Owner’s Manual

Non-Swinging Wall-Mounted

SmartRack® Enclosures

Table of Contents

Applies to Model Series: SRWxxU

(Agency Series Number: AG-00E9)

1. Important Safety Instructions 2

2. Overview 2

3. Feature Identification 3

4. Enclosure Installation 4

4.1 Preparation 4

4.2 Unpacking 4

4.3 Ground Connection 4

5. Enclosure Configuration 5

5.1 Door Locks 5

5.2 Cable Access & Management 5

5.3 Reversing the Enclosure 5

5.4 Mounting Rails 6

5.5 Adjusting Mounting Rail Depth 6

6. Wall Mounting the Enclosure 6

7. Equipment Installation 7

7.1 Installing or Removing Cage Nuts 7

7.2 Alternate Mounting: 8

Tapped Hole Mounting Rail

8. Storage and Service 9

9. Warranty and Product Registration 9

Español 10

Français 19

28

PROTECT YOUR INVESTMENT!

Register your product for quicker service and ultimate peace of mind.

You could also win an ISOBAR6ULTRA surge protector—a $50 value!

www.tripplite.com/warranty

1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/support

Copyright © 2015 Tripp Lite. All trademarks are the sole property of their respective owners.

1. Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains instructions and warnings that must be followed during the installation and operation of the product described in this manual.

Failure to comply may invalidate the warranty and cause property damage or personal injury.

• Keep the enclosure in a controlled indoor environment, away from moisture, temperature extremes, flammable liquids and gasses, conductive

contaminants, dust and direct sunlight.

• Leave adequate space at the front and rear of the enclosure for proper ventilation. Do not block, cover or insert objects into the external ventilation

openings of the enclosure.

• The enclosure is extremely heavy. Use caution when handling the enclosure. Do not attempt to unpack, move or install it unassisted. Use a

mechanical device such as a forklift or pallet jack to move the enclosure in the shipping container.

• Do not place any object on the enclosure, especially containers of liquid, and do not attempt to stack the enclosures.

• Inspect the shipping container and the enclosure for shipping damage. Do not use the enclosure if it is damaged.

• Leave the enclosure in the shipping container until it has been moved as close to the final installation location as possible.

• Install the enclosure in a structurally sound area capable of handling the load, or on a level floor that is able to bear the weight of the enclosure, all

equipment that will be installed in the enclosure and any other enclosures and/or equipment that will be installed nearby.

• For permanent wall mounting, be sure to securely fasten the enclosure to the building structure before operation.

• Use caution when cutting packing materials. The enclosure could be scratched, causing damage not covered by the warranty.

• Save all packing materials for later use. Repacking and shipping the enclosure without the original packing materials may cause product damage

that will void the warranty.

• Do not reship the enclosure with additional equipment unless the enclosure was shipped with a special shock pallet (“SP1” models only). The

combined weight of the enclosure and installed equipment must not exceed the load capacity of the pallet. Tripp Lite is not responsible for any

damage that occurs during reshipment.

• Use of this equipment in life support applications where failure of this equipment can reasonably be expected to cause the failure of the life support

equipment or to significantly affect its safety or effectiveness is not recommended. Do not use this equipment in the presence of a flammable

anesthetic mixture with air, oxygen or nitrous oxide.

2. Overview

Non-swinging wall-mounted SmartRack enclosures accommodate all standard 19-inch rackmount equipment, regardless of vendor, and ship fully

assembled for quick and easy deployment. They feature adaptable, heavy-duty cabinets in various heights.

Non-swinging wall-mounted SmartRack enclosures have variable mounting depths, ideal for servers. The cabinets include quick-release doors and side

panels for convenient maintenance. Front access doors are reversible for installation flexibility. Front door and side panels are lockable. An optional

rolling caster kit (SRCASTER) is available for easy maneuvering of enclosures.

