Page 1

0

d

0

D

0

7

C

.

u

a

l

c

o

n

t

r

o

A

n

t

i

l

q

u

e

m

i

x

e

O

F

N

F

O

T

R

S

R

I

E

T

O

W

N

O

S

H

C

O

T

O

L

D

H

o

r

h

s

w

.

r

e

Installation and Operating Instructions

INSTALLERS PLEASE NOTE THESE INSTRUCTIONS ARE TO BE LEFT WITH THE USER

2180290B May 2000

Page 2

DC7000 ANTIQUE

UKAS

QUALITY

MANAGEMENT

003

Page 3

DC7000 ANTIQUE

CONTENTS Page

Introduction 2

Safety warnings 2

Main components and pack contents 3

Site requirements 4

Temperature adjustment range 5

Preparing and siting of the shower 6

Installation – general 7 - 8

Installation

solid wall 9

hollow wall 10

cubicle or panel 11

Connecting the supply pipes 12

Fitting Showerhead 13

Using the tiling shroud 14

Fitting the face plate and knobs 14 -15

Commissioning 16 - 17

Operating the shower 17

Maintenance 18 - 19

Spare Parts 20

Inspection and maintenance record 21

Fault finding 22

Guarantee, service policy, etc. rear cover

1

Page 4

DC7000 ANTIQUE

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your Triton dual control

mixer shower. Please read them carefully. Read

through the whole of this book before beginning

your installation.

The shower installation must be carried out by a

suitably competent person and in sequence of this

instruction book.

Care taken during the installation will ensure a

long and trouble free life from the shower.

This thermostatic shower valve has been

independently tested and approved to all the

requirements of

Specification D08 Thermostatic Mixing Valves

(Healthcare Premises) to the following

designations and for the following applications:

HP-S Shower with supply pressures of

LP -S Shower with supply pressures of

For optimum performance within the specified

running pressure range a minimum flow of 8 litres

per minute should be available to both inlets.

The valve is suitable for fully modulating

type combination boilers and multi-point hot

water heaters. Also suitable for thermal

storage, unvented systems and pumped

gravity systems.

Important: Before installing with a gas

instantaneous water heater, ensure the

appliance is capable of hot water delivery at

a minimum switch on flowrate of 3 litres per

minute. At flow rates between 3 and 8 litres

per minute the appliance must be capable of

raising the water temperature by 45°C.

Water temperature at the inlet to the mixer

must remain relatively constant when

flowrate adjustments are made.

The valve unit can be fitted in any orientation. For

a wall mounted sprayhead installation, the

plumbing will be simplified if the outlet is fitted

upwards.

The valve is supplied with an integral single check

valve and integral large area filter on each inlet.

Inlet connections are by compression fittings for

NHS Estates Model Engineering

1 - 5 Bar and unrestricted flow rate.

0.2 - 1 Bar and unrestricted flow rate.

15mm copper pipe.

This valve unit is supplied with a mounting bracket

to suit installation in a chased out cavity in a solid

wall, a stud partition wall, dry lined wall or fixing

to a shower cubicle or panel. It is also supplied

with an attached tiling shroud which provides

protection for the unit.

SAFETY WARNINGS

1

Layout and sizing of pipework must be such

that when other services are used, pressures

at the shower control inlets do not fall below

the recommended minimum.

2 DO NOT choose a position where the shower

could become frozen.

3 The outlet of this appliance must not be

connected to any form of tap or fitting not

recommended by the manufacturer.

4 The sprayhead must be cleaned regularly to

remove scale and debris.

5 Conveniently situated isolating valves in each

inlet supply must be fitted as an independent

method of isolating the shower should

maintenance or servicing be necessary.

6 If it is intended to operate the shower in areas

of hard water it is advisable to fit a scale

inhibitor.

7 If it is intended to operate the shower outside

the guidelines laid out in the requirements

then see NOTE below.

NOTE: In the event of items 2 and 7, contact

Triton Customer Service for advice.

Tel: (024) 7637 2222.

Replacement parts can be ordered from Triton

Customer Service. See

part numbers.

Due to continuous improvement and updating,

specification may be altered without prior notice.

