Page 1

MODEL FT5000 (X2)

UTOMATED TELLER MACHINE

A

USER MANUAL

TDN 07103-00093 May 19, 2014

CORPORATE HEADQUARTERS

21405 B Street

Long Beach, MS 39560

Phone: (228) 575-3100

Fax: (228) 575-3101

© 2014 T riton. All Rights Reserved. TRITON logo is a

registered trademark of Triton Systems of Delaware.

COPYRIGHT NOTICE

Page 2

MODEL FT5000 (X2) USER MANUAL

DOCUMENT UPDATES

May 1, 2008 Original

May 19, 2014 Added Appendix G - T9 EPP Keypad

NOTICES

Copyright © Triton Systems of Delaware, LLC. 2014

A

LL RIGHTS RESERVED

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced

or transmitted by any means or in any form, without prior consent in writing from Triton Systems of

Delaware, LLC.

The information in this publication has been carefully checked and is believed to be accurate. However,

Triton Systems of Delaware, LLC. assumes no responsibility for any inaccuracies, errors, or omissions

that may be contained in this document. In no event will Triton Systems of Delaware, LLC. be liable for

direct, indirect, special, incidental, or consequential damages resulting from any defect or omission in

this manual, even if advised of the possibility of such damages.

In the interest of continued product development, Triton Systems of Delaware, LLC. reserves the right

to make improvements in its documentation and the products it describes at any time, without notice or

obligation.

T

RADEMARK ACKNOWLEDGEMENTS

Microsoft W indows is a registered trademark of Microsoft Corporation in the United States and/or other

countries. Triton Connect is a trademark of Triton Systems of Delaware, LLC. VISA® is a registered

trademark of VISA of the United States and other countries.

ii

Page 3

MODEL FT5000 (X2) USER MANUAL

CONTENTS

SECTION 1 - INTRODUCTION .........................................................................................1

WHAT’S IN THIS MANUAL ....................................................................................................2

F

EATURE HIGHLIGHTS / CHANGES .............................................................................................................3

S

TANDARD FEATURES ..............................................................................................................................4

SECTION 2 - BASIC OPERATION ....................................................................................7

INTRODUCTION ........................................................................................................................................8

C

ONTROL PANEL LAYOUT ........................................................................................................................8

F

UNCTION KEYPADS ................................................................................................................................9

M

AIN KEYPAD ........................................................................................................................................9

N-SCREEN KEYPAD OPERATION..............................................................................................................10

O

R

EAR SERVICE PANEL (S) ........................................................................................................................10

M

ENU-BASED OPERATION ........................................................................................................................11

C

USTOMER TRANSACTIONS .......................................................................................................................12

V

OICE-ENABLED TRANSACTIONS ..............................................................................................................14

SECTION 3 - CASSETTE CLOSE / CASH REPLENISHMENT ...............................................15

INTRODUCTION ........................................................................................................................................16

ISPENSING MECHANISMS ........................................................................................................................16

D

N

OTE CONDITION ....................................................................................................................................17

REPARING NOTES ...................................................................................................................................17

P

C

ASSETTE CLOSE PROCEDURES (FRONT DISPLAY) ..................................................................................18

C

ASSETTE CLOSE PROCEDURES (REAR SERVICE PANEL) ........................................................................19

EPLENISH CASSETTE(S) ........................................................................................................................20

R

R

EMOVE CASSETTE(S) .............................................................................................................................20

O

PENING NOTE CASSETTE .......................................................................................................................20

L

OADING NOTE CASSETTE .......................................................................................................................21

NSTALLING NOTE CASSETTE ....................................................................................................................22

I

R

EMOVING THE REJECT CASSETTE ............................................................................................................22

O

PENING THE REJECT CASSETTE ...............................................................................................................22

I

NSTALLING THE REJECT CASSETTE ...........................................................................................................23

V

ERIFY OPERATION OF DISPENSER ............................................................................................................24

SECTION 4 - GENERAL MAINTENANCE ..........................................................................25

INTRODUCTION ........................................................................................................................................25

R

EPLENISHING THE RECEIPT PAPER ...........................................................................................................25

C

LEANING THE ENCLOSURE ......................................................................................................................29

C

LEANING THE DISPLAY ...........................................................................................................................29

C

ARD READER CLEANING ........................................................................................................................29

iii

Page 4

MODEL FT5000 (X2) USER MANUAL

CONTENTS

APPENDIX A - SOFTWARE LICENSE AGREEMENT ..........................................................A-1

PPENDIX B - WARRANTY STATEMENT ........................................................................B-1

A

APPENDIX C - ELECTRONIC LOCKS ..............................................................................C-1

PPENDIX G - T9 EPP KEYPAD...................................................................................G-1

A

S

UPPLEMENT A - T7 T5 EPP BATTERY REPLACEMENT PROCEDURES.........................SA-1

S

UPPLEMENT B - TERMINAL ERROR CODES................................................................SB-1

iv

Page 5

SECTION 1

INTRODUCTION

1

Page 6

2

MODEL FT5000 (X2) USER MANUAL

WHAT’S IN THIS MANUAL

The User manual describes the operating features of the Model FT5000 (X2) ATM and shows how to

perform the procedures that would typically be performed by the owner or operator personnel.

The manual is divided into the following sections:

SECTION 1, INTRODUCTION. Summarizes the basic features of the Model FT5000 ATM.

SECTION 2, BASIC OPERATION. Describes the basic operation of the terminal.:

Control Panel Layout.

Keypads (Function, Main, On-Screen)

Menu-Based Operation

Customer Transaction Process

Voice-Enabled Transactions

SECTION 3, CASSETTE CLOSE / CASH REPLENISHMENT. Describes the menu functions for cassette close

procedures. Cash replenishment steps for the NMD-100 dispenser and standards are covered as well.

SECTION 4, GENERAL MAINTENANCE. Describes normal preventative and corrective maintenance proce-

dures appropriate for user personnel.

Replenishing Receipt Paper

Cleaning the Enclosure/Card Reader

APPENDIX A - SOFTWARE LICENSE AGREEMENT / COMPLIANCE STATEMENTS

APPENDIX B - WARRANTY STATEMENT

APPENDIX C - COMBINA TION LOCKS

SUPPLEMENT B - TERMINAL ERROR CODES. Error code listing peculiar to hardware and communications

protocol.

SUPPLEMENT A - T5 AND T7 BATTERY REPLACEMENT PROCEDURES

IMPORT ANT : Follow the instructions provided in SUPPLEMENT A of this manual for replacing

the battery for either the T5 or T7 PCI-EPP . Failure to follow the explicit instructions for the T5

will permanently damage the keypad!

Page 7

3

INTRODUCTION

Important features of the FT5000 (X2) ATM are highlighted in the following list:

Highly reliable, state-of-the-art operating system PC platform design. The FT5000 uses Microsoft®

Windows® CE.5.0 operating system with Triton’s X2™ technology. Supports Windows file formats

for adding custom logos and advertisements. In addition, it features Triton’s completely custom

design X2 motherboard..

Modular architecture eases troubleshooting and servicing.

Cabinet design allows flexibility for “Island” installations (wall thickness up to 6.3") or “Standard”

existing structures (wall thickness up to 10"). UL 291 Business Hours cabinet; optional UL291 Level 1

(Safe).

Rear-access unit and rear service panel allows accessibility to the dispenser and some Management

functions for security and ease of cassette loading and diagnostics.

Note: The current rear service panel (metal assembly mounted on top of cabinet sleeve) will be

replaced with the “touchscreen” display used for Model RT2000 units at a date TBD.

Supports communication types Dial-up (56K baud USB modems), TCP/IP , VSA T (satellite), and wireless.

(Note: For wireless option, please contact your account representative for more information).

VGA color Liquid Crystal Display (LCD) screen 10.4" (264 mm) with 640x480 resolution supports

attention-getting graphics.

Multi-lingual capabilities. Satisfies Americans with Disabilities Act (ADA) specifications for height

and access; audio transactions for the visually impaired. Complies with UK accessibility guidelines

(DDA) and California access compliance, Title 24.

FEA TURE HIGHLIGHTS / CHANGES

The VISA®-approved Encrypting PIN Pad (VEPP) has been replaced with a T5 PCI-compliant EPP.

The major differences between these two keypads:

1. Remote Key T ransfer (RKT) - The T5 (plastic and metal-cased body) has the capability

(upgradeable), the VEPP does not.

2. Key Management Passwords - Requirements for entering/changing User passwords in the

Key Management function are different for the T5 PCI-EPP . The pr ocess is detailed in

SUPPLEMENT C in the X-Scale/X2 Configuration Manual included on the CD.

3. User now has access to replace the battery (T5). CAUTION: Follow the instructions provided

in SUPPLEMENT A of this manual for replacing the battery for the T5 PCI-EPP .

4. The optional “METAL” T5 EPP (Metal casing) has a built-in heater - a feature more applicable

for through-the-wall units (RT2000/FT5000).

PCI-compliant EPP to comply with international encryption standards and Triple DES compliant.

Page 8

4

MODEL FT5000 (X2) USER MANUAL

Multi-function, dip-style card reader supports magnetic stripe cards; optional dip EMV “smart” card

reader (Track 1, 2, 3 Read) or EMV motorized card reader/encoder (Track 1, 2, 3 Read, Track 3 W rite).

FEA TURE HIGHLIGHTS / CHANGES

Graphics-capable 80 mm thermal printer (w/presenter) designed for quiet operation. Prints receipts,

coupons, and management reports.

Electronic combination lock; Kaba Mas Cencon optional.

Supports remote setup, configuration, and monitoring via T riton Connect™ A TM monitoring software.

