Page 1

MODEL RL/FT5000

XP

PC-BASED ATMS

USER MANUAL

VERSION 2.0

TDN 07102-00057B Oct 23 2009

CORPORATE HEADQUARTERS:

21405 B Street

Long Beach, MS 39560

Phone: (228) 575-3188

Fax: (228) 575-3200

COPYRIGHT NOTICE

© 2008 Delaware Capital Formation, Inc. All Rights Reserved. T riton Systems

of Delaware, Inc. is an operating company of Dover Electronics, Inc., a subsidiary of Dover Corporation (NYSE-DOV). DOVER, the DOVER logo and the

Dover family of marks and TRITON, the TRITON logo and the Triton family

of marks are registered trademarks of Delaware Capital Formation, Inc., a wholly

owned subsidiary of Dover Corporation.

Page 2

MODEL RL/FT5000XP USER MANUAL

DISCLAIMER

The manufacturer of the Automated T eller Machine (ATM) product(s) described

herein makes no representations or warranties, either expressed or implied, by or

with respect to anything in this manual, and shall not be liable for any implied

warranties of fitness for a particular purpose or for any indirect, special, or

consequential damages. Information in this document is subject to change

without notice and does not represent a commitment on the part of the

manufacturer.

** CAUTION **

Changes or modifications not expressly approved by Triton

Systems could void the regulatory compliance approval

and the warranty. Use of this pr oduct in a manner other

than those described in this manual may result in personal

injury!

FCC COMPLIANCE

(US units with modems)

Statement of Compliance: This equipment complies with Part 68 of the FCC

rules. Located in the control area of the ATM is the product label. This label

lists the FCC registration number and ringer equivalence number of the unit. If

requested, this information must be provided to the telephone company. USOC/

FIC Codes: When ordering service from the telephone company for the XPseries ATMs, the following information should be supplied:

Universal Service Order Code (USOC): RJ-11C

The Facility Interface Code (FIC): 02LS2

Plug and Jack: The plug and jack used to connect this equipment to premise

wiring and telephone network must comply with the applicable FCC Part 68 rules

and requirements adopted by ACTA. A compliant telephone cord and modular

plug is provided with this product. The telephone cord is designed to be

connected to a compatible modular jack that is also compliant.

Ringer Equivalent Number (REN): The REN is used to determine the number of

the devices that may be connected to a telephone line. Excessive RENs on a

telephone line may result in the devices not ringing in response to an incoming

call. In most but not all areas, the sum of the RENs should not exceed five (5). T o

be certain of the number devices that may be connected to a line, as determined

by the local RENs, contact the local telephone company.

ii

Page 3

MODEL RL/FT5000

Harm to the Network: If the XP-series ATMs cause harm to the telephone

network, the telephone company will notify the customer that a temporary

discontinuation of service may be required. If advanced notice is not possible,

the telephone company will notify the customer as soon as possible. You will be

advised of your right to file a complaint with the FCC if you believe it’s necessary .

Notification of Changes in Telephone Company Equipment: The telephone

company may make changes in its facilities, equipment, operations, or procedures

that could affect the operation of the equipment. If this happens, the telephone

company will provide advanced notice in order for you to make necessary

modifications to maintain uninterrupted service.

Repairs and Returns: If telecom compatibility trouble is experienced with the

XP- series ATMs, you may contact for repairs and warranty information: T riton

at 1-228-868-1317

Triton Systems of Delaware, Inc.

522 East Railroad Street

Long Beach, MS 39560

If the equipment is causing harm to the network, the telephone company may

request that you disconnect the equipment until the problem is resolved. Repairs

should be made only by qualified factory representatives.

XP

USER MANUAL

Party Lines: The XP-series ATMs must not be used on party lines.

Alarm Equipment: The XP-series ATMs should have their own dedicated phone

line. Do not install the ATMs on the same line as alarm equipment.

Electrical Safety Advisory: Telephone companies report that electrical surges,

typically lightening transients, are very destructive to customer equipment

connected to AC power sources. This has been identified as a major nationwide

problem. A commercially available, power surge suppressor, is recommended

for use with the XP-series ATMs to minimize damage in the event of an electrical

surge.

CANADIAN IC COMPLIANCE

Notice:

The Industry Canada label identifies certified equipment. This certification

means that the equipment meets telecommunications network protective, operational, and safety requirements as prescribed in the appropriate terminal equipment technical requirements document(s). The department does not guarantee

the equipment will operate to the user’s satisfaction.

iii

Page 4

MODEL RL/FT5000XP USER MANUAL

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The equipment must also be installed using an acceptable method of connection. The

customer should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the supplier. Any repairs or alterations made by the user to this

equipment or equipment malfunctions may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas. Caution: Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection

authority or electrician, as appropriate.

NOTICE:

The Ringer Equivalence Number (REN) assigned to each terminal device provides an indication of the maximum number of terminals allowed to be connected

to a telephone interface. The termination on an interface may consist of any

combination of devices subject only to the requirement that the sum of the

Ringer Equivalence Numbers of all the devices does not exceed 5.

AVIS:

L ’étiquette d’Industrie Canada identific le matériel homologué. Cette étiquette

certifie que le matériel est conforme aux normes de protection, d’exploitation et

de sécurité des réseaux de télécommunications, comme le prescrivent les documents concernant les exigences techniques relatives au matériel terminal. Le

Ministère n’assure toutefois pas que le matériel fonctionnera à la satisfaction de

l’utilisateur.

Avant d’installer ce matériel, l’utilisateur doit s’assurer qu’il est permis de le

raccorder aux installations de 1’entreprise locale de télécommunication. Le

matériel doit également être installé en suivant une méthode acceptée de

raccordement. L ’abonné ne doit pas oublier qu’il est possible que la comformité

aux conditions énoncées cidessus n’empêche pas la dégradation du service

dans certaines situations.

iv

Page 5

MODEL RL/FT5000

Les réparations de matériel homologué doivent être coordonnées par un

représentant désigné par le fournisseur. L’entreprise de télécommunications

peut demander à I’utilisateur de débrancher un appareil à la suite de réparations

ou de modifications effectuées par l’utilisateur ou à cause de mauvais

fonctionnement.

Pour sa propre protection, l’utilisateur doit s’assurer que tous les fils de mise à

la terre de la source d’énergie électrique, des lignes téléphoniques et des

canalisations d’eau métalliques, s’fl y en a, sont raccordés ensemble. Cette

précaution est particulièrement importante dans les régions rurales.

Avertissement: L’utilisateur ne doit pas tenter de faire ces raccordements luimême; il doit avoir recours à an service d’inspection des installations électriques,

ou à un électricien, selon le cas.

XP

USER MANUAL

AVIS:

L’indice d’équivalence de la sonnerie (IES) assigné à chaque dispositif terminal

indique le nombre maximal de terminaux qui peuvent étre raccordés à une interface.

La terminaison d’une interface téléphonique peut consister en une combinaison de

quelques dispositifs, à la seule condition que la somme d’indices d’équivalence de

la sonnerie de tous les dispositifs n’exède pas 5.

UNITED KINGDOM

This equipment has been approved in accordance with Council Decision 98/

482/EC for pan-European single terminal connection to the Public Switched

Telephone Network (PSTN). However, due to differences between the individual PSTNs provided in the different countries, the approval does not, of

itself, give unconditional assurance of successful operation on every PSTN

network termination point. In the event of problems, contact your equipment

supplier in the first instance. This unit uses only Dual-Tone Multi-Frequency

(DTMF) address signaling.

