Page 1

Installers please note these InstructIons are to be left wIth the user

2180403L - June 2012

Installation and

operating

instructions

AS2000X

power shower

Page 2

Aquasensation AS2000X

CONTENTS Page

Plumbing and electrical notes ......................................................... 1

Introduction ................................................................................... 2

Safety warnings .............................................................................. 2

Main components .......................................................................... 3

Specifications .................................................................................. 3

Site requirements ........................................................................ 4 − 5

General installation notes ............................................................... 5

Siting of the shower ....................................................................... 6

Removing the cover........................................................................ 7

Plumbing connections ................................................................. 7 − 9

Fitting the shower to the wall ........................................................ 10

Electrical connections .................................................................... 11

Commissioning .......................................................................... 12 − 14

Fitting the riser rail .................................................................... 15 − 16

Operating the shower................................................................ 17 − 18

Adjusting the maximum temperature stop .................................... 18

Cleaning the filters ........................................................................ 19

Spare parts .................................................................................... 20

Fault finding .............................................................................. 21 − 22

Water/Cable entry points diagram .................................... 23

Guarantee, service policy, etc. ..................................................rear cover

To check the product suitability for commercial and multiple installations, please contact Triton’s

specification advisory service before installation.

Telephone:

Facsimile:

E mail:

0844 980 0730

0844 980 0744

technical@tritonshowers.co.uk

Page 3

Aquasensation AS2000X

1

1 PLUMBING NOTES

1.1 All installations must comply with Water

Regulations or Water Bylaws.

1.2 Supply pipes must be flushed to clear

debris before connecting the shower unit.

1.3 DO NOT connect the shower unit to

the mains cold water supply as it would

damage the unit and also, the installation

would be in breach of Water Regulations.

1.4 DO NOT use excessive force when making

connections to the flexible hose or

showerhead – finger tight is sufficient.

1.5 ALL plumbing connections are to be

completed and water supplies turned on

BEFORE switching on the electricity supply.

The shower must not be operated dry

without water.

1.6 DO NOT solder pipes or fittings within

300 mm of the shower appliance, as heat

transfer can damage components.

1.7 When installed, the top of the shower unit

must be at least 75 mm lower than the

base of the cold water storage cistern to

prevent the pump being run dry without

water.

1.8 A dedicated cold water supply must be

taken directly from the cold water cistern

to the shower. This draw-off must be on

the opposite side of the cistern to the float

operated valve to reduce the risk of air

entering the unit.

1.9 The action of the pump is to increase the

flow rate. If the supply pipework cannot

handle the resulting flow rate then:

1.9.1 The anticipated flow rate may not

be achieved.

1.9.2 Air may be drawn into the hot

supply from the vent pipe causing

spluttering and temperature fluctuations at

the showerhead.

1.10 Fullway isolating valves MUST be fitted

on the hot and cold water supplies to

the shower as an independent means

of isolating the water supplies should

maintenance or servicing be necessary. DO

NOT use stop taps or ball-o-fix type valves

which restrict flow.

2 ELECTRICAL NOTES

2.1 The installation must comply with BS 7671

‘Requirements for electrical installations’

(IEE wiring regulations). Make sure the

incoming hot and cold water supplies to

the shower are adequately earth bonded.

2.2 DO NOT turn on the electrical supply

until the plumbing connections have been

completed. Only then can the electricity be

switched on in order to power the solenoid

to turn water on to the shower when

commissioning. The shower must not be

operated dry without water.

2.3 The mains supply must be 230/240V, at

50Hz, connected to the unit via a double

pole switched 3 Amp fused connection

unit (not supplied) with a minimum 3 mm

contact separation gap in each pole.

2.4 In accordance with ‘The Plugs and Sockets

etc. (Safety) Regulations 1994’, this unit

is intended to be permanently connected

to the fixed electrical wiring of the mains

system.

2.5 Fuses do not give personal protection

against electric shock.

2.6 A 30mA residual current device (RCD)

MUST be installed. This may be part of the

consumer unit or a separate unit.

Page 4

Aquasensation AS2000X

2

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your Triton Power

Shower. Please read them carefully.

The shower installation must be carried out by

suitably competent person and in sequence of

this instruction book.

Care taken during the installation will ensure a

long and trouble free life from your shower

IMPORTANT: All plumbing connections must

be completed BEFORE making the electrical

connections.

Please read through the whole of this book

before beginning your installation.

IMPORTANT: The fittings on the pipe inlet

elbows are of the push-in type. The pipework

must be cut with a pipe cutter and all burrs

and rough edges removed from the end

of the tube. The fittings can be used with

copper and plastic pipe.

Where chrome plated pipe is used, remove

the first 25 mm of plating.

Note: The pump inside this product is rated

15 minutes on / 45 minutes off duty cycle.

SAFETY WARNINGS

a. DO NOT insert fingers into the push-in inlet

fittings. Doing so could cause injury.

b. Under no circumstances must this product

be connected to mains cold or hot water

supplies. Failure to comply will invalidate

the guarantee.

c. The shower MUST NOT be used if

suspected of being frozen.

d. The outlet of this appliance MUST NOT be

connected to any form of tap or fitting not

recommended by the manufacturer.

e. The showerhead cartridge MUST be cleaned

regularly to remove scale and debris.

f. This appliance MUST be earthed.

g. Switch off immediately at the isolating

switch if water ceases to flow during use.

h. DO NOT operate the shower outside the

guidelines laid out in ‘site requirements’.

i. DO NOT operate the shower if the

showerhead or spray hose becomes

damaged.

j. DO NOT restrict flow out of the shower by

placing the showerhead in direct contact

with your body.

Replacement parts can be ordered from Triton

Customer Service. See ‘spare parts’ for details and part

numbers.

WARNING!

The power shower does not contain

a thermostatic valve – it will not shut

off in the event of failure of either

the hot or cold water supplies.

A 30mA residual current device (RCD) MUST

be installed in all UK 230V electric and

pumped shower circuits. This may be part of

the consumer unit or a separate unit.

Page 5

Aquasensation AS2000X

3

Hot water temperature

Maximum temperature 65°C.

BS 6700 recommends that the temperature

of stored water should never exceed 65°C. A

stored water temperature of 60°C is considered

sufficient to meet all normal requirements and

will minimise the effects of scale in hard water

areas.

Maximum static inlet pressures

100 Kpa (1 bar) or 10m (supplies must be

gravity fed at nominally equal pressures).

Minimum static inlet pressure

0.75 Kpa (0.0075 bar) or 75mm (required to

prime the integral centrifugal pump).

Maximum supply head 10m.

