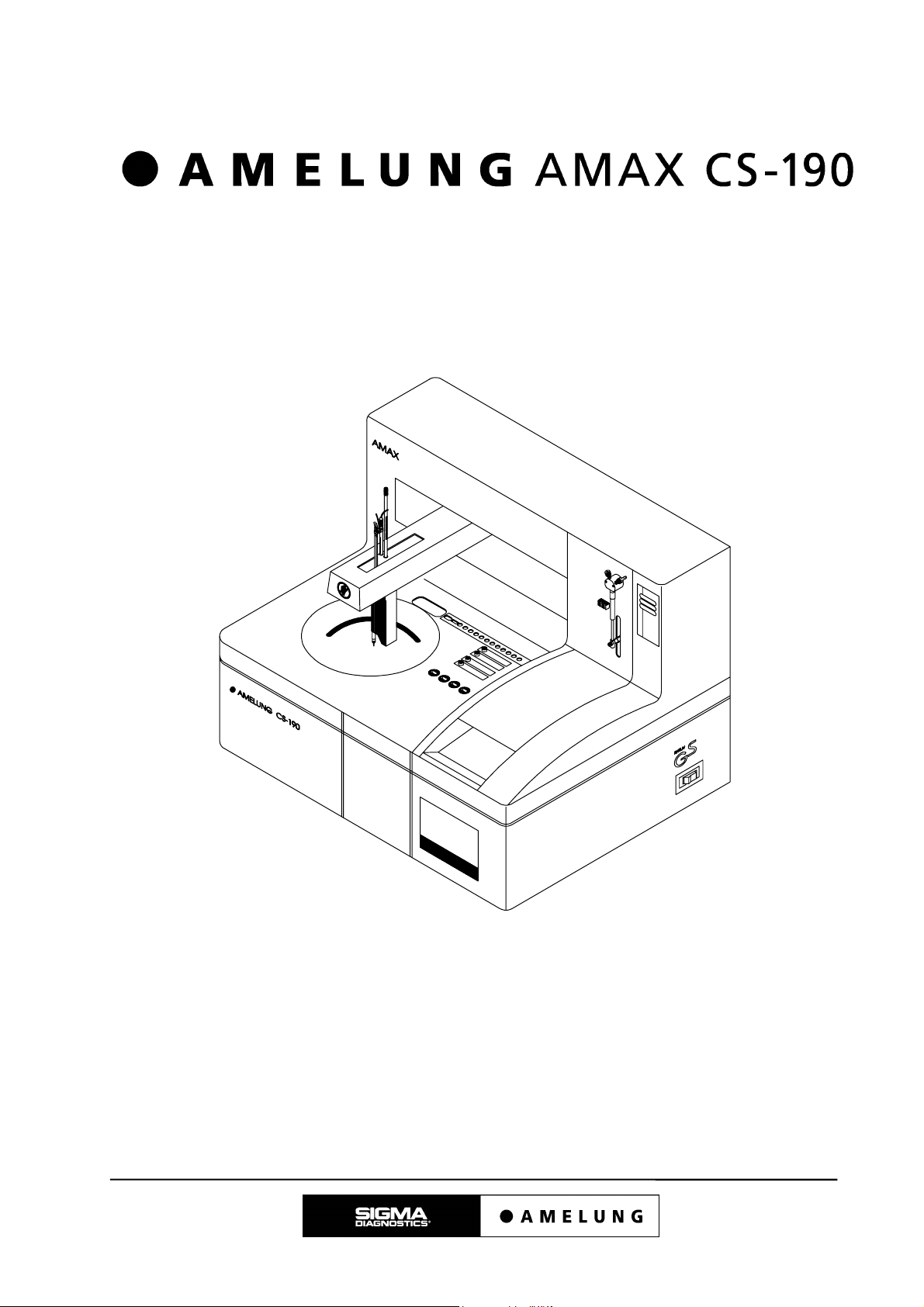

Service Manual

Instrument manufactured by

Heinrich Amelung GmbH

Lemgo, Germany

Juni, 98

Distributed by

Sigma Diagnostics

St. Louis, Missouri, USA

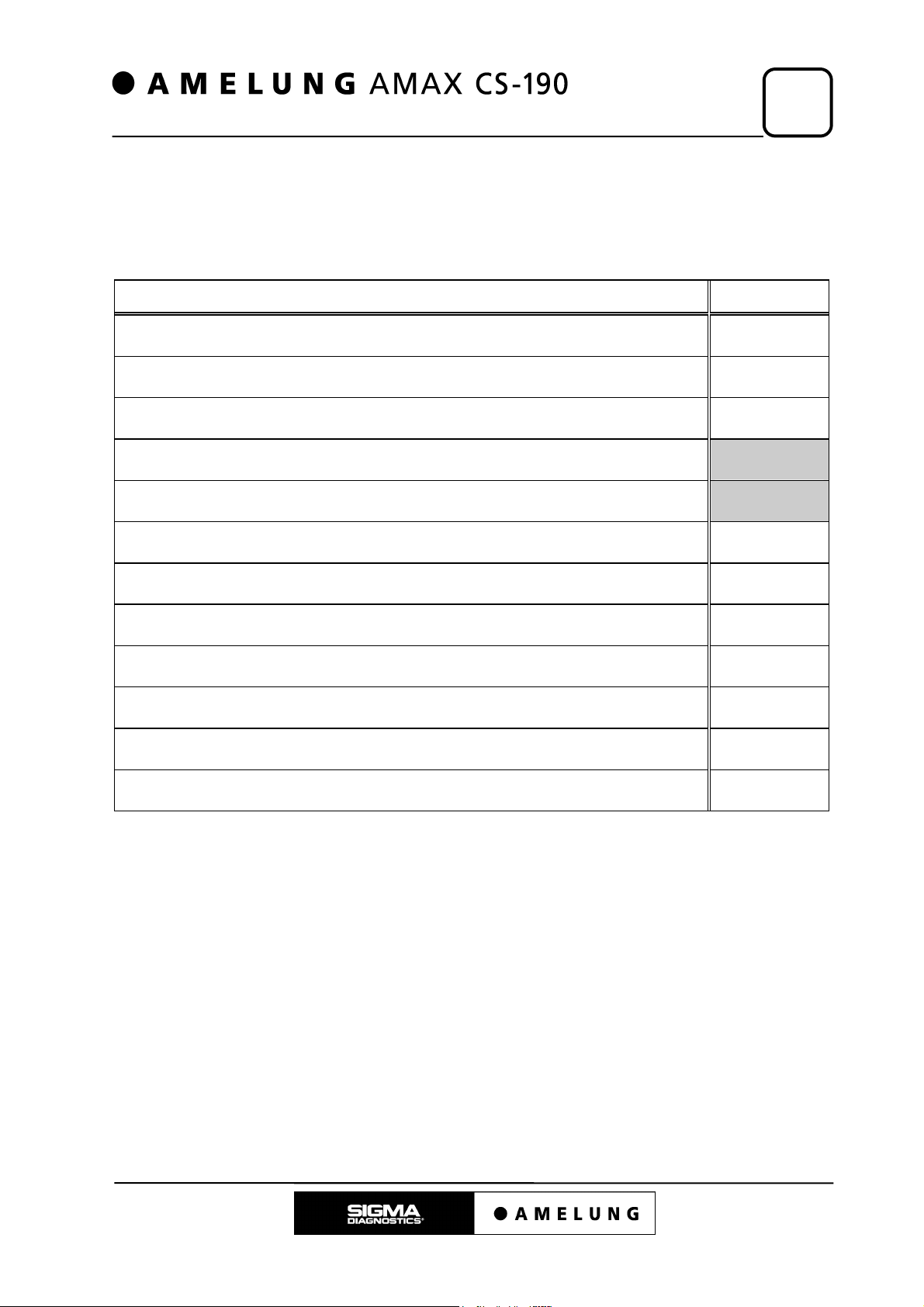

Table of Contents

1

1. Table of Contents

2. Introduction

2.1 Brief Description of the Operational

Characteristics of the AMAX CS-190

2.2 Traffic Lights

2.3 Pictograms

3. Safety Regulation

3.1 Information on How to Avoid Danger to Life and

Health

3.1.1 General Information

3.1.2 Information on the Repair of the AMAX CS-190

4. Accessories / Equipment

4.1 Measurement and Adjustment Tools for Repairs

5. Technical Data

5.1 Measurements

5.2 Weights

5.3 Electrical Connection Data

5.4 Temperatures

5.4.1 Temperatures of the Individual Modules

5.5 Intended Use

5.6 Throughput of the AMAX CS-190

1 – 1

2 – 0

2 – 1

2 – 2

2 – 2

3 – 0

3 – 1

3 – 1

3 – 1

4 – 0

4 – 1

5 – 0

5 – 1

5 – 2

5 – 2

5 – 3

5 – 3

5 – 4

5 – 5

6. Measuring Methods

6.1 Mechanical Measuring Mode

6.2 Optical Measuring Mode (Clotting)

6.3 Optical Measuring Mode (Chromogenic)

7. Instrument Installation

7.1 Instrument Overview

7.2 Installation of the AMAX CS-190

7.3 PC & Accessories

7.3.1 Jumper Settings of the AML-BUS-PC-Board

7.3.2 Jumper Settings of the Modem Boards

7.4 Printer Installation

7.5 Connections

7.5.1 Fresh Water / Waste Water System

7.5.2 Electrical Connections

7.6 Turning on the Instrument

6 – 0

6 – 1

6 – 2

6 – 4

7 – 0

7 – 1

7 – 2

7 – 3

7 – 4

7 – 4

7 – 5

7 – 7

7 – 7

7 – 8

7 – 9

June, 98 1 – 1

Table of Contents

8. Subassemlies

1

8 – 0

8.1 Dilutor

8.1.1 Adjusting the Temperature of the Pre-heater

8.2 Mechanical Measuring Unit

8.2.1 Removing the Measuring Unit

8.2.2 Adjusting the Measuring Block Temperature

8.2.3 Adjusting the PC Temperature Display

8.2.4 Adjusting the Inductive Ball Sensors

8.2.5 Adjusting the Hinge Mechanism Voltage (knee joint)

8.2.6 Adjusting the Rotational Speed

8.2.7 Adjusting the Motor Torque Voltage of the

Measuring Units

8.2.8 Adjusting the Dip-switches on the PH-M-MB

(D05601) Board

8.3 Cuvette Magazine

8.3.1 Removing the Cuvette Magazine or the Incubation

Rail

8.3.2 Adjusting the Mixer in the Incubation Rail (Q10005)

8.3.3 Adjusting the Ejector (Q10030)

8.3.4 Checking the Lifting Solenoid of the Incubation Rail

8.3.5 Adjusting the Temperature of the Incubation Rail

8.3.6 Adjusting the PC Temperature Display

8.3.7 Checking the Lifting Solenoids

8.3.8 Alignment Tools Magazine

8.3.9 Adjusting the Pusher 1 Unit

8.3.10 Alignment of the Cuvette Magazine in the

AMAX CS-190

8.3.11 Adjusting the Light Barriers and the Cuvette Comb

8.3.12 Adjusting the Cuvette Comb

8.3.13 Checking the Reflex Light Barriers

8.3.14 Checking the Conveyors

8.4 Reagent-Plasma-Barcode

8.4.1 Adjusting the Cooling Circuits

8.4.2 Adjusting the PC Temperature Display

8.4.3 Adjusting the Cutoff Voltage of the Servo Power

Amplifier

8.4.4 Adjusting the Mixer Voltage

8.4.5 Mechanical Reset Adjustments at the RPB

8.4.6 Adjusting the Barcode Scanner Position

8.5 Photometer

8.5.1 Removing the Measuring Unit

8.5.2 Adjusting the Temperature of each Measuring

Channel

8.5.3 Adjusting the Photometer Lamp Voltage

8.5.4 Adjusting the Photometer Measuring Amplifier

8.6 XYZZ-Robot (gantry)

8.6.1 Adjusting the Safety Systems of the Control Unit

June, 98 1 – 2

8 – 1

8 – 2

8 – 3

8 – 4

8 – 4

8 – 5

8 – 5

8 – 6

8 – 7

8 – 7

8 – 8

8 – 9

8 – 11

8 – 11

8 – 12

8 – 12

8 – 13

8 – 13

8 – 14

8 – 15

8 – 16

8 – 16

8 – 18

8 – 20

8 – 22

8 – 23

8 – 24

8 – 25

8 – 25

8 – 26

8 – 26

8 – 27

8 – 27

8 – 29

8 – 30

8 – 30

8 – 31

8 – 31

8 – 34

8 – 35

Table of Contents

1

8.6.2 Voltage Cutoff of the X-Motor Amplifier

8.6.3 Voltage Cutoff of the Y-Amplifier

8.6.4 Speed Cutoff of the X-Motor Amplifier

8.6.5 Mechanical Reset Adjustment of the XYZZ-Robot

8.6.6 Adjusting the XY-Motors

8.6.7 Adjusting the Level Sensors (liquid level sensors

and height sensors)