Dispenses U.S. and international currency types; NMD-100 capable of dispensing other paper-based

media such as coupons or tickets.

High-capacity electronic journal stores transaction details for later printout and analysis.

Supports LED lead through indicators and integrated lighted advertising panel.

Bayou Bronze control panel and trim color .

STANDARD FEATURES

MANAGEMENT FUNCTIONS. Enable extensive control and customization of the ATM’ s operating

parameters (see “X-SCALE/X2 CONFIGURATION MANUAL” included on CD).

PASSWORD PROTECTION. Access to Management Functions and Key Management areas are protected

with passwords.

MAC ENCRYPTION SUPPORT. Message Authentication Code (MAC) data encryption protocol. Provides

increased protection for message traffic to and from the ATM. Triple DES compliant.

PCI-COMPLIANT ENCRYPTING PIN PAD (EPP) ENTRY DEVICE SUPPORT. Secure EPP device encrypts the

customer PIN during a transaction. T riple DES and PCI-compliant.

MULTI-LANGUAGE SUPPORT. Enables the customer to select a preferred language (such as French or

Spanish) for customer screens and receipts.

TRANSACTION AND ACCOUNT TYPE CONFIGURATION. Enables selection of transactions (transfers or

balance inquiries) or accounts (savings or credit card) that will be presented to the customer . Does not

affect availability of checking account withdrawal.

Page 9

5

INTRODUCTION

CASSETTE AND DAY CLOSE REPORTS. Provide summary information about the number and type of

transactions being performed by the ATM.

ELECTRONIC JOURNAL. Stores the details of each transaction in solid-state memory . Journal data can be

retrieved, printed, saved to an external storage device, or transferred to a remote Triton Connect™

computer.

AD SCREENS. An Ad screen is a promotional or advertising graphic that is displayed on the LCD screen

during idle periods. Ad screens are downloaded to the terminal by either using an external storage

device (jumpdrive) or a remote Triton Connect™ computer. Text-only (non-graphic) ad screens can

also be displayed.

RECEIPT PRINTER GRAPHICS. This feature allows informational or promotional graphics to be printed on

customer receipts. Graphics can be loaded from an external storage device or Triton Connect™.

MESSAGES. Informational and promotional messages that are displayed to the customer on-screen or

printed on receipts.

COUPONS. Coupons can be printed by the receipt printer or dispensed (NMD-100). Prizes may be

awarded to customers based on random and/or withdrawal amount-based transactions. Coupon text

can be entered locally or downloaded along with coupon graphics using Triton Connect™ software.

STATUS MONITORING. The ATM can periodically transfer status information to the host processor. In

addition, Triton Connect™ remote monitoring software can be used to view the journal, monitor

operation and alarm conditions, update operating parameters, and reset the terminal.

UL 291 BUSINESS HOURS AND LEVEL 1 (SAFE) CABINETS. Business hours cabinet means currency should

be removed from the dispenser and stored in a safe location when the business is closed to the public.

REAR -ACCESS UNIT. Rear access unit allows access to the dispensing mechanism and rear service panel

provides ability for some Management functions - provides security and ease of cassette loading and

diagnostics.

Page 10

6

MODEL FT5000 (X2) USER MANUAL

THIS PAGE INTENTIONALL Y LEFT BLANK

Page 11

SECTION 2

BASIC OPERATION

7

Page 12

8

MODEL FT5000 (X2) USER MANUAL

INTRODUCTION

This section describes the basic operation of the terminal. The following topics are covered:

1. CONTROL PANEL LAYOUT. Describes the layout of the terminal’s control panel.

2. KEYPAD OPERATION. Describes the use of the function, alphanumeric (main), and on-screen keypads.

3. REAR SERVICE PANEL (RSP). Describes the RSP and its hardware.

4. MENU-BASED OPERATION. Gives a general overview of the terminal display interface.

5. CUSTOMER TRANSACTIONS. Summarizes the actions involved in typical customer transactions. In addition,

the voice-enabled transactions feature is described.

CONTROL PANEL LA YOUT

The user interface of the terminal consists of the

LCD screen, receipt chute, card reader, speaker,

headphone jack (visually impaired), and 24 keys on

three keypads. The Function keys are arranged in

two four-key groups, one group on either side of

the LCD display. The main keypad consists of 10

alphanumeric keys, two arrow keys and four large

control keys, all located in a 16-key group beneath

the LCD screen.

The main keypad and control keys have an integral

raised Braille symbol to conform to the requirements

of the Americans with Disabilities Act (Figure 2-1).

Figure 2-1. Control panel layout.

LCD screen

Receipt

chute

Card

reader

Main keypad

Bill chute

Function

keys

Page 13

9

BASIC OPERATION

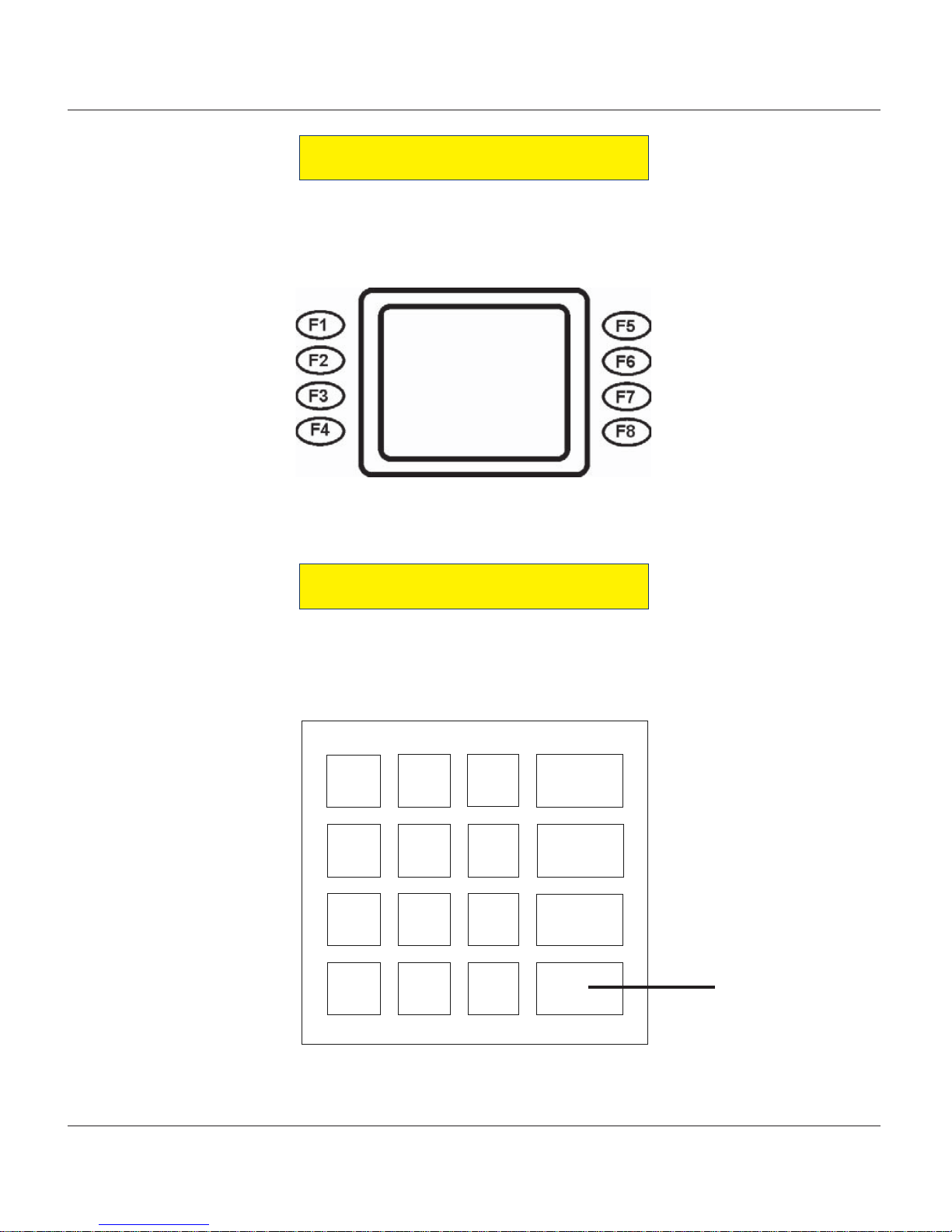

FUNCTION KEYS

The eight (8) keys, arranged in two four-key groups, are called screen function keys. A screen function key

is only active when a corresponding function or menu option is present next to that key. The Function keys

are designated F1 through F8, as shown in Figure 2-2.

Figure 2-2. Function key layout.

MAIN KEYPAD

The entry of numeric characters via the main keypad is straightforward: simply press the desired key.

However, in certain Management Function screens it may be necessary to enter alphabetic characters, a

procedure that’s available with the On-Screen keypad, explained on next page.

1

QZ

2

ABC3DEF

4

GHI

5

JKL6MNO

7

PRS8TUV9WXY

0

<>

x

CANCEL

<

CLEAR

O

ENTER

CTRL

Figure 2-3.

Alphanumeric

keypad.

