Construction sites

Trade shows

State parks

Government locations with restricted access

Islands

Please note that due to fluctuating fuel costs, any freight costs quoted will only be valid for 3

business days.

Page 5 of 20

Page 6

Our freight carriers assume that when a customer provides a business name, the business

is open from 8AM-5PM Monday-Friday, the business is located at a commercial address,

and that the business does not have a home or any other living residences on the property.

We will not be responsible for redelivery charges to businesses that are not open during the

above mentioned hours when the first delivery attempt was made. Any redelivery or

residential delivery cost that are incurred due to misrepresentation or fault of the customer,

must be paid in full to us or the warranty on the respective product is void. Any storage

charges from the respective freight company must be paid in full before equipment will be

released for delivery. Any costs left unpaid will void the warranty. Customers are responsible

for unloading from delivery truck at time of delivery. Lift gate service cannot and will not be

provided for auto lift delivery.

ANCHORING TIPS

1. Concrete needs to be fully cured and a minimum of 4000 PSI compressive strength.

Thickness 4-6 inches in order to achieve minimum anchor embedment of 3.25”. When

using the standard anchor bolts - if the top of the embedded anchor exceeds 2.25”

above floor grade, you DO NOT have enough embedment.

2. Use the holes in base plates as guide for drilling the ¾” holes needed. Do not drill over

an edge or a seam or a crack. Hole to hole spacing should be a minimum 6.5” in any

direction. Concrete thickness or hole depth should be a minimum of 4”.

CAUTION: DO NOT install on asphalt or other similar unstable surface. Concrete

only. Columns are supported only by anchors in the floor.

3. Using the horseshoe shims provided, shim each column base until each column is

plumb. If one column has to be elevated to match the the other column, full size base

shim plates should be used (not provided).

4. Torque anchors to 120 ft-lbs. Shim thickness MUST NOT exceed ½” when using the

supplied anchors with the lift.

5. If anchors cannot be torqued to 120 ft-lbs. then replace concrete under each column

base with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under, and flush

with, the top of the existing floor. Let concrete fully cure before installing lifts and

anchors.

6. Anchors must be at least 6” from the edge of the slab or any seam.

7. Use a concrete hammer drill with a ¾” carbide bit. Do not use excessively worn bits or

bits which have been incorrectly sharpened.

8. Keep the drill perpendicular while drilling.

Page 6 of 20

Page 7

9. Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down

occasionally to remove residue to reduce binding.

10. Drill the hole to depth equal to the length of anchor. You can drill completely through the

floor so that when you remove the lift at a later date you can hammer them down instead

of just cutting off with a saw.

11. For better holding power blow dust from the hole.

12. Place a flat washer and hex nut over threaded end of anchor, leaving approximately ½

inch of thread exposed. Carefully tap anchor. Do not damage threads. Tap anchor into

the concrete until nut and flat washer are against base plate. Do not use an impact

wrench to tighten. Tighten the nut, two or three turns on average concrete (28 day

minimum cure). If the concrete is very hard only one or two turns may be needed. Check

each anchor bolt with torque wrench set to 120 foot pounds.

13. Recheck Anchors periodically to be sure they have not loosened and retighten as

needed.

INSTALLATION

Check for ceiling clearance first to confirm the lift can be set up in your shop bay. You will

need at least 144” of ceiling height.

CAUTION: DO NOT install on asphalt or other similar unstable surface. Concrete only.

Columns are supported only by anchors in the floor.

1. After unloading the lift, place it near the intended installation location. Remove the

shipping bands and packing materials. Remove the parts from inside that columns.

2. Unbolt columns from packing brackets. You will need a fork lift to remove the columns

due to their weight. Do not discard bolts as they are used in the assembly of the lift.

3. Make sure your choice of installation leaves enough distance from all walls and

obstacles. The ceiling height must be at least 12 feet. It is recommended locate the

power side column on the vehicle driver’s side for ease of operation later.

