Page 1

MODEL FT5000

XP

PC-BASED ATM

INSTALLATION GUIDE

VERSION 1.0

TDN 07102-00059 Mar 24 2009

CORPORATE HEADQUARTERS: RM A (RETURN MATERIAL AUTHORIZATION)

ETURN ADDRESS:

R

522 E. Railroad Street 21405 Avenue “B”

Long Beach, MS 39560 Long Beach, MS 39560

PHONE: (228) 868-1317

FAX: (228) 868-0437

COPYRIGHT NOTICE

© 2008 Delaware Capital Formation, Inc. All Rights Reserved. TRITON, TRITON

WHERE MONEY COMES FROM, TRITON WAVES, DOVER and DOVER logo are

registered trademarks of Delaware Capital Formation, Inc., a wholly-owned subsidiary

of Dover Corporation.

Page 2

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

WHAT ’S IN THIS INSTALLATION GUIDE

This Installation Guide provides information for the preparation and installation of the FT5000XP ATM. It contains requirements for site preparation, electrical specifications, and cabinet accessibility that comply with all relevant codes,

laws and regulations. The Installation Guide is divided into the following sec-

tions:

COMPLIANCE NOTIFICATIONS.

ATM INSTALLATION FOR ACCESSIBILITY. Describes the basic Americans with

Disabilities Act (ADA) requirements for ATM location and access. Note:

These are the general requirements that should be applicable to most

installation locations. Please verify the specific requirements with the state

where the ATM is to be installed, prior to installation. For state contact

information, you may call the ADA information line at 1-800-514-0301.

ATM E NVIRONMENTAL P RECAUTIONS C HECKLIST. Describes the general

environmental precautions considered when installing the ATM. To help

ensure proper operation of the ATM, ensure the environmental criteria

listed in this checklist are met.

SITE PREPARATION/INSTALLATION. Describes site preparation for exterior wall

or vestibule locations. Instructions provide dimensions of the unit and

clearances needed for operability/serviceability. Physical installation of

the cabinet and front trim is described as well as raising/leveling of unit, if

needed.

POWER AND C OMMUNICATION. Describes how to connect the ATM to the

facility power and Ethernet connections.

DISPENSING MECHANISM INSTALLATION. Describes how to install/remove the

dispensing mechanism into the ATM security cabinet.

2

Page 3

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

INTRODUCTION

This document contains the information necessary for the preparation and installation of an FT5000XP Triton ATM. It’s important that the site complies with

the requirements specified in this document. In addition, electrical wiring and

mechanical systems must also comply with all relevant laws and regulations.

The site must be prepared by the customer or his agent who is fully conversant

with the requirements of installing through-the-wall ATM equipment. The responsibility for ensuring that the site is prepared in compliance with this document remains with the customer.

For information and guidance only, a list is provided in general terms of those

matters for which the customer is responsible. The list is not intended to be

comprehensive and in no way modifies, alters, or limits the responsibility of the

customer for all aspects of adequate site preparation.

1. Location of the equipment and site preparation.

2. Site wiring (power, communication).

3. Location of other equipment that may cause electrical, electromagnetic

or heat induced interference.

4. Make building alterations to meet wiring and other site requirements.

5. Install all communication cables, wall jacks, and associated hardware.

6. Provide and install necessary power distribution boxes, conduits and

grounds.

7. Ensure all applicable codes, regulations and laws (electrical, building,

safety) are adhered to.

8. Ensure the environmental requirements of this unit are met.

9. Install the unit at a height which meets the ADA accessibility regulations for the state/country installed.

3

Page 4

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

DISCLAIMER

The manufacturer of the Automated Teller Machine (ATM) product(s) described

herein makes no representations or warranties, either expressed or implied, by or

with respect to anything in this manual, and shall not be liable for any implied

warranties of fitness for a particular purpose or for any indirect, special, or

consequential damages. Information in this document is subject to change

without notice and does not represent a commitment on the part of the

manufacturer.

** CAUTION **

Changes or modifications not expressly approved by Triton

Systems could void the regulatory compliance approval

and the warranty. Use of this product in a manner other

than those described in this manual may result in personal

injury!

FEDERAL COMMUNICATIONS COMMISSION (FCC) COMPLIANCE

Statement of Compliance: This equipment complies with Part 68 of the FCC rules.

Located in the control area of the Automated Teller Machine (ATM) is the product

label. This label lists the FCC registration number and ringer equivalence number of

the unit. If requested, this information must be provided to the telephone company.

USCO/FIC Codes: When ordering service from the telephone company for the

FT5000XP ATM, the following information should be supplied:

Universal Service Order Code (USOC): RJ-11C

The Facility Interface Code (FIC): 02LS2

Plug and Jack: The plug and jack used to connect this equipment to premise wiring

and telephone network must comply with the applicable FCC Part 68 rules and

requirements adopted by ACTA. A compliant telephone cord and modular plug is

provided with this product. The telephone cord is designed to be connected to a

compatible modular jack that is also compliant.

Ringer Equivalent Number (REN): The REN is used to determine the number of the

devices that may be connected to a telephone line. Excessive RENs on a telephone

line may result in the devices not ringing in response to an incoming call. In most but

not all areas, the sum of the RENs should not exceed five (5). To be certain of the

number devices that may be connected to a line, as determined by the local RENs,

contact the local telephone company.

4

Page 5

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

Harm to the Network: If the FT5000XP ATM causes harm to the telephone network,

the telephone company will notify the customer that a temporary discontinuous of

service may be required. If advanced notice is not possible, the telephone company

will notify the customer as soon as possible. You will be advised of your right to file

a complaint with the FCC if you believe it’s necessary.

Notification of Changes in Telephone Company Equipment: The telephone company

may make changes in its facilities, equipment, operations, or procedures that could

affect the operation of the equipment. If this happens, the telephone company will

provide advanced notice in order for you to make necessary modifications to maintain

uninterrupted service.

Repairs and Returns: If telecom compatibility trouble is experienced with the FT5000

ATM, you may contact for repairs and warranty information: Triton at 1-228-8681317

Triton Systems of Delaware, Inc.

522 East Railroad Street

Long Beach, MS 39560

If the equipment is causing harm to the network, the telephone company may request

that you disconnect the equipment until the problem is resolved. Repairs should be

made only by qualified factory representatives.

Party Lines: The FT5000

XP

ATM must not be used on party lines.

XP

Alarm Equipment: The FT5000XP ATM should have its own dedicated phone line.

Do not install the FT5000XP on the same line as alarm equipment.

Electrical Safety Advisory: telephone companies report that electrical surges, typically

lightening transients, are very destructive to customer equipment connected to AC

power sources. This has been identified as a major nationwide problem. A

commercially available, power surge suppressor, is recommended for use with the

FT5000XP to minimize damage in the event of an electrical surge.

CANADIAN IC COMPLIANCE

NOTICE:

The Industry Canada label identifies certified equipment. This certification means

that the equipment meets telecommunications network protective, operational and

safety requirements as prescribed in the appropriate terminal equipment technical

requirements document(s). The department does not guarantee the equipment will

operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company . The equipment must also be installed using an acceptable method of connection. The customer should be aware that compliance with the above conditions may not prevent

degradation of service in some situations.

5

Page 6

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

Repairs to certified equipment should be coordinated by a representative designated by the supplier. Any repairs or alterations made by the user to this equipment,

or equipment malfunctions, may give the telecommunications company cause to

request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections

of the power utility, telephone lines, and internal metallic water pipe system, if present,

are connected together. This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should

contact the appropriate electric inspection authority, or electrician, as appropriate.

NOTICE:

The REN assigned to each terminal device provides an indication of the maximum

number of terminals allowed to be connected to a telephone interface. The termination on an interface may consist of any combination of devices subject only to the

requirement that the sum of the RENs of all the devices does not exceed 5.

AVIS:

L’étiquette d’Industrie Canada identific le matériel homologué. Cette étiquette certifie

que le matériel est conforme aux normes de protection, d’exploitation et de sécurité

des réseaux de télécommunications, comme le prescrivent les documents concernant

les exigences techniques relatives au matériel terminal. Le Ministère n’assure toutefois

pas que le matériel fonctionnera à la satisfaction de l’utilisateur.

Avant d’installer ce matériel, l’utilisateur doit s’assurer qu’il est permis de le raccorder

aux installations de 1’entreprise locale de télécommunication. Le matériel doit

également être installé en suivant une méthode acceptée de raccordement. L’abonné

ne doit pas oublier qu’il est possible que la comformité aux conditions énoncées cidessus n’empêche pas la dégradation du service dans certaines situations.

Les réparations de matériel homologué doivent être coordonnées par un représentant

désigné par le fournisseur. L’entreprise de télécommunications peut demander à

I’utilisateur de débrancher un appareil à la suite de réparations ou de modifications

effectuées par l’utilisateur ou à cause de mauvais fonctionnement.

Pour sa propre protection, l’utilisateur doit s’assurer que tous les fils de mise à la

terre de la source d’énergie électrique, des lignes téléphoniques et des canalisations

d’eau métalliques, s’fl y en a, sont raccordés ensemble. Cette précaution est

particulièrement importante dans les régions rurales. Avertissement: L’utilisateur ne

doit pas tenter de faire ces raccordements lui-même; il doit avoir recours à an service

d’inspection des installations électriques, ou à un électricien, selon le cas.

AVIS:

L’indice d’équivalence de la sonnerie (IES) assigné à chaque dispositif terminal

indique le nombre maximal de terminaux qui peuvent étre raccordés à une interface.

La terminaison d’une interface téléphonique peut consister en une combinaison de

quelques dispositifs, à la seule condition que la somme d’indices d’équivalence de

la sonnerie de tous les dispositifs n’exède pas 5.

6

Page 7

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

UNITED KINGDOM

This equipment has been approved in accordance with Council Decision 98/482/EC

for pan-European single terminal connection to the Public Switched Telephone

Network (PSTN). However, due to differences between the individual PSTNs provided in the different countries, the approval does not, of itself, give unconditional

assurance of successful operation on every PSTN network termination point. In the

event of problems, contact your equipment supplier in the first instance. This unit

uses only Dual-Tone Multi-Frequency (DTMF) address signaling.

EMISSIONS (EMI)

This device complies with Part 15 of the FCC rules. Operation is subject to the

following two (2) conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received, including interference that

may cause undesired operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

CANADIAN EMISSION REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set in the Radio Interference Regulations of the Canadian

Department of Communications. This Class A digital apparatus complies with

Canadian ICES-003.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les

limites applicables aux appareils numeriques de la Class A prescrites dans le Reglement

sur le brouillage radioelectrique edicte par le ministere des Communications du

Canada. Cet appareil numerique de la classe A est conforme a la norme NMB-003

Canada.