Page 14

10

MODEL FT5000 (X2) USER MANUAL

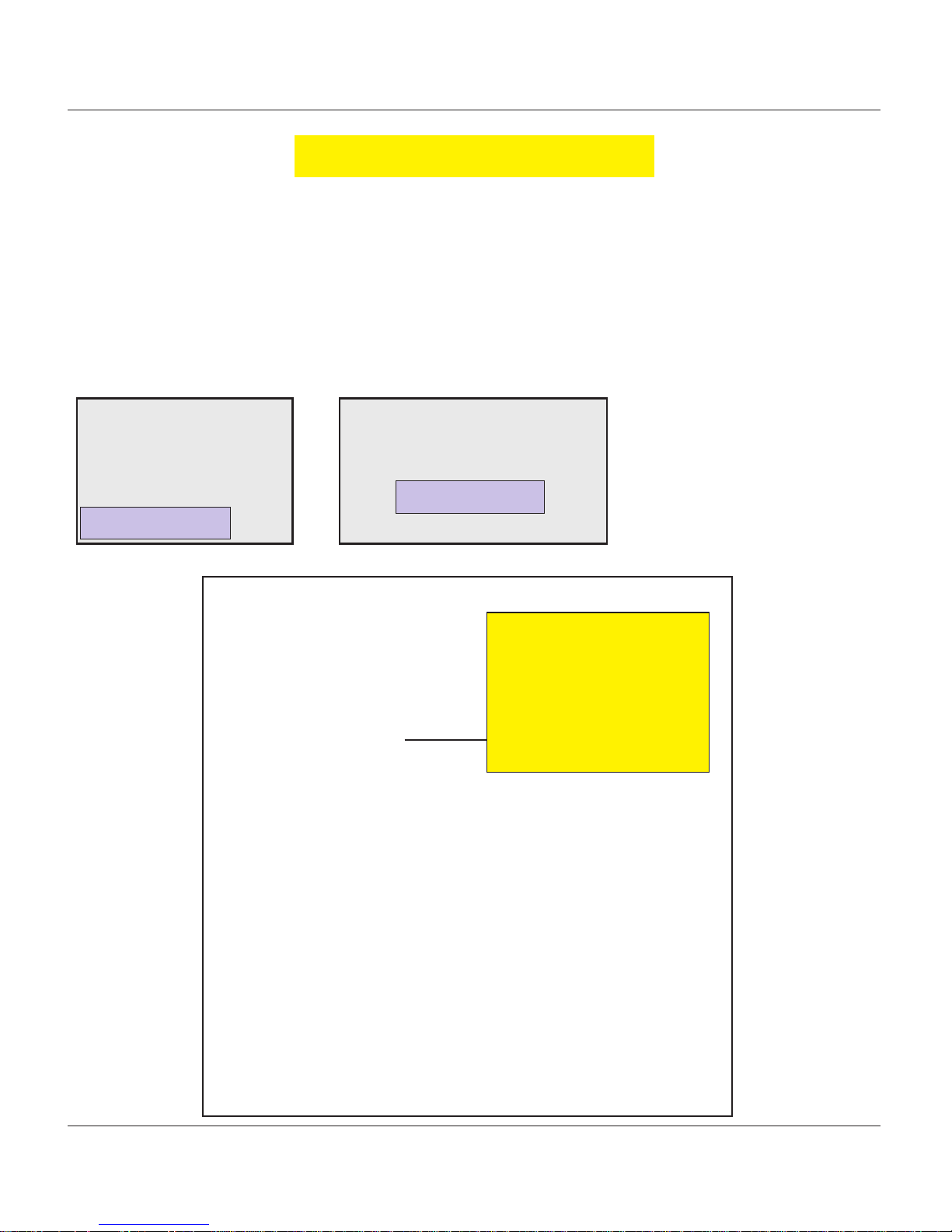

ON-SCREEN KEYP AD OPERATION

To enter text characters into the dialog boxes that are displayed by the Management Functions, press the

F8 key to display the screen keyboard. Use the keys described below to navigate and enter required data

(see Figure 2-4).

Figure 2-4. On-screen keyboard.

REAR SERVICE PANEL

The current Rear Service Panel (RSP) houses a 5.7"

(145mm) monochrome display , keypad, and 60mm

thermal printer. This provides convenient user -access for day-to-day Management functions from

inside the facility. Note: This assembly will be re-

placed with the Rear Operator Panel (touchscreen)

shown at right.

Rear Service Panel.

• The Arrow keys (< and >), the <8> key - (UP), and

the <0> key - (DOWN) navigate the keyboard.

• Press the <ENTER> key to select the highlighted

key entry.

• Press the <CTRL> key to switch between upper

and lower case characters.

• Press the <CANCEL> key to Exit the keyboard.

• Press the <CLEAR> key for the Backspace opera-

tion.

• Press the <1> key to reposition the keyboard to

another location on the display.

• Press the <2> key to position the cursor on a new

line.

The Rear Operator Panel (ROP) is a touchscreen

display that provides convenient user-access for

day-to-day Management functions from inside the

facility . The capability for cassette closes, terminal

restart/shutdowns, and print commands are some

of the functions available.

Rear Operator Panel.

Page 15

11

BASIC OPERATION

MENU-BASED OPERATION

The terminal operates as a menu driven system. Messages and menu options presented on the LCD display

screen guide the user’s actions. The desired menu option is selected by pressing one of the keys located to

the left and right of the display . For the purpose of security many screens timeout after a preset time interval,

usually 30 seconds. The timeout length may vary depending on the function being performed.

When a screen timeout occurs, a screen is presented which asks the user if more time is needed. If the user

chooses NO, the Customer Welcome screen will be presented. If YES is chosen, the user is returned to the

function that was active prior to the timeout. If the user does not make a selection within an additional 30second countdown period the terminal will automatically go to the Customer Welcome screen.

Shortly after the unit is turned on, the top menu will be displayed. An example top menu is shown in

Figure 2-5. From the top menu, you can either:

1. Activate the terminal to perform customer transactions by pressing the key next to CUSTOMER

TRANSACTIONS.

2. Enter the terminal system management area by pressing the key next to MANAGEMENT FUNCTIONS.

Note: You will have to enter an appropriate password to view the Management Functions menu.

Figure 2-5. Top menu screen.

If you do not select a menu choice within 30 seconds the terminal will automatically default to the Customer

Welcome screen (a benefit of this feature is that in the event of a power interruption the terminal will

automatically begin accepting customer transactions shortly after power is restored).

Page 16

12

MODEL FT5000 (X2) USER MANUAL

CUSTOMER TRANSACTIONS

A customer begins a transaction by selecting from the Customer screen options. They insert their ATM

card into the card reader of the terminal. The card must be inserted so that the magnetic stripe can be

scanned by the card reader’s sensor . If the customer inserts the card incorrectly , a warning message will be

displayed, accompanied by several beeps to get their attention.

If there is a problem reading a card, make sure the customer is inserting the card correctly . Most problems

are the result of inserting the card incorrectly .

Once the card has been read in successfully, a surcharge message, if applicable, may be displayed (the

surcharge message may be displayed at the end of the customer’s transaction selection). The customer

must then enter their Personal Identification Number (PIN) code. Once the PIN has been entered, the

transaction type and account are selected, and the desired amount of the transaction, if needed. The

transaction will be processed, typically in a matter of seconds.

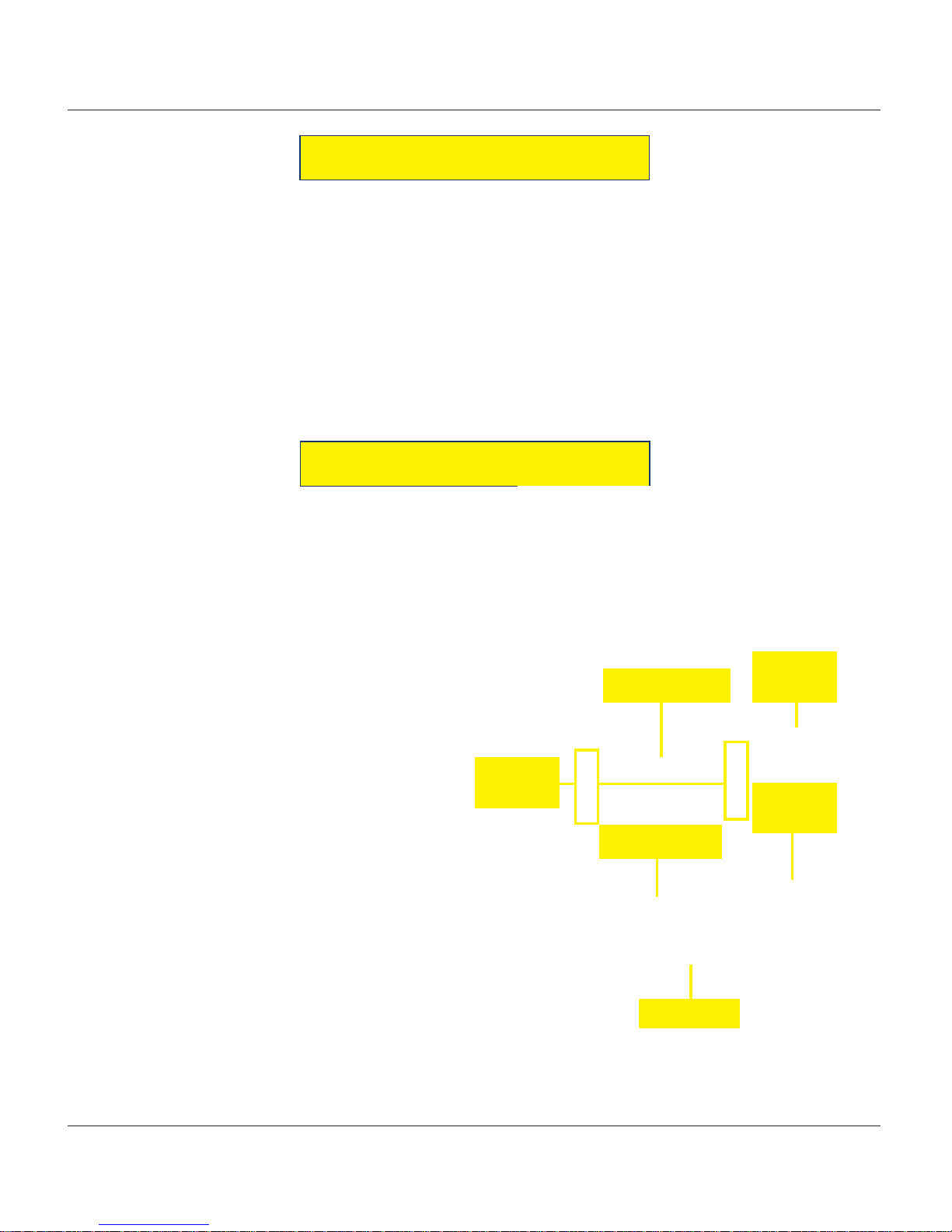

Figure 2-6 shows how ATM transactions are handled. If the transaction was processed successfully, the

customer is prompted to retrieve the requested cash (for withdrawal transactions) and/or the applicable

transaction receipt, as needed. If the transaction was declined, a short receipt indicating the problem is

printed.