4. Raise the offside column (not power unit column) to vertical position.

5. Position the columns facing each other at 103.5” inside base plates. Square the columns

by measuring diagonally from corner points on base plates (within ¼”). Or by dropping a

chalk line to help you keep both base plates on the same plane. (Columns must be

parallel to each other).

Page 7 of 20

Page 8

6. Using a ¾” concrete drill, drill the anchor holes in the offside (not power unit) column,

installing anchors as you go. Use a block of wood or rubber mallet to drive anchor bolts

in. drill to a minimum depth of 4” to insure maximum holding power. Drilling through

concrete recommended) will allow the anchors to be driven through the bottom if ever

the anchor needs to be replaced later. Or you decide to move the live at a later date.

(Showing Installation of first Anchor Bolt)

7. Using a level, check column for side to side plumb and from to back plumb. If needed,

use horseshoe shims provided by placing shims under the base plates and around the

anchor bolts. This will prevent bending the column bottom plates (Shim thickness should

not exceed ½”). Tighten anchor bolts to 120 ft-lbs.

8. DO NOT ANCHOR THE POWER UNIT COLUMN AT THIS TIME.

9. Install the overhead cross beam. Be sure to bolt them together by installing the bolts

from inside the cross beam out to avoid interference with the cables when operating the

lift. Bolt the cross beam to the two columns.

10. Assemble cable sheaves on each end of top rail. Flat side of sheaves to the inside to

help when stringing cable later. Assembly consists of O-Rings Plastic spacers, sheaves

and protection shields. Assemble before raising the top rail and bolting to lift.

Page 8 of 20

Page 9

11. After fastening the cross beam, check and confirm that the remaining column is plumb.

(Making sure the power column on left and offside column are plumb. Critical.)

12. Secure the power column, and make plumb. In same fashion as the first column.

13. At this point you can put in all anchors in both columns once you are sure they are

positioned properly and plumb and square. Also make sure you have securely bolted the

top rail. Install the rubber door protectors on both columns with bolts provided.

14. Install the equalizing cables.

a. Manually set both carriages on the first safety latch. Be sure each carriage is at

the same height by measuring from the top of the base to the bottom of the

carriage. DOUBLE CHECK THE LATCHES ARE ENGAGED BEFORE

WORKING UNDER OR AROUND THE CARRIAGES). This dimension should be

within ¼”.

b. Run the first cable. Tighten nut on one cable stud. Pull the other end of the cable

and run nut on it. Tighten both nuts. Repeat above for second cable.

Note: the cable stud that connects to the front right corner of the carriage should be

connected first by pulling the stud through the carriage hold and up where it is easy

to be held by locking pliers. Pull the stud past the locknut. Connect the other ends to

the rear right corners of the carriage with at least ½” of thread showing past the lock

nut (cables run on the inside of the carriage). It may be necessary to manually raise

both carriages above the cylinder to prodi enough space to use the locking pliers.

Make sure the carriage is set in the LOCK position.

Page 9 of 20

Page 10

c. Adjust cables to same tightness. This will allow them to keep the carriages level

as the lift rises.

d. Adjust the carriage cable tension. This is accomplished by tightening the carriage

adjustment nut on top of each carriage. The rear carriage adjustment nut adjust

the opposite post carriage height.

e. The left post carriage nut adjusts the right column carriage, and the right column

carriage nut adjusts the left column carriage. Adjust each cable to approximately

½” side to side play. Check the latch releases to insure the carriage is still

engaged in the appropriate latch.

15. Check cylinders are in place properly. They were installed in factory but may have

moved. Make sure the tip on the bottom of the cylinders fit into the center hole on top of

the cylinder mount in base plate.

16. Pull the pre-attached leaf chain in both sides up and over the chain sheaves on top of

the cylinders if not already done at factory.