EMISSIONS (EMI)

(US Requirements)

This device complies with Part 15 of the FCC rules. Operation is subject to the

following two (2) conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received, including interference

that may cause undesired operation.

v

Page 6

MODEL RL/FT5000XP USER MANUAL

NOTE:

This equipment has been tested and found to comply with the limits for a Class

A digital device pursuant to Part 15 of FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense. Changes or modifications to this unit not

expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

CANADIAN REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set in the Radio Interference Regulations of the Canadian

Department of Communications. This Class A digital apparatus complies with

Canadian ICES-003.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant

les limites applicables aux appareils numeriques de la Class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada. Cet appareil numerique de la classe A est conforme

a la norme NMB-003 Canada.

UK REQUIREMENTS

Warning:

This is a Class A product. In a domestic environment, this product may cause

radio interference in which case the user may be required to take adequate

measures.

vi

Page 7

MODEL RL/FT5000

XP

USER MANUAL

NOTICES

Copyright © Delaware Capital Formation, Inc., 2006.

ALL RIGHTS RESERVED

This publication is protected by copyright and all rights are reserved. No part of

it may be reproduced or transmitted by any means or in any form, without prior

consent in writing from Triton Systems of Delaware, Inc.

The information in this publication has been carefully checked and is believed

to be accurate. However, Triton Systems of Delaware, Inc. assumes no responsibility for any inaccuracies, errors, or omissions that may be contained in this

document. In no event will Triton Systems of Delaware, Inc. be liable for direct,

indirect, special, incidental, or consequential damages resulting from any defect

or omission in this manual, even if advised of the possibility of such damages.

In the interest of continued product development, Triton Systems of Delaware,

Inc. reserves the right to make improvements in its documentation and the

products it describes at any time, without notice or obligation.

TRADEMARK ACKNOWLEDGEMENTS

Microsoft Windows is a registered trademark of Microsoft Corporation in the

United States and/or other countries. Triton Connect and Prism are trademarks

of Triton Systems of Delaware, Inc. CashWorks is a trademark of CashW orks,Inc.

PaySpot is a trademark of Euronet Worldwide. Western Union is a registered

trademark of Western Union Holdings, Inc. Intel is a registered trademark of

Intel Corporation.

vii

Page 8

MODEL RL/FT5000XP USER MANUAL

WARRANTY STA TEMENT

Manufacturer warrants that the products delivered to a distributor will perform

in accordance with the Manufacturer’s published specifications for thirteen

months from date of shipment in Long Beach, MS.

Manufacturer’s warranty shall not apply to any damage resulting from abuse,

negligence, accident, or to any loss or damage to the products while in transit.

Written notice and explanation of circumstances surrounding any claims that

the goods have proved defective in material or workmanship shall be given

promptly from the distributor to the manufacturer. No claim may be made, or

action brought, by or through a distributor after the expiration of 14 months

following any alleged breach of warranty.

Distributor’s sole and exclusive remedy in the event of defect is expressly

limited to the replacement or correction of such defective parts by manufacturer at its election and sole expense, except there shall be no obligation to

replace or repair items which, by their nature, are expendable. If Manufacturer

is unable to replace or repair the defective parts, Manufacturer shall refund to

Distributor that portion of the purchase price allocable pays to such goods.

No representation or other affirmation of fact not set forth herein, including but

not limited to statements regarding capacity, suitability for use, or performance

of the goods, shall be or be deemed to be a warranty or representation by

Manufacturer for any purpose, nor give rise to any liability or obligation of

Manufacturer whatever.

Except as specifically provided in this document, there are no other warranties

expressed or implied including, but not limited to, any implied warranties or

merchantability or fitness for a particular purchase.

LIMITATION OF LIABILITY

In no event shall manufacturer be liable for loss of profits or incidental, indirect, special, consequential or other similar damages arising out of any breach

of this contract or obligations under this contract.

DEFENSE OF INFRINGEMENT CLAIMS

If notified promptly in writing of any action (and all prior claims relating to such

action) brought against the Distributor based on a claim that Distributor’s use of

the goods infringes a patent or other intellectual property right, and if given

access by Distributor to any information distributor has regarding such alleged

infringement, Manufacturer agrees to defend Distributor in such action at its

expense and will pay any costs or damages finally awarded against Distributor

viii

Page 9

MODEL RL/FT5000

in any such action, provided the Manufacturer shall have had sole control of the

defense of any such action and all negotiations for its settlement or compromise.

In the event that a final injunction shall be obtained against the Distributor’s use

of the goods or any of their parts by reason of infringement of a patent or other

intellectual property right or if in Manufacturer’s opinion the goods are likely to

become the subject of a claim of infringement of a patent or other intellectual

property right, Manufacturer will, at its option and at its expense, either procure

for the Distributor the right to continue using the goods, replace or modify the

same so they become non-infringing or grant the Distributor a credit for such

goods as depreciated and accept their return. The depreciation shall be an equal

amount per year over the lifetime of the goods as established by Manufacturer.

Manufacturer shall not have any liability to the Distributor under any provision

of this clause if any infringement, or claim thereof, is based upon: (i) the use of

the goods in combination with other goods or devices which are not made by

Manufacturer; (ii) the use of the goods in practicing any process; (iii) the furnishing to the Distributor of any information, date, service, or applications assistance; or (iv) the use of the goods with modifications made by the Distributor.

The Distributor shall hold Manufacturer harmless against any expense, judgment or loss for infringement of any patent or other intellectual property right

which results from Manufacturer’s compliance with the Distributor’s designs,

specifications or instructions. No costs or expenses shall be incurred for the

account of Manufacturer without the written consent of Manufacturer. The

foregoing states the entire liability of manufacturer with respect to infringement of patents or other intellectual property right by the goods or any part

thereof, or by their operation.

XP

USER MANUAL

INTERPRETATION AND OTHER PAROLE EVIDENCE

This writing is intended by the parties as final expression of their agreement and

is intended also as a complete and exclusive statement of the terms of their

agreement. No course of prior dealing between the parties and no usage of the

trade shall be relevant to supplement or explain any term used in these terms and

conditions. Acceptance or acquiescence in a course of performance rendered

under these terms and conditions shall not be relevant to determine the meaning

of these terms and conditions even though the accepting or acquiescing party

has knowledge of the performance and opportunity for objection. Whenever a

term defined by the Uniform Commercial Code, as adopted in Mississippi, is

used in these terms and conditions, the definition contained in the code is to

control.

ix

Page 10

MODEL RL/FT5000XP USER MANUAL

MODIFICATIONS

These terms and conditions can be modified or rescinded only by writing signed

by both the parties or their duly authorized agents.

WAIVER INEFFECTIVE

No claim or right arising out of or relating to a breach of these terms and conditions can be discharged in whole or in part by a waiver or renunciation of the

claim or right unless the waiver or renunciation is supported by consideration

and is in writing signed by the aggrieved party. Waiver by either Manufacturer

or Distributor of a breach by the other of any provision of these terms and

conditions shall not be deemed a waiver of future compliance therewith, and

such provisions shall remain in full force and effect.

STATUTE OF LIMITATIONS

Any action by the Distributor or Manufacturer for breach of these terms and

conditions must be commenced within one (1) year after the cause of action has

accrued.

APPLICABLE LAW

These terms and conditions shall be governed by and construed in accordance

with the provisions of the Uniform Commercial Code as adopted by the State of

Mississippi.

BANKRUPTCY

In the event of any proceedings, voluntary or involuntary, in bankruptcy or

insolvency by or against Distributor, or in the event of the appointment, with or

without the Distributor’s consent, of an assignee for the benefit of creditors or

of a receiver or of a liquidator, then Manufacturer shall be entitled to cancel any

unfilled part of these terms and conditions without any liability whatsoever.