‘spare parts’ for details and

2

Page 5

DC7000 ANTIQUE

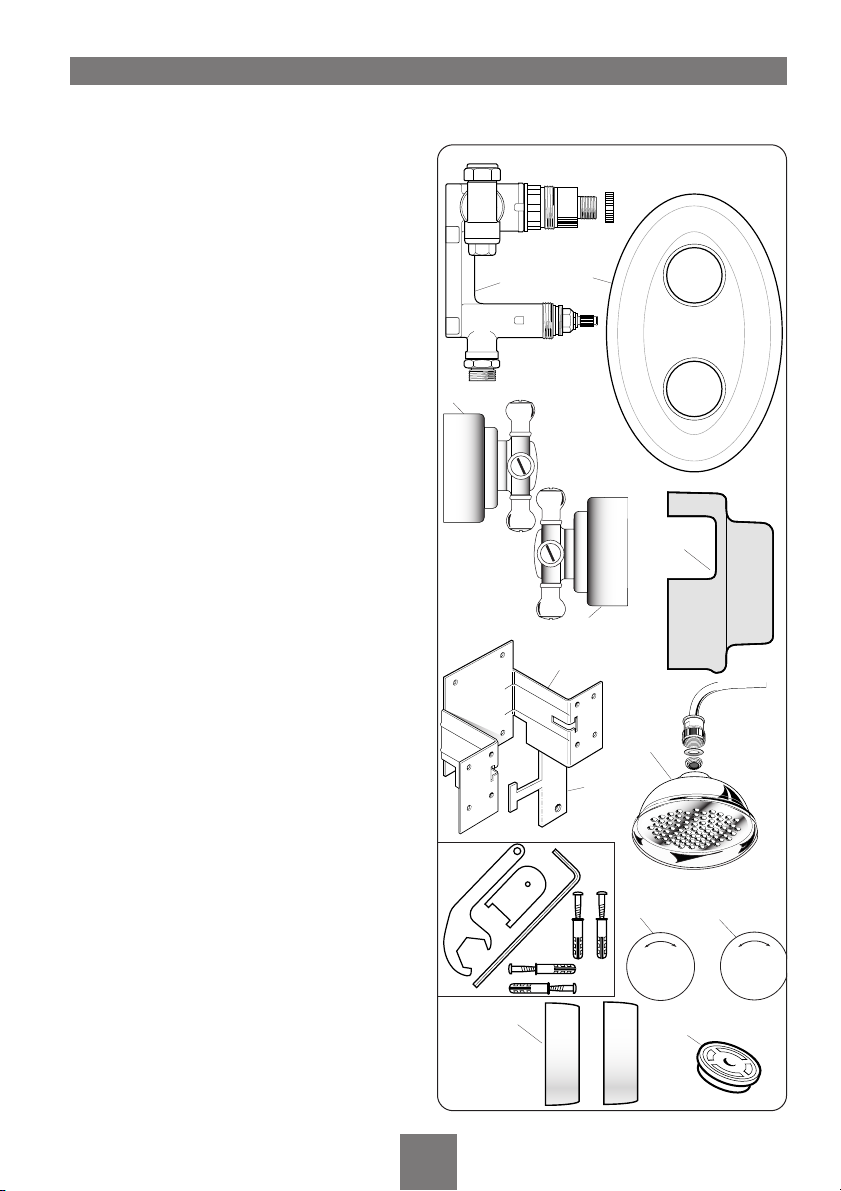

MAIN COMPONENTS and PACK CONTENTS

1 Mixer valve body

2 Face plate

3 Temperature control knob

4 On/off control knob

5 Tiling shroud

6 Mounting bracket

7 Flat bracket - 2 off

8 Sprayhead and arm

9 Tool and screw pack

10 Ceramic on / off cap

11 Ceramic temperature cap

12 Trim rings

13 Flow limiter

- Face plate template

Fig.1

1

2

3

5

4

6

8

7

9

12

10

N

O

T

R

I

11

O

F

F

S

R

E

T

W

O

O

N

H

S

C

O

T

O

L

D

H

13

3

Page 6

DC7000 ANTIQUE

H

O

T

C

O

L

D

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

2 metres

minimum

Isolating

valves

Other draw-offs

Gate

valve

Vent pipe

tee

Cold supply

Hot

supply

Alternative

connection

Mixer valve

Stop

tap

Cold

water

mains

supply

Hot

water

cylinder

Drain

valve

Cold water

cistern

H

O

T

C

O

L

D

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

CH flow

Cold mains supply

Hot

water

CH return

Service

valves

Mixer

valve

Stop tap

Pressure

reducing

valve

Combination

boiler

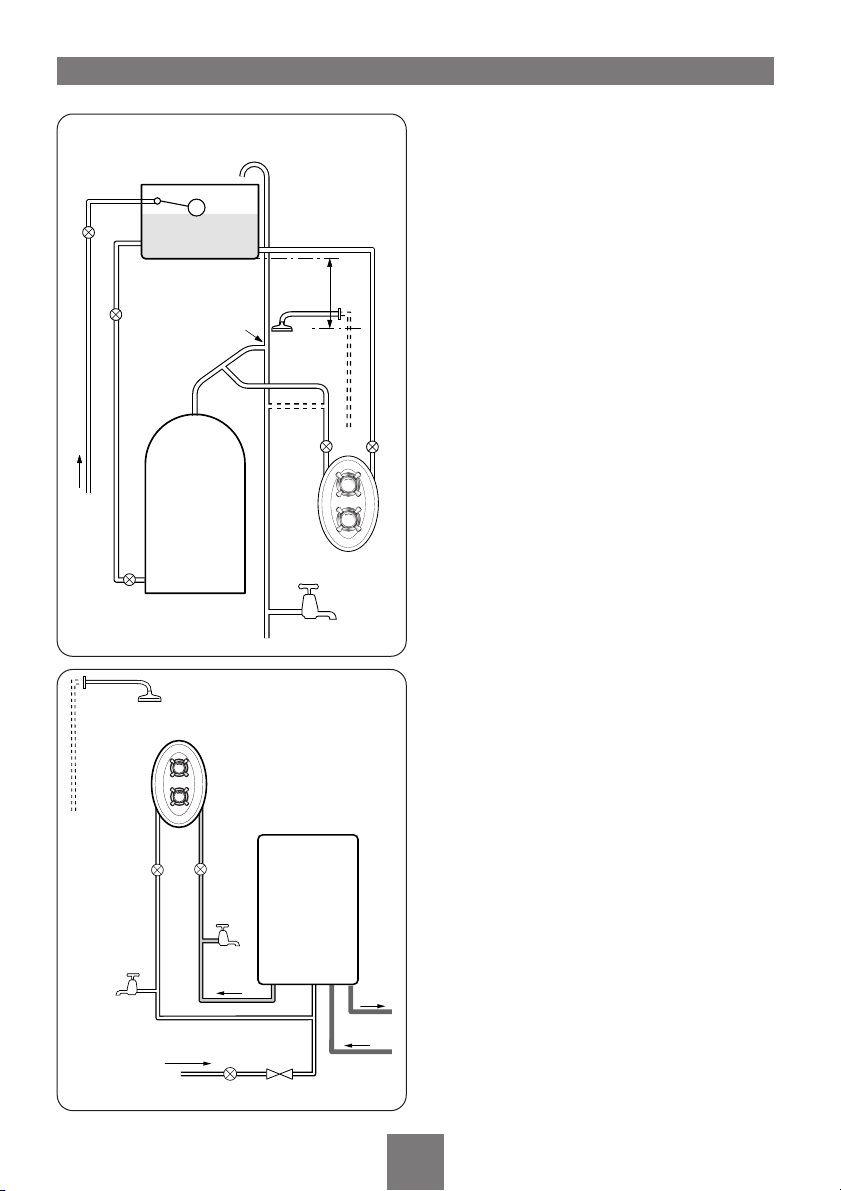

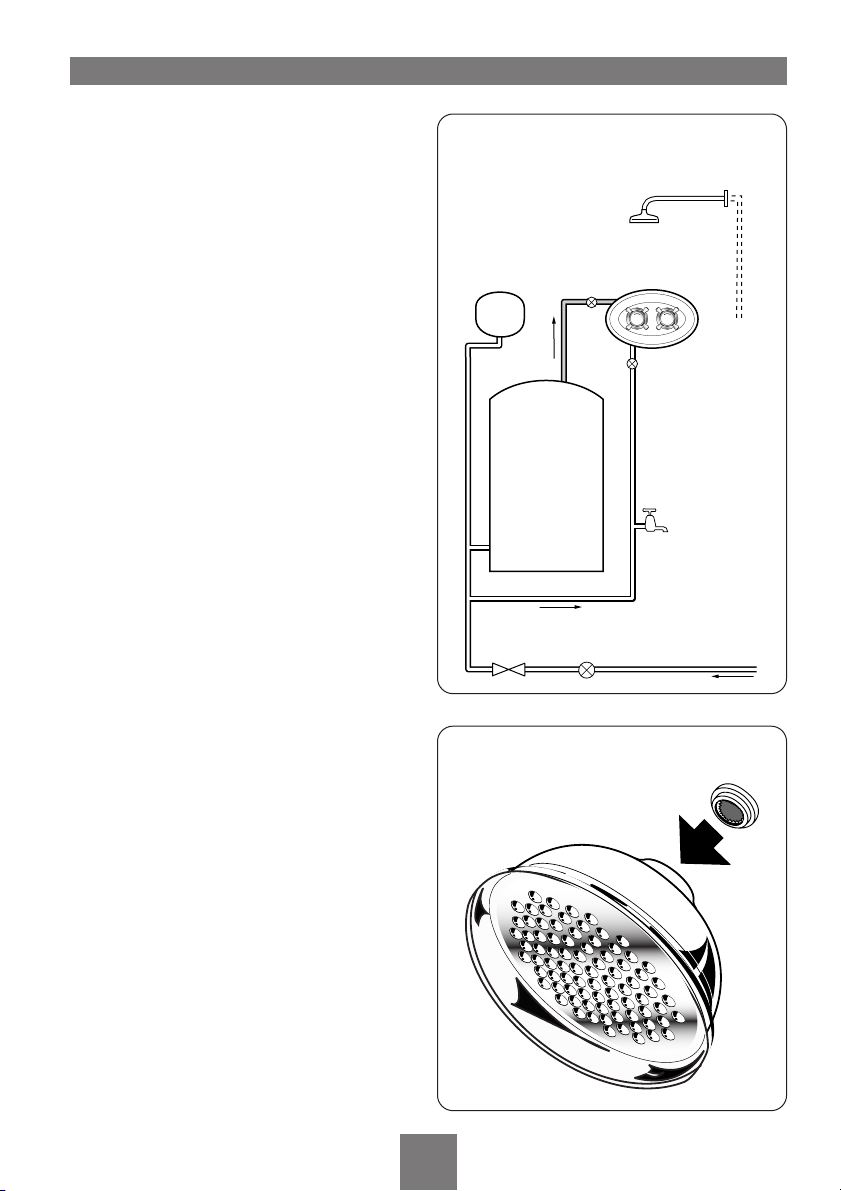

Fig.2 (diagrammatic view – not to scale)

Fig.3 (diagrammatic

view – not to scale)

SITE REQUIREMENTS

The installation must be in accordance with Water

Regulation Byelaws and BS6700.

Minimum running water pressure: 0.2 bar.

Maximum running water pressure: 5 bar.

Maximum static water pressure: 10 bar.

For optimum performance within the specified

running pressure range a minimum flow of 8 litres

per minute should be available to both inlets.

Whilst the mixer valve is operational (open outlet),

inlet pressures must not be capable of exceeding 7

bar. For effective operation of the internal seals,

the maximum static pressure must not be

exceeded.

NOTE: On sites where the running pressure is

above 5 bar, the use of a suitably sized pressure

reducing valve fitted in the cold mains supply

pipework can provide nominally equal pressures at

the mixer valve.

For optimum performance of this shower both hot

and cold water supplies to the shower valve

should be fed at nominally equal pressures.

The pipework should be installed such that the

flow is not significantly affected by other taps and

appliances being operated elsewhere on the

premises.

