Page 1

Page 2

2

Smoke

Fumes

Wood

Fiberglass

Food Mixes

Composites

Plastics

Marble

Carbon

Ceramics

Cotton

Dry Chemicals

Powders

Rubber

Toner

Cement

Applications By Contaminant

The Power in Dust Control

Exposure to dust has been associated with a variety of

adverse health conditions, product quality issues and

increased equipment and plant maintenance costs. In

addition, government regulators mandate that poor air

quality must be remediated. Choosing the right dust

collection system provides both environmental and

economic benefits by improving the air in the workplace,

product quality and reducing energy costs.

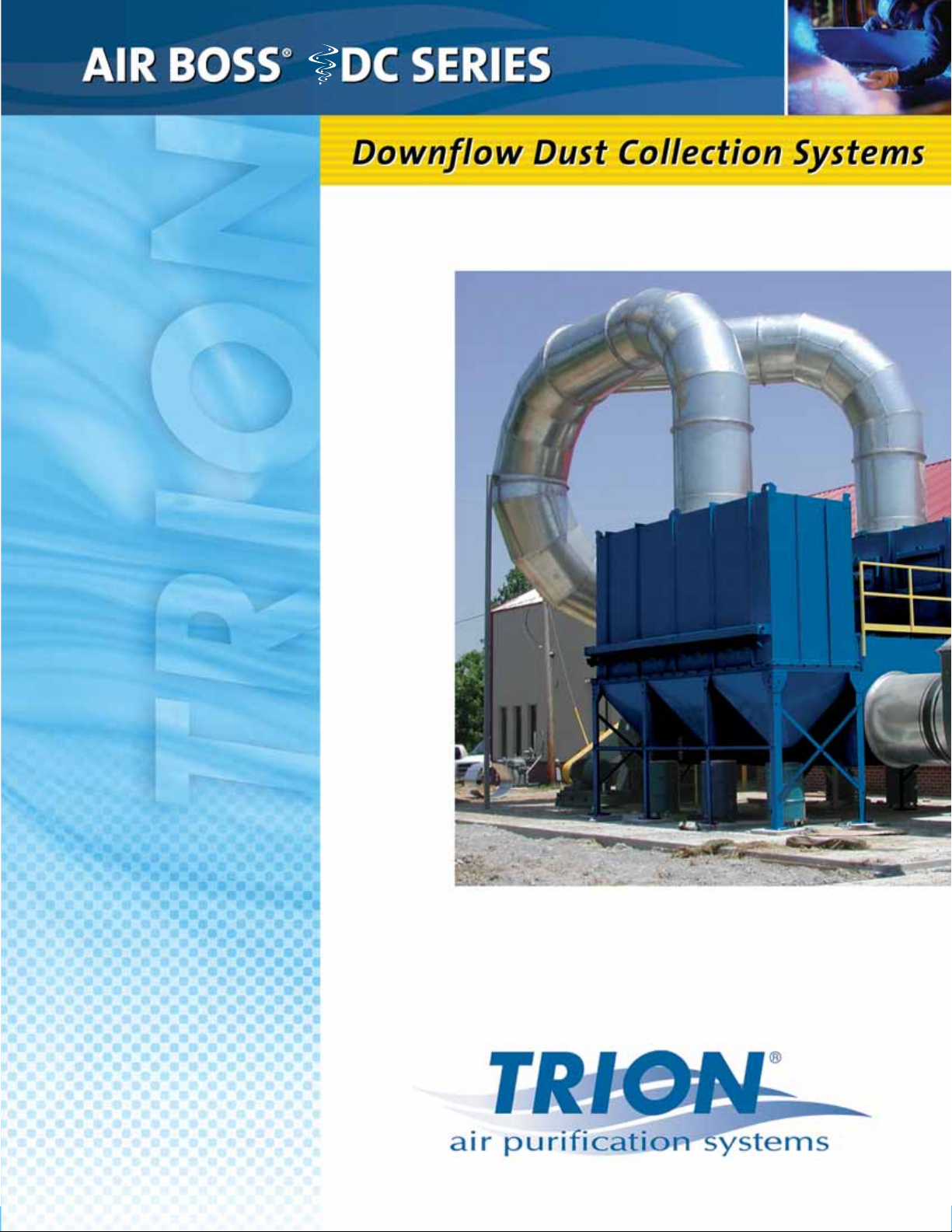

Modular Design for Specialized Needs

Air Boss®Vertical Cartridge Dust Collectors offer

a broad spectrum of cost-effective solutions for the

most difficult dust, smoke and fume collection

applications. Their modular design allows for an infinite

range of sizes for the largest dust collection tasks.