PARTS ONLY LIMITED MANUFACTURER’S WARRANTY

Triton Systems of Delaware, Inc. warrants the components of each XP-series

ATM, excluding software and related documentation, against any defect in

materials and/or workmanship for a period of 13 months from the shipping date.

If a component fails due to defects in materials and/or workmanship within the

warranty period, Triton will furnish a new or refurbished component, at its discretion. Triton shall not be responsible for labor or other costs associated with

installing the components and the failed component shall be returned to Triton

at the purchaser’s expense. T riton shall not be responsible for misuse or abuse

of a unit and any attempts to remove or deface the serial number or date code on

a unit or any component thereof, or any attempt to repair a unit or to repair or

replace any component by anyone other than a service technician authorized by

Triton shall void this warranty.

x

Page 11

MODEL RL/FT5000

Limited Warranty covers normal use. T riton does not warrant or cover

damage:

• occurring during shipment of the equipment or components from or to

Triton’ s facilities;

• caused by accident, impact with other objects, dropping, falls, spilled liquids, or immersion in liquids;

• caused by a disaster such as fire, flood, wind, earthquake, lightning, or

other acts of God;

• caused by failure to provide a suitable installation environment for the

equipment, including but not limited to, faulty wiring in the building in

which the equipment is installed, installation in a facility with uncontrolled

environmental conditions, failure to provide a dedicated electrical circuit on

which the equipment operates, and/or lack of proper earth grounding for

the equipment;

• caused by the use of the equipment for purposes other than those for

which it was designed;

• resulting from improper maintenance;

• caused by any other abuse, misuse, mishandling, or misapplication.

Under no circumstances shall Triton or its suppliers be liable for any special,

incidental, or consequential damages based upon breach of warranty, breach of

contract, negligence, strict liability, or any other legal theory. Such damages

include, but are not limited to, loss of profits, loss of revenue, loss of data, loss

of use of the equipment or any associated equipment, cost of capital, cost of

substitute or replacement equipment, facilities or services, downtime, purchaser’s

time, the claims of third parties, including customers, and injury to property.

XP

USER MANUAL

DISCLAIMER OF WARRANTIES

The warranty stated above is the only warranty applicable to this product. All

other warranties, expressed or implied (including all implied warranties of merchantability or fitness for a particular purpose or quality of service), are hereby

disclaimed. No oral or written information, or advice given by Triton, its agents

or employees shall create a warranty or in any way increase the scope of this

warranty.

SHIPPING DAMAGE

All equipment is shipped Free On Board (FOB), Triton’ s facilities. The organization or individual who has purchased the equipment assumes responsibility for

the equipment once it leaves Triton’s facilities.

Should your equipment be damaged in the process of shipment or delivery to

your place of destination, we recommend the following course of action:

xi

Page 12

MODEL RL/FT5000XP USER MANUAL

• If possible, call the shipping company before the driver leaves your delivery site. Make note of the damage on the “receipt of delivery” paperwork.

If this is not possible, call them as soon as possible to report the damage.

• T ake photographs of the damaged packaging prior to opening the boxes. If

this is not possible, make note of key points, such as whether the equipment is on a pallet, if the banding is intact, how the boxes are damaged, etc.

Keep all of the packaging for inspection by the shipping company.

• If you unpack the equipment, take photographs of the damaged equipment.

If this is not possible, make note of the damages.

• You must file a claim with the shipper for shipping damages immediately

after reporting the damages.

Should you specify the carrier, we recommend that you explore with this chosen

carrier the policies and procedures regarding shipping damage claims prior to

selecting them as your preferred carrier.

If the equipment receives structural damage and is in an un-installable condition, Triton will work with you to arrange for a replacement unit to be shipped as

soon as possible. The purchaser will be billed for the replacement unit. T riton’s

repair technicians will repair the damaged unit after it is returned to our facilities.

W e will credit the purchaser’s account for the full purchase price of the damaged

unit, minus the cost of returning the unit to “like new” condition. Under no

circumstances does Triton authorize anyone to complete structural damage

repairs in the field. Therefore, we will not ship primary structural parts, such as

a cabinet head or main cabinet body for repair in the field.

AUTHORIZED INSTALLATION AND SERVICE PROVIDERS

Triton utilizes several nationwide and regional authorized third party maintenance providers. Triton recommends all ATMs be installed and serviced by

service technicians certified by Triton. This includes authorized third party

service technicians and technicians who have been factory trained by Triton to

service ATM equipment. Installation or repairs attempted by unauthorized service technicians may void the warranty or warranty claims denied on the product.

Please contact Triton’ s T echnical Services department at (800) 259-6672 for a list

of our third party service providers and/or to obtain information on the requirements and procedures for becoming a certified Triton service technician.

xii

Page 13

MODEL RL/FT5000

XP

USER MANUAL

TRITON’S TECHNICAL SERVICES DEPARTMENT

The primary purpose of the Technical Services department is to provide assistance to customers in the operation, trouble shooting, and repair of equipment

manufactured by Triton. A toll-free phone number (1-800-259-6672) is provided

for convenience. The Technical Services department operates to serve our

customers. The staff is trained to follow our policies and procedures to ensure

fair and uniform treatment of all our customers.

AUTOMATED VOICE MAIL SYSTEM

Our goal is to have a ‘live’ person answer 100% of all incoming calls (during

regular support hours). On occasion, however, call loads may exceed the capacity of the staff. When this occurs, an automated voice mail system will answer

the call, indicate to the caller that all Technical Support specialists are busy

assisting others, and ask the caller to leave detailed information about the nature of the call.

Should it become necessary to leave a voice mail message, the caller should

state:

• their name,

• the organization for which they work,

• the serial number of the equipment they are calling about,

• detailed description of the problem that they are experiencing, and

• phone number where they can be reached, including area code.

As Technical Support specialists become available, they check for voice mail

messages and return calls in the order in which they were received. By providing the information requested in the voice mail, the technician can be prepared

when your call is returned. Triton asks you to be patient if you must leave voice

mail and assures you that your call is important to us and that we will respond

promptly .

CALLS FOR SERVICE OR REPAIR

Calls for service or repair will be accepted from authorized service technicians

only. End users must contact either the sales organization that placed the

equipment or an authorized third party service organization to obtain service.

The sections that follow describe the policies and procedures that relate to the

repair and replacement of malfunctioning equipment.

xiii

Page 14

MODEL RL/FT5000XP USER MANUAL

QUESTIONS ON OPERATION OF EQUIPMENT

Technical support is available to owners of Triton equipment and to qualified

service personnel. When calling for help with the configuration or operation of

a Triton product, the caller must provide either positive identification as a service technician or the serial number of a Triton terminal. Technical support is

provided during normal business hours for the life of the product.

When calling for help with an operational problem, please have available information pertaining to the nature of the trouble. This includes the type of equipment, examples of what is or is not happening, and the name of the processor

that supports your terminal.

All questions pertaining to the settlement of accounts, transaction inquiries,

and fund status must be directed to the processor. Triton does not have access

to the information needed to answer questions relating to specific transactions.

CONT ACT INFORMATION

Triton Systems of Delaware, Inc.