NOTE: Where thermal store/combi boilers or

multi-point heaters are used, if excessive draw offs

take place the boiler may not be able to maintain

an adequate output temperature. This could result

in the shower temperature becoming noticeably

cooler.

Water temperature requirements

Maximum hot water temperature 80°C

Recommended maximum 65°C

Minimum hot water temperature 52°C

Maximum cold water temperature 20°C

BS6700 recommends that the temperature of

stored water should never exceed 65°C.

A stored water temperature of 60°C is considered

sufficient to meet all normal requirements and will

minimise the affects of scale in hard water areas.

4

Page 7

TEMPERATURE ADJUSTMENT RANGE

H

O

T

C

O

L

D

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

Service

valves

Balanced cold mains supply

Hot

supply

Cold mains supply

Mixer

valve

Expansion

vessel

Pressure

reducing valve

Stop

tap

Unvented

hot water

storage unit

(safety devices

not shown)

The mixed water temperature can be adjusted

from cold through to a top limit (which can be

pre-set during installation – factory set at

approximately 39°C), with full anti-scald

protection throughout the range.

Fig.2 shows a typical gravity fed installation. (The

distance between the bottom of the cold water

cistern and the sprayhead must be at least 2

metres).

Fig.3 depicts a typical combination boiler

installation.

Fig. 4 illustrates an unvented mains pressurised

hot water storage system.

DO NOT use jointing compounds on

pipework.

INSTANTANEOUS WATER HEATERS

APPLIANCE CAPABILITIES

In order to ensure the optimum performance from

the shower when connected to an instantaneous

water heater, the appliance must be capable of

raising the temperature of the incoming water by

45°C (81°F) and delivering a flow rate of not less

than 8 litres per minute.

A flow limiter is supplied for the insertion into the

shower head which controls the maximum flow of

8 litres per minute.

To fit the flow limiter unscrew the shower head

from the ball joint. Insert the flow limiter flat face

up into the shower head (fig.5) fit the flat face

washer and refit the shower head to the ball joint.

With the flow limiter fitted and when the system

is in use, the on/off flow control should be turned

fully anti-clockwise to full flow setting.

DC7000 ANTIQUE

Fig.4

(diagrammatic view – not to scale)