BANK

PROCESSOR

A

TM

ATM

NETWORK

Figure 2-6. ATM transaction processing.

Page 17

13

BASIC OPERATION

The ATM sends the customer transaction request to a processor. A processor is a financial intermediary,

such as an Independent Sales Organization (ISO), bank, or other financial institution that provides transaction-processing services for ATMs. The ATM must be set up with a particular processor before customer

transactions can take place.

The processor routes the transaction to the appropriate ATM network. An A TM network is a regionally or

nationally organized clearing house for financial transactions, that deals directly with the appropriate

financial institution, such as the customer’s bank or credit card company , in order to complete the transaction. The processor will select the appropriate ATM network to use based on factors such as the type of

ATM or credit card used, location of the customer’s bank, or other considerations. The transaction may be

transferred between several networks before ultimately reaching the customer’s bank or credit card company.

The ATM network routes the transaction to the appropriate bank or other institution, confirms successful

completion of the transaction, and sends a confirmation message back to the processor. If the request was

for a cash withdrawal, an Electronic Funds Transfer (EFT) takes place to debit the funds (including any

surcharge fee, if applicable) from the customer’s bank account and credit the funds to the processor’s bank

account.

The processor forwards a confirmation message to the ATM (and an authorization to dispense currency , in

the case of a cash withdrawal). The ATM dispenses the requested currency, if necessary, and provides the

customer with a printed receipt as a record of the transaction.

The processor credits the merchant’s account for the amount of any cash withdrawals (plus surchar ge fees,

if collected), typically by the end of the next business day).

Page 18

14

MODEL FT5000 (X2) USER MANUAL

VOICE-ENABLED TRANSACTION

The terminal provides voice feedback via an integrated output jack, enabling sight-impaired users to plug

in a set of headphones and receive spoken instructions to assist them in using the ATM (Figure 2-7).

A raised symbol helps a user locate the headphone jack. The A TM will automatically detect when a headphone has been plugged into the jack, and will immediately switch into voice mode. Initially , a brief spoken

tutorial will orientate the customer to the ATM control panel interface. Once the customer begins a transaction, spoken prompts will provide feedback and guide the customer through the successful accomplishment of the transaction.

Figure 2-7.

Headphone jack location.

Headphone jack

Page 19

15

SECTION 3

CASSETTE CLOSE

CASH REPLENISHMENT

Page 20

16

MODEL FT5000 (X2) USER MANUAL

INTRODUCTION

The purpose of this section of the manual is to describe the procedures for cassette closing and replenishment. Information concerning note handling and quality issues are explained where appropriate.

DISPENSING MECHANISM

The Model FT5000 (X2) ATM uses an NMD-100, friction-fed dispensing mechanism to store and deliver

notes and other media to the customer . The mechanism is located in the lower security container of the unit.

It holds multiple cassettes and a single reject cassette. The note capacity for a cassette is approximately

2750.

The dispensing mechanism delivers the appropriate number of notes from the note cassette to fulfill the

customer’s withdrawal request. The purpose of the reject area or cassette is to accept and hold notes that

have been transferred from the note cassette but not dispensed.

**CAUTION**

DO NOT RECYCLE REJECTED NOTES INTO A CASSETTE!

Doing so could cause more rejects and/or currency jams.

The mechanism is able to reject single notes or bundles. A bundle reject occurs when more than one note is

rejected at the same time. There are two compartments within the reject cassette to keep notes in these two

categories separated. The top compartment within the cassette can hold a maximum of 250 bundle notes;

the lower compartment can hold up to 100 single note rejects.

IMPORTANT! The first time the dispenser is set up, or if a new note cassette is installed, the mechanism

will enter a learning mode, during which it will reject 7-15 notes as it learns the thickness of the currency or

other media. With multiple cassettes installed, the number of test rejects could almost fill the single note

compartment of the reject cassette. In such cases, it is recommended that you remove any rejected notes

from the unit before placing the ATM back into service.

Some situations that could cause the mechanism to reject notes are:

(1) Multiple notes stuck together (2) Note width too short or long.

Other conditions that could cause a reject are described in the next section, Note Condition.

Page 21

17

CASSETTE CLOSE / CASH REPLENISHMENT

NOTE CONDITION

The number of rejects can be directly influenced by the technique used to load the cassettes and the quality

of the currency. Notes loaded into the mechanism cassettes must be in “fit” condition if a high level of

performance (low reject and failure rate) is expected from the unit. “Fit” notes are defined as those that do

not possess any of the defects listed here:

USED NOTE DEFECTS

Adhesive or “sticky” substances on the surface of the paper.

T ears extending more than 1/2” from the edge of the currency.

Tears, holes, or missing sections in the body of the currency.

Tape on the surface of the currency used for repairing, patching or any other purpose.

Staples, pins, or any other foreign body attached to the notes.

Corner folds of a size greater than 1/2” on either axis.

T wo or more notes joined by any means.

Excessively crumpled or crinkled.

PREP ARING NOTES

Use the following procedures to prepare notes before inserting them into a note cassette.

PREPARING USED NOTES

Remove the band around each bundle of notes.

Remove foreign objects (e.g. pins, paper clips, crumbs,

etc.).

Remove torn or very worn notes.

Straighten any folded notes.

Figure 3-1. Removing

band.

Figure 3-2. Removing

torn/worn notes.

NEW OR UNCIRCULATED NOTES

Remove the band around each bundle of notes. Separate the notes from each other by:

Striking the bundle hard against the edge of a table or similar object.

Flipping through each bundle of notes in both directions at each end.

Using a note counter.

Page 22

18

MODEL FT5000 (X2) USER MANUAL

CASSETTE CLOSE PROCEDURES

Follow Access instructions to enter MANAGEMENT FUNCTIONS. Select TERMINAL CLOSE FUNCTIONS. Select

CASSETTE CLOSE.

Select cassette(s) to Close. A check mark ( √ )

identifies which cassette(s) are selected. Press

<ENTER>.

After cassette(s) have been reinserted in the

dispenser, press <ENTER>.

Note: For an NMD-50/100 dispenser installed, wait

for the cassettes to LOCK (this is done automatically).

Press <Enter> if applicable.

A Close report is displayed to be printed or

saved. This operation will reset the number of bills

in the cassette(s) to ZERO (0). Press <ENTER>.

Remove and Replenish the selected cassette(s).

Procedures for cassette replenishment

start on page 20.

Note: For an NMD-50/100 dispenser installed, wait

for the cassettes to UNLOCK (this is done automatically).

Place selected cassette(s) IN SERVICE. Press

<ENTER>. Note: The NMD-50/100 cassettes Must be

Locked and In Service for normal operation.

Enter Cassette Quantity (number of notes, NOT

value) for the selected cassette(s). Press <ENTER>

to accept entry. Repeat for each selected cassette.

A Trial Cassette Close report automatically is

displayed to be printed or saved. Print and retain a

copy for starting point reference. Press <ENTER> to

return to Close functions.

Page 23

19

CASSETTE CLOSE / CASH REPLENISHMENT

CASSETTE CLOSE PROCEDURES

FROM THE REAR SERVICE PANEL OR REAR OPEATOR PANEL:

Press <ENTER> from the RSP keypad or ROP touchscreen.

When prompted, enter your Management function password.

The Main menu options are displayed.

THE CASSETTE CLOSE SEQUENCE OPERATE THE SAME AS THE FRONT

DISPLAY

SEQUENCE.

3. CLEAR JOURNAL

4. JOURNAL PROPERTIES

MAIN MENU

1. TRIAL CLOSE

2. DAY CLOSE

3. TRIAL CASSETTE CLOSE

4. CASSETTE CLOSE

1. TERMINAL CLOSE

1. DISPLAY UNAUDITED RECORDS

2. DISPLAY LAST X

2. DIAGNOSTICS

3. ELECTRONIC JOURNAL

1. CURRENT TERMINAL ERROR

2. DISPENSER

3. CARD READER STATUS

4. PRINTER

5. MODEM / ETHERNET

6. KEYPAD

4. RESET TERMINAL ERROR

5. SHUT DOWN THE TERMINAL

6. RESTART THE TERMINAL

SELECT CASSETTE(S) TO CLOSE

CLOSE REPORT

REMOVE/REPLENISH CASSETTE(S)

REINSTALL CASSETTE(S)

PLACE CASSETTE(S) IN-SERVICE

ENTER CASSETTE QUANTITY

TRIAL CASSETTE CLOSE REPORT

Press ENTER to

begin.

