Page 1

Page 2

Engineered Solutions For Clean Air

How It Works

Trion’s CA3000C and CA6000C Cartridge Air Cleaners used in

either source capture or unducted applications will help solve

heavy welding smoke, dust and other indoor air pollution problems. They have been designed for high-efficiency, self-cleaning, easy serviceability, and long filter life.

Features/Benefits

• 4 or 9 Long-Life Filter Cartridges - provide up to 99%

efficiency. Cartridges have 8 times more surface

collecting area than comparable bag media type air

cleaners, resulting in greater dirt-holding capacity

and longer filter life

• In-place, cartridge cleaning utilizing compressed

air - minimizes maintenance and reduces downtime

• Each filter is pulsed independently - better cleaning of

cartridge during cleaning cycle

• 3 Pulse Options

- Manual Pulse - initiate when desired

- Timed Pulse with 7 Day-Clock - initiate at

predetermined intervals

- "On Demand” Sensed Pulse - initiate at

set static pressure

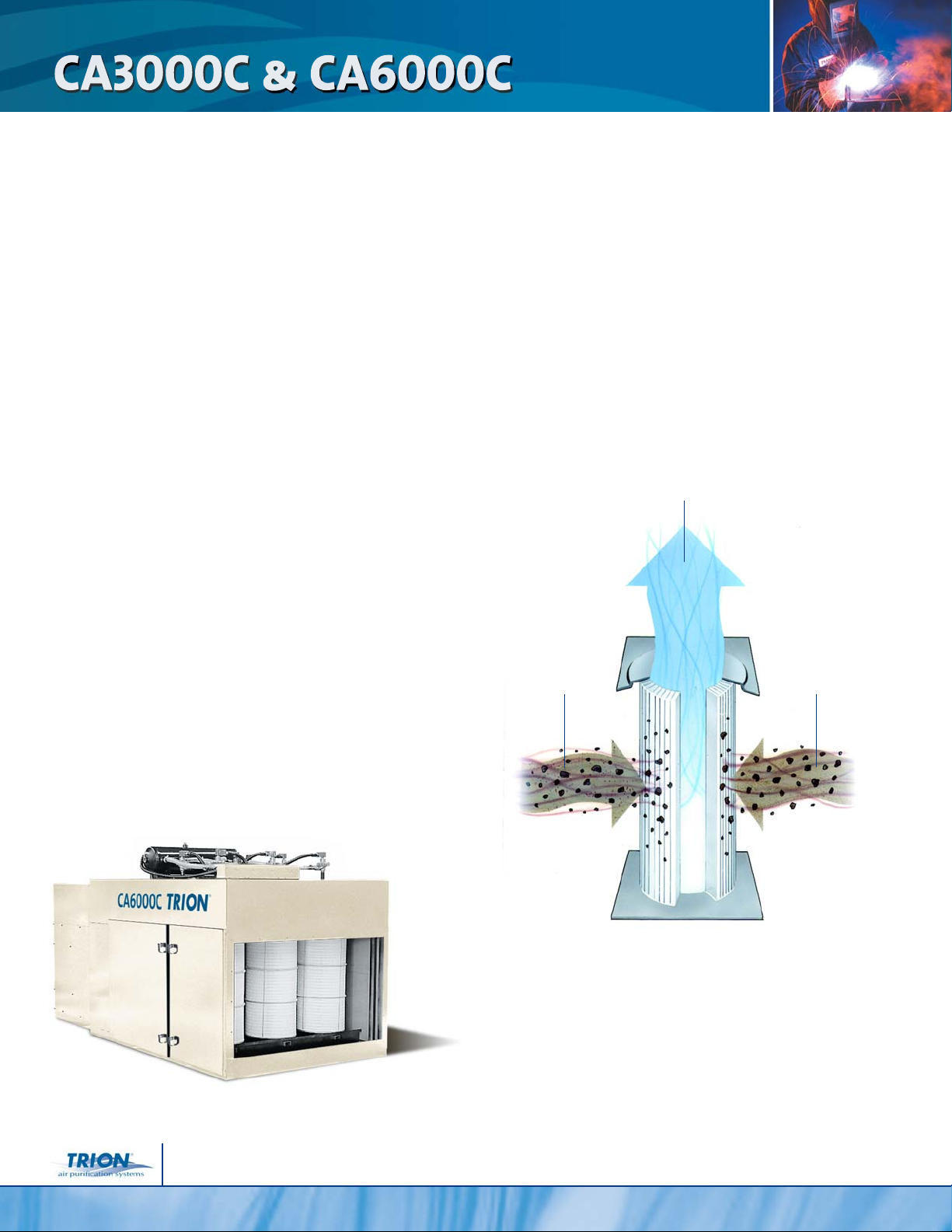

Trion’s CA3000C and CA6000C Cartridge Air Cleaners pull the

dirty, polluted air through the high-efficiency cellulose pleated

cartridge filters where the particulate is collected on the outside

of the media. The filtered air then passes through the clean air

plenum and is exhausted.