8.7 Water Temperatures

8.7.1 Adjusting the Water Reservoir II Temperature

(D10068)

8.7.2 Adjusting the PC Temperature Display

9. Maintenance

9.1 Refilling the System Fluids

9.2 Cleaning the Air Filter

9.3 Replacing the Photometer Lamp

9.3.1 Removing the Photometer Lamp

9.3.2 Inserting a New Lamp

9.4 Dilutor Syringe

9.4.1 Removing the Dilutor Syringe

9.4.2 Replacing the Teflon Seal

9.5 Cleaning the Photometer Channels

9.6 Pump Tubing, Waste Water Pump

9.7 Needle XYZZ-Robot

9.7.1 Replacing the Needle

9.7.2 Installing a New Needle

9.8 Cuvette Waste Drawer

8 – 35

8 – 36

8 – 37

8 – 38

8 – 39

8 – 40

8 – 42

8 – 43

8 – 43

9 – 0

9 – 1

9 – 2

9 – 3

9 – 3

9 – 4

9 – 5

9 – 5

9 – 6

9 – 7

9 – 8

9 – 9

9 – 9

9 – 10

9 – 11

10. Spare Parts List

Spare Parts List

11. Service Software

Description

11.1 Dilutor

11.2 Mechanical Measuring Unit

11.3 Cuvette Magazine

11.4 Reagent-Plasma-Tray

11.5 Photometer

11.6 XYZZ-Robot

11.7 Liquid Management

11.8 Text Viewer

11.9 Service Logbook

11.10 AMAX Teach in Program

11.10.1 Adjustable XY-Positions

11.10.2 Adjustable Z-Positions

11.11 Barcode Setup

11.12 AMAX Continuous Test Program

June, 98 1 – 3

10 – 0

10 – 1

11 – 0

11 – 1

11 – 6

11 – 11

11 – 15

11 – 19

11 – 23

11 – 33

11 – 38

11 – 41

11 – 42

11 – 43

11 – 47

11 – 49

11 – 51

11 – 52

Table of Contents

1

11.13 AMAX Continuous Test II

11.14 AMAX Self Test Program

11.15 Error Codes

11.16 AD Converter

11.17 Photometer Auto Align

11.18 Drip Test

12. Troubleshooting

12.1 Error Examples

13. Drawings

Dilutor Block Diagram 13 – 1

Dilutor Circuit Diagram 13 – 2

Dilutor 13 – 3

Mechanical Measuring Unit (Knee Joint) Block Diagram 13 – 4

Mechanical Measuring Unit Block Diagram 13 – 5

Measuring Block Heating Block Diagram 13 – 6

Mechanical Measuring Unit Circuit Diagram 13 – 7

Mechanical Measuring Unit 13 – 8

Cuvette Magazine PC Board PH-K1 Block Diagram 13 – 9

Cuvette Magazine PC Board PH-K5 Block Diagram 13 – 10

Cuvette Magazine Circuit Diagram 13 – 11

Cuvette Magazine 13 – 12

Slide Pusher I 13 – 13

Slide Pusher II 13 – 14

Incubation Rail 13 – 15

Reagent-Plasma-Tray Block Diagram 13 – 16

Reagent-Plasma-Tray Circuit Diagram 13 – 17

Reagent-Plasma-Tray 13 – 18

Photometer Block Diagram 13 – 19

Optical Measuring Unit Circuit Diagram 13 – 20

Optical Measuring Unit 13 – 21

Measuring Unit 13 – 22

XYZZ-Cantilever Arm Block Diagram 13 – 23

XYZZ Circuit Diagram 13 – 24

Cantilever Arm 13 – 25

Water Temperature Block Diagram 13 – 26

Water Circulation System Circuit Diagram 13 – 27

Water Temperature Control 13 – 28

Water Tank 13 – 29

11 – 53

11 – 54

11 – 55

11 – 55

11 – 56

11 – 57

12 – 0

12 – 1

13 – 0

June, 98 1 – 4

Introduction

2. Introduction

2

2.1 Brief Description of the Operational Characteristics

of the AMAX CS-190

2.2 Traffic Lights

2.3 Pictograms

2 – 1

2 – 2

2 – 2

June, 98 2 – 0

Table of Contents

Water Circulation System 13 – 30

Base Unit 13 – 31

Base Unit 13 – 32

Casing 13 – 33

Light Current Control 13 – 34

Photometer Amplifier 13 – 35

PC-AMAX Circuit Diagram 13 – 36

Wirering for AC/DC-Supply 13 – 37

Moduls PCB Location 13 – 38

1

14. LIS

14.1 Bidi-Protocol

14.1.1 Data Records

14.1.2 Header

14.1.3 Identification

14.1.4 Result /Test Order

14.1.5 ID-Query

14.1.6 Result

14.2 Communication Protocol

14.2.1 Master to Slave

14.2.2 Slave to Master

14.2.3 Command Characters and Symbols

14.2.4 Import

14.2.5 Result Transmission

14.2.6 Export

14.2.7 ID-Query

14.3 Host-Communication

14.3.1 Procedure of Processing Real-Time with Barcode

14.3.2 Master to Slave

14.3.3 Slave to Master

14.3.4 Result Transmission

14.3.5 Import of Requests (AMAX = MASTER)

14.3.6 Export of Results (AMAX = MASTER)

14 – 0

14 – 1

14 – 1

14 – 1

14 – 1

14 – 1

14 – 2

14 – 2

14 – 3

14 – 3

14 – 4

14 – 5

14 – 6

14 – 8

14 – 9

14 – 11

14 – 13

14 – 14

14 – 15

14 – 15

14 – 16

14 – 17

14 – 18

15. DOS Parameters

15.1 AMAX CS-190 DOS Parameters

15.2 Files in AMAX Directory

June, 98 1 – 5

15 – 0

15 – 1

15 – 3

Introduction

2.1 Brief Description of the Operational Characteristics of the

AMAX CS-190

• The AMAX CS-190 is a fully automated coagulation instrument.

• The AMAX CS-190 is used for measuring the in-

vitro coagulation times. Both plasma and whole

blood samples can be used.

• The instrument features an optical and a

mechanical measuring unit.

• In addition to the clotting tests, chromogenic

(kinetic) tests can be carried out by using the

optical measuring unit.

• The measured results can be converted to concentration or activity data with the

help of storable standard curves.

5.5

6.

5.5

2

• The PC identifies and stores patient samples and data.

• The samples are aspirated from their primary

containers with a needle by way of the XYZZrobot probe. Then the samples are mixed in a

measuring cuvette with either a reagent and/or a

buffer. After that the samples are incubated in the

incubation rail (12 incubation slots).

• At the end of the incubation period, the XYZZrobot moves the cuvette into the optical or

mechanical measuring unit.

8.6

8.3

8.6

6.1

6.2

6.3

• After the addition of the starting reagent by the XYZZ-robot, the coagulation time is

measured.

• Reagents, volumina and incubation periods can be programmed individually.

• Measured results and their calculations can be printed out in a protocol and stored

simultaneously in the PC’s patient archive.

• In addition, the results can be transferred to an external EDP (laboratory EDP) via

bidirectonial data transfer.

June, 98 2 – 1

2

Introduction

2.2 Traffic Lights

The traffic lights are positioned in the upper, right corner of the AMAX CS-190 next to

the dilutor unit (user position in front of the instrument). The light signals have the

following meanings:

Tab. 2.2.1

Light signal Meaning

no light

green light

yellow light WARNING: missing cuvettes, waste water reservoir full, fresh

red light ERROR: temperature outside operating range, photometer lamp

green + red light ERROR: XYZZ - waste water well full

running light CANCEL: press any key - Instrument is aborting current process.

AMAX CS-190 software booted, no errors registered, processing

not yet started.

AMAX CS-190 software booted, no errors registered, processing

started

water reservoir empty, plasma-reagent-tray cover open,

photometer lamp switched off

not yet ready

2.3 Pictograms

This service manual describes the maintenance and repair of the automatic coagulation

instrument AMAX CS-190.

These instructions are written for qualified medical and technical personnel.

IMPORTANT!

Read these instructions carefully and work only in the prescribed

manner!

Pay attention to warnings and notices!

Only in this way can damage to man and machine be avoided!

2 – 2 June, 98

Introduction

To increase the overall understanding of this manual, the following pictograms are

used:

ATTENTION!

There is DANGER TO LIFE of the user!

Read these instructions carefully and work only in the prescribed

manner!

Pay attention to warnings and notices!

Only in this way can damage to man and machine be avoided!

2

ATTENTION!

The AMAX CS-190 can be damaged!

Read these instructions carefully and work only in the prescribed

manner!

Pay attention to warnings and notices!

Only in this way can damage to man and machine be avoided!

IMPORTANT / NOTICE!

Requires additional operator action

or alteration of the adjustment parameters.

also see chapter

#

one turn to the ‘right’ (clockwise)

one turn to the ‘left’ (anti clockwise)

Amelung specific part number

1¬

1«

(Q00000)

Key on the PC-keyboard

June, 98 2 – 3

<X>

Safety Regulations

3. Safety Regulations

3

3.1 Information on How to Avoid Danger to Life and

Health

3.1.1 General Information

3.1.2 Information on the Repair of the AMAX CS-190

3 – 1

3 – 1

3 – 1

June, 98 3 – 0

Safety Regulations

3

It is guaranteed that the user is protected from danger to life and health

when using the AMAX CS-190 in compliance with the regulations (§ 3(1)

MedGV).

3.1 Information on How to Avoid Danger to Life and Health

3.1.1 General Information

• If the AMAX CS-190 shows any defects which might endanger patients or user

personnel, it must not be operated (§ 6(1) MedGV).

• Wear protective clothing, especially protective gloves. It is a possibility that infected

plasma (dangerous substances) might be touched.

• Protective clothing, especially protective gloves which were in contact with

dangerous substances (e.g. infected plasma) have to be changed and disposed

immediately (Technical rules for dangerous Substances (TRGS)).

• Plasma samples, reagents and waste water are toxic waste. The toxic waste has to

be disposed in compliance with the operative regulations (laboratory regulations).

3.1.2 Information on the Repair of the AMAX CS-190

• While under repair the instrument must not be used for testing.

• After a repair, the AMAX CS-190 has to undergo a functionality check. This involves

the carrying out of checking measurements. These actual values have to be

equivalent to the theoretical values.

ATTENTION!

Live parts (power unit and connection panel) must not be

touched!

DANGER TO LIFE!

ATTENTION!

On certain parts (photometer lamp or lamp casing) there is a

DANGER OF BURNS!

IMPORTANT!

Regular maintenance helps to avoid malfunctions and protects

the AMAX CS-190 from damage.

