Page 1

Warranty

Owner’s Manual

Registration

Register online today for a chance

www.tripplite.com/warranty

to win a FREE Tripp Lite product!

PDUMH15AT,PDUMH15ATNET

PDUMH20AT,PDUMH20ATNET

Switched/Metered Rack PDU with

Automatic Transfer Switch

1. Important Safety Instructions 2

2. Installation 3

2.1 Mounting the PDU 3

2.2 Connecting the PDU 3

2.3 Networking the PDU 5

2.3.1 Dynamic IP Address Assignment 5

2.3.2 Static IP Address Assignment 5

2.3.3 Testing Network Connection 7

3. Features 8

4. Configuration and Operation 10

4.1 Automatic Transfer Switch 10

4.1.1 Preferred Configuration 10

4.1.2 Automatic Transfer Switch Source Selection 10

4.1.3 Quick Test 11

4.2 Remote Monitoring and Control 11

5. Technical Support 12

6. Warranty and Warranty Registration 12

Español 13

Français 25

1111 W. 35th Street • Chicago, IL 60609 USA

(773) 869-1234 • www.tripplite.com

Copyright © 2008 Tripp Lite. All rights reserved. SmartOnline™ is a trademark of Tripp Lite.

Page 2

2

1. Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains instructions and warnings that should be

followed during the installation, operation, and storage of this product.

Failure to heed these instructions and warnings will void the product

warranty.

The PDU provides convenient multiple outlets, but it DOES NOT provide surge or line noise •

protection for connected equipment.

The PDU is designed for indoor use only in a controlled environment away from excess moisture, •

temperature extremes, conductive contaminants, dust or direct sunlight.

Do not connect the PDU to an ungrounded outlet or to extension cords or adapters that eliminate the •

connection to ground.

The power requirement for each piece of equipment connected to the PDU must not exceed the •

individual outlet’s load rating.

The total power requirement for equipment connected to the PDU must not exceed the maximum load •

rating for the PDU.

Do not drill into or attempt to open any part of the PDU housing. There are no user-serviceable parts •

inside.

Do not attempt to modify the PDU, including the input plugs and power cables.•

Do not attempt to use the PDU if any part of it becomes damaged.•

Do not attempt to mount the PDU to an insecure or unstable surface.•

Never attempt to install electrical equipment during a thunderstorm.•

Use of this equipment in life support applications where failure of this equipment can reasonably be •

expected to cause the failure of the life support equipment or to significantly affect its safety or

effectiveness is not recommended. Do not use this equipment in the presence of a flammable

anesthetic mixture with air, oxygen or nitrous oxide.