SPECIFICATIONS

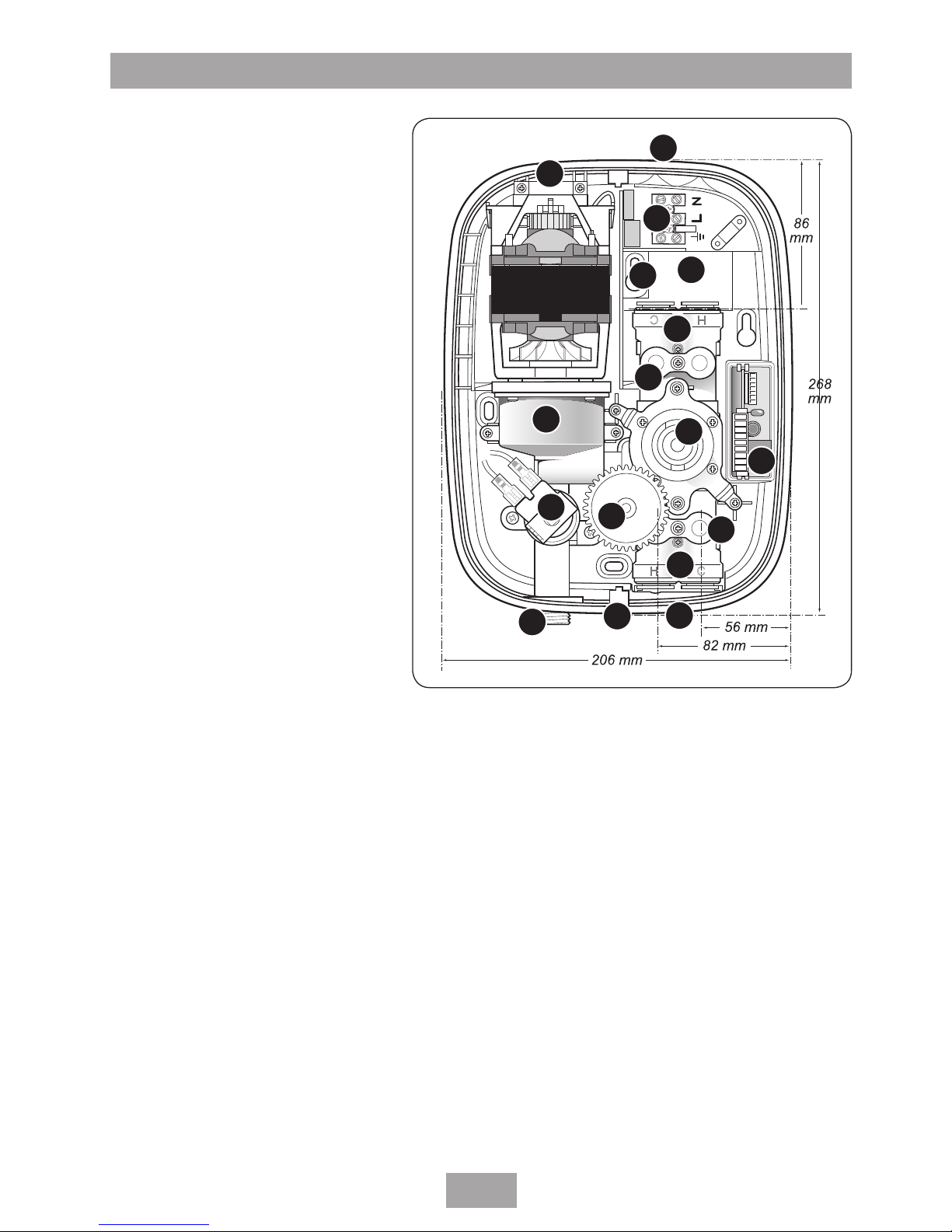

MAIN COMPONENTS

1. Top pipe entry and cable entry

2. Terminal block

3. Cover screw fixing

4. Motor retaining bracket

5. Rear pipe entry and cable entry

6. Wall fixing holes

7. Pipe inlet elbow - top

(contains single check valves)

8. Filter cover - top

9. Pump

10. PCB

11. Temperature control valve

12. Solenoid

13. Filter cover - bottom

14. Pipe inlet elbow - bottom

(contains single check valves)

15. Outlet

16. Bottom pipe entry

17. Potentiometer gear

Fig.1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Page 6

Aquasensation AS2000X

4

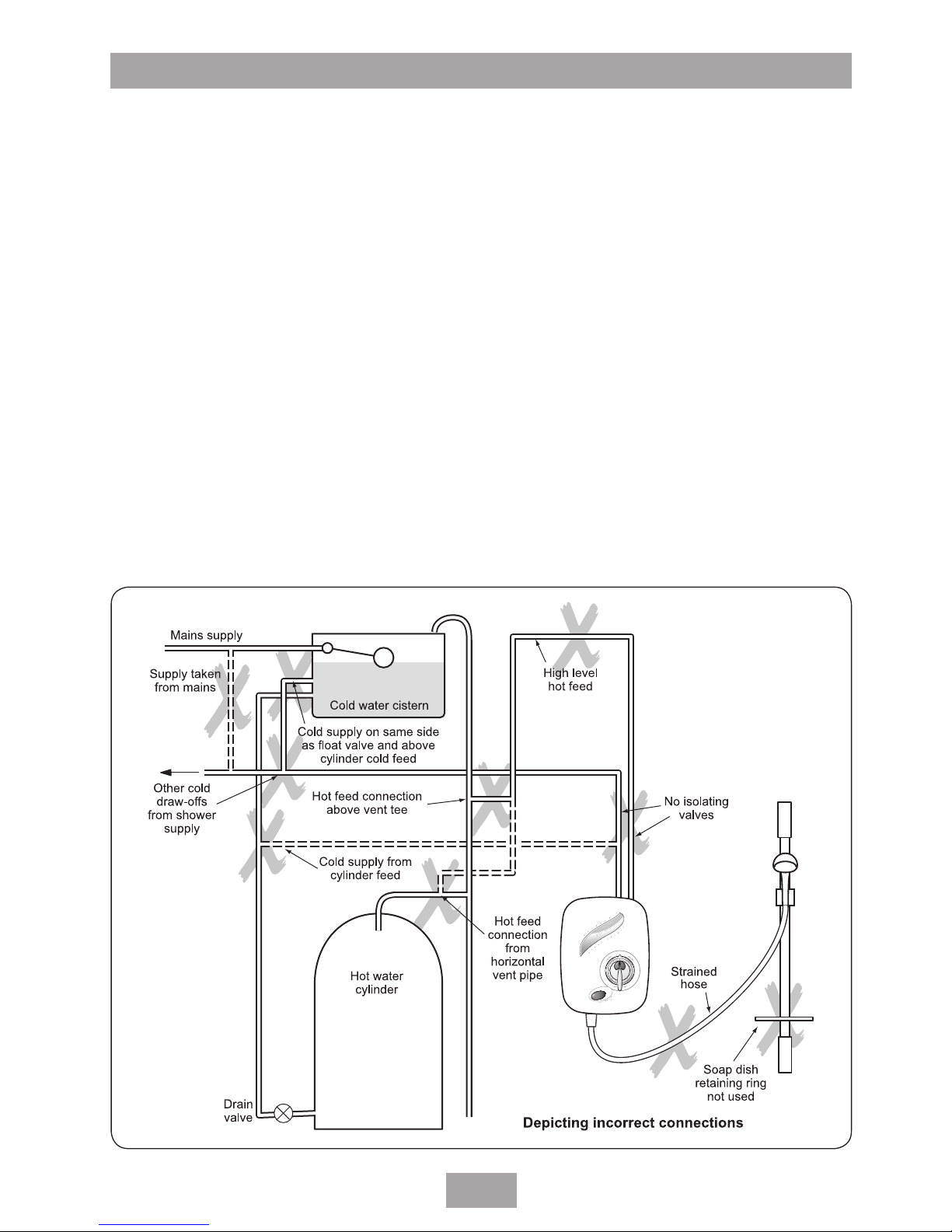

Fig.3 illustrates all the incorrect connections that

must be avoided.

All pipework to the shower unit must be routed

where it remains below the level of water in

the cistern. In the case of horizontal sections

of pipework in lofts, it may be necessary to

fit automatic air vents at high points on the

supplies to remove the possibility of air locks.

For the operation of the shower only, it is

recommended that the cold water storage

cistern is capable of holding at least 114 litres

(25 gallons). Where other hot and cold outlets

are likely to be in use simultaneously, the storage

capacity should be increased to 228 litres (50

gallons) in accordance with BS 6700.

Do ensure compliance with the Water

Regulations/Bylaws.