2

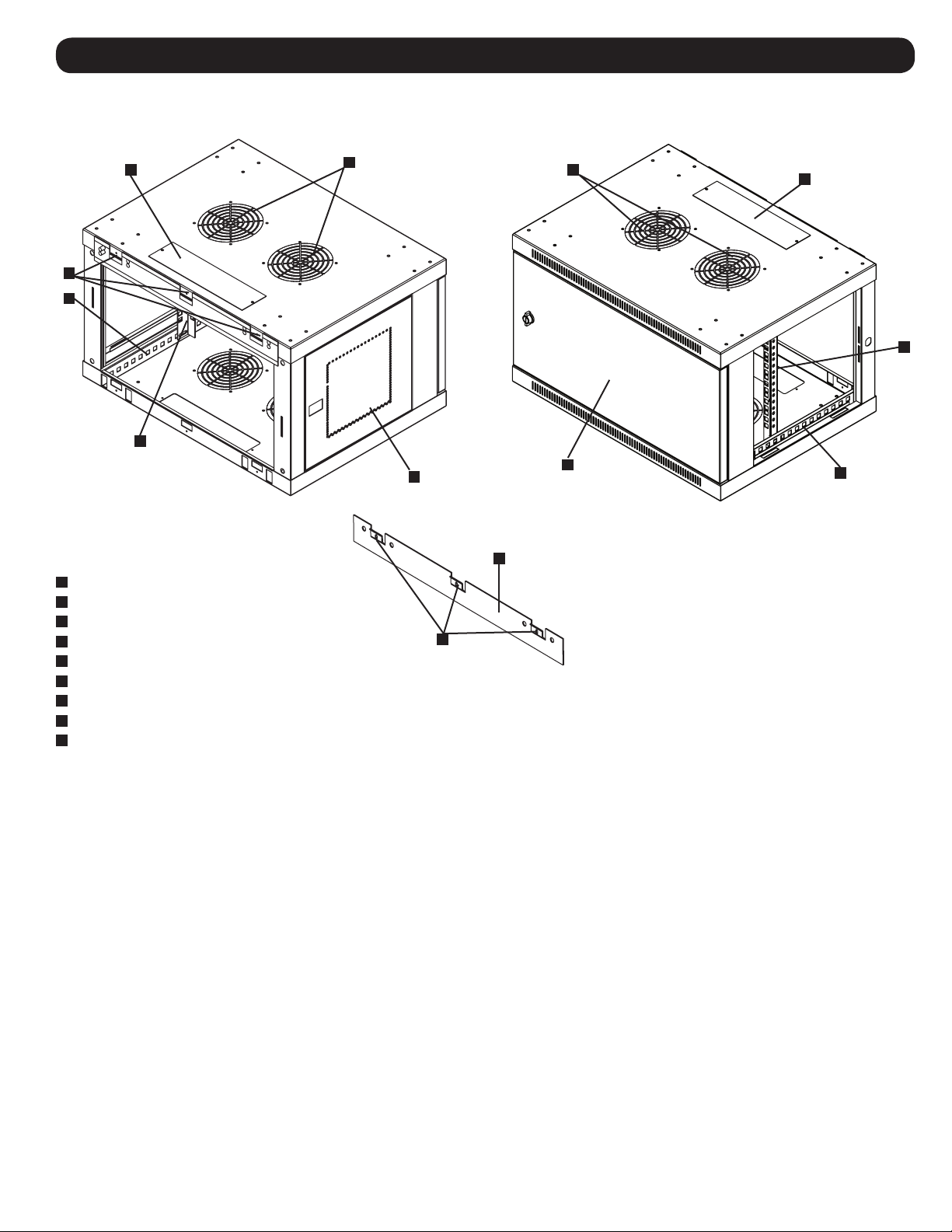

3. Feature Identification

Model SRW6U is shown. The other models have similar features, with the only differences being rack height and depth.

4

7

2

3

1

Front Door

2

Horizontal Rails

3

Vertical Mounting Rails

4

Removable Cable Access Hole Cover

5

Vents

6

Locking/Removable Side Panels

7

Mounting Notches (found on the enclosure’s back panel)

8

Mounting Plate (separate piece)