Page 3

3

2. Installation

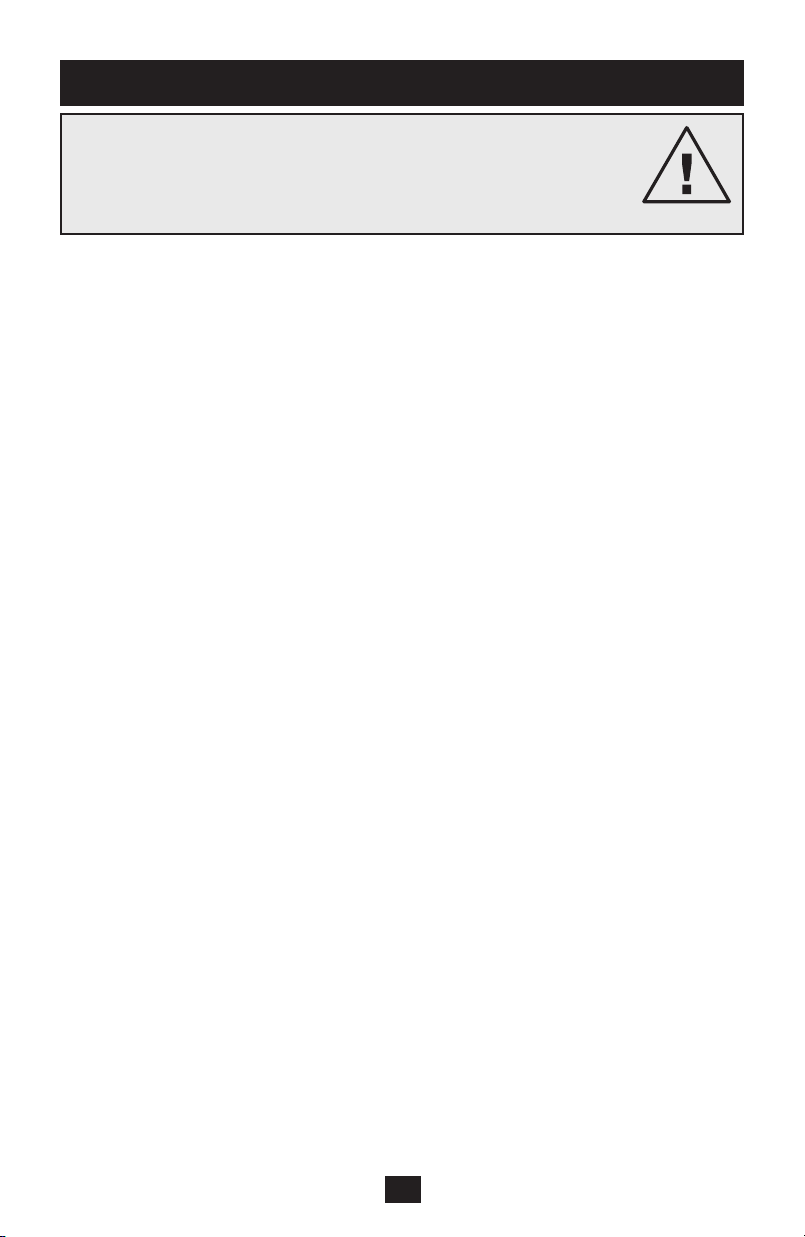

2.1 Mounting the PDU

The PDU supports four primary mounting

configurations: 1U Rack, 0U Rack, Wall and

Under-Counter.

Note: Regardless of configuration, the user must determine the

fitness of hardware and procedures before mounting. The PDU

and included hardware are designed for common rack and rack

enclosure types and may not be appropriate for all applications.

Exact mounting configurations may vary.

1-1 1U Rack Mounting: Attach the PDU to the

rack by inserting four user-supplied screws A

through the PDU mounting brackets B and into

the mounting holes of the rack rail as shown.

1-2 0U Rack Mounting: Remove the screws C

attaching the mounting brackets to the PDU,

change the orientation of the brackets as shown

and reattach the brackets. Use only the screws

supplied by the manufacturer or their exact

equivalent (#6-32, 1/4" flat head). Attach the

PDU vertically by inserting two or more usersupplied screws A through the PDU mounting

brackets B and into mounting points in the rack

or rack enclosure.

1-3 Wall or 1-4 Under-Counter Mounting:

Remove the screws C attaching the mounting

brackets to the PDU, change the orientation of the

brackets as shown and reattach the brackets. Use

only the screws supplied by the manufacturer or

their exact equivalent (#6-32, 1/4" flat head).

Attach the PDU to a stable mounting surface by

inserting two or more user-supplied screws A

through the PDU mounting brackets B and into

secure points on the mounting surface.