17. Mount the power unit on the main side leg to the power unit bracket using the two bolts

and nuts provided.

(Make sure power unit securely attached as it weighs a lot when full of fluid)

Page 10 of 20

Page 11

18. Install all swing arms, make sure that gear rack are engaging the moon gear on the arms

properly. There are two triple and a two double stage arms. The triple arms should be

toward the front of the car as you are sitting in it, two stage arms will hold up the

rear of the vehicle.

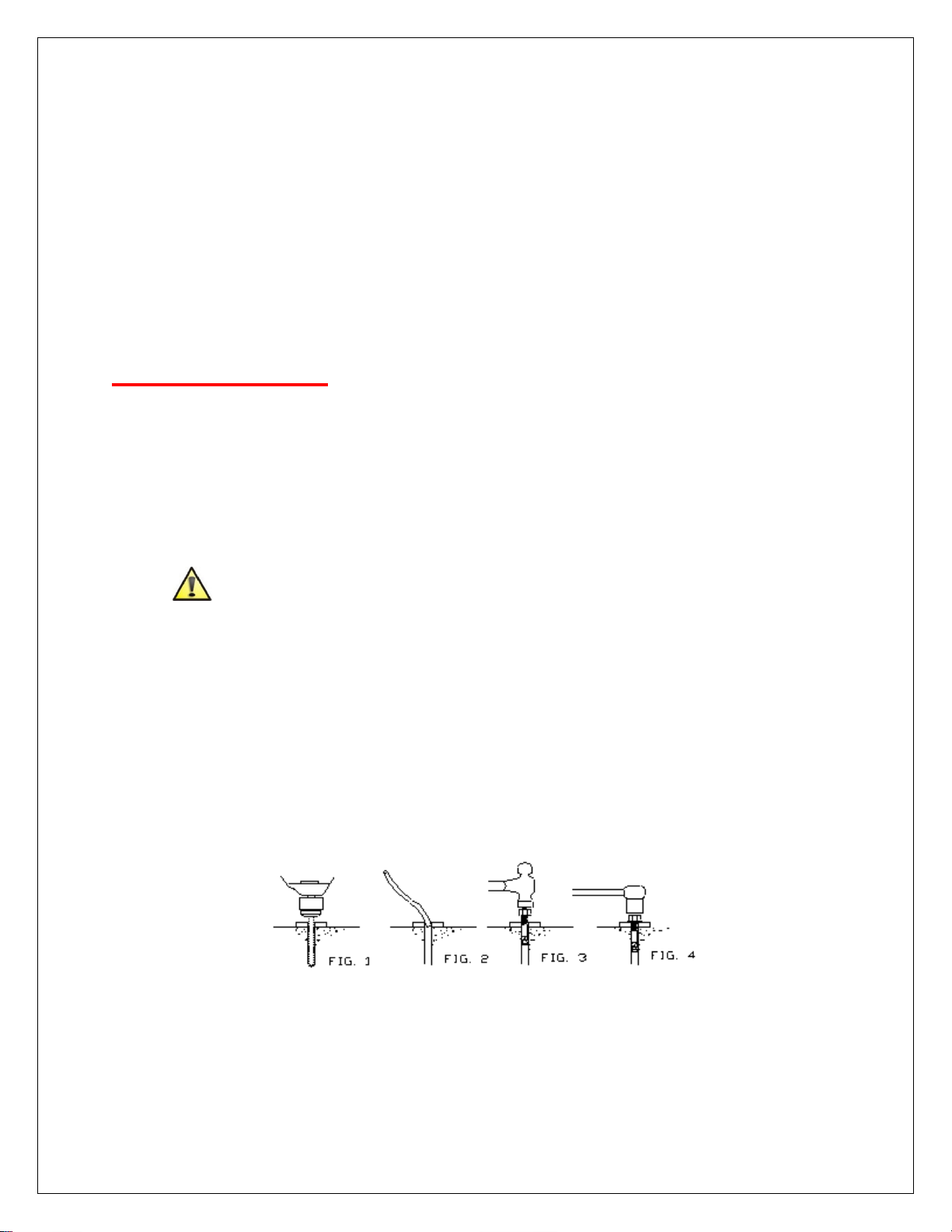

19. Truck Adapters – When using lift you can use the three sizes of drop in adapters.

Especially useful on trucks.