522 East Railroad Street

Long Beach, MS 39560

SALES:

1 (800) 367-7191

1 (228) 868-1317

1 (228) 868-0437 (Fax)

SERVICE:

1 (800) 259-6672 (Technical Support)

1 (228) 575-3229 Fax (T echnical Support)

1 (228) 868-0859 Fax (Parts)

xiv

Page 15

MODEL RL/FT5000

XP

USER MANUAL

CONTENTS

SECTION 1 - INTRODUCTION ........................................................1

WHAT’S IN THIS MANUAL ................................................................................2

PC-BASED MODELS .........................................................................................2

CLASS OF SERVICE (BUSINESS-VS-LEVEL 1).......................................................... 2

OPERATING SYSTEM ......................................................................................... 2

FEATURE HIGHLIGHTS ....................................................................................... 4

STANDARD FEATURES ....................................................................................... 5

ACCESS AND TRANSACTION SECURITY ........................................................ 5

MULTIMEDIA INTERFACE (AUDIO/VIDEO).................................................... 6

STORAGE OF FILES .................................................................................... 6

VOICE-ENABLED TRANSACTIONS ................................................................ 6

COMMUNICATIONS .....................................................................................7

ELECTRONIC JOURNAL ............................................................................... 7

TERMINAL SETTLEMENT ............................................................................7

MULTI-LANGUAGE SUPPORT ......................................................................8

MESSAGES ...............................................................................................8

REAR SERVICE PANEL (MODEL FTXP) ........................................................8

SECTION 2 - BASIC OPERATION ................................................... 9

INTRODUCTION ................................................................................................. 10

CONTROL PANEL LAYOUT ................................................................................. 10

KEYPAD OPERATION ........................................................................................ 11

SCREEN FUNCTION KEYS ..................................................................................12

REAR SERVICE PANEL (MODEL FTXP) ............................................................... 13

MENU-BASED OPERATION................................................................................. 14

VOICE-ENABLED TRANSACTIONS ....................................................................... 15

SECTION 3 - REPLENISHING CASSETTES ........................................ 17

INTRODUCTION ................................................................................................. 18

DISPENSING MECHANISM (NMD-100) ............................................................... 18

NOTE CONDITION ............................................................................................. 18

REPLENISHING CASSETTES ................................................................................ 20

REMOVING NOTE CASSETTES ...................................................................... 20

OPENING NOTE CASSETTES ........................................................................ 21

LOADING NOTE CASSETTES ........................................................................ 22

INSTALLING NOTE CASSETTES ..................................................................... 23

REMOVING THE REJECT CASSETTE ...................................................................... 24

OPENING THE REJECT CASSETTE ........................................................................ 24

INSTALLING THE REJECT CASSETTE ..................................................................... 25

VERIFY OPERA TION ..........................................................................................26

xv

Page 16

MODEL RL/FT5000XP USER MANUAL

CONTENTS

SECTION 4 - PREVENT ATIVE MAINTENANCE .................................... 27

INTRODUCTION ................................................................................................. 28

REPLENISHING THE RECEIPT PAPER (MODEL RLXP)............................................ 28

REPLENISHING THE RECEIPT PAPER (MODEL FTXP)............................................ 31

REPLENISHING THE JOURNAL PRINTER (OPTIONAL) .............................................33

CLEANING THE ENCLOSURE .............................................................................. 37

CLEANING THE DISPLAY ................................................................................... 37

CARD READER CLEANING ................................................................................. 37

SECTION 5 - MANAGEMENT FUNCTIONS ....................................... 39

INTRODUCTION ................................................................................................. 40

WHAT IS PRISM 912-EMULATION ........................................................................ 40

XP PRISM SOFTWARE ARCHITECTURE .................................................................42

DISPLAY POWER-UP SEQUENCE ........................................................................ 44

ACCESSING THE MANAGEMENT FUNCTIONS MENU ............................................. 44

SWITCHING SCREENS (MODEL FT

FUNCTION AVAILABILITY .................................................................................. 47

MANAGEMENT REPORTS ................................................................................... 48

TERMINAL SETTLEMENT FUNCTIONS ................................................................49

TERMINAL CLOSE FUNCTIONS ........................................................................... 50

VIEW A TM SETTLEMENT TOTALS ...................................................................... 51

CLEAR A TM SETTLEMENT TOTALS.................................................................... 52

REPLENISH CASSETTE(S) ................................................................................... 53

XP)

................................................................................................................