1-1

1-2

1-3

1-4

B

A

B

B

C

C

B

A

A

C

A

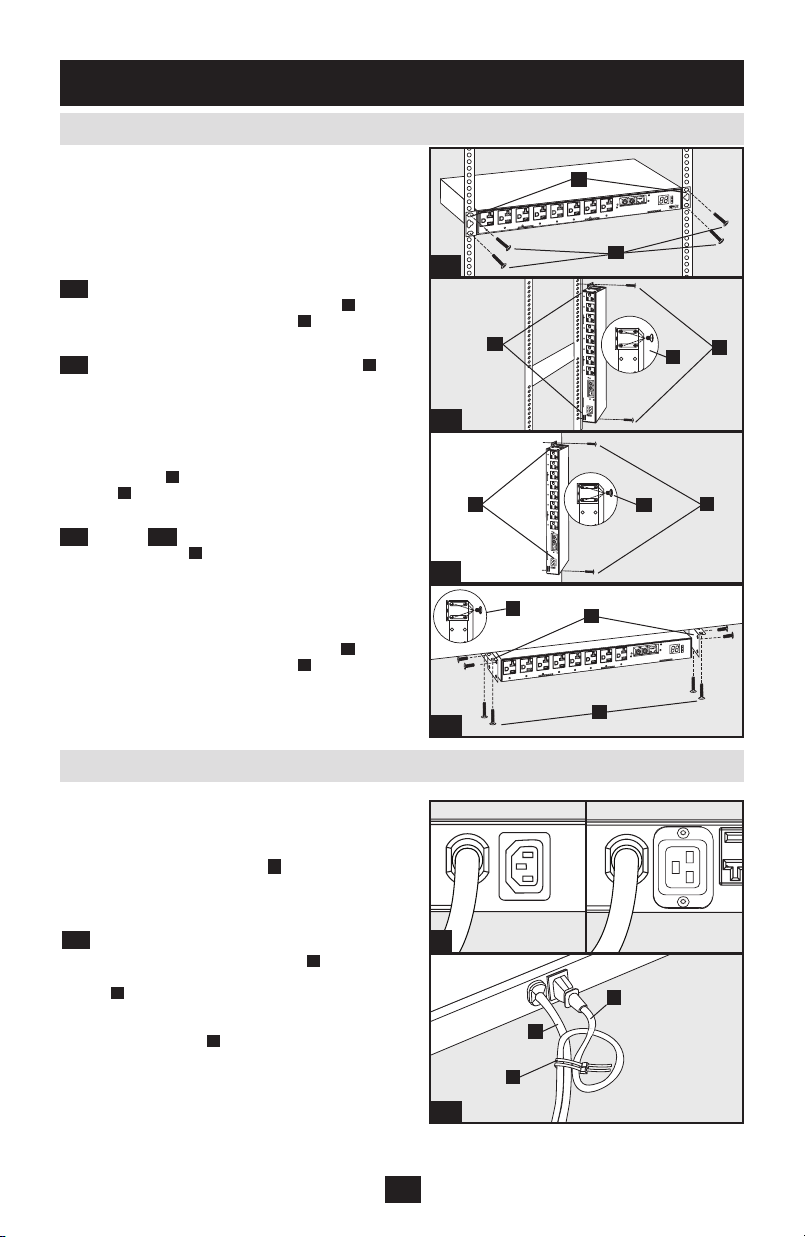

2.2 Connecting the PDU

The PDU includes two AC power inputs: Primary

and Secondary. The Primary input cord is

permanently attached to the rear of the PDU.

The Secondary input cord is detachable and

connects to the IEC power inlet 2 at the rear of

the PDU (PDUMH15AT,PDUMH15ATNET IEC-320-C14 inlet; PDUMH20AT,

PDUMH20ATNET - IEC-320-C20 inlet).

2-1 To connect the Secondary input cord:

Form a loop in the Secondary cord 1.

secure the juncture of that loop to the Primary

cord B with a zip tie. Be sure the zip tie is

secured around the Secondary and Primary

cords, as well as through the loop created in

the Secondary cord C. (See diagram). Note:

Give the cord as much slack as possible

between the loop and the cord’s outlet.

Once you’ve secured the two cords together 2.

and ensured that the Secondary cord has a

comfortable amount of slack, insert the

Secondary cord outlet into the IEC power inlet.

A

and

PDUMH20AT

PDUMH20ATNET

A

2

PDUMH15AT

PDUMH15ATNET

B

C

2-1

Page 4

4

2. Installation

(

continued

)

2.2 Connecting the PDU

(

continued

2-2 Connect Input Plug Adapters (Optional -

Models PDUMH20AT, PDUMH20ATNET

Only): The PDU includes two adapters that

convert one or both of the L5-20P input plugs to

5-20P input plugs. Connecting the adapters is

optional. The PDU will function normally without

connecting the adapters.