(Shown with no adapter, 1.5”, 3”, and 6”)

20. Remove the vent plug from the power unit and fill the reservoir. Use a light weight non

foaming, non-detergent hydraulic oil. The unit will hold 12 quarts. Fill to within two inches

of top. Measure with screw driver or finger.

21. Have a qualified electrician hook up the power unit to the power supply. The electrical

wiring must comply with local code. Protect circuit with time delay fuse or circuit breaker.

22. Installation of Overhead Cut-Off Beam

a. The cut off beam is installed on the top rail and protects against over raising the

lift. There is an electric cut off switch. Remove the wires and thread through the

small tubes on the inside of the power beam. Start from bottom and when you

get to the top reattached to the switch.

Page 11 of 20

Page 12

23. Install hydraulic hoses

a. Connect the hydraulic hoses. Make sure all guides are in place on top of the top

rail for pulling the hoses through.

24. Operate the lift and apply pressure to the safety cut off to insure motor shuts off prioe to

any part of vehicle coming in contact with cut off bar. Adjust as needed.

25. Do not place any vehicle on the lift at this time. Cycle the lift up and down several times

to insure latches engage properly and all air is removed from the system. To lower the

lift, first raise the lift to clear the latches and then pull the two lock release cables and hit

the dump valve to lower the lift to the nearest lock. If latches are out of sync, tighten the

cable on the latch that engages first.

NOTE: Re-Check That All Hardware Has Been Properly Tightened

Page 12 of 20

Page 13

FOR SINGLE POINT RELEASE LIFTS ONLY

(NTO-9A & NTO-10A)

For lifts equipt with a single point lock releae (a leaver that release both sides simultaneously) will require these

additional steps.

1. Route cable up the column, over the release pulleys and back down to the second lock release.

1a. NOTE: Pulleys are attached to the upper outside of each column with supplied hex head bolts.

2. Insert one end of the cable into the hole in the lock lever, leaving 2-3 inches of cable sticking through, then

tighten jam nuts to clamp the cable into place in the lock lever. With the cable attached at the lever end and

routed over both release pulleys, draw the cable under the lock release shaft (as shown) and back up through

the hole in the provided stud. Secure cable end with jam nuts (same as lever side) and trim excess cable.

Page 13 of 20

Page 14

MAINTENANCE

The following is the suggested maintenance schedule for this lift. If you hear or see any sign of

impending failure, cease operation immediately and inspect, correct and replace failed or

failing parts.

USERS SHOULD ALWAYS INSPECT LIFTING EQUIPMENT AT THE START OF EVERY

SHIFT. THESE AND OTHER PERIODIC INSPECTIONS ARE THE RESPONSIBILITY OF THE

USER/OWNER.

NOTE: Relocating or changing components may cause problems. Each component in the

system must be compatible; an undersized or restricted line will cause a drop in pressure. All

valve, pump, and hose connections should be sealed and/or capped until just prior to use. Air

hoses can be used to clean fittings and other components. However, the air supply must be

filtered and dry to prevent contamination. Most important - cleanliness - contamination is the

most frequent cause of malfunction or failure of hydraulic equipment.

a. DAILY PRE-OPERATION CHECK

ATTENTION! LOOK OUT! Daily check of safety latch system is very important- the

discovery of device failure before needed could save you from expensive property

damage, lost production time, serious personal injury or even death.

i. Check safety lock audibly and visually while in operation. Check safety latches

for free movement and full engagement with rack.