46

DIAGNOSTICS ................................................................................................. 54

DIAGNOSTIC FUNCTIONS ................................................................................... 56

CASH DISPENSER ............................................................................................. 57

CASH DISPENSER STATUS ........................................................................... 58

PURGE .....................................................................................................59

TEST DISPENSE ......................................................................................... 60

FORCE UNLOCK CASSETTE .........................................................................61

INJECT NEW CASSETTE ID .......................................................................... 6 2

UNLOCK / LOCK ALL CASSETTES ...............................................................63

CARD READER .................................................................................................64

CARD READER STATUS .............................................................................. 65

SCAN CARD .............................................................................................66

TRACK 3 READ / WRITE ............................................................................ 67

RESET ...................................................................................................... 67

PRINTER .......................................................................................................... 68

DEVICE STATUS ......................................................................................... 69

PRINT TEST DATA ...................................................................................... 70

RESET ...................................................................................................... 70

xvi

Page 17

MODEL RL/FT5000

XP

USER MANUAL

CONTENTS

KEYPAD.......................................................................................................... 71

KEYPAD DEVICE STATUS ............................................................................ 72

TEST KEYPAD .......................................................................................... 73

CLEAR TAMPER ........................................................................................ 74

RESET ...................................................................................................... 74

GENERAL I/O DIAGNOSTICS .............................................................................. 75

LED INDICATORS ...................................................................................... 75

HEADPHONE TEST ....................................................................................76

SAFE DOOR TEST ...................................................................................... 76

CABINET DOOR TEST ................................................................................. 77

PRINTER POSITION TEST ............................................................................. 77

PREVIEW SAMPLE VOICE ........................................................................... 77

ELECTRONIC JOURNAL .................................................................................... 78

ELECTRONIC JOURNAL FUNCTIONS ..................................................................... 79

EXPORT UNAUDITED RECORDS ........................................................................... 80

DISPLAY LAST X RECORDS ................................................................................ 81

JOURNAL STATISTICS ......................................................................................... 82

JOURNAL SETTINGS ............................................................................................... 83-84

AUTO EXPORT .......................................................................................... 83

AUTO DELETE .......................................................................................... 83

DELETE INTERVAL (DAYS) .......................................................................... 84

DELETE RECORDS OLDER THAN (DAYS) ..................................................... 84

SAVE SETTINGS / EXIT ................................................................................ 84

PASSWORD MAINTENANCE .............................................................................. 85

PASSWORD MAINTENANCE FUNCTIONS .............................................................. 86

CHANGE USER PASSWORD ................................................................................ 87

CHANGE USER NAME .......................................................................................88

MODIFY USER A CCESS ......................................................................................... 89-91

ADD USER ...................................................................................................... 92

REMOVE USER ................................................................................................. 93

TERMINAL USERS ............................................................................................. 94

USER ACCESS REPORT ...................................................................................... 95

CHANGE USERS PASSWORD .............................................................................. 96

SYSTEM PARAMETERS .....................................................................................97

SYSTEM PARAMETERS FUNCTIONS ......................................................................98

GENERAL SETTINGS .......................................................................................... 99

TIME ZONE / DATA / TIME ......................................................................... 99

SELECT SCREEN FILE ....................................................................................... 100

SHUTDOWN / RESTART TERMINAL ...................................................................... 101

PERFORM SOFTWARE UPDATES .......................................................................... 102

xvii

Page 18

MODEL RL/FT5000XP USER MANUAL

CONTENTS

TERMINAL CONFIGURATION ............................................................................ 103

TERMINAL CONFIGURATION FUNCTIONS ............................................................. 106

GENERAL PARAMETERS .................................................................................... 107

TERMINAL NUMBER .................................................................................. 107

SEND CABINET ALARM STATUS ..................................................................107

SELECT CABINET ALARM STATUS CODE ......................................................107

SEND SAFE DOOR ALARM STATUS .............................................................. 107

ENTER / EXIT MAINTENANCE STATUS OPTIONS .............................................108

SAVE GENERAL PARAMETERS / EXIT ............................................................ 108

COUPONS ........................................................................................................109

STATE SETTINGS ...............................................................................................110

USE OVERLAY SCREEN FOR AMOUNT ENTRY ............................................... 110

USE ENTER KEY TO TERMINATE AMOUNT ENTRY .........................................110

MAP ENTER KEY FOR AMOUNT ENTRY .......................................................110

USE ENTER KEY TO TERMINATE INPUT INFORMATION ................................... 110

MAP ENTER KEY FOR INPUT INFORMATION ................................................. 110

SAVE SETTINGS / EXIT ................................................................................ 110

CASH DISPENSER SETUP ................................................................................... 111

GENERAL SETTINGS ................................................................................... 112

REPORT ERROR STATUS AS LOGICAL ..................................................... 112

TRAP STATUS THRESHOLD (CONSECUTIVE SHUTTER ERRORS) ................. 112

AUTOMATIC CASH RETRACT ................................................................113

REPORT DISPENSER COMPLETION STATUS .............................................113

SELECT PARTIAL DISPENSE STATUS ...................................................... 113

SAVE SETTINGS / EXIT ........................................................................113

912 HOST LOGICAL CASSETTE MAPPING ................................................... 114-115

CONFIGURE CASSETTES .............................................................................. 116

MEDIA TYPE .................................................................................... 117

CURRENCY CODE .............................................................................. 117

CURRENCY VARIANT .......................................................................... 118

CURRENCY VALUE ............................................................................. 118

NON-CURRENCY VALUE ..................................................................... 118

MEDIA WIDTH.................................................................................. 118

MEDIA LENGTH .................................................................................118

SAVE SETTINGS / EXIT ........................................................................118

SCREEN SETUP ................................................................................................119

GEOMETRY (ROW, COLUMN) ......................................................................119

SAVE SETTINGS / EXIT ................................................................................ 119

AUDIO SETUP ..................................................................................................120

GENERAL SETTINGS ................................................................................... 121

IMPORT - REPEAT KEY SPEECH DATA / ORIENTATION MESSAGE .................... 122

PREVIEW - REPEAT KEY SPEECH / ORIENTATION MESSAGE / SAMPLE VOICE .. 123

xviii

Page 19

MODEL RL/FT5000

XP

USER MANUAL

CONTENTS

PRINTER SETUP ................................................................................................ 124

GENERAL SETTINGS ................................................................................... 125

USE BLACK MARK PAPER .................................................................. 125

CONFIGURE - RECEIPT PRINT FORM / COUPON PRINT FORM ......................... 126

TEST - RECEIPT FORM SETTINGS / COUPON FORM SETTINGS .......................... 127

COMMUNICATION ............................................................................................. 128

GENERAL SETTINGS ................................................................................... 129

MAC-ING ........................................................................................ 129

ETHERNET SETTINGS .................................................................................. 130

USE DHCP TO OBTAIN TERMINAL IP ADDRESS ....................................132

TERMINAL IP ADDRESS ......................................................................132

SUBNET MASK .................................................................................. 132

GATEWAY ADDRESS ........................................................................... 132

USE DHCP SERVER TO OBTAIN DNS SERVER ADDRESS ........................ 132

PRIMARY / A LTERNATE DNS SERVER ................................................... 132

PRIMARY WINS SERVER .................................................................... 133

HOST COMMUNICATION PROTOCOL SETTINGS ............................................... 134

TCP/IP PROTOCOL SETTINGS .............................................................. 134

SNA SETTINGS .................................................................................. 136

EICON CARD SETTINGS .............................................................................. 138

KEY MANAGEMENT ......................................................................................... 139

KEY MANAGEMENT FUNCTIONS ........................................................................140

KEY MANAGEMENT LOGIN ............................................................................... 140

ENTER A KEY .................................................................................................. 141

ENTER B KEY ..................................................................................................143

CHANGE PASSWORD FOR USER 1 / USER 2 ......................................................... 1 4 4

TERMINAL STATUS ..........................................................................................145

TERMINAL STATUS FUNCTIONS ........................................................................... 146

DISPLAY CONFIGURATION SUMMARY ................................................................. 147

SAVE PARAMETERS TO EXTERNAL STORAGE ........................................................ 148

RESTORE PARAMETERS FROM EXTERNAL STORAGE ..............................................149

EXPORT TRACE FILES ....................................................................................... 150

XP SOFTWARE ARCHITECTURE WITHOUT PRISM (VDM)................................... 151

VENDOR DEPENDENT MODE (VDM) DIAGNOSTICS MENU .................................. 152

JOURNAL PRINTER ............................................................................................ 153

DEVICE STATUS ................................................................................................ 154

PRINT TEST DATA ............................................................................................. 1 55

RESET ............................................................................................................. 155

XP SOFTWARE ARCHITECTURE WITHOUT PRISM (3RD PARTY APPLICATION) ...... 156

xix

Page 20

MODEL RL/FT5000XP USER MANUAL

CONTENTS

SECTION 6 - ERROR CODES (WOSA / TERMINAL) ....................... 157

INTRODUCTION ................................................................................................. 158

NMD ERROR CODES ........................................................................................ 159

CARD READER ERROR CODES ........................................................................... 162

RECEIPT PRINTER ERROR CODES ........................................................................ 163

APPENDIX A - ELECTRONIC LOCK ................................................ A-1

ENTERING THE COMBINATION ............................................................................A-2

LOCKOUT FEATURE .......................................................................................... A-2

CHANGING THE COMBINATION ........................................................................... A-2

BATTERY LOW WARNING ................................................................................. A-3

CHANGING THE BATTERY .................................................................................. A-3

APPENDIX B - GLOSSARY OF TERMS ............................................ B-1

PRISM 912 RELEASE NOTES:

1.0.21

1.2.22

1.0.23

DOCUMENT UPDATES

Oct 23 2009 Journal printer no longer offered

xx

Page 21

SECTION 1

NTRODUCTION

I

1

Page 22

MODEL RL/FT5000XP USER MANUAL

What’s in This Manual

This manual describes the operating features of the RL/FT5000

family. The setup and operating procedures given in this manual are generally

applicable to any RL5000XP or FT5000

XP

PC-based ATM. If your ATM does not

have the ability to perform some of the features described in this manual, it is

because your processor does not support the feature or the dispenser was

purchased without that particular option.

XP

-series A TM

PC-BASED MODELS

The PC-based units consist of Models RL5000 and FT5000 operating on

Microsoft® Windows® XP application. Furthermore, Triton’s Prism™ ATM

software provides banks with a simple HTML interface. This revolutionary configuration offers vendors independence through XFS and makes possible a

long list of revenue generating value-added services.

Both units are equipped with an NMD-100 multi-cassette dispenser mechanism

capable of dispensing currency and non-currency items (stamps, coupons, etc)

from up to four (4) cassettes, configurable.

CLASS OF SERVICE (BUSINESS-VS-LEVEL 1)

The basic RL/FT5000XP cabinet is UL certified for Business Hours Service. This

means that the currency should be removed from the dispenser and stored in a

safe location when the business is closed to the public. Other cabinets may be

UL certified as “Level 1”, providing additional security and the ability to store

currency during non-business hours. The RL5000

allowing access to the dispensing mechanism and currency cassettes from the

front (control-panel side) of the unit. The FT5000XP is a rear-access machine.