DO NOT connect to a combination cylinder

unless there is a guaranteed 114 litre cold supply

to the cylinder as the shower can deliver up to

14 litres per minute. It is advisable to check that

Mains supply

Isolating

valve

Cold water cistern

Vent pipe tee

Isolating

valve

Hot supply

Hot water

cylinder

Drain

valve

Other hot water

draw-offs

Alternative

connection

Shower unit

Ring main

25mm min

Isolating spur

(3A fused)

outside bathroom

Dedicated cold supply

10m

max

75mm

min

Isolating

valves

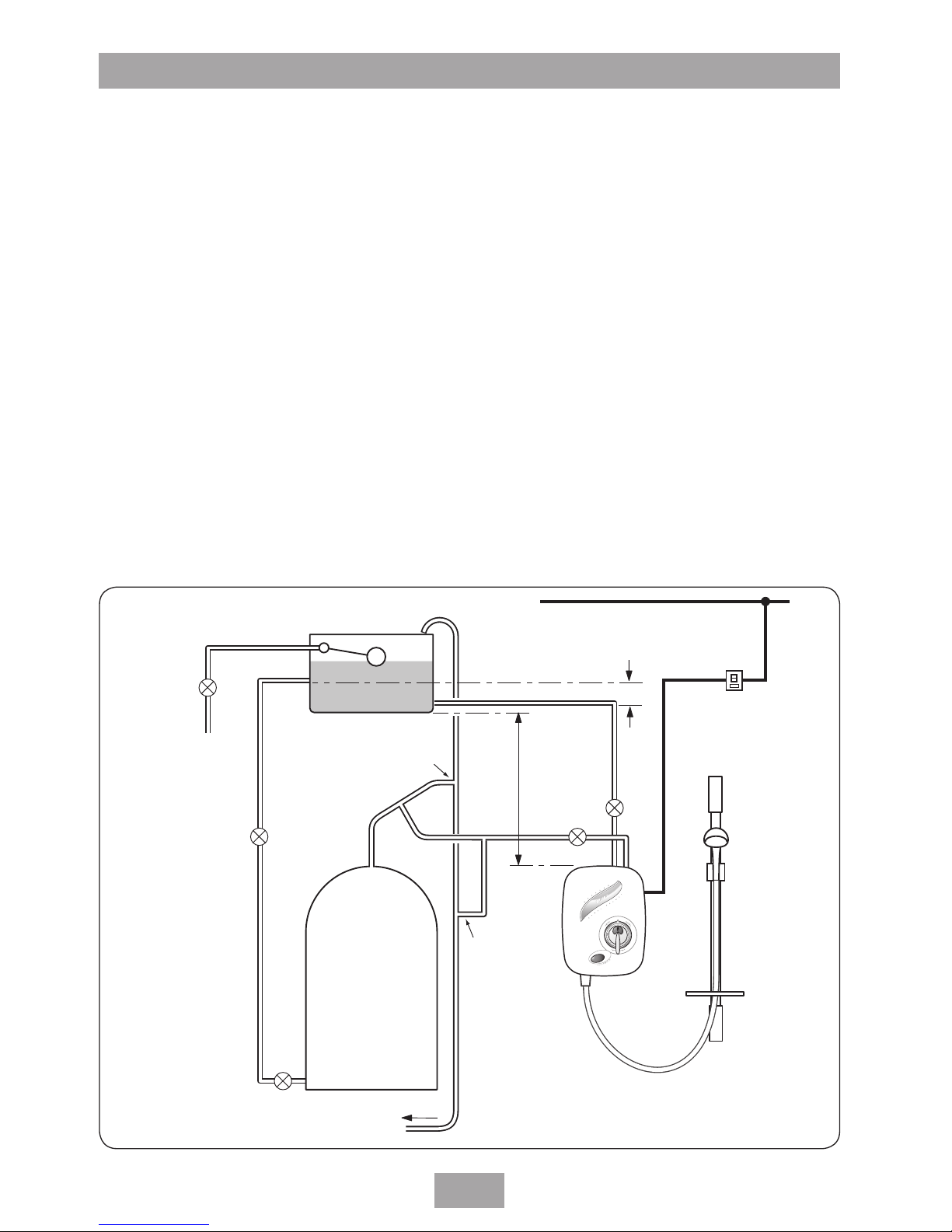

SITE REQUIREMENTS

Water

The installation must be in accordance with

Water Regulations/Bylaws and BS 6700.

For correct operation of this shower unit, both

hot and cold water supplies to the appliance

must be gravity fed, at nominally equal

pressures, from a cold water storage cistern and

a hot water storage cylinder.

The water circuit should be installed so that the

flow is not significantly affected by other taps

and appliances being operated elsewhere on the

premises.

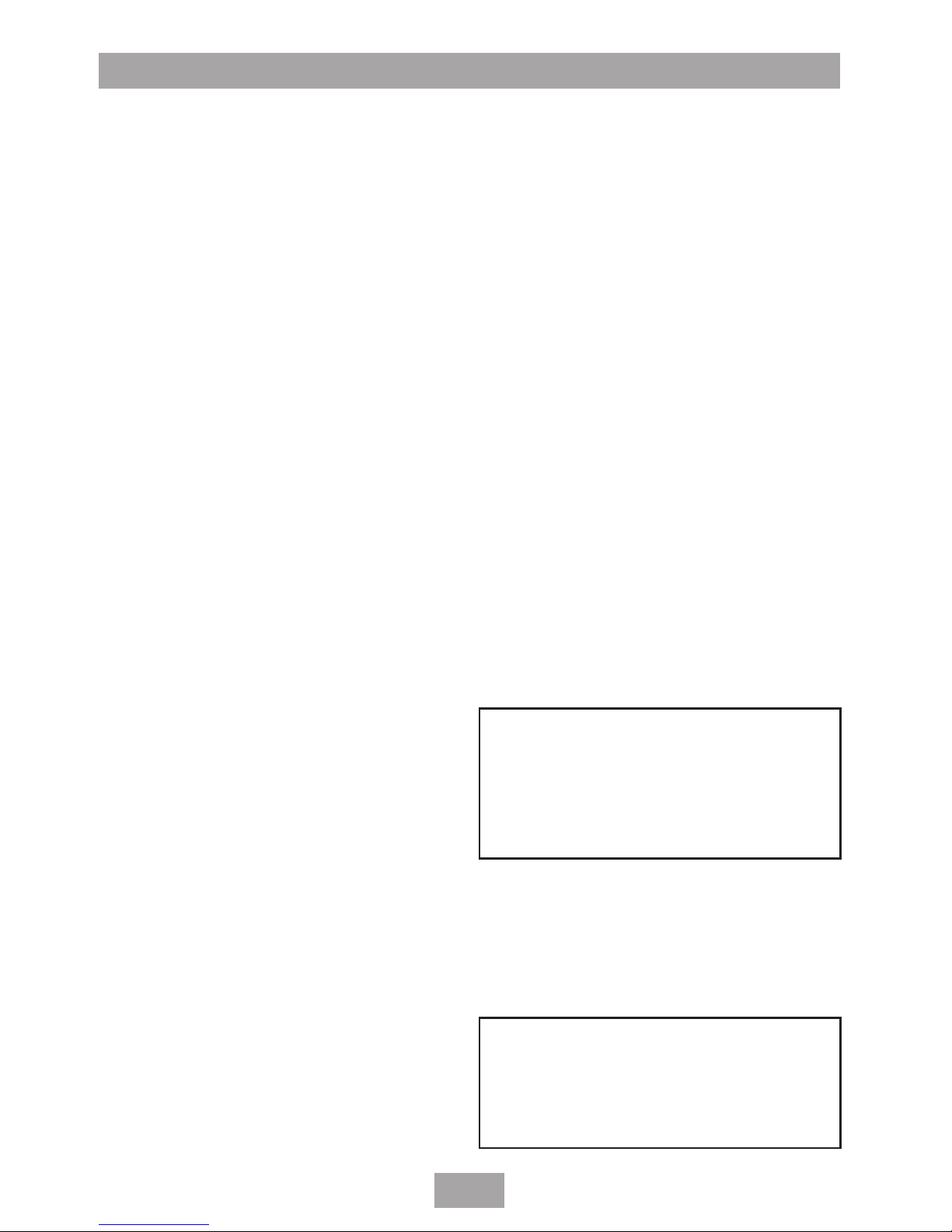

Fig.2 shows a recommended installation where

the hot water supply for the shower is made

via a tee connection on the underside of the

horizontal section of pipework from the cylinder.

Alternatively, the connection can be taken from

the hot supply pipe to other outlets as long as it

is the first draw-off below the ventilation pipe tee.

