Page 1

THAMES

concentric exposed

thermostatic mini mixer shower

Installation and

operating instructions

Installers ple ase note these I nstruc tIons are to be lef t wIth the user

2180766D - July 2012

Page 2

Concentric exposed thermostatic mixer shower

CONTENTS Page

MAIN COMPONENTS .................................................................... 1

INTRODUCTION............................................................................ 2

SITE REQUIREMENTS

SAFETY WARNINGS ....................................................................... 2

PLUMBING REQUIREMENTS

WATER SYSTEM REQUIREMENTS .................................................... 3

TYPICAL DOMESTIC INSTALLATIONS

INSTALLATION

FITTING THE MIXER

ANTI-SCALD PROTECTION

LEAK TESTING ............................................................................... 9

COMMISSIONING ......................................................................... 9

ADJUSTING THE MAXIMUM TEMPERATURE SETTING

OPERATING THE SHOWER

APPROVALS

FLOW CHART ............................................................................... 12

DIMENSIONS

SPARE PARTS

MAINTENANCE

Cleaning the filters ........................................................................ 15

FAULT FINDING

Guarantee, service policy, etc.

.................................................................................. 12

..................................................................... 2

.......................................................... 3

...........................................4 - 6

............................................................................... 7

....................................................................... 8

............................................................ 9

................... 10

............................................................ 11

............................................................................... 13

................................................................................. 14

............................................................................ 15

.........................................................................16 - 17

..................................................rear cover

To check the product suitability for commercial and multiple installations, please contact Triton’s

specification advisory service before installation.

Telephone:

Facsimile:

0844 980 0730

0844 980 0744

E mail:

technical@tritonshowers.co.uk

Page 3

Concentric exposed thermostatic mixer shower

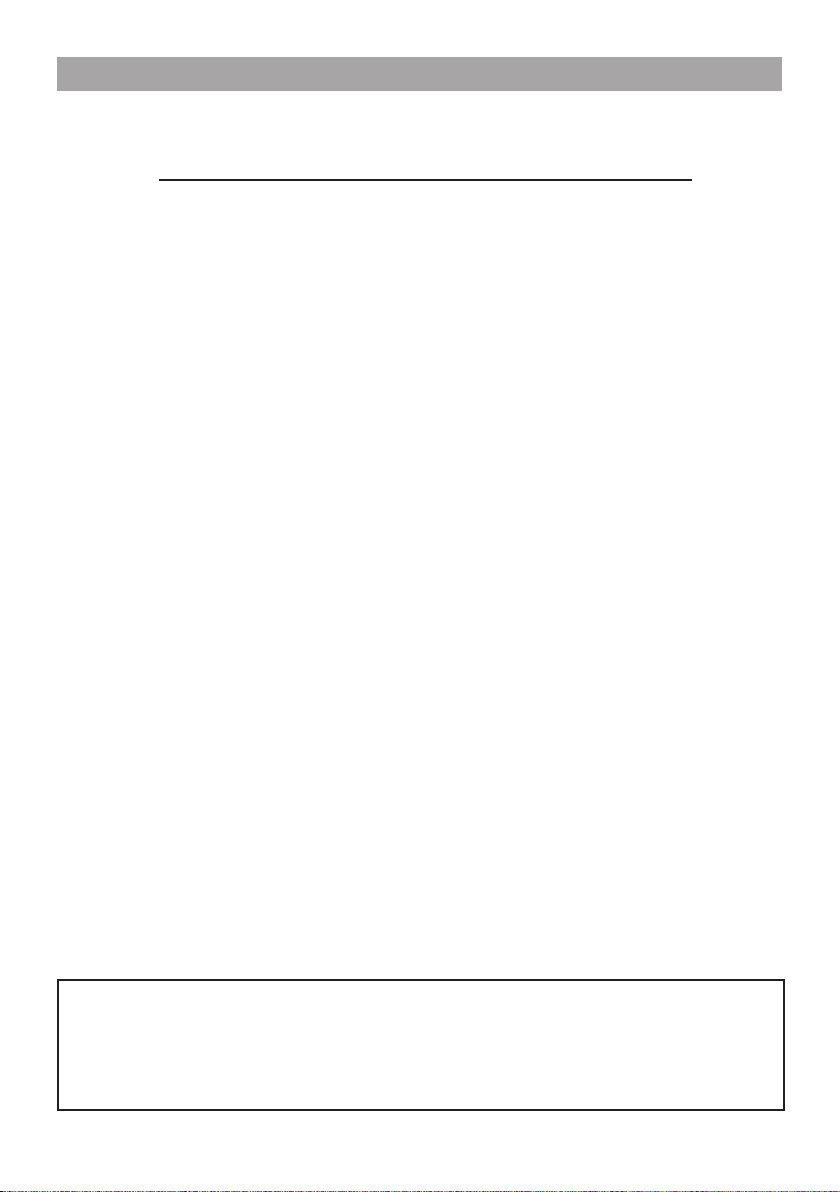

MAIN COMPONENTS

Main components

Fig.1

1

2

5

6

3

7

4

Ref. Description

1. Mixer shower body

2. Blanking plug

3. Outlet adapter

4. Flow regulator

All dimensions listed in this fitting book regarding the product and installation are approximate.