2-3 Connect Secondary Input Cord to PDU:

Although the PDU will operate without

connecting the Secondary input cord, the

Secondary input is required for the PDU's

Automatic Transfer Switch function.

2-4 Connect PDU Input Plugs: (See the

Configuration and Operation section for more

information.) Connect the Primary input plug A

to a preferred source of grounded 120V AC

power, such as a SmartOnline™ UPS System. The

UPS system must not share a circuit with a heavy

electrical load (such as an air conditioner or

refrigerator). Under normal operating conditions,

the PDU will distribute AC power from the

Primary input source. Connect the Secondary

input plug B to an alternative source of grounded

120V AC power, such as a redundant

SmartOnline UPS System. The UPS system must

not share a circuit with a heavy electrical load

(such as an air conditioner or refrigerator). Do not

plug the Secondary input into the same power

source as the Primary input. The PDU will

distribute AC power from the Secondary input

only if the Primary input becomes unavailable.

Note: Immediately after the PDU is connected to live AC

power, you may notice a series of soft clicking sounds emitted by

electrical relays within the PDU. The relays may also click

occasionally during the operation of the PDU. This is normal.

3 Connect Equipment to PDU: Do not exceed

the load rating of the PDU. The total electrical

current used by the PDU will be displayed on the

digital meter in amperes. Each outlet includes a

green LED that illuminates when the outlet is

receiving AC power.

)

PDUMH20AT,

2-2

2-3

PDUMH15AT,

PDUMH15ATNET

A

B

B

PDUMH20ATNET

PDUMH20ATNET

PDUMH15ATNET

A

PDUMH20ATNET

PDUMH20AT,

PDUMH15AT,

PDUMH20AT,

2-4

PDUMH15AT

PDUMH20AT

PDUMH15ATNET

PDUMH20ATNET

33

Page 5

5

2. Installation

(

continued

)

2.3 Networking the PDU

Note: The MAC address of the PDU (a 12-digit string in this format: 000667xxxxxx) is printed on a label attached to the PDU enclosure.

The MAC address is also printed on a label attached to the internal network card.

(Only Applicable to Models with SNMP Network Card Installed)

If your network's DHCP server will assign a dynamic IP address to the PDU automatically, go to Step

4-1

. If you will assign a static IP address to the PDU manually, go to Step

5-1

. If you are uncertain which

method to use, contact your network administrator for assistance before continuing the installation

process.

2.3.1 Dynamic IP Address Assignment

4-1 Connect PDU to Network: While the

PDU is powered, connect a standard Ethernet

A

patch cable to the RJ-45 Ethernet port

on the

A

PDU. Note: This port is not compatible with PoE

(Power over Ethernet) applications. The PDU

will attempt to obtain an IP address via DHCP.

This may take as long as several minutes,

depending on your network environment.

4-1

4-2 Discover IP Address: Contact your network administrator to determine which dynamic IP address

has been assigned to the PDU by the DHCP server. The PDU can be identified on the DHCP server by

referring to its MAC address. (The MAC address is a 12-digit string in this format: 000667xxxxxx. Refer

to the MAC address label attached to the PDU.) You may wish to request a long-term lease period for the

5-1

IP address, depending on your application. After you have discovered the IP address, skip Steps

through

5-6

and proceed directly to Step

6-1

.