9

Mounting Plate Hooks

5

5

6

8

9

1

4

3

2

3

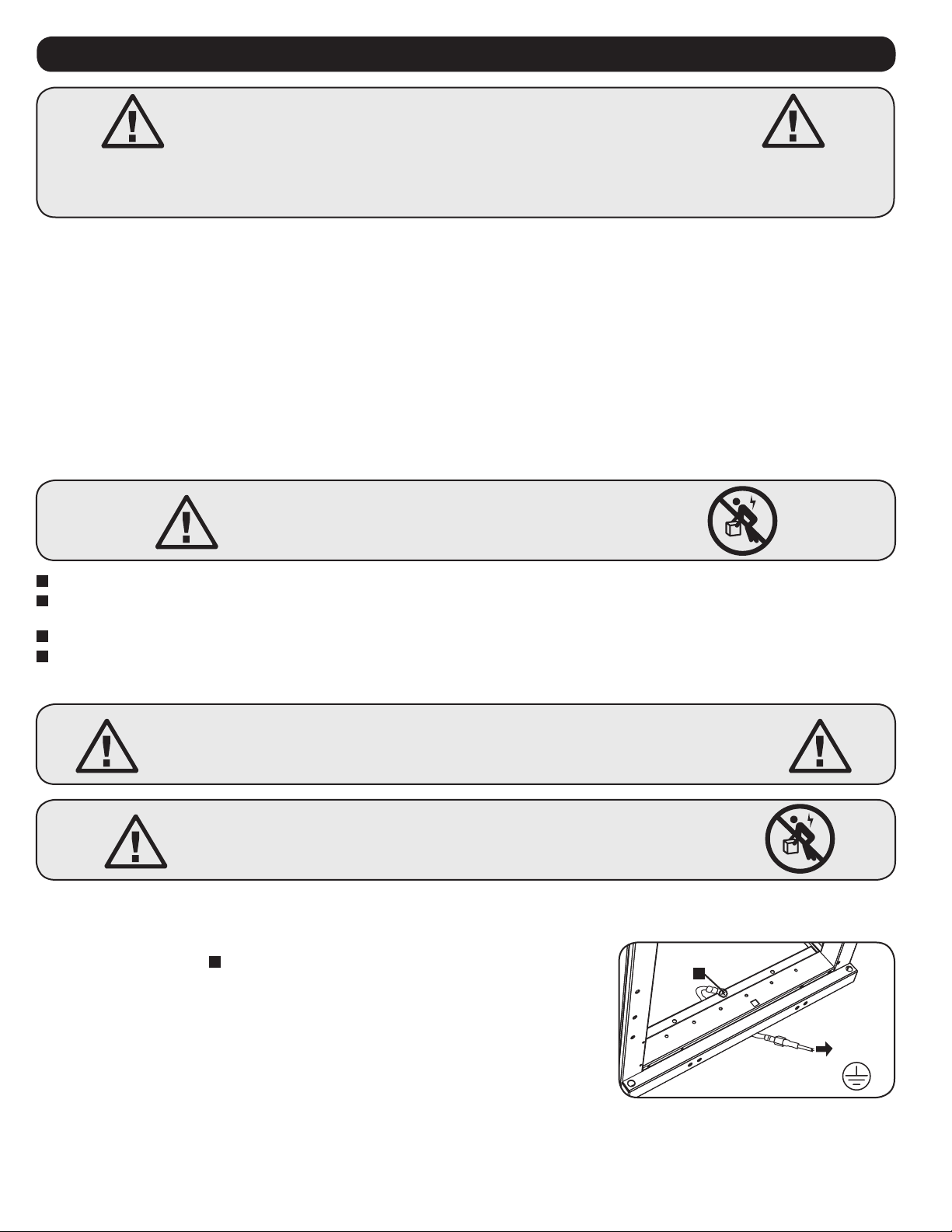

4. Enclosure Installation

EARTH

GROUND

Caution! Read All Instructions and Warnings Before Installation!

Warning: Rack enclosures can be extremely heavy. Do not attempt to unpack, move or install the enclosure without assistance.

Use extreme caution when handling the enclosure and be sure to follow all handling and installation instructions. Do not

attempt to install equipment without first stabilizing the enclosure.

4.1 Preparation

The enclosure must be installed in a structually sound area that is able to bear the weight of the enclosure, all the equipment that will be installed in

the enclosure and any other enclosures and/or equipment that will be installed nearby. Before unpacking the enclosure, you should transport the

shipping container closer to the final installation location to minimize the distance you will need to move the unit after the protective packaging has

been removed. If you plan to store the enclosure for an extended period before installation, follow the instructions in the Storage and Service

section.

You need several tools:

• Level

• Phillips-head screwdriver

• Appropriate tools for wall mounting

4.2 Unpacking

You also need the following hardware:

• Appropriate hardware for wall mounting (not included)

Use at least two people to unpack the enclosure.

1

Move shipping pallet to a firm, level surface.

2

Open box and remove the four foam corner protectors. Save all packing materials for later use unless you are certain they will not be required.

Packing materials are recyclable.

3

With one person on each side, carefully lift the enclosure out of the box and place on a firm, level surface.

4

Examine the enclosure for any damage or loose parts. Confirm all parts are present. If anything is missing or damaged, contact Tripp Lite for

assistance. Do not attempt to use the enclosure if it has been damaged.

Never extend more than one component from the enclosure at a time.

Warning: Never attempt to lift or install without adequate help.

Do not try lifting the enclosure alone.

4.3 Ground Connection

All parts of the enclosure are grounded to the frame of the enclosure. Use the enclosure’s front or

rear threaded grounding point

directly to your facility’s earth ground connection with an 8 AWG (3.264 mm) wire. Route the

ground wire under the enclosure’s frame to ensure unhindered door operation. Warning: Attach

each enclosure to earth ground separately. Do not use the enclosure without an earth

ground connection.

A

and an M6 screw (included) to connect the frame of the enclosure

A

4

5. Enclosure Configuration

Before installation, be sure to plan the location and arrangement of components within the enclosure. Be sure all mounting rails are reversed or

adjusted for depth, depending on your equipment configuration.

