Page 1

Operating and

Safety Instructions

Jigsaw Kit

AJA300

www.tritontools.com

Page 2

2

GB

Thank you for purchasing this Triton tool. These instructions contain information necessary

for safe and effective operation of this product.

Please read this manual to make sure you get the full benefit of its unique design.

Keep this manual close to hand and ensure all users of this tool have read and fully understand the

instructions.

CONTENTS

Symbols 2

Parts List 3

Safety 4

Assembly 5

Warranty 7

SYMBOLS

Always wear ear, eye and respiratory

protection.

Contents / Symbols

Instruction warning.

Do not use before viewing

and fully understanding the

operating instructions

Page 3

3

GB

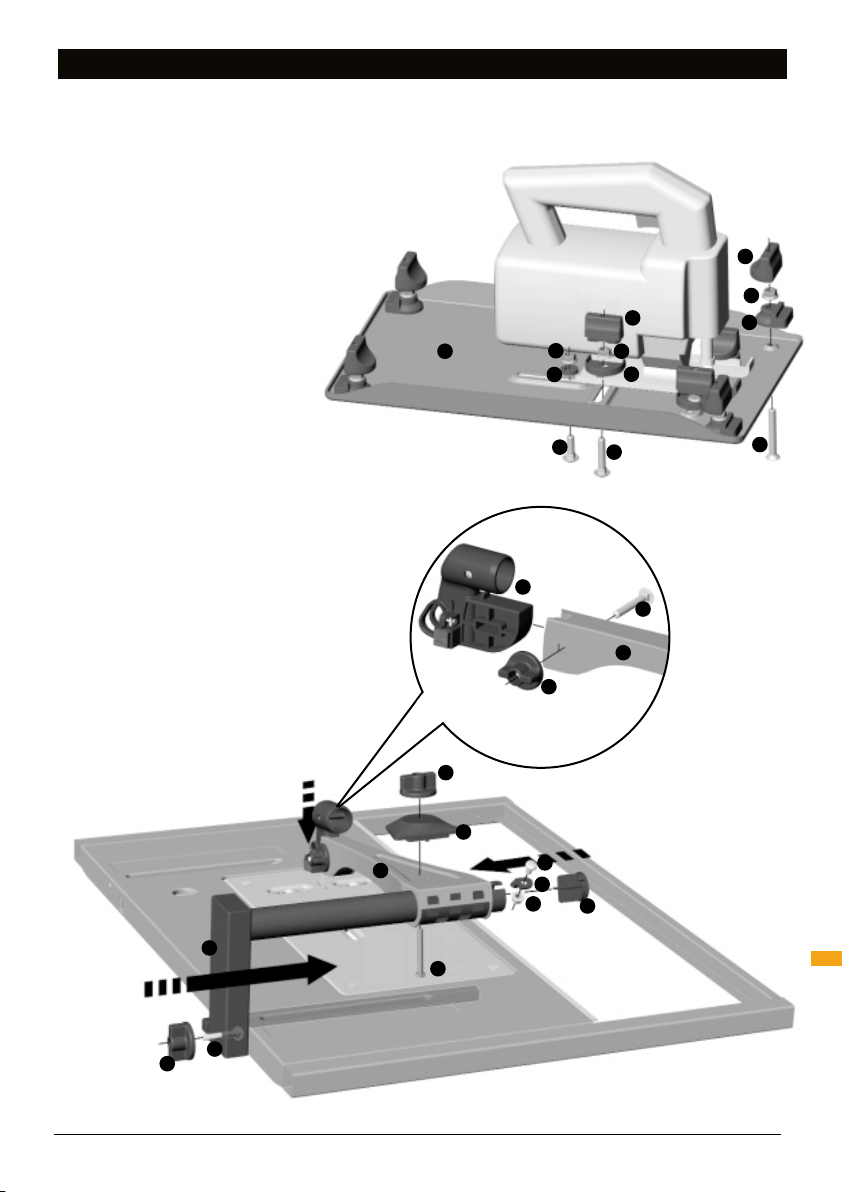

PARTS LIST

1. Jigsaw plate (1)

2. Overhead arm (1)

3. Support arm (1)

Fastener Bag 1 - Jigsaw Plate

4. Plate clamp base (4)

5. M6 x 45 Countersunk screw (4)

6. M6 Flange nut (9)

7. Plate clamp knob (flat bottom) (4)

8. Back stop (1)

9. M6 x 20 Coach bolt (1)

10. Clamp base (4)

11. M6 x 40 Coach bolt (4)

12. Clamp knobs (recessed bottom) (4)

Fastener Bag 2 - Support Arm

13. Blade guard (1)

14. M6 x 40 Coach bolt (2)

15. Small round knob with M6 nut (1)

16. Bridge (1)

17. M6 x 55 Hex bolt (1)

18. Arm locator (1)

19. M6 x 10 Screw (1)

20. M6 Flange nut (1)

21. Tube plug (1)

22. Large roung knob with M6 nut (2)

7

6

12

1

22

6

8

9

13

15

6

10

11

14

2

4

5

16

2

3

17

14

22

19

18

6

21

Parts List

Page 4

4

GB

GENERAL SAFETY INSTRUCTIONS

WARNING. Read all safety warnings

and all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term 'power tool' in the warnings refers