5. Mounting plate

6. Wall trim X2

7. Inlet nut and Olive X2

- 110mm elbow adaptors X2 - not shown

*All kits are for illustration purposes only and are not supplied unless otherwise stated.

1

Page 4

Concentric exposed thermostatic mixer shower

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your Triton mixer

shower. Please read them carefully and read

through the whole of this book before beginning

your installation.

The shower installation must be carried out by

a suitably competent person and in sequence of

this instruction book.

Care taken during the installation will give a long

and trouble free life from your mixer shower.

SITE REQUIREMENTS

The installation must be in accordance with

water supply (water fittings) regulation 1999

and/or local Bylaws.

Water pressure requirements

Running water pressure:

Low presure - 0.1 bar min.

1.0 bar max.

High pressure - 0.5 bar min.

5.0 bar max.

Maximum static water pressure:

Low & High pressure - 10 bar

This mixer shower is designed for use with

traditional low pressure ‘gravity’ water systems,

using a cold water cistern and hot water cylinder

as well as for the higher pressure systems found

in the UK up to a maximum of 5 bar running

pressure.

For effective operation of the internal seals, the

maximum static pressure must not be exceeded.

Pressure reducing valve

On sites where the running pressure is above 5

bar, the use of a suitably sized pressure reducing

valve fitted in the cold mains supply pipe work

can provide nominally equal pressures at the

mixer shower.

Replacement parts can be ordered from Triton Customer

Service. See ‘spare parts’ for details and part numbers.

Water minimum flow rate

For best performance within the specified running

pressure range a minimum flow of 8 litres per

minute should be available to both inlets.

Water temperature requirements

Maximum hot water temperature: = 80°C

Recommended maximum: = 65°C

Minimum hot water temperature: = 55°C

Maximum cold water temperature: = 25°C

NOTE: Valves operating outside these conditions

cannot be guaranteed by the Scheme to operate

as Type 2 valves.

The mixer shower MUST NOT be subjected to

water temperatures above 80°C.

BS 6700 recommends that the temperature of

stored water should never exceed 65°C.

A stored water temperature of 60°C is

considered sufficient to meet all normal

requirements and will minimise the effects of

scale in hard water areas.

Water temperature adjustment and

thermal safety

The mixed water temperature can be adjusted

from cold through to a top limit which must

be preset during installation with full anti-scald

protection throughout the range (35°C to 40°C)

providing the hot water temperature at the inlet

remains 10°C above the outlet temperature.

Should there be a loss of flow to either incoming

supply then- water from the shower will stop or

be reduced until both supplies are restored.

SAFETY WARNINGS

a. DO NOT choose a position where the shower

could become frozen.

b. DO NOT connect this mixer shower to any

form of tap or fitting not recommended by

the manufacturer.

c. DO NOT allow the inlet pressure or flow

rates to operate outside the guidelines laid

out in ‘site requirements’.

d. DO NOT connect the mixer shower to a

gravity hot supply and a mains cold supply

(or vice versa).

2

Page 5

Concentric exposed thermostatic mixer shower

PLUMBING REQUIREMENTS

DO NOT use jointing compounds on any pipe

fittings for the installation,

DO NOT solder fittings near the mixer unit

as heat can transfer along the pipework and

damage the mixer valve.

IMPORTANT:

• ThelayoutandsizingofpipeworkMUST

be such that nominally equal inlet supply

pressures are achieved and the effects of

other draw-offs are minimised.

• Thepipe-workshouldbeinstalledsuch

that other taps and appliances being

operated elsewhere on the premises do not

significantly affect the flow

• Whenconnectingpipe-workavoidusing

tight 90° elbows; swept or formed bends will

give the best performance.

• Thehotwaterpipeentrymustbemadeto

the left-hand side inlet, marked HOT, ‘H’ or

with a red/orange label.

• Suitableisolatingvalves(complyingwith

Water Regulations and Bylaws) must be fitted

on the hot and cold water supplies to the

shower as an independent means of isolating

the water supplies should maintenance or

servicing be necessary.

• Itispreferabletoushthepipe-worktoclear

the system of debris and check for leaks

before connecting to the mixer.

• Themixerinletscontainremovablelters

that may become blocked if debris is not

flushed through before fitting.

(Commercial applications)

• Tritonrecommendsforallcommercial

applications that, easily accessible, in-line

filters are used to aid maintenance.

Hard water areas

a. If it is intended to operate the shower

in areas of hard water (above 200-ppm

temporary hardness), a scale inhibitor may

have to be fitted. For advice on the Triton

scale inhibitor, please contact Customer

Service.

b. For best performance the showerhead MUST be

regularly cleaned to remove scale and debris.

WATER SYSTEM REQUIREMENTS

This mixer shower is suitable for: -

• Gravitywatersystems

• Pumpedgravitysystems.

• Fullymodulatingtypecombinationboilers

• Multi-pointhotwaterheaters.

• Thermalstorage,

• Unventedsystems

When installing this mixer with a Combination or

multi-point boiler, it may be necessary to install

flow regulation.