Fig.5

5

Page 8

DC7000 ANTIQUE

H

O

T

C

O

L

D

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

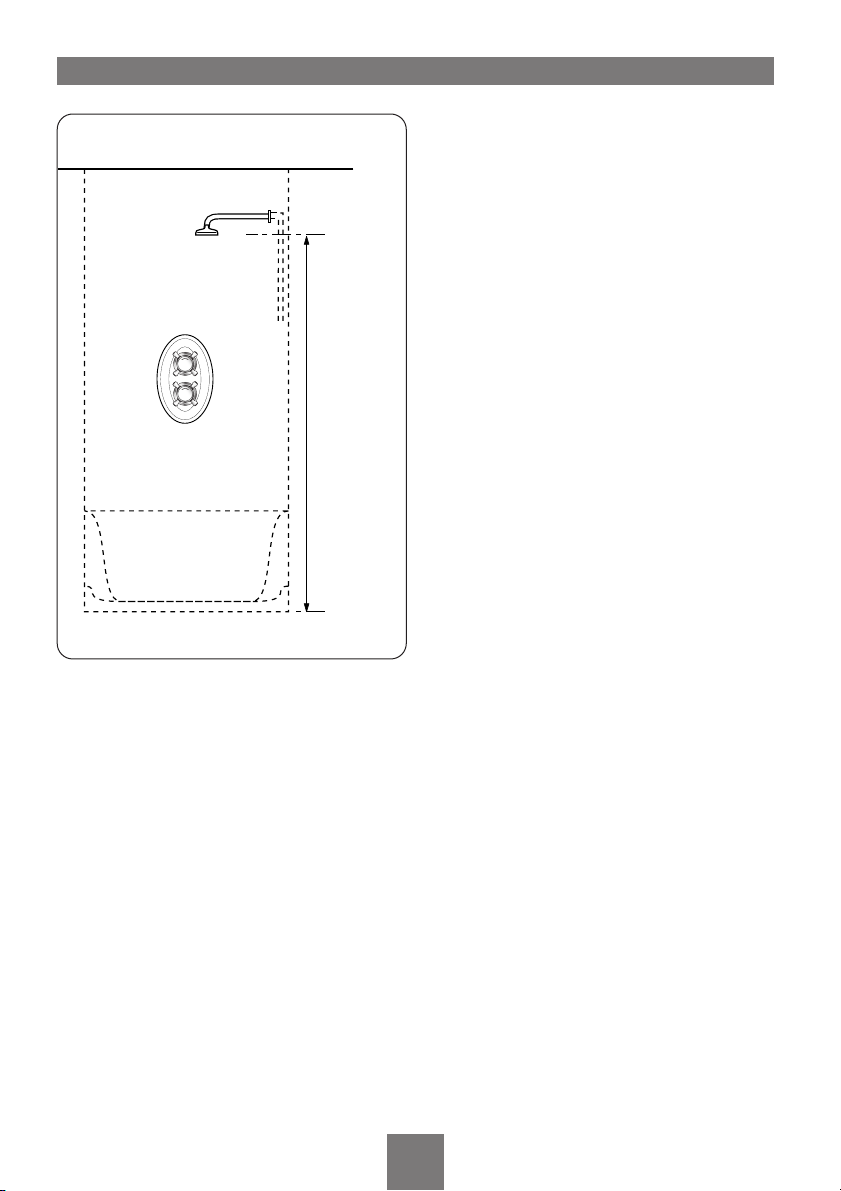

Height of

sprayhead

and shower

to suit user’s

requirement.

Shower can

be mounted

either side of

the shower head.

Fig.6 (diagrammatic view – not to scale)

PREPARING THE MIXER VALVE

Check the contents to ensure all parts are present.

Ensure the supplied metal fixing bracket, tiling

shroud, cranked spanner, lock nut key and allen

key are all to hand.

Before commencing the installation, make sure all

the apertures on the valve are carefully covered to

prevent ingress of any debris etc.

The valve unit is supplied with a mounting bracket

to suit installation in a chased out cavity in a solid

wall, a stud partition wall, dry lined wall or fixing

to a shower cubicle or panel. It is also supplied

with an attached tiling shroud which provides

protection for the valve both for transit and on

site. It should be left on at all times until such time

when it is being installed.

The hot and cold water pipes should not be

permanently attached to the wall closer than 2m

from the valve prior to installation to allow for

final adjustment of the valve position.

SITING OF THE SHOWER

WARNING:

THE SHOWER MUST NOT BE

POSITIONED WHERE IT WILL BE SUBJECT TO

FREEZING CONDITIONS.

Refer to fig.6 for correct siting of the shower.

Position the shower and sprayhead on the wall so

that all controls can be comfortably reached whilst

using the shower. The spray head can be

positioned either side of the shower.

The valve unit can be fitted in any orientation. For

a wall mounted sprayhead installation, the

plumbing will be simplified if the outlet is fitted

upwards.

6

Page 9

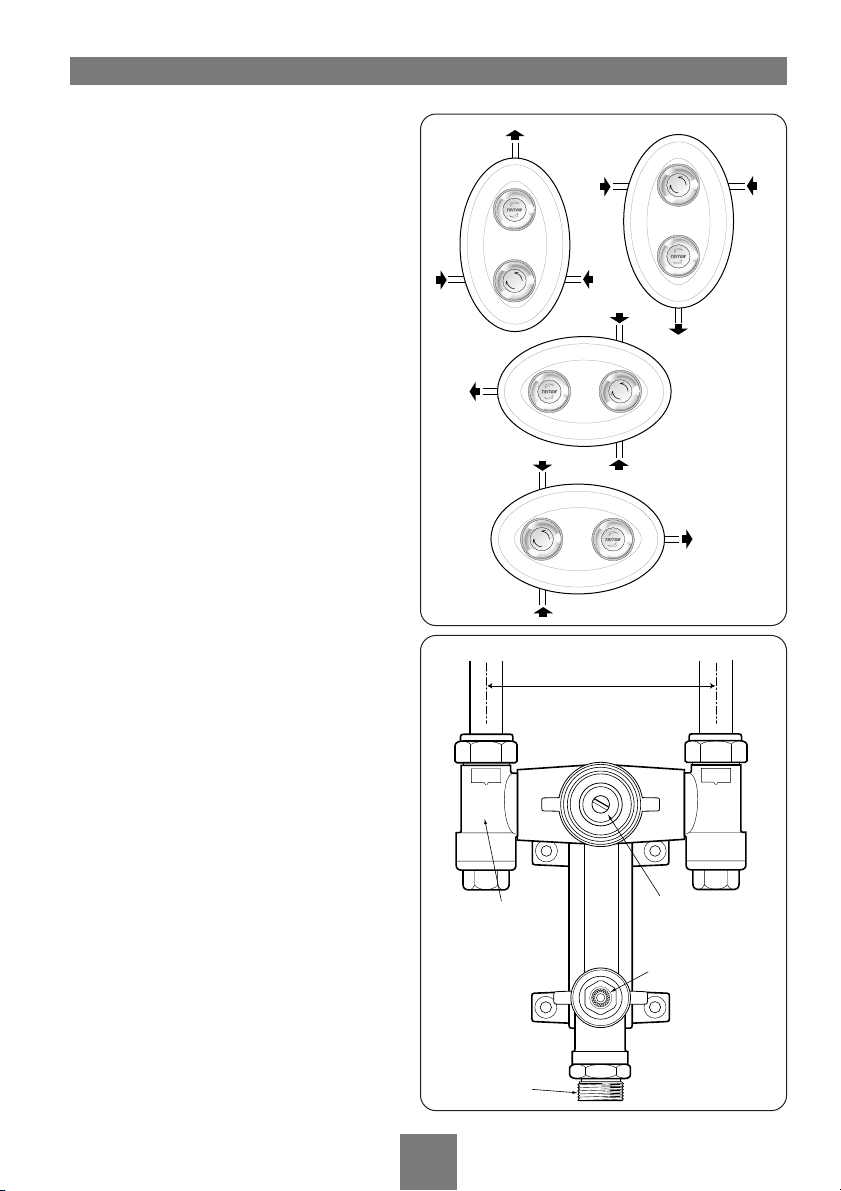

115 mm

pipe centres

Cold water supply

Hot water supply

Thermostatic

assembly

On/off

assembly

Swivel inlet

(Do not tighten

against body)

Mixed water

outlet

INSTALLATION

H

H

H

Outlet

C

C

C

H

Outlet

Outlet

Outlet

C

a) General conditions

NOTE: The outlet of the shower must not be

connected to any tap or fitting not

recommended by Triton Plc.

DO NOT use jointing compounds on any pipe

fittings for the installation.

Use only the compression fittings supplied. DO

NOT solder fittings within the vicinity of the

valve unit as heat transfer can damage the seals

and thermostatic components.

NOTE: Suitable isolating valves (complying with

Water Regulation Byelaws) MUST be fitted on

the hot and cold water supplies to the shower

as an independent means of isolating the water

supplies should maintenance or servicing be

necessary.

When connecting pipework avoid using tight

90° elbows. Swept or formed bends will ensure

optimum performance.