to your mains-operated (corded) power tool or

battery operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep the cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the

risk of electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. Personal safety

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

General Safety Instructions

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

a. Use safety equipment. Always wear eye

protection. Safety equipment such as dustmask, non-slip safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

b. Avoid accidental starting. Ensure the switch is

in the off position before plugging in. Carrying

power tools with your finger on the switch or

plugging in power tools that have the switch

on invites accidents.

c. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

d. Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

e. Wear suitable cloting and footwear. Do not

wear loose clothing or jewellery. Keep your

hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

f. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use

of these devices can reduce dust related

hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c. Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

Page 5

5

GB

e. Always unplug your power tool when leaving

it unattended. Such preventative safety

measures reduce the risk of starting the

power tool accidentally by untrained users.

f. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

operation of the power tool. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

g. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

ASSEMBLY

Step 1

Fit the Plate Clamp Bases (4) to the corners

of the underside of the Jigsaw Plate (1) with

the M6 x 45 Countersunk Screws (5) and M6

Flange Nuts (6), as shown. Do not yet fully

tighten.

Fit the jigsaw plate into the router table cutout (clamp bases facing down) with the slots

at the front (switchbox end). Push the clamp

bases outward until they locate against the

square tube supports while tightening with a

Phillips-head screwdriver.

Screw the Plate Clamp Knobs (7) onto the

screws until they hold the plate firmly into the

table (they cut their own thread).

In use: The clamps have flat side edges.

When all four cut-aways are facing outward

the plate can be removed. Turn the knobs

clockwise about half a turn to tighten it back

down.

Step 2

For this step, release the plate clamp knobs

and turn the plate upside down in the router

table cut-out, with the clamps upward.

Use a square to ensure the jigsaw blade is set

at 90° to its base, and make any necessary

adjustments.

Place your jigsaw onto the plate with the blade

locating approximately central through the

jigsaw blade slot. Position the jigsaw base

approximately parallel to the sides of the plate.

h. Use the power tool, accessories and tool bits,

in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from

those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

Fit the Back Stop (8) to the rear slot using the

M6 x 20mm Coach Bolt (9) and a flange nut,

as shown. Tighten into position against the

back edge of the jigsaw base.

Position the four Clamp Bases (10) into the

slots on either side of the jigsaw base with

their straight edges touching the sides of the

base. Tighten them into position with the M6

x 40mm Coach Bolts (11) and M6 flange nuts,

as shown.

Screw the Clamp Knobs (12) on (they cut their

own thread) until they tighten firmly onto the

top edge of the jigsaw base. The flat sides of

the clamps should be facing away from the

jigsaw. Note: It may be necessary to remove

the jigsaw while screwing the clamp knobs

into position.

In use: When the flat sides of all four clamps

are facing inward the jigsaw can be removed.

Turn the knobs clockwise half a turn to tighten

it back down.

Remove the plate then re-fit and lock it into

the Router Table with the blade pointing

upward.

Step 3

Push the Blade Guard (13) into the front of

the Overhead Arm (2) and fit the M6 x 40mm

Coach Bolt (14) and Small Round Knob (15),

as shown. As the bolt is designed for a firm

fit pulling the guard forward slightly will allow

easier assembly.

General Safety Instructions / Assembly

Page 6

6

GB

Step 4

Insert the M6 x 40mm Coach Bolt (14) from

inside the edge of the Router Table. Fit the

Support Arm (3) into the square hole and

onto the coach bolt and slide it fully home, as

shown.

Tighten into position with a Large Round Knob

(22).

Slide the overhead arm onto the round tube of

the support arm.

Raise the arm and fit the Bridge (17) using the

Hex Bolt (18) and Large Round Knob (22), as

shown.

Lower the the arm onto the jigsaw blade and

position the arm until the blade is central

within the guard. Tighten the arm in place.

Storage note: Loosen the arm clamp when

storing for extended periods to avoid fatigue.

Step 5

Insert the Arm Locator (19) into the slot on the

support arm round tube, with the side wall

of the overhead arm engaging in the groove

on the locator. Tighten the locator firmly in

position using the M6 x 10mm Screw (20) and

Flange Nut (6), as shown.

