Page 1

Installation Guide

DIGITAL MIXER

SH WER

2181516D - April 2018

Installers please note these InstructIons are to be left wIth the user

European Union Registered Design No

004558245-0001/10

Page 2

2

3

3

7

7

8

10

11

12

13

13

14

15

16

17

18

20

21

22

22

23

24

26

28

30

31

32

34

38

39

Important Information .....................................................................

Standards and approvals .................................................................

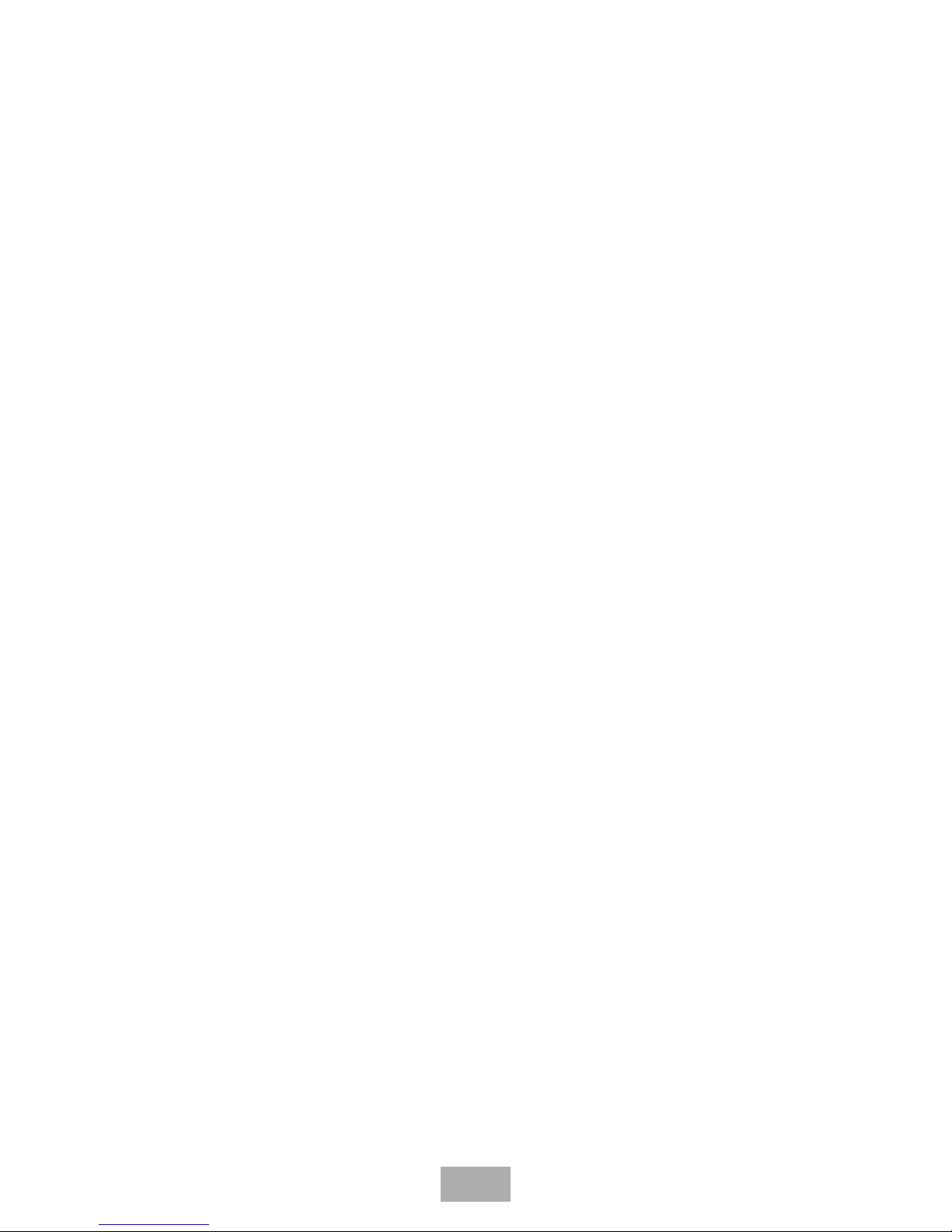

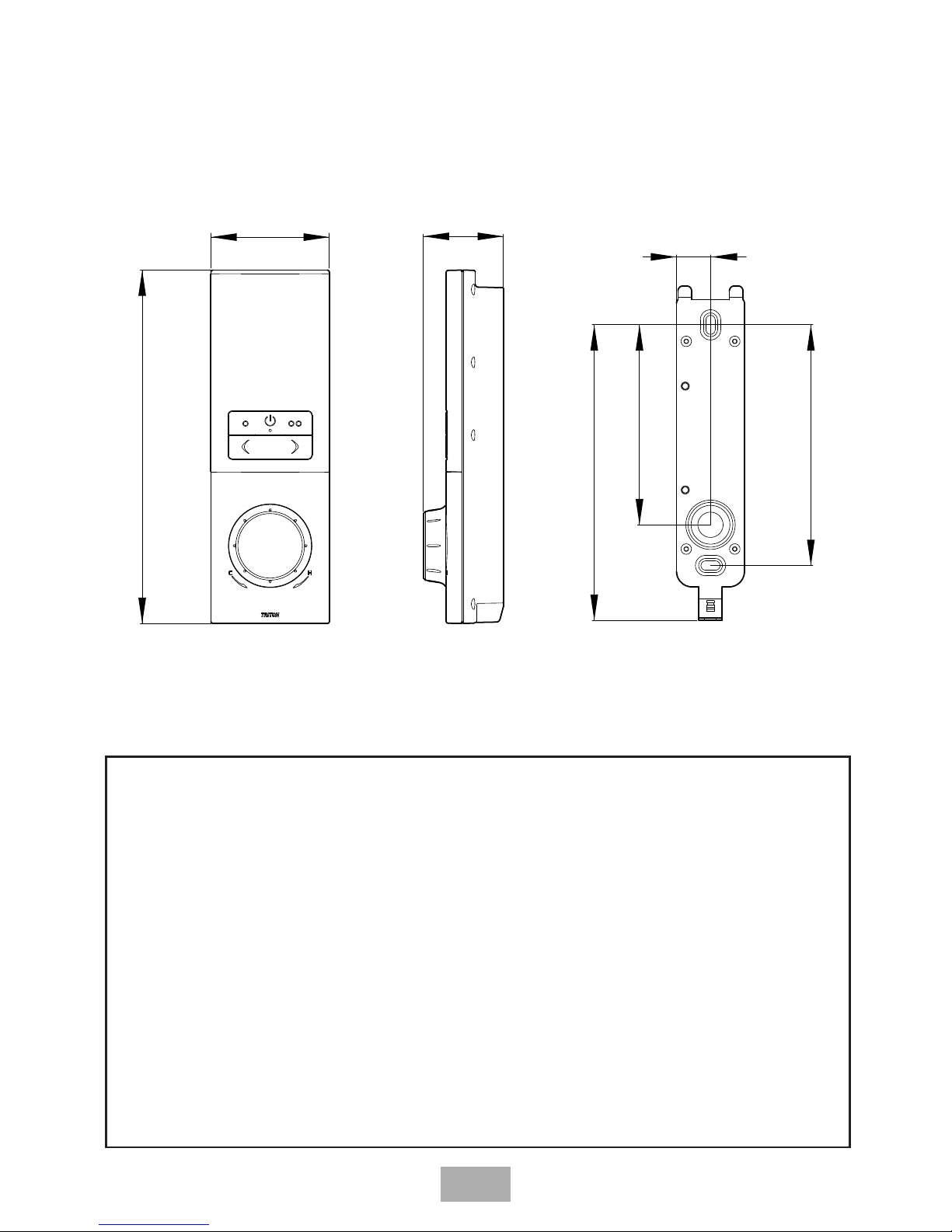

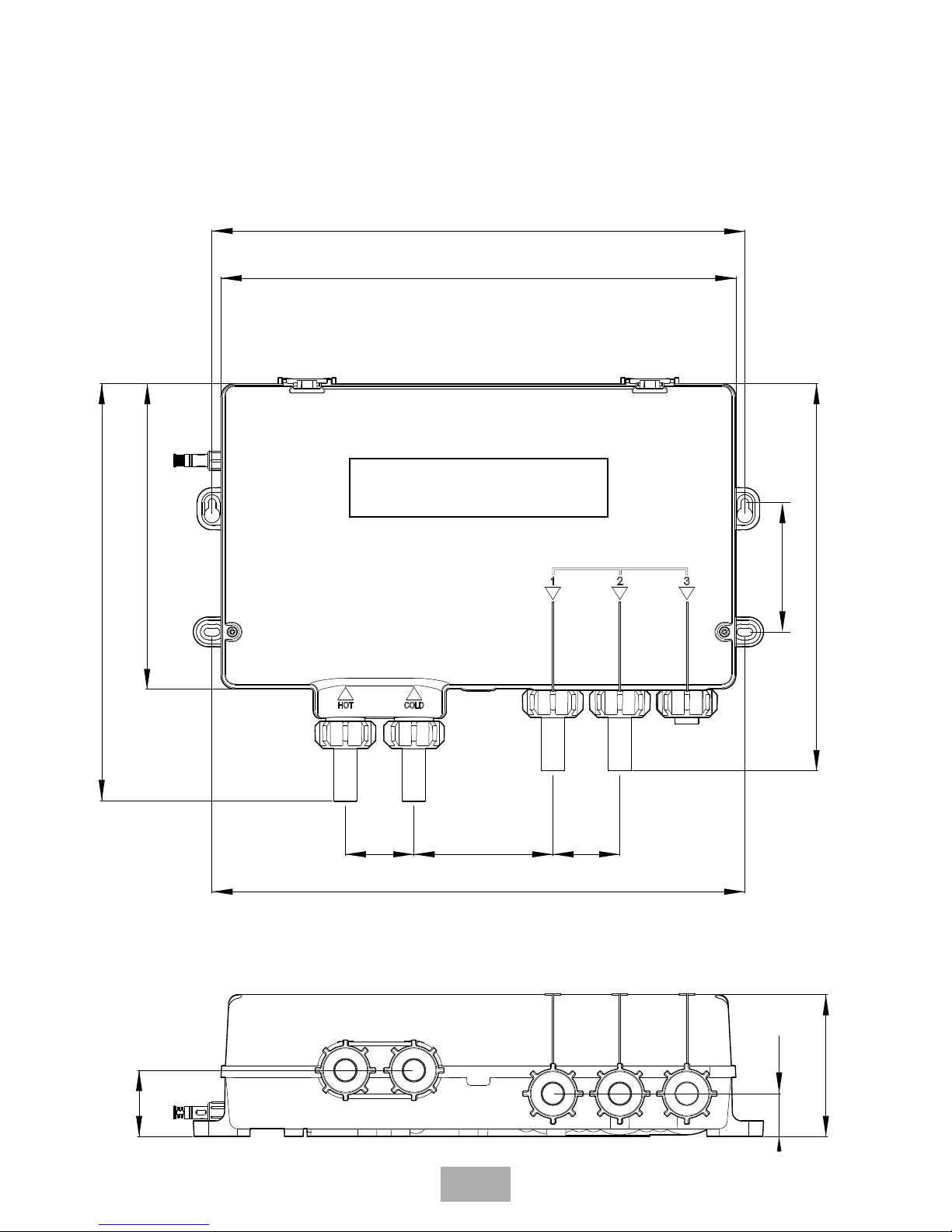

Dimensions ..........................................................................................

Digital Controller ........................................................................

Digital Mixer Processor Unit .....................................................

Specifications ......................................................................................

Main Components .............................................................................

General Installation Information ..................................................

Typical suitable Installations ..........................................................

High Pressure Instantaneous Hot Water Systems .................

High Pressure Unvented Mains Pressure Cylinders ..............

High Pressure Thermal Store Systems .........................................

Low Pressure Gravity Fed Systems .........................................

Digital Mixer Processor Installation .............................................

Plumbing Connections ........................................................................

Electrical Connections ..........................................................................

Installation Schematic ...............................................................

Digital Controller Installation ........................................................

Data Cable Installation ..............................................................

Fixing Bracket Installation ........................................................

Digital Controller Fitting (Wired Connectivity) ...................

Digital Controller Fitting (Wireless Connectivity) ...............

Commissioning ..................................................................................

Quick Start ...........................................................................................

General Maintenance .......................................................................

Spare parts ...........................................................................................

Fault Diagnosis ...................................................................................

Disposal and Recycling ....................................................................

Guarantee, Service policy, etc .......................................................

Contents

Page 3

3

This book contains all the necessary installation

instructions for your Digital Mixer Shower – please

read them carefully.

Care taken during the installation will provide a long,

trouble-free life from your shower.

The installation must be in accordance with Water