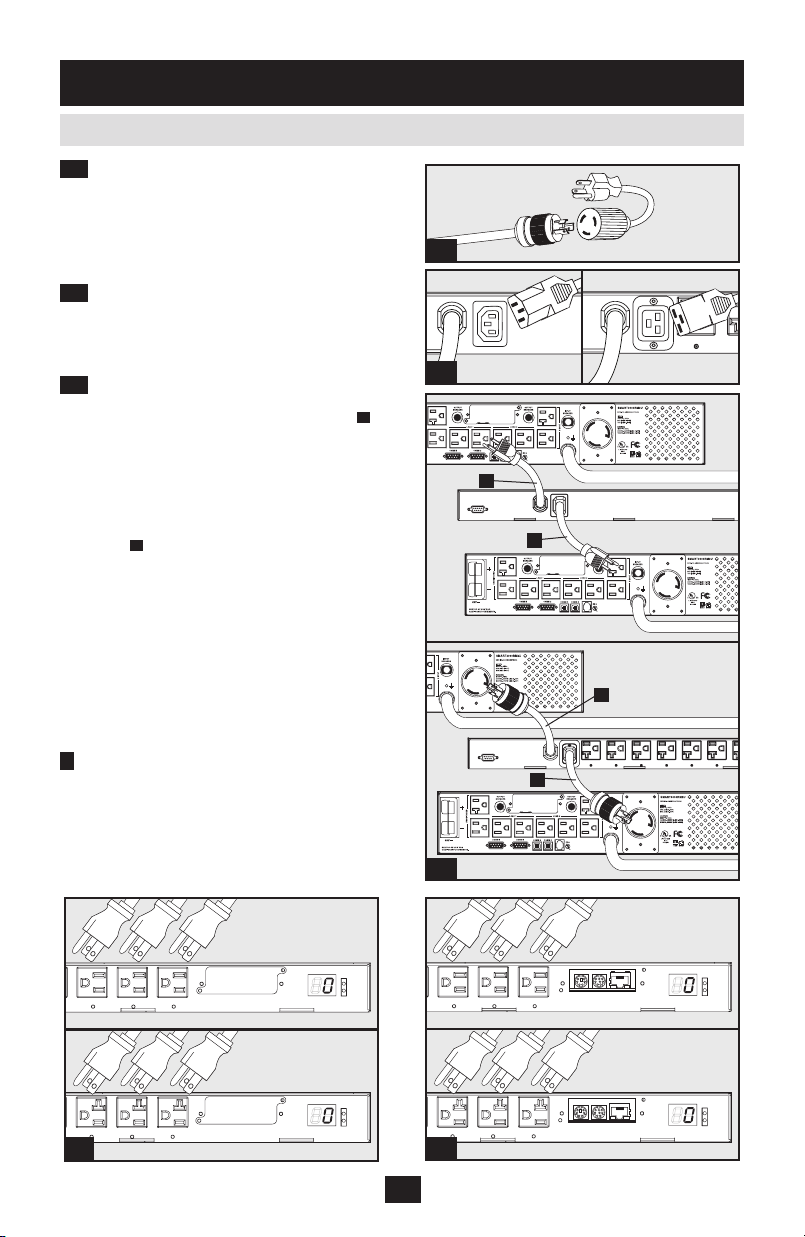

2.3.2 Static IP Address Assignment

5-1 Determine IP Information: Before

assigning a static IP address, you'll need to know

the IP address, gateway address and subnet mask.

If you do not have this information, contact your

network administrator for assistance.

5-2 Configure Terminal Emulation Program:

Open a VT100-compatible terminal emulation

program (such as the HyperTerminal program

bundled with Microsoft

®

Windows®) on a

A

computer with an available DB9 serial port. (A

notebook computer may be the most convenient

choice.) Set the terminal emulation program to

A

use the COM port

that corresponds to the

computer’s DB9 serial port. Specify the

parameters B required to communicate with the

PDU terminal interface:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

B

If the terminal emulation program supports

multiple emulation modes, you may also need to

specify VT100 emulation C.

C

Page 6

6

2. Installation

(

continued

)

2.3 Networking the PDU

2.3.2 Static IP Address Assignment

5-3 Connect PDU to Computer: Use the mini-

DIN to DB9 serial cable (part number 73-1025)

included with the PDU to connect the PDU to

the computer. The circular connector A at one

end of the cable attaches to the 8-pin mini-DIN

serial port B on the PDU. (Align the connector

carefully to avoid damaging the pins.) The DB9

connector C at the other end of the cable

connects to the computer's serial port D.

5-4 Connect PDU to Network: While the PDU

is powered, connect a standard Ethernet patch

cable to the RJ-45 Ethernet port A on the PDU.

Note: This port is not compatible with PoE (Power over Ethernet)

applications.