UK / AUSTRALIAN EMISSION REQUIREMENTS

WARNING:

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

7

Page 8

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

THIS PAGE INTENTIONALLY LEFT BLANK

8

Page 9

ATM INSTALLATION FOR ACCESSIBILITY

9

Page 10

FT5000

XP

- SITE PREPARATION AND INSTALLATION GUIDE

ATM INSTALLATION FOR

ACCESSIBILITY

1. This document supersedes all other

information provided by Triton for

ATM installation for accessibility.

2. Information provided in this

manual is based on federal guidelines (ADA Accessibility Guidelines

for Buildings and Facilities –

ADAAG) as amended through

January 1998. You should verify it

has not been amended. States may

also have accessibility codes.

These codes may be more restrictive than the federal guidelines.

Please verify this with the state

where the ATM is to be installed

prior to installation. For state contact information, you may call the

ADA information line at 1-800-514-

0301.

3. For countries other than the US,

please use the guidelines for accessibility for that country.

4.34 Automated Teller

Machines.

4.34.1 General. Each machine re-

quired to be accessible by 4.1.3

(Accessible Buildings: New Construction) shall be on an accessible

route and shall comply with 4.34

(Automated Teller Machines).

4.34.2 Clear Floor Space. The auto-

mated teller machine shall be located so that clear floor space complying with 4.2.4 (Clear Floor or

Ground Space for Wheelchairs)

is provided to allow a person using

a wheelchair to make a forward approach, a parallel approach, or both

to the machine.

4.34.3 Reach Ranges.

(1) Forward Approach Only. If only a

forward approach is possible, operable

parts of all controls shall be placed within

the forward reach range specified in

4.2.5 (Forward Reach).

4. A complete copy of the ADAAG

referred to here can be found at

http://www.access-board.gov. In-

cluded in this document is the section of the ADAAG specifically for

ATMs. For additional information

on floor surfaces and other

ADAAG requirements, please see

the complete specification.

(2) Parallel Approach Only. If only a

parallel approach is possible, operable

parts of controls shall be placed as follows:

(a) Reach Depth Not More Than 10

inches (255 mm). Where the reach

depth to the operable parts of all controls as measured from the vertical plane

perpendicular to the edge of the unobstructed clear floor space at the farthest

protrusion of the automated teller machine or surround is not more than 10

inches (255 mm), the maximum height

above the finished floor or grade shall

be 54 inches (1370 mm).

10

Page 11

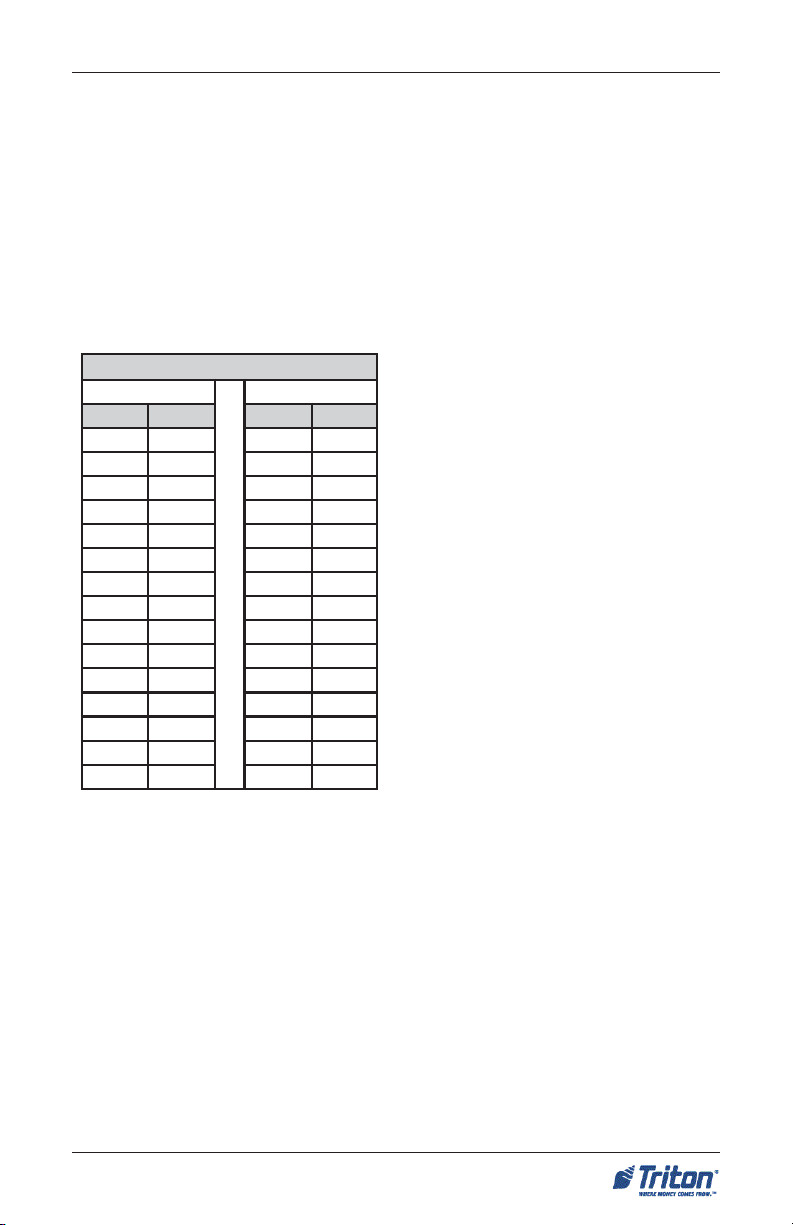

ATM INSTALLATION FOR ACCESSIBILITY

(b) Reach Depth More Than 10 inches

(255 mm). Where the reach depth to

the operable parts of any control as measured from the vertical plane perpendicular to the edge of the unobstructed

clear floor space at the farthest protrusion of the automated teller machine or

surround is more than 10 inches (255

mm), the maximum height above the finished floor or grade shall be as follows:

SNOITACIF ICEPSYTILIBISSECCA

H T P E DH C A E RTH G I E HM UM I X AM

sehcnI sretemilliM sehcnI sretemilliM

01552450731

110822/ 13 50631

21503355431

310332/ 12 55331

415532/ 11 50131

51083155921

615042/ 10 55821

71034050721

815542/ 19 45521

91584945421

020152/ 18 40321

125352/ 17 45021

22065745911

325852/ 16 40811

42016640711

(3) Forward and Parallel Approach. If

both a forward and parallel approach

are possible, operable parts of controls

shall be placed within at least one of the

reach ranges in paragraphs (1) or (2) of

this section.

EXCEPTION: Where a function can be

performed in a substantially equivalent

manner by using an alternate control,

only one of the controls needed to perform that function is required to comply

with this section. If the controls are identified by tactile markings, such markings

shall be provided on both controls.

4.34.4 Controls. Controls for user

activation shall comply with 4.27.4

(Operation).

4.34.5 Equipment for Persons with

Vision Impairments. Instructions and

all information for use shall be made accessible to and independently usable

by persons with vision impairments.

(20) Where automated teller machines (ATMs) are provided, each ATM

shall comply with the requirements of

4.34 (Automated Teller Machines) ex-

cept where two or more are provided at

a location, then only one must comply.

EXCEPTION: Drive-up-only automated

teller machines are not required to comply with 4.27 (Controls and Operating

Mechanisms) and 4.34.3 ( Reach

Ranges).

(4) Bins. Where bins are provided for

envelopes, waste paper , or other pur poses, at least one of each type provided shall comply with the applicable

reach ranges in paragraph (1), (2), or (3)

of this section.

11

Page 12

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

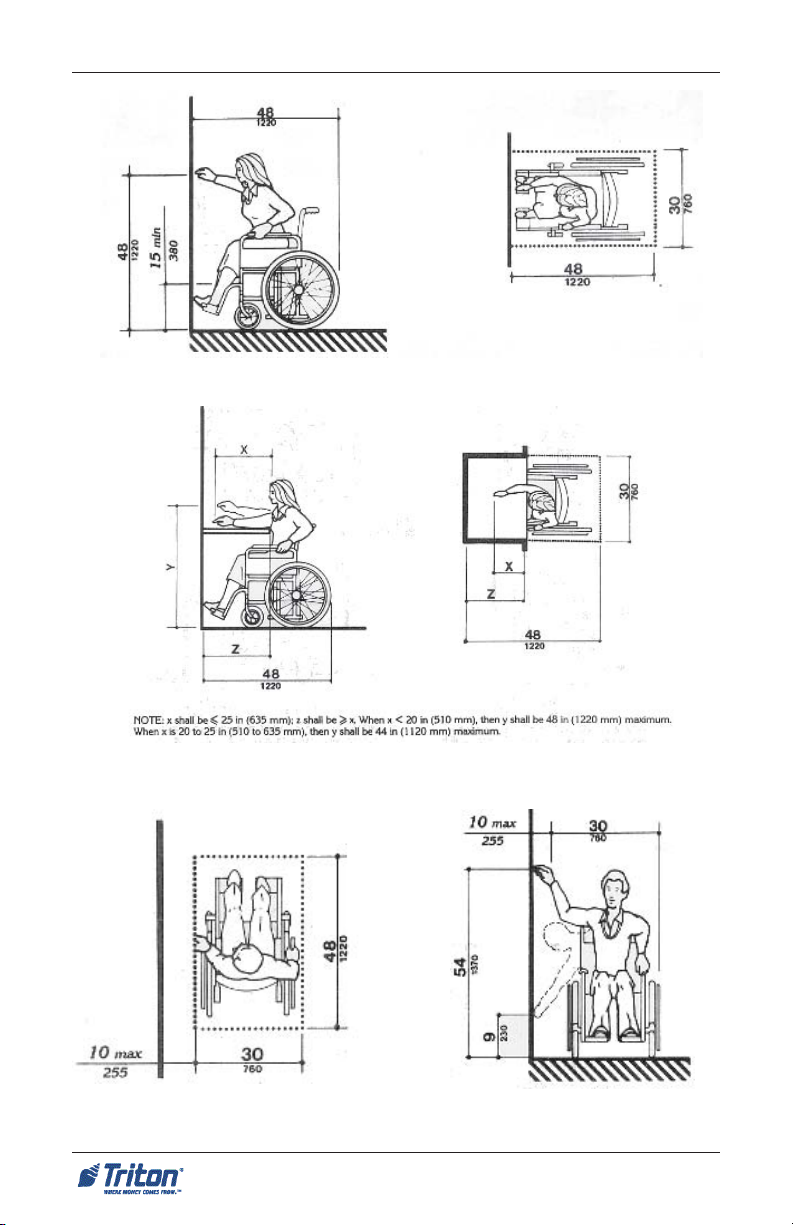

4.2.4 Clear Floor or Ground

Space for Wheelchairs.