Status: IDLE

Please enter your password

to access the Management

Functions.

ENTER

REAR SERVICE PANEL

REAR OPERATOR PANEL

Page 24

20

MODEL FT5000 (X2) USER MANUAL

REMOVING NOTE CASSETTES

1. UNLOCK the cassettes, using the Cassette Close procedures. Open the vault door to gain access to

the dispensing mechanism.

2. To remove the selected note cassette, grasp the cassette handle with one hand while holding mechanism in place with the other hand. Pull the cassette out slightly . Place one hand underneath to support

the cassette as you slide it completely out of the unit. Continue to support the bottom of the cassette to keep

it level as you place it on a table or other flat surface.

OPENING NOTE CASSETTES

1 . Insert the cassette key into the cassette lock. T o unlock the cassette, apply inward pressure on the key

while turning it “clockwise” to the stop position (approximately a quarter-turn). Open the cassette by

simultaneously pressing the release button and lifting the lid. Flip the lid back fully , allowing it to rest

on the table or other flat surface.

Press release button and lift top.

REPLENISH CASSETTE (NMD-100)

Removing note cassette.

Insert key to unlock cassette.

Page 25

21

CASSETTE CLOSE / CASH REPLENISHMENT

LOADING NOTE CASSETTES

4. Level the note pile and move the packer plate against the notes with just enough pressure to hold the

notes.

5. Move the white plastic levers (Pawls) on the pusher plate to their fully extended position. This will

allow the pusher plate to retract and relieve pressure from the note stack when an unlock command

is sent to the dispenser .

“Pawls” extended.

2. Count the number of bills that remain in the cassette, if any. Next, count the number of bills that are

being added into the cassette.

3. Add the number of bills being placed into the cassette to the number that remained. The “Total”

number of these bills will be entered in the “ENTER CASSETTE QUANTITY” option.

1. Move the pusher plate to the rear of the cassette (toward the handle). Ensure the pusher plate is fully

back. It should stay in this position.

Slide packer plate

against notes.

Slide packer plate

towards rear.

Load/level notes.

6. Close the cassette lid. Fold the lid down to its locked position. The release button should “pop” out,

allowing the lid to mate cleanly with the body of the cassette. You may need to “tap” the lid firmly along

the front edge to achieve this. Turn the key “counterclockwise” to lock the cassette.

Page 26

22

MODEL FT5000 (X2) USER MANUAL

REMOVING THE REJECT CASSETTE

INSTALLING NOTE CASSETTES

Once the cassettes have been loaded with currency, reinstall them in the mechanism. Make sure each

cassette is fully inserted.

IMPORTANT!

If you remove the reject vault with power applied, the terminal will sense this and automatically

reset the rejected note count to ZERO. Therefore, to ensure an accurate rejected note count

NEVER REMOVE THE REJECT V AUL T WITH POWER APPLIED WITHOUT CHECKING FOR

AND REMOVING ANY REJECTED NOTES.

1 . T o remove the reject cassette (top channel), grasp the cassette handle with one hand while holding the

mechanism in place with the other hand. Pull the cassette out slightly. Place one hand underneath to

support the cassette as you slide it completely out of the unit. Place it on a level surface.

Removing the reject cassette.

Reject cassette ready to open.

OPENING THE REJECT VAULT

1. Insert the key into the cassette lock. To unlock, apply inward pressure on the key while turning it

“clockwise” to the stop position (approximately a quarter-turn). Open the vault by simultaneously

pressing the release button and lifting the lid. Flip the lid back fully .

Key inserted. Opening lid.

Page 27

23

CASSETTE CLOSE / CASH REPLENISHMENT

INSTALLING THE REJECT CASSETTE

2. The reject vault is now open for collecting any rejected bundle notes. These will be present in the

folding tray . After retrieving any rejected bundle notes, lift the folding tray and check underneath for

any rejected single notes.

3. After removing any rejected notes, close the vault lid. Fold the lid down to its locked position. The

release button should “pop” out, allowing the lid to mate cleanly with the body of the cassette. Turn

the key “counterclockwise” to lock the vault.

Bundle reject tray.

Single reject compartment.

Using the reverse of the steps taken to remove the reject cassette, slide the cassette back into its slot in the

mechanism. Make sure the cassette is fully inserted. Ensure the cassettes are LOCKED and IN SERVICE using

the Cassette Close procedures.

Page 28

24

MODEL FT5000 (X2) USER MANUAL

VERIFY OPERATION

1. Close and lock the security cabinet.

2 . Verify the cassettes are Locked and In Service.

3 . In Management Functions, select DIAGNOSTICS > DISPENSER.

4 . Select the TEST DISPENSE option. Select either individual cassettes that are installed (“A”, “B”, “C”, or

“D”) or “All Cassettes ”. A prompt appears asking how many notes to dispense. The Test Dispense

operation will start.

5. The Test Dispense command instructs the dispenser to dispense, minimum, one note from each

installed and operational cassette into the reject vault. This test exercises the dispenser without

sending notes to the exit.

6 . After completion of the T est Dispense, the following prompt is displayed. “Test Dispense Completed

Successfully - Dispense Count , A: (# of notes), B: #, etc.

Enter # of notes.

**IMPORTANT**

Ensure the MULTIPLE AMOUNT parameter matches the

denomination of currency in each Note Cassette!

Page 29

SECTION 4

GENERAL MAINTENANCE

25

Page 30

26

MODEL FT5000 (X2) USER MANUAL

This section of the manual covers preventive and corrective maintenance procedures appropriate for user

personnel. The following areas are covered:

INTRODUCTION

1. REPLENISHING RECEIPT PAPER. Describes how to replace a

spent receipt paper roll.

2. CLEANING THE ENCLOSURE. The proper way to clean the A TM

housing.

3. CARD READER CLEANING. The recommended card reader

cleaning technique.

*Important*

Only qualified service personnel

are authorized to repair or service the terminal. Should a malfunction occur , DO NOT attempt

to service the unit yourself! Contact your T riton cer tified service

provider!

NOTE: This operation must be completed with the AC power applied to the ATM.

1. Open the rear cabinet sleeve door.

2. If paper remains on the roll, cut or tear the paper between the roll and the printer.

3 . Remove the existing paper and spindle from the paper bracket.

REPLENISHING THE RECEIPT PAPER

Cut/tear paper.

Remove paper roll/spindle.

Page 31

27

GENERAL MAINTENANCE

4. Pull the printer bracket release handle up and rotate the

printer assembly down.

5 . Release (OPEN) the blue tension lever located on the printer/

cutter assembly . Remove any paper from the printer/cutter

assembly. Move the tension lever back to the CLOSED

position (blue lever facing towards the right). Rotate the

printer assembly up to the operate position.

** CAUTION **

DO NOT pull receipt paper backwards through the printer with the tension rollers closed!

This may leave paper fragments that can cause paper jams.

Open

Closed

Grasp handle and lift up.

Pivot assembly down.

Tension lever on printer/cutter assembly.

6 . Install the new paper roll on the spindle. Unwind enough

paper to ensure the glued end that secured the paper roll is

removed.

Note: The spindle is inserted so that the paper will feed

from the TOP of the roll when it is installed on the paper

bracket.

7. Place the paper roll (w/spindle) on the paper support

bracket by sliding ends of spindle on to the bracket.

Paper roll installed in bracket.

Page 32

28

MODEL FT5000 (X2) USER MANUAL

8 . Feed the end of the paper into the printer take-up slot. The printer will activate and automatically feed

the paper through the printer and slightly out the front of the control panel.

9 . If the printer does not feed automatically, rotate the printer assembly down again and check the tension

lever on the printer/cutter assembly for correct (Closed) position (Step 5).

Paper feeds automatically

slightly out front of unit.

1 0 . Go to MANAGEMENT FUNCTIONS > DIAGNOSTICS and perform a RESET/TEST PRINTER.

Feed paper into the printer take-up slot.

* NOTE *

Triton recommends the use of 20# thermal

printer paper (Triton P/N 05403-00053). This

receipt paper has been shown to improve

performance and reliability.

Page 33

29

GENERAL MAINTENANCE

The ATM front panel is highly durable, resisting scratches and finger smudges. However, occasional

cleaning of the front panel and the plastic enclosure may be desirable. A soft dry or slightly damp cloth may

be used for cleaning. For best results, use a weak solution of a mild detergent and water .

** Caution **

A void using abrasive cleaners on any surface of the terminal.

Do not spray liquid cleaner directly on the unit.

The Liquid Crystal Display (LCD) on the front of the ATM has a plastic protective window that should be

cleaned only with a soft cloth, dampened with a weak solution of a mild detergent and water.

** Caution **

Do not use any abrasive cleaners on the window as it will scratch.

Do not spray liquids onto the screen as they may run down inside

the unit and cause damage.

Special cleaning cards (P/N 06200-00055) are available for proper maintenance of the card reader. The reader

should be cleaned at least once a month by inserting and removing a cleaning card, as shown below. It may

be necessary to clean the card reader more often in locations that see heavy usage.

1. Remove the cleaning card from the sealed pouch.

2. Insert the cleaning card into the card reader and move in and out several times.

3. Remove the cleaning card and turn over to use other side.

4. Insert again several times.

5 . Remove cleaning card and discard.