June, 98 3 – 1

Accessories / Equipment

4. Accessories / Equipment

4.1 Measurement and Adjustment Tools for Repairs 4 – 1

4

June, 98 4 – 0

Accessories / Equipment

4

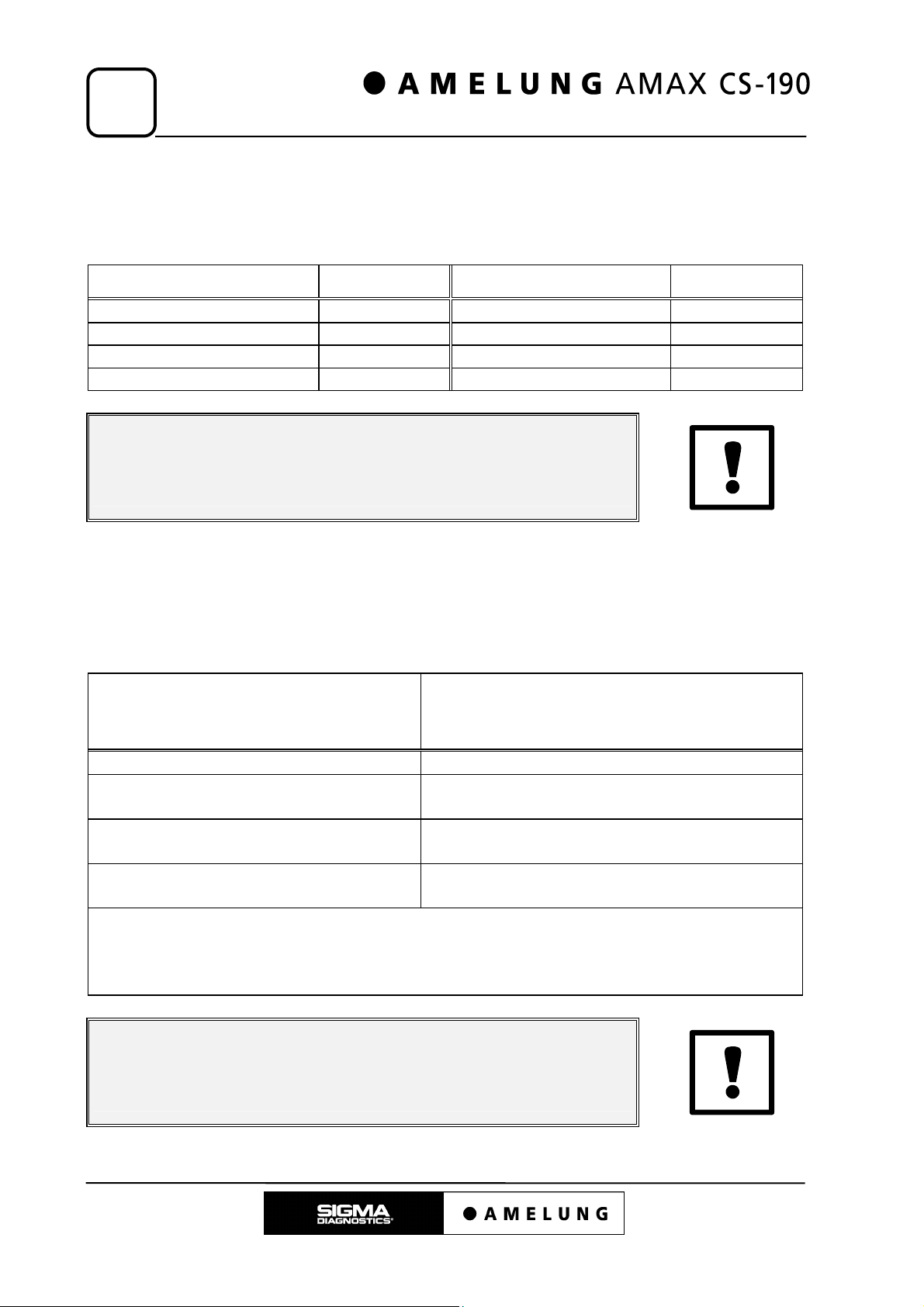

4.1 Measurement and Adjustment Tools for Repairs

It is recommended to always carry the following tools and adjustment gauges at every

AMAX CS-190 service intervention:

Tab. 4.1.1

Measuring instruments / Tools Catalog no.

Thermometer 121563

Surface probe 121565

Immersion probe 121564

Digital multimeter

Oscilloscope incl. probes: 1:1 / 1:10

Adjustment gauge I (magazine light barriers) J01847

Adjustment gauge II (row pusher end light barrier) J01827

Adjustment gauge III (adjustment gauge lifting solenoid) J01819

Adjustment gauge (alignment pusher 1 unit) J01820

Needle ejector tool J01818

Spring balance 890300

Adjustment tool auto photometer height J01817

June, 98 4 – 1

Technical Data

5. Technical Data

5

5.1 Measurements

5.2 Weights

5.3 Electrical Connection Data

5.4 Temperatures

5.4.1 Temperatures of the Individual Modules

5.5 Intended Use

5.6 Throughput of the AMAX CS-190

5 – 1

5 – 2

5 – 2

5 – 3

5 – 3

5 – 4

5 – 5

June, 98 5 – 0

Technical Data

5.1 Measurements

5

AMAX CS-190

• Height

• Width

• Depth

Commander PC

• Height

• Width

• Depth

Monitor (14 inches)

• Height

• Width

• Depth

optional: Monitor (15 inches)

ca. 56 cm ( 22.5 inches)

ca. 82 cm (32.75 inches)

ca. 69 cm (27.75 inches)

ca. 12 cm ( 4.75 inches)

ca. 40 cm ( 16 inches)

ca. 44 cm (17.75 inches)

ca. 37 cm ( 15 inches)

ca. 35 cm ( 14 inches)

ca. 39 cm (15.75 inches)

• Height

• Width

• Depth

Keyboard

• Height

• Width

• Depth

Printer

• Height

• Width

• Depth

Base cabinet for the AMAX CS-190

• Height

• Width

• Depth

ca. 39 cm (15.75 inches)

ca. 39 cm (15.75 inches)

ca. 36 cm ( 14.5 inches)

ca. 4 cm ( 1.5 inches)

ca. 46 cm ( 18.5 inches)

ca. 17 cm ( 6.75 inches)

ca. 17 cm ( 6.75 inches)

ca. 36 cm ( 14.5 inches)

ca. 21 cm ( 8.5 inches)

ca. 71 cm (28.25 inches)

ca. 82 cm (32.75 inches)

ca. 69 cm (27.75 inches)

June, 98 5 – 1

5

5.2 Weights

Technical Data

• AMAX CS-190

• Base cabinet for AMAX CS-190

• Commander PC

• Monitor

• Printer

ca. 130 kg ( 286 pounds)

ca. 78 kg ( 172 pounds)

ca. 10 kg ( 22 pounds)

ca. 11 kg (24.2 pounds)

ca. 2,5 kg ( 5.5 pounds)

5.3 Electrical Connection Data

AMAX CS-190

• supply voltage

• supply frequency

• power consumption cold, max:

warm, min:

• heat emission

Commander PC

90-132 /

180-265

47-63 Hz

1240 kJ/h

VAC

690

230 VAVA

• supply voltage

• supply frequency

• power consumption

Monitor

• supply voltage

• supply frequency

• power consumption

Printer

• supply voltage

• supply frequency

• power consumption

90-132 /

180-264

50-60 Hz

145 VA

100-240 VAC

47-63 Hz

80 VA

230 VAC

50 Hz

30 VA

VAC

5 – 2 June, 98

Technical Data

5

5.4 Temperatures

The internal components of the Amelung Amax CS-190 are heated or cooled

automatically. In order to guarantee the perfect performance of the AMAX CS-190, the

following instructions have to be followed:

• The AMAX CS-190 must not be placed directly in front of a wall.

(minimum distance 15 cm)

• The ventilation grids must never be obstructed in any way.

(Cooling the AMAX CS-190 would be impossible)

• The system fluid supply has to be sufficient at all

times.

• To provide a sufficient air flow, the air filter has to

be clean.

• Do not expose the AMAX CS-190 to direct sunshine. The room temperature must

not exceed 32°C.

9.1

9.2

ATTENTION!

Disregard may lead to malfunction of and cause damage to the

AMAX CS-190!

5.4.1 Temperatures of the Individual Modules

• reagent plasma barcode tray ca. 16.5 ± 1.5°C

• incubation rail ca. 37.5 ± 0.3°C

• optical measuring unit ca. 37.5 ± 0.3°C

• mechanical measuring unit ca. 37.5 ± 0.3°C

• cuvette magazine ca. 37.5 ± 0.3°C

• pre-heater ca. 40.0 ± 0.5°C

• cooling water system ca. 25 - 55°C

• warm water circuit (37°C)

washing in the well ca. 38.5 ± 0.5°C

pumping in the well ca. 38.5 ± 0.5°C

The temperature in the well is measured by a liquid thermometer.

In the user software

is measured during the process “Wash” and “Fill”.

The warning limits for the temperatures can be entered in the user interface software.

(main menu), select “Maintenance”, then “Wash”. The temperature

In the case of a divergence, a message will be

displayed on the monitor and the status lights will

June, 98 5 – 3

2.2

5

show yellow.

In addition, an acoustic signal will sound and the AMAX CS-190 will not reactivate.

Technical Data

5.5 Intended Use

The AMAX CS-190 measures in-vitro coagulation times and chromogenic test

reactions. Both citrated whole blood and citrated plasma samples can be used.

You can choose between the mechanical measuring and the optical measuring mode.

Depending on the used reagents and measuring methods the following hemostasis

parameters can be determined:

• Prothrombin time (PT/Quick)

• Hepato-Quick

• Activated Partial Thromboplastin Time (APTT)

• Thrombin time (TT)

• Fibrinogen (Clauss)

• Fibrinogen (derived, optical density measurement)

• Normotest

• Thrombotest

• Factor assays: II, V, VII, VIII, IX, X, XI and XII

• AT III

• Plasminogen

• Antiplasmin

• PAI

• Heparin

• Protein S

• Protein C

• APC-Resistance

• and more

5 – 4 June, 98

Technical Data

5

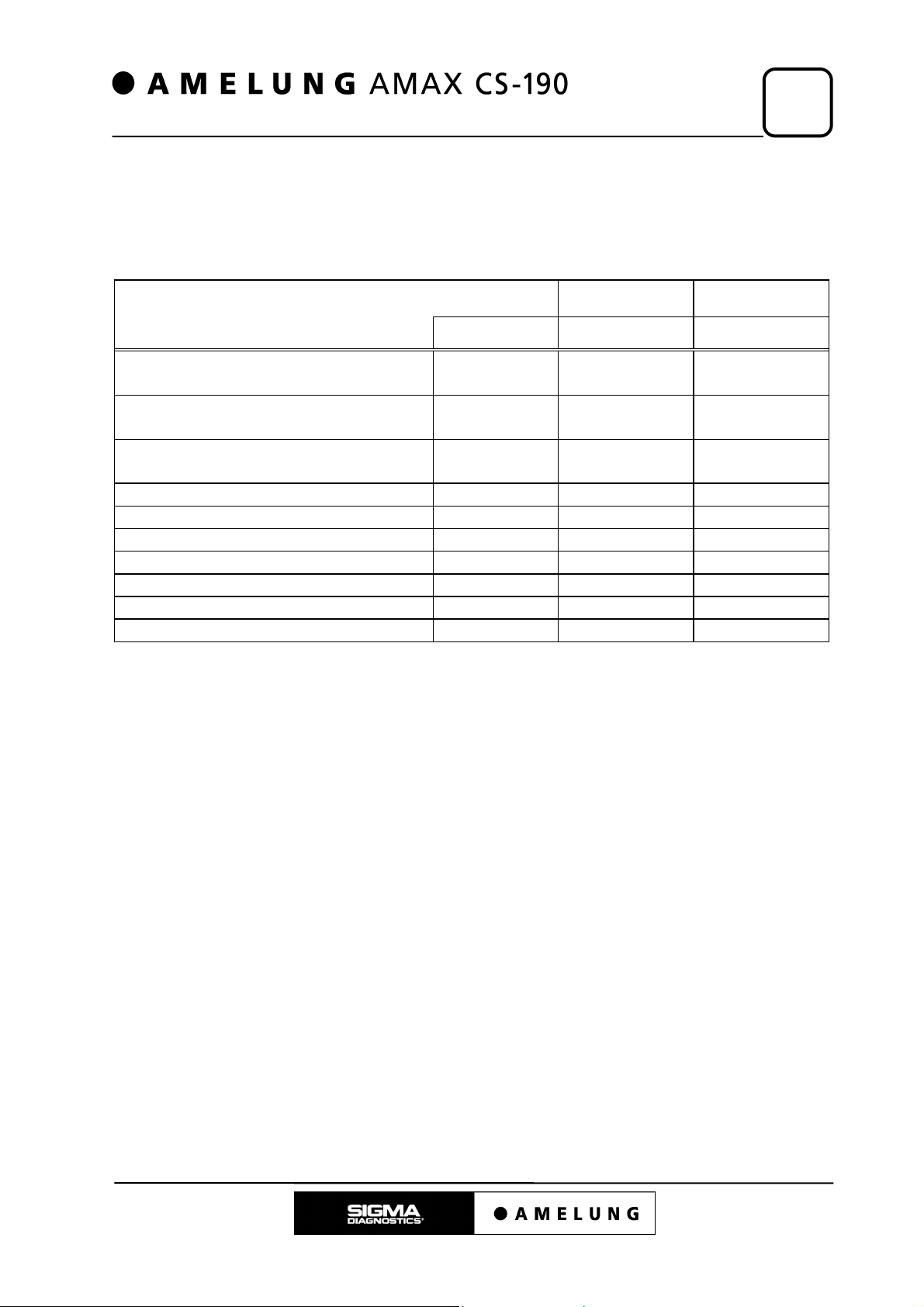

5.6 Throughput of the AMAX CS-190

The throughput of the AMAX CS-190 is influenced by the type of measuring method

used.