Regulations and Bylaws.

BS EN 806 recommends that the temperature of stored

water should never exceed 65°C.

A stored water temperature of 60°C is considered

sufficient to meet all normal requirements and will

minimise the effects of scale in hard water areas.

Standards and approvals

The processing unit is an independently mounted

electronic control. Complies with the requirements

of current British and European safety standards for

household and similar electrical appliances.

Meets with Compliance with European New Approach

Directives (CE).

Declaration of conformity

Triton Showers declares that the HOST/HOME products,

in conjunction with controllers, complies with the

essential requirements and other relevant provisions

of the Low Voltage Directive (2014/35/EU) and the EMC

Directive (2014/30/EU) and the RE Directive (2014/53/

EU)

Important information

Page 4

4

The showerhead and hose supplied with this product

are a safety critical part of your shower. Failure to use

genuine Triton parts may cause injury and invalidate

your guarantee.

Please read this book thoroughly and familiarise

yourself with all instructions before commencing

installation and keep it for future reference.

The shower installation MUST be carried out by a

suitably qualified person, following the sequence of this

instruction book.

Plumbing

Supply pipes must be flushed to clear debris before

connecting the processing unit.

Layout and sizing of pipework MUST be such that

when other services are used, pressures at the shower

control inlets DO NOT fall below the recommended

minimum.

DO NOT use excessive force when making connections

to the Digital Mixer Processor unit.

DO NOT choose a position where the Digital Mixer

Processor will become frozen.

DO NOT connect the Digital Mixer Processor unit to

any form of tap or fitting not recommended by the

manufacturer.

The length of pipework from the Digital Mixer

Processor unit to any outlet fitting MUST NOT exceed

5m.

Important information

Page 5

5

The showerhead or other approved Triton device

MUST be regularly cleaned to remove scale and debris.

If it is intended to operate the shower in areas of hard

water (above 200 ppm temporary hardness), a scale

inhibitor may have to be fitted. For advice on the Triton

scale inhibitor, please contact Customer Service.

DO NOT operate the Digital Mixer Processor unit

outside the guidlines as laid out in ‘site requirements’

and ‘specifications’.

DO NOT connect to a combination cylinder unless the

minimum cold storage can be achieved as the shower

can deliver up to 16 litres/min.

DO NOT connect the low pressure Digital Mixer

Processor unit to the mains water supply as this would

damage the unit.

When installed, the top of the low pressure Digital

Mixer Processor unit MUST be at least 100 mm lower

than the base of the cold water cistern to prevent the

unit running dry.

A dedicated cold water supply MUST be taken directly

from the cold water cistern to the low pressure Digital

Mixer Processor unit.This draw-off MUST be on the

opposite side of the cistern to the float operated valve

to reduce the risk of air entering the unit.

The infill to the cistern should be checked to ensure an

adequate infill rate occurs.