CLEANING THE ENCLOSURE

CLEANING THE DISPLAY

CARD READER CLEANING

Page 34

30

MODEL FT5000 (X2) USER MANUAL

THIS PAGE INTENTIONALL Y LEFT BLANK

Page 35

APPENDIX A

SOFTWARE LICENSE AGREEMENT

COMPLIANCE / EMISSION STATEMENTS

A-1

Page 36

APPENDIX A

AUTOMATED TELLER MACHINE (“ATM”) SOFTWARE

END-USER AGREEMENT

IMPORTANT: PLEASE READ CAREFULLY:

BY INST ALLING OR OTHER WISE USING THE ATM, YOU (AS THE OWNER OR LESSEE OF THE ATM).

AGREE TO BE BOUND BY THE FOLLOWING TERMS AND CONDITIONS, INCLUDING, WITHOUT

LIMITATION, THE WARRANTY DISCLAIMERS, LIMITATIONS OF LIABILITY AND TERMINATION

PROVISION WHICH APPLY TO YOUR USE OF THE ATM SOFTW ARE CONTAINED IN THIS ATM AND

IS HEREBY LICENSED BY TRITON SYSTEMS OF DELAWARE, LLC. (“Triton”) TO YOU PURSUANT

TO THIS AGREEMENT.

IF YOU DO NOT AGREE TO OR ARE NOT WILLING TO BE BOUND BY THE TERMS AND CONDITIONS OF THIS AGREEMENT, DO NOT INSTALL OR OTHERWISE USE THIS ATM AND PROMPTLY

CONT ACT YOUR VENDOR. INST ALLING OR OTHERWISE USING THE ATM INDICA TES THAT YOU

ACCEPT THESE TERMS.

This ATM is manufactured by, and utilizes proprietary software owned by Triton Systems of Delaware, LLC.

and/or its suppliers. All right, title and interest in and to all component software installed or embedded in the

ATM (“ATM Software”) including all associated intellectual property rights, are and will remain the property

of Triton and/or its suppliers.

LICENSE: Triton grants you a limited, nonexclusive license to use the ATM Software but only in connection

with the operation of this ATM subject to the terms and restrictions set forth in this License Agreement. You are

not permitted to use the ATM Software in any manner not expressly authorized by this License. You acknowledge and agree that ownership of the ATM Software and all subsequent copies thereof regardless of the form or

media are held by Triton or its suppliers.

The software is licensed for use on this specifi c Triton ATM product and may not be used on any other product.

Otherwise, the supporting documentation, if any, may be copied only as essential for backup or archive purposes in support of your use of the ATM. You must reproduce and include all copyright notices and any other

proprietary rights notices appearing on any copies that you make.

ASSIGNMENT: NO REVERSE ENGINEERING: You may transfer the ATM Software to another party

but only in connection with a transfer of all your right, title and interest in and to this ATM and if such party accepts the terms and conditions of this License Agreement. If you transfer the A TM, you must at the same time

transfer the supporting documentation, if any, to the same party or destroy any such materials not transferred.

Modifi cation, reverse engineering, reverse compiling, or disassembly of the ATM and/or the ATM Software is

expressly prohibited.

A-2

Page 37

SOFTWARE LICENSE AGREEMENT / COMPLIANCE/EMISSION STATEMENTS

DISCLAIMER OF WARRANTIES AND LIMITATION OF DAMAGES

TO THE EXTENT PERMITTED BY LAW, THIS ATM SOFTWARE, INCLUDING ALL INCORPORATED

THIRD P AR TY SOFTW ARE, AND DERIVA TIVES IS PROVIDED, “AS IS”. TRITON MAKES NO REPRESENT A TIONS WITH RESPECT TO, AND DOES NOT W ARRANT THE PERFORMANCE OR RESUL TS YOU

OR YOUR CUSTOMERS MAY OBT AIN BY USING THE A TM. TRIT ON SPECIFICALL Y DISCLAIMS ANY

AND ALL WARRANTIES, EXPRESS, IMPLIED OR ST ATUTORY, INCLUDING WITHOUT LIMIT A TION,

W ARRANTIES OF QUALITY, PERFORMANCE, NONINFRINGEMENT, AND MERCHANT ABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

TRITON MAKES NO REPRESENTATIONS OR WARRANTIES AND ASSUMES NO OBLIGATIONS TO

YOU OR YOUR CUSTOMERS WITH RESPECT TO ANY TRANSACTION OR SERVICES ACCESSED

AND/OR UTILIZED IN CONSUMER-INITIATED TRANSACTIONS MADE FROM THIS ATM. IN NO

EVENT WILL TRITON, ITS AFFILIATES, DIRECTORS, OFFICERS, EMPLOYEES, AGENTS OR SUPPLIERS BE LIABLE TO YOU UNDER ANY THEORY OF TORT, CONTRACT, STRICT LIABILITY OR

OTHER LEGAL OR EQUITABLE THEORY FOR ANY PUNITIVE, CONSEQUENTIAL, INCIDENTAL,

SPECIAL OR SIMILAR DAMAGES, INCLUDING ANY LOSS PROFITS OR LOST SAVINGS, EVEN IF A

TRITON AGENT OR REPRESENTA TIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY THIRD PARTY.

YOUR SOLE REMEDY AGAINST TRITON FOR DEFECTIVE PERFORMANCE OF THE A TM SOFTWARE

WILL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT OF THE ATM AND/OR THE ATM

SOFTWARE, AT TRITON’S SOLE DISCRETION.

Any warranty pertaining to the ATM, its mechanical components exclusive of the ATM software, shall be governed and controlled by any warranty given to you by Triton in a separate document accompanying this ATM.

The foregoing limitation of liability and exclusion of certain damages will apply regardless of the success or

effectiveness of other remedies.

GOVERNING LAW: This License Agreement shall be governed by the laws of the State of Mississippi and

by the laws of the United States, excluding their confl icts of laws principles.

SEVERABILITY: In the event any provision of this License Agreement is found to be invalid, illegal or unenforceable, the validity, legality and enforceability of any of the remaining provisions shall not in any way be

affected or impaired.

ENTIRE AGREEMENT : This License Agreement and the accompanying Limited Warranty set forth the entire

agreement between you and Triton, supersedes all prior agreements, whether written or oral, with respect to the

ATM Software, and may be amended only in writing signed by both parties.

A-3

Page 38

APPENDIX A

COMPLIANCE / EMISSION STATEMENTS

DISCLAIMER

The manufacturer of the Automated T eller Machine (ATM) product(s) described herein makes no representations

or warranties, either expressed or implied, by or with respect to anything in this manual, and shall not be liable for

any implied warranties of fi tness for a particular purpose or for any indirect, special, or consequential damages.

Information in this document is subject to change without notice and does not represent a commitment on the

part of the manufacturer.

MISSIONS (EMI)

E

** CAUTION **

(US Requirements)

Changes or modifi cations not expressly approved by

Triton Systems could void the r egulatory compliance

approval and the warranty. Use of this product in a

manner other than those described in this manual

may result in personal injury!

This device complies with Part 15 of the FCC

rules. Operation is subject to the following two (2)

conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received,

including interference that may cause undesired

operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of FCC rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense. Changes or

modifi cations to this unit not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

CANADIAN REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set

in the Radio Interference Regulations of the Canadian Department of Communications. This Class A digital

apparatus complies with Canadian ICES-003.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils

numeriques de la Class A prescrites dans le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada. Cet appareil numerique de la classe A est conforme a la norme NMB-003 Canada.

UK / AUSTRALIA / SOUTH AFRICA REQUIREMENTS

This is a Class A product. In a domestic environment, this product may cause radio interference in which case

the user may be required to take adequate measures.

Warning:

A-4

Page 39

APPENDIX B

WARRANTY SERVICE STATEMENT

B-1

Page 40

APPENDIX B

W

ARRANTY STATEMENT

Manufacturer warrants that the Products delivered to Distributor will perform in accordance with the Manufacturer’s published specifi cations, and as outlined in the Manufacturer’s booklet entitled “Thirteen Months Parts

Only Limited Warranty” for thirteen months from date of shipment in Long Beach, MS. Distributor acknowledges that it has received a copy of such booklet, that it has read its entirety and that it understands and agrees

with its contents.

Manufacturer’s warranty shall not apply to any damage resulting from abuse, negligence, accident, or to any

loss or damage to the products while in transit.

Written notice and explanation of circumstances surrounding any claims that the goods have proved defective

in material or workmanship shall be given promptly from the distributor to the manufacturer. No claim may

be made, or action brought, by or through a distributor after the expiration of 14 months following any alleged

breach of warranty.

DISTRIBUTOR’S SOLE AND EXCLUSIVE REMEDY IN THE EVENT OF DEFECT IS EXPRESSLY

LIMITED TO THE REPLACEMENT OR CORRECTION OF SUCH DEFECTIVE PARTS BY MANUFACTURER AT ITS ELECTION AND SOLE EXPENSE, EXCEPT THERE SHALL BE NO OBLIGATION TO REPLACE OR REPAIR ITEMS WHICH, BY THEIR NATURE, ARE EXPENDABLE. If

Manufacturer is unable to replace or repair the defective parts, Manufacturer shall refund to Distributor that

portion of the purchase price allocable pays to such goods.

No representation or other affi rmation of fact not set forth herein, including but not limited to statements regarding

capacity, suitability for use, or performance of the goods, shall be or be deemed to be a warranty or representation by Manufacturer for any purpose, nor give rise to any liability or obligation of Manufacturer whatever.

EXCEPT AS SPECIFICALLY PROVIDED IN THIS DOCUMENT, THERE ARE NO OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING, BUT NOT LIMITED T O, ANY IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURCHASE.

LIMITATION OF LIABILITY

IN NO EVENT SHALL MANUFACTURER BE LIABLE FOR LOSS OF PROFITS OR INCIDENT AL,

INDIRECT, SPECIAL, CONSEQUENTIAL OR OTHER SIMILAR DAMAGES ARISING OUT OF

ANY BREACH OF THIS CONTRACT OR OBLIGATIONS UNDER THIS CONTRACT.