Tab. 5.6.1

patients/hour patients/hour

PT-mechanical

(pipetting mode 0)

PT- mechanical

(pipetting mode 2)

PT-optical

(pipetting mode 0)

PT-optical, derived fibrinogen 240 120 60

APTT-mechanical or optical 110 110 55

Fibrinogen (Clauss) 115 115 57

AT III 80 80 40

Factor assays 120 120 60

PT-mechanical/APTT 120 60 30

PT-mechanical/APTT/AT III 90 30 15

tests/hour single double

180 180 90

240 240 120

190 190 95

June, 98 5 – 5

Measuring Methods

6. Measuring Methods

6

6.1 Mechanical Measuring Mode

6.2 Optical Measuring Mode (Clotting)

6.3 Optical Measuring Mode (Chromogenic)

6 – 1

6 – 2

6 – 4

June, 98 6 – 0

Measuring Methods

The AMAX CS-190 features a mechanical and an optical measuring unit.

The mechanical measuring unit has 4 measuring cells which work with the ball method.

The optical measuring unit (photometer) has 4 measuring channels for measurement of

the optical density. The wavelength of the light is 405nm.

The necessary total volumes for the measurements are:

• Mechanical measuring mode,

• Optical measuring mode

• Maximum volume (mechanical, optical): 600µl

The individual measuring modes are described on the following pages.

minimum volume: 75µl

, minimum volume: 150µl

6

6.1 Mechanical Measuring Mode

The time between the addition of the starting reagent and the beginning of the

formation of fibrin is measured.

The sample and if necessary the reagent and/or buffer are pipetted into a measuring

cuvette. After the incubation time it is placed into one of the mechanical measuring

channels automatically.

There is a special steel ball on the bottom of the cuvette.

With the addition of the starting reagent, the cuvette starts to rotate around its

longitudinal axes while the ball is held in a certain position by a magnet.

As coagulation begins, the ball is removed from its position by the forming fibrin

threads, because the force of the magnet is overcome. A sensor detects the change of

the ball’s position and ends time measurement.

Pic. 6.1.1

schematic display of the

mechanical measuring mode

cuvette

sensor

magnet

June, 98 6 – 1

6

A

Measuring Methods

Impulse measurement

In order to detect very unstable clots with the mechanical method, the continuous

rotation of the cuvette can be changed to a rotation with intervals after a predefined

time.

In the example on Pic 6.1.2, the continuous movement is switched to interval

movement after 25.6s. During the intervals, which prolong automatically, a clot cannot

be detected, but it has time to stabilise itself. The CV rises in dependence with the

length of the interval.

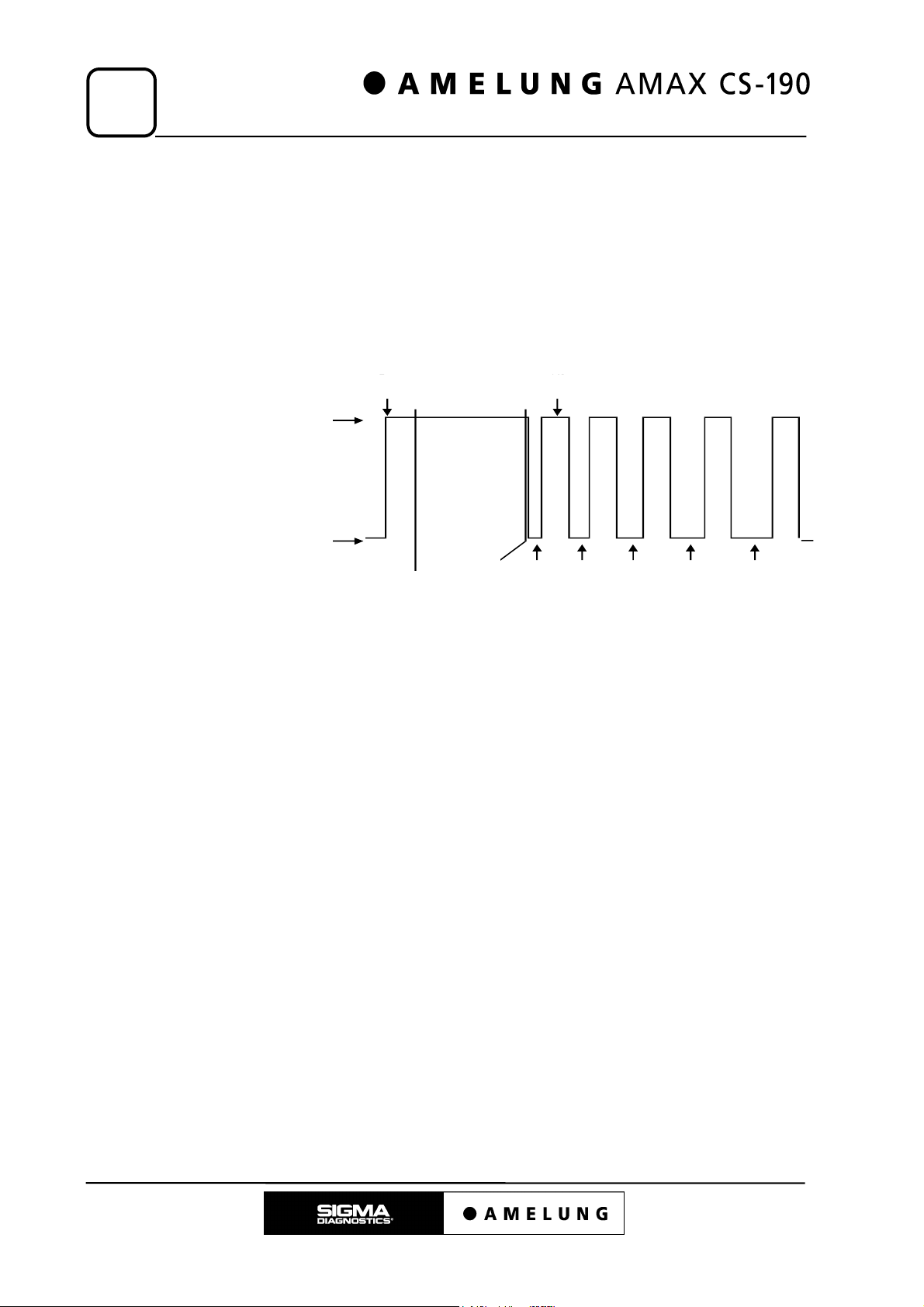

Pic. 6.1.2

Impulse measurement

Cuvette

rotates

Cuvette

stops

dd ition s tarting

reagent

activation

4s

Begin of

impulsemovement

25 .6 s

Movement:

½ rotation

pause

0.2s

pause

+0.1s

pause

+0.2s

pause

+0.3s

pause

+0.4s

6 – 2 June, 98

[s]

t

Measuring Methods

6

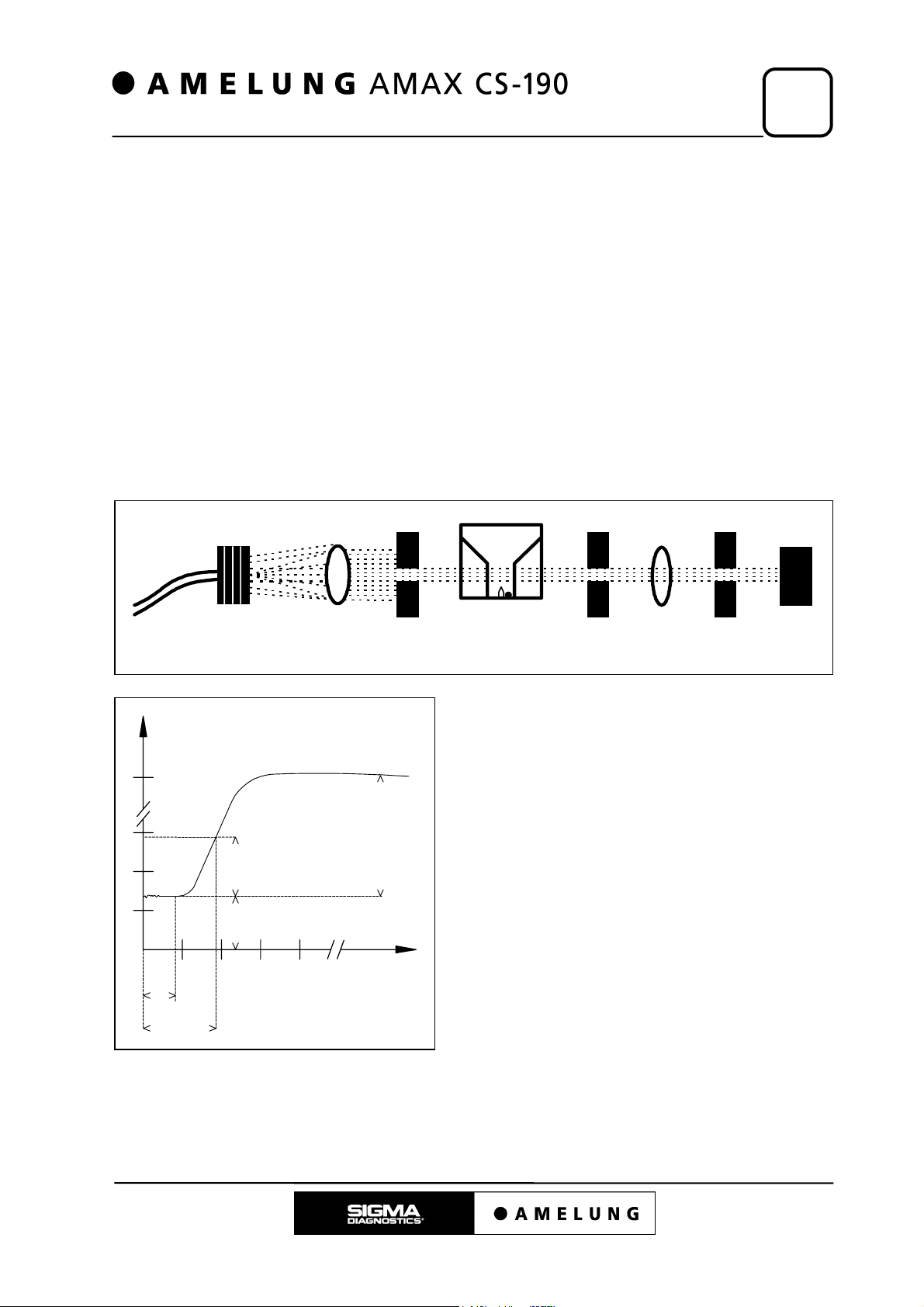

6.2 Optical Measuring Mode (Clotting)

The time between the addition of the starting reagent and the beginning of the

formation of fibrin is measured.