Important information

Page 6

6

Electrical

The installation must comply with BS 7671

‘Requirements for electrical installations’ (IEE wiring

regulations). Make sure metal incoming hot and cold

water supplies to the Digital Mixer Processor unit are

adequately earth bonded.

DO NOT turn on the electrical supply until the

plumbing connections have been completed. Only

then can the electricity be switched on in order to

undertake commissioning. The Digital Mixer Processor

unit must not be operated dry without water.

The Digital Mixer Processor unit MUST be permanently

connected to a 3Amp fused connection unit and be

provided with means for disconnection incorporated

in the fixed electrical wiring in accordance with current

wiring regulations.

A 30mA Residual Current Device (RCD) MUST be

included in the electrical circuit. This may be part of

the consumer unit or a separate unit.

If the Digital Mixer Processor unit is to be installed

within a bath or shower room the electrical installation

MUST conform to Part P Building Regulation

Requirements for Special Locations.

The Digital Mixer Processor unit MUST only be used

with the AC power supply cable provided. If this supply

cable is damaged, it must be replaced by a Triton

engineer or similar qualified persons to avoid a hazard.

Important information

Page 7

7

182

61

41

18

124

152

103

Digital Controller (Including Wall Fixing Bracket)

Professional installer Notes

In premises with metallic surfaces e.g. metal ceiling

panels, metal ducting and metallic insulating

materials, wireless transmissions MAY BE BLOCKED

from the control panel and prevent correct

operation of the shower.

To check the product suitability for commercial

and multiple installations, Please contact Triton’s

Specication Advisory Service on: 024 7637 2222

for guidance on installations.

Dimensions

Page 8

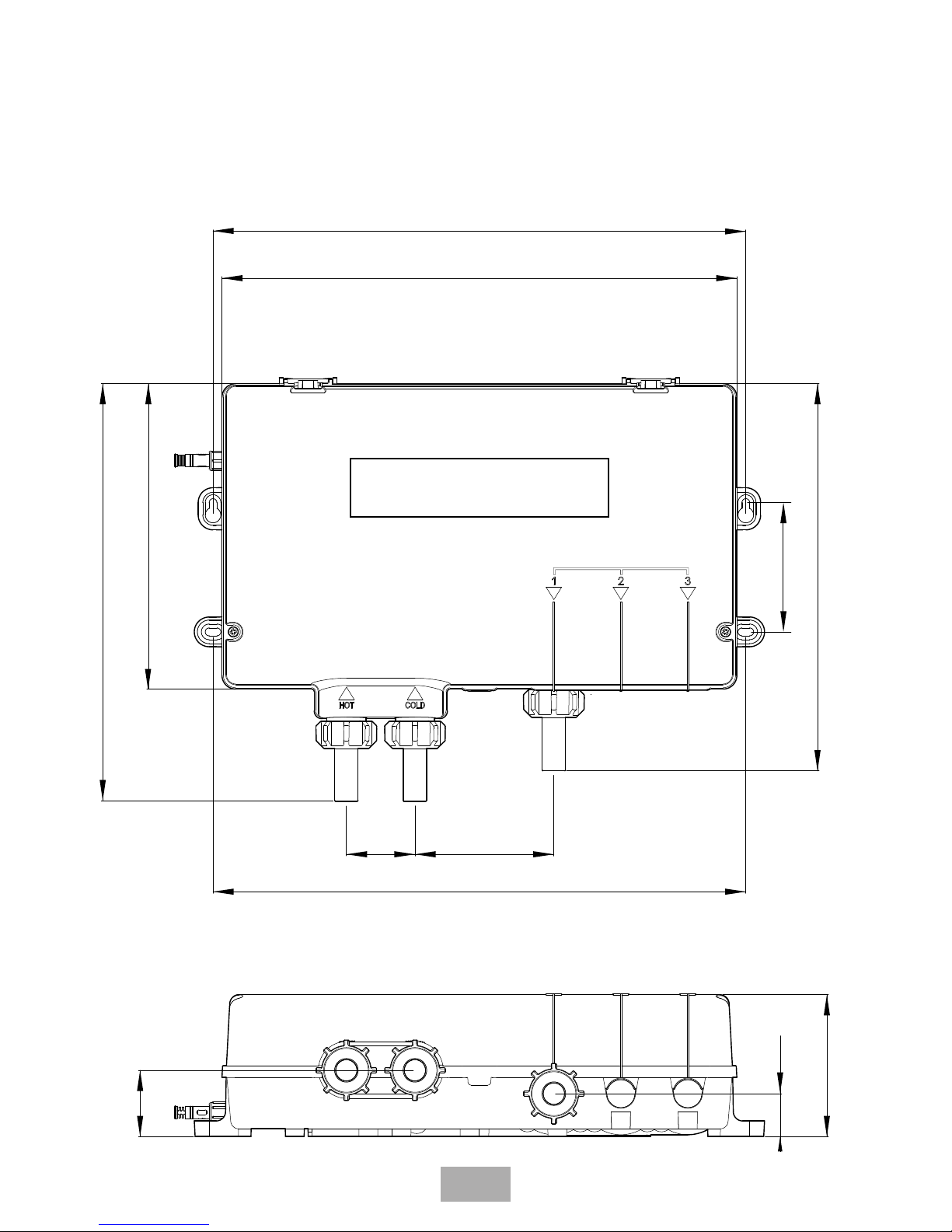

8

330

196

44 43

342

83

89

268

248

342

91

27.5

42.5

INLETS

OUTLETS

Dual Outlet Processor Unit

(High Pressure and Low Pressure)

Dimensions

Page 9

9

Dimensions

330

196

44

342

83

89

268

248

342

91

27.5

42.5

INLETS

OUTLETS

Single Outlet Processor Unit

(High Pressure and Low Pressure)

Page 10

10

Electrical

Mains Supply

Maximum Load

Water

Inlet Connections

Outlet Connections

Water Pressures

Maximum Static

Minimum Running

Supply Pressure

Differential

Temperatures

Hot water temperature

Cold water temperature

Ambient temperature

Showering temperature

adjustment range

Splashproof rating

Digital processor unit

Low pressure/gravity

system

230V 50Hz

125 W

15 mm push-fit

connectors**

15 mm push-fit

connectors**

100 kPa (1bar/10m head)

1 kPa (0.01bar/0.1m

head)

Nominally Equal

55°C - 65°C

1°C - 20°C

5°C - 40°C

32°C to 47°C*

IP24

Digital processor unit

High pressure

system

230V 50Hz

30 W

15 mm push-fit

connectors**

15 mm push-fit

connectors**

500 kPa (5 bar)

100 kPa (1 bar)

Nominally Equal

55°C - 65°C

1°C - 20°C

5°C - 40°C

32°C to 47°C*

IP24

*Max Temperature setting can be adjusted between 41°C and 47°C (factory set at 47°C)

Specication

**The Digital Mixer Shower is supplied with 15mm push t connectors, DO NOT use any

other type of tting

Page 11

11

4

3

6

1

2

7

8

1. Digital Processor Unit Cover

2. Digital Processor Unit Fixing positions

3. Digital Processor Unit AC Power Lead

4. 15mm push fit connectors with Isolating valves

5. 15mm push fit connectors

6. Digital Processor Unit Inlets (HOT & COLD)

7. Digital Processor Unit Outlets*

8. Digital Processor Unit Data Cable connector

5

9. Digital Controller

10. Controller Fixing Bracket

11. 10m Data Cable

*(The number of outlets will vary depending on the configuration of the Digital Mixer

Shower purchased).

10

9

7

11

Main components

Page 12

12

The installation MUST BE carried out in accordance with these instructions, and

MUST BE undertaken by a qualied competent person.

The Digital Mixer Processor unit may be installed in a loft space, under the bath or in a

convenient cupboard space, provided there is enough room for maintenance. Safe and easy

access to the Digital Mixer Processor unit should be available at all times.