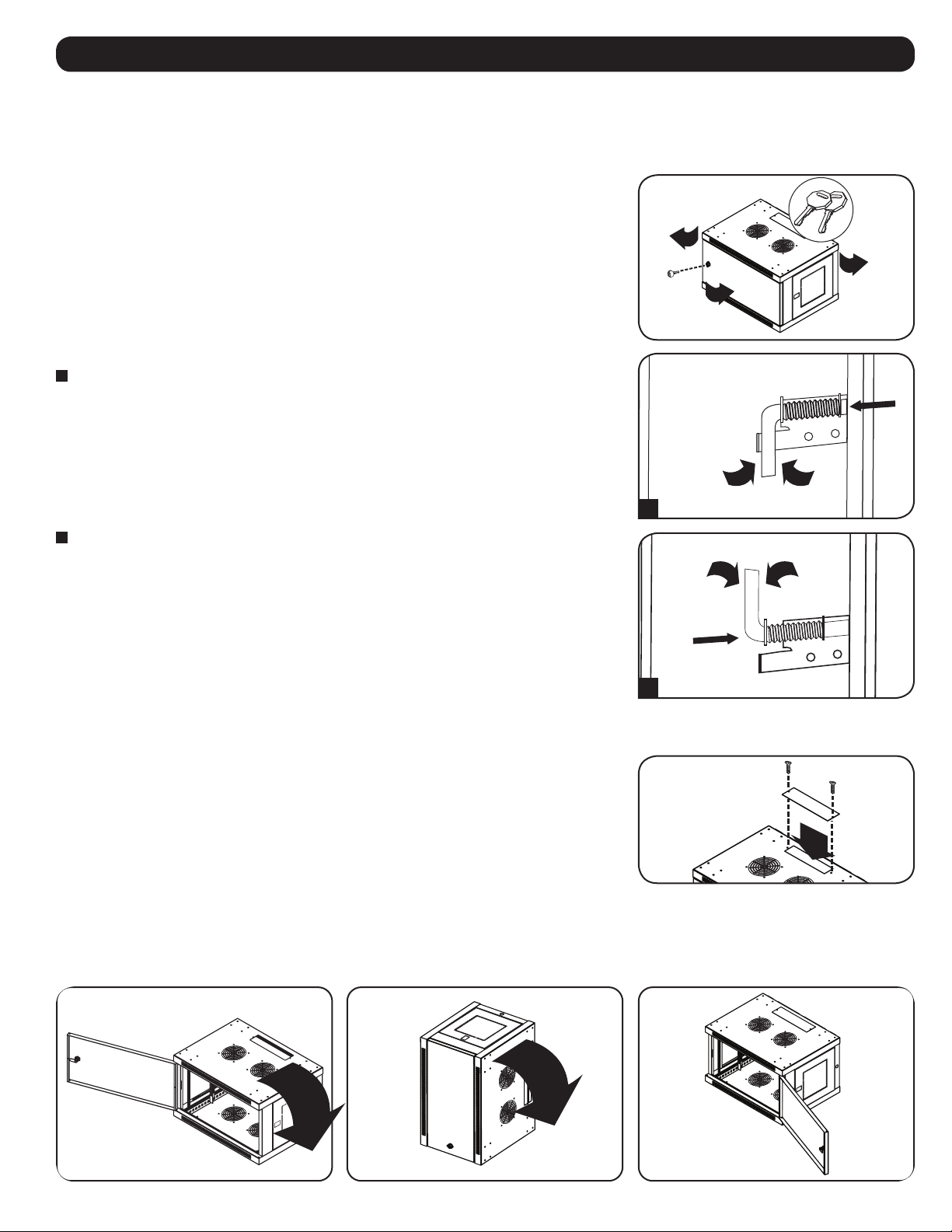

5.1 Door Locks

The front and back doors have locks that are accessible by the included keys.

Each side panel locks using an L-shaped lever on the inside of the enclosure.

1

To unlock and remove the side panels, lift the shorter leg of the “L” up and pull it away from the

side panel. Pull the tab on the side panel and remove it from the enclosure.

1

2

To re-lock the side panels, secure it in the proper position, lift the shorter leg of the “L” up and

push it toward the side panel, back into the hole that it was in initially. Once it is in place, push

the shorter leg of the “L” down to lock it. Note: To lock and unlock the side panels, you will

need to have access to the interior of the enclosure.

2

5.2 Cable Access and Management

The top of the cabinet has a rectangular opening for cable access and management. This opening

can be opened or closed by unscrewing or screwing in the removable cable access panel.

5.3 Reversing the Enclosure

In order to accommodate various rack configurations, the enclosure can be reversed. To do so, simply turn the enclosure over so that the doors open

in the opposite direction.

5

5. Enclosure Configuration continued

A

A

B

B

C

C

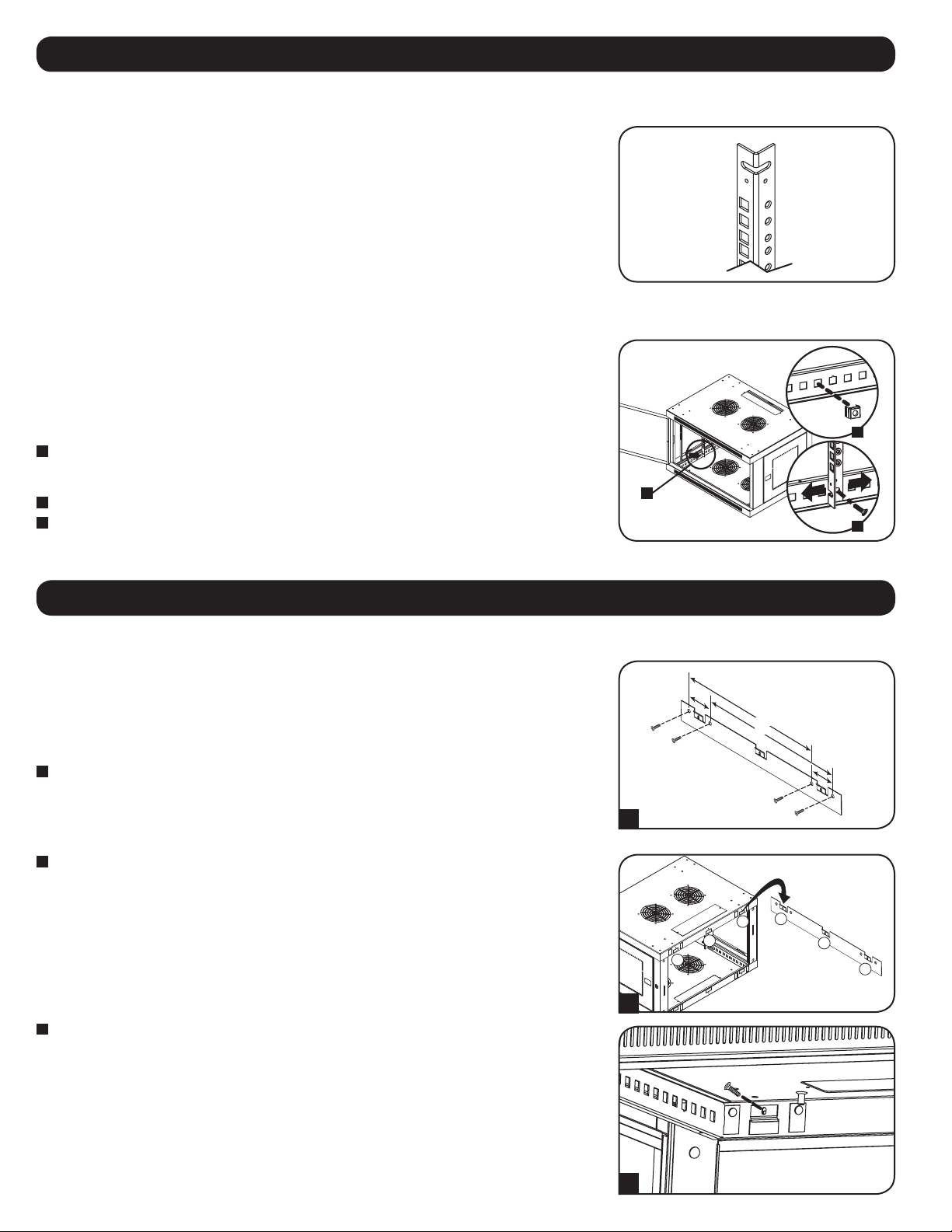

5.4 Mounting Rails

The enclosure comes with mounting rails that have both square and tapped holes for mounting rack