ii. Check hydraulic connections, and hoses for leakage.

iii. Check chain and cable connection for bends, cracks and looseness.

iv. Check for frayed cables in both raised and lowered positions.

v. Check snap rings on all rollers and sheaves.

vi. Check bolts, nuts, and screws and tighten as needed.

vii. Check wiring & switches for damage.

viii. Clean any dirt, grease or any other corrosive substances from base plates.

ix. Check floor for stress cracks near anchor bolts.

x. Check swing arm restraints.

b. WEEKLY MAINTENANCE

i. Check anchor bolts torque to 120 ft-lbs.

ii. Check floor for stress cracks near anchor bolts

iii. Check hydraulic oil level and if low find leak you may have to replace or repair

cylinder or power unit.

iv. Check and tighten bolts and nuts, and screws.

v. Check cylinders for free movement. Look out for excessive ware on cylinder

yokes or pulley pins.

vi. Check cable pulleys for free movement and excessive ware.

c. YEARLY MAINTENANCE

i. Lubricate chain

ii. Grease rub blocks and column where they rub

iii. Change hydraulic fluid. Good maintenance procedure makes it mandatory to

keep hydraulic fluid clean. No hard fast rules can be established;, operating

temperature, type of service, contamination levels, filtration, and chemical

composition of fluid should be considered. If operating in dusty environment

shorter intervals may be needed.

Page 14 of 20

Page 15

d. The following items should only be performed by trained maintenance expert

i. Replace hydraulic hoses.

ii. Replace chains and rollers.

iii. Replace cables and sheaves.

iv. Replace or rebuild air and hydraulic cylinders.

v. Replace or rebuild power units

vi. Check hydraulic cylinder rod and rod ends for deformation or damage.

vii. Check cylinder mount for looseness or damage.

OPERATION

1. Each support arm is provided with an automatic arm restraint which unlatches

automatically when the lift is fully lowered. When the carriages are in the raised

position, the arm restraint can be disengaged by pulling the two release cables.

2. Fully lower the lift and swing the arms to full drive through position.

3. Slowly position vehicle midway between adapters. Apply the parking brake

4. Swing the adjust the telescope arms as required to position adapters under vehicle

manufacturer's recommended lifting points for the vehicle you are working on.

5. Turn the disk adapters so they evenly contact all four lifting points. Add the 1.5”, 3”,

or 6” truck adapter extensions as needed to fully contact the lifting points.

6. Make sure lifting points are free of grease or oil as this might make the adapters slip

off the lifting point when vehicle is raised. VERY IMPORTANT!

7. Do not place any vehicle on the lift at this time. Cycle lift up and down several times

to insure latches click together and all air is removed from the system. To lower the

lift, latch releases must be manually released. Latches will automatically reset once

the lift ascends approximately 20” from base.

8. If latches click out of synchronization, tighten the cable on the one that clicks first.

9. Once the disk adaptors contact the lifting points check arm restraints for

engagement. If necessary, slightly move arms until the gear segments mesh.

10. Never unlatch the arm restraints when the lift is under load.

11. Do not stand under lift when lift is moving and before locks are engaged..

12. Always lift the vehicle using all four adapters.

RAISING VEHICLE

1. During raising and lowering cycle closely watch the vehicle and the lift, do not allow

anyone to stay in lift area and make sure the vehicle doors are closed.

2. Once the disk adapters contact the lift points, check arm restraints for engagement.

After raising the vehicle briefly, stop and check adapters for secure contact.

3. Press button on power unit to begin raising the lift. It may take about 40 to 50

seconds if raising to full height. Remember there are many other stopping points in

between should you not want to raise to full height.

4. Lift stops once button is released or upward travel limit is reached.

5. Observe all accident prevention regulations.

6. Do not allow unauthorized persons to stay under the raised vehicle.

7. Avoid rocking of vehicle. Use stabilizer stands (not provided) to stabilize long

vehicles for extra safety.