The valve unit can be fitted in any orientation

(fig.7), but for a wall mounted sprayhead

installation, the plumbing will be simplified if

the outlet is fitted upwards. Access to the

integral strainers will also be improved with this

configuration.

The hot water inlet is identified with a red mark,

the cold water inlet with a blue mark. The

swivel inlets allow for either rising or falling hot

and cold water supplies. Note the swivel inlets

have ‘O’ seals to the body and do not require

PTFE tape or other means of sealing.

Gently screw the swivel inlets into the body of

the valve unit and stop as soon as resistance is

felt. Then back off by up to 1.5 turns to align

the inlet with the hot and cold supply pipes.

THE SWIVEL INLETS MUST NOT BE TIGHTENED

AGAINST THE VALVE BODY TO MAKE A SEAL

(fig.8).

The Triton dual control mixer valve includes a

mounting bracket which allows the installer to

mount the shower into a solid, stud partition or

other hollow wall structures. The bracket can

also be used for fitting in a shower cubicle or

panel providing the back of the cubicle or panel

is accessible.

DC7000 ANTIQUE

Fig.7

Fig.8

7

Page 10

Wall surface

65 mm

Tolerance

for varying

tile thickness

Tiles

Fig.9

DC7000 ANTIQUE

When installing into a stud partition or other

hollow wall structure the installer may wish to

consider fabricating rear supports or other

options. Such options are beyond the scope of this

guide.

Before starting, ensure the available depth of

recess or cavity is at least 65 mm (fig.9) measured

from the face of the wall upon which the

mounting bracket is screwed (excluding the tile

thickness).

The allowance for varying thickness of tiles up to

10mm is accommodated by a limited degree of

tolerance between the control knobs and their

trim rings.

If the valve unit is to be fitted behind an existing

wall panel, use the supplied self-adhesive template

(fig.16) as a guide when cutting the aperture.

8

Page 11

DC7000 ANTIQUE

135 mm

maximum

235 mm

maximum

b) Valve installation in a solid wall

Remove the tiling shroud if fitted to the valve unit.

The shroud is retained by a 2.5mm hex socket

screw, replace the screw in the valve immediately

to avoid it being lost.

Decide on the shower position and determine

whether the hot and cold water supplies will enter

the shower from the top (falling) or bottom

(rising) or rear.

The building depth should be at least 70mm deep

from the surface of the wall. It is recommended to

use the supplied mounting bracket (fig.10) at all

times when installing the shower valve. It provides

the correct visible amount of shower control

through the face plate when the installation is

complete. There is limited tolerance between the

control knobs and trim rings to allow for varying

thickness of tiles up to 10mm.

As a guide for the size of hole, place the tiling

shroud on the wall and trace around it (fig.11).

Remove the plaster and brickwork to the required

depth and chase out any additional areas of the

wall to facilitate pipework to and from the valve.

Offer the mounting bracket up to the wall and

mark the four outer plain holes (fig.12). Remove

the bracket then drill and plug the wall. Screw the

bracket to the wall. Route the pipework to valve

position.

Flush out the pipework in accordance with

Water Regulation Byelaws .

Offer the valve up to the mounting bracket, and

secure using the four screws provided.

Proceed to ‘connecting supply pipes’ section.

Fig.10

Fig.11

Fig.12

9

Page 12

Flat bracket

positioned inside

of panel

Fig.13

Fig.14

DC7000 ANTIQUE

c) Valve installation in a hollow wall

The wall mounting bracket supplied with the

shower is suitable for use on a plasterboard wall

of 10mm - 13mm thickness.

Decide on the shower position and determine

whether the hot and cold water supplies will enter

the shower from the top (falling) or bottom

(rising) or rear.

The hollow cavity should be at least 65mm deep

from the surface of the wall. It is recommended to

use the supplied mounting bracket (fig.10) at all

times when installing the shower valve. It provides

the correct visible amount of shower control

through the face plate when the installation is

complete. There is limited tolerance between the

control knobs and trim rings to allow for varying

thickness of tiles up to 10mm.

Mark the route of the incoming and outgoing

pipework. As a guide for the size of hole, place

the tile shroud on the wall and trace around it

(fig.11).

Take out the plasterboard and offer the mounting

bracket up to the wall and mark the four outer

plain holes (fig.13). Remove the bracket and drill

the wall.

Two additional flat brackets are supplied for

hollow wall fixing. Slide the ‘T’ piece section

through the slot either side of the mounting

bracket then insert it into the wall cavity and

position the two flat brackets in line with the

outer holes (fig.14). Secure using the bolts

provided. Route the pipework to the valve

position.

Flush out the pipework in accordance with

Water Regulation Byelaws .

Offer the valve up to the mounting bracket and

secure using the four screws provided.

Proceed to ‘connecting supply pipes’ section.

10

Page 13

DC7000 ANTIQUE

33 mm dia

43 mm dia

99 mm

centres

Panel

surface

70.5 to 76.5 mm

Blocks

d) Valve installation in a panel or cubicle

To use the wall mounting bracket supplied with a

shower cubicle or a laminated panel, wooden

blocks are required to increase the depth of the

bracket. These blocks need to increase the depth

of the bracket to between 70.5 mm and 76.5 mm

from the finished surface (fig.15).

Decide on the shower position and determine

whether the hot and cold water supplies will enter

the shower from the top (falling) or bottom

(rising) or rear.

Mark the route of the incoming and outgoing

pipework. Only the two holes for the control

knobs require to be cut out of the panel or

cubicle. Use the supplied template as a guide

(fig.16).

After cutting the two holes, fit the valve to the

mounting bracket and secure using the four

screws provided.

Offer the valve and mounting bracket up to the

back of the panel ensuring the thermostatic and

on/off assemblies are protruding and centralised

through the apertures. Mark the four inner tapped

holes (fig.17). Remove the valve and bracket and

drill the panel and wooden blocks. Route the

pipework to valve position.

Flush out the pipework in accordance with

Water Regulation Byelaws .

Fit the mounting bracket together with the valve

to the panel and secure using the bolts and

washers provided.

Proceed to ‘connecting supply pipes’ section.

Fig.15

Fig.16

Fig.17

11

Page 14

DC7000 ANTIQUE

Hose end

(flat)

Pipe end

(chamfered)

Fig.18

CONNECTING THE SUPPLY PIPES

Gently screw the swivel inlets into the body of the

valve unit and stop as soon as resistance is felt.

Then back off by up to 1.5 turns to align the inlet

with the hot and cold supply pipes. THE SWIVEL

INLETS MUST NOT BE TIGHTENED AGAINST THE

VALVE BODY TO MAKE A SEAL.

Connect the hot water supply to the inlet marked

RED, and connect the cold water supply to the

inlet with the BLUE mark.

Remember the swivel inlet has an ‘O’ ring seal and

that no other sealing means is required.

Tighten the compression fittings with the cranked

spanner, supplied for when access is restricted.