4.2.4.1 Size and Approach. The mini-

mum clear floor or ground space required to accommodate a single, stationary wheelchair and occupant is 30

inches by 48 inches (760 mm by 1220

mm) (see Fig. 4a). The minimum clear

floor or ground space for wheelchairs

may be positioned for forward or parallel approach to an object (see Fig. 4b

and 4c). Clear floor or ground space for

wheelchairs may be part of the knee

space required under some objects.

4.2.4.2 Relationship of Maneuvering

Clearance to Wheelchair Spaces. One

full unobstructed side of the clear floor

or ground space for a wheelchair shall

adjoin or overlap an accessible route or

adjoin another wheelchair clear floor

space. If a clear floor space is located in

an alcove or otherwise confined on all

or part of three sides, additional maneuvering clearances shall be provided as

shown in Fig. 4(d) and 4(e).

Figure 4a. Clear floor space.

Figure 4b. Forward approach.

4.2.4.3 Surfaces for Wheelchair

Spaces. Clear floor or ground spaces

for wheelchairs shall comply with 4.5

(Ground and Floor Surfaces).

4.2.5 Forward Reach. If the clear

floor space only allows forward approach to an object, the maximum high

forward reach allowed shall be 48 inches

(1220 mm) (see Fig. 5(a)). The minimum

low forward reach is 15 inches (380 mm).

If the high forward reach is over an obstruction, reach and clearances shall be

as shown in Fig. 5(b).

Figure 4c. Parallel approach.

12

Page 13

ATM INSTALLATION FOR ACCESSIBILITY

4.2.6 Side Reach. If the clear floor space allows parallel approach by a person in

a wheelchair, the maximum high side reach allowed shall be 54 inches (1370 mm) and

the low side reach shall be no less than 9 inches (230 mm) above the floor (Fig. 6(a)

and 6(b)). If the side reach is over an obstruction, the reach and clearances shall be

as shown in Fig 6(c).

Figures 4d . Clear Floor Space in

Alcoves.

For a front approach, where the depth

of the alcove is equal to or less than 24

inches (610 mm), the required clear floor

space is 30 inches by 48 inches (760 mm

by 1220 mm).

Figures 4e. Clear Floor Space in

Alcove.

For a front approach, if the depth of the

alcove is greater than 24 inches (610 mm),

then in addition to the 30-inch (760 mm)

width, a maneuvering clearance of 6

inches (150 mm) in width is required.

For a side approach, where the depth of

the alcove is equal to or less than 15

inches (380 mm), the required clear floor

space is 30 inches by 48 inches (760 mm

by 1220 mm).

For a side approach, where the depth of

the alcove is greater than 15 inches (380

mm), then in addition to the 48-inch (1220

mm) length, an additional maneuvering

clearance of 12 inches (350 mm) is

required.

13

Page 14

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

Figure 5a. Forward reach, unobstructed.

Figure 5b. Forward reach, obstructed.

Figure 6a. Parallel approach - side

reach.

Figure 6b. Parallel approach - high/

low side reach.

14

Page 15

ATM INSTALLATION FOR ACCESSIBILITY

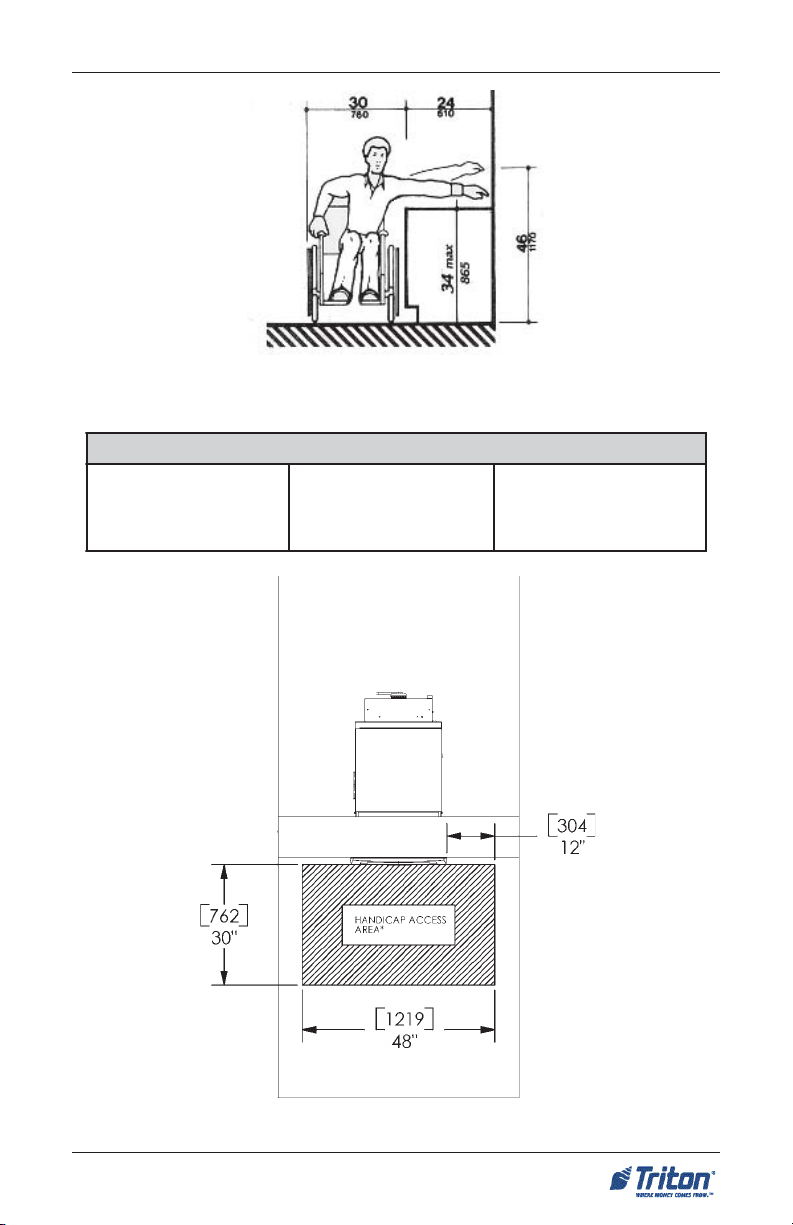

Figure 6c. Side reach, ob structed.

"84

)mm9121 (

- s s o r c A-

"03

)mm267 (

-p e eD-

Floor Interior

*

ae rAsseccApac i dnaHed i s t uO

de r usa eM

fore tnecmor f

l e n a P l o r t n oC

*a i c s aF

Ground exterior

Figure 7. ADA access dimensions for FT5000XP ATM.

15

Page 16

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

THIS PAGE INTENTIONALLY LEFT BLANK

16

Page 17

ENVIRONMENTAL PRECAUTION CHECKLIST

17

Page 18

ATM ENVIRONMENTAL PRECAUTIONS CHECKLIST

When installing an ATM, some general environmental and power precautions need to be considered. Evaluate the location where the ATM will be

installed. To help ensure proper operation of the ATM, ensure the environmental criteria listed in this checklist are met.

TEMPERATURE/HUMIDITY

1. The ATM will operate over a range

of temperatures and humidity.

Generally, these parameters must

fall within the following ranges:

Temperature (Interior)

• 10°C - 40°C

• 50°F - 104° F

Relative Humidity

• 20% - 80%

• (Non-Condensing)

Temperature (Exterior)

• -35°C - 50°C

• -30°F - 122°F

Relative Humidity

• 20% - 100%

AC POWER REQUIREMENTS

2. Ensure the following AC power

requirements are met:

Current (Max)

• 5.05A @ 120V

• 2.01A @ 240V

Voltage

• 90V - 136V @ 50/60 Hz

• 198V - 257V @ 50/60 Hz

Power Consumption (Idle)

• 2.0A @ 115 VAC at 60 Hz

• 1.0A @ 230 VAC at 50 Hz

Dedicated source. The ATMs AC

power feed will be a dedicated line to

which no other electrical devices are

connected. The ATM power line will

be wired for a single “duplex”-style

outlet and connected directly to the

AC service panel.

Isolated G round. An equipment

grounding conductor that is insulated

from the conduit or raceway and all

other grounding points throughout its

entire length. The only points of electrical connection will be at the duplex

outlet and service panel ends of the

line.

* IMPORTANT *

AC power for the terminal should

come from a dedicated source with

an isolated ground.

RF INTERFERENCE

3. Ensure there are no devices near

the terminal that may cause RF interference, such as:

TVs

Coolers

Security Devices

Neon Signs

Devices with Compressors

Power Consumption (Max Load)