When planning the installation, if you are using the wired connectivity ensure that the

distance between the Digital Mixer Processor unit and Digital Control Panel is within the

range of the 10m data cable supplied, ensuring that the data cable routing is taken into

consideration.

Ensure that the Digital Mixer Processor unit is installed in a position that will minimise

the length of pipe run between the Digital Mixer Processor outlets and the showerhead/

accessory fittings.

The length of pipework running from the Digital Mixer Processor unit to the showerhead/

accessory fittings will have an effect on the showering temperature and the response time

when changing the showering temperature on the Digital Control Panel. The shorter the

length of pipework the better the Digital Mixer Processor unit will respond.

When installing the Digital Mixer Processor unit in an area not regularly accessed,

consideration for potential leaks must be taken into account.

While such events are unlikely, it is advisable to periodically check the installation for traces

of water on or around the processor unit. If possible site the Digital Mixer Processor unit in

a location where any leak would be contained or routed to avoid areas sensitive to water

damage.

Isolation valves are integrated into the push connection fittings supplied for the hot & cold

inlets, ensure that after installation these valves are left in the fully open position as failure

to do this will result in poor flow performance from the Digital Mixer Shower.

The shower MUST NOT be positioned where it will be subjected to freezing

conditions.

All pipe work MUST be rigidly supported to avoid any strain on the connections and

vibrations during use.

Long inlet pipework (dead-legs) should be kept to a minimum to avoid showering

temperature fluctuations

DO NOT connect the Digital Processor unit to a gravity hot supply and a mains cold supply

(or vice versa).

The pipework should be installed such that the flow is not significantly affected by other

taps and appliances being operated elsewhere on the premises.

There are no user-serviceable components beneath the cover of the Digital

Processor unit.

General installation

information

Page 13

13

High pressure system – Instantaneous hot water systems, e.g.

combination boilers (Fig.1)

The high pressure Digital Mixer Processor unit MUST be installed with a multipoint gas

water heater or combination boiler of a fully modulating design (i.e. where the water drawoff rate indirectly controls the gas flow rate to the burner).

A drop tight pressure reducing valve MUST be fitted if the supply pressures exceed 500kPa

(5 bar) running.

An expansion vessel MUST be fitted, (and regularly maintained) if any form of backflow

prevention device is fitted ie. PRV. This will ensure that excess expansion or pressure pulses

Important if using wireless connected devices

Metal objects such as steel baths, cold water storage tanks, hot water cylinders, radiators,

foil lined plaster board and even thick brick walls can all dramatically reduce the wireless

operational range.

Interference from other wirelessly controlled devices and radio signals can dramatically

reduce the ability of the wireless Digital Mixer Shower to maintain a good, consistent

wireless signal. This may include mobile phones, cordless phones, radio controlled toys,

wireless doorbells etc.

If you encounter difficulty whilst setting up the wireless connectivity of the Digital Mixer

Shower, ensure all other radio interference is temporary switched off.

Failure to follow these wireless connectivity guidlines can result in poor, intermittent or

failure of the communication between the Digital Control panel and Digital Mixer Processor

unit.

Typical suitable

installations

CH flow

Cold

mains

supply

Hot water

CH return

Processor Unit

Stop

tap

Mini

Expansion

vessel

Pressure

reducing valve

Combination

boiler

Kit

Control

panel

Fig.1

do not damage the product. This may already

be installed within the boiler (check with

manufacturer) and is in addition to the normally

larger central heating expansion vessel.

The layout and sizing of pipework MUST

be such that nominally equal inlet supply

pressures are achieved and the effects of other

draw-offs are minimised.

Combination boilers are not always able to

supply an adequate ow rate of hot water,

particularly in winter, Triton recommends

tting a ow regulator (supplied with

the Shower) into the Hot inlet of the High

Pressure Digital Processor Unit prior to

installation. Refer to the table for details

(see Fig.2).

Page 14

14

If using the Warm Up feature of the Remote Start/Stop Switch (optional accessory) with a

instantaneous water heater appliance the user may experience a brief temperature variation

upon restart. This is due to the way in which a combination boiler operates, such that the

boiler will turn off after the warm up process has been completed. When restarted, the

processing unit will release a cold slug of water followed by a hot slug as the hot water

supply stabilises.

High pressure system – Unvented mains pressure cylinders (Fig.3)

The high pressure Digital Mixer Processor unit MUST be installed with an unvented, stored

hot water cylinder.

For systems with no cold water take off after the appliance reducing valve, it will be

necessary to fit an additional drop tight pressure reducing valve when the mains pressure is

over 500kPa (5 bar). The drop tight pressure reducing valve MUST be set at the same value

as the unvented package pressure reducing valve.

Note: An additional expansion vessel (Fig.3) may be required if a second pressure

reducing valve is installed. This does not apply to packages with a cold take off

after the pressure reducing valve to the cylinder.

The layout and sizing of pipework MUST be such that nominally equal inlet supply

pressures are achieved and the effects of other draw-offs are minimised.

Typical suitable

installations

Flow

Regulator

Flow

Regulator

Housing

Inlet

Filter

O Ring

Seal

Inlet

Pipe

Hot

Inlet Nut

Fig.2

Boiler Rating Regulator

24 to 30kW 7 L/min

White/

Green

30 to 36kW 9 L/min

White/

Orange

36kW + None required

To t ow regulator

1. Unscrew the hot inlet nut and remove the inlet pipe, O ring seal, inlet lter and ow

regulator housing.

2. Fit the ow regulator into the ow regulator housing.

3. Ret the ow regulator housing, Inlet lter, O ring seal and inlet pipe, secure with the hot

inlet nut. Note: the hot inlet nut only requires to be hand tightened.

Page 15

15

Processor Unit

Kit

Service

valves

Balanced cold mains supply

Cold mains supply

Expansion

vessel

Pressure

reducing valves

Stop tap

Unvented

hot water

storage unit

Safety devices

not shown

Control

panel

Fig.3

Blender

valve

Flow

Cold mains

supply

Hot

water

Stop tap

Expansion

vessel

Pressure

reducing

valve

Return

Service valves

Processor unit

Boiler

Kit

Control panel

Fig.4

High pressure system – Mains pressurised thermal store systems

(Fig.4)

The high pressure system MUST be fitted with a tempering valve (blender valve).

The appliance must be capable of raising the temperature of the incoming water to a

minimum of 55°C and delivering a flow rate of not less than 8 L/minute

A drop tight pressure reducing valve MUST be fitted if the supply pressures exceed 500kPa

(5 bar) running.

An expansion vessel (shown in Fig.4) MUST be fitted, and regularly maintained, to ensure

the unit is not damaged by excess pressures. This may already be installed externally or

internally within the thermal store (check with thermal store manufacturer).

Typical suitable

installations

Page 16

16

100mm

minimum

Hot water

cylinder

Digital Mixer

Processor unit

Kit

Service

valves

Cold supply

Hot

supply

Cold

water

mains

supply

Drain

valve

Gate

valve

Other

draw-offs

Stop valve

Cold water

cistern

Digital

Control

Panel

Draw-off must point

down to avoid airlock

issues.

Alternative

supply (must

be below vent

pipe tee)

Fig.5

Only install the low-pressure

Digital Mixer Processor with a

gravity fed system. Never install

a high-pressure digital mixer

shower with a gravity fed system

Low pressure system – Gravity fed systems (Fig.5)

The low pressure Digital Mixer Processor unit MUST be fed from a cold water cistern and

hot water cylinder providing nominally equal pressures.

For the operation of the shower only, it is recommended that the cold water storage cistern

is capable of holding at least 114 litres (25 gallons). Where other hot and cold outlets are

likely to be in use simultaneously, the storage capacity should be increased to 228 litres (50

gallons) in accordance with BS EN 806.