Check that the appliance is capable of delivering

hot water at a minimum switch-on flow rate

of 3 litres per minute. At flow rates between 3

and 8 litres per minute, the appliance must be

capable of raising the water temperature to 52°C

(minimum).

Water temperature at the inlet of the mixer valve

must remain relatively constant when flow rate

adjustments are made (refer to the applianceoperating manual to confirm compatibility with

this mixer shower).

Where thermal store systems and instantaneous

gas water heaters are used, if excessive drawoff take place the appliance may not be able to

maintain an adequate output temperature. This

could result in the shower temperature becoming

noticeably cooler.

Flow regulators can be fitted with high-pressure

water systems to reduce flow rate and assist

economy.

The hot supply temperature MUST remain a

minimum of 10°C hotter than the required blend

temperature for optimum performance.

3

Page 6

Concentric exposed thermostatic mixer shower

*Fig.2

Stop valve

supply

*Fig.3

*(diagrammatic view – not to scale)

Cold supply

Minimum head

Hot supply

Alternative supply

(must be below

vent pipe tee)

Cold water

cistern

Gate

valve

Cold

water

mains

Hot water

cylinder

Drain

valve

Other

draw-offs

Draw-off must point down

to avoid airlock issues

*(diagrammatic view – not to scale)

Service

valves

Mixer

Mixer

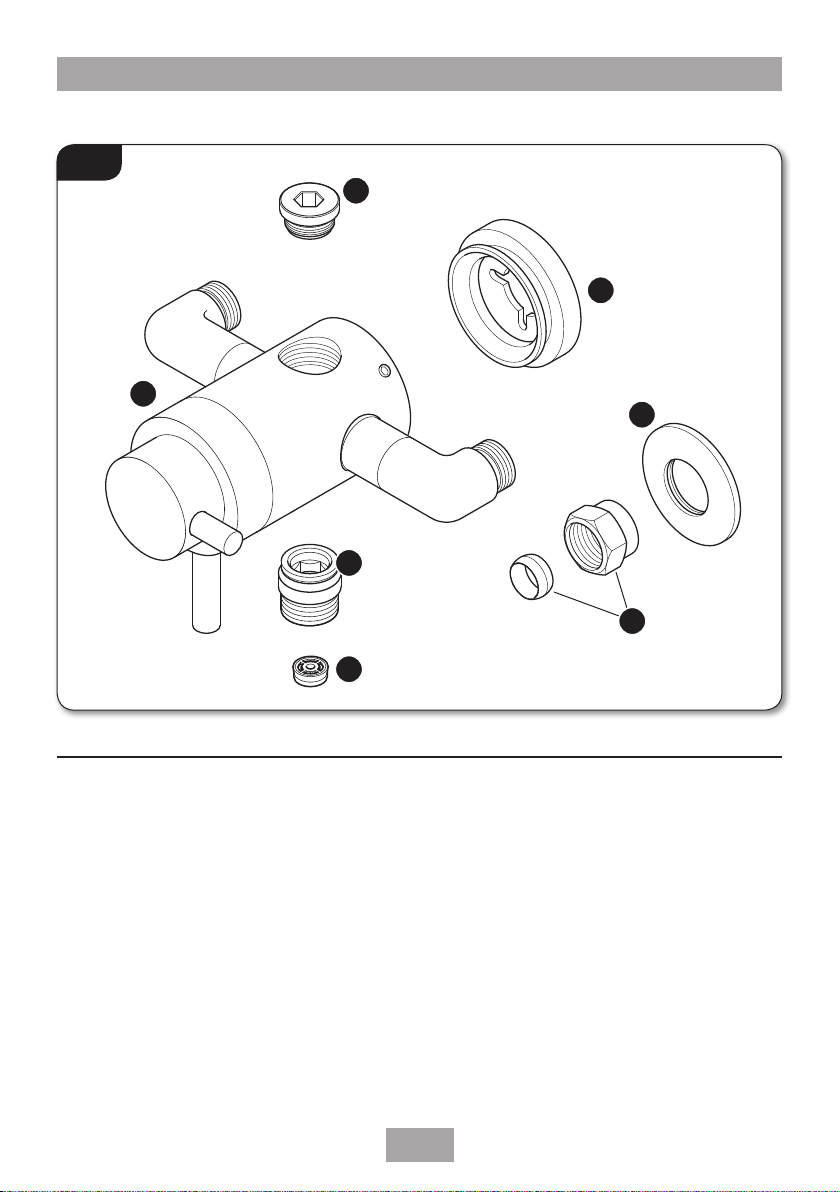

TYPICAL DOMESTIC INSTALLATIONS

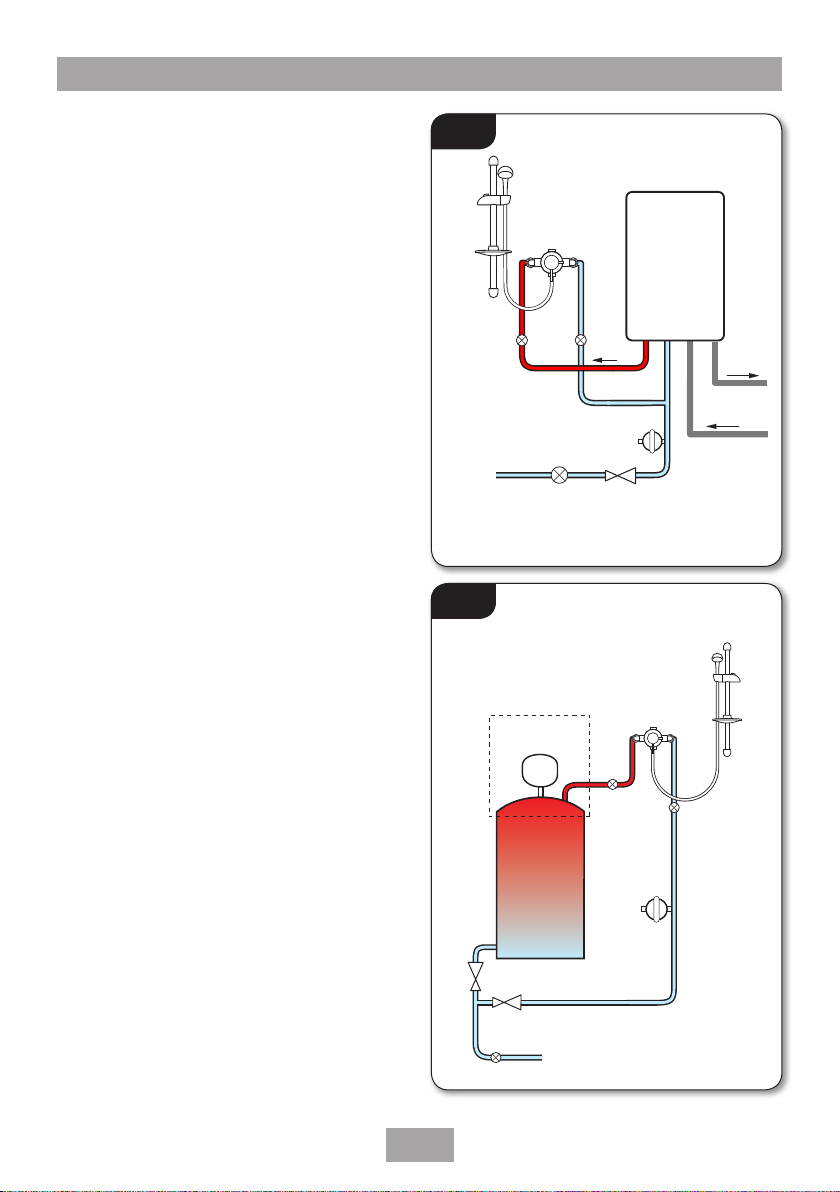

Domestic gravity fed systems (fig.2)

The shower control MUST be fed from a cold

water cistern and hot water cylinder providing

nominally equal pressures. There must be a

minimum of one metre head of water. The

minimum head distance is measured from the

base of the cold water cistern to top of the

showerhead.

Kit

If valves are gravity, fed then supply pressure

should be verified to ensure conditions of use

are appropriate for the valve.

Pumped gravity fed systems (fig.3)

The shower control MUST be fed from a cold