XP

is a front-access machine,

OPERA TING SYSTEM

Both PC-based units use Windows® XP platform, a robust technological design

that provides increased stability and improved speed while maintaining reliability and low cost of ownership. The operating system supports Windows file

formats for adding custom logos and advertisements. In addition, it features

Triton’s completely custom designed motherboard.

2

Page 23

INTRODUCTION

metsySgnitarepO

IIImuitnePletnIlanoitporonoreleCletnI

PXswodniWtfosorciM

:snoitpoerawtfoS

noitalumE-ecnailpmoCSFX-dradnatSnotirT

elbadnapxe,evirddrah)mm98("5.3BG04

elbadnapxe,MARDSBM652

mm462("4.01

PX

0005TF(

elbaweivthgilnuslanoitpo-)

noituloser006x008htiwyalpsidrolocAGVS)

lanoitpo,evirdlanretxeMOR-DVD/DC

PX

)

0005TF(

htiwyalpsidrolocAGVS)mm462("4.01htiwlenaPecivreSraeR

draobyekhtiwnoituloser006x008

ruoJ

lanoitpo,retnirplan

stropretsamBSU)6(xiS

troplellarap)1(enO

stroplaires)6(xiS

stolsnoisnapxeICPtib-23)2(owT

PX

snoitacificepSgnitarepO

erutarepmeT

0005TF

O

04ot01

O

05ot53-

)scinortcelE/tluaV(

O

401ot05;C

F

)lanretxE(

O

221ot03-;C

F

04ot01

PX

0005LR

O

O

401ot05;C

F

ytidimuHevitaleR

noitpmusnoCrewoP

%08ot%02

gnisnednoc-non

zH06taCAV511@A0.2

AV032@A0.1

zH05taC

%08ot%02

gnisnednoc-non

zH06taCAV511@A0.2

zH05taCAV032@A0.1

3

Page 24

MODEL RL/FT5000XP USER MANUAL

Feature Highlights

Important features of the RLXP/FTXP family are highlighted in the following list:

One to four cassette friction feed multi-denomination dispensing mechanism.

Front or rear delivery of banknotes and other value media such as tickets,

stamps, phone cards, and vouchers.

(Model FT5000

and keyboard. Allows access to Management functions for security and

ease of cassette loading and diagnostics.

XP

) Rear Service Panel (RSP) with 10.4" SVGA color display

Graphics- capable 80 mm thermal receipt printer with presenter. Optional

journal printer is available for saving journal records using traditional method

of printed copy of the electronic journal.

Enlarged (800-by-600) SVGA color LCD display (10.4 ") supports attention-getting

graphics and full-motion video.

High capacity electronic journal (2 Mb) stores transaction information for

viewing, printout, or analysis.

Dip-style card reader; optional dip EMV smart card reader, EMV motorized

card reader (Track 1, 2, 3 read), or EMV motorized card reader / encoder

(Track 1, 2, 3 read, Track 3 write).

Americans with Disabilities Act (ADA) compliant.

Audio transactions for the visually impaired.

Encrypting Pin Pad (EPP) to comply with all international encryption

standards, Triple DES compliant, optional metal EPP.

UL291 Business Hours cabinet or optional UL291 Level 1 Safe.

Electronic lock or optional Kaba Mas Cencon lock.

Multi-lingual capabilities.

Dial-up 56k baud internationally certified modem and TCPIP (Ethernet)

communications; optional wireless, SNA / SDLC, and Bisync.

4

Page 25

INTRODUCTION

RL5000

XP

FT5000

XP

ST ANDARD FEATURES

Standard features of the XP-series ATMs are summarized in the following paragraphs.

ACCESS AND TRANSACTION SECURITY

Password-Controlled Access.

Access to the ATM’ s Management Functions is protected by a password-based

access scheme. The ATM provides a “Master” password level of access and a

flexible system of “User-level” passwords. The master password provides full

access to the ATM’s Management Functions, while User-level passwords provide access to a subset of those functions, as determined by the holder of the

master password.

T ransaction Encryption.

The ATM protects all transaction and message traffic to and from the unit, using

strong encryption techniques.

MAC Data Encryption Support

The ATM implements support for the Message Authentication Code (MAC)

data encryption protocol. This capability is typically referred to as “MACing”.

MACing is a protocol supported by some processors and provides another

level of encryption protection for message traffic to and from the ATM.

5

Page 26

MODEL RL/FT5000XP USER MANUAL

Encrypting PIN Pad (EPP) Entry Device Support

Secure EPP entry device is an encryption system that offers additional protection for the customer PIN during entry at the ATM keypad. The EPP is compliant

with all international encryption standards, Triple DES, and Visa® requirements.

MULTIMEDIA INTERFACE (AUDIO/VIDEO)

The ATM’ s SVGA color display can display text and graphical content in a wide

range of colors, providing an interesting and dynamic experience to the customer. In addition, graphics can be printed on receipts. Supported multimedia

features include: T ext Effects, Ad Screens, Receipt Graphics, and Audio Output.

T ext Effects

Various special effects such as scrolling, blinking, or fading can be applied to

text messages that appear on the color display.

Ad Screens

An ad screen is a promotional or advertising graphic or motion video clip that is

displayed on the screen. Ad screens can be displayed while the terminal is idle

and while the customer transaction is being processed.

Receipt Printer Graphics

Bit-mapped graphic images (BMP) can be printed on the receipt. Like ad screen

graphics, receipt graphics are usually downloaded to the terminal via the host

processor.

Audio Output

The integrated speakers enhance the media experience by offering audio output

of voice and/or music content.

STORAGE OF FILES

The ATM can store management reports, such as the results of close operations

or diagnostic tests. Graphics files are stored and retrieved from the internal hard

disk. You may also save reports to an external memory device.

VOICE-ENABLED TRANSACTIONS

The ATM is able to provide voice feedback to sight-impaired users. By plugging

a set of headphones into the integrated headphone jack, users can receive

spoken assistance as they perform a transaction.

6

Page 27

INTRODUCTION

COMMUNICATIONS

The XP-series ATMs support communication with the transaction processor

using a variety of communications technologies. These include TCPIP, SNA/

SDLC, and BiSync.

TCPIP (Ethernet)

This method is used in applications where a central Local Area Network, or

LAN, is used to connect multiple ATMs to a central server. The ATM can be

treated as either a client or server on the network, while the server provides the

interface to a transaction processing system.

SNA/SDLC

Systems Network Architecture/Synchronous Data Link Control (SNA/SDLC) is

IBM’s version of bit-oriented protocol. SDLC is the link level protocol and SNA

provides the intelligence for the connection. SNA and SDLC use a series of

commands to control the flow of data through the network

BiSync

A major category of synchronous communications protocols used in mainframe

networks. Bisync communications require that both sending and receiving devices are synchronized before transmission of data is started. In the IBM world,

bisync was superseded by SDLC.

ELECTRONIC JOURNAL

The ATM stores transaction records, status, and other activity data in a journal

record that is stored in the ATM’ s PC hard drive. The number of journal entries

that can be stored is only limited by how much memory is available on the hard

drive.

This information can be retrieved at a later date. When needed, just the information desired can be recalled and a printout of those records can be made. Journal

entries may be viewed, printed, saved, and archived to the terminal hard drive or

to an external memory device.

TERMINAL SETTLEMENT

A suite of close functions are provided to facilitate daily balancing of the ATM’ s

internal record of transaction activity with the processor’s transaction records.

7

Page 28

MODEL RL/FT5000XP USER MANUAL

MULTI-LANGUAGE SUPPORT

The ATM has a screen language option. This option allows the terminal user to

select a preferred language (such as Spanish or French) to conduct a transaction.