equipment. To install equipment, use the included cage nuts and other hardware. (section 7.1 for

installation of cage nuts.) Warning: Be sure to have the enclosure securely mounted to

the wall, or in its final position on the floor, before mounting any equipment inside.

Also be sure to have all the right adjustments on your rails before mounting

equipment. (See below for Adjusting Mounting Rail Depth.)

5.5 Adjusting Mounting Rail Depth

Warning: Do not attempt to adjust rails while equipment is installed in the enclosure.

Do not attempt to use rails without screws installed. (2 per rail.)

The 2 mounting rails are pre-installed to accommodate different mounting depths, depending on

the model. Do not adjust the mounting rails unless your equipment requires a different mounting

depth. The front and rear sets of rails can be adjusted independently in 1/4-inch (6mm)

increments.

1

Each rail is connected to the enclosure with 2 screws and 2 cage nuts: 1 set in the upper

corner and another in the lower corner. Using a Phillips-head screwdriver, remove the screws

that fasten the rails to the enclosure.

2

Move cage nuts to the desired depth and reinstall.

3

Slide the mounting rails to the desired depth and reattach them using the screws you removed in

Step 1.

2

1

3

6. Wall Mounting the Enclosure

Warning: Do not attempt to mount the enclosure to the wall with equipment in the enclosure.

Note: Enclosure must be installed by a qualified technician. Before mounting, use a level and tape

measure to position your mounting area precisely. Use appropriate fasteners (not included) to secure the

enclosure to the wall. Use suitable mounting means when installing to cinder block, concrete, drywall or

wood studs. Warning: The supporting surface must be able to safely support the combined load of

the equipment and all attached hardware and components. For the actual weight, size and load

capacity of the enclosure, view the product specifications and other support resources at

www.tripplite.com/support.

1

Using user-supplied hardware, attach the mounting plate to a wall or other suitable mounting

surface. Each mounting hole can accommodate an M8 or 5/16” bolt and the holes are spaced

16" apart to accommodate standard stud placement as reflected in the diagram. Note: When

mounting the mounting plate to the wall, be sure the three mounting hooks are facing outwards

and away from the wall.

2

After the mounting plate has been securely attached to the mounting surface, hang the

enclosure’s three mounting notches onto the three mounting hooks on the plate attached to the

wall. The notches will fit over the hooks and the enclosure should slide down onto the hooks

until secure. Note: Mounting notches exist on both the upper and lower rails of the back panel.

This allows for mounting in the standard or reversed positions.

3

After the mounting plate has been secured and the enclosure hung properly, secure the

enclosure to the mounting plate by installing the three supplied screws in the holes on the

mounting hooks as shown.

1

2

2.75”

16”

16”

2.75”