water cistern and hot water cylinder providing

nominally equal pressures.

The mixer unit may be used with a gravity fed

system with a pump to boost pressures as shown;

please refer to the pump installation guide to

establish the minimum head requirements for

automatic operation of the pump.

Stop valve

Cold

water

mains

supply

Drain

valve

Cold water

cistern

Alternative supply

(must be below

vent pipe tee)

Gate

valve

Hot water

cylinder

Other

draw-offs

Draw-off must point

down to avoid airlock

issues

Cold supply

Minimum head

Hot

supply

Service

valve

Mixer

Mixer

Pump

Isolating switch or

pull cord switch

(both fused at 3A)

Ring main

Service

valve

*(kits are for illustration purposes only)

4

Page 7

Concentric exposed thermostatic mixer shower

Instantaneous gas-heated systems, e.g.

combination boilers (

The shower control MUST be installed with a

multi-point gas water heater or combination

boiler of a fully modulating design (i.e.

to maintain relatively stable hot water

temperatures).

A drop tight pressure reducing valve MUST

be fitted if the supply pressures exceed 5 bar

running.

An expansion vessel MAY be fitted, and regularly

maintained, to prevent the shower mixer

being damaged by excess pressures. This may

already be installed within the boiler (check with

manufacturer) and is in addition to the normally

larger central heating expansion vessel.

fig.4)

Unvented mains pressure systems (fig.5)

The shower control can be installed with an

unvented, stored hot water cylinder.

For systems with no cold water take off after the

appliance reducing valve, it will be necessary to

fit an additional drop tight pressure-reducing

valve when the mains pressure is over 5 bar. The

drop tight pressure reducing valve must be set at

the same value as the unvented package pressure

reducing valve.

Note: An additional expansion vessel may be

required if a second pressure-reducing valve is

installed. This does not apply to packages with a

cold take off after the pressure-reducing valve to

the cylinder.

