Page 1

Ultrafryer Systems, Inc.

Right Size Fryer

Sales ID #:

P30-RS-2-UCP P30-RS-3-UCP P30-RS-4-UCP

Project __________________

Item ____________________

Quantity _________________

Approval _________________

Date ____________________

All Ultrafryers are specifi cally designed to meet ENERGY STAR

qualifi cations, lowest fl ue temperatures, highest frying volume for all fried products.

Right Size Fryer 65 lb. Gas Fryer with UltraClear Plus Filtration

Standard Features:

● ENERGY STAR qualified.

Eligible for energy rebates

● Cook Zone Size -

20”Long x 14”Wide x 4”Deep

● Production capacity 110 lbs.

per hour

● 65 lb. nominal shortening

capacity

● Input Power 110,000 BTU’s

per hour

● Ultrastat 104 - Dial thermostat

control

● Ultraguard - Automatic melt

cycle with vat protection

● Fry basket 3 each 13 1/8”

Long x 6 1/2” wide x 5 1/8”

deep

● Total Stainless steel

construction

● Casters

● Fast flow filter envelope

Options and Accessories:

□ 2 product Ultrastat® cooking computer

□ 10 product Ultrastat® cooking computer

□ Vat covers

□ Splash guards

□ Basket lifts

□ Triple baskets

□ Dump station

□ Fast Flow fi lter pads

□ Triple fi ltration

□ Stainless steel fi lter screen

□ Drain valve for fi lter tub

□ Boil out hose

□ Shortening disposal line

□ 48” gas quick disconnect

□ Heat tape

Specifi cations

Designed to meet high production frying needs with low energy and shortening cost

The P30-RS Ultrafryer is the Right Sized fryer for your restaurants frying needs. A battery

of two P30-RS fryers can increase production by up to 10% over a traditional three vat

battery making it the right size for high production needs. A battery of two P30-RS fryers

uses up to 15% less shortening than traditional three vat frying system making the P30RS the right size for your shortening management needs. The P30-RS Ultrafryer is the

right size for energy usage. Two P30-RS Ultrafryer fryers is rated at 220,000 Btu’s per

hour versus a rating of 270,000 Btu’s per hour to 450,000 Btu’s per hour for a typical 3

vat 50 lb. fryer.

When combined with the Ultra Clear Plus shortening management option to control

your shortening costs and quality the P30-RS clearly becomes the right fryer for your

operation.

for

ualifies

Q

Q

California

energy

rebates

Pending

Ultrafryer Systems, Inc. • 302 Spencer Lane • San Antonio, TX 78201 • (800) 545-9189 • (210) 731-5000 • FAX (210) 731-5099 • www.ultrafryer.com