8. Fasten the vehicle to the support arms using lashing straps when removing or

installing heavy components. This will keep vehicle for shifting and possibly falling so

very important.

Page 15 of 20

Page 16

LOCKING

1. The latch mechanism will 'trip over' when the lift raises and drop into each latch stop. But, to

lock the lift you must press the lowering lever to relieve the hydraulic pressure and let the

latch set tight in the nearest lock position.

2. Always lock the lift before going under the vehicle. Never allow anyone to go under the lift

when raising or lowering.

3. Read the safety procedures in the manual.

LOWERING VEHICLE

1. Note: It is normal for an empty lift to lower slowly. It may be necessary to add weight.

2. Raise the lift until the latch clears.

3. Pull both latch releases

4. Warning: Always release both sides.

5. Press and hold the lowering lever at the power unit to lower the lift.

SAFETY

1. The lift is designed for the safe lifting of automotive vehicles within the lifting capacity of the

lift. Observe the rated load capacity and load distribution of the lift.

NTO-9AE Max Load 9,000lbs

NTO-9A Max Load 9,000lbs

NTO-10A Max Load 10,000lbs

2. In principle, the lift is designed for both approach directions. For long service life, use the

short (Two Section) support arms for engaging the engine side of the vehicle.

3. The lift should be installed by professional lift installers. If you do it yourself be careful on

ladders and using heavy equipment like forklifts. Do not install near explosive or flammable

liquids, outdoors or in moist rooms (e.g. car wash) or where rain can reach the power unit. It

is not rated for use in wet conditions. If you do set it up outside you must keep all water from

reaching the power unit. This is not just for safety but also will ruin the power unit and that is

not covered under warranty.

4. SAFETY TIPS FOR OPERATION

a. Read and understand this manual before install or using the lift.

Page 16 of 20

Page 17

b. Lift should only be operated by fully trained personnel.

c. Keep the lift and lift area clean and free of tools, parts, debris, etc.

d. Once the disk adaptors contact the lift points, check arm restraint mechanisms on

each arm for engagement.

e. When you start raise the vehicle a little and then check the disk adapters have

secure contact with vehicle lifting points. Always lift the vehicle using all four

adapters.

f. Close vehicle doors are closed during raising and lowering cycles.

g. Closely watch the vehicle and the lift during raising and lowering cycles. Do not allow

anyone to stay in lift area during raising and lowering cycles.

h. Never allow anyone on lift or inside when raising or lowering the lift.

i. Only use the lift for its intended purpose.

j. Comply with the applicable accident prevention regulations of your area.

k. Do not overload the lift. The rated load capacity is indicated on the lift nameplate.

l. Only use the vehicle manufacturer’s recommenced lift points

m. After positioning the vehicle on the lift apply the parking brake.

n. Use caution when removing or installing heavy components (center-of-gravity

displacement). And be careful when picking up trucks with heavy equipment in

the bed as this will change the center of gravity of the truck and could lead to

accident. This is very important.

o. Protect all parts of the electrical equipment from humidity and moisture.

i. You must hold the controls in the engaged position to raise or lower the lift.

p. Equalizing System

i. The lift has equalizing cables to ensure level movement of both carriages.

Make sure they are adjusted properly.

q. Collision Prevention Switch

i. A cut off is provided to prevent collision between vehicle roof and cross

member. Test frequently to be sure it is fully operational.

r. Pinch Point Protection

i. During lowering cycles the support arms automatically stop at a height of 4.5

inches from ground.

ii. To lower the lift completely, raise lift off the lock, and hold the dump handle to

lower. Lift travel to the lower limit stops is accompanied by an audible click.

iii. Automatic Arm Restraint = Once the lift is raised, the arm restraints are

locked automatically to avoid any swivel under load. Make sure the locking

gears engage when lifting a load for safety.