*Fig.4

Cold

mains

supply

*Fig.5

*(diagrammatic view – not to scale)

Kit

Mixer

Mixer

Service

valves

Stop

tap

Expansion

Hot water

vessel

Pressure

reducing valve

Combination

boiler

*(diagrammatic view – not to scale)

Mixer

Safety devices

not shown

Service

valves

CH flow

CH return

Kit

*(kits are for illustration purposes only)

Unvented

hot water

storage unit

Pressure

reducing valves

Stop tap

Balanced cold mains supply

Cold mains supply

Expansion

vessel

5

Page 8

Concentric exposed thermostatic mixer shower

*Fig.6

*(diagrammatic view – not to scale)

Mixer

Blender

Hot

Service

valves

Expansion

vessel

Pressure

reducing valve

Cold mains supply

water

Stop tap

valve

Return

Mains pressurised thermal store systems (fig.6)

Packages of this type, fitted with a tempering

valve (blender valve) can be used. A drop tight

pressure reducing valve MUST be fitted if the

supply pressures exceed 5 bar running.

An expansion vessel MUST be fitted, and

regularly maintained, to ensure, the unit, is

not damaged by excess pressures. This may

already be installed externally or internally within

the thermal store (check with thermal store

manufacturer).

Flow

Boiler

*(kits are for illustration purposes only)

6

Page 9

Concentric exposed thermostatic mixer shower

Height of

showerhead

and shower

to suit user’s

requirement.

Approx

30 - 35mm

Approx

150mm

or

110mm

INSTALLATION

Preparing the mixer valve

Check the contents to make sure all parts are

present.

Before starting the mixer installation, make

sure all the openings on the valve are carefully

covered to stop ingress of any debris, etc. while

routing the supply pipework.

The shower valve is suitable for exposed installation

onto solid wall, a stud partition wall, dry lined wall

or fixing to a laminate cubicle or panel.

Siting of the shower and accessories

Refer to (fig.7) for correct siting of the shower.

The mixer valve should be positioned, as

detailed, with all controls within comfortable

reached of the user.

The accessories (showerhead, riser rail) can be

positioned above or to either side of the shower,

refer to (fig.7).

The valve must be installed in a position that

allows for easy access for future maintenance

and commissioning.

Supply pipe work

Complete the pipework to the shower area

having decided on the position of the shower

and direction of pipe entry (for example rising,

falling or rear entry)

The hot and cold water pipes should not

be permanently attached to the wall within

one metre of the valve, before installation is

complete, to allow for final adjustment of the

valve position.

*Fig.7

*(diagrammatic view – not to scale)

Rear entry supplies

Using a spirit level, mark the route of incoming

hot and cold water supply pipes at a distance

of either 150mm, or 110mm (approximately)

between centres (depending on the adaptors

fitted (fig.8).

*(kits are for illustration purposes only)

Fig.8

Please note: Mixer is supplied with 150mm and

110mm adaptors.

7

Page 10

Concentric exposed thermostatic mixer shower

Fig.9

Fig.10

Elbow

150mm adaptor

O ring seal

Grub screw

Elbow

110mm adaptor

Grub screw

Fig.11

FITTING THE MIXER

Mark the position of the four locating screws

for the mounting plate, although if installing to

a solid brick wall using two diagonal holes will

usually be enough.

Drill and plug the wall.

(An appropriate drill bit should be used. If the

wall is brick, plasterboard or a soft building block,

appropriate wall plugs and screws should be fitted).

Fit the mounting plate onto the wall (fig.9).

The inlet elbows allow for either rising, falling or

rear entry hot and cold water supplies. The elbows

have ‘O’ ring seals (fig.10) to the body and do

not require PTFE tape or other means of sealing

- (see page 15 Fig.A for elbow disassembly and filter

cleaning).

See (fig.11) for how to install the 150mm or

110mm adaptors and elbows. A suitable tool

should be used to tighten the adaptors into the

body - (a 20 pence coin for example).

Note: Do not over tighten the adaptors

and care should be taken not to create

sharp edges on the tightening surfaces.

IMPORTANT:

Make sure that all the supply pipework has

been flushed through before fitting the mixer.

Fit the trim onto the inlet water pipes followed

by the nut and olive (fig.12).

Connect the hot water supply to the inlet marked

HOT, ‘H’ or red/orange label and connect the

cold water supply to the inlet marked COLD, ‘C’

or blue label (fig.12).

Tighten all compression fittings.

Tighten all the grub screws to secure the mixer to

mounting plate.

Flow regulation

A flow regulator is supplied for use with highpressure water systems and may be fitted with

any of the systems listed to reduce flow rate and

assist economy.

Elbow

8

Page 11

Concentric exposed thermostatic mixer shower

To fit the flow regulator

To fit the flow regulator, place it into the

bottom of the outlet adaptor. Please note the

flow regulator is only designed to work in one

direction (fig.13).

ANTI-SCALD PROTECTION

It is important that the mixer valve is tested

regularly to prevent the risk of scalding and

guarantee user safety. This can be carried out as

follows: with the mixer blend temperature set

at 38°C isolate the cold water supply. The outlet

flow rate will reduce to a safe level.

LEAK TESTING

Direct the outlet of the mixer to waste. Open the

isolating valves to the shower and check for leaks.

Remedy any leaks found.

COMMISSIONING

Start the water flow by rotating the flow control.