3

6

7. Equipment Installation

2

22

3

2

22

3

2

22

3

2

22

3

24

25

26

27

28

29

23

24

25

26

27

28

29

23

24

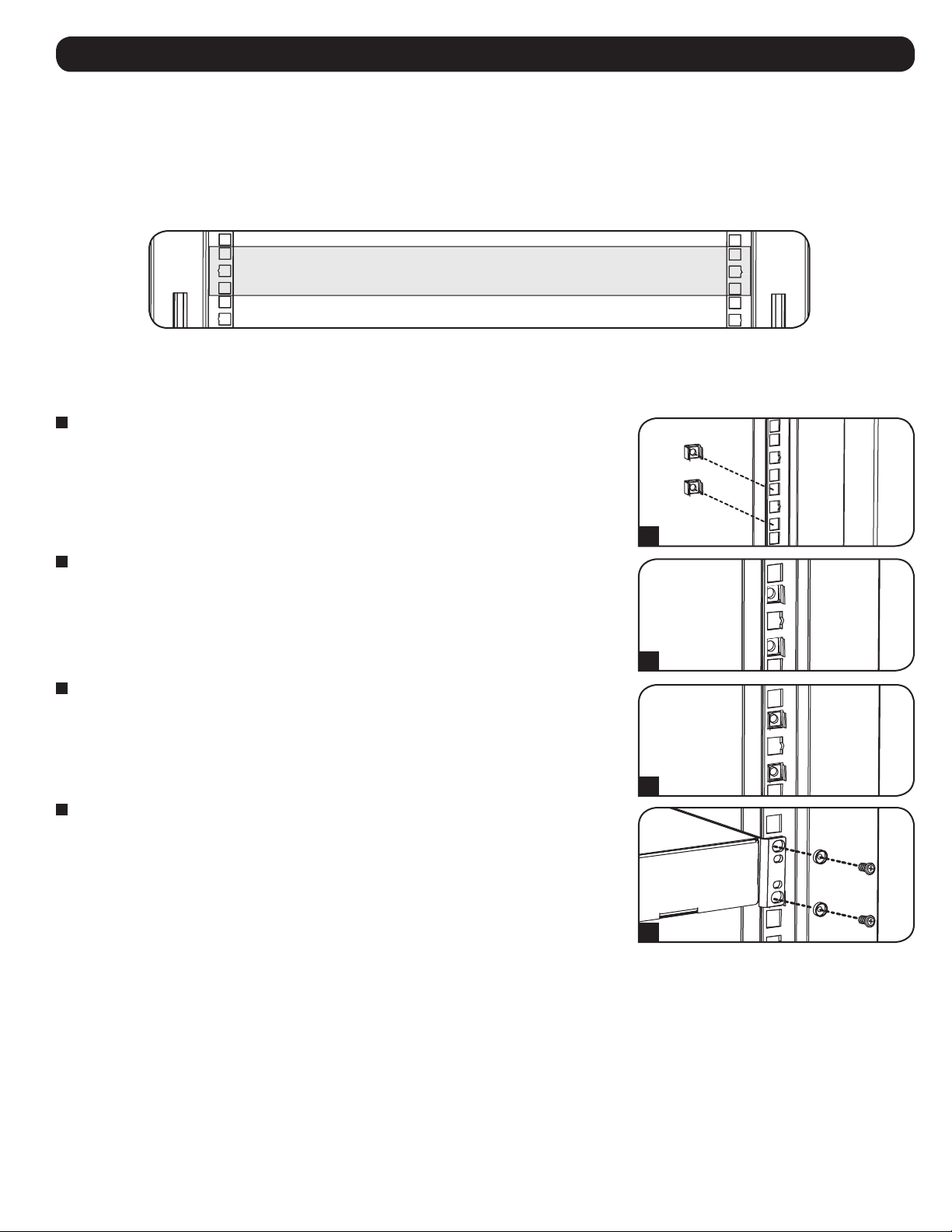

1 Rack Unit

Warning: Do not install equipment until you have stabilized the enclosure. Install heavier equipment first towards the bottom of

the enclosure. Install equipment starting from the bottom of the enclosure and proceed toward the top of the enclosure - never

the reverse. If using sliding equipment rails, be careful when extending the rails. Do not extend more than one set of sliding

equipment rails at one time. Avoid extending sliding equipment rails near the top of the enclosure.

Note: The unit comes with two different kinds of screws for equipment installation, black and silver. Use the black mounting screws if you are securing your

equipment to the square hole side of the mounting rail. Use the silver screws if you are securing your equipment to the tapped hole side of the mounting rail.

Note: The square holes in the middle of each rack unit are numbered and also include a small notch to aid identification. A single rack unit includes the space

occupied by the numbered hole and the holes directly above and below.

7.1 Installing or Removing Cage Nuts

WARNING: The flanges of the cage nuts should engage the sides of the square opening in the rail, not the top and bottom. Follow

the instructions in your equipment documentation to ensure proper installation of your equipment.

1

Locate the numbered square openings in the mounting rails where you plan to install your

equipment. You will install cage nuts (included) into the square openings in order to provide an

attachment point for the mounting screws (included). Note: Consult your equipment

documentation to determine how many cage nuts will be required and where they will need to

be installed.

2

From the inside of the mounting rail, insert one of the flanges of the cage nut through the

square opening. Press it against the side of the square opening. Each flange should engage one

side of the square opening, not the top or bottom.

3

Compress the cage nut at the sides slightly to allow the remaining flange to fit through the

square opening. When the cage nut is properly installed, both flanges will protrude through the

square opening and will be visible on the outer surface of the mounting rail. Repeat steps 1-3

until all required cage nuts are installed.

4

After installing the required cage nuts, use the included black mounting screws and cup washers

to secure your equipment to the rack rail. Place the cup washers between the screws and the

equipment mounting brackets.

Note: Your equipment may also include mounting hardware. Read the mounting instructions that came

with your equipment before installing your equipment.

To Remove Cage Nuts, Reverse Steps 1-3

Note: You may wish to use a cage nut tool (user-supplied) to aid cage nut installation and removal.