B-2

Page 41

WARRANTY STATEMENT

EFENSE OF INFRINGEMENT CLAIMS

D

If notifi ed promptly in writing of any action (and all prior claims relating to such action) brought against the

Distributor based on a claim that Distributor’s use of the goods infringes a patent or other intellectual property

right, and if given access by Distributor to any information distributor has regarding such alleged infringement,

Manufacturer agrees to defend Distributor in such action at its expense and will pay any costs or damages fi nally

awarded against Distributor in any such action, provided the Manufacturer shall have had sole control of the

defense of any such action and all negotiations for its settlement or compromise.

In the event that a fi nal injunction shall be obtained against the Distributor’s use of the goods or any of their

parts by reason of infringement of a patent or other intellectual property right or if in Manufacturer’s opinion

the goods are likely to become the subject of a claim of infringement of a patent or other intellectual property

right, Manufacturer will, at its option and at its expense, either procure for the Distributor the right to continue

using the goods, replace or modify the same so they become non-infringing or grant the Distributor a credit for

such goods as depreciated and accept their return. The depreciation shall be an equal amount per year over the

lifetime of the goods as established by Manufacturer.

Manufacturer shall not have any liability to the Distributor under any provision of this clause if any infringement,

or claim thereof, is based upon: (i) the use of the goods in combination with other goods or devices which are

not made by Manufacturer; (ii) the use of the goods in practicing any process; (iii) the furnishing to the Distributor of any information, date, service, or applications assistance; or (iv) the use of the goods with modifi cations

made by the Distributor. The Distributor shall hold Manufacturer harmless against any expense, judgment or

loss for infringement of any patent or other intellectual property right which results from Manufacturer’s compliance with the Distributor’s designs, specifi cations or instructions. No costs or expenses shall be incurred for

the account of Manufacturer without the written consent of Manufacturer. THE FOREGOING ST A TES THE

ENTIRE LIABILITY OF MANUFACTURER WITH RESPECT TO INFRINGEMENT OF PATENTS

OR OTHER INTELLECTUAL PROPERTY RIGHT BY THE GOODS OR ANY PART THEREOF, OR

BY THEIR OPERATION.

B-3

Page 42

APPENDIX B

INTERPRETATION AND OTHER PAROLE EVIDENCE

This writing is intended by the parties as fi nal expression of their agreement and is intended also as a complete

and exclusive statement of the terms of their agreement. No course of prior dealing between the parties and

no usage of the trade shall be relevant to supplement or explain any term used in these terms and conditions.

Acceptance or acquiescence in a course of performance rendered under these terms and conditions shall not be

relevant to determine the meaning of these terms and conditions even though the accepting or acquiescing party

has knowledge of the performance and opportunity for objection. Whenever a term defi ned by the Uniform

Commercial Code, as adopted in Mississippi, is used in these terms and conditions, the defi nition contained in

the code is to control.

ODIFICATIONS

M

These terms and conditions can be modifi ed or rescinded only by writing signed by both the parties or their duly

authorized agents.

AIVER INEFFECTIVE

W

No claim or right arising out of or relating to a breach of these terms and conditions can be discharged in whole

or in part by a waiver or renunciation of the claim or right unless the waiver or renunciation is supported by

consideration and is in writing signed by the aggrieved party . Waiver by either Manufacturer or Distributor of a

breach by the other of any provision of these terms and conditions shall not be deemed a waiver of future compliance therewith, and such provisions shall remain in full force and effect.

STATUTE OF LIMITATIONS

Any action by the Distributor or Manufacturer for breach of these terms and conditions must be commenced

within one (1) year after the cause of action has accrued.

PPLICABLE LAW

A

These terms and conditions shall be governed by and construed in accordance with the provisions of the Uniform

Commercial Code as adopted by the State of Mississippi.

ANKRUPTCY

B

In the event of any proceedings, voluntary or involuntary, in bankruptcy or insolvency by or against Distributor, or in the event of the appointment, with or without the Distributor’s consent, of an assignee for the benefi t

of creditors or of a receiver or of a liquidator, then Manufacturer shall be entitled to cancel any unfi lled part of

these terms and conditions without any liability whatsoever.

P

ARTS ONLY LIMITED MANUFACTURER’S WARRANTY

Triton Systems of Delaware, LLC. warrants the components of each ATM, excluding software and related

documentation, against any defect in materials and/or workmanship for a period of 13 months from the shipping

date. If a component fails due to defects in materials and/or workmanship within the warranty period, Triton will

furnish a new or refurbished component, at its discretion. Triton shall not be responsible for labor or other costs

associated with installing the components and the failed component shall be returned to Triton at the purchaser’ s

expense. Triton shall not be responsible for misuse or abuse of a unit and any attempts to remove or deface the

serial number or date code on a unit or any component thereof, or any attempt to repair a unit or to repair or

replace any component by anyone other than a service technician authorized by Triton shall void this warranty.

B-4

Page 43

WARRANTY STATEMENT

Limited Warranty covers normal use. Triton does not warrant or cover damage:

• occurring during shipment of the equipment or components from or to Triton’s facilities;

• caused by accident, impact with other objects, dropping, falls, spilled liquids, or immersion in liquids;

• caused by a disaster such as fi re, fl ood, wind, earthquake, lightning, or other acts of God;

• caused by failure to provide a suitable installation environment for the equipment, including but not limited

to, faulty wiring in the building in which the equipment is installed, installation in a facility with uncontrolled

environmental conditions, failure to provide a dedicated electrical circuit on which the equipment operates,

and/or lack of proper earth grounding for the equipment;

• caused by the use of the equipment for purposes other than those for which it was designed;

• resulting from improper maintenance;

• caused by any other abuse, misuse, mishandling, or misapplication.

Under no circumstances shall Triton or its suppliers be liable for any special, incidental, or consequential damages based upon breach of warranty, breach of contract, negligence, strict liability, or any other legal theory.

Such damages include, but are not limited to, loss of profi ts, loss of revenue, loss of data, loss of use of the

equipment or any associated equipment, cost of capital, cost of substitute or replacement equipment, facilities

or services, downtime, purchaser’s time, the claims of third parties, including customers, and injury to property .

ISCLAIMER OF WARRANTIES

D

The warranty stated above is the only warranty applicable to this product. All other warranties, expressed or

implied (including all implied warranties of merchantability or fi tness for a particular purpose or quality of ser-

vice), are hereby disclaimed. No oral or written information, or advice given by Triton, its agents or employees

shall create a warranty or in any way increase the scope of this warranty.

HIPPING DAMAGE

S

All equipment is shipped Free On Board (FOB), Triton’s facilities. The organization or individual who has

purchased the equipment assumes responsibility for the equipment once it leaves Triton’s facilities.

Should your equipment be damaged in the process of shipment or delivery to your place of destination, we

recommend the following course of action:

• If possible, call the shipping company before the driver leaves your delivery site. Make note of the damage

on the “receipt of delivery” paperwork. If this is not possible, call them as soon as possible to report the

damage.

• Take photographs of the damaged packaging prior to opening the boxes. If this is not possible, make note

of key points, such as whether the equipment is on a pallet, if the banding is intact, how the boxes are damaged, etc. Keep all of the packaging for inspection by the shipping company.

• If you unpack the equipment, take photographs of the damaged equipment. If this is not possible, make note

of the damages.

• You must fi le a claim with the shipper for shipping damages immediately after reporting the damages.

B-5

Page 44

APPENDIX B

Should you specify the carrier, we recommend that you explore with this chosen carrier the policies and procedures regarding shipping damage claims prior to selecting them as your preferred carrier.

If the equipment receives structural damage and is in an un-installable condition, Triton will work with you to

arrange for a replacement unit to be shipped as soon as possible. The purchaser will be billed for the replacement unit. Triton’s repair technicians will repair the damaged unit after it is returned to our facilities. We will

credit the purchaser’s account for the full purchase price of the damaged unit, minus the cost of returning the unit

to “like new” condition. Under no circumstances does Triton authorize anyone to complete structural damage

repairs in the fi eld. Therefore, we will not ship primary structural parts, such as a cabinet head or main cabinet

body for repair in the fi eld.

AUTHORIZED INSTALLATION AND SERVICE PROVIDERS

Triton utilizes several nationwide and regional authorized third party maintenance providers. Triton recommends all ATMs be installed and serviced by service technicians certifi ed by Triton. This includes authorized

third party service technicians and technicians who have been factory trained by Triton to service ATM equipment. Installation or repairs attempted by unauthorized service technicians may void the warranty or warranty

claims denied on the product.

Please contact Triton’s Technical Services department at (800) 259-6672 for a list of our third party service providers and/or to obtain information on the requirements and procedures for becoming a certifi ed Triton service

technician.

T

RITON’S TECHNICAL SERVICES DEPARTMENT

The primary purpose of the T echnical Services department is to provide assistance to customers in the operation,

trouble shooting, and repair of equipment manufactured by Triton. A toll-free phone number (1-800-259-6672)

is provided for convenience. The Technical Services department operates to serve our customers. The staff is

trained to follow our policies and procedures to ensure fair and uniform treatment of all our customers.

AUTOMATED VOICE MAIL SYSTEM

Our goal is to have a ‘live’ person answer 100% of all incoming calls (during regular support hours). On occasion, however, call loads may exceed the capacity of the staff. When this occurs, an automated voice mail

system will answer the call, indicate to the caller that all Technical Support specialists are busy assisting others,

and ask the caller to leave detailed information about the nature of the call.