The sample and if necessary the reagent and/or buffer are pipetted into a measuring

cuvette. After the incubation time it is placed into one of the optical measuring channels

automatically.

The timing begins with the addition of the starting reagent. The intensity of the light

beam that passes through the cuvette is monitored by a sensor. When clots are

forming, the sample/reagent mixture becomes cloudy and the intensity of the light

reaching the sensor decreases (turbidimetrical measurement).

As soon as the change in the optical density reaches a pre-set threshold, the time

measurement stops.

Pic. 6.2.1 schematic display of the optical measurement (clotting)

Optical wave guide filter lens aperture cuvette aperture lens aperture sensor

Pic. 6.2.2

Analysis of the optical measurement (clotting)

mE

The coagulation time t2 is the time taken

from addition of the starting reagent to the

point when the absorbance change has

30

15mE

20

0

E

1-E

achieved the predefined threshold value.

The absorbance change is measured from

the stable baseline value at E

0.

Example: 15mE (threshold value).

10

0

E

The derived fibrinogen is calculated from

10 20 30

lag-

1

phase

Coag. time

t

t

2

the difference between the maximum

absorbance E

1 and the baseline value E0.

June, 98 6 – 3

6

Measuring Methods

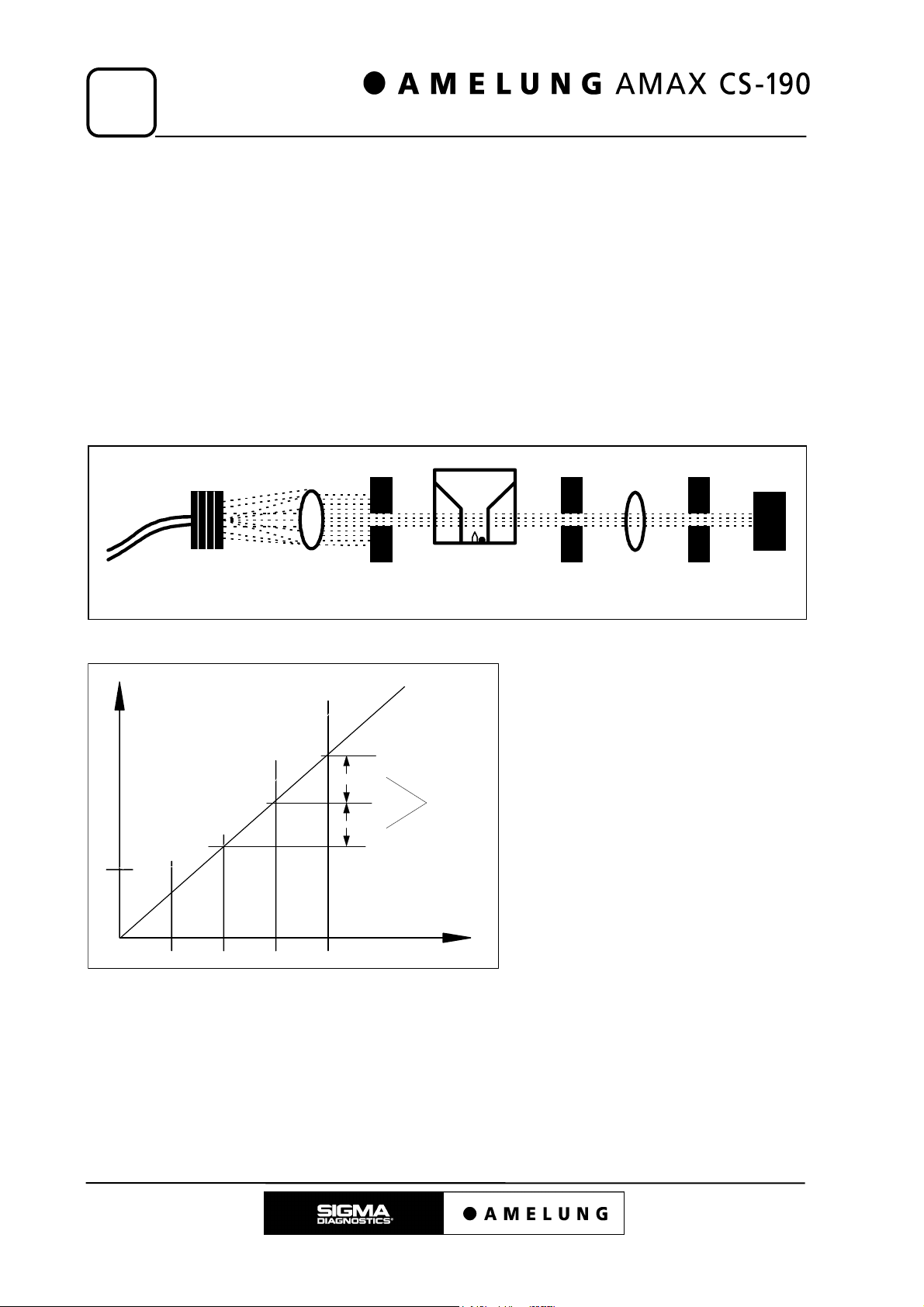

6.3 Optical Measuring Mode (Chromogenic)

The rate of absorbance change is measured at predetermined intervals.

Sample and reagent are pipetted into a measuring cuvette and placed into one of the

optical measuring channels. After the addition of the starting reagent, measurements

are taken in defined intervals.

A monochrome light beam (405nm) passes through the cuvette. The change in optical

density is measured by a sensor behind the cuvette at pre-defined intervals (kinetic

measurement).

The values of change in mE/t are further mathematically processed.

Pic. 6.3.1 schematic display of the optical measurement (chromogenic)

Light source filter lens aperture cuvette aperture lens aperture sensor

Pic. 6.3.2

Analysis of the optical measurement

(chromogenic)

E

The absorbance increase within a

25mE

50mE/min

25mE

defined interval (30/60/90) is

measured and converted into

E/min.

The rate of absorbance change

must be constant (linear).

60

90

t[s]

6 – 4 June, 98

Instrument Installation

7. Instrument Installation

7

7.1 Instrument Overview

7.2 Installation of the AMAX CS-190

7.3 PC & Accessories

7.3.1 Jumper Settings of the AML-BUS-PC-Board

7.3.2 Jumper Settings of the Modem Boards

7.4 Printer Installation

7.5 Connections

7.5.1 Fresh Water / Waste Water System

7.5.2 Electrical Connections

7.6 Turning on the Instrument

7 – 1

7 – 2

7 – 3

7 – 4

7 – 4

7 – 5

7 – 7

7 – 7

7 – 8

7 – 9

June, 98 7 – 0

Instrument Installation

5

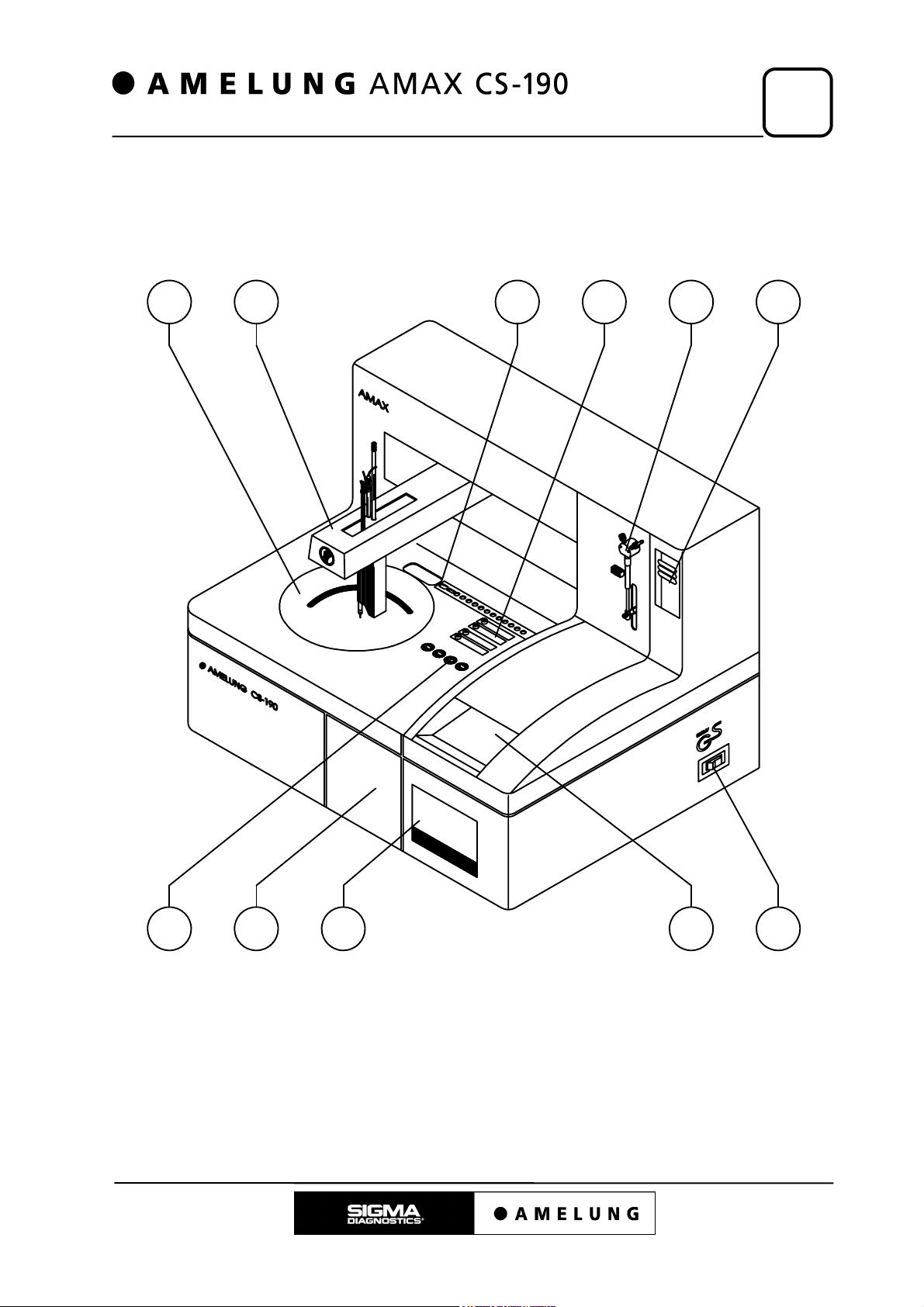

7.1 Instrument Overview

Pic. 7.1.1

6 7 8 9 10 11

7

1234

June, 98 7 – 1

7

Tab. 7.1.1

Instrument Installation

Overview

1. Mains switch 7.5

2. Cuvette magazine (front feed chute) 8.3 / 11.3

3. Cuvette magazine (front disposal chute) 8.3 / 11.3

4. Drawer (Disposal) 9.8

5. Mechanical measuring unit 8.2 / 11.2

6. Reagent-plasma-barcode 8.4 / 11.4

7. Robot (XYZZ) 8.6 / 11.6

8. Incubation rail 8.3 / 11.3

9. Photometer 8.5 / 11.5

10. Dilutor 8.1 / 11.1

11. Traffic lights 2.2

[Chapter]

7.2 Installation of the AMAX CS-190

1. Remove the packaging material of the AMAX CS-190 and level the instrument on

the base cabinet.

Fasten the connecting bolts which connect the base cabinet and the instrument.

2. Do not turn on the instrument yet!

All movable parts were secured for transport.

(XYZZ-robot: all axes were secured)

Remove all shipping clamps.

(check driving belt XY-axes, tapes, paper boards, etc.)

Check all movable parts for free movement.

3. Check the system coolant level,

if necessary fill up with original system liquid.

(830040 (500ml bottle)).

4. Configure PC & Accessories.

5. Connect the fresh/waste water reservoir and the

liquid level sensors.