1

2

3

4

7

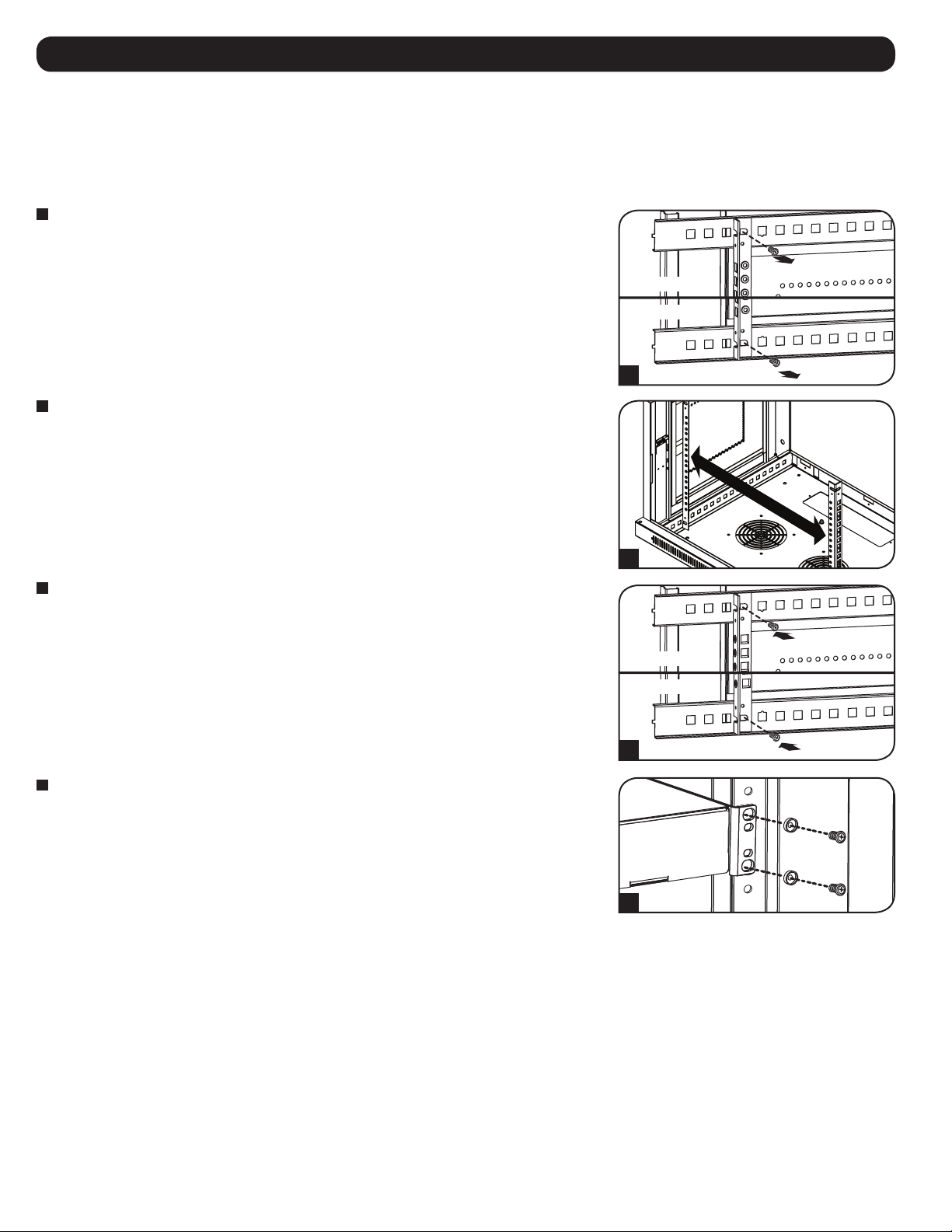

7. Equipment Installation continued

2

7.2 Alternate Mounting: Tapped Hole Mounting Rail

Warning: Do not attempt to adjust rails while equipment is installed in the enclosure. Do not attempt to use rails without screws

installed. (2 per rail.)

The 2 mounting rails are pre-installed for securing equipment using the square hole side of the mounting rail. To switch to the tapped hole side of the

mounting rail, follow the steps below:

1

Each rail is connected to the enclosure with 2 screws: 1 in the upper corner and another in the

lower corner. Using a Phillips-head screwdriver, remove the screws that fasten the rails to the

enclosure.

Upper Rail

Lower Rail

1

2

Switch the rail locations. Ensure the tapped hole side of each rail is facing the front door.

3

Reattach the mounting rails.

4

Use the included silver mounting screws to secure your equipment to the rack rail. Place the

cup washers between the screws and the equipment mounting brackets.

Note: Your equipment may also include mounting hardware. Read the mounting instructions that

came with your equipment before installing.

2

Upper Rail

Lower Rail

3

4

8

8. Storage and Service

Storage

The enclosure should be stored in a controlled indoor environment, away from moisture, temperature extremes, flammable liquids and gasses,

conductive contaminants, dust and direct sunlight. Store the enclosure in its original shipping container if possible.

Service

Your Tripp Lite product is covered by the warranty described in this manual. A variety of Extended Warranty and On-Site Service Programs are also

available from Tripp Lite. For more information on service, visit www.tripplite.com/support. Before returning your product for service, follow these steps:

1. Review the installation and operation procedures in this manual to insure that the service problem does not originate from a misreading of the

instructions.

2. If the problem continues, do not contact or return the product to the dealer. Instead, visit www.tripplite.com/support.

3. If the problem requires service, visit www.tripplite.com/support and click the “Request Return (RMA)” link. From here you can request a Returned

Material Authorization (RMA) number, which is required for service. This simple on-line form will ask for your unit’s model and serial numbers, along

with other general purchaser information. The RMA number, along with shipping instructions will be emailed to you. Any damages (direct, indirect,

special or consequential) to the product incurred during shipment to Tripp Lite or an authorized Tripp Lite service center are not covered under

warranty. Products shipped to Tripp Lite or an authorized Tripp Lite service center must have transportation charges prepaid. Mark the RMA number

on the outside of the package. If the product is within its warranty period, enclose a copy of your sales receipt. Return the product for service using

an insured carrier to the address given to you when you request the RMA.

9. Warranty and Product Registration

5-Year Limited Warranty

Seller warrants this product, if used in accordance with all applicable instructions, to be free from original defects in material and workmanship for a

period of 5 years from the date of initial purchase. If the product should prove defective in material or workmanship within that period, Seller will repair

or replace the product, at its sole discretion.

THIS WARRANTY DOES NOT APPLY TO NORMAL WEAR OR TO DAMAGE RESULTING FROM ACCIDENT, MISUSE, ABUSE OR NEGLECT. SELLER MAKES

NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY EXPRESSLY SET FORTH HEREIN. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW,

ALL IMPLIED WARRANTIES, INCLUDING ALL WARRANTIES OF MERCHANTABILITY OR FITNESS, ARE LIMITED IN DURATION TO THE WARRANTY PERIOD

SET FORTH ABOVE; AND THIS WARRANTY EXPRESSLY EXCLUDES ALL INCIDENTAL AND CONSEQUENTIAL DAMAGES. (Some states do not allow

limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may have other rights which vary from

jurisdiction to jurisdiction).