Fig.2 (Diagrammatic view – not to scale)

Page 7

Aquasensation AS2000X

5

the infill rate from the float operated valve meets

the output requirements..

It is recommended that there is a minimum

of approximately 114 litres (25 gallons) of hot

water storage per appliance.

The shower MUST NOT be connected to the

mains cold water supply.

DO NOT use jointing compounds.

GENERAL INSTALLATION NOTES

1. DO NOT take risks with plumbing or

electrical equipment.

2. DO NOT install this unit in a position where

it could become frozen.

3. Isolate electrical and water supplies BEFORE

proceeding with installation work.

4. Shower control MUST be fed from a cold

water storage cistern and hot water cylinder

that provides nominally equal pressures.

Fig.3 (Diagrammatic view

not to scale)

5. The unit must be mounted onto the finished

wall surface (on top of tiles).

DO NOT tile up to the unit after fixing to

the wall.

6. If installing with rear inlet supplies, it is

recommended the supply pipework is sealed

to the wall so as to prevent water from

leaking back into the wall.

7. In solid wall installations, the supply

pipework should be housed within

ducting in order to allow some free lateral

movement when making connections and

to ensure compliance with requirements of

accessibility of pipes and pipe fittings.

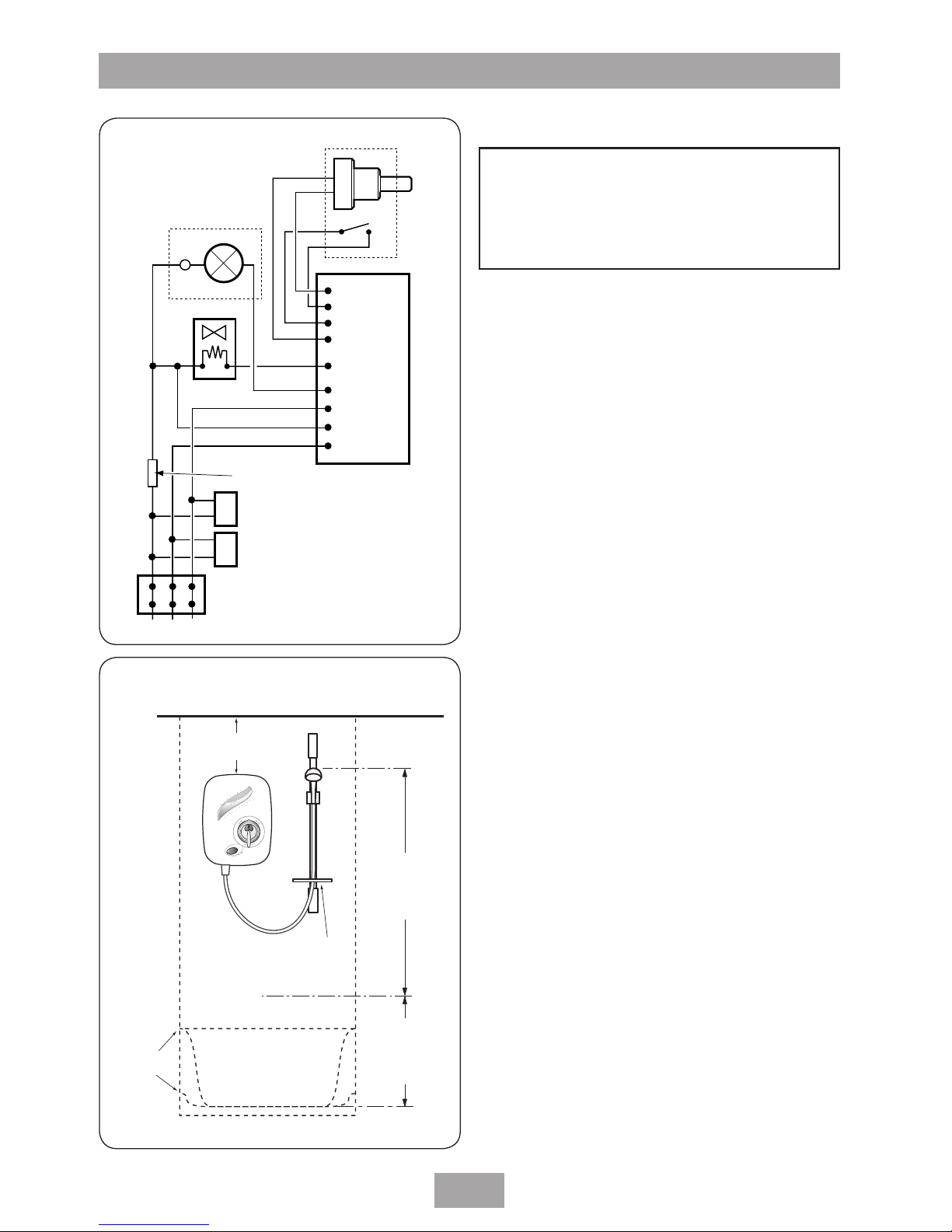

Fig.4 shows a schematic wiring diagram of the

unit.

Page 8

Aquasensation AS2000X

6

Shower can

be mounted

either side of

the riser rail

Spill-over

level

Ceiling

Use soap dish

retaining ring

Height of

sprayhead

and shower

to suit user’s

requirement

Shower unit

must not be

within an area

1 metre

from base

Space for cover

screw access

Fig.5

SITING OF THE SHOWER

IMPORTANT: If fitting to a tiled wall, always

mount the unit on the surface of the tiles.

NEVER tile up to the unit.

Refer to fig.5 for correct siting of the shower.

Position the unit vertically where it will NOT

be in direct contact with water from the

showerhead.

Note: Allow sufficient room between the ceiling

and the shower unit to access the top cover

screw.

Position the shower and showerhead on the wall

so that all controls can be comfortably reached

when using the shower.

The showerhead and riser rail can be positioned

either side of the shower unit.

Note: Water Regulations require the showerhead

be ‘constrained by a fixed or sliding attachment

so that it can only discharge water at a point

not less than 25 mm above the spill-over level

of the relevant bath, shower tray or other fixed

appliance’. The use of the supplied soap dish will

in most cases meet this requirement, but if the

showerhead can be placed within a bath, basin

or shower tray, then a device must be fitted to

prevent back-flow.

L E N

Potentiometer

Switch

Solenoid

Motor

Capacitor 2

RFI suppression coil

Capacitor 1

PCB

Thermal

fuse

Fig.4 (schematic view )

WARNING!

The shower must not be positioned

where it will be subject to freezing

conditions.