Air Boss (DC) series includes a full range of units —

from the DC-2 which collects dust at a single

workstation to a DC-128 which controls contaminants

in large manufacturing facilities.

Air Boss helps meet and exceed NIOSH and OSHA

codes for recirculation of plant air, providing 99%

efficiency on submicron particles (.5) with low energy

and operating costs.

Page 3

3

From a Leader in Clean Air Technology

Trion, a leading global manufacturer and marketer of

indoor air quality products, designed the world’s first

air cleaner for the U.S. Navy nuclear submarine fleet

in 1947. Since then, Trion has continued to provide

advanced and specialized air cleaning systems for a

wide range of applications in the commercial and

industrial markets.

Air Boss Systems Can Help You:

• Protect employee health

• Boost employee morale

• Comply with government regulations

• Increase product quality

• Enhance company image

• Improve productivity

• Reduce maintenance costs

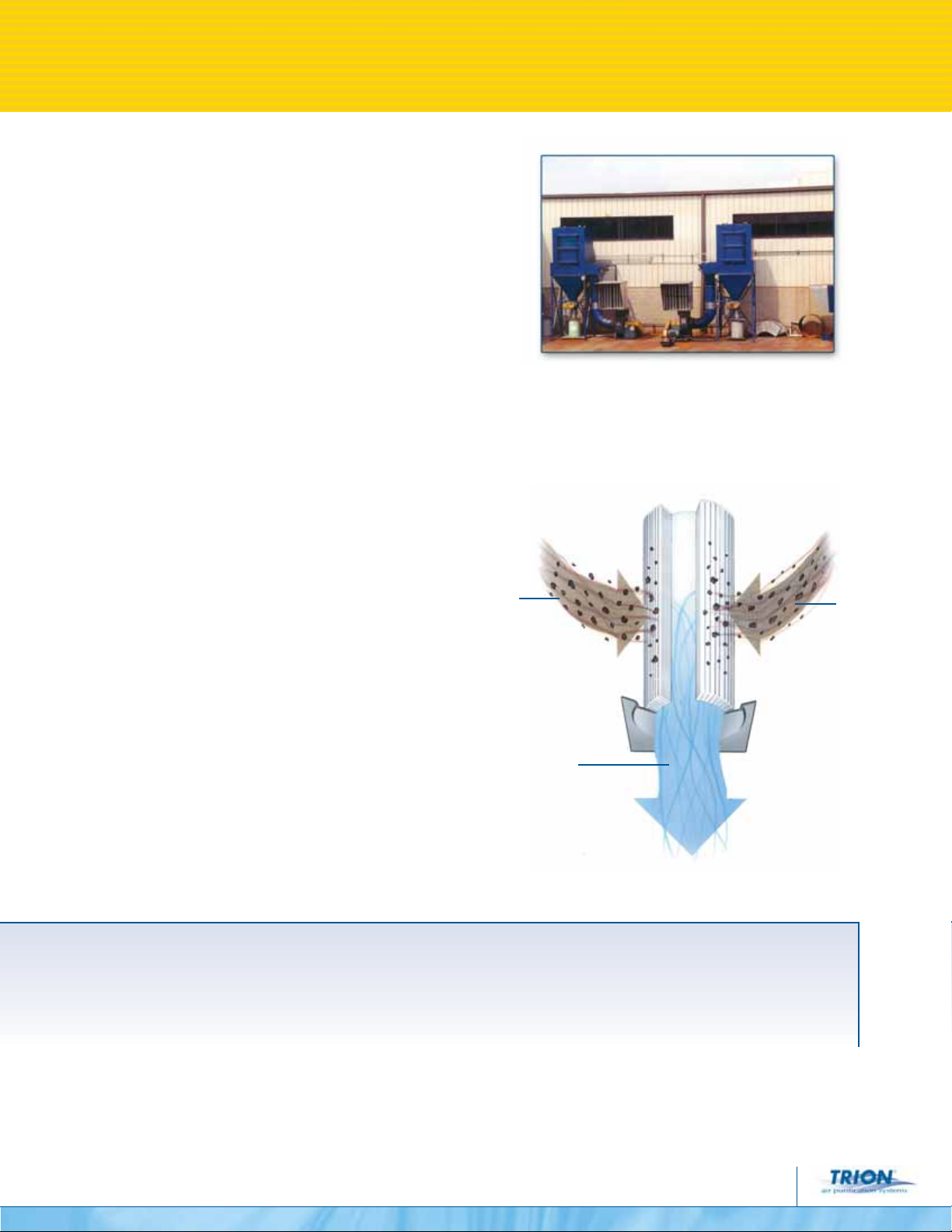

Cartridge Air Cleaning

Contaminated air is drawn through high-efficiency

cartridge filters, where the particulate is collected on

the outside of the media. Filtered air is pulled through

the system and exhausted. Standard units feature

Venturi reverse pulse cleaning systems to enhance

filter life.