Push-fit the Tube Plug (21) into the end of the

tube, as shown. Note the notch in the plug

must line up with the arm locator.

Loosen the round knob on the blade guard and

adjust the guard forward or backward until the

teeth on the jigsaw blade are just in front of the

two wooden guide blocks, then tighten. Loosen

the two Philips-head screws in the blade guard

and move the guide blocks in until they almost

touch the sides of the blade, then tighten. See

Fig. 2.

In use: When the guide blocks wear down,

over time, they should be re-adjusted close

to the blade. Blocks can be reversed and

rotated until all sides are worn. Replacement

blocks can be ordered through your local Triton

stockist, or alternatively you can make your

own from any fine grained hardwood.

Dust Extraction

The Jigsaw Kit has been designed for use with

any vacuum cleaner for sawdust extraction.

While the stroke of the jigsaw forces most dust

beneath the table, connecting to a vacuum

source provides better visibility of the cut line

and reduces airborne dust.

Screw the vacuum hose, supplied with your

Router Table, onto the dust port in the back

of the blade guard (left-hand thread) and

plug the wand of your vacuum cleaner into

the hose adaptor. For a larger collection

capacity, consider fitting a Triton Dust Collector

(DCA300) to your vacuum.

OPERATION

• Always disconnect your jigsaw from power

when making any tool adjustments.

• Always wear eye protection whenever

operating power tools. The use of a dust mask

and ear muffs is also recommended.

• Do not wear loose clothing or jewellery when

operating power tools. Tie back long hair.

• If the power switch on your jigsaw does not

permanently lock on, use tape or a releasable

cable tie to hold the switch on during

operation. Alternatively a trigger strap (part

no. AGA001) can be ordered through your local

Triton stockist.

• Always adjust the overhead arm to suit the

thickness of your workpiece. Loosen the arm

clamp and set the height of the arm until it

rests on top of your workpiece, then tighten

(Fig. 1).

Assembly / Warranty

• Do not over-tighten the arm clamp. This will

allow the arm to raise should the blade contact

it during use - rather than breaking your blade.

• Before turning on the jigsaw check that the

blade extends beyond the thickness of your

workpiece at the bottom of its stroke. At least

one blade tooth should always project above

the work (Fig.1) and the blade should never

exit the guide blocks. Failing to ensure this can

Page 7

7

GB

damage your blade, or cause the overhead arm

to “fling” up.

• Regularly check that the blade is located

centrally inside the guard with the guide blocks

close to the blade but back from the blade

teeth (Fig. 2).

• Always keep ngers well clear of the blade and

never trail your fingers behind the cut line.

• The overhead arm should be tted and

correctly adjusted at all times.

• Never start the jigsaw with the blade touching

the workpiece.

• Remove all loose objects from the table before

operating to prevent them from vibrating into

the cutter.

• Feed the workpiece slowly, particularly when

cutting along the grain, or when using fine

toothed blades (Fig. 3). Smoking or burn marks

on the cut edges indicate the curves were too

tight, or the feed rate was too fast. Overheating

can dull a blade rapidly.

• Hold the workpiece rmly and evenly against

the table while guiding it smoothly through the

blade.

• If you wish to stop mid-way through a cut,

switch off the power with your knee and hold

the workpiece steady until the blade has

completely stopped.

• Don’t try to cut too tight a radius in thick

material. If necessary, edge up to the line in

a series of shallow cuts, whittling away the

waste.

• There is a wide selection of jigsaw blades

available, and using the right blade for the

material being cut will ensure best results.

For cutting small circles and sharp curves we

suggest you fit a narrow blade.

• Ensure all fasteners are regularly checked for

tightness as jigsaw vibration can loosen them.

• Always disconnect power when work is

completed for the day, or when leaving the unit

unattended.

WARRANTY

To register your guarantee visit our web site at

www.tritontools.com* and enter your details.

Your details will be included on our mailing list

(unless indicated otherwise) for information on

future releases. Details provided will not

be made available to any third party.

PURCHASE RECORD

Date of Purchase: ___ / ___ / ____

Model: AJA300

Retain your receipt as proof of purchase

Triton Precision Power Tools guarantees to

the purchaser of this product that if any part

proves to be defective due to faulty materials

or workmanship within 12 MONTHS from the

date of original purchase, Triton will repair, or

at its discretion replace, the faulty part free of

charge.

This guarantee does not apply to commercial

use nor does it extend to normal wear and

tear or damage as a result of accident, abuse

or misuse.

* Register online within 30 days.

Terms & conditions apply.

This does not affect your statutory rights

Loading...

Loading...