Page 9

Aquasensation AS2000X

7

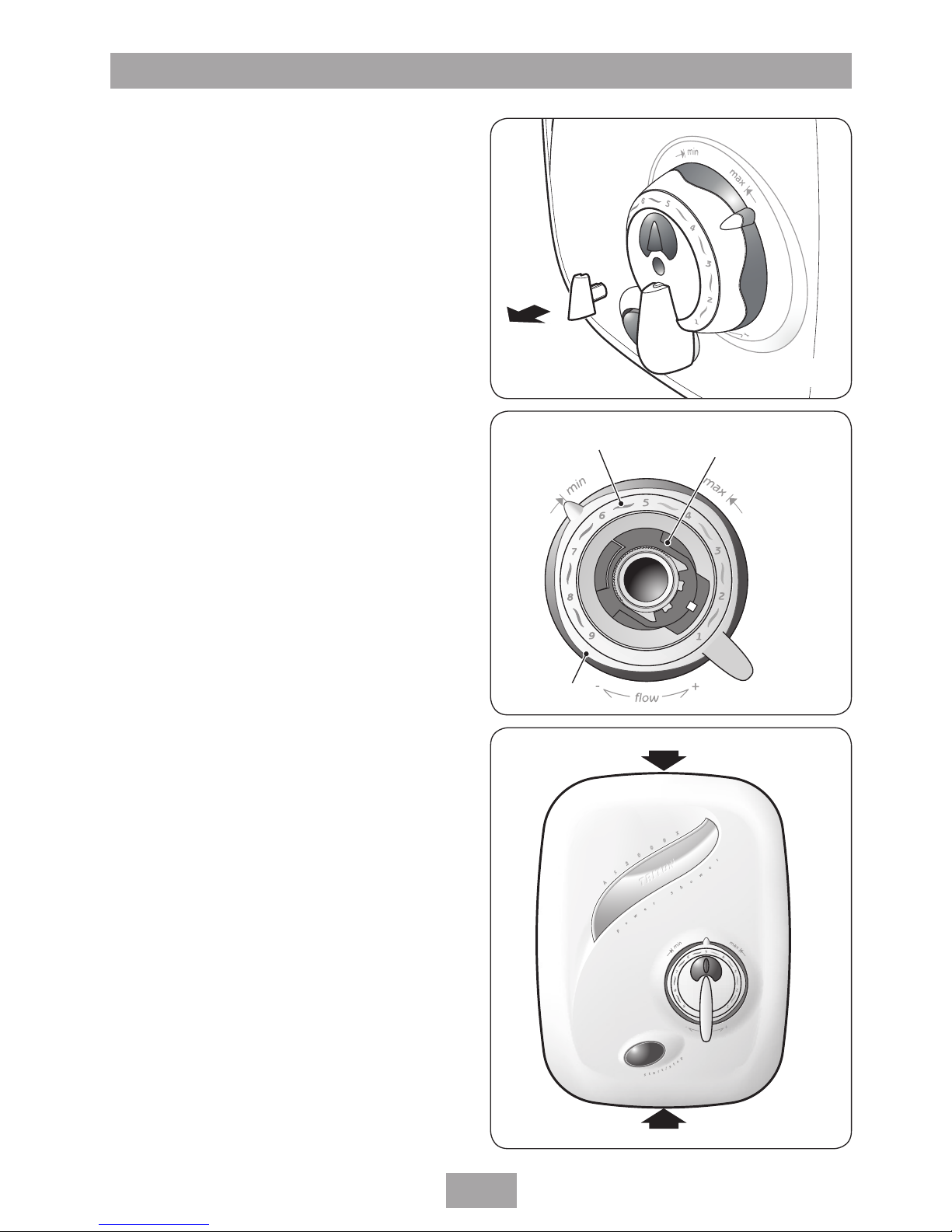

Fig.6

REMOVING THE COVER

To remove the cover, first pull off the cover trim

(fig.6) to reveal the retaining screw.

Undo the screw and pull off the inner

temperature control. Now remove the outer flow

control assembly comprising of the flow control,

maximum temperature stop and temperature

disc (fig.7).

Note: If adjustment of the maximum

temperature stop is required, refer to section

’Adjusting the maximum temperature stop’.

Remove the two cover fixing screws – top and

bottom (fig.8).

Carefully lift the cover away from the backplate.

Lay aside the cover and screws until the unit is

fully installed.

Note: When removing the cover for future

maintenance purposes be aware of the lead

connecting the Start/Stop switch to the PCB

harness. To release, squeeze the connection

block arms and pull apart. DO NOT let the unit

dangle by the lead.

PLUMBING CONNECTIONS

Plumbing to be carried out before wiring

Note: The outlet of the shower must not be

connected to anything other than the hose and

showerhead supplied.

DO NOT use jointing compounds on any pipe

fittings for the installation.

When connecting pipework avoid using tight

90° elbows. Swept or formed bends will give

optimum performance.

Isolate the mains water supply to the cold water

cistern. Drain the hot and cold pipes by opening

all taps.

The hot water supply can be taken from the hot

supply pipe from the cylinder. Make sure that it

is the first draw-off below the ventilation pipe

tee in order to minimise the effects of water

draw-off elsewhere in the house (see fig.2).

Note: There must not be any other draw-offs

between the take-off point and the shower.

A dedicated cold water supply must be taken

directly from the cold water cistern to the

shower. This draw-off must be positioned

Temperature

disc

Flow control

Maximum

temperature

stop

Fig.7

Fig.8

Page 10

Aquasensation AS2000X

8

25 mm below the cold feed connection to the

hot water cylinder on the opposite side of the

cistern to the float operated valve (see fig.2).

This minimises air ingress into the pipework.

Plumbing options other than those outlined

in these fitting instructions could impair the

performance. For example, if hot and cold

connections are made after draw-off points

to other outlets, (eg. washing machine, taps,

etc.) it could result in unstable flows and

temperatures should other appliances operate at

the same time.

Run the hot and cold pipework to the shower

position, making sure that the pipework does

not rise above the level of water in the cold

cistern at any point to avoid air locks. Under

normal site conditions 15 mm pipework will be

adequate.

Decide the position of the shower. Cut the

pipework to the dimensions relevant to the

chosen direction of water entry into the shower.

IMPORTANT: For rear entry only, the supplied

elbows must be used. For ease of installation,

the backplate area adjacent to the top pipe

inlet must be cut out, including the top left

wall fixing hole.

When fitting the elbows to incoming pipework,

ensure the elbow collets are fully engaged with

the pipe.

Dimensions are shown in fig.9 and fig.10.

Note: The pipe inlets are marked for hot and

cold connections – left-hand side for hot inlet on

bottom entry (fig.11), but right-hand side for

hot inlet on top or rear entry (fig.12).

IMPORTANT: The fittings on the inlet elbows

are the push-in type. The pipework must be

cut with a pipe cutter and all burrs and rough

edges removed from the end of the tube. The

fittings can be used with copper and plastic

pipe.

If using chrome plated copper pipe, remove

the first 25 mm of plating completely from

the connecting surfaces. If not completely

removed then the collet will not grip the pipe

and under pressure the pipe may be forced

out.

Fig.9

Top

19 mm

26 mm

Cold

Hot

Area of

backplate

to remove

Wall

19 mm

34 mm

26 mm

Rear edge

of

backplate

Hot Cold

Wall

Rear

23.5 mm

Bottom

Fig.10

Page 11

Aquasensation AS2000X

9

Note: Pipework must be clipped or fixed to the

wall so that it cannot be moved or removed

without the aid of a tool.

Note: The pipe inlets contain filters. These

should be periodically removed and cleaned

in order to maintain the performance of the

shower. See section ‘cleaning’ on how to access

the filters.

IMPORTANT: The inlets contain check valves,

so before completing the connection of the

water supplies to the shower flush out the

pipework to remove all swarf and system

debris that may cause damage to internal

parts. This can be achieved by connecting

a hose to the pipework and turning on the

water supplies long enough to clear the

debris to waste.

IMPORTANT: Two factory fitted blanking

plugs are fitted to the top pipe inlets. These

should be left in position if bottom pipe entry

is required.

For top or rear pipe entry, the two plugs

MUST be removed and refitted into the

bottom pipe inlets. Failure to fit the

blanking plugs will result in the unit working

erratically.

Insert the pipe removal tool supplied between

the flange of the plug and the grey collet and

lever the plug outward (fig.13). Whilst holding

back on the collet, pull out each plug by hand.

When refitting the plugs in the bottom pipe

inlets, make sure they are pushed fully home.

Note: The unit is supplied with a splash guard

(fig.14) to prevent water ingress when top

entry pipework is used. If fitting top entry

pipework, make sure the splash guard is

correctly fitted (fig.14) before replacing the

cover.

Bottom

(rising)

supply

Top

(falling)

or rear

supply

Hot

side

Hot

side

Top

(falling)

or rear

supply

Hot

side

Fig.11

Fig.12

Blanking

plug

Fig.13

Splash guard

Fig.14

Page 12

Aquasensation AS2000X

10

FITTING THE SHOWER TO THE WALL

IMPORTANT: Before fitting the shower,

make sure the pipework is flushed out to

remove all debris, flux, etc.

For top pipe entry or top cable entry, remove

the relevant cut-outs by either breaking out or

by using a knife or junior hacksaw (fig.15).

If top entry for both pipe and cable is required,

then additionally remove the shaded area

(fig.15) by using a knife or junior hacksaw.