Grinding

Sanding

Foundry

Welding

Blasting

Soldering

Powder Coating

Metallizing

Pharmaceutical

Deburring

Polishing

Material Handling

Laser

Plasma Cutting

Mixing

Milling

Applications By Process

Dirty Air

Dirty Air

Clean Air

Page 4

4

Air Boss Advantages

High-Performance Cartridges.

With a 99% efficiency

rating for submicron (.5) particulate, extra-large

circular filters are vertically oriented for uniform dust

loading and efficient cleaning.

Efficiency.

Many competitors’ products operate

with a high level of re-entrainment, which means

that energy and filter life are wasted by repeatedly

collecting the same dust. Air Boss patented

downflow/vertical design ensures consistent filtration

and efficient dust handling from capture to disposal.

Size Availability.

Air Boss is designed with a full

range of capacities for a vast array of applications.

From the DC-2 with (2) cartridges to DC-128 with

(128) cartridges, every Air Boss has the media

capacity and optimal filtering velocity for every

type of contaminant and process.

Powerful Cleaning.

The patented venturi-assisted

design optimizes reverse jet pulse cleaning and

increases filter life. With four available methods to

initiate the cleaning cycle, every Air Boss collector

is equipped with the control system that best fits

the application.

Improved Fan Operation.

Venturi and innovative

cylindrical fan housing increases performance,

reduces noise, simplifies maintenance and eliminates

the need for a discharge damper.

Easy Maintenance.

Outstanding design features

combine to promote long filter life. Easy access

allows each filter to be changed in several minutes.

Space Economy.

The downflow/vertical design

has a smaller footprint than comparable units with

horizontal filters.

Rock-Solid Construction.

Air Boss is built for

durability and reliability with 11-gauge steel fabrication

and welded seams/joints. Air Boss units are designed

and tested for Seismic Zone 4.

Dust Collection Efficiency:

Problem. The #1 challenge to dust collection efficiency is re-entrainment – dust collected is stirred up and has

to be filtered all over again. The goal is to dislodge the dust and allow it to settle in a hopper below and not

be redeposited on the filters.

TM

Page 5

5

How Downflow/Vertical Systems Operate

Contaminated air enters the collector above the filter

cartridges. Specially designed components in the

cabinet uniformly distribute the contaminated air

across the top of the filters. The contaminated air

flows downward without the detrimental velocity

spikes that are common with competitive designs.

Dust is conveyed to the settling area below the filters

by both air movement and gravity. The extremely small

particulate is collected on the filter media, allowing

clean air to return to the workplace. Once particulate

collection is sufficient to reduce airflow, the patented

reverse jet pulse cleaning system is initiated to

propel the collected dust off the filters and into the

settling area.

Downflow

Air Boss’ downflow/vertical design has zero velocity

at the base of each filter stack, allowing dust to

settle uninhibited below the cartridges, thereby

eliminating re-entrainment.

Cartridge Filters

The standard 100% cellulose cartridge media is

high in resin content for mechanical resilience and

has pleat-lock construction. Standard cartridges are

rated for temperatures up to 160° F – high temperature

cartiridges are available.

Dust Settling

The Air Boss design allows larger dust contaminants

to have a clear path to the settling area and finer dust

to be collected by the filters.

Venturi

Venturi Reverse Pulse Cleaning is the quick release of

pressure through a blowtube into a venturi enductor

tube into a cartridge filter. A higher volume of air is

induced via this principle. The resulting burst of compressed air is more equally dispersed across the filter

resulting in greater cleaning effectiveness compared to

standard reverse pulse cleaning.

Pulse Jets

Pulse jet performance and economy are maximized by

optimizing the orifice size and position. There are four

methods of initiating jet pulse cleaning to best fit the

end user’s needs.

Cylindrical Fan Housing

The motor, fan and full-length venturi are packaged

into a tubular centrifugal fan arrangement for

greater performance, quieter operation and

simplified maintenance.