Ensure the on/off assembly is turned to the off

position by temporarily fitting the on/off control

and turning clockwise until resistance is felt.

Open the supplies and test for leaks in the

pipework upstream of the valve.

OUTLET ADAPTOR

The mixed water outlet adaptor needs to be

removed and replaced using PTFE tape to ensure a

water tight seal.

NOTE: The outlet adaptor is reversible with one

side suitable for connection to a flexible hose –

flat end (fig.18), and the other is a chamfered end

for a 15 mm compression fitting.

12

Page 15

DC7000 ANTIQUE

Ball swivel

Locking ring

'O' ring

18mm

Wall

surface

FITTING THE FIXED HEAD

Complete outlet pipework from the valve ending

in a 1/2” BSP female threaded fitting – not

supplied (fig 19).

Note the depth of thread on the fixed head unit

from the finished wall surface is 10mm (fig 20). It

is advisable that pipework installed in solid walls

be provided with sufficient free play inside a cavity

to enable any slack to be accommodated.

At this point it is advisable to fit a blanking plug in

the female fitting, turn on the valve and check for

leaks from the outlet fittings.

Make good the wall, tiling etc.

Screw in place the showerhead arm and mark the

position of the three fixing holes (fig 21).

Drill and plug the holes using the plugs supplied.

NOTE: If fitting to a hollow wall structure, use

suitable cavity wall fixtures.

Apply PTFE tape to the 1/2” BSP thread on the

shower head arm before fitting.

Secure the showerhead arm to the wall with the

three screws supplied (fig 22) .

Screw the ball swivel and locking ring onto the

end of the showerhead arm (fig 23) ensuring the

‘O’ ring is in place.

NOTE: The ball swivel must be screwed on tight in

order to provide a water tight connection. The use

of an appropriate tool may be used if necessary.

Screw on the fixed showerhead ensuring the

supplied tapered sealing washer is in place as

shown in (fig 24). The showerhead must be

screwed on tight in order to ensure a water tight

connection.

Fig. 19

Fig. 21

Fig. 20

Fig.22

Fig.23

Fig.24

13

Page 16

DC7000 ANTIQUE

Remove

shaded

area to

allow

for the

mounting

bracket

Fig.25

USING THE TILING SHROUD

The tiling shroud will need a section removed

(fig.25) in order to accommodate the mounting

bracket.

Replace the tiling shroud over the mixer valve.

Plaster or tile up to the edge of the shroud. Note

that if the tiles are accurately cut to match the

profile of the shroud, then the face plate will seal

around the hole in the tiles, and the valve unit will

be able to be removed from the mounting bracket

without the need to break any tiles.

Ensure the grout lines are flush with the tiles in

order to provide a smooth sealing surface for the

face plate.

FITTING THE FACE PLATE AND KNOBS

Unscrew the face plate retaining rings from the

valve unit (if fitted).

See fig.26 for the assembly of parts. Position the

face plate over the valve unit and place the trim

rings onto the face plate ensuring the indicator

notch is in the 12 ‘o’ clock position. It must be in

this position regardless in which orientation the

unit is mounted.

Secure by screwing on the two brass face plate

retaining rings.

Gently tighten the rings by hand until the face

plate clamps gently against the wall. Do not overtighten or the face plate may distort. The face

plate incorporates a silicon sponge seal which will

satisfactorily seal against a smooth wall.

Temperature control knob assembly

Place the temperature knob temporarily onto the

splined adaptor, and rotate fully anti-clockwise.

Remove the knob and reposition onto the splined

adaptor again, but this time ensuring the ceramic

tap handles are in a 2 o’clock and 10 o’clock

position (fig.27).

Screw the locknut down against the knob and

tighten using the key supplied. Do not fit the

finishing cap just yet as when the commissioning

is carried out, the maximum temperature

adjusting screw may have to be altered.

14

Page 17

DC7000 ANTIQUE

Face plate

Temperature

control knob

Ceramic

Splined

adaptor

On/off

control knob

Slotted

screws

Ceramic

tap handles

Brass rings

Locknut

key

finishing cap

Brass

face plate

retaining ring

(small hole)

Brass face plate retaining ring

(large hole)

Locknut

Screw and

washer

Trim rings

H

O

T

C

O

L

D

Fig.26

On/off control knob assembly

Place the splined on/off knob onto the splined

shank and secure with the washer and fixing

screw.

Push fit the finishing cap onto the on/off knob.

Note the cap with the hot and cold lettering fits

on the temperature control knob and the on/off

cap fits on the on/off knob. The caps are not

interchangeable.

Note that should the knobs and faceplate require

cleaning then care must be taken not to scratch

them in the process. Wash away any surface dust

before cleaning with soapy water.

DO NOT USE ABRASIVE CLEANERS AND

SOLVENTS OR THE SURFACES MAY BECOME

DAMAGED.

15

Fig.27

Page 18

Maximum temperature

adjusting screw

Fig.28

DC7000 ANTIQUE

COMMISSIONING

(The following conforms to NHS Estates Model

Engineering Specification D08 for when the mixer

has been installed in healthcare premises).

ENSURE THAT ALL SUPPLY PIPEWORK HAS BEEN

FLUSHED THROUGH PRIOR TO COMMISSIONING.

Ensure that both hot and cold water supplies are

fully open and at (or near to) their design

temperature and pressures and are within the

requirements as stated.

Set the temperature control to the maximum

temperature setting – by rotating the knob fully

anti-clockwise until resistance is felt.

Open the on/off control by turning it anticlockwise. Placing a burst polythene bag over the

shower head will catch and deflect the spray

during commissioning.

Allow the shower to run at maximum temperature

setting until the water temperature has stabilised.

Should the temperature rise in an uncontrolled

manner, then the hot and cold supplies are

probably reversed. This must be corrected before

proceeding further.

The mixer valve is factory set to provide a

maximum outlet temperature of 39°C but this

should be checked on site to ensure the setting

has not been altered and also to ensure user

safety.

Should the maximum temperature require

adjustment, remove the temperature knob

finishing cap (if it has been placed in position

when assembling the temperature controls

previously) . Adjust the small slotted screw in the

centre of the spindle (fig.28) – anti-clockwise to

increase the temperature, clockwise to decrease

the temperature.

The maximum temperature should not exceed

41°C. For installations complying with NHSE

specifications.

After setting the maximum temperature, turn the

shower on and off several times and check the

maximum setting is correct. Record the

commissioning data on the maintenance record at

the rear of this book in order for the in-service

performance of the mixer valve to be assessed.

Finally, check the thermal shut off facility of the

16

Page 19

DC7000 ANTIQUE

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

H

O

T

C

O

L

D

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

H

O

T

C

O

L

D

valve by performing a thermal shut off test. Shut

off the cold supply. The flow from the shower

should stop immediately or reduce to a trickle in

which case the water temperature should be less

than 43°C.

In either case there is no risk of scalding.