For bottom pipe entry, remove the cut-out and

break off the two circular parts (fig.16). Replace

the cut-out.

For rear pipe entry only, the supplied elbows

must be used with the necessary portion of

backplate cut away as shown in fig.9.

It will be necessary if rear cable entry is required,

for conduit or other routing of the electrical

cable to be completed before fixing the shower

to the wall.

Offer the backplate unit up to the completed

pipework and manoeuvre so that the end of the

pipes enter fully into the inlet fittings.

Mark positions for wall fixing holes using

backplate as template (fig.17). Note that four

fixing holes are provided but using only two

should be adequate for most site conditions.

Using the pipe removal tool supplied, push back

and hold the collets from the pipework (fig.18)

to disengage the pipework from the inlet elbows.

Remove unit from the wall.

Drill and plug the wall.

(An appropriate drill bit should be used. If the

wall is brick, plasterboard or a soft building block,

appropriate wall plugs and screws should be fitted).

Note: If fitting rising supplies to the unit, ensure

debris does not enter the pipes when drilling the

wall.

Offer the backplate unit up to the completed

pipework and manoeuvre so that the end of the

pipes enter fully into the inlet fittings.

Check the backplate is square and the fixing

holes are aligned (fig.17).

Secure to the wall with fixing screws supplied.

Remove shaded area

Cut out

for cable

Fig.15

Fig.16

Fig.17

Page 13

Aquasensation AS2000X

11

ELECTRICAL CONNECTIONS

The supply cable must conform to relevant

tables in current IEE regulations. In most cases

1 mm² twin and earth will be adequate.

The electrical rating of the shower is on the

rating label within the unit.

SWITCH OFF THE ELECTRICITY SUPPLY AT

THE MAINS.

Cable entry points are shown in fig.1. Conduit

entry can only be from the rear.

Route the cable into the shower, taking care to

avoid the area of the wall fixings and connect to

the terminal block (fig.19) as follows:

Earth cable to terminal marked E

Neutral cable to terminal marked N

Live cable to terminal marked L

IMPORTANT: Fully tighten the terminal block

screws and check that no cable insulation is

trapped under the screws.

Note: The supply cable earth conductor must

be sleeved.

The earth continuity conductor of the electrical

installation must be effectively connected

electrically to all exposed metal parts of other

appliances and services in the room in which the

shower is to be installed, to conform to current

IEE regulations.

Note: Fuses do not ensure user protection

against electric shock. In the interest of electrical

safety, all mains electric and pumped showers

should be fitted with a 30mA residual current

device (RCD). This may be part of the consumer

unit or a separate unit.

DO NOT switch on the electricity supply until

the water has been turned on to the unit and

connections have been tested for leaks.

IMPORTANT: The cover may be left off

initially only for commissioning.

Fig.18

Terminal block

Fig.19

WARNING!

This unit must be earthed. Isolate the

supply before starting.

Page 14

Aquasensation AS2000X

12

COMMISSIONING

The first operation of the shower is intended to

flush out any remaining system debris and to

ensure water is purged through the unit. This

operation must be carried out with the flexible

hose screwed to the shower outlet but without

the sprayhead attached.

Make sure the outlet of the flexible hose is

directed to waste.

Check the isolating valves controlling the water

supply to the unit are fully open.

Note: There is no need to fit the cover at

this stage but be aware of live parts when the

electricity is switched on temporarily.

Fit the temperature control onto the splined

spindle (fig.20).

On the PCB, make sure the commissioning link is

positioned on the middle two pins (fig.21).

Switch on the electric supply at the isolating

switch. Water will begin to flow under gravity

pressure.

Once the unit has been commissioned,

disconnect the electricity supply before removing

the commissioning link.

In order to dispel air and to prime both supplies

to the shower unit, turn the temperature control

several times within its rotational limits. ONCE

WARNING!

Before normal operation of the

shower, it is essential that the

commissioning and setup procedure

are correctly completed. Failure to do

so could cause the pump to run dry

without water and invalidate your

guarantee.

WARNING!

Be aware of live parts in the unit

when the electricity is switched on.

DO NOT tamper with any parts and

DO NOT deviate from the following

instructions.

Temperature control

Fig.20

Commissioning

link

Fig.21

Cold

Hot

Fig.22

Fig.23

Page 15

Aquasensation AS2000X

13

RESISTANCE IS FELT, DO NOT FORCE THE

CONTROL FURTHER.

Note: The temperature control rotates less than

one complete turn (fig.22). DO NOT force it

beyond these limits.

To stop the water flow, switch off the electricity

supply at the isolating switch.

Check for leaks in the pipework and remedy

if necessary. If rear entry has been used then

seal around pipes with mastic to prevent the

possibility of water entering the wall cavity.

DO NOT use plaster as this could cause difficulty

if maintenance is required later.

Setup procedure

MAKE SURE THE ELECTRICITY TO THE UNIT IS

SWITCHED OFF.

Pull off the temperature control. Remove the

commissioning link from the PCB (fig.23) and

store safely for future use.

Inside the cover, attached to the flow control

potentiometer is a 4-wire lead. Fit the connector

on the end of this lead to the 4 pins on the PCB

(fig.24) – it can fit either way.

Make sure the potentiometer control is rotated

fully anti-clockwise (fig.25).

Replacing the cover

Offer the cover to the backplate unit. Inside

the cover, attached to the stop/start switch is

a two wire lead. The socket on the end of this

lead must connect to the plug attached to the

backplate unit (fig.26).

Fit the cover, making sure the connector is fitted

to the PCB and the wires are clear of obstructions.

Secure with the top and bottom fixing screws

(fig.8).

WARNING!

Once the unit has been commissioned,

turn off the electricity supply at

the mains before removing the

commissioning link.

Fig.24

Fig.25

Fig.26

Page 16

Aquasensation AS2000X

14

With your fingers, rotate the valve spindle fully

anti-clockwise (fig.27) to the fully hot position.

Replace the flow control so that it aligns with

the ‘min’ position.

Fit the temperature disc (it will only fit one way)

and maximum temperature stop (fig.28).

Note: If adjustment of the maximum

temperature stop is required, refer to section

’Adjusting the maximum temperature stop’.

Replace the temperature control onto the valve

spindle. Make sure the pointer aligns with

setting ‘9’ on the temperature disc (fig.29).

Secure with the retaining screw and fit the cover

trim.

Switch on the electricity supply at the isolating

switch. Make sure both water supplies are still

turned on.

Once the installation of the riser rail is complete,

the shower is ready for normal operation.

Fig.29

Flow control

Temperature

disc

Temperature

control

Retaining

screw

Cover

trim

Maximum

temperature

stop

Fig.28

Fig.27

Page 17

Aquasensation AS2000X

15

*FITTING THE RISER RAIL

Decide the position for the rail on the wall within

the shower area. Proceed as follows:

Fit the showerhead holder onto the riser rail.

The correct orientation of the holder is when the

showerhead holder is sloping DOWN (fig.30).

To fit the showerhead holder onto the riser

rail unit, press and hold the button on the

underneath of the showerhead holder to release

the locking mechanism, then slide onto the rail.

Slide the supplied soap dish onto the riser rail

below the showerhead holder (fig.31).

Slide the top and bottom finishing trims onto the

riser rail (fig.32).

Push the two fixing brackets into the ends of the

riser rail (fig.33).

Offer the rail assembly to the wall (fig.34).

Using the brackets as templates, mark two upper

holes and two lower holes. Note there are four

provisions for screws per bracket – select the two

most suitable for your requirements. Make sure

the rail is aligned vertically.

Drill and plug the wall.

(An appropriate drill bit should be used. If the

wall is brick, plasterboard or a soft building block,

appropriate wall plugs and screws should be fitted).

Screw to the wall.

Slide the finishing trims onto the brackets. Make

sure the lug on each rail bracket end engages

into the slot on the fatter end of each trim before

push fitting the thinner ends in place (fig.35).

WARNING!