Make sure that both the hot and cold water

supplies are fully open and at (or near to) their

design temperature and pressures, and are within

the requirements as stated.

Make sure the temperature control is at the

maximum temperature setting.

Allow the shower to run at the maximum

temperature setting until the water temperature

has stabilised. Rotate the temperature control

until your desired maximum showering

temperature is reached.

The mixer has a temperature stop to prevent

accidental rotation to higher temperatures. This

is adjustable to provide a maximum temperature

of 35°C - 45°C and should be checked on site to

guarantee user safety.

Temperature adjustment range

The mixed water temperature can be adjusted

from cold through to a top limit (which can

be pre-set during installation – factory set

at approximately 38°C) with full anti-scald

protection throughout the range.

Fig.12

HOT

Trim

Nut

Olive

COLD

Fig.13

Water ow

leaving mixer

Outlet adaptor

Insert in this direction

Angled top

section

Flow regulator

Note: the angled top section of the flow

regulator MUST be facing the outgoing

direction of the water leaving the mixer.

9

Page 12

Concentric exposed thermostatic mixer shower

Fig.14

Flat edge of

the Maximum

temperature stop

in the 12 o’clock

Maximum

temperature

stop pin

position

Fig.15

ADJUSTING THE MAXIMUM

TEMPERATURE SETTING

(and fitting the levers)

The maximum temperature stop factory set to

38°C (this can be adjusted during installation).

Note: Before fitting the levers the

maximum temperature should be checked

on site to guarantee user safety

• Toadjustthemaximumtemperaturesetting,

remove the temperature control knob.

• Allowthewatertorununtilthetemperature

has stabilised, adjust the temperature control

spindle by hand (fig.14).

• Whentheshoweringtemperatureis

satisfactory turn off the shower.

• Fitthetemperatureknob,makingsurethe

maximum temperature stop pin is as close to

the flat edge of the maximum temperature

stop as possible (fig.15).

• Toassembletheflowandtemperature

controls, please see (fig.16) (see fig.15 for

the position of the maximum temperature stop).

Secure the controls in place with the retaining

grub screws and fit the levers (fig.16).

Recommended outlet temperatures

The BuildCert TMV scheme recommends the

following set maximum mixed water outlet

temperatures for use in all premises:

44°C - for bath fill but see notes below.

41°C - for showers.

41°C - for washbasins.

38°C - for bidets.

The mixed water temperatures must never

exceed 46°C at terminal fitting.

Pin positioned as close

to the at edge as possible

The British Burns Association recommends 37 to

37.5°C as a comfortable bathing temperature

for children. In premises covered by the Care

Standards Act 2000, the maximum mixed water

outlet temperature is 43°C.

10

Page 13

Concentric exposed thermostatic mixer shower

Temperature

control

Flow control

On

Off

Hot

Cold

OPERATING THE SHOWER

(fig.17)

• Tostarttheshower,turntheOn/Offow

control clockwise until it hits the stop for

maximum flow.

• Tostoptheshower,turntheOn/Offow

control anti-clockwise until it hits the stop.

• Toadjusttheshoweringtemperaturerotate

the temperature control – clockwise for cooler

and anti-clockwise for hotter.

CAUTION: Exposed metal surfaces may

become hot during use.

Fig.16

Temp

control

Fig.17

Washer A

Flow control

Washer B

Maximum

temp stop

Grub

screw

Levers

11

Page 14

Concentric exposed thermostatic mixer shower

APPROVALS

This mixer valve has been designed to comply with the requirements of: BS EN 1111

BS EN 1287

WRAS

FLOW CHART

bar

4.8

4.2

3.6

3.0

2.4

1.8

1.2

0.6

0.0

0.0 3

•Flowrateat38°C

•Flowcontrolfullyopen

•Openoutlet

•Noowregulatortted

6 9 12 15 18 21 24 27 30 33 36

Pressure/Flow rate

l/min

12

Page 15

DIMENSIONS

Concentric exposed thermostatic mixer shower

117mm

35mm

G1/2

ø55mm

G1/2

150mm

All dimensions listed in this fitting book regarding the product and installation are approximate.

13

69mm

Page 16

SPARE PARTS

Concentric exposed thermostatic mixer shower

3

1

8

9

4

Ref. Description Part No.

1. Elbow assembly complete: 83313870

2. Nut and Olive 83312790

3. Mounting plate 83313890

4. Handle assembly 86002960

5. Plug 83313900

6. Adapter 83313910

5

9

2

6

7

Ref. Description Part No.

7. Flow regulators are available from Triton at

the following ratings:

(3 Ltr/min) 22010310

(4 Ltr/min) 22011740

(5 Ltr/min) 22011750

(6 Ltr/min) 22011760

(7 Ltr/min) 22011610

(8 Ltr/min) Supplied 22011280

8. 110mm adaptor 86003140

9. Ser vice kit 83314150

14

Page 17

Concentric exposed thermostatic mixer shower

MAINTENANCE

The following maintenance procedure must

be carried out for commercial and health care

premises, but is not necessarily required for

domestic installations.

Maintenance of the unit is required to give

continued performance after installation and that

it continues to provide scald prevention.