If however the temperature is above 43°C then it

is likely there is contamination in the valve

preventing it from shutting off the hot supply. In

this case refer to the maintenance section or

contact Customer Service.

In domestic installations where D08 specification is

not required, the maximum temperature setting

should not exceed 45°C.

OPERATING THE SHOWER

To start the shower, rotate the on/off control fully

anti-clockwise (fig.29) for maximum flow.

To stop the water flow, rotate the on/off control

fully clockwise (fig.30) until resistance is felt.

To adjust the water temperature, rotate the

temperature control – clockwise in the direction of

the cold arrow (fig.31) for a cooler shower or anticlockwise in the direction of the hot arrow (fig.32)

for a hotter shower.

Fig.29

Fig.30

Fig.31

Fig.32

17

Page 20

DC7000 ANTIQUE

Inlet strainer body

Strainer

basket

Swivel

seal

15mm

ferrule

15mm

compression

nut

End cap

Cap seal

On/off unit

Seal

Retaining nut

1/2" Washer

Valve cover

Piston

seal

Temp

adjustment

piston

Control

stem

Max temp

adjustment

screw

Temp knob

adaptor

Thrust

washer

Adaptor

circlip

Baffle

tube

Return

spring

Slide valve

seal

Slide valve

sub assembly

Thermostat

element

Element

spring

Valve cover

seal

Fig.33

Fig.34

Fig.35

When cleaning the external faceplate and

knobs, never use cleaners containing

abrasives or solvents as they may damage

the chrome plating. Use only soap and a

soft cloth.

MAINTENANCE

(The following maintenance procedure must be

carried out for commercial and health care

premises, but is not necessarily required for

domestic installations).

Maintenance of the unit is required to ensure

continued performance after installation and that

it continues to provide scald prevention.

The frequency of routine maintenance of the

internal of the valve will depend mainly on the

water supply condition. Local knowledge will

dictate suitable intervals. In addition, the following

precautions should be observed:

a) Initially check the strainer baskets (fig.33) for

debris once every three months and clean if

necessary. This period can be increased if

appropriate once the general condition and

cleanliness of the water is established. Where the

water supplies come from beneath (rising) the

mixer valve, lifting out the strainer basket may not

remove all of the trapped debris. Full flushing out

may be necessary if debris is found or suspected.

b) Perform a thermal shut off test every three

months, and check the maximum temperature

setting. See the ‘Commissioning’ section for the

details of this test and re-adjustment of the

maximum temperature setting if required.

c) If the maximum water temperature varies by

more than 2°C from the commissioned setting

then ensure the strainers are clean and that the

isolating valves are fully open. Test the non return

valves as described below. If these tests do not

highlight the reason for the temperature variation,

then follow the procedure below for investigating

failure of the thermal shut off test.

d) If the mixer valve fails the thermal shut off

test then remove the knobs, faceplate and control

valve cover. Check the internal surface for scaling.

If the body requires descaling then it should be

removed from the pipework to carry this work out

– the valve should be able to be removed through

the aperture without breaking tiles. All rubber

parts must be removed prior to descaling. The

slide valve seal (fig.34) located inside the body

should always be replaced with a new seal after

removal. Maintenance kits are available which

contain ‘O’ rings and/or the thermostatic element.

18

Page 21

DC7000 ANTIQUE

Smear all ‘O’ rings with silicon grease prior to

installing them. Torque the valve cover to 13 Nm

(10 lb.ft.). This is to prevent inadvertently

unscrewing the cover during temperature

adjustment. Do not over-tighten the valve cover or

the mounting arrangement may be damaged.

e) Replace the ‘O’ rings every three years –

maintenance kits with spare ‘O’ rings are

available. Smear silicon grease on all ‘O’ rings

before assembling. At the same time replace the

slide valve assembly (fig.34). Lightly smear the

outside diameter with silicon grease before

installing.

f) Replace the thermostatic element (fig.34) at

least once every six years, or more often if

problems are experienced or in installations where

water is particularly hard.

g) The on/off mechanism (fig.35) has a 1/2” tap

washer which should be replaced when it is found

to be leaking. Remove the trim plate and unscrew

the on/off assembly. The washer is retained by a

small nut. When replacing, do not overtighten –

torque to 25Ncm. Ensure the on /off assembly is

torqued down to 13Nm (10 lb.ft.) to prevent the

user from inadvertently unscrewing the assembly

during flow control. Do not over-tighten the

assembly or the mounting arrangement may be

damaged.

h) The non return valves (NRVs) prevent crossflow between hot and cold supplies under

unequal pressure conditions. They are designed

for long life with no maintenance. Their function

can be tested as follows:

i) To test the NRV on the hot side, shut off the

hot supply and ensure the cold supply is open. Be

prepared for leakage of trapped water in the pipe

and remove the strainer basket on the hot side.

Evidence of continuing leakage from the strainer

body is coming through the hot supply NRV.

j) To test the NRV on the cold side, shut off the

cold supply and ensure the hot supply is open. Be

prepared for leakage of trapped water in the pipe

and remove the strainer basket on the cold side.

Evidence of continuing leakage from the strainer

body is coming through the cold supply NRV.

If either NRV is leaking then the inlet elbow –

complete with NRV and strainer basket, should be

replaced. It is not possible to satisfactorily remove

the NRV itself from the elbow and should not be

attempted.

IN-SERVICE TESTING

Periodic testing should be undertaken to check

whether deterioration has occurred in the

performance of the mixer valve.

A thermal shut off test, as described under

maintenance, should be carried out. If water

coming from the shower head is at a temperature

of more than 2°C above the maximum mixed

water temperature setting then the valve unit is

due for maintenance.

NOTE: A thermostatic mixing valve in need of

maintenance can be undetectable in normal use

and only becomes apparent when a disruption

occurs in the hot or cold water supply

temperatures or pressures.

The frequency of in-service testing depends upon

the water condition passing through the unit. Inservice testing should be between six to twelve

months, but less than six month intervals in areas

of hard water.

Experience of local conditions and the in-service

testing record will dictate the frequency of inservice testing.

19

Page 22

DC7000 ANTIQUE

O

N

O

F

F

T

R

I

T

O

N

S

H

O

W

E

R

S

H

O

T

C

O

L

D

Ref. Description Part No.

1 Valve unit 7102447

comprising:spline adaptor

tiling shroud

button screw

2 Tiling shroud 7102446

3 Face plate

chrome 7102444

gold 7102445

4 Temperature knob

chrome 83306420

gold 83306430

4 On/off knob

chrome 83306440

gold 83306450

5 Trim rings

chrome 7102525

gold 7102526

6 Spray arm

chrome 22009380

gold 22009390

7 Sprayhead

chrome 22009340

gold 22009330

8 Mounting bracket 7012435

SPARE PARTS

2

1

4

3

8

5

9 Flat bracket 7012436

Bracket assembly 83306290

(comprising 8 & 9)

10 Utilities pack 7102523

comprising:tool and screw pack

brass retaining rings

locknut

button screw washer

mounting bracket

flat bracket

11 Ceramic on / off cap 86000250

12 Ceramic temperature cap 86000240

13 Flow limiter 22003530

20

11

12

10

6

9

7

13

Page 23

DC7000 ANTIQUE

COMMISSIONING, MAINTENANCE and IN-SERVICE TESTING RECORD

Where installed (establishment)

Mixer valve location

Date installed Installed by

Commissioning details Hot water temp. °C Pressure Bar

Equip.used Cold water temp. °C Pressure Bar

Equip.used Max.temp.setting °C C.W. fail °C (max)

Replacement dates: ‘O’ ring seals (recommended every 3 years)

Thermostatic element and slidevalve (every 6 yrs.)