Solution. With Air Boss’ patented downflow/vertical airflow technology, re-entrainment and its effects have been

minimized for maximum efficiency and filter life. Carefully managed inlet velocity ensures that the air only flows

downward, never up or sideways. This prevents air movement below the cartridges, where the dust has settled,

and facilitates effective cleaning, both when the collector is operating and when it is shut down.

Downflow Inlet

Cartridge Filters

Dust Settling Area

Venturi

Pulse Jets

Cylindrical Fan Housing

Page 6

6

FEATURES

• Cartridges arranged in vertical

orientation

• Patented downflow/vertical air flow

• Small, solid-welded tube sheet below

vertical cartridge

• Solid welded construction separating

clean air and dirty air plenums

• Reverse jet pulse design

• Pulse valve silencers

• Programmable Smart Boss

pulse control with digital pressure

differential sensor

OPTIONS

• Side Inlet

• Explosion Vent Door/Latches

• Centrifugal Partial Width Fan

• Fan Silencer

BENEFITS

• Acts as dropout box for sparks

• Reduces overhead ductwork clearance

• Latches designed to release, eliminating replace-

ment of expensive membrane panels

• Eliminates need for volume outlet damper

• Reduces sound levels to comply

with OSHA and EPA standards

BENEFITS

• Structural integrity of filter is maintained

• Ensures consistent air-to-cloth ratio for each filter

• Ensures uniform loading of filters while

minimizing abrasion

• Process air assists cleaning action during

online pulsing

• No-flow area below filters acts as settling

chamber for dusts

• Eliminates 90° filter rotation and 22% to 25% filter

area loss inherent with horizontal filters

• Gasket seals enhanced as filters load and cartridge

becomes heavier

• Eliminates potential for metal distortion and

possible leakage

• Reduces potential for leakage

• Venturi-assisted to optimize cleaning effectiveness

• Reduces overall system dB

A

• Standard vs. competitor’s option

• Allows for on and offline initiation of cleaning cycle

• 15 digital display functions

• Saves compressed air and increases filter life

Page 7

7

www.trioninc.com

Trion Model

DC-2

DC-4M

DC-4

DC-6M

DC-6

DC-8

DC-12

DC-18

DC-24

DC-32

DC-40

DC-48

DC-56

DC-64

DC-72

DC-80

DC-88

DC-96

DC-112

DC-128

Unit

Weight lbs.

1,025

1,598

1,160

2,205

1,888

1,790

2,465

3,395

4,050

5,025

4,880

5,575

6,245

6,980

7,657

8,450

9,495

10,236

12,490

13,960

2

4

4

6

6

8

12

18

24

32

40

48

56

64

72

80

88

96

112

128

508

1,016

1,016

1,524

1,524

2,032

3,048

4,572

6,096

8,128

10,160

12,192

14,224

16,256

18,288

20,320

22,352

24,384

28,448

32,512

130 1/8”

130 1/8”

155 1/8”

160 5/16”

171 1/4”

158 1/8”

171 1/4”

171 1/4”

191”

189 1/4”

203 1/8”

187 1/2”

187 1/2”

192 1/2”

199 5/16”

206 1/4”

199 5/16”

199 5/16”

187 1/2”

192 1/2”

32”

63 3/4”

32”

83 3/4”

80”

63 3/4”

83 3/4”

88 3/4”

105 25/32”

105 25/32”

80 1/4”

106 1/4”

122 1/4”

138 1/4”

154 1/4”

170 1/4”

186 1/4”

202 1/4”

244 1/2”

276 1/2”

44 3/4”

33”

44 3/4”

38 1/4”

24”

33”

33 1/4”

48 1/4”

48 1/4”

64 1/4”

90 1/4”

74 1/4”

74 1/4”

74 1/4”

74 1/4”

74 1/4”

74 1/4”

74 1/4”

80 1/4”

80 1/4”

Filters

Sq. Ft.

Media

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

3

3

4

4

Hoppers

Standard

Height

Standard

Width

Standard

Depth

Notes: 1) Models DC-2 thru DC-32 dimensions & weights include standard top mount blowers & top inlets.

2) Models DC-40 thru DC-128 dimensions & weights do not include ground mount/remote blowers.

3) All dimensions & weights include hopper/leg sets for a 55-gallon drum base.

Page 8

Headquartered in Sanford, North Carolina

Leading Technology for Cleaner Exhaust Air Since 1947

Air Purification Systems

Loading...

Loading...