IMPORTANT: Pipework layouts and connections MUST be such that other draw-offs will

not effect water supplies to the digital mixer processor unit, shared supplies may lead to air

locking or water starvation. It is therefore best practice to have independent hot and cold

supplies to the digital mixer processor unit.

If the hot water draw-off is incorrectly positioned, air may be drawn into the hot supply

from the vent pipe causing spluttering, temperature fluctuations at the showerhead.

Any draw-off for the processor unit must point DOWN (to avoid air-lock problems) and

must be BELOW the vent pipe tee.

Failure to correctly position the draw-off will result in poor performance or other problems

with the Digital Mixer Processor unit.

Typical suitable

installations

IMPORTANT: The minimum head for

operation of the Digital Mixer Processor

unit is 100 mm. For correct operation the

Digital Mixer Processor unit must not be

sited more than 5 metres away from the

hot water cylinder.

Page 17

17

The Digital Mixer Processor unit MUST only be positioned as shown.

The Digital Mixer Processor unit can be mounted on a horizontal surface in any orientation

(Fig.6).

When mounting on a vertical surface the processing unit outlet MUST be at the bottom

(Fig.7). Failure to position the unit correctly could result in a significant reduction in

performance.

Decide on the position for the Digital Mixer Processor unit. Position the Digital Mixer

Processor unit in a dry, well ventilated area.

The Digital Mixer Processor unit MUST always be positioned either flat on a suitable surface

or on a wall so that there is easy access for installation and maintenance.

Mark the four locating screw points for the base. If fixing to brick or a stud partition drill

and plug the wall. (The wall plugs provided are suitable for most brick walls — use an

appropriate masonry drill, but if the wall is plasterboard or a soft building block, you must

use suitable wall plugs and an appropriate drill bit). Secure the Digital Mixer Processor unit

in position using the 4 screws supplied (Fig.8)

Hot

& Cold

Inlets

Outlets

Ensure sufcient space is left surrounding

the processor unit to allow for pipework,

connections and

maintenance

Fig.6

Inlets and Outlets

MUST be

at the bottom

Fixing

Screws

(x4)

Fig.8

IMPORTANT

If wall mounting the Digital

Mixer Processor unit the out-

lets MUST always be at the

BOTTOM (Fig.7)

Fig.7

Mixer processor

installation

Page 18

18

If the Digital Mixer Processor unit is installed in a loft area the following requirements must

be met for future servicing purposes:

a. There must be no risk of the Digital Mixer Processor unit or water pipe becoming frozen.

b. The Digital Mixer Processor unit MUST NOT be covered with any form of insulating

material that may give rise to electrical circuits overheating during periods of high

ambient temperature.

c. A safe means of access must be provided into the loft, e.g. via a fixed loft ladder.

d. The Digital Mixer Processor unit MUST be installed in an accessible and safe location.

e. Ceiling joists MUST be adequately boarded to provide safe and unobstructed access to,

from and around the Digital Mixer Processor unit.

f. There MUST be adequate lighting in the loft for servicing purposes.

Note: If mounting the Digital Mixer Processor unit in a loft it is worth considering building a

catchment tank with an overflow pipe directed to an external point. In the unlikely event of

a problem occurring with the Digital Mixer Processor unit this will give a visual indication of

any failure.

Plumbing connections

Plumbing/Pipe installation to be carried out before electrical wiring

installation

DO NOT use jointing compounds on any pipe fitting for the installation.

DO NOT solder fittings near the shower unit as heat can transfer along pipework and

damage components.

Fig.9 shows the plumbing connections layout.

Hot

Inlet

Outlet Pipe work*

Inlet Pipe work

Cold Inlet

Fig.9

*The number of outlets connections will vary depending on the configuration of the Digital Mixer Shower

purchased.

Mixer processor

installation

Page 19

19

IMPORTANT: The fittings on the inlet and outlets are the push-fit type. The pipework must

be cut with a pipe cutter and all burrs and rough edges removed from the end of the tube.

The fittings can be used with copper and plastic pipe.

If using chrome plated copper pipe, remove the first 25 mm of plating completely from the

connecting surfaces. If not completely removed then the collet will not grip the pipe and

under pressure the pipe may be forced out.

Before completing the connection of the water supplies to the inlets of the Digital Mixer

Processor unit, flush out the pipework to remove all swarf and system debris.

1. Turn off the water supplies either at the mains stop valve or the isolating stop valve.

2. Having decided on the position of the unit and direction of pipe entry, complete the

pipework to the Digital Mixer Processor unit.

3. Check for leaks before connecting the pipework to the Digital Mixer Processor unit.

4. Insert the incoming pipework into the 15 mm push-fit connectors (Fig.10).

5. Check that the isolating valves on the inlet connectors are fully open (Fig.11).

For products that have more than one outlet then the above procedure of fitting the pipe

work will need to be conducted for each outlet.

All pipework should be insulated. DO NOT attempt to insulate or

cover the Digital Processor unit

15mm PUSH FIT

CONNECTOR

INCOMING

PIPE

ISOLATING VALVE

Fig.10

ON

OFF

Fig. 11

ISOLATING

VALVE

Mixer processor

installation

Page 20

20

Mixer processor

installation

Before any electrical work is attempted, ensure the electricity supply

is isolated at the mains switch.

Electrical installation may only be carried out by a qualied person.

Electrical connections

Connect the Digital Processor Unit AC Power Lead to a double pole 3Amp switched

fused spur (Fig.12), incorporated in the wiring circuit, in accordance with current wiring

regulations.

The 3Amp fused spur MUST be located in a dry, easily accessible position. Access to

the fused spur is required for servicing and maintenance

Neutral cable marked N Blue

Live cable marked L Brown

DO NOT switch on the electricity supply until all the pipe connections have been tested for

leaks and the commissioning procedure has been followed.

3A Switched

Fused Spur Box

Ring Main Cable

Digital Processor

Unit AC Power Lead

Fig.12

Page 21

21

Digital Mixer Shower

Fittings

Digital Control

Panel

Digital Mixer

Processor

Junction

Box

Hot Inlet

Cold Inlet

Outlet

3Amp switched

fused spur

MUST be easily accessible

To mains

electricity

supply

Digital Processor

to be within

10 metre range

Installation schematic

Examples of poor installation practices

DO NOT install the Digital Mixer Processor unit where it can become frozen

DO NOT install the Digital Mixer Processor unit where it can subjected to ambient

temperatures in excess of 40°C

DO NOT position the Digital Mixer Processor unit where maintenance access is poor or

unsafe

DO NOT install into a system where the cold water cistern holds less than 115 litres (230

litres if other outlets use the same cistern)

DO NOT install into a system where air locking could occur

DO NOT install the wireless Digital Control Panel in a position where communication with

the Digital Mixer Processor unit is poor e.g installed under a metal bath, in front of a metal

cistern, on foil backed plasterboard, outside of the 10 metre range.

DO NOT install the Digital Mixer Processor unit onto shared water supplies

DO NOT fit plastic pipework unless rigidly supported

DO NOT install the low pressure (gravity) Digital Mixer Processor unit less than 100mm from

the lowest level of water in the cistern

DO NOT install a high pressure/combination boiler Digital Mixer Processor unit to a low

pressure pumped gravity system

Mixer processor

installation

Page 22

22

The Digital Controller can be connected to the Digital Mixer Processor unit in two ways,

these are: a) 10 metre data cable or b), wirelessly using AA sized batteries.

The Digital Controller has been designed to allow for the installation within a shower cubical

or above a bath. The controller must be located whereby the user can start and stop the

shower immediately.

Select the desired method of communication and then choose a suitable location for the

Digital Controller.

If using wired connectivity, the distance between the Processor unit and Controller

MUST BE within the range of the 10m data cable.

Data cable installation (Wired Connectivity Only)

If connecting the Digital Controller to the Digital Mixer Processor unit using the data cable,

the first operation is connect the data cable (ferrite end, see fig.13) to the Digital Mixer

Processor unit.