To clean the cartridges: clean, dry, compressed air is connected,

and the timer (which is actuated either manually or automatically)

sequentially opens and closes air valves. The valves

direct pulses or bursts of compressed air from the inside to the

outside of the cartridge. This pulsing action dislodges the

collected contaminants from the filters. The contaminants then fall

to the bottom of the unit or into the hopper (optional accessory).

Clean Air

Dirty Air

Dirty Air

• Side Access Doors - simplifies maintenance and

cartridge removal

• Backward-inclined Airfoil Fan - energy efficient

and quiet operation

2

Cartridge Air Cleaning

Applications

For industrial work environments, Trion Cartridge Air Cleaners

are excellent for applications where heavy smoke, powders, and

dust create unhealthy and hazardous environments.

Page 3

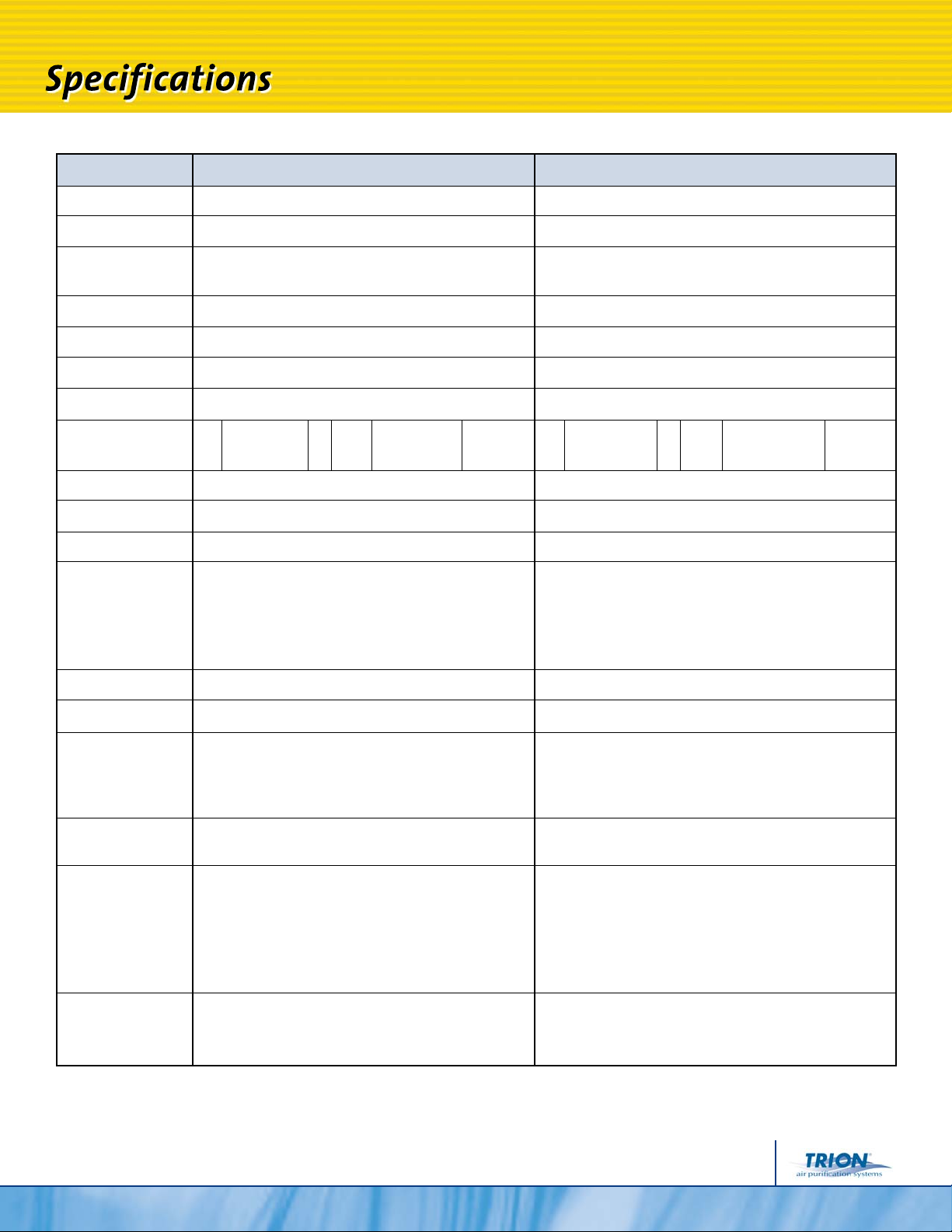

CA3000C

CA6000C

Cabinet

Color/ Finish

Air Flow

Dimensions

Installation

Unit Wt.

Motor Description

Motor

Motor Sheave

Blower

Air Volume

General

11 & 16 gauge welded galvanized steel

Pearl white epoxy, baked on, oil resistant

Horizontal - Right to Left or Left to Right - Standard,

Side Discharge - Optional

68" L x 46" W x 35" H

Suspended or Frame mounting

750 lbs., Shipping Wt: 890 lbs. (Standard unit)

TEFC, ball bearing, 3,450 RPM, continuous duty, U.L. Listed

HP VAC Hz Phase Amp.Max Watts Max

5 208/230/460 60 3 13.3/12.0/6.0 4,288

N/A

Direct drive backward inclined airfoil blower wheel

See blower curve

Throw distance: To 80-ft.

Filter Access: Hinged side doors with sealing gaskets

and easy open latches - no tools required

Side mounted pre-wired electrical junction box for

valve connections

11 & 16 gauge welded galvanized steel

Pearl white epoxy, baked on, oil resistant

Horizontal - Right to Left or Left to Right - Standard,

Side Discharge - Optional

99" L x 49" W x 53" H

Suspended, Wall, or Frame mounting

1,100 lbs., Shipping Wt. 1,400 lbs. (Standard unit)

TEFC, ball bearing, 1,750 RPM, continuous duty, U.L. Listed