5-5 Configure PDU in Terminal Mode: After

a brief pause, an initialization page should appear

in the terminal emulation program. Press any key

on the keyboard within 10 seconds to change the

PDU settings. (If the 10-second period has

elapsed, you can reboot the PDU by powering

down completely and then restoring power.)

Follow the sequence of responses below in order

to assign an IP address to the PDU. The default

terminal mode root password is TrippLite.

Sample IP settings are shown - supply your own

IP information when you configure your PDU.

(

continued

(

continued

)

)

5-3

B

A

A

C

D

5-4

5-5

Press A to Accept the settings, or M to Modify? M

Enter the root password: *********

Reset configuration to default values (Y/N)? N

For each of the following questions, you can press <Return> to select the value shown in

braces, or you can enter a new value.

NETWORK INTERFACE PARAMETERS:

Should this target obtain IP settings from the network?[N] N

Static IP address [192.168.1.19]? 192.168.0.123

Static IP address is 192.168.0.123

Subnet Mask IP address [255.255.0.0]? 255.255.255.0

Subnet Mask IP address is 255.255.255.0

Gateway address IP address [192.168.1.1]? 192.168.0.1

Gateway address IP address is 192.168.0.1

You can also change the root password, real-time clock and other settings. (Tripp Lite recommends

against changing the default settings unless you are an advanced user with a specific purpose.) After you

have finished entering settings, the PDU will save changes to memory and reboot (this may take several

minutes). After the PDU reboots, the initialization page should display the new static IP settings.

5-6 Remove Serial Cable: Remove the serial cable from the PDU and proceed to Step

6-1

.

Page 7

7

2. Installation

(

continued

)

2.3 Networking the PDU

2.3.3 Testing Network Connection

6-1 Access PDU with Web Browser: After an

IP address has been assigned to the PDU, attempt

to access it with a Web browser that supports

frames, forms and Java

on a computer connected to the LAN and enter

the IP address assigned to the PDU. You should

be prompted for a password

admin and the default password is admin. After

you enter the user name and password, the

PowerAlert Status page B will appear in the

browser window. For more information about

configuration and operation of the PDU via the

PowerAlert interface, refer to the

SNMPWEBCARD User's Guide, included on the

CD-ROM bundled with the PDU.

Note for Network Management System Users Only: Two MIB

files - Tripplite.mib and RFC1628.mib - must be loaded on each

Network Management Station that will monitor the PDU via

SNMP. The files are provided on the CD-ROM included in the

product package.

™

. Open a Web browser

(

continued

A

. The user name is

)

A

B

Page 8

8

3. Features

Primary AC Input Power Cord (Model

PDUMH15AT/15ATNET):The cord is permanently attached to the

PDU and has a NEMA 5-15P plug.

Primary AC Input Power Cord (Model PDUMH20AT/20ATNET):

The cord is permanently attached to the PDU and has a NEMA L5-20P

plug.

Secondary AC Input Power Inlet (Model PDUMH15AT/15ATNET):

The IEC-320-C14 inlet connects to the detachable Secondary AC Input

Power Cord.

Secondary AC Input Power Inlet (Model PDUMH20AT/20ATNET):

The IEC-320-C20 inlet connects to the detachable Secondary AC Input

Power Cord.

Secondary AC Input Power Cord (Model PDUMH15AT/15ATNET):

The detachable cord has an IEC-320-C13 connector and a NEMA 5-15P

plug.

Secondary AC Input Power Cord (Model PDUMH20AT/20ATNET):

The detachable cord has an IEC-320-C19 connector and a NEMA

L5-20P plug.

Input Plug Adapters (Model PDUMH20AT/20ATNET): The adapters

convert NEMA L5-20P input plugs to NEMA 5-20P input plugs.

NEMA 5-15R Outlets (Model PDUMH15AT/15ATNET): During

normal operation, the outlets distribute AC power to connected

equipment. When an outlet is live, the associated LED illuminates.

Page 9

9

3. Features

(

continued

)

NEMA 5-15/20R Outlets (Model PDUMH20AT/20ATNET): During

normal operation, the outlets distribute AC power to connected

equipment. When an outlet is live, the associated LED illuminates.