Page 2

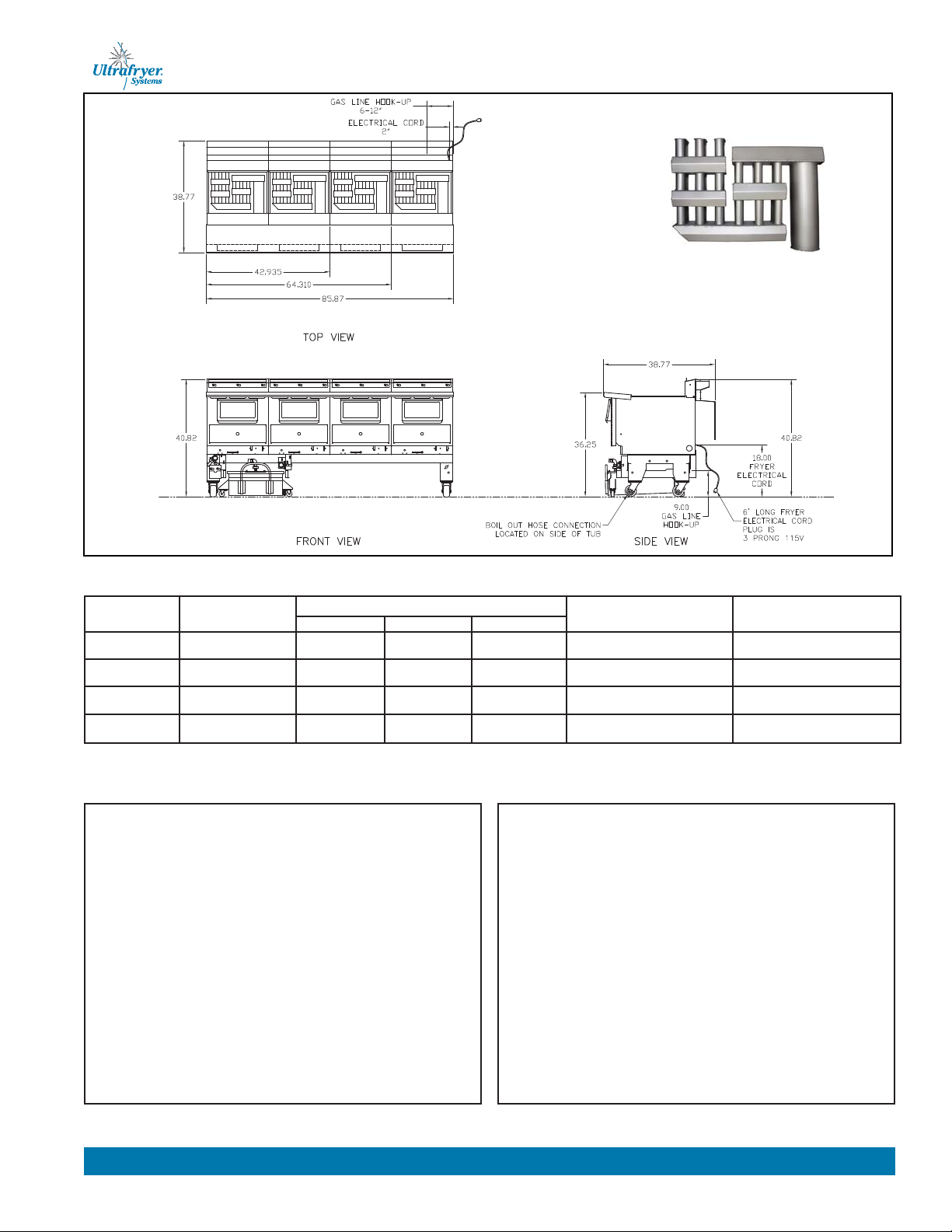

Patented PAR3

heat exchanger

w/ vortex boxes

Dimensions - inches (mm)

Sales Shortening Overall Size Net Shipping Info

ID #: Capacity Weight

P30-RS-2-UCP

P30-RS-3-UCP

P30-RS-4-UCP

65 lbs. per vat

65 lbs. per vat

65 lbs. per vat

Height Depth

40.82”

40.82”

40.82”

38.5”

38.5”

38.5”

Width

43”

64.50”

590 lbs. (257.6 kgs)

810 lbs. (353.8 kgs)

987 lbs. (442.3 kgs)86”

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

Power Requirements: Notes:

ELECTRICAL REQUIREMENTS FOR

OPERATING SYSTEM

120 V, 60 HZ, 1 phase, 8.5 amps.

Electrical cord is 8’ long and located on RH side in rear.

GAS REQUIRED AT FRYER MANIFOLD

7” water column natural gas

14” water column propane/butane

3/4” Gas Line connection required for 2 vat

1 1/4” Gas Line connection required for 3-6 vats

Due to continuing engineering development and improvements, specifi cations are subject to change without notice.

© May 15, 2014 Ultrafryer Systems, Inc.

Ultrafryer Systems, Inc. • 302 Spencer Lane • San Antonio, TX 78201 • (800) 545-9189 • (210) 731-5000 • FAX (210) 731-5099 • www.ultrafryer.com

PERFORMANCE SPECIFICATIONS

Determined in accordance with ASTM F2144 Standard Test Method

for the performance of large open vat fryers:

Nominal Energy Shortening

Vat Size Input Rate Capacity

20” L x 14” W x 4” D 110,000 BTU/hr 65lbs.

Cooking Energy Use

Energy (Idle Energy Rate)

Effi ciency (%) (Btu/hr)

58 5737

Loading...

Loading...