WARNING: The individual user should take care to determine prior to use whether this device is suitable, adequate or safe for the use intended. Since

individual applications are subject to great variation, the manufacturer makes no representation or warranty as to the suitability or fitness of these

devices for any specific application.

Product Registration

Visit www.tripplite.com/warranty today to register your new Tripp Lite product. You’ll be automatically entered into a drawing for a chance to win a FREE

Tripp Lite product!*

* No purchase necessary. Void where prohibited. Some restrictions apply. See website for details.

Tripp Lite has a policy of continuous improvement. Specifications are subject to change without notice.

1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/support

9

Manual del Propietario

Gabinetes SmartRack® No

Giratorios para Instalar en la Pared

Aplica a Serie de Modelo: SRWxxU

(Número de Serie de Agencia: AG-00E9)

Índice

1. Instrucciones de Seguridad Importantes 11

2. Vista General 11

3. Identificación de Características 12

4. Instalación del Gabinete 13

4.1 Preparación 13

4.2 Desempacado 13

4.3 Conexión a Tierra 13

5. Configuración del Gabinete 14

5.1 Cerraduras de la Puerta 14

5.2 Acceso y Administración del Cableado 14

5.3 Invirtiendo el Gabinete 14

5.4 Rieles para Instalación 15

5.5 Ajuste de Profundidad del 15

Riel de Instalación

6. Instalando el gabinete en la pared 15

7. Instalación del Equipo 16

7.1 Instalación o Remoción de las 16

Tuercas de Fijación

7.2 Instalación Alterna: Riel de 17

Instalación con Orificio Roscado

8. Almacenamiento y Servicio 18

9. Garantía 18

English 1

Français 19

28

1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/support

Copyright © 2015 Tripp Lite. Todas las otras marcas registradas son propiedad de sus respectivos dueños.

10

1. Instrucciones de Seguridad Importantes

CONSERVE ESTAS INSTRUCCIONES

Este manual contiene instrucciones y advertencias que deben observarse durante la instalación y operación del producto descrito en este manual. El no

hacerlo puede invalidar la garantía y causar daños a la propiedad o lesiones personales.

• Mantenga el gabinete en un entorno interior controlado lejos de humedad excesiva, temperaturas extremas, líquidos y gases inflamables,

contaminantes conductores, polvo o luz solar directa.

• Deje un espacio adecuado al frente y detrás del gabinete para una ventilación adecuada. No bloquee, cubra o inserte objetos en las aberturas de

ventilación externa del gabinete.

• El gabinete es extremadamente pesado. Tenga cuidado al manejar el gabinete. No intente desempacarlo, moverlo o instalarlo sin ayuda. Use un

dispositivo mecánico como un montacargas o gato para tarimas para mover el gabinete en el contenedor de embarque.

• No coloque objeto alguno sobre el gabinete, especialmente recipientes de líquidos y no intente apilar los gabinetes.

• Inspeccione el contenedor de embarque y el gabinete para detectar daños en el embarque. No use el gabinete si está dañado.

• Deje el gabinete en el contenedor de embarque hasta que haya sido movido tan cerca a su ubicación final como sea posible.

• Instale el gabinete en un área estructuralmente firme, capaz de manejar la carga o sobre una piso nivelado que sea capaz de soportar el peso del

gabinete, todo el equipo que se instale en el gabinete y otros gabinetes y/o equipo que se instalen cerca.

• Para instalación permanente en la pared, asegúrese de fijar firmemente el gabinete a la estructura del edificio antes de la operación.

• Tenga cuidado al cortar los materiales de empaque. El gabinete podría ser arañado, causando daños no cubiertos por la garantía.

• Guarde todo el material de empaque para uso posterior. El reempacar y embarcar el gabinete sin los materiales de empaque originales puede

causar daños al producto que anulen la garantía.

• No reembarque el gabinete con equipo adicional a menos que el gabinete haya sido embarcado con una tarima especial anti-impacto (solo

modelos “SP1”). El peso combinado del gabinete y el equipo instalado no debe exceder la capacidad de la tarima. Tripp Lite no es responsable por

daño alguno que ocurra durante el reembarque.

• No se recomienda el uso de este equipo en aplicaciones de soporte de vida en donde la falla de este equipo pueda consecuentemente causar la

falla del equipo de soporte de vida o afectar significativamente su seguridad o efectividad. No use este equipo en presencia de una mezcla

inflamable de anestésicos con aire, oxígeno u óxido nitroso.

2. Vista General

Los gabinetes SmartRack no giratorios para Instalación en la pared acomodan todo el equipo para instalación en rack estándar de 19", sin importar el

proveedor y se embarcan completamente ensamblados para una instalación rápida y fácil. Cuentan con gabinetes adaptables de servicio pesado en

diversas alturas.

Los gabinetes SmartRack no giratorios para instalación en la pared tienen profundidades de instalación variables, ideales para servidores. Para

comodidad en el mantenimiento, los gabinetes incluyen puertas y paneles laterales de liberación rápida. Para flexibilidad de instalación, las puertas de

acceso frontal son reversibles. La puerta frontal y los paneles laterales pueden cerrarse con cerradura. Para fácil movilidad de los gabinetes está

disponible un juego opcional de ruedas (SRCASTER).

11

Loading...

Loading...