6. Establish all electrical connections between the

PC and the AMAX CS-190.

7. Now the AMAX CS-190 can be turned on.

7 – 2 June, 98

9.1

7.3

7.5

7.6

Instrument Installation

ATTENTION!

Remove all shipping clamps and securing devices before turning

on the instrument.

Disregard may lead to malfunction of and cause damage to the

AMAX CS-190!

Packaging material is recycable!

7.3 PC & Accessories

7

1. Remove all packaging material of the PC, monitor, printer, etc.

In case the AML-Bus-Board (Board PH-PC (D02801)) or the modem board (Z04005)

have not yet been installed, the PC has to be opened and the boards have to be

placed into free slots.

Check and correct the jumper settings (see below) before the installation. Disregard

may lead to malfunction or conflicts with other components.

2. Connect all components (except for the PC and the AMAX CS-190!) and establish

all electrical connections.

3. Install the software:

First, switch on the PC, screen and printer. The PC installs its operating system

automatically (selection: WINDOWS 3.1) After approx. 30 min. the installation is

complete and you can continue by yourself. Deinstall WINDOWS with only the DOS

prompt remaining on the hard drive.

Now the main software can be installed.

It consists of three or five 3,5” disks:

a. Disk with main menu AMAX CS-190

b. Disk for service software

c. Disk for AMAX CS-190 (instrument specific data)

d. Disk for modem software (option)

e. Disk for printer driver

(printer specific)

7.4

June, 98 7 – 3

7

7.3.1 Jumper Settings on the AML-BUS-PC-Board

There are two dip-switches on the Board PH-PC for adjusting the address.

The following switch adjustments have to be made so that the board can be identified:

Tab. 7.3.1

Dip-switch S1 Position Dip-switch S2 Position

Switch 1 on Switch 1 on

Switch 2 on Switch 2 off

Switch 3 on Switch 3 off

Switch 4 off Switch 4 off

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

Instrument Installation

7.3.2 Jumper Settings of the Modem Boards

The different modems are not distinguishable by their names. For their differentiation,

the BZT-No. is used here. This BZT-No. is printed on the packaging and on a label on

the modem itself.

Tab. 7.3.2

Designation Switch position for Com 3 IRQ 5

Internal fax-modem BZT-No.

(Company)

BZT - No. A109 822D

BZT - No. A107 434D

(YAKUMO)

BZT - No . A121 250F

(CREATIX)

BZT - No. A106 901D

The initialisation string for these modems is:

ATE0Q0V0L1X3%C1\N3\V1S0=2S7=100^M

2 and 7 (7 is a soldering bridge)

switch 1 and 6 to ON

all others to Off

switch 1 and 6 to ON

all others to Off

2,3,8

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

7 – 4 June, 98

Instrument Installation

7

7.4 Printer Installation

There are different types of printer which can be used in combination with the AMAX

CS-190.

Examples for installation:

1. Printer type Canon BJC-240

An installation disk (BJ-setup program) for DOS

Installation is carried out according to the disk label or the printer’s user manual

(directory: C:\bjprn). The printer has to be turned on and connected to the PC.

After the initiation of the printer software the settings of the printer control mode can

be checked. The mode must be set to LQ-Mode

adjusted data has to be transferred to the printer with the function key <F10>.

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

is delivered along with the printer.

. To complete the installation, the

2. Printer type Canon BJ-200

There is no installation disk for this printer. This printer is adjusted manually by

using the dip switches:

Tab. 7.4.1

Dip-switch Position

Switch no. 01 on

Switch no. 02 on

Switch no. 03 off

Switch no. 04 on

Switch no. 05 on

Switch no. 06 off

Switch no. 07 on

Switch no. 08 off

Switch no. 09 off

Switch no. 10 on

Switch no. 11 off

Switch no. 12 off

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

June, 98 7 – 5

7

3. Printer type Canon BJ-200 ex

There is no installation disk for this printer. This printer is adjusted manually by

using the dip switches:

Tab. 7.4.2

Dip-switch Position

Switch no. 01 on

Switch no. 02 on

Switch no. 03 off

Switch no. 04 on

Switch no. 05 off

Switch no. 06 off

Switch no. 07 off

Switch no. 08 off

Switch no. 09 off

Switch no. 10 off

Switch no. 11 on

Switch no. 12 off

Instrument Installation

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

7 – 6 June, 98

Instrument Installation

7

7.5 Connections

7.5.1 Fresh Water / Waste Water System

There is a connection panel for the fresh water / waste water system. Pic. 7.5.1.1

shows the connection panel.

Connect the tubing (Q90006 / Q90007) with the panel and each fresh water / waste

water reservoir (Q90004 / Q90005). In order to ensure perfect functioning, the tubing

connectors have to lock into place precisely (audible). The tubing sets each have a

cable with a BNC connector, which also have to be connected. The cables must not be

interchanged because they are the control cables for the liquid level sensors in the

reservoirs. Pic. 7.5.1.2 shows the position of the reservoirs. Pic. 7.5.1.3 shows the

connections of a reservoir.

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

Pic. 7.5.1.1

Connection panel with level

sensor connections

1

34

Pic. 7.5.1.2

Position of the reservoirs in the base cabinet

3

2

1

1. Base cabinet (left door)

2. Waste water reservoir

3. Fresh water reservoir

1. Plug contact - Fresh water level

sensing

2

2. Fresh water connection

3. Plug contact - Waste water level

sensing

4. Waste water connection

Pic. 7.5.1.3

Reservoir screw-lid with connections

12

3

4

1. Tubing

2. Connection socket for the tubing

3. Cable - Level sensor

4. Connection socket for the cable

June, 98 7 – 7

7

7.5.2 Electrical Connections

67 891011

Pic. 7.5.2.1

Before working on the electrical connections:

Instrument Installation

12345

IMPORTANT!

AMAX CS-190, PC, monitor and printer have to be turned off

(switch position 0/AUS or OFF).

Pic 7.5.2.1 No. 1 shows the instrument main switch.

Technical data:

Switch:

Version (230V / 3.5A) (244210)

Version (110V / 6A) (244216)

The instrument fuse (reversible fuse) is positioned inside the

mains switch. Replacing it after an activation is not necessary!

Disregard may lead to malfunction of the AMAX CS-190!

ATTENTION!

ATTENTION!

7 – 8 June, 98

Instrument Installation

7

On the rear side of the AMAX CS-190 is a

connection panel for the electrical connections

(user position in front of the instrument).

Connect the 15-pin AML-Bus-cable (X10183)

between the AMAX CS-190 and the PC.

The cable has to be screwed into the panel and the

PC correctly in order to function normally.

Now connect the power cable to the AMAX CS-190

and a suitable power supply. (Fuse protection: 16A

(safety cut-out: slow)).

In addition, PC, monitor and printer have to be

connected to the power supply.

Pic. 7.5.2.2

Connection panel

1

2

1. AML-Bus connection

2. Power connection

5.3

ATTENTION!

Disregard may lead to malfunction of the AMAX CS-190!

7.6 Turning on the Instrument

If you have completed all steps successfully, you now may switch on all devices:

First turn on the AMAX CS-190, then all other components!

The AMAX CS-190 moves to its home position (all modules are initialised).

The instrument is ready when the traffic light shows

no light and the screen shows the main menu.

ATTENTION!

The instrument must not be turned on and off in short intervals

(wait at least 10-15 seconds).

Disregard may lead to malfunction of the AMAX CS-190!

2.2

June, 98 7 – 9

Subassemblies

8. Subassemblies

8

8.1 Dilutor

8.1.1 Adjusting the Temperature of the Pre-heater

8.2 Mechanical Measuring Unit

8.2.1 Removing the Measuring Unit

8.2.2 Adjusting the Measuring Block Temperature

8.2.3 Adjusting the PC Temperature Display

8.2.4 Adjusting the Inductive Ball Sensors

8.2.5 Adjusting the Hinge Mechanism Voltage (knee joint)

8.2.6 Adjusting the Rotational Speed

8.2.7 Adjusting the Motor Torque Voltage of the

Measuring Units

8.2.8 Adjusting the Dip-switches on the PH-M-MB

(D05601) Board

8.3 Cuvette Magazine

8.3.1 Removing the Cuvette Magazine or the Incubation

Rail

8.3.2 Adjusting the Mixer in the Incubation Rail (Q10005)

8.3.3 Adjusting the Ejector (Q10030)

8.3.4 Checking the Lifting Solenoid of the Incubation Rail

8.3.5 Adjusting the Temperature of the Incubation Rail

8.3.6 Adjusting the PC Temperature Display

8.3.7 Checking the Lifting Solenoids

8.3.8 Alignment Tools Magazine

8.3.9 Adjusting the Pusher 1 Unit

8.3.10 Alignment of the Cuvette Magazine in the

AMAX CS-190

8.3.11 Adjusting the Light Barriers and the Cuvette Comb

8.3.12 Adjusting the Cuvette Comb

8.3.13 Checking the Reflex Light Barriers

8.3.14 Checking the Conveyors

8.4 Reagent-Plasma-Barcode

8.4.1 Adjusting the Cooling Circuits

8.4.2 Adjusting the PC Temperature Display

8.4.3 Adjusting the Cutoff Voltage of the Servo Power

Amplifier

8.4.4 Adjusting the Mixer Voltage

8.4.5 Mechanical Reset Adjustments at the RPB

8.4.6 Adjusting the Barcode Scanner Position

8.5 Photometer

8.5.1 Removing the Measuring Unit

8.5.2 Adjusting the Temperature of each Measuring

Channel

8.5.3 Adjusting the Photometer Lamp Voltage

8.5.4 Adjusting the Photometer Measuring Amplifier

8.6 XYZZ-Robot (gantry)

8.6.1 Adjusting the Safety Systems of the Control Unit

8 – 1

8 – 2

8 – 3

8 – 4

8 – 4

8 – 5

8 – 5

8 – 6

8 – 7

8 – 7

8 – 8

8 – 9

8 – 11

8 – 11

8 – 12

8 – 12

8 – 13

8 – 13

8 – 14

8 – 15

8 – 16

8 – 16

8 – 18

8 – 20

8 – 22

8 – 23

8 – 24

8 – 25

8 – 25

8 – 26

8 – 26

8 – 27

8 – 27

8 – 29

8 – 30

8 – 30

8 – 31

8 – 31

8 – 34

8 – 35

June, 98 8 – 0

8

Subassemblies

8.6.2 Voltage Cutoff of the X-Motor Amplifier

8.6.3 Voltage Cutoff of the Y-Amplifier

8.6.4 Speed Cutoff of the X-Motor Amplifier

8.6.5 Mechanical Reset Adjustment of the XYZZ-Robot

8.6.6 Adjusting the XY-Motors

8.6.7 Adjusting the Level Sensors (liquid level sensors

and height sensors)

8.7 Water Temperatures

8.7.1 Adjusting the Water Reservoir II Temperature

(D10068)

8.7.2 Adjusting the PC Temperature Display

8 – 35

8 – 36

8 – 37

8 – 38

8 – 39

8 – 40

8 – 42

8 – 43

8 – 43

8 – 0 June, 98

Subassemblies

8.1 Dilutor

8

Pic. 8.1.1

Dilutor unit (10)

Tab. 8.1.1 Structure dilutor unit (Q10007)

mechanical subassemblies electronic subassemblies

Dilutor component XL 3000W (246005)

Pre-heater (Q10020)

There is a dip-switch on the PH-MCK II board for adjusting the module address. It also

contains the program-IC (integrated chip) IC1, which can be replaced to update to a

new program version.

67 891011

12345

AM-DIL board (D05701)

PH-MCK II board (D03601)

The following switch adjustments have to be carried out so that the module can be

identified.

Tab. 8.1.2

Dip-switch S1 position

Switch no. 1 on

Switch no. 2 off

Switch no. 3 off

Switch no. 4 off

Module address: 1

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

June, 98 8 – 1

8

8.1.1 Adjusting the Temperature of the Pre-heater

In order to carry out the adjustments, the following instrument casings have to be

removed:

Rear casing (123268)

The pre-heater is positioned in the top left corner (dilutor unit) of the instrument (user

position behind the instrument).