Check there are no hidden cables or

pipes before drilling holes for wall

plugs. Use great care when using

power tools near water. The use of

a residual current device (RCD) is

recommended.

Fig.33

Fig.30

Fig.32

Fig.31

Fig.34

*All kits are for illustration purposes only and are not

supplied unless otherwise stated.

Page 18

Aquasensation AS2000X

16

Washers

Shower

Showerhead

Showerhead

Holder

To remove a trim, push a small screwdriver or

similar through the slot in the trim end and

carefully pull away from the wall bracket.

Slide the soap dish down the rail so that its

bracket engages on top of the lower finishing

trim.

Adjusting the showerhead holder

To adjust the height, press the button

underneath the holder to release the locking

mechanism (fig.36). Still pressing the button,

move the holder up or down to suit user’s

requirement.

Fitting the hose and showerhead

Feed the flexible hose through the soap dish

aperture (fig.37) so the dish acts as a retaining

ring (Water Regulations).

Screw the flexible hose to the shower outlet and

showerhead, checking the supplied washers

are in place at both ends of the flexible hose

(fig.38).

Place the showerhead into the holder and check

that it fits correctly (fig.39).

Note: The holder is slightly tapered and the

showerhead and hose will only fit from one

direction.

IMPORTANT: It is the conical end of the hose

which grips into the holder. The showerhead

will not fit in the holder without the hose

attached. At this stage, disconnect the

showerhead and lay aside until the shower

unit has been commissioned.

CAUTION: This appliance is not intended

for use by persons (including children)

with reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of

the appliance by a person responsible for

their safety.

Children should be supervised to ensure that

they do not play with the appliance.

Fig.35

Fig.37

Fig.39

Fig.36

Fig.38

Page 19

Aquasensation AS2000X

17

OPERATING THE SHOWER

Check all plumbing and electrical supplies are

connected and switched on.

To start the shower, press the ‘Start/Stop’ button

(fig.40).

Adjust the control (fig.41) until the flow rate is

satisfactory.

For maximum flow, turn the flow control fully

anti-clockwise. For minimum flow, rotate the

flow control fully clockwise.

To adjust the temperature rotate the control

(fig.42). The temperature is numbered for ease

of use. The temperature ranges from-‘1’ – fully

cold to ‘9’ – fully hot.

Once the preferred temperature is reached, no

further adjustment is required, providing the hot

and cold water supplies remain constant.

To stop the shower, press the ‘Start/Stop’ button

once more. This stops the pump and water flow.

Unless the shower is to be used again

immediately, the shower should also be switched

off at the electricity isolating switch.

As a safety feature, the temperature control

has a built-in stop to prevent you accidentally

exceeding your highest desired temperature. If

adjustment is required see section ‘Adjusting the

maximum temperature stop’.

To override this stop, depress the button

(fig.43) while the control is up against the stop

and turn the control anti-clockwise to the higher

settings (pressing the button before the stop will

not operate the override mechanism even if the

control is turned with the button depressed).

To return to the normal temperature range just

turn the temperature control clockwise until it

is past the maximum temperature stop. Make

sure the temperature control is in the normal

temperature range when the shower is switched

off. The stop comes in a factory set position

based on 65°C stored hot water temperature.

Note: As the flow control is adjusted it is normal

for the sound of the pump to alter in pitch.

Temperature

control

Override

button

Fig.40

Fig.42

Fig.41

Fig.43

Page 20

Aquasensation AS2000X

18

ADJUSTING THE MAXIMUM

TEMPERATURE STOP

As a safety feature the shower has a built-in

maximum temperature stop to prevent you

accidentally exceeding your highest desired

temperature. This is set in the factory to provide

a maximum temperature based on the hot

and cold water supplies being 65°C and 15°C

respectively.

IMPORTANT: Only adjust the maximum

temperature stop when the hot water is at its

usual storage temperature.

Procedure

Rotate the temperature control to setting ‘9’ on

the temperature disc.

Remove the cover trim to reveal the retaining

screw (fig.44).

Undo the retaining screw and carefully pull off

the temperature control, making sure it is still

aligned to setting ‘9’.

Now remove the maximum temperature stop.

To increase the temperature stop setting,

reposition the mechanism anti-clockwise within

the arc of the grooves (fig.45).

To decrease the temperature stop setting,

reposition the mechanism clockwise within the

arc of the grooves (fig.45).

Replace the temperature control onto the valve

spindle. Make sure the pointer aligns with

setting ‘9’ on the temperature disc (fig.28).

Secure with the retaining screw and refit the

cover trim.

Fig.44

Maximum

temperature

stop

Increase stop position

Decrease stop position

Fig.45

Page 21

Aquasensation AS2000X

19

CLEANING THE FILTERS

Note: Turn off the electricity and both hot

and cold water supplies to the unit before

proceeding further.

To remove the cover, first pull off the flow knob

cover trim (fig.6) to reveal the retaining screw.

Undo the screw and pull off the temperature

control. Now remove the outer flow control

assembly comprising of the flow control,

maximum temperature stop and temperature

disc.

Remove the two cover fixing screws – top

and bottom (fig.8). Carefully lift the cover

away from the backplate. To release the

PCB connector, squeeze the connection block

arms and pull apart.

Remove the single retaining screw from either

the upper or lower filter cover (fig.46),

depending upon whether top/rear entry or

bottom entry is used. Pull off the filter cover.

Carefully hook out the filters together with ‘O’

rings. Thoroughly clean and replace making sure

the ‘O’ rings are in position.

Refit the filter cover and secure with the

retaining screw.

Make sure the potentiometer control is rotated

fully anti-clockwise (fig.25).

With your fingers, rotate the valve spindle fully

anti-clockwise (fig.26) to the fully hot position.

Fit the cover, making sure the PCB connector is

fitted and the wires are clear of obstructions. Secure

with the top and bottom fixing screws (fig.8).

Replace the flow control so that it aligns with

the ‘min’ position.

Fit the temperature disc (it will only fit one way)

and maximum temperature stop (fig.27).

Replace the temperature control onto the valve

spindle. Make sure the pointer aligns with

setting ‘9’ on the temperature disc (fig.28).

Secure with the retaining screw and fit the cover

trim.

Switch on the electricity supply to the unit and

then turn on both water supplies.

INSTRUCTIONS FOR INSTALLERS AND SERVICE ENGINEERS ONLY

Retaining screw

Filter cover

Filter

Filter

Upper filter shown Fig.46

WARNING!

Switch off the electricity supply

and turn off both hot and cold

water supplies to the unit before

proceeding further.

Page 22

Aquasensation AS2000X

20

SPARE PARTS

Ref. Description Part No.

1 Terminal block ........................... 22001320

2 Plastic inlet elbow plug x1 ......... 7052140

3 Pump and motor assembly ........ 84000130

4 Pipe inlet elbow ........................83305320

c/w filters and check valves

5 Temperature valve ..................... 83305280

6 Link pin ..................................... 22009060

7 PCB unit .................................... 7073738

8 Solenoid assembly .................... 22012190

9 Gear .......................................... 7052184

10 Filter (pair) ................................83305330

– Pipe trim ...................................7052146

– Pipe removing tool .................... 7052144

– Potentiometer harness ...............P09440900

– Bracket ...................................... 7052183

– Wire kit .....................................83311410

11 Cover assembly .........................P09440600

– Maximum temperature stop ......7052186

– Temperature control ..................P09441000

c/w override button

– Flow control .............................. 7053275

– Temperature disc .......................7053277

– Flow control trim .......................7053276

– Temp control cover trim ............7053280

– Rear entry elbow ....................... 22008180

11

1

3

4

5

6

7

8

9

10

2

Page 23

Aquasensation AS2000X

21

FAULT FINDING

IMPORTANT: Switch OFF the electricity at the mains supply and remove the correct circuit

fuse before attempting any fault finding inside the unit.

Symptom Cause Action/Cure

1.1.1 Turn the temperature control clockwise.

1.2.1 Turn the temperature control clockwise.

1.3.1 Remove filter and clean. If problem is with

check valve, contact Customer Service.