HP VAC Hz Phase Amp. Max Watts Max

7.5 208/230/460 60 3 22.8/20.6/10.3 7,098

Variable pitch

Belt driven backward inclined airfoil blower wheel

See blower curve

Throw distance: To 80-ft.

Filter Access: Hinged side door with sealing gaskets

and easy open latches - no tools required

Side mounted pre-wired electrical junction box for

valve connections

Sound Rating

Pre-Filter

Main Filter

Plenum Options

Optional

Accessories

Pulse System

72 dBA

Aluminum mesh, Impinger or Perforated Plate

4-Cellulosic pleated cartridge filters

226 sq. ft. each filter area

Efficiency to 99.9% @ 0.5 micron

Other filter media cartridges available

Source capture with 14" round starting collar

Source capture with dual arm feature

Filter change indicator gauge

Automatic pulse control (photohelic switch/gauge)

7-Day time clock pulse control

Hopper assembly

55-gallon drum lid cover

4-way diffuser for directional air discharge

Sequential pulse timer control (115v Single Phase)

4 each - 3/4" valves

Compressed air required: 90 PSIG. 1.11 SCF/Pulse

72 dBA

Aluminum mesh or Perforated Plate

9-Cellulosic pleated cartridge filters

226 sq. ft. each filter area

Efficiency to 99.9% @ 0.5 micron

Other filter media cartridges available

Source capture with 20" round starting collar

Filter change indicator gauge

Automatic pulse control (photohelic switch/gauge)

7-Day time clock pulse control

Hopper assembly

55-gallon drum lid cover

4-way diffuser for directional air discharge

Sequential pulse timer control (115v Single Phase)

9 each - 3/4" valves

Compressed air required: 90 PSIG. 1.11 SCF/Pulse

3

Page 4

TOP VIEW

TOP VIEW

DISCHARGE END VIEW

DISCHARGE END VIEW

SIDE VIEW

SIDE VIEW

INLET END VIEW

INLET END VIEW

4

Page 5

Standard Blower Assembly

Direct Drive

High Static Blower Assembly

Direct Drive

5

Page 6

TOP VIEW

DISCHARGE END VIEW

SIDE VIEW

INLET END VIEW

6

Page 7

7

Page 8

Headquartered in Sanford, North Carolina

Leading Technology for Cleaner Exhaust Air Since 1947

Air Purification Systems

Loading...

Loading...