Pre-heater (Q10020) (1)

Heating:

PH-I-HZ II board (D01101) (2)

Subassemblies

Pic. 8.1.1.1

1

2

The theoretical value of the heating is adjusted on the PH-I-HZ II (D01101) board (on

which the pre-heater is mounted) by using the potentiometer R16.

1¬ = approx. - 1.0°C / 1« = approx. + 1.0°C

As long as the LED V1 is lit, the heating is active and the temperature rises. The

temperature of the reservoir should be 40°C ± 0.5°C .

The temperature is measured using a contact thermometer directly at the brass

container through a hole in the pre-heater insolation.

8 – 2 June, 98

Subassemblies

8.2 Mechanical Measuring Unit

8

Pic. 8.2.1

Mechanical measuring unit (5)

Tab. 8.2.1 Structure mechanical measuring unit (Q10011)

mechanical subassemblies electronic subassemblies

knee joint (D10074) AM-M-SH board (D06901)

67 891011

AM-M-HT board (D06301)

PH-TF board (D06801)

AM-S-HY board (D06201)

PH-HALL board (D05201)

12345

The PH-MCK (D00801) board is not in the module. It is integrated in the subassembly

reagent/measuring unit drive (Q10080).

There is a dip-switch for adjusting the module address on the PH-MCK board. It also

contains the program-IC (integrated chip) IC1, which can be replaced to update to a

new program version.

The following dip switch adjustments have to be carried out so that the module can be

identified.

Tab. 8.2.2

Dip-switch S1 position

switch no. 1 off

switch no. 2 off

switch no. 3 on

switch no. 4 off

Module address: 2

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

June, 98 8 – 3

8

8.2.1 Removing the Measuring Unit

In order to remove the measuring unit, the following instrument casings should be

removed:

Upper structure (123290)

Side casing left (123289)

Working area (123292)

Front plate left (123293)

Side casing right (123291)

Front plate right (123294)

Magazine cover (122432)

8.2.2 Adjusting the Measuring Block Temperature

The adjustments have to be carried out on the AM-M-SH (D06901) board. Place

cuvettes, filled with approx. 200 µl water in the measuring channels.

In order to adjust the temperature of the measuring unit, the following instrument

casings should beremoved:

Subassemblies

Upper structure (123290)

Side casing left (123289)

Working area (123292)

The supply voltage should be turned on. The theoretical value of the heating is adjusted

with potentiometer R27.

1¬ = approx. + 1.0°C / 1« = approx. - 1.0°C

As long as the light-emitting diode LED V4 is lit, the heating is active and the

temperature rises. The current temperature can be measured in the cuvettes using the

liquid thermometer.

The temperature should be at 37.5°C ± 0.3°C when

LED V4 goes out (after approx. 15 minutes).

The adjustment process is complete when the temperature of each cuvette is constant.

After successful adjustment, the measuring block has a temperature of approx. 38.5°C.

The temperature if measured on the sides of the aluminium block.

The adjustment can be carried out outside the instrument as well. The ambient air

around the instrument should not be too cold (avoid draughts).

The adjustment should be checked again after the measuring unit has been reinstalled.

5.4

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8 – 4 June, 98

Subassemblies

8.2.3 Adjusting the PC Temperature Display

This adjustment is carried out on the PH-TF (D06801) board.

The current temperature of the measuring block can

be queried using the service program.

The displayed value can be altered (adjusted) with

potentiometer R7.

1¬ = approx. - 0.5°C / 1« = approx. + 0.5°C

The temperature should be measured on the sides of the aluminium-block using the

contact thermometer. This value should then be adjusted to approx. 38.5 °C.

IMPORTANT!

The temperature displayed by the PC in the service program

should always be equivalent to the current temperature.

11.2

8

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.2.4 Adjusting the Inductive Ball Sensors

The adjustment is carried out at the ball sensors (D10079).

The mechanical measuring unit should be operational before the adjustment. The

supply voltage should be turned on and the temperature should be adjusted correctly.

Otherwise, the temperature adjustment has to be repeated (see: Adjusting the

measuring block temperature).

An empty cuvette with a ball should be placed into every measuring channel. It is

important that all measuring channels are closed.

The voltage to be adjusted can be measured on the AM-S-HY board (D06201) at MP2

using a multimeter. First, a voltage of approx. 2.9-3.1 Volt is adjusted. The adjustment

is altered using the potentiometer in the ball sensor.

¬ = - / « = +

After an operation time of about 10 minutes, a voltage of 3.8 volts should be adjusted.

Now, in order to check its functionality, the

measuring unit can be started in the service

program.

After the measuring channels have been started, they are stopped by blocking the ball

using a non-metallic object. The LED V4 flashes once. It signals the stop-impulse.

When the measuring unit stops, the sensor system is ready for operation. The electrical

11.2

June, 98 8 – 5

8

adjustment and functionality check should be rechecked after another 15 minutes. If

necessary, 3.8 volts should be readjusted.

Finally, the ball is glued solid in the cuvette and the measuring channel is started. An

oscilloscope is now connected to MP2. The X18 plug has to be disconnected from the

AM-M-SH board or the X1 plug from the PH-M-MB board in order to interrupt the

monitoring of the AM-S-HY board. Otherwise, the measuring channels would stop

again.

An amplitude of at least 1.5 volts should be visible.

After the measurement, the X18 or X1 plugs have to be plugged back into the AM-MSH board or the AM-M-MB board.

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

Subassemblies

8.2.5 Adjusting the Hinge Mechanism Voltage (knee joint)

The supply voltage for the hinge mechanism stepper motors is adjusted using the

potentiometer on the AM-M-SH (D06901) board.

1¬ = approx. + 1.0 V / 1« = approx. - 1.0 V

For that purpose, a digital voltmeter is connected to the LED V2 anode. The voltage

should be 15 Volt ± 0.5 to guarantee a safe opening and closing of the hinge.

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8 – 6 June, 98

Subassemblies

8.2.6 Adjusting the Rotational Speed

In order to carry out the adjustment, the following instrument casings should

beremoved:

Side casing left (123289)

Front plate left (123293)

The measuring unit should be operational.

One oscilloscope probe is connected to PIN 1 of

plug X1 on the PH-M-MB (D05601) board.

The measuring unit channel no. 4 is started with the

service program.

Using the potentiometer R21, the speed is adjusted so that the interval length of the

signal is 375ms.

1¬ = approx. - 30ms / 1« = approx. + 30ms

This equals to 80 rpm (2 impulses per rotation of the measuring unit).

11.2

8

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.2.7 Adjusting the Motor Torque Voltage of the Measuring Units

The stepper motor supply voltage used for turning the measuring units is adjusted

using the potentiometer R22 on the PH-M-MB (D05601) board.

1¬ = approx. + 300mV / 1« = approx. - 300mV

For this purpose, a digital multimeter is connected to the coil L1. The voltage must be

approx. 6 volts ± 0.3 so that the measuring units can start smoothly and safely.

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

June, 98 8 – 7

8

8.2.8 Adjusting the Dip-switches on the PH-M-MB (D05601) Board

In order to carry out this adjustment, the following instrument casings should be

removed:

Side casing left (123289)

Front plate left (123293)

There are two dip-switches on the PH-M-MB board: dip-switch S1 affects the stepper

motors (complete- or half-step, direction of rotation); dip switch S2 affects the number

of measuring units.

The following dip switch adjustments have to be carried out so that the mechanical

measuring unit can function correctly.

Tab. 8.2.8.1

Dip-switch S1 position Dip-switch S2 position

switch no. 1 on switch no. 1 off

switch no. 2 on switch no. 2 on

switch no. 3 on switch no. 3 on

switch no. 4 off switch no. 4 off

Subassemblies

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8 – 8 June, 98

Subassemblies

8.3 Cuvette Magazine

8

Pic. 8.3.1

Cuvette magazine (2 & 3)

Tab. 8.3.1 Structure cuvette magazine (D10007)

mechanical subassemblies electronic subassemblies

Pusher I (D10032)

Pusher II (D10033)

Side part I (D10060)

Side part II (D10061)

Conveyor I (D10062)

Conveyor II (D10063)

Lifting solenoid stops (D10038)

Incubation rail (Q10005)

67 891011

12345

PH-K5 board (D03401)

PH-MCK board (D08001)

There is a dip-switch for adjusting the module address on the PH-MCK board. It also

contains the program-IC (integrated chip) IC1, which can be replaced to update to a

new program version.

The following dip switch adjustments have to be carried out so that the module can be

identified.

Tab. 8.3.2

Dip-switch S1 position

switch no. 1 off

switch no. 2 off

switch no. 3 on

switch no. 4 on

Module address: 3

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

June, 98 8 – 9

8

Subassemblies

Cuvette magazine cover (1)

Cuvette box loading area (2)

Cuvette box disposal chute (3)

Cuvette box (4)

Pic. 8.3.2

123 4

Cuvette box loading area (1)

Cuvette box (2)

Cuvette comb (3)

Feed conveyor (4)

Disposal conveyor (5)

Row pusher (6)

Incubation rail (7)

Pic. 8.3.3

7

6

5

4

3

2

1

8 – 10 June, 98

Subassemblies

8.3.1 Removing the Cuvette Magazine or the Incubation Rail

In order to remove the cuvette magazine or the incubation rail, the following instrument

claddings should be removed:

Upper structure (123290)

Side cladding left (123289)

Work area (123292)

Front plate left (123293)

Side cladding right (123291)

Front plate right (123294)

Magazine cover (122432)

After that each module can be removed. The corresponding cable connections have to

be detached: supply voltage, module connections, light barrier cable, BUS-connections.

8.3.2 Adjusting the Mixer in the Incubation Rail (Q10005)

In order to carry out the adjustment, the following instrument claddings should be

removed:

8

Upper structure (123290)

Side cladding left (123289)

Work area (123292)

The incubation rail (2) with the integrated mixer

unit (D10071) is positioned under the incubation

rail cover. The mixer-position (4) is in front of the

ejector-position (3) and the lifting solenoidposition (4). (Blocking position1).

The mixer can be started with the service

program.

The ball turns when a cuvette is positioned on

the mixer position.

A stroboscopic effect can be observed when a line-powered (electric discharge lamp/

fluorescent lamp) lamp is held above the cuvette (assuming the rotational speed has

been adjusted correctly). When the rotational speed is correct, “3-4 stationary balls”

can be observed.

Pic. 8.3.2.1

1

23

45

The rotational speed is adjusted with the potentiometer R43 on the PH-K1 (D03001)

board.

¬ = - / « = +

June, 98 8 – 11

8

8.3.3 Adjusting the Ejector (Q10030)

Subassemblies

The cuvette ejector (6) plunger (1) is adjusted with the

alignment gauge (J0XXX). The ejector unit (6) has to

be connected to the incubation rail (5). The plunger is

brought into the lower position. The alignment tool (3)

is then held into the incubation rail. The short spike

(4.5mm) has to be placed into the plunger exit position.

The flat surface of the alignment gauge should now lie

on the base of the incubation rail (4). Otherwise the

two set-screws in the fish-plate (7) have to be loosened

which allows the plunger to be pushed downwards until

the flat surface of the alignment gauge comes to rest

on the incubation rail base. The upper flat surface (2)

of the plunger has to be 4.5mm deeper than the base

of the incubation rail (4).

It must not be possible to move the plunger upwards

against the alignment gauge. In this case, the ejectorplunger-position would be too deep.

After completing the alignment, the set-screws have to

be tightened again.

Pic. 8.3.3.1

5

6

1

2

3

4

Nach Einstellung

wieder festziehen!

7

4.5 mm

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.3.4 Checking the Lifting Solenoid of the Incubation Rail

In the incubation rail is a lifting solenoid (see Pic. 8.3.2.1 no.4) which blocks the

position 1(ejector position).

The function of the lifting solenoid can be checked

with a continuous test program in the service

11.3

program.

The lifting solenoid is activated and then powered

off, it should spring out without any delay.