Digital Load Meter (Ammeter): The total electrical current used by the

PDU is displayed on the digital meter in amperes.

Input Source Indicator: When the PDU is connected to a live AC

power source, the Primary or Secondary input LED illuminates to

indicate which source is supplying power to the PDU outlets.

Accessory Slot: An optional SNMP card may be installed in the slot,

allowing the PDU to be configured, controlled and monitored remotely.

Contact Tripp Lite Customer Support at (773) 869-1234 for more

information.

Factory Port: The port is reserved for configuration by factory

authorized personnel only. Do not connect anything to the port.

For Models with SNMP Network Card Installed:

PS/2 Port: Use this port to connect a Tripp Lite ENVIROSENSE

environmental sensor to provide remote temperature/humidity monitoring and

a dry contact interface to control and monitor alarm, security and telecom

devices. Contact Tripp Lite Customer Support at (773) 869-1234 for ordering

information. Note: Do not connect a keyboard or mouse to this port.

Mini-DIN Serial Port: Use this port to provide a direct terminal

connection to a computer with a terminal emulation program. A serial

cable (part number 73-1025) is included with the PDU. If you need to

order a replacement cable, contact Tripp Lite Customer Support at (773)

869-1234.

Ethernet Port: Use this RJ-45 jack to connect the PDU to the network

A

with a standard Ethernet patch cable. The Link LED

B

indicate several operating conditions, as shown in the table below.

and Status LED

This port is not compatible with PoE (Power Over Ethernet)

applications.

A

A

Link LED Color

Off No Network Connection Off Card Not Initialized

Flashing Amber 100 Mbps Network Connection Steady Green Card Initialized and Operational

Flashing Green 10 Mbps Network Connection Flashing Amber Error - Card Not Initialized

B

Network Operating Conditions

B

Status LED Color

Page 10

10

4. Configuration and Operation

4.1 Automatic Transfer Switch

When the Primary and Secondary inputs are both connected to Tripp Lite UPS Systems, the PDU

operates as an Automatic Transfer Switch, providing redundant input power for high availability

applications. Under normal operating conditions, the PDU will distribute power from the Primary input

source, switching to the Secondary input source under certain conditions. The PDU will switch to the

Primary source whenever it is Good according to the PDU input voltage definitions (see below).

4.1.1 Preferred Configuration

The Automatic Transfer Switch function provides

increased availability when the Primary and

Secondary inputs of the PDU are connected to

separate Tripp Lite UPS Systems that are

connected to separate utility power sources. For

maximum availability, Tripp Lite recommends

using matching SmartOnline UPS Systems with

pure sine wave output for the Primary and

Secondary input power sources. The automatic

transfer switch function will be compromised if the

primary and secondary inputs are connected to the

same utility power source.

Warning: DO NOT connect the primary input

to a line-interactive UPS, due to transfer time

issues, or to any source that does not supply a

pure sine wave. Such sources may be used to

power the secondary input.

Utility B

Facility Circuit

Secondary UPS

Secondary Input Cord

Critical Equipment

Facility Circuit

Loads

Utility A

Primary UPS

Primary Input Cord

PDUMH15ATNET

4.1.2 Automatic Transfer Switch Source Selection

Upon power-up, the PDU looks for a source ≥85V. If it is unable to find a source ≥85V, it remains off.

Input voltage definitions:

99V ≤ Vin < 139V Good

in

75V ≤ V

V

< 99V Fair

in

< 75V Bad

In normal operation (after power-up), if the selected source is no longer Good, the PDU will attempt to

switch to the other source, but only if the other source is Good. If the selected source becomes Fair and

the other source is not Good, the PDU will keep the loads connected to the selected source until the

selected source becomes Bad, at which point the loads will be disconnected (note that the source

selection doesn't change). After the loads are disconnected, they remain disconnected until the selected

source becomes ≥85V, or until the other source becomes Good.

Page 11

11

4. Configuration and Operation

(

continued

)

4.1 Automatic Transfer Switch

(

continued

4.1.3 Quick Test

After installing the PDU and connecting

equipment, you may test the Automatic Transfer

Switch function by temporarily shutting down the

UPS system connected to the Primary AC input.