Should it become necessary to leave a voice mail message, the caller should state:

• their name,

• the organization for which they work,

• the serial number of the equipment they are calling about,

• detailed description of the problem that they are experiencing, and

• phone number where they can be reached, including area code.

As Technical Support specialists become available, they check for voice mail messages and return calls in the

order in which they were received. By providing the information requested in the voice mail, the technician can

be prepared when your call is returned. Triton asks you to be patient if you must leave voice mail and assures

you that your call is important to us and that we will respond promptly.

B-6

Page 45

WARRANTY STATEMENT

CALLS FOR SERVICE OR REPAIR

Calls for service or repair will be accepted from authorized service technicians only. End users must contact

either the sales organization that placed the equipment or an authorized third party service organization to obtain

service. The sections that follow describe the policies and procedures that relate to the repair and replacement

of malfunctioning equipment

Technical support is available to owners of Triton equipment and to qualifi ed service personnel. When calling

for help with the confi guration or operation of a Triton product, the caller must provide either positive identi-

fi cation as a service technician or the serial number of a Triton terminal. Technical support is provided during

normal business hours for the life of the product.

When calling for help with an operational problem, please have available information pertaining to the nature

of the trouble. This includes the type of equipment, examples of what is or is not happening, and the name of

the processor that supports your terminal.

All questions pertaining to the settlement of accounts, transaction inquiries, and fund status must be directed

to the processor. Triton does not have access to the information needed to answer questions relating to specifi c

transactions.

.

QUESTIONS ON OPERATION OF EQUIPMENT

CONTACT INFORMATION

Triton Systems of Delaware, LLC.

21405 B Street

Long Beach, MS 39560

SALES:

1 (800) 367-7191

1 (228) 575-3100

1 (228) 575-3101 (Fax)

SERVICE:

1 (800) 259-6672 (Technical Support)

1 (228) 575-3101 Fax (Technical Support)

B-7

Page 46

APPENDIX B

THIS PAGE INTENTIONALLY LEFT BLANK

B-8

Page 47

APPENDIX C

COMBINATION LOCKS

C-1

Page 48

C-2

MODEL FT5000 (X2) USER MANUAL

INTRODUCTION

The security cabinet can be secured using an electronic combination locks. This appendix covers how to

change the combination of either lock. Procedures specific to the electronic lock, such as changing the

battery, are also covered.

OPERATING THE ELECTRONIC LOCK (LAGARD)

The electronic lock combination consists of six digits. Upon arrival, the combination of the lock should

already be preset to 1-2-3-4-5-6.

ENTERING THE COMBINATION

1. Enter the preset combination and check for proper operation. After each keypress, the lock will beep.

After the final digit has been entered, the lock will beep twice, and the open period will begin.

2. When a valid combination has been entered, the operator will have approximately 4 seconds to open

the lock.

3. To open the lock, turn the dial clockwise.

4. After the lock is opened, the cabinet door may be opened.

LOCKOUT FEATURE

The lock includes a ‘Wrong Try Penalty’ lockout feature that prevents entry from unauthorized person-

nel. This feature performs as follows:

• Entry of four (4) consecutive invalid combinations starts a 5-minute delay period.

- LED flashes red at ten (10) second intervals.

• At the end of the delay period, two (2) more consecutive invalid combinations will restart an addi-

tional 5-minute delay.

CHANGING THE COMBINATION

To change the combination of the lock, simply follow these directions.

1. Enter six (6) zeros ‘0’.

2. Enter the current combination (initially set at 1-2-3-4-5-6).

3. Enter the new six (6) digit combination twice.

- If a mistake is made, wait thirty (30) seconds and repeat the first 3 steps.

4. Test lock combination several times before closing the door. The combination is now changed.

Valid Code Entry - Double signal after valid six (6) digit code is entered.

Invalid Code Entry - Triple signal and old code is still valid.

Page 49

C-3

APPENDIX C - COMBINATION LOCKS

BATTERY LOW WARNING

Repeated beeping during an opening indicates that the battery is low or dead and needs to be replaced.

The battery box is located on the inside of the door.

Note: If the lock will not operate (i.e. repeated beeping or no beeping) while the door is closed and locked,

the battery must be energized from the two external terminals on the front of the push-button panel.

To energize the lock, connect a 9-volt alkaline battery on the external terminal points. Maintain contact,

enter a valid combination, and turn the dial clockwise to open the lock.

Note: You must maintain battery contact at all times throughout this procedure.

CHANGING THE BATTERY

1. Open the ATM vault door. Remove the battery box cover by

pulling the front portion away from the vault door.

2. The connector is easily removed by unsnapping it from the

two (2) terminal on the top of the battery.

3. Remove the old battery. Install/connect a new 9-volt alkaline

battery.

4. Push the battery and the leads completely up into the battery

compartment.

5. Reinstall the cover and test the unit several times before

closing the vault door.

Page 50

C-4

MODEL FT5000 (X2) USER MANUAL

Each lock is shipped from the factory in Shelved Mode, operating on a standard combination (50-25-50).

ENTERING THE COMBINATION

1. Turn the dial left (CCW) until the letters “EC” (Enter Combination) appear on the LCD.

2. Enter the factory combination of 50-25-50 by sequentially pressing those six (6) buttons. The LCD

will display these numbers as they are entered.

3. When the combination has been correctly entered, the LCD will read “OPr”, meaning “OPen right”.

Turn the dial right (CW) until it stops. The locks bolt is now retracted and the lock is open.

4. After the lock is opened, the cabinet door may be opened.

11. Cnf - Enter New Combination - POC

Enter new combination again to confirm. POC (Pull Out Change key) willbe displayed.

12. POC - Remove Change Key - EOP

Remove the change key. EOP (End OPeration) is displayed.

OPERATING THE ELECTRONIC LOCK (KABA MAS)

10. EnF - Enter New Combination - Cnf

Select and enter the new combination. “CnF” (Confirm new Factory combination) will be displayed.

TO CHANGE THE COMBINATION:

1. Power Lock - EC

Turn the dial to the left (CCW) until “EC” (Enter Combination) is displayed.

2. EC - Enter Shelved Mode Combination - OPr

Enter the current combination (either 50-25-50 or a changed combination) by sequentially pressing those

digits on the lock keypad. The numbers will be displayed on the LCD as they are entered.

3. OPr - Retract Bolt

Turn the Dial to the right (CW) to retract the bolt

4. Open Door

5. Insert Change Key

Insert the change key into the change key socket on the back of the lock.

6. Extend Bolt

Turn the Dial to the left (CCW) to extend the bolt. Do not close the door

7. Power Lock - EC

Turn the dial to the left (CCW) until EC (the Change Key symbol along with Enter Combination) is

displayed.

8. EC - Press #8 - EcF

Press the “#” button followed by the “8” button. EcF (Enter combination,Factory) will be displayed.

9. EcF - Enter Current Shelved Mode Combination - EnF

Enter the current shelved mode combination, “EnF” (Enter new Factory combination) will be displayed

Page 51

C-5

APPENDIX C - COMBINATION LOCKS

9. “OPR” = OPEN RIGHT

10. “CC” = CONFIRM COMBINATION

11. “EC2” = ENTER COMBINATION 2

12. “C00” = CLOSE SEAL NUMBER

13. “EOP” = END OPERATION

14. “

!!

!!

!” = (ERROR LIGHTNING BOLT)

15. “AUD” = DISPLAYS WHILE AUDIT DATA IS BEING WRITTEN

16. “?-” = DISPLAYS WHEN # HAS BEEN PRESSED TO ENTER A KEYPAD COMMAND

13. EOP - Power Lock - EC

Turn the dial to the left (CCW) until EC (Enter Combination) is displayed.

14. EC - Enter New Shelved Mode Combination - OPr

Enter the new shelved mode combination by pressing those digits on the lock’s keypad. The numbers will be

displayed on the LCD as they are entered.

15. OPr - Retract Bolt

Turn the dial to the right (CW) to retract the bolt.

16. Close Door

17. Extend Bolt

Turn the dial to the left (CCW) to extend the bolt.

CODE DESCRIPTIONS:

1. “EC” = ENTER COMBINATION

2. “ EC” = (CHANGE) KEY ENTER COMBINATIONS

3. “D-” = DELAY TIME

4. “INI” = DISPLAYS WHILE LOCK IS BEING INITIALIZED

5. “IP1” = INSERT PERSONAL IDENTIFIER 1

6. “IP2” = INSERT PERSONAL IDENTIFIER 2

7. “ISA” = INSERT SUPERVISOR A UDIT KEY

8. “POC” = PULL OUT CHANGE KEY

Page 52

C-6

MODEL FT5000 (X2) USER MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

Page 53

APPENDIX G

T9 KEYPAD

© 2014 Triton. All Rights Reserved. TRITON logo is a

registered trademark of Triton Systems of Delaware, LLC

COPYRIGHT NOTICE

Page 54

APPENDIX G

Document Updates

May 14, 2014 Original

** WARNING **

Once the T9 EPP Keypad is installed and activated

in the unit, it CANNOT be removed.

If the keypad is removed from the unit after activation, reactivation is

required and can only be performed by Triton Technical Support.

The T9 EPP Keypad is mostly identical to the T5 EPP Keypad except for:

• The T9 EPP contains a removal detection switch that deactivates / TAMPERS the EPP if the EPP is

ever removed from the ATM.

• Left and right halves of 3DES keys must be different.

• No two 3DES keys may have the same value.

• When replacing current keypad with a T9 EPP, activation is required upon installation.

Contents

NEW ERROR CODES....................................................................................................................3