• 606 Watts @ 120V

• 482 Watts @ 240V

18

Page 19

SITE PREPARATION / INSTALLATION

19

Page 20

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

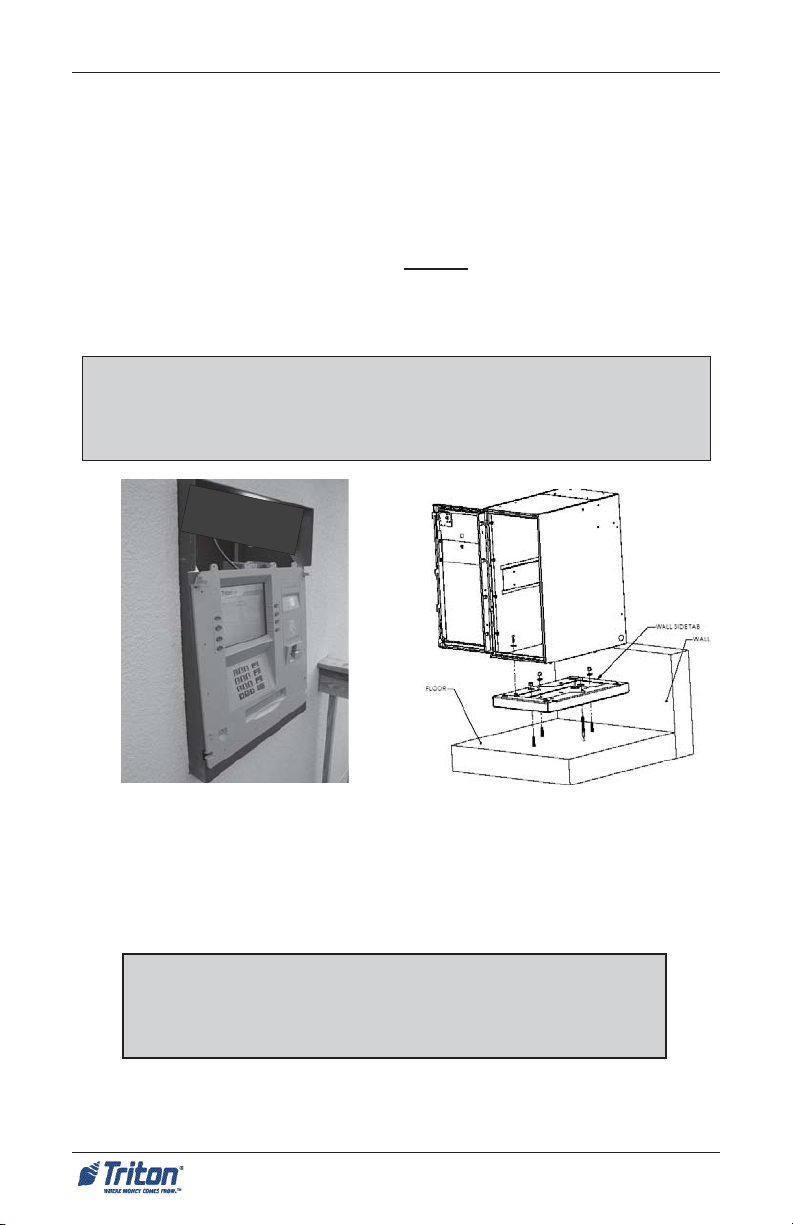

INTRODUCTION

The Triton FT5000XP is a self-serviced, weatherized terminal adaptable for any suitable exterior wall or vestibule location. The cabinet design allows flexibility for

“Island” installations (wall thickness up to 6-1/4") or existing structures (wall thickness up to 10"). Built-in leveling feet and optional platforms (“plinths”) allow the

unit to be raised to the desired height of the wall opening. The following section

provides the physical dimensions and requirements for installing the FT5000XP for

your particular site location. To assist you in preparing your site, a check list is

provided of various procedures that should be carried out prior to the arrival of the

ATM. The Business Hours Cabinet is no longer offered.

T S I LKCEHCNO I T ARAP ERPE T I S

na l pr oo l fang i s eddnae t i st c e l eS

t emsno i t i dnoc l a t n emno r i vn ee r usnE

se l udehc sr odne vdnar o t c a r t nochs i l b a t sE

s t n eme r i uqe ren i lno i t a c i nummock c ehC

sdeeny rosseccano i t a l l a t sn ina l P

sno i t a r e t l a

s t neme r i uqe r l ac i r t ce l el l a t sn I

y rassecenekamdnana l proo l fkcehC

sdeenno i t a c i nummocr o fe t i se r ape rP

) l a no i t po (gn i n i a r t r o t a r e pon a l P

t s e tdnas en i lno i t a c i nummoc l l a t sn I

e l ba l i avae r ase i r osseccano i t a l l a t sn ierusnE

INSTALLATION ACCESSORIES

When installing the FT5000XP, it is recommended that you or your agent have the

following items available:

» Lifting/moving device

» Wooden/metal safety blocks

to support the ATM during

install

» Framing square

» Hammer

» Water-resistant sealant

(caulk,etc)

» Level

» Tape measure

» Crowbar(s)

» Circular/Jig saws

» Tool kit consisting of open/ closed box wrenches, magnetic Phillips/flat

screwdrivers, socket set, crescent wrench, pliers, Allen wrench set, etc.

20

Page 21

SITE PREPARATION/INSTALLATION

EXTERIOR WALL DIMENSIONS

The following illustrations show the nominal wall area dimensions required for

installation. Wall opening dimensions have a plus/minus (+/-) 1/4" tolerance. The

height of the opening is from exterior sidewalk level to the base of the opening to

comply with Federal ADA requirements.

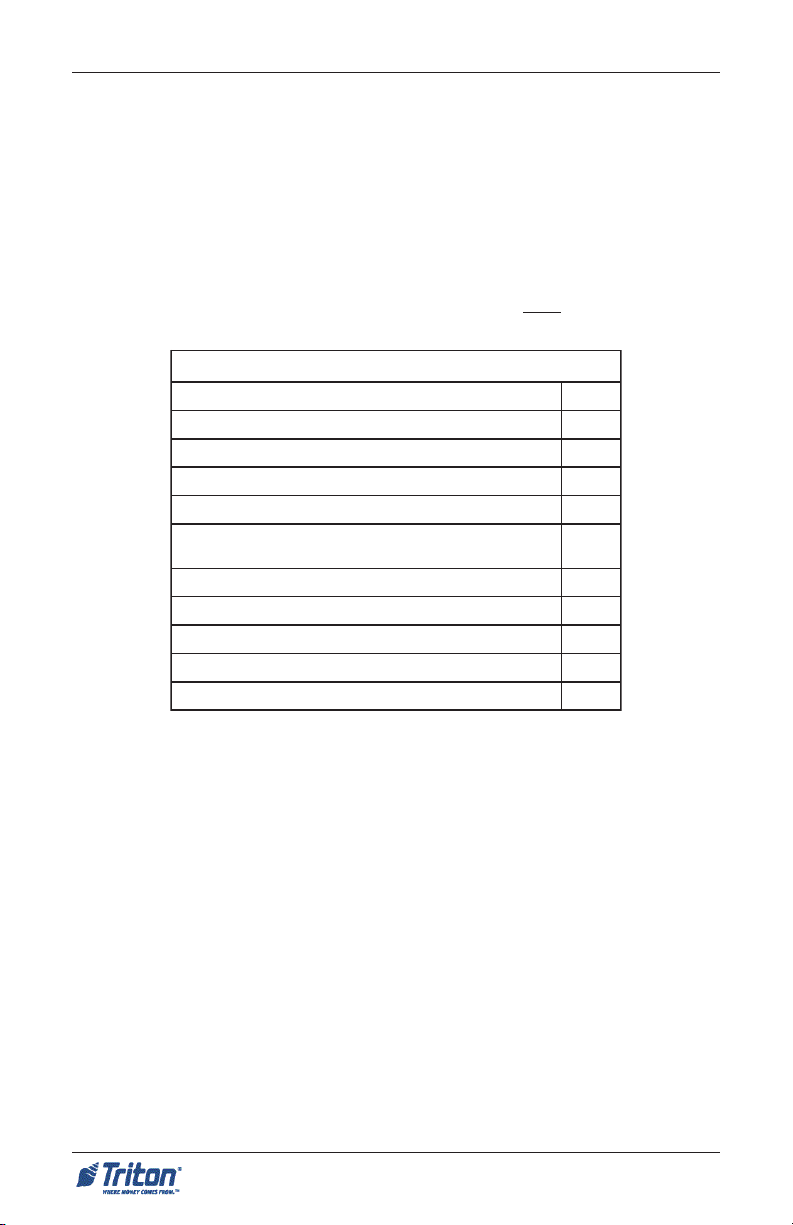

gn i nepOl l aWf osno i snemi D

t hg i eHht d iW

" 8 / 5-92

)mm157 (

roi retxemor f (thgieH

) dnuo r g

" 4 / 3-12

)mm255 (

" 8 / 1-13

)mm987 (

Wall

Floor - exterior

Note

Dimensions listed comply with US Federal ADA Guidelines. For USA

installations, check for additional guidance. For non-USA installations,

check regulations relating to the country of install.