MESSAGES

These are informational messages that give important information to the customer before, during, and after a transaction. Messages can be locally customized to meet local requirements. They include greeting and exit messages, terminal owner and surcharge owner identification, marketing messages, and news

tickers.

TRANSACTION AND ACCOUNT TYPE CONFIGURATION

This feature enables the terminal operator to select the types of transactions

(transfers or balance inquiries) or accounts (e.g. savings or credit card) that will

be presented to the customer. This feature does not affect the availability of

checking account withdrawal transactions, which are always presented.

REAR SERVICE PANEL (RSP)

(MODEL FT5000XP)

The RSP provides convenient user-access to most Management functions from

inside the facility. It also provides easy access to the dispensing mechanism,

loading receipt paper, and terminal shutdown.

Rear Service Panel

8

Page 29

SECTION 2

BASIC OPERA TION

9

Page 30

MODEL RL/FT5000XP USER MANUAL

INTRODUCTION

This section describes the basic operation of the terminal. The following topics

are covered:

1. Control Panel Layout. Describes the layout of the terminal’s control panel.

2. Keypad Operation. Describes the use of the alphanumeric keypads.

3. Screen Function Keys. Describes the use of the screen keys.

4. Rear Service Panel.

5. Menu-Based Operation. Provides a general overview of the terminal display

interface.

6. Accessing Management Functions. Describes the password entry

procedure that must be followed in order to access the Management

Functions area.

7. Voice-Enabled Transactions. Provides voice feedback via an integrated

output jack, enabling sight-impaired users to plug in a set of headphones

and receive spoken instructions to assist them in using the ATM.

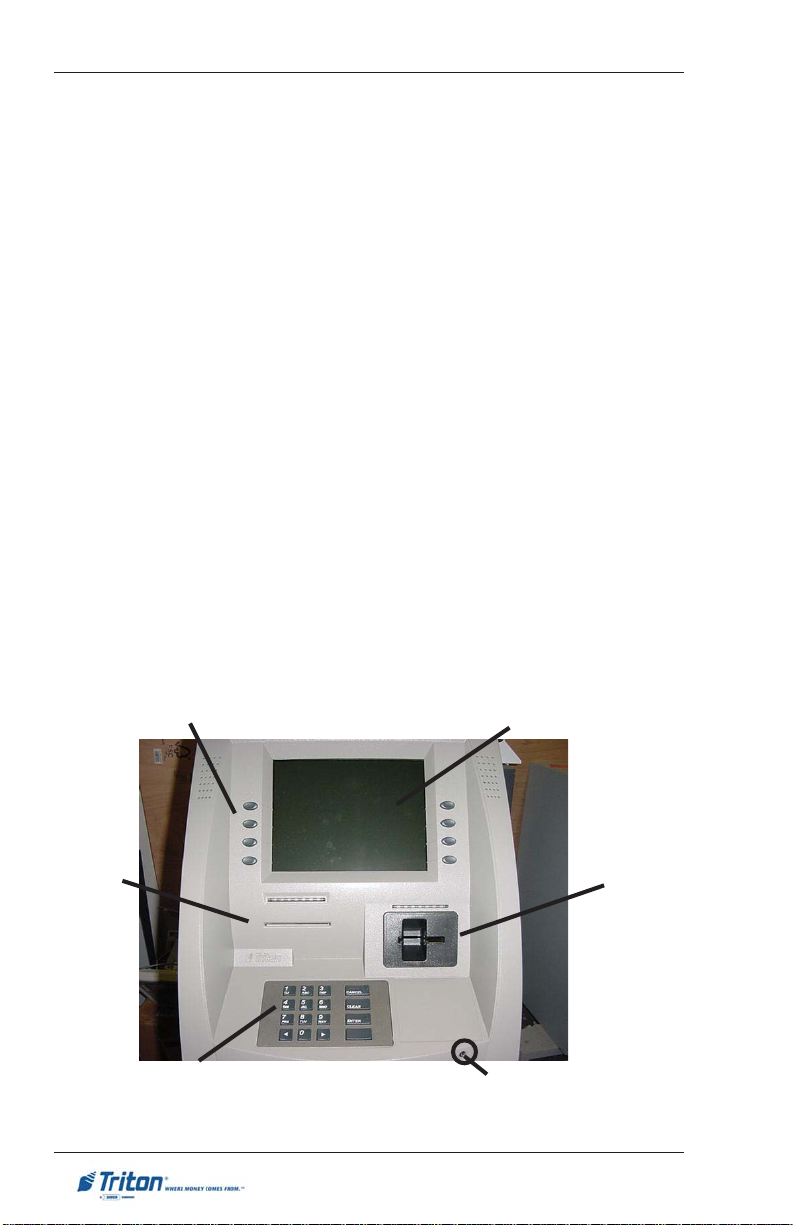

CONTROL PANEL LAYOUT (RL/FTXP)

The user interface of the terminal consists of the LCD display, receipt chute,

card reader, headphone jack (visually impaired), and 24 keys on three keypads

(menu and main keypads).

Receipt

chute

Menu keys

Main keypad Headphone jack

Fig. 2-1a. Control panel layout (RL

10

LCD screen

XP

)

Card reader

Page 31

BASIC OPERATION

Main keypad

Headphone

jack

Menu keys

Fig. 2-1b. Control panel layout (FT

KEYP AD OPERATION

LCD screen

XP

)

Receipt

chute

Card

reader

See Figure 2-2 and Table 2-1. The main keypad consists of 10 alphanumeric

keys, two arrow keys and four large control keys, all located in a 16-key group

beneath the LCD display. The table lists the keys and their functions.

The keypad has integral raised Braille symbols to conform to the requirements

of the Americans with Disabilities Act.

CTRL key

Fig. 2-2. Alphanumeric keypad

11

Page 32

MODEL RL/FT5000XP USER MANUAL

PAMDRAOBYEKTNORF-1-2ELBAT

YEKPAMDRAOBYEKNOITCA

worrAtfeL

worrAthgiR

retnEretnE .nottubde

lecnaCepacsE.golaiDehtnoLECNACstceleS

raelCBAT .enilwenatresnilliw,

yeKLRTC

)yeKknalB(

9-09-0

pUroworrAtfeL

worrA

roworrAthgiR

worrAnwoD

-

ecapS

.lortnoctsilanipusevoM-

.nottubsucofehtstceleS-

.lortnoc

suoiverpehtotsucofegnahC-

(dleiFtnerruCnidrawroFllorcS-

.lortnoctxenehtotsucofegnahC-

.lortnoctsilaninwodsevoM-

.nottuboidarroxobkcehcaselggoT

.noitpoxobgolaiddeificepsehttceleS-

liw,xobtidenaedisninehW-

.)sexoBtidEdnaobmoCrof(dleiFtnerruCnikcaBllorcS-

.)sexoBtidEdnaobmoCrof

tcelesasesserprogolaiDehtnoRETNEstceleS

sexobtxetenil-itlumroF.golaiDehtnodleiFtxeNotevoM

.retcarahcciremundeificepsehtyalpsidl

Table 2-1. Keyboard map.

SCREEN FUNCTION KEYS

Refer to Figure 2-3. The eight keys, 4 on each side of the LCD, are called screen

function keys. They are used in the selection of screen options that can appear

along the right and left side of the display. These keys are designated F1 through

F8. A screen function key is only active when a corresponding function or menu

option is present next to that key.

F1

F2

F3

F4

Figure 2-3. Screen function keys.