Note: A thermostatic mixing valve in need of

maintenance can be undetectable in normal

use and only becomes apparent when a

disruption occurs in the hot or cold water supply

temperatures or pressures.

The frequency of routine maintenance of the

internal of the valve will depend mainly on the

water supply condition. Experience of local

conditions will dictate the intervals for inspection

and in-service testing; guidance has been

given below which can be adjusted for local

requirements.

a) Initially check the filters for debris once every

three months and clean if necessary.

b) Perform a thermal shut off test

every three months, and check the

maximum temperature setting. See the

‘Commissioning’ section for the details of

this test and readjustment of the maximum

temperature setting if required.

c) If the maximum water temperature varies

by more than 2°C from the commissioned

setting then carry out the following checks

•Checktheisolatingvalvesarefullyopen.

•Checktheinternalsurfaceforscaling.

If the body requires descaling then it should be

removed from the pipework to carry this work out

(all rubber parts must be removed before descaling).

•Checkthefunctionofthenon-returnvalves

The non-return valves (NRVs) prevent cross-flow

between hot and cold supplies under unequal

pressure conditions. They are designed for long

life with no maintenance.

If these checks do not highlight the reason

for the temperature variation, then internal

components will require replacement; please see

the spare parts list.

Cleaning

Triton recommends that all products are cleaned

using warm, soapy water.

Do not use abrasive or aggressive chemical

cleaning products as this may affect the product

surface finish and invalidate your guarantee.

Cleaning the filters (fig.A)

It is advised that this should be carried out by a

qualified person.

• Turnoffthewatersuppliesbeforestarting.

• RemoveHotandColdelbows.

• Loosentheretaininggrubscrewandpullthe

adaptor from the elbow assembly.

• Removetheretainingclipandvalve.

• Washthelterthoroughlyunderrunningwater,

use a suitable brush to remove all debris.

• Reassembleinreverseorder.

Elbow

Elbow adaptor

Non-return

valve

Grub screw

Filter

Retaining clip

Fig.A

Disinfection

Where chlorine is used for the disinfection

of water systems all relevant guidelines and

approved codes of practice must be strictly

followed. Failure to comply with the relevant

guidelines and approved codes of practice may

invalidate your guarantee.

WARNING!

DO NOT use ‘powerful’ abrasive or

solvent cleaning fluids when cleaning the

shower as they may damage the fittings.

15

Page 18

Concentric exposed thermostatic mixer shower

FAULT FINDING

The following can be carried out by a competent person

Problem/Symptom Cause Action/Cure

1 Water too hot.

2

Water too cold.

1.1 Temperature control

incorrectly commissioned.

1.2

Not enough cold

water flowing through

shower.

1.3

Increase in the

ambient cold water

temperature.

1.4

Cold water supply

blocked.

1.5

High volume of cold

water drawn off elsewhere.

Temperature control

2.1

incorrectly commissioned.

2.2

Not enough hot

water flowing through

shower.

2.3

Decrease in the

ambient cold water

temperature.

2.4

Insufficient hot water

supplies from the heating system.

1.1.1 Refer to commissioning section.

1.2.1

Reposition the temperature control.

1.3.1

Reposition the temperature control.

1.4.1

Turn off shower and consult a competent

plumber or contact Customer Service.

1.5.1

Reduce the simultaneous demand from the

mains supply.

Refer to commissioning section.

2.1.1

2.2.1

Reposition the temperature control

2.3.1 Reposition the temperature control

2.4.1

Make sure heating appliance is set to maxi-

mum or has sufficient stored hot water.

2.4.2

Make sure heating appliance is igniting by

trying a hot water tap elsewhere.

3

High water flow

and/or poor

performance

on a mains fed

system.

2.5

Hot water supply

blocked or restricted.

Flow regulator not

3.1

fitted.

Turn off shower and consult a competent

2.5.1

plumber or contact Customer Service.

3.1.1

Fit the supplied flow regulator (see ‘To fit a

flow regulator’ on page 9).

16

Page 19

Concentric exposed thermostatic mixer shower

FAULT FINDING

Problem/Symptom Cause Action/Cure

4 Water does not

flow or shower

pattern collapses

when another

outlet is turned

on.

The following is recommended for a professional qualified installer only

Water too cold.

5

Shower controls

6

noisy when in

use.

7

Shower will not

shut off.

4.1 Water supplies cut off.

4.2

Shower unit blocked.

4.3

Blockage in pipework.

4.4

Showerhead blocked.

4.5

System not capable

of supplying multiple

outlets at the same

time.

5.1

Running pressure is

excess of maximum

recommended.

Running pressure in

6.1

excess of maximum

recommended.

7.1

. Pipework not flushed

out before connecting

to the unit. Internal

components damaged.

4.1.1 Check water elsewhere in house and if

necessary contact local water company.

4.2.1

Inspect the filters. Clean if necessary.

4.3.1 Turn off the shower and consult a suitably

competent plumber.

4.4.1

Clean the showerhead.

4.5.1 Reduce the simultaneous demand.

4.5.2 Make sure stop or service valve is fully

open.

4.5.3 Check if there is sufficient water pressure.

5.1.1 Fit a pressure reducing valve.

Fit a pressure reducing valve.