5. SAFETY TIPS FOR SERVICING LIFT

a. Maintenance or repair work by trained service personnel only.

b. Turn off the electricity to lift before doing any maintenance or repair work. Any

electrical work on the lift should only be done by certified electricians. This is

especially critical when initially installing the power unit because errors here, if

not done by qualified electricians, will not be covered under warranty.

c. Ensure that ecologically harmful oils are disposed of only in accordance with the

appropriate regulations.

d. Do not use high pressure/steam jet cleaners or caustic cleaning agents on the lift.

Risk of Damage.

e. Do not replace or override the safety devices

Page 17 of 20

Page 18

f.

PROBLEM

POSIBLE CAUSES

SOLUTIONS

Motor Not Running

Breaker or fuse blown

Call Electrician

Motor thermal overload tripped

Wait for overload to cool

Faulty wiring connections

Call electrician

Defective button

Call electrician for checking

Motor runs but lift does

not rise

A piece of trash is under check

valve

Push handle down and push the up

button at the same time. Hold for

10-15 seconds. This should flush

the system.

The clearance between the

plunger valve of the lowering

handle is too small

Check the clearance between the

plunger valve of the lowering

handle. There should be 1/16”

Remove the check valve cover and

clean ball and seat

Oil level should be just under the

vent cap port when the lift is down

Oil Blows out breather

of power unit

Remove excessive weight from lift.

Oil reservoir overfilled

Reduce the oil to the oil level

Motor hums and does

not run

Take off and straighten

Faulty wiring

Call electrician

Bad capacitor

Call electrician

Low voltage

Call electrician

Remove excessive weight from lift

Lift Jerks going up and

down

Air in hydraulic system

Rails lift all the way to the top and

return to the floor. Repeat 4-6

times. Do not let this overheat

power unit.

Oil Leaks

Oil Leaks around the tankmounting flange. Oil reservoir

overfilled

Check the oil level to the tank. The

level should be two inches below

the flange of the tank. Check with a

screwdriver

Oil leaks around the rod end of

the cylinder. The rod seal of

the cylinder is out

Rebuild or replace the cylinder

Oil leaks around the breather

end of the cylinder. The piston

seal of the cylinder is out.

Rebuild or replace the cylinder

Lift makes excessive

noise

Leg of the lift is dry and

requires grease.

Grease the legs

Grease the pulley assembly.

Replace the pins or cylinder yoke.

TROUBLESHOOTING

Dirty on the ball and seat of

check valve

Oil level too low

Lift lowered too quickly while

under a heavy load

Impeller fan cover is dented

Lift Overloaded

Cylinder pulley assembly or

cable pulley assembly is not

moving freely

May have excessive wear on

pins or cylinder yoke

Page 18 of 20

Page 19

PURCHASE TERMS AND WARRANTY

DAMAGE/MISSING PARTS POLICIES:

All parts you find defective must be returned for inspection before a replacement is shipped. All

parts will be inspected and if found to be defective a replacement and/or repair to parts will be

sent. If no defect is found, customer is responsible for all shipping costs of all parts. The

shipping costs must be paid by customer prior to any parts being sent back to customer. Auto

Lift Motors are for use indoors and will not be warranted if installed outside.

All shop equipment must be inspected upon receipt. Make note of any visible damage or

missing pieces on the bill of lading. We will not be liable for damages occurred by the freight

company if not noted on the bill of lading. Missing power units and/or motors must be reported

at time of delivery. Any missing parts or incorrect equipment needs to be reported within three

days of receipt. Anything reported after three days of receipt will be replaced or returned to us at

the customer’s expense.

PAYMENT POLICIES:

We accept all major credit cards, money orders, cashiers checks and wires. If paying by

personal or business check please allow 7 business days for check to clear. All checks must

clear bank before we ship an order. Payment must be received before product will ship. We do

not ship COD. Deposits for custom orders are non-refundable. If payment is tendered by credit

card or check by phone, purchaser/customer agrees to instruct their credit card or banking

institution honor payment. Purchaser/Customer further agrees to not initiate a credit card

charge back and/or cancel check payment by phone at any time once automotive equipment

has shipped. Purchaser/Customer agrees that all sales are final once product has shipped.