21

Page 22

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

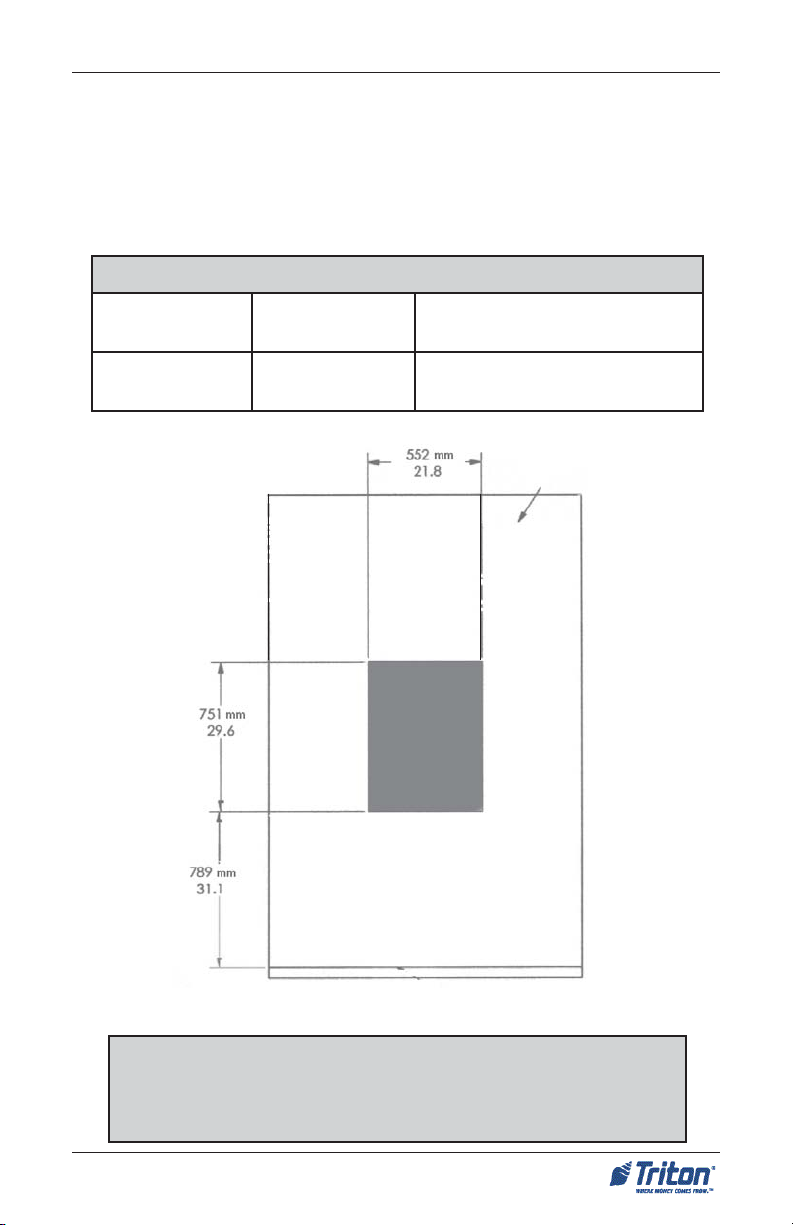

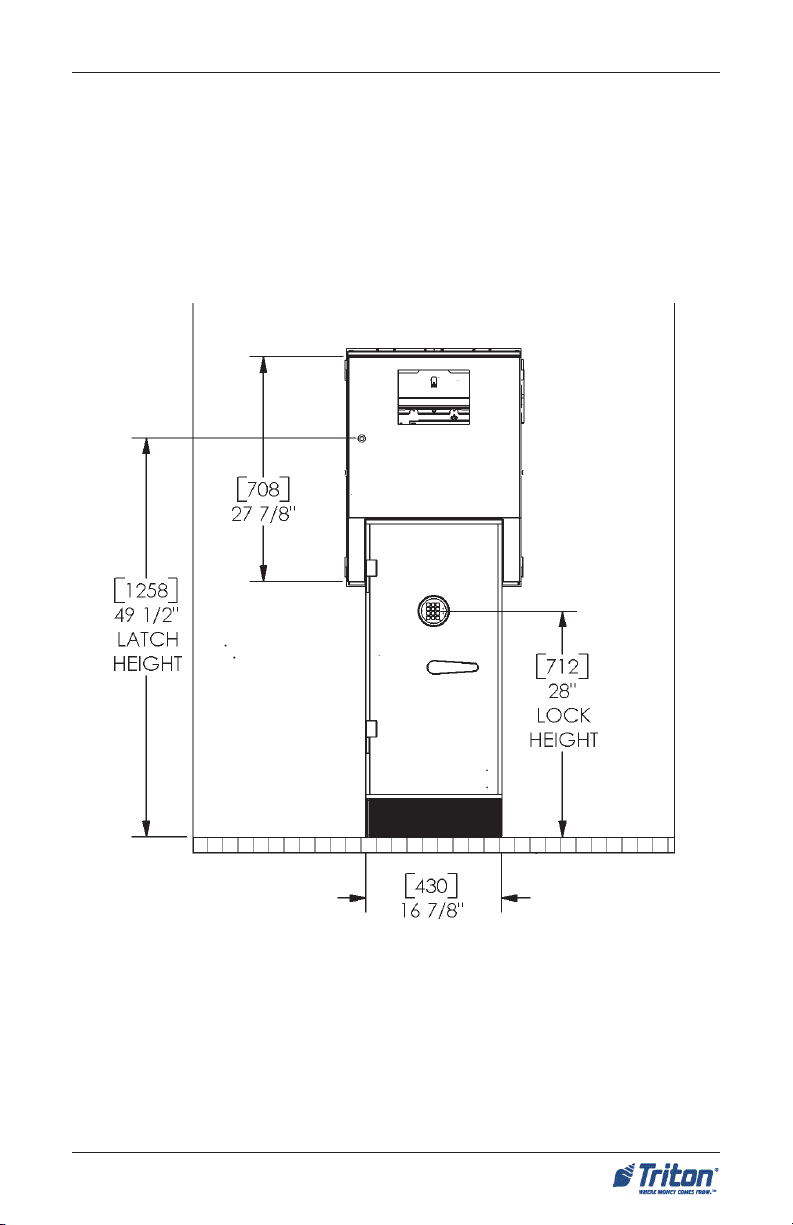

HEIGHTS TO MAIN CONTROL PANEL

The following illustrations show the heights and the Federal ADA requirements

to the main control panel items located on the FT5000

XP.

All the height dimen-

sions are calculated from the base of the exterior ground level to each item.

sme t I l en aPl o r t noCn i aMo ts t hg i eH

f o . t Hp o T

no i t cnuF

dapyeK

"84

)mm0221 (

fore tneC

d r aC

r e d a eR

" 8 / 3-1 4

)mm1501 (

fore tneC

yalpsiD

" 8 / 5-7 4

)mm0121 (

fore tneC

yarTlliB

" 4 / 1-6 3

)mm129 (

fore tneC

enohpd a eH

kcaJ

" 61 / 5-63

)mm229 (

Wall

Floor - exterior

22

Page 23

SITE PREPARATION/INSTALLATION

DETERMINE IF UNIT NEEDS A PLINTH

Triton Systems offers two (2) metal-constructed optional “plinths” w/leveling

feet. A plinth is a platform on which the ATM rests or is secured and enables the

ATM to be installed at the required height through the wall. The plinths come in

2 heights: 2-3/8” (61mm) and 4-3/4” (122 mm). You can raise the unit by a fixed

amount (2-3/8"or 4-3/4") and still be able to adjust up using the plinths leveling

feet. To determine if you need to order a plinth with your unit, a few measurements will be needed at the site.

For sites that currently have a wall opening:

1. Measure from the bottom of opening to inside floor (Figure 1).

2. Cabinet dimensions are 26-1/2" from bottom of sleeve to base of cabinet

(Figure 2).

3. Subtract the difference to determine if a plinth is needed or what size plinth

to order or build. If difference is less than 2-3/8" (for example), you may

construct your own to fit. (Caution: The leveling feet on the cabinet itself

should not be used to raise the unit more than 3/4").

Figure 1. Determine height of

opening to inside floor .

Cabinet

“footprint”

26- 1/2"

Figure 2. Height of cabinet base to

bottom of sleeve (26-1/2").

23

Page 24

FT5000

XP

- SITE PREPARATION AND INSTALLATION GUIDE

ISLAND CONFIGURATION SERVICE AREA

6 -1/4" max

* Dimensions shown in inches and millimeters. Maximum wall thickness - 6-1/4" inches (160 mm)

6 -1/4" max

6 -1/4" max

24

Page 25

SITE PREPARATION/INSTALLATION

EXTENDED CONFIGURATION SERVICE AREA

10" max

10" max

* Dimensions shown in inches and millimeters. Maximum wall thickness - 10 inches (254 mm)

10" max

25

Page 26

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

SECURING UNIT

It’s recommended that the unit be secured to the facility floor and plinth structure.

If a plinth was used, we recommend anchoring that structure first due to accessibility may be limited once the unit is mounted on the plinth. The footprint of the

cabinet floor allows for securing to either a concrete pad or plinth structure. Anchor bolts may be too short to go straight from the cabinet to the floor, depending

how high the unit was raised to accommodate the wall opening. It is the customer

or their agent’s responsibility to determine how the unit is af fixed to the facility.

Listed are some general considerations when securing the unit:

1. What is the floor structure?

(concrete, wood, etc) Do you have

anchors, lag bolts, screws to secure

cabinet/plinth?

2. Is the unit a UL Level 1 Safe cabinet

or Business Hours? Will the floor

support the weight of the cabinet?

What is the plinth constructed of?

(If you build -concrete, metal, wood,

etc).

3. Is the inside floor level the same as

the outside ground? If inside floor

is higher or lower than outside, will

you need the optional 2-3/8” or 43/4” plinths?

4. Is the floor level? Will the unit need

to be raised using the plinth/cabinet

leveling feet? (Leveling feet are for

minimal corrections to level cabinet)

5. Is exterior wall solid? (brick,

concrete) W ood framed?

Aluminum siding? Do you need to

insulate the wall cavity?

6. After cabinet is anchored, is the

control panel trim flush against the

exterior wall? Is the trim sufficiently

sealed to prevent moisture from

entering the control panel

electronics?

LEVEL 1 CABINET SAFETY

Level 1 cabinets are considerably heavier than Business Hours

cabinets! Exercise extreme cau-

tion when moving Level 1 cabinets! At least two persons should

work together to move the cabinet into position for mounting!

LEVEL FLOORING

REQUIREMENT

It is very important that the ATM

cabinet be located on flat, level

flooring! If the floor is not flat

and level, the cabinet bottom and/

or walls may become distorted

when the mounting bolts are tightened down! This could prevent

the security vault door from closing!

TOOL U SE/SAFETY

Observe ALL safety precautions

for operating hand and power

tools! Wear eye and ear protection while operating the electric

drill!

USE A BACK-SUPPORT BELT

WHEN LIFTING AND MOVING

THE ATM!

26

Page 27

SITE PREPARATION/INSTALLATION

INSTALLING CABINET THROUGH WALL OPENING

1. Carefully inspect the unit for any

shipping damage and report any

damage immediately to the

shipping company. Refer to the

warranty information in the user or

service manual (as applicable) for

information about reporting

shipping damage.

2. After unpacking the unit, remove

the dispensing mechanism

following the procedures in the

section “NMD-100 Dispensing

Mechanism:Removal/

Installation” found on pages 44-

47. After removal of the dispenser,

move the cabinet using the proper

lifting/moving device towards the

wall opening.