1.4.1 Isolate shower and consult a competent

plumber or contact Customer Service.

2.1.1 Turn temperature control anti-clockwise.

2.2.1 Turn temperature control anti-clockwise.

2.3.1 Turn shower off and wait for hot water

cylinder to reheat.

2.4.1 Remove filter and clean. If problem is with

check valve, contact Customer Service.

2.5.1 Turn shower off. Consult a competent

plumber or contact Customer Service.

3.1.1 Blown fuse. Check supply. Renew fuse. If it

fails again consult a competent electrician.

3.1.2 Power cut. Check other appliances and if

necessary, contact local Electricity Supply Co.

3.2.1 Consult a competent electrician or contact

Customer Service.

3.3.1 Thermal protection on motor has

operated. Allow appliance to cool and reset

itself. If it persists, contact Customer Service.

3.4.1 Remove cover and connect start/stop

switch.

1 Water too hot.

2 Water too cold.

3 Pump does not

operate.

1.1 Not enough cold water

flowing through shower.

1.2 Increase in the ambient

cold water temperature.

1.3 Cold inlet filter blocked

or check valve sticking.

1.4 Cold water supply

blocked or cut off.

2.1 Not enough hot water

flowing through shower.

2.2 Decrease in ambient

cold water temperature.

2.3 No hot water in the

storage cylinder.

2.4 Hot inlet filter blocked

or check valve sticking.

2.5 Hot water supply

blocked or otherwise cut off.

3.1 Interrupted power

supply.

3.2 Electrical malfunction.

3.3 Motor overheated.

3.4 Start/stop switch not

connected.

Any maintenance or repair to the shower must be carried out by a suitably

competent person.

Page 24

Aquasensation AS2000X

22

FAULT FINDING

Symptom Cause Action/Cure

4.1.1 Check water elsewhere in house and if

necessary contact the local Water Company.

4.2.1 Switch off shower and contact Customer

Service.

4.3.1 Clean showerhead.

4.4.1 Clean filters.

5.1.1 Isolate water to unit. Remove check valves.

Clean and replace.

6.1.1 Call Customer Service.

6.2.1 Call Customer Service.

7.1.1 Call Customer Service.

7.2.1 Replace pump.

8.1.1 Fit blanking plugs into unused inlets.

4 Water does not

flow or is reduced.

5 Cross flow of

hot and cold water

into system.

6 Water dripping

from showerhead

when turned off.

7 Pump is noisy or

air lock in pump.

8 Unit running

erratically.

4.1 Water supplies cut off.

4.2 Shower blocked or air

in the system.

4.3 Showerhead blocked.

4.4 Blocked filters.

5.1 Dirt/debris in check

valves.

6.1 Debris in solenoid

valve.

6.2 Potentiometer faulty.

7.1 Air lock in pump.

7.2 Worn pump bearings.

8.1 Blanking plugs not

fitted into unused inlets.

In the unlikely event of a fault occurring please contact Triton Customer service.

DO NOT remove the shower from the installation.

Page 25

Aquasensation AS2000X

23

Entry Points

Diagram Key:

Water Entry Points

Cable Entry Points

Page 26

Aquasensation AS2000X

24

Page 27

Aquasensation AS2000X

25

Page 28

Triton Showers

Triton Road

Nuneaton

Warwickshire CV11 4NR

Triton is a division of Norcros Group (Holdings) Limited

Customer Service: % 0844 980 0750

Trade Installer Hotline:

%

0844 980 0730

Fax:

0844 980 0744

www.tritonshowers.co.uk

E-mail: serviceenquiries@tritonshowers.co.uk

TRITON reserve the right to change product specification without prior notice. E&OE. © TRITON SHOWERS 2012

Extended Warranty AVAILABLE NOW. Call 0844 980 0740 for more details.

UK SERVICE POLICY

In the event of a product fault or complaint occurring, the following

procedure should be followed:

1. Telephone Customer Service on 0844 980 0750 having available,

your details including post code, the model number and power

rating of the product, together with the date of purchase and, where

applicable, details of the particular fault.

2. If required, the Customer Service Advisor will arrange

for a qualified engineer to call.

3. All products attended to by a Triton service engineer must be

installed in full accordance with the Triton installation guide

applicable to the product. (Every product pack contains an installation

guide, however, they can also be bought via our Customer Service Spares

Department).

4. Our engineer will require local parking and if a permit is required this

must be available to the engineer on arrival at the call.

5. It is essential that you or an appointed representative (who must

be over 18 years of age) is present for the duration of the service

engineer's visit. If the product is in guarantee you must produce

proof of purchase.

6. Where a call under the terms of guarantee has been booked and

the failure is not product related (i.e. scaling and furring, incorrect

water pressure, pressure relief device operation or electrical/plumbing

installation fault) a charge will be made. A charge will also be issued

if nobody is at home when the service engineer calls or adequate

parking/permit is not available.

7. If the product is no longer covered by the guarantee an up front

fixed fee will be charged before the site visit.

8. Should proof of purchase not be available on an “in-guarantee” call,

or should the service engineer find that the product is no longer

under guarantee, the engineer will charge the same fixed price and

the customer will be expected to pay the engineer before he leaves.

If payment is not made on the day an administration charge will be

added to the fixed charge.

9. If a debt is outstanding from a previous visit, or from any other Triton

purchase. Triton reserves the right to withhold service until the debt

has been settled.

10. Triton takes the health, safety and wellbeing of its employees very

seriously and expects customers to treat all staff members with respect.

Should any employee feel threatened or receive abuse, either verbally

or physically, Triton reserves the right to withhold service and will

support the employee with a legal prosecution.

Replacement Parts Policy

It is the policy of Triton Showers to maintain parts availability for the

duration of production and a period of 5 years thereafter in accordance

with industry standards. In the event of a spare part not being available a

substitute part will be supplied.

Spare parts can be ordered via our online spare parts store, or by

telephoning Triton Spares Department. Payment should be made by

credit/debit card (excluding American Express or Diners Card). Payment

can also be made by pre-payment of a pro-forma invoice, by cheque or

postal order.

Telephone orders are based on information given during of the call.

Before contacting Triton, please verify your requirements using the

information contained in the user guide. Triton cannot accept liability for

incorrect part identification.

TRITON STANDARD GUARANTEE

Triton guarantee this product against all

mechanical and electrical defects arising from

faulty workmanship or materials for a period of

one year for domestic use only, from the date of

purchase, provided that it has been installed by

a competent person in full accordance with the

fitting instructions.

Any part found to be defective during this

guarantee period we undertake to repair or replace

at our option without charge so long as it has been

properly maintained and operated in accordance

with the operating instructions, and has not been

subject to misuse or damage.

This product must not be taken apart, modified or

repaired except by a person authorised by Triton.

This guarantee applies only to products installed

within the United Kingdom and does not apply to

products used commercially. This guarantee does

not affect your statutory rights.

What is not covered:

1. Breakdown due to: a) use other than domestic

use by you or your resident family; b) wilful act

or neglect; c) any malfunction resulting from the

incorrect use or quality of electricity, gas or water

or incorrect setting of controls; d) failure to install

in accordance with this installation guide.

2. Repair costs for damage caused by foreign

objects or substances.

3. Total loss of the product due to non-availability

of parts.

4. Compensation for loss of use of the product or

consequential loss of any kind.

5. Call out charges where no fault has been found

with the appliance.

6. Call out charges where the water supply cannot

be isolated, this includes consequential losses

arising from unserviceable supply valves.

7. The cost of repair or replacement of pressure

relief devices, showerheads, hoses, riser rails

and/or wall brackets, isolating switches,

electrical cable, fuses and/or circuit breakers or

any other accessories installed at the same time.

8. The cost of routine maintenance, adjustments,

overhaul modifications or loss or damage arising

therefrom, including the cost of repairing

damage, breakdown, malfunction caused by

corrosion, furring, pipe scaling, limescale,

system debris or frost.

3-1-2012

Loading...

Loading...