When the Primary input UPS is no longer

supplying AC power, the PDU will switch from

the Primary input to the Secondary input, and the

Secondary input LED will illuminate. When the

Primary input UPS has been restarted and resumes

supplying AC power, the PDU will switch back to

the Primary input.

Note: The primary and secondary inputs must be connected to

separate sources of utility power. The automatic transfer switch

function will be compromised if the primary and secondary inputs

are connected to the same utility power source. Do not perform a

test with equipment that must remain in productive operation. Any

test procedure must prepare for the contingency that the equipment

may lose power. Do not test the PDU by detaching power cords

which are connected to live power sources, as this eliminates the

connection to ground and places your equipment at risk.

4.2 Remote Monitoring and Control

The PDU provides remote monitoring A, outlet

B

control

SNMP-based Network Management Systems.

For more information about configuration and

operation of the PDU via the PowerAlert Web

browser interface, refer to the SNMPWEBCARD

User's Guide, included on the CD-ROM bundled

with the PDU.

and more via Web browser, telnet and

)

Primary Input Active

A

Secondary Input Active

B

Page 12

5. Technical Support

Telephone: (773) 869-1233

8:00 AM - 6:00 PM CST Monday - Thursday

8:00 AM - 5:30 PM CST Friday

(CST is Central Standard Time in the United States.)

E-mail: techsupport@tripplite.com

6. Warranty and Warranty Registration

LIMITED WARRANTY

Seller warrants this product, if used in accordance with all applicable instructions, to be free from original defects in material

and workmanship for a period of 2 years (except internal UPS system batteries outside USA and Canada, 1 year) from the

date of initial purchase. If the product should prove defective in material or workmanship within that period, Seller will repair or

replace the product, in its sole discretion. Service under this Warranty can only be obtained by your delivering or shipping the

product (with all shipping or delivery charges prepaid) to: Tripp Lite, 1111 W. 35th Street, Chicago, IL 60609 USA. Seller will

pay return shipping charges. Call Tripp Lite Customer Service at (773) 869-1234 before sending any equipment back for

repair.

THIS WARRANTY DOES NOT APPLY TO NORMAL WEAR OR TO DAMAGE RESULTING FROM ACCIDENT, MISUSE,

ABUSE OR NEGLECT. SELLER MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY EXPRESSLY SET

FORTH HEREIN. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ALL IMPLIED WARRANTIES, INCLUDING

ALL WARRANTIES OF MERCHANTABILITY OR FITNESS, ARE LIMITED IN DURATION TO THE WARRANTY PERIOD SET

FORTH ABOVE; AND THIS WARRANTY EXPRESSLY EXCLUDES ALL INCIDENTAL AND CONSEQUENTIAL DAMAGES.

(Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This Warranty

gives you specific legal rights, and you may have other rights which vary from jurisdiction to jurisdiction).

WARNING: The individual user should take care to determine prior to use whether this device is suitable, adequate or safe for

the use intended. Since individual applications are subject to great variation, the manufacturer makes no representation or

warranty as to the suitability or fitness of these devices for any specific application.

WARRANTY REGISTRATION

Visit www.tripplite.com/warranty today to register the warranty for your new Tripp Lite product. You'll be automatically entered

into a drawing for a chance to win a FREE Tripp Lite product!*

* No purchase necessary. Void where prohibited. Some restrictions apply. See website for details.

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense. The user must use shielded cables and connectors with this product. Any changes or

modifications to this product not expressly approved by the party responsible for compliance could void the user's authority to

operate the equipment.

Regulatory Compliance Identification Numbers

For the purpose of regulatory compliance certifications and identification, your Tripp Lite product has been assigned a unique

series number. The series number can be found on the product nameplate label, along with all required approval markings and

information. When requesting compliance information for this product, always refer to the series number. The series number

should not be confused with the marking name or model number of the product.

The policy of Tripp Lite is one of continuous improvement. Specifications are subject to change without notice.

Made in China.

12

200810115 93-2857

Loading...

Loading...