On the ends of both the Data Cable and Processor Data Cable Connector are screw

connectors, which provide a water tight seal. To ensure that the connectors are correctly

assembled and sealed, ALIGN the two arrows on both connectors so that they point

towards one another, and follow the 3 steps in (Fig 13).

A 15mm diameter hole needs to be made within the showering area to allow for the data

cable connection (Fig.14).

Make sure there is enough slack cable at the controller end in order for the Digital Controller

to be removed should the need arise for future maintenance. Approx 150mm protruding

length should be sufficient (Fig 15).

Under NO circumstances should the data cable be extended or shortened. The data

cable must be connected with the ferrite end attached to the processor unit, as

not only will it impair the performance of the shower but it will also invalidate the

guarantee.

1

2

3

Fig. 13

124mm

Ø15mm

Hole

Wall Fixing

Wall Fixing

Data Cable

Fixing

Bracket

Fig. 14

Digital controller

installation

Ferrite

Processor Unit

Page 23

23

If the data cable is being routed through wall cavities, chased into

solid walls or surface mounted then appropriate trunking/conduit

MUST be used. Data cables MUST be fitted in such a way so that they

can later be removed for maintenance or servicing

150mm

Fig. 15

Fixing bracket installation

With the Digital Mixer Processor Unit located and the data cable routed it is now time to fit

the Digital Controller.

Using the fixing bracket and a spirit level locate the bracket in the desired location,

remembering to consider your cable routing position (Fig. 16).

Hold the fixing bracket in position and mark the top and bottom screw fixing holes A (Fig

16). Remove the bracket from the wall then drill and plug the wall for the fixing positions A.

(An appropriate drill bit should be used. If the wall is brick, plasterboard or a soft building

block, appropriate wall plugs and screws should be fitted).

Secure the mounting bracket to the wall using the appropriate fixings.

For Wired Connectivity Only: Whilst securing the mounting bracket to the wall, the data

cable must be pulled through so that approx 150mm protrudes from the wall, see (Fig 15).

A

A

Fig. 16

Digital controller

installation

Page 24

24

If installing the Digital Controller onto a tiled wall, always mount the

xing bracket on the surface of the tiles. NEVER tile up to the Digital

Controller.

Digital Controller fitting (Wired connectivity only)

Remove the Battery Compartment Cover on the rear of the Digital Controller by undoing

the two fixing screws (Fig 17).

Using a pair of side cutters remove from the Battery Compartment Cover the small plastic

tag as shown in (Fig 18).

Connect the 3 pin coupler of the Data Cable Connector Lead into the connector located on

the PCB within the Digital Controller. Taking care, push the connector lead in to the grooves

and slot of the Battery Compartment (Fig 19).

The 3 pin coupler can ONLY be tted one way into the PCB connector,

take care with assembly to avoid damage.

Fig. 19

Fig. 17

Fig. 18

Digital controller

installation

Page 25

25

Replace the Battery Compartment Cover and secure in place using the two fixing screws

previously removed.

Ensure that the Battery Compartment Cover sits flush with the rear housing of the Digital

Controller and that both retaining screws are tight (Fig 20). Do not over tighten the

screws.

Connect the Data Cable Connector Lead from the Digital Controller to the Data Cable

protruding from the fixing bracket (Fig 21).

Fig. 20

On the ends of both the Data Cable and Data Cable Connecting Lead are screw connectors,

which provide a water tight seal. To ensure that the connectors are correctly assembled and

sealed, ALIGN the two arrows on both connectors so that they point towards one another,

and follow the 3 steps in (Fig 22).

Fig. 21

1

2

3

Fig. 22

Digital controller

installation

Page 26

26

Fig. 24

DO NOT turn on the electricity supply to the Digital Mixer Shower

until commissioning

Digital Controller fitting (Wireless Connectivity Only)

Triton recommends that any drilling of holes to secure the wireless Digital Controller is NOT

undertaken until after commissioning, as the exact final location will need to be tested to

ensure that a good, consistent wireless signal is present between the Digital Controller and

Digital Mixer Processor unit.

The approximate position of the wireless Digital Control Panel should be no more than 10

metres from the Digital Mixer Processor unit.

Remove the Battery Compartment Cover on the rear of the Digital Controller by undoing

the two fixing screws (Fig 17).

Fit 3 x AA sized batteries (not supplied) into the Digital Controller as shown in Fig 25.

TRITON recommend the use of Lithium batteries to maximise

battery life of the Digital Controller.

Digital controller

installation

Offer the Digital Controller up to the Fixing Bracket. Whilst doing so push the excess Data

Cable/Data Cable Connection Lead through the hole within the fixing bracket, and back

into the wall cavity.

Fit Digital Controller cut-outs over the Bracket Fixing Lugs (Fig 23) and slide down into

place. Secure with the single screw at the bottom of the Digital Controller (Fig 24). Do not

over tighten the screw.

Control Panel

Cut-Outs

Bracket

Fixing Lugs

Fig. 23

Page 27

27

Make sure the tting of the batteries is carried out correctly

otherwise the PCB within the Digital Controller could be damaged.

Replace the Battery Compartment Cover and secure in place using the two fixing screws

previously removed.

Ensure that the Battery Compartment Cover sits flush with the rear housing of the Digital

Controller and that both retaining screws are tight (Fig 20). Do not over tighten the

screws.

Offer the Digital Controller up to the Fixing Bracket.

Fit Digital Controller cut-outs over the Bracket Fixing Lugs (Fig 23) and slide down into

place. Secure with the single screw at the bottom of the Digital Controller (Fig 24). Do

not over tighten the screw.

Digital controller

installation

1 2

3

Fig. 25

Page 28

28

While the Digital Mixer Shower is in commissioning mode all other

functionality is locked out.

Ensure that the isolating valves on the hot and cold inlets connectors are fully on (Fig.11).

Turn on the water supplies and check the entire installation for water leaks.

Commissioning MUST be carried out with suitable pipework/hose attached to the shower

outlet and with the outlet directed to waste.

Commissioning is to ensure water is purged through the unit and any air is dispelled from

the system.

DO NOT run the low pressure Digital Mixer Shower (Pumped version) without water.

Failure to commission the Digital Mixer Shower correctly could cause

long term damage to the shower.

Turn on the electrical supply to the Digital Mixer Processor unit.

Wireless connectivity only

With batteries fitted into the Digital Controller, electricity supply to the Digital Processor

unit turned on, the wireless connectivity between the Digital Controller and Digital Mixer

Processor unit will be automatically undertaken.

If however either of the messages in Fig. 26 are displayed on the Digital Controller

permanently then wireless connectivity should be undertaken manually.

To manually connect the Digital Controller with Digital Mixer Processor unit, ensure that fully

charged batteries are fitted into the Digital Controller.

1 Isolate the electricity supply to the Digital Mixer Processor Unit

2 After at least 1 minute restore the electricity to the Digital Mixer Processor Unit

3 Within 2 minutes press and hold the ow control buttons together and hold

themdown for at least 5 seconds.

4 Wireless connectivity should now be reset, if this does not resolve the loss of

connection, this process can be repeated.

ºC

4

1

Lost Signal

Symbol

Connection Error!

Fig. 26

Commissioning

Page 29

29

Procedure

The message in Fig.28 will be displayed on the Digital Controller. To begin the

commissioning procedure, press the ‘Start/Stop’ button (Fig.27).

Allow the unit to run for five minutes to dispel any air in the system and to prime both

supplies to the unit.

Press and hold outlet 2 ( symbol) for 5 seconds when the commissioning process is

complete, this will set the Digital Mixer Shower into normal operation mode.

It may be necessary to repeat the commissioning procedure , i.e following servicing or

maintenance.

This can be reactivated from the configuration menu. Refer to the ‘Settings and

configuration’ section within the user guide.

ENSURE that the position of the wireless Digital Controller is within a

10 metres range of the Digital Mixer Processor unit.