Inspection and maintenance record

Date Mixed temp Hot temp Hot press Cold temp Cold press Flowrate CW failure test Signed

21

Page 24

DC7000 ANTIQUE

FAULT FINDING

Symptom Cause Action/cure

1 Water too

hot.

1.1 Not enough cold water

flowing through shower.

1.2 Increase in the ambient cold

water temperature.

1.3 High volume of cold water

being drawn off elsewhere.

1.4 Dirty filters.

1.5 Internal parts failure

1.1.1 Turn the temperature control clockwise.

1.2.1 Turn the temperature control clockwise.

1.3.1 Reduce the simultaneous demand from the

supply – ensure supply pressures are within

specification.

1.4.1 Clean – refer to maintenance section.

1.5.1 Replace – refer to maintenance section.

2 Water too

cold

3 Water does

not flow or

shower pattern

collapses when

another outlet

is turned on.

4 Shower will

not shut off

2.1 Not enough hot water

flowing through the shower.

2.2 Decrease in the ambient

cold water temperature.

2.3 Insufficient hot water

supplies from the heating

appliance.

2.4 Hot water supply blocked or

restricted.

2.5 Dirty filters.

2.6 Internal parts failure

3.1 Water supplies cut off.

3.2 Shower unit blocked.

3.3 Blockage in pipework.

3.4 Sprayhead blocked.

3.5 Reduced flow rate when

other outlets in use.

4.1 Debris damage to on/off

washer.

4.2 On/off washer worn.

2.1.1 Turn temperature control anti-clockwise.

2.2.1 Turn temperature control anti-clockwise.

2.3.1 Ensure hot water appliance is set to deliver

correct hot water output temperature.

2.3.2 Combi boiler mutipoint installations check

flow limiter fitted.

2.4.1 Turn shower off and consult a competent

plumber or contact Triton Customer Service.

2.5.1 Clean – refer to maintenance section.

2.6.1 Replace – refer to maintenance section.

3.1.1 Check water elsewhere in property and if

necessary contact local water company.

3.2.1 Inspect filters – refer to maintenance

section. Clean if necessary.

3.3.1 Turn the shower off and consult a suitably

competent plumber.

3.4.1 Clean sprayhead.

3.5.1 Reduce the simultaneous demand at other

outlets.

3.5.2 Ensure service valves are fully open.

4.1.1 Replace washer – refer to maintenance

section.

4.2.1 Replace washer – refer to maintenance

section.

Any maintenance or repair to the shower must be carried out by a suitably qualified person.

22

Page 25

DC7000 ANTIQUE

23

Page 26

DC7000 ANTIQUE

24

Page 27

Page 28

TRITON STANDARD G UARANTEE

Triton Plc guarantee this product against all

mechanical and electrical defects arising from faulty

workmanship or materials for a period of three

years for domestic use only, from the date of

purchase, provided that it has been installed by a

competent person in full accordance with the fitting

instructions.

Any part found to be defective during this

guarantee period we undertake to repair or replace

at our option without charge so long as it has been

properly maintained and operated in accordance

with the operating instructions, and has not been

subject to misuse or damage.

This product must not be taken apart, modified or

repaired except by a person authorised by Triton

Plc. This guarantee applies only to products installed

within the United Kingdom and does not apply to

products used commercially.

This guarantee does not affect your statutory rights.

What is not covered:

1 Breakdown due to: a) use other than domestic

Service Policy

In the event of a complaint occurring, the following

procedure should be followed:

1 Telephone Customer Service on (024) 7637 2222

(08457 626591 in Scotland and in Northern Ireland),

having available the model number and power rating

of the product, together with the date of purchase.

2 Triton Customer Service will be able to confirm

whether the fault can be rectified by either the

provision of a replacement part or a site visit from a

qualified Triton service engineer.

3 If a service call is required it will be booked and the

date of call confirmed. In order to expedite your

request, please have your postcode available when

booking a service call.

4 It is essential that you or an appointed

representative (who must be a person of 18 years of

age or more) is present during the service engineer's

visit and receipt of purchase is shown.

5 A charge will be made in the event of an aborted

service call by you but not by us, or where a call under

the terms of guarantee has been booked and the

failure is not product related (i.e. scaling and furring,

incorrect water pressure, pressure relief device

operation, electrical installation faults).

6 If the product is no longer covered by the

guarantee, a charge will be made for the site visit and

for any parts supplied.

7 Service charges are based on the account being

settled when work is complete, the engineer will then

request payment for the invoice. If this is not made to

the service engineer or settled within 10 working days,

an administration charge will be added.

use; b) wilful act or neglect; c) any malfunction

resulting from the incorrect use or quality of

electricity, gas or water or incorrect setting of

controls; d) faulty installation.

2 Repair costs for damage caused by foreign objects

or substances.

3 Call out charges where no fault has been found

with the appliance.

4 The cost of repair or replacement of pressure

relief devices, sprayheads, hoses, riser rails and/or

wall brackets, isolating switches, electrical cable,

fuses and/or circuit breakers or any other

accessories installed at the same time as these do

not form the mechanical and electrical components

contained within the unit..

5 The cost of routine maintenance, adjustments,

overhaul modifications or loss or damage arising

there from, including the cost of repairing damage,

breakdown, malfunction caused by corrosion,

furring, pipe scaling, lime scale, system debris or

frost.

Replacement Parts Policy

Availability: It is the policy of Triton to maintain

availability of parts for the current range of products

for supply after the guarantee has expired. Stocks of

spare parts will be maintained for the duration of the

products’ manufacture and for a period of five years

thereafter.

In the event of a spare part not being available a

substitute part will be supplied.

Payment: The following payment methods can be

used to obtain spare parts:

1 By post, pre-payment of pro forma invoice by

cheque or money order.

2 By telephone, quoting credit card (MasterCard or

Visa) details.

3 By website order, www.tritonshowers.co.uk

Triton Plc, Shepperton Park, Caldwell Road,

Nuneaton, Warwickshire. CV11 4NR

Customer Service

(024) 7637 2222

☎

Scottish and Northern Ireland

Customer Service

08457 626591

☎

Trade Installer Hotline

(024) 7632 5491

☎

Fax: (024) 7632 4564

E mail: technical@triton.plc.uk

Loading...

Loading...