RETURN POLICIES:

ALL SALES ARE FINAL ONCE YOUR AUTO EQUIPMENT HAS SHIPPED. Orders canceled

after payment is processed but before shipment, will be charged a 15% cancellation fee of the

total invoice. If a product is shipped and purchaser/customer refuses product then

customer/purchaser will be responsible for shipping costs both ways and a 30% restock fee. We

do not accept returns of used equipment. All equipment must be in original undamaged

packaging. Pictures on site are for display purposes only and may not represent exact design of

equipment. Customer is responsible for all charges associated with returning equipment,

including but no limited to fork lift or loading equipment needed to put product on freight truck,

costs associated with returning equipment to authorized freight terminal, packaging equipment

in a manner sufficient for shipping on freight truck. There is no compensation for cost of time or

packaging materials needed to return product.

WARRANTY POLICIES:

There is no labor warranty on any products.

The supplier is not responsible for any problems or damage that occurs from the installation of

the power unit and/or motor by anyone who is not a certified electrician. It is required by law that

we cannot provide an electrical wiring diagram. The supplier is not responsible for any cost that

may arise from the certified electrician or any repair costs caused by improper installation of

Page 19 of 20

Page 20

power units and/or motors. If any disputes arise, the supplier requires a copy of the invoice from

the certified electrician with an itemized report of the work done.

The lift is warranted by our supplier for one year. Auto Lifts carry a 2 year structural warranty if

installed indoors. Warranty is for parts only. No labor warranty exists. Hydraulics and Electronics

are covered under 1 year parts replacement. Warranty does not cover rubber lifting pads on two

post lifts. Replacement parts or replacement equipment being sent to the customer does not

represent an extension or renewal of the warranty period. Shipping of warranted parts is for

normal ground shipping only within the USA.

NOTE: All Shipping costs are paid by customer after first 60 days of warranty period, no

exceptions.

No warranties exist for any incidental cost occurring from loss of use of product. Warranty is not

transferable. Warranty is issued to original purchaser only and cannot be transferred to anyone

else.

Any attempts at charge backs or legal action will void the warranty on the product purchased

regardless of the decisions made by all companies involved in the transaction and or the

decision of the courts. Once warranty is voided, it cannot be reinstated. No other warranty is

expressed or implied. Warranty is governed by the laws of the State of Texas, County of

Tarrant. Our supplier will not enter into any verbal agreements regarding changes to the stated

warranty policy. We reserve the right to change or amend any measurements, instructions,

policies, pictures, and warranties, as stated in our manuals, on our website, and on any other

printed or published materials, without notice to customers prior to changes being made.

Any and all vehicles pictured with our products do not imply a set measurement or dimension in

regards to the lift with which they are pictured. Purchaser/Customer has read and understands

the whole of this document and all parts thereof. Purchaser/Customer further understands that

this document and all parts thereof is governed in whole or in part by the law of the State of

Texas. Any action at law, suit in equity, or other judicial proceedings for the enforcement of this

document or any provision thereof shall be instituted only in the courts of the State of Texas,

County of Tarrant. The covenants and conditions contained in this document shall apply to and

bind the parties, purchasers, customers, heirs, legal representatives and assigns of the parties.

ISO 9001 AND CE CERTIFICATION

This lift is built in a factory that carries an ISO-9001 Quality Certification. This is an

internationally accepted quality control standard. ISO-9001 is overseen by an independent third

party with no vested interest in the company seeking certifications. The power unit carries the

CE mark which is a mandatory safety mark and ensures that your products are tested and safe.

Page 20 of 20

Loading...

Loading...