If the symbols in Fig. 26 are still displayed, then a repositioning of the Digital Controller

is required. Ensure that a good, consistent wireless signal is present between the Digital

Controller and Digital Mixer Processor unit.

During the commissioning mode, the pump is disabled (LP gravity version only), Outlet 1 is

opened, flow control is set to maximum and temperature control is set in mid position.

DO NOT run the low pressure Digital Mixer Shower (Pumped version)

without a water supply for longer than 5 minutes.

Flow Control

Buttons

Fig. 27

Start/Stop

Button

Commissioning

Fig. 28

Commissioning

Mode

PRESS TO

START SHOWER

HOLD FOR

5 SECONDS

WHEN COMPLETE

Page 30

30

Press the start

button to activate

the shower

Alternatively, select

your preferred preset,

‘Relax / User 1’ ( ) or

‘Energise / User 2’ ( )

Adjust the ow rate

with the decrease ( )

and increase ( )

buttons.

Adjust the temperature

with the temperature

dial

Select between your two outlets*

using the outlet buttons ( ) /

( )or press both to run them at

the same time

1

To power down the shower, press

the start button , or

alternatively deselect the outlets

using buttons ( ) / ( )

2 3

4 5

Quick start

(*outlet selections are only available on multi outlet product versions)

Page 31

31

If the Digital Mixer Processor unit is dismantled for any reason during servicing or

maintenance, then it MUST be inspected to ensure there are no leaks, it is also advised to

follow the commissioning procedure to ensure no air has become trapped during the work.

Cleaning

Many household cleaners contain abrasive and chemical substances, and should not be

used for cleaning the Digital Controller or any chrome plated fittings. It is recommended

that your Digital Mixer Shower system is cleaned regularly with warm, soapy water using a

micro bre cleaning cloth (eg: E-cloth) or sponge ONLY.

DO NOT use a general purpose cleaning cloth (eg: J-cloth) dish cloth or scourer.

DO NOT use abrasive or aggressive chemical cleaning products as this may aect the

product surface nish and invalidate your guarantee..

It is recommended that the filter is periodically cleaned in order

to maintain the performance of the shower. It is essential that this

operation is carried out by a competent person.

Cleaning the filters

Using an appropriate flat bladed screwdriver, isolate both the hot and cold inlet valves

(Fig. 11).

Isolate the electricity supply to the Digital Mixer Processor unit.

Unscrew the inlet nut and remove the inlet pipe, O ring seal, ow regulator housing/Inlet

lter.

Remove the inlet lter from the ow regulator housing (Fig. 28) and wash thoroughly under

running water to remove all debris.

Ret the ow regulator housing/Inlet lter, O ring seal and inlet pipe, secure with the inlet

nut. Note: the inlet nut only requires to be hand tightened.

Flow Regulator

Housing/Inlet Filter

O Ring

Seal

Inlet

Pipe

Inlet Nut

Flow Regulator

Housing/Inlet Filter

Non Return

Valve

Fig.28

General

maintenance

Page 32

32

8

2

4

5

6

7

15

11

14

12

10

13

1

3

9

Spare parts

Page 33

33

Ref. Description Part No.

1. Temperature Control Valve

Low pressure ....................................................................................................... 83316750

High pressure ..................................................................................................... 83316760

2. Digital Mixer Processor PCB

Single Outlet ........................................................................................................ 7073756

Multi Outlet ........................................................................................................... 7073763

3. Temperature Control Motor ........................................................... 22013594

4. Flow Control Valve ....................................................................................... 83316770

5. Flow Control Motor .................................................................................... 22013595

6. Thermistor Assembly .............................................................................. 83316780

7. Solenoid Assy & O Ring Seals ........................................................ 83316800

8. Pump Assembly .............................................................................................. 83316790

(Low Pressure Digital Mixer Processor Only)

9. Check Valve and Inlet Filter Pack .............................................. 83316810

10. Digital Controller

Black Finish ............................................................................................................ 83316820

White Finish .......................................................................................................... 83316830

Cloud Grey Finish ............................................................................................ 83316840

11. Battery Cover & Screws Assembly

Black Finish ............................................................................................................ 83316720

White Finish .......................................................................................................... 83316710

Cloud Grey Finish ............................................................................................ 83316730

12. Digital Controller Fixing Bracket ............................................... 83316740

13. Digital Controller Fixing Screw ................................................... 20801180

14. 10m Data Cable ............................................................................................... 2160636

15. Data Cable Connection Lead .......................................................... 2160634

Spare parts

Page 34

34

Digital Mixer

Shower will not

turn on/no water

flow

Interrupted power

supply

Blown fuse or circuit breaker. Check

supply Renew or reset fuse or circuit

breaker. If it fails again, consult a

qualified electrician

Power cut? Check other appliances and

if necessary, contact local Electricity

Supply Company

Batteries in Digital

Control panel are flat

(wireless only)

Fit new batteries, refer to ‘Digital

Control Panel Installation’

Digital Control panel is

installed out of range

(wireless only)

Reposition the Digital Control Panel,

refer to ‘Digital Control Panel

Installation’

Inlet Isolating valves

not fully open

Check if isolating valves are fully open

Inlet filters or check

valves blocked

Check for a blockage, refer to

‘Maintenance’

Air lock in water

supplies (LP unit

only)

Purge air from hot and cold supplies to

the connectors on the mixer unit, see

‘Commissioning’

Failure of either water

supply

Check water elsewhere in the house

and, if necessary, contact the local water

company

Loss of wireless

connection between

control Panel and

Processor unit

(wireless connectivity

only)

Repeat wireless connectivity process, see

‘Commissioning’

Unit malfunction Contact Triton Customer Service

Problem/Symptom Cause Action/Cure

If any maintenance is required then it MUST be carried out by a competent trade person

or a Triton Engineer. ENSURE that the underlying cause of malfunction is resolved before

replacing any parts

IMPORTANT - Isolate the electricity supply and remove the circuit

fuse before attempting any fault diagnosis inside the Digital Mixer

processor

Fault diagnosis

Page 35

35

Water too cool

or cold

Temperature setting

too low

Increase temperature via rotary

temperature control. See ‘Quick Start’

‘Max Shower Temp’

setting set to low

Increase Max Shower Temp setting,

refer to ‘Configure Settings’ in the user

manual

Supply temperature

below 50°C

Set system temperature to a minimum of

55°C, see ‘Specification

Water pressure above

maximum specified or

imbalanced

Check water pressures are normally equal,

refer to ‘Specification’

Combination boiler

cutting in/out

Check the use of flow regulators, see

‘Typical Suitable Installations’

Insufficient supply of

stored hot water

Check storage capacity of hot water, see

‘Typical Suitable Installations’

Air lock in Digital

Mixer Processor unit

(LP unit only)

Prime to remove air from the mixing unit,

see ‘Commissioning’

Inlet supply

connection reversed

Check and if necessary correct, see

‘Digital Mixer Processor Installation’

Outlet pipe run is too

long

Ensure outlet pipe is thermally lagged,

see ‘Digital Mixer Processor Installation’

Low Flow Rate Flow setting too low

Increase flow by pressing the flow

increase button, see ‘Quick Start

Inlet Isolating valves

not fully open

Check if isolating valves are fully open

Blockage in inlet filters

or check valves

Check for a blockage, refer to

‘Maintenance

Blockage in pipework

Turn off the shower and consult a suitably

competent plumber

Blocked showerhead

or hose

Clean sprayplate or replace blocked hose

Inlet water pressure

low

Check if sufficient water pressure, see

‘Specifications

Problem/Symptom Cause Action/Cure

Fault diagnosis

Page 36

36

Low Flow Rate

Air lock in Digital

Mixer Processor unit

Prime to remove air from the mixing unit,

see ‘Commissioning’

Hot inlet flow

regulator not suitable/

wrongly fitted

Check and refer to ‘Typical Suitable

Installation’