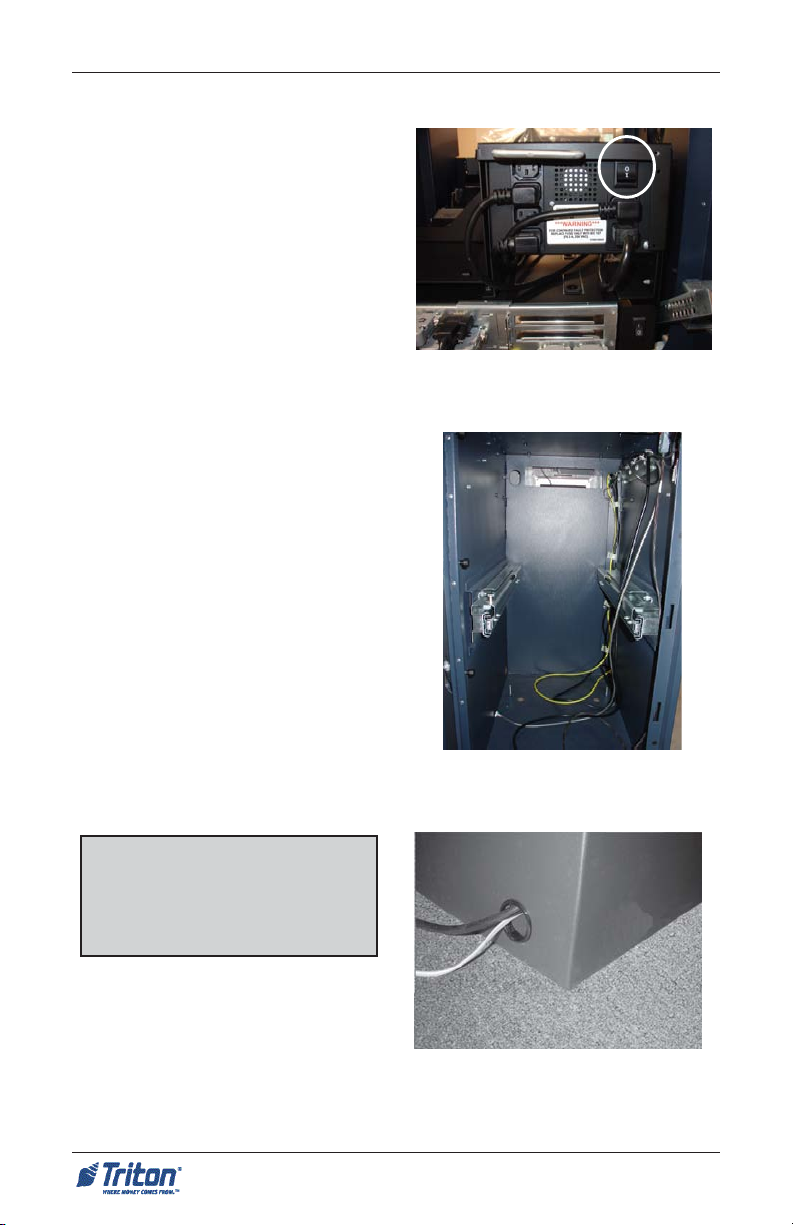

* Important*

Open the control panel sleeve door .

Verify that the power switch located

on the unit power supply is in the OFF

(0) position. See Figure 1.

3. Slide the unit up to the opening

until the sleeve portion of the

cabinet is near the wall (Figure 2).

Note

DO NOT install the control

panel trim at this time.

Figure 1. Ensure power supply is in

the OFF (0) position.

Figure 2. Slide unit up to interior

wall.

4. Measure the distance from the

bottom of the wall opening to the

bottom of the sleeve. This will be

the height requirement of the

“plinth”, if needed. Add an

additional 1/8” (3.175mm) to your

measurement for clearance (Figure

3).

Figure 3. Measure from bottom of

wall opening to bottom of sleeve.

* See Note next page for additional

measurement.

27

Page 28

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

5. If no plinth is needed, slide the unit forward towards the wall opening so the

sleeve protrudes slightly out the front exterior (Figure 4). This is needed to

temporarily affix the control panel trim. Minor adjustments for raising the

unit can be made using the cabinet leveling feet (See “Adjusting Height of

Unit” page 30).

6. If a plinth is used (either built or purchased), mount the cabinet on the plinth

Figure 5). The optional plinths have a wall tab that is aligned facing the outside

exterior wall. Anchor the cabinet to the plinth using the bolts provided (optional

plinth) or secure to your built plinth. Tighten bolts enough to secure the two

together for moving the unit.

Note

Before installing the plinth, adjust the leveling feet a 1/4" (6mm) below the

platform to gain access with an open-end box wrench for additional

adjustments.

Sleeve

Figure 4. Sleeve pr otrudes slightly.

7. Slide/move the unit forward towards the wall opening so the sleeve protrudes

slightly out the front exterior (Figure 4). This is needed to temporarily affix

the control panel trim. Minor adjustments for raising the unit can be made

using the plinths leveling feet (See “Adjusting Height of Unit” page 30).

**Caution**

When placing the unit on the plinth, be careful not to damage the

front of the sleeve as this has the control panel electronics and

hardware mounted.

8. Locate the control panel trim included with the unit accessories. On the back

side are 4 clips (Figure 6a) that will align with 4 slots on the control panel (Figure

6b).

Figure 5. Mount cabinet on plinth.

28

Page 29

SITE PREPARATION/INSTALLATION

Figure 6a. Location of clips on control panel trim.

9. Temporarily mount the trim on the

protruding sleeve. DO NOT secure

with screws at this time.

10. Slide the unit back until the control

panel trim is flush to the exterior

wall (Figure 7).

11. Adjust the plinth’s leveling feet to

ensure the control panel trim is flush

against the exterior wall and the

cabinet is level.

12. Mark the anchor holes through the

cabinet floor or mark around the

plinth structure using masking

tape, pencil, etc. Remove the

control panel trim and slide the unit

back inside.

13. Remove the unit from the plinth (if used). Align the plinth over the markings and

mark the anchor holes. Drill the anchor holes and secure the plinth (if used) to

the floor. Mount the unit back on the plinth (if used) and again slide the unit

forward towards the wall opening until the sleeve protrudes slightly out the

front exterior.

If no plinth was used, after drilling the anchor holes, again slide the unit forward

towards the wall opening until the sleeve protrudes slightly out the front exterior.

Figure 6b. Location of slots on sleeve

control panel.

Figure 7. Slide unit back flush to wall.

Page 31 continues with the installation of the control panel trim.

29

Page 30

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

Adjusting Height of Unit

Triton Systems offers two (2) metal-constructed optional plinths w/leveling

feet. The plinths come in 2 heights: 2 - 3/8" (61 mm) and 4 - 3/4" (122 mm).

Based on the height requirement needed, you can either:

1) Raise the unit with the leveling feet installed in the cabinet (Business

Hours and Level 1) using a 1/4" (6mm) nut driver/socket.

Caution: The leveling feet are primarily for that purpose - leveling the ATM,

not to raise the unit by more than 3/4".

2) Construct your own. A “plinth” is a platform on which the ATM rests or

is secured. A plinth enables the ATM to be installed at the required height

through the wall. If built, it must be no smaller than the base of the cabinet

and must be constructed of a material that is capable of supporting the

weight of the ATM.

3) Purchase an optional plinth (Figure below). Raise the unit by a fixed

amount (2 - 3/8" or 4 - 3/4") and, if needed, adjust up using the plinths

leveling feet (see Note below).

Caution: Leveling feet are primarily used for that purpose - leveling the

ATM, not to raise the unit by more than 3/4".

4) “Stack” the optional plinths. Before securing two (2) plinths together ,

remove the leveling feet from the top plinth.

cc

c Anchor hole

cc

dd

d Leveling foot

dd

ee

e Cabinet hole

ee

Note

Before installing the plinth, adjust the leveling

feet a 1/4" (6mm) below the platform to gain

access with an open-end box wrench for

additional adjustments.

30

Page 31

SITE PREPARATION/INSTALLATION

INSTALLING CONTROL PANEL TRIM

1. Locate the control panel trim

included with the unit accessories.

On the back side are 4 clips (Figure

1a) that will align with 4 slots on

the sleeve control panel (Figure 1b).

2. Before mounting the trim, ensure

the speaker wires and LED light

cables are routed through the

opening above the control panel.

These will be connected later. Align

the trim clips with the sleeve slots

and insert until the trim is seated

on the control panel.

3. Once the trim is in place, open the

side panels on the cabinet sleeve

and secure the trim panel with 16

Phillips head screws included in the

accessory kit (4 on each side).

Figure 1a. Location of clips on control panel trim.

Note

2 screws holes are accessed inside

the small silver panel (Figure 2a).

Slide the dispensing mechanism

back approximately one (1) foot and

use a magnetic Phillips driver to hold

screws. Screw holes are located in

upper slots shown in Figure 2b.

Figure 2a. Remove retaining screw

to open panel.

Figure 1b. Location of slots on control panel.

Figure 2b. Screw locations for securing bottom of trim .

31

Page 32

FT5000

4. After the control panel trim has

been secured, route the speaker

wires through the cable clip shown

in Figure 3. Connect the speaker

wires to the audio input circuit

board located in the lower right

corner of the cabinet (Figure 4).

5. Connect the trims upper LED light

cable to the cabinets LED light

assembly shown in Figure 5.

Connect the lower cable to the

docking board assembly (J3)

shown in Figure 6.

6. With 2 persons (inside/outside),

slide the whole unit back inside

until the control panel trim is flush

with the outside wall.

7. Before securing/anchoring the

cabinet, check to ensure the control

panel trim is flush against the

exterior wall. Minor adjustments

can be made using the cabinet

leveling feet.

XP

- SITE PREPARATION AND INSTALLATION GUIDE

Figure 3. Route speaker wires.

Speaker wires

Figure 4. Connect speaker wires to

audio board.

8. Secure/anchor the cabinet to the

floor or plinth, if used. Cabinet/trim

installation is complete.

Figure 5. Upper trim cable con-

nected to LED light assembly.

Figure 6 (Left). Lower cable

connected to docking board (J3).

32

Page 33

SITE PREPARATION/INSTALLATION

EXTENDED CONFIGURATION

The illustration on right shows the

FT5000XP extended. The primary purpose for this configuration is for installation in facilities with exterior walls having a maximum thickness of 10 inches

(254 mm). The dispensing mechanism

has a bill chute extension designed for

the elongated configuration. A protective plate is inserted on the underside

of the cabinet sleeve for security and

environmental purpose.

**Warning**

Units are shipped as specified configurations and the dispensing mechanism assembled with the required bill

chute extension. Changing configurations require dispenser modifications and/or additional hardware.

YOU CAN NOT CHANGE

CABINETCONFIGURATIONS

WITHOUT THE REQUIRED

HARDWARE.

Figure 1 2. Extended co nfiguration.

Figure 13. Screw holes for

Island configuration.

ISLAND CONFIGURATION

The illustration on right shows the

FT5000XP “collapsed” or Island configuration. The cabinet sleeve is moved

back approximately 5 - 7/16" inches (137

mm). This configuration allows installation in facilities with exterior walls having a maximum thickness of 6 - 1/4"

inches (160 mm). The dispensing mechanism has a shortened bill chute extension due to the collapsed state of the

unit.

Figure 14. Island con figuration.

33

Page 34

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

SEALING THE CONTROL PANEL TRIM

To ensure that the temperature around the unit is maintained during cold weather,

it’s important that the wall opening is prepared correctly . Any cavity in the wall

should be sealed to provide a flush surface. The gap between the ATM and the

inside wall opening should be left clear to allow air to circulate at room temperature.

After the control panel trim is installed, a good weather seal is needed between the

exterior wall and the trim. A suitable water -resistant sealant product is required

around the periphery of the control panel trim. There are also products that are color

tinted to closely match the trim color.

Drain hole location

Figure 15. Control panel trim sealed.