6.1.1

7.1.1

Service valve.

17

Page 20

UK SERVICE POLICY

In the event of a product fault or complaint occurring, the following

procedure should be followed:

1. Telephone Customer Service on 0844 980 0750 having available,

your details including post code, the model number and power

rating of the product, together with the date of purchase and, where

applicable, details of the particular fault.

2. If required, the Customer Service Advisor will arrange

for a qualified engineer to call.

3. All products attended to by a Triton service engineer must be installed

in full accordance with the Triton installation guide applicable to the

product. (Every product pack contains an installation guide, however,

they can also be bought via our Customer Service Spares Department).

4. Our engineer will require local parking and if a permit is required this

must be available to the engineer on arrival at the call.

5. It is essential that you or an appointed representative (who must

be over 18 years of age) is present for the duration of the service

engineer's visit. If the product is in guarantee you must produce proof

of purchase.

6. Where a call under the terms of guarantee has been booked and

the failure is not product related (i.e. scaling and furring, incorrect

water pressure, pressure relief device operation or electrical/plumbing

installation fault) a charge will be made. A charge will also be issued

if nobody is at home when the service engineer calls or adequate

parking/permit is not available.

7. If the product is no longer covered by the guarantee an up front fixed

fee will be charged before the site visit.

8. Should proof of purchase not be available on an “in-guarantee” call,

or should the service engineer find that the product is no longer

under guarantee, the engineer will charge the same fixed price and

the customer will be expected to pay the engineer before he leaves.

If payment is not made on the day an administration charge will be

added to the fixed charge.

9. If a debt is outstanding from a previous visit, or from any other Triton

purchase. Triton reserves the right to withhold service until the debt

has been settled.

10. Triton takes the health, safety and wellbeing of its employees very

seriously and expects customers to treat all staff members with respect.

Should any employee feel threatened or receive abuse, either verbally

or physically, Triton reserves the right to withhold service and will

support the employee with a legal prosecution.

Replacement Parts Policy

It is the policy of Triton Showers to maintain parts availability for the

duration of production and a period of 5 years thereafter in accordance

with industry standards. In the event of a spare part not being available a

substitute part will be supplied.

Spare parts can be ordered via our online spare parts store, or by

telephoning Triton Spares Department. Payment should be made by

credit/debit card (excluding American Express or Diners Card). Payment

can also be made by pre-payment of a pro-forma invoice, by cheque or

postal order.

Telephone orders are based on information given during of the call. Before

contacting Triton, please verify your requirements using the information

contained in the user guide. Triton cannot accept liability for incorrect part

identification.

TRITON STANDARD GUARANTEE

Triton guarantee this product against all mechanical

defects arising from faulty workmanship or materials

for a period of five years for domestic use only, from

the date of purchase, provided that it has been

installed by a competent person in full accordance

with the fitting instructions.

Any part found to be defective during this guarantee

period we undertake to repair or replace at our

option without charge so long as it has been

properly maintained and operated in accordance

with the operating instructions, and has not been

subject to misuse or damage.

This product must not be taken apart, modified or

repaired except by a person authorised by Triton.

This guarantee applies only to products installed

within the United Kingdom and does not apply to

products used commercially. This guarantee does

not affect your statutory rights.

What is not covered:

1. Breakdown due to: a) use other than domestic

use by you or your resident family; b) wilful act

or neglect; c) any malfunction resulting from the

incorrect use or quality of electricity, gas or water

or incorrect setting of controls; d) failure to install

in accordance with this installation guide.

2. Repair costs for damage caused by foreign

objects or substances.

3. Total loss of the product due to non-availability

of parts.

4. Compensation for loss of use of the product or

consequential loss of any kind.

5. Call out charges where no fault has been found

with the appliance.

6. Call out charges where the water supply cannot

be isolated, this includes consequential losses

arising from unserviceable supply valves.

7. The cost of repair or replacement of pressure

relief devices, showerheads, hoses, riser rails and/

or wall brackets, isolating switches, electrical

cable, fuses and/or circuit breakers or any other

accessories installed at the same time.

8. The cost of routine maintenance, adjustments,

overhaul modifications or loss or damage arising

therefrom, including the cost of repairing

damage, breakdown, malfunction caused by

corrosion, furring, pipe scaling, limescale, system

debris or frost.

Triton Showers

Triton Road

Nuneaton

Warwickshire CV11 4NR

Triton is a division of Norcros Group (Holdings) Limited

3-1-2012

TRITON reserve the right to change product specification without prior notice. E&OE. © TRITON SHOWERS 2012

Customer Service: % 0844 980 0750

Trade Installer Hotline:

www.tritonshowers.co.uk

E-mail: serviceenquiries@tritonshowers.co.uk

0844 980 0730

%

0844 980 0744

Fax:

Page 21

Check out our full range of Showers

Electric Showers

Digital Showers

Mixer Showers

Power Showers

Smart Showers

Shower Towers

From Top Shower Brands

Mira Showers

Aqualisa Showers

Triton Showers

Gainsborough Showers

Shower Pumps can upgrade your showering experience even more

Stuart Turner Shower Pumps

Salamander Shower Pumps

Grundfos Shower Pumps

Loading...

Loading...