Shower stops

during showering

Maximum showering

time reached

Restart the shower by pressing the ‘Start’

button, refer to ‘Configure Settings’ in

the user manual

Loss of wireless

connection between

digital Control Panel

and Processor unit

(wireless connectivity

only)

Repeat wireless connectivity process, see

‘Commissioning’

Loss of either water

supply

Check water elsewhere in the house

and, if necessary, contact the local water

company

Check that water is available to the

shower when other outlets are in use

Wait for stored water to reach

temperature

Air lock in Digital

Mixer Processor unit

Check for correct installation, repeat

priming to remove air from the mixing

unit, see ‘Commissioning’

Combination boiler

cutting in/out

Check the use of flow regulators, see

‘Typical Suitable Installations’

Digital Control

Panel is not very

responsive

Loss or Poor wireless

signal between Digital

control Panel and

Processor unit

Check wireless connectivity, see

‘Commissioning’

Unit malfunction Contact Triton Customer Service

Shower Pulsing

(HP mixer unit on

combination boiler)

Water supply

temperature too low

Increase domestic hot water

temperature

Unbalanced water

pressures

Fit a pressure reducing valve in the cold

supply to the mixer and set to the same

pressure as the hot supply

Problem/Symptom Cause Action/Cure

Fault diagnosis

Page 37

37

Noise

Air lock in Digital

Mixer Processor unit

Check for correct installation, repeat

priming to remove air from the mixing

unit, see ‘Commissioning’

Water hammer

Ensure all pipework is securely fixed, see

‘General Installation Information’

Unit malfunction Contact Triton Customer Service

Problem/Symptom Cause Action/Cure

Fault diagnosis

Page 38

38

WEEE Directive – Policy Statement

As a producer and a supplier of electric showers, Triton Showers is committed to the protection of the environment

via our own environmental policy and the compliance with the WEEE directive.

Triton Showers is fully registered with the Environment Agency under the following schemes:

Repic: Producers take-back scheme (PTS), registration number WEE/EJ3466QV

Valpak: Distributor take-back scheme (DTS), registration number 9659

All our electric products are labelled accordingly with the crossed out wheeled bin symbol. This indicates, for

disposal purposes at end of life, that these products must be taken to a recognised collection points, such as

local authority sites/local recycling centres; this will be free of any charges. Do not return to Triton Showers.

Batteries

Spent batteries should NOT be disposed of with your normal household waste

NEVER dispose of batteries in fire as this may cause them to explode

ALWAYS dispose of batteries in an environmentally friendly manner and in accordance

with local regulations

Disposal and

recycling

Page 39

39

In the event of a product fault or complaint occurring,

the following procedure should be followed:

DO NOT REMOVE THE PRODUCT

1. Telephone Customer Service on 024 7637 2222 having

available your details including post code, the model number

and power rating of the product, together with the date of

purchase and, where applicable, details of the particular fault.

2. If required, the Customer Service Advisor will arrange for a

quali ed engineer to call.

3. All products attended to by a Triton service engineer must be

installed in full accordance with the Triton installation guide

applicable to the product. (Every product pack contains an

installation guide, however, they can also be downloaded free at

www.tritonshowers.co.uk).

4. Our engineer will require local parking and if a permit is

required, this must be available to the engineer on arrival at the

call.

5. It is essential that you or an appointed representative (who must

be over 18 years of age) is present for the duration of the service

engineer’s visit. If the product is in guarantee you must produce

proof of purchase.

6. Where a call under the terms of guarantee has been booked

and the failure is not product related (i.e. scaling and furring,

incorrect water pressure, pressure relief device operation or

electrical/plumbing installation fault) a charge will be made. A

charge will also be issued if nobody is at home when the service

engineer calls or adequate parking/permit is not available.

7. If the product is no longer covered by the guarantee an

up-front xed fee will be charged before the site visit.

8. Your receipt must be retained as proof of purchase. Should proof

of purchase not be available on an ‘in-guarantee’ call, or should

the service engineer nd that the product is no longer under

guarantee, the engineer will charge the same xed price and the

customer will be expected to pay the engineer before he leaves.

If payment is not made on the day an administration charge will

be added to the xed charge.

9. If a debt is outstanding from a previous visit, or from any other

Triton purchase, Triton reserves the right to withhold service until

the debt has been settled.

10. Triton takes the health, safety and wellbeing of its employees

very seriously and expects customers to treat all staff members

with respect. Should any employee feel threatened or receive

abuse, either verbally or physically, Triton reserves the right to

withhold service.

Replacement Parts Policy

In line with AMDEA guidelines, Triton retains functional spares

for as long as there is a market for them and in most cases, well

beyond. Due to the vast array of product types, the life cycle of

products can vary and therefore so can the length of time parts

can be supplied. Spare parts can be ordered via our online spare

parts store or by telephoning Triton Customer Service Spares

Department on 024 7637 2222. Payment should be made by

credit / debit card (excluding American Express or Diners Card).

Payment can also be made by pre-payment of a pro-forma

invoice, by cheque or postal order.

Telephone orders are based on information given during

the call. Before contacting Triton, please verify your

requirements using the Information contained in the

user guide. Triton cannot accept liability for incorrect part

identi cation.

TRITON STANDARD GUARANTEE

With the exception of accessories, Triton guarantee the

product against all manufacturing defects for a period of

5 years (for domestic use only) from the date of purchase,

provided that it has been installed by a competent person in

full accordance with the tting instructions.

All accessories such as shower heads, hoses and riser rails

carry a 1 year parts only guarantee against manufacturing

defects.

Any part found to be defective during this guarantee period

we undertake to repair or replace at our option without

charge, so long as it has been properly maintained and

operated in accordance with the operating instructions and

has not been subject to misuse or damage. This product must

not be taken apart, modi ed or repaired except by a person

authorised by Triton. This guarantee applies only to products

installed within the United Kingdom and does not apply to

products used commercially. This guarantee does not affect

your statutory rights.

What is not covered:

1. Breakdown due to:

a) use other than domestic use by you or your resident

family;

b) wilful act or neglect;

c) any malfunction resulting from the incorrect use or

quality of electricity, gas or water or incorrect setting of

controls;

d) failure to install in accordance with this installation

guide.

2. Claims for missing parts once the product has been

installed.

3. Repair costs for damage caused by foreign objects or

substances.

4. Total loss of the product due to non-availability of parts.

5. Compensation for loss of use of the product or

consequential loss of any kind.

6. Call out charges due to an abortive visit or where no fault

has been found with the appliance.

7. The cost of repair or replacement of isolating switches,

electrical cable, fuses and/or circuit breakers or any other

accessories installed at the same time. Replacement of the

Pressure Relief Device that only activates when the shower

outlet is blocked is also excluded.

8. The cost of routine maintenance, adjustments, overhaul

modi cations or loss or damage arising therefrom,

including the cost of repairing damage, breakdown,

malfunction caused by corrosion, furring, frost or

exposure to freezing conditions.

9. Call out charges where the water supply cannot be

isolated, this includes consequential losses arising from

unserviceable supply valves.

For the latest Terms & Conditions please see:

www.tritonshowers.co.uk/terms

UK SERVICE POLICY

Guarantee and

service policy

Page 40

Triton Showers

Triton Road

Nuneaton

Warwickshire

CV11 4NR

Installer Hotline:

+44 (0) 2476 378 320

Customer Services:

+44 (0) 2476 372 222

Email:

technical@tritonshowers.co.uk

enquire@tritonshowers.co.uk

Website:

tritonshowers.co.uk

Brochure enquiries:

+44 (0) 24 7632 4460

Triton Showers is a division of

Norcros Group (Holdings) Limited.

Triton Showers, Triton Road, Nuneaton,

Warwickshire CV11 4NR

It is our policy to improve the design and specification of our products and we reserve the right to depart from the design

given without prior notice.

#rstthing

Loading...

Loading...