**IMPORTANT**

SEAL THE TRIM TO THE EXTERIOR WALL WITH A

WATER-RESISTANT SEALANT TO PREVENT WATER

INTRUSION. DO NOT SEAL AROUND THE BOTTOM

OF THE TRIM! A SMALL DRAIN HOLE IS LOCATED

ON THE UNDERSIDE THAT MUST BE CLEAR.

34

Page 35

SITE PREPARATION/INSTALLATION

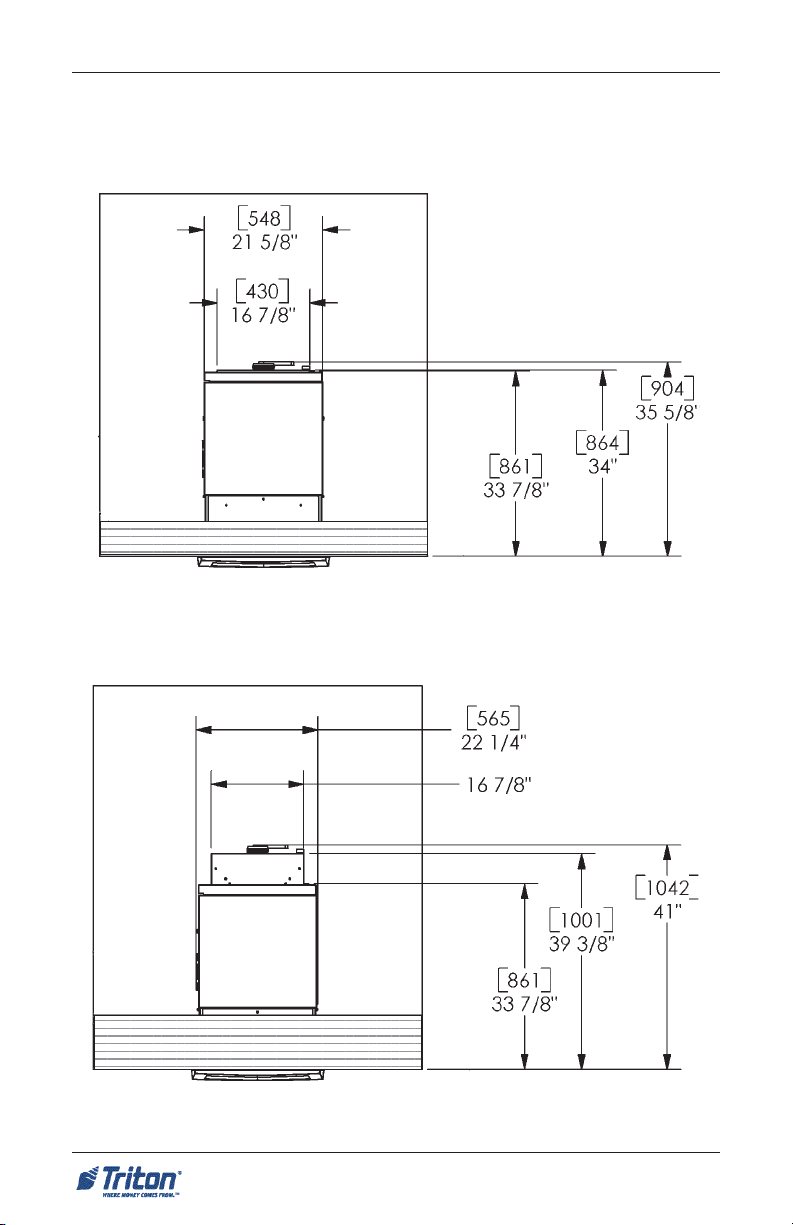

CABINET DIMENSIONS

The following illustrations show dimensions of the cabinet in the Extended and

Island configurations. Note: Plinths shown are with the 4-3/4" option.

* These dimensions are only accurate if inside and outside “floor” level is the

same. If not, the dimensions should be modified accordingly.

Rear View

Floor-interior

35

Plinth

(4-3/4")

Floor-interior

Page 36

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

CABINET DIMENSIONS

Top View (Island)

Wall (6-1/4” max)

Top View (Extended)

Wall (10” max)

36

Page 37

* 4-3/4"

SITE PREPARATION/INSTALLATION

CABINET DIMENSIONS

6-1/4"

WALL

Side View (Island)

Cable

entry

Plinth

Floor-interior Ground-

Side View (Extended)

* 4-3/4"

Floor-interior

exterior

Plinth

10"

WALL

Cable

entry

Ground-

exterior

37

Page 38

FT5000

XP

- SITE PREPARATION AND INSTALLATION GUIDE

THIS PAGE INTENTIONALLY LEFT BLANK

38

Page 39

POWER AND COMMUNICATION

39

Page 40

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

CONNECTING AC POWER AND ETHERNET CABLE

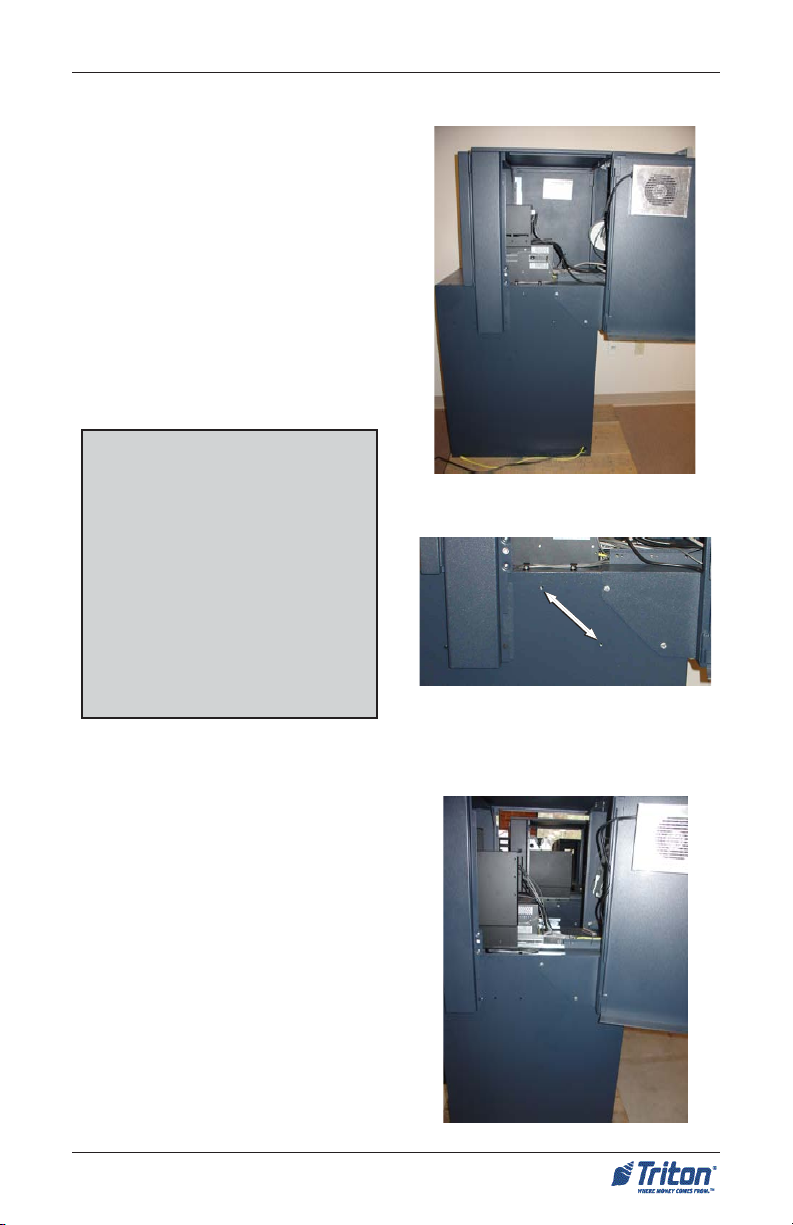

1. Unlock and open the control

panel sleeve door. Rotate the Rear

Service Display and Keyboard

Assembly out by pulling down

the locking pin. Verify that the

power switch located on the

power supply (Figure 1) is in the

OFF (0) position. Close the

control panel door.

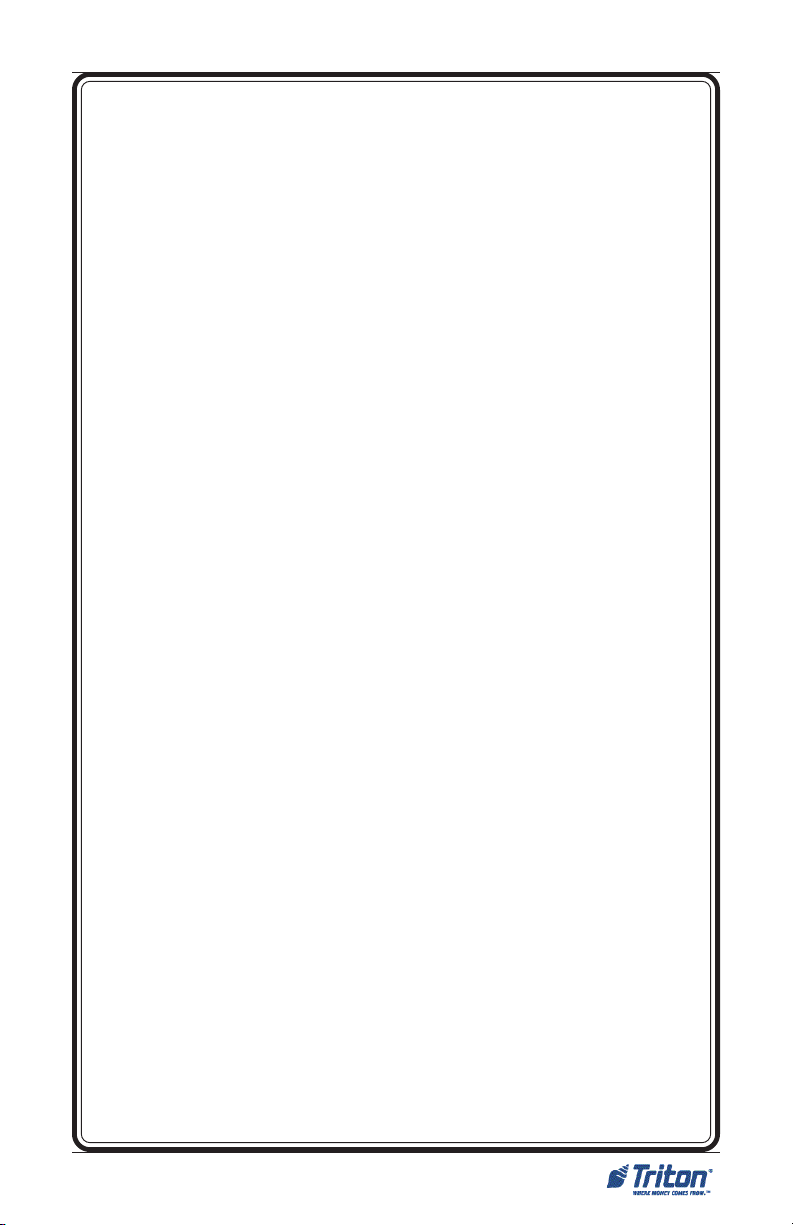

2. Open the security vault door .

Ensure the power and Ethernet

cables are routed through the

cable clips located in the vault

cabinet (Figure 2).