12

F5

F6

F7

F8

Page 33

BASIC OPERATION

REAR SERVICE PANEL (MODEL FTXP)

The Rear Service Panel (RSP) houses a 10.4" (264mm) SVGA color display with

800 x 600 resolution and a keyboard with mouse pad. This provides convenient

user-access to most Management functions from inside the facility . The assembly also pivots out allowing access to the PC assembly, power supply, and

optional printer assembly.

Figure 2-4. Rear service panel (display/keyboard).

13

Page 34

MODEL RL/FT5000XP USER MANUAL

MENU-BASED OPERATION

The terminal operates as a menu driven system. Messages and menu options

presented on the LCD display screen guide the user’s actions. The desired

menu option is selected by pressing one of the screen keys located to the left

and right of the display. For the purpose of security, many screens timeout after

a preset time interval, usually 30 seconds. The timeout length may vary depending on the function being performed.

When a screen timeout occurs, a screen is presented which asks the user if more

time is needed. If the user chooses NO, the Customer Welcome screen will be

presented. If YES is chosen, the user is returned to the function that was active

prior to the timeout. If the user does not make a selection within an additional

30-second countdown period the terminal will automatically go to the Customer

W elcome screen.

Shortly after the unit is turned on, the top menu will be displayed. An example

top menu is shown in Figure 2-5. From the top menu, you can either:

Activate the terminal to perform customer transactions by pressing the

key next to Customer Transaction.

Enter the terminal system management area by pressing the key next to

Management Functions.

If you do not select a menu choice within 30 seconds the terminal will automatically default to the Customer W elcome screen (a benefit of this feature is that in

the event of a power interruption the terminal will automatically begin accepting

customer transactions shortly after power is restored).

Fig. 2-5. Top menu.

14

Page 35

BASIC OPERATION

VOICE-ENABLED TRANSACTIONS

The terminal provides voice feedback via an integrated output jack, enabling

sight-impaired users to plug in a set of headphones and receive spoken instructions to assist them in using the ATM. Figure 2-6, headphone jack location,

shows the location of the headphone jack on the RL5000XP.

Fig. 2-6. Headphone jack location.

Raised symbols helps a user locate the headphone jack. The ATM will automatically detect when a headphone has been plugged into the jack, and will immediately switch into voice mode. Initially, a brief spoken tutorial will orientate the

customer to the ATM control panel interface. Once the customer begins a transaction, spoken prompts will provide feedback and guide the customer through

the successful accomplishment of the transaction.

15

Page 36

MODEL RL/FT5000XP USER MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

16

Page 37

SECTION 3

REPLENISHING CASSETTES

17

Page 38

MODEL RL/FT5000XP USER MANUAL

INTRODUCTION

The purpose of this section of the

manual is to describe the procedures for:

(1) removing and replacing note cassettes, (2) loading cassettes, and (3) removing and replacing the reject notes

(as applicable). Information concerning

note handling and quality issues are explained where appropriate.

DISPENSING MECHANISM

The RL/FTXP-series ATMs use an NMD100, friction-feed dispensing mechanism

to store and deliver notes and other media to the customer. The mechanism is

located in the lower security container

of the unit. It holds multiple cassettes

and a single reject cassette. The note

capacity for the cassettes is approximately 2750.

The dispensing mechanism delivers the

appropriate number of notes from the

note cassettes to fulfill the customer’s

withdrawal request. The purpose of the

reject cassette is to accept and hold

notes that have been transferred from

the note cassettes but not dispensed.

Some situations that could cause the

mechanism to reject notes are:

The mechanism is able to reject single

notes or bundles. A bundle reject occurs when more than one note is rejected at the same time. There are two

compartments within the reject cassette to keep notes in these two categories separated. The top compartment within the cassette can hold a

maximum of 250 bundle-notes; the

lower compartment can hold up to 100

single-note rejects.

IMPORTANT! The first time the dispenser is set up, or if a new note cassette is installed, the mechanism will

enter a learning mode, during which it

will reject 7-15 notes as it learns the

thickness of the currency or other media. W ith multiple cassettes installed,

the number of test rejects could almost fill the single-note compartment

of the reject cassette. In such cases, it

is recommended that you remove any

rejected notes from the unit before

placing the ATM back into service.

**CAUTION**

DO NOT RECYCLE REJECTED

NOTES INTO A CASSETTE!

Doing so could cause more rejects

and/or currency jams.

Multiple notes stuck together

Note width too short or long

Notes skewed in feed path

Notes too close together in

feed path

Notes not claimed by customer

(after a preset timeout the mechanism will retract the notes and

send them to the reject cassette).

NOTE CONDITION

The number of rejects can be directly

influenced by the technique used to

load the cassettes and the quality of

the currency. Notes loaded into the

mechanism cassettes must be in “fit”

condition if a high level of performance (low reject and failure rate) is

expected from the unit. “Fit” notes

are defined as those that do not possess any of the defects listed here:

18

Page 39

REPLENISHING CASSETTES

U

SED NOTE DEFECTS

Adhesive or “sticky” substances

on the surface of the paper.

Tears extending more than 1/2”

from the edge of the currency.

Tears, holes, or missing sections

in the body of the currency.

Tape on the surface of the currency

used for repairing, patching or any

other purpose.

Remove foreign objects (e.g. pins, pa-

per clips, crumbs, etc.).

Remove torn or very worn notes.

Straighten any folded notes.

Staples, pins, or any other foreign

body attached to the notes.

Corner folds of a size greater than

1/2” on either axis.

Two or more notes joined by any

means.

Excessively crumpled or crinkled.

NEW OR UNCIRCULATED NOTE DEFECTS

All the conditions listed for used

notes.

Excessive bowing due to condi-

tions of packing and storing.

New or uncirculated currency must

be “burst” and fully separated prior

to loading into cassettes.

PREP ARING NOTES

Use the following procedures to prepare notes before inserting them into a

note cassette.

Figure 4-1. Removing band.

Figure 4-2. Removing torn/worn

notes.

N

EW OR UNCIRCULATED NOTES

Remove the band around each bundle

of notes. Separate the notes from each

other by:

Striking the bundle hard against

the edge of a table or similar ob ject.

Flipping through each bundle of

notes in both directions at each

end.

Using a note counter.

PREPARING USED NOTES

Remove the band around each

bundle of notes.

19

Page 40

MODEL RL/FT5000XP USER MANUAL

REPLENISHING CASSETTES

To perform a cash replenishment, enter Management Functions > Terminal

Settlement Functions > Replenish Cassette(s). Follow the prompts to <Unlock>, load cassettes, and <Lock> cassettes.

REMOVING NOTE CASSETTES

1. Open the electronic lock on the security container door and open the door

to gain access to the dispensing mechanism.

2. To remove the selected note cassette, grasp the cassette handle with one

hand while holding the mechanism in place with the other hand (See Figures

4-3a and 4-3b). Pull the cassette out slightly. Place one hand underneath to

support the cassette as you slide it completely out of the unit.

Figure 4-3a. Cassette removal

(Model RL5000XP shown).

**CAUTION**

The “throat” assembly on the mechanism is not a load bearing structure!

Do not grasp or apply any pressure

to the throat.

3. Continue to support the bottom of

the cassette to keep it level as you

place it on a table or other flat surface. If the cassette has a loading

arm, fold it down, which will raise

the rear of the cassette and allow

gravity to help keep the notes

neatly stacked during the loading

process (Figure 4-4).

Figure 4-3b. Cassette removal.

Figure 4-4. Cassette w/loading

arm down.

20

Page 41

REPLENISHING CASSETTES

OPENING NOTE CASSETTES

1. Insert the key into the cassette lock (Figure 4-5). To unlock the cassette,

apply inward pressure on the key while turning it clockwise to the stop

position (approximately a quarter-turn). Open the cassette by simultaneously