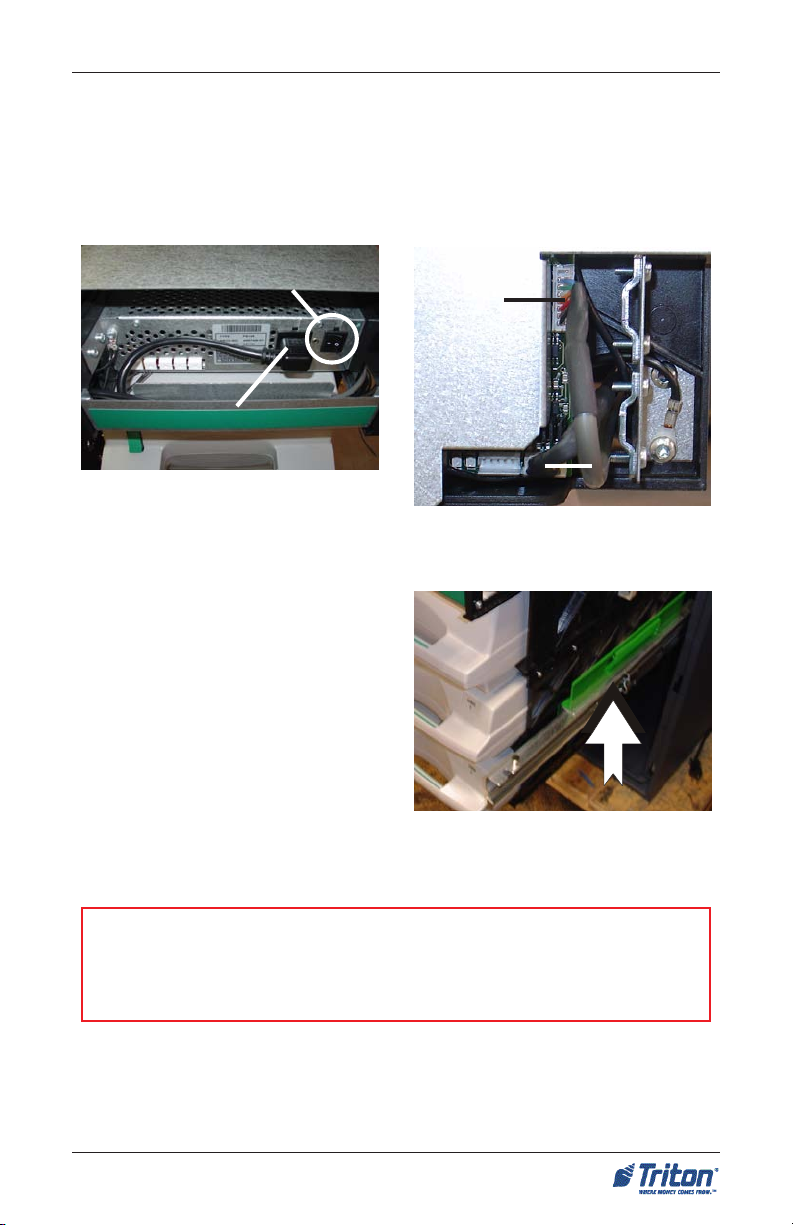

3. Route the AC power cord and the

Ethernet (CAT-5) cable through

either of the cable access holes

(as applicable) in the security

cabinet, as shown in Figure 3.

4. Install the supplied snap bushing

into the access hole that carries

the power and phone cords. See

Figure 3.

5. Plug the AC power plug into the

wall outlet.

* IMPORTANT *

AC power for the terminal should

come from a dedicated source with

an isolated ground.

Figure 1. Ensure power supply is in

the OFF (0) position.

Figure 2. Power and Ethernet cables

secured to cabinet.

6. Plug the Ethernet (CAT-5) cable

into the wall mounted jack.

Figure 3. Route cables through access

holes. I nstall snap bushing.

40

Page 41

POWER AND COMMUNICATION

*** WARNING***

This unit may be equipped with more than one power

cord. DISCONNECT ALL POWER CORDS PRIOR

TO SERVICING!

POWER OUTLET

ACCESSIBILITY

Whether you are installing a new

outlet, or plan to use an existing

outlet to supply power to the ATM,

make sure the following requirements are met:

1. The outlet is located near the

cabinet.

2. The outlet is easily accessible.

3. Access to the outlet will not be

blocked once the cabinet is installed!

POWER SUPPLY CORD

SPECIFICATIONS

For European applications, the power

supply cord must conform to the following specifications:

1. Two-conductor with physical

earth ground.

2. IEC 320 molded connector on

one end and molded plug on the

other end.

3. Certified for country of

installation.

4. Rated minimum H05VV-F with

minimum 0.75 mm2 (except where

specific countries require 1.0

mm2) conductors.

5. Maximum length: 3 meters.

41

Page 42

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

THIS PAGE INTENTIONALLY BLANK

42

Page 43

NMD-100 DISPENSING MECHANISM

REMOVAL / INSTALLATION

43

Page 44

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

REMOVING/INSTALLING THE NMD-100 DISPENSING MECHANISM

The dispensing mechanism for the

FT5000XP unit is shipped mounted on

the slide rails inside the security

vault. Several protective foam packs

have been strategically placed behind

and along each side of the dispensing

mechanism to reduce any movement

during transit. The foam packs and

cardboard that secures the cassettes

must be removed before the dispensing mechanism can be extended out.

Follow the procedures below for removal.

Locking pin

Figure 1. Ensure power supply is in

the OFF (0) position.

REMOVING THE NMD-100

1. Unlock and open the control

panel sleeve door. Verify that the

power switch located on the

power supply (Figure 1) is in the

OFF (0) position. Close the

control panel door.

2. Open the security vault and remove all protective foam packs

from around the dispensing

mechanism.

3. Remove the transport 5/32" Allen

screws located on top front of

both slide rails (Figure 2). DIS-

CARD SCREWS AFTER REMOVAL!

4. Pull the dispensing mechanism

out of the cabinet until it reaches

its fully extended position (Figure 3). The left slide rail has a

locking pin that must be disengaged to extend the rail (Figure

2).

Locking pin

Allen screw

Figure 2. Remove and discard

transport screw, if applicable.

Figure 3. Dispenser fully extended.

44

Page 45

NMD-100 DISPENSING MECHANISM REMOVAL/INSTALLATION

5. Turn the dispenser power switch located just to the right of the power

connector to OFF (0) (Figure 4).

6. Refer to Figures 4 and 5. Disconnect the DC power, serial communications,

and shutter cables from the dispensing mechanism. Remove the cables

from the cable clips attached to sides of dispenser.

On/Off switch

AC power cable

Figure 4. Remove AC power cable.

7. Using two persons, grasp the

green handles and lift the dispenser off the rails and slide out

of the cabinet (Figure 6). Place the

dispenser in a safe location where

it will not get accidently damaged.

8.* If installing the cabinet at this

time, follow the procedures provided in “Site Preparation” section of this manual.

Shutter

cable

Serial cable

Figure 5. Remove shutter and serial

cables (left side of dispenser).

Figure 6. Lift dispenser off rails and

guide out of cabinet. Use 2-person lift!

***WARNING***

Two persons recommended to remove the dispenser from the cabinet. When

removing dispenser from cabinet, use caution not to damage the throat

extension on front of dispenser mechanism.

45

Page 46

FT5000XP - SITE PREPARATION AND INSTALLATION GUIDE

INSTALLING THE DISPENSING MECHA-

NISM INTO THE CABINET

**CAUTION**

Be certain that you have not applied

power to the ATM before you continue! See Pg.44 for the ATMs power

supply location and On/Off switch.

1. Refer to Figure 1. Pull the slide

rails out of the cabinet until they

reach their fully extended position. The left slide rail has a locking pin that must be disengaged

to extend the rail. Ensure all cables

have been moved out of the way

so they will not be damaged while

installing the dispensing mechanism in the cabinet.

2. Pick up the dispensing mechanism by the handles and load it

on to the slide rail by aligning the

tabs (under handle) into the rail

slots. (Figures 1 and 2)

Rail slots

Figure 1. Slide rails extended.

Tab

Rail slot

Figure 2. T ab into rail slot. Use 2person lift!

***WARNING***

Use only the green handles and

drive motor in rear of dispenser to

lift the mechanism. Two persons

recommended t o install the dispenser on to the slide rails.

3. Refer to Figure 3. Route the dispensers AC power, shutter, and serial data cables as shown in Figure

3 (right side of dispenser).

Figure 3. Route cables through cable

clip.

46

Page 47

NMD-100 DISPENSING MECHANISM REMOVAL/INSTALLATION

4. Refer to Figure 4. Connect the serial communication data cable and

the shutter cable to the connectors

on the left side of the dispenser .

For the serial data cable, use the

forward -most connector as shown.

The plug is keyed to ensure proper

installation.

5. Connect the AC power cable to the

dispenser power supply (Figure

5).

6. Disengage the slide rails by lifting

up/down on the locking lever located in Figure 6 (both sides). Slide

the dispenser into the cabinet until

the slide rail locking pin is engaged.

(Figure 7)

7. Turn the dispenser power switch

located just to the right of the power

connector to ON (I).

Shutter cable

connector

Serial cable

connector

x

Figure 4. Shutter and data cable

connectors.

AC power cable connector

Figure 5. AC power cable connection.

Figure 7. Slide dispenser into cabinet.

Figure 6. Disengage slide rails.

47

Page 48

FT5000

XP

- SITE PREPARATION AND INSTALLATION GUIDE

THIS PAGE INTENTIONALLY LEFT BLANK

48

Loading...

Loading...