8 – 12 June, 98

Subassemblies

8.3.5 Adjusting the Temperature of the Incubation Rail

8

The supply voltage has to be turned on. The

adjustment is carried out on the AM-I-HZ

(D07401) board. Two cuvettes (2), which are filled

with approx. 200 µl water, are placed into the

incubation channel (1) (see Pic. 8.3.5.1).

The theoretical value of the heating is adjusted with

the potentiometer R22. As long as the LED V1 is lit,

the heating is active and the temperature increases.

The temperature in the cuvettes should be at 37.5°C

± 0.3°C.

The actual temperature in the cuvettes can be measured with the liquid thermometer.

1¬ = approx. - 1°C / 1« = approx. + 1°C

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

Pic. 8.3.5.1

1

2

5.4

8.3.6 Adjusting the PC Temperature Display

The current temperature of the measuring unit can

be queried with the service program.

The displayed value is matched to the adjusted value (value displayed on the

thermometers) using the potentiometer R23.

1¬ = approx. + 0.5°C / 1« = approx. - 0.5°C

IMPORTANT!

The temperature displayed on the PC in the service program

should always be equal to the true temperature!

11.3

June, 98 8 – 13

8

8.3.7 Checking the Lifting Solenoids

Before aligning the cuvette magazine the function of the lifting solenoids should be

checked (stop pins for the 1st cuvette box).

The lifting solenoids (stop pins for the positioning of

the 1st cuvette box) can be “extended” or “retracted”

with the service program.

In the retracted position, the pins have to be sunk completely so that the cuvette boxes

can be transported over them without hitting them.

”Extension“ of both pins should happen at the same time if possible so that accurate

positioning of the cuvette box can be guaranteed. In addition, the lifting solenoids pins

should be positioned in the center of the “conveyor 1” plate borings. Should one of the

steps not be carried out correctly, the lifting solenoids have to be checked and

realigned if necessary.

IMPORTANT!

The lifting solenoids should not be turned on for longer

than 30 sec!

Subassemblies

11.3

ATTENTION!

Disregard can lead to malfunction of and cause damage to the

AMAX CS-190!

8 – 14 June, 98

Subassemblies

8.3.8 Alignment Tools Magazine

8

Pic. 8.3.8.1

Highest point for

cuvette comb

(1)

Alignment gauge I (J01847)

Step

(magazine light barriers)

Check position

(2)

Alignment gauge (J01820)

(Alignment Pusher Unit 1)

(3)

Alignment gauge III (J01819)

(gauge lifting solenoid)

(4)

Alignment gauge II (J01827)

(light barrier for row pusher end position)

2

1

Base surface

3

Cuvette comb

driven back

IMPORTANT!

All alignment gauges have to be removed after the alignment!

4

June, 98 8 – 15

8

8.3.9 Adjusting the Pusher 1 Unit

Subassemblies

The alignment of the Pusher Unit 1 can

be checked after inserting the

alignment gauge (6) (J01820) and

attaching it with the centering pins (4)

and the fastening screw (5). The base

plate of Pusher Unit 1(1) should lie on

the alignment gauge support points

and the whole unit should fit closely to

the alignment gauge impeders (2)

In order to carry out the alignment, the

four M4 nuts have to be unscrewed so

that moving the unit is possible.

After completing the alignment, tighten

the nuts and remove the alignment

gauge.

Pic. 8.3.9.1

1

2

3

4

5

6

ATTENTION!

Disregard can lead to malfunction of and cause damage to the

AMAX CS-190!

8.3.10 Alignment of the Cuvette Magazine in the AMAX CS-190

The alignment of the complete magazine can be carried out only when the incubation

rail (Q10005) has already been mounted to the instrument. The incubation rail has to

be mounted as far as possible in the direction of the amplifier unit and the cuvette

magazine. Now the alignment gauge (J01819) (gauge III, alignment gauge lifting

solenoid) can be inserted into the incubation rail. The cuvette magazine can be moved

after unscrewing the fastening screws (3 hexagonal headed screws). The cuvette

magazine is now adjusted so that both lifting solenoids (impeders for the 1st cuvette

box) fit closely in front of the alignment gauge. At the same time Ensurethat the

incubation rail gauge III of the does not protrude into the cuvette magazine. For

example, if a ruler or the alignment gauge II is put against the inside of the cuvette

magazine’s left side, the incubation rail gauge III may extend no further than the ruler or

the gauge II.

After completing the alignment, both fastening screws have to be tightened again.

Perform a function check by pushing the lifting solenoids downwards and releasing

them again. They should spring back from the alignment gauge without any delay.

Pic. 8.3.10.1

8 – 16 June, 98

Subassemblies

Lifting solenoids (1)

Alignment gauge III (2)

Alignment gauge II (3)

8

1

2

3

Alignment check: The row pusher is moved in the direction of the incubation rail.The

pusher should be positioned in the middle of the incubation rail opening.

When processing the cuvettes, these should move into the incubation rail in a straight

line. The opening in the cuvette box should be in alignment with the opening in the

incubation rail.

June, 98 8 – 17

8

8.3.11 Adjusting the Light Barriers and the Cuvette Comb

The alignments for the light barriers are listed in tab. 8.3.11.1.

Tab. 8.3.11.1

Light barrier Position Alignment

Subassemblies

Row pusher

see

Pic. 8.3.11.1(3)

see

Pic. 8.3.11.1(2)

Pic. 8.3.11.1

End Insert the alignment gauge (J01827) (gauge II,

row pusher end light barrier). Gauge II is

inserted to the incubation rail end. The light

barrier may change its signal (display “High”)

only when the row pusher touches the

alignment gauge II. The alignment can be

altered by moving the straight pin (2). For this

purpose, the set-screw (M4) (3) in the motor

block (1) has to be loosened.

Tension A value of 4N is adjusted with the help of a

spring scale (1) (890300). For this purpose, the

spring scale has to be attached to the tip of the

row pusher. Now hold the pusher 1 in its

position while pulling on the spring scale until

the desired value is archived. The display of

the light barrier has to change then. If it

doesn’t, the elastic force has to be adjusted

with the screw (2) “stop pin”.

Pic. 8.3.11.2

Federwaage am

äußersten Punkt dieser

Kante ansetzen.

1

2

8 – 18 June, 98

Subassemblies

8

Motor block (1)

Straight pin (2)

Set screw (3)

Row pusher (4)

Alignment gauge II (5)

(row pusher end light barrier)

Pic. 8.3.11.3

1

2

3

4

5

June, 98 8 – 19

8

8.3.12 Adjusting the Cuvette Comb

Subassemblies

Lifting solenoids (1)

Alignment gauge I (2)

(magazine light barriers)

Pusher 2 unit (3)

Pic. 8.3.12.1

1

3

2

Straight pin (1)

Alignment: Cuvette comb moved

backwards

Set-screw (2)

Set-screw (3)

Alignment: Cuvette comb moved

downwards

Straight pin (4)

Alignment: Cuvette comb moved

backwards

Set-screw (5)

Alignment: Cuvette comb moved

upwards

Set-screw (6)

Pic. 8.3.12.2 Pusher 2 unit (D10033)

12

5

3

4

6

8 – 20 June, 98

Subassemblies

Tab. 8.3.12.1

Light barrier Position Alignment

8

Cuvette comb

see

Pic. 8.3.12.1

8.3.12.2

see

Pic. 8.3.12.3

Alignment gauge I (J01847)

(Magazine light barriers)

moved upwards Insert the alignment gauge (J01847) (gauge

moved downwards The alignment is defined by the base of

I, magazine light barriers). Pic. 8.3.12.1

The cuvette comb “guide pins” have to be

positioned on the highest point (front edge) of

the alignment gauge. Only then the signal for

the light barrier (Display “Low”) may change.

The height of the cuvette comb is adjusted

with the set-screw (5) seated in the reset

bracket. The set-screw (6) has to be

unscrewed first. When the screw (5) is

loosened, the position is lowered.

When the screw (5) is tightened, the position

is raised.

gauge I. That means that the light barrier

may change its signal (display “Low”) only

when the “guide pins” are positioned on the

base. The stepper motor switch off position

can be adjusted with the set-screw (3). The

set-screw (2) must be unscrewed first.

Pic. 8.3.12.3

Highest point for

cuvette comb

Cuvette comb

moved backwards

Step

Check position

Base

June, 98 8 – 21

8

Continuation Tab. 8.3.12.1

Light barrier Position Alignment

Subassemblies

see

Pic. 8.3.12.3

see

Pic. 8.3.12.3

Check: The check position of the alignment gauge is calculated so that when the comb

is in the “Comb moved backwards” position, the light barriers “Comb moved

backwards” and “Comb under tension” change their signal (display “Low”) at the same

time. Ensure to smooth running of the spring tension beam.

moved backwards This position is used when the cuvette box is

changed. The comb must be in the position

“Comb moved backwards”. The alignment

gauge 1 may not be moved from its original

position. The position is aligned with the

fillister head screw

pusher unit 2.

in back position The cuvette comb “guide pins” have to be

positioned on the alignment gauge step. The

light barrier signal (display “Low”) the must

change when the comb is pushed against

the step. The position is aligned with the

fillister head screw

the pusher 2 unit.

seated in motor block 1 of

seated in motor block 1 of

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.3.13 Checking the Reflex Light Barriers

Three reflex light barriers are positioned at the left side of the cuvette magazine (user

position in front of the instrument). These light barriers monitor the cuvette boxes on

the conveyors.

The function check can be carried out with the

service program.

A cuvette box is positioned in front of a single light barrier. The corresponding display in

service program has to change its status. The reflex light barrier “magazine jam

the

disposal” is positioned in the lower part of the cuvette magazine (disposal chute).

Ensure correct allocation of the light barriers.

1. Light barrier “Magazine supply“

2. Light barrier “Magazine front“

3. Light barrier “Magazine jam disposal”

11.3

8.3.14 Checking the Conveyors

8 – 22 June, 98

Subassemblies

The conveyors can be turned on and off with the

service program.

Ensure that the supply and the disposal conveyor belts are moving in the correct

direction. When the conveyors are operating, a “clean”, ”smooth” running noise should

be audible. Otherwise, check the tension of each conveyor belt and adjust it if

necessary. The driving tapered cogwheels must intermesh perfectly, correct if

necessary. The tapered cogwheels must be lubricated.

IMPORTANT!

The conveyors should not be turned on for longer than 30 sec.

ATTENTION!

Disregard can lead to malfunction of and cause damage to the

AMAX CS-190!

11.3

8

June, 98 8 – 23

8

8.4 Reagent-Plasma-Barcode

Subassemblies

Pic. 8.4.1

RPB (6)

Tab. 8.4.1 Structure RPB (Q10004)

electronic subassemblies

AM-RPB board (D01101)

PH-MCK II board (D03601)

PH-TF board (D08501)

Cover sensor comp. (Q90022)

67 891011

12345

There is a dip-switch for adjusting the module address on the PH-MCK board. It also

contains the program-IC (integrated chip) IC1, which can be replaced to update to a

new program version.

The following dip-switch adjustments have to be carried out so that the module can be

identified.

Tab. 8.4.2

Dip-switch S1 Position

Switch no. 1 off

Switch no. 2 on

Switch no. 3 on

Switch no. 4 off

Module address: 6

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8 – 24 June, 98

Subassemblies

8.4.1 Adjusting the Cooling Circuits

IMPORTANT!

This adjustment may be carried out only when the instrument is

switched on, that means only when the cooling circuit is working

In order to carry out the adjustment, the following instrument casings have to be

removed:

Side casing left (123289)

Front plate left (123293)

The adjustment is carried out on the PH-R2R (D06101) board. The actual temperature

value of the cooling is adjusted with potentiometer P1.

1¬ = approx. - 1.0°C / 1« = approx. + 1.0°C

The cooling is active and the temperature decreases as long as the LED V3 is lit. The

actual temperature is measured with a contact thermometer on the aluminium-block.

8

When the LED V3 has gone out, the temperature

should be at 16.5°C ± 1.5°C.

ATTENTION!

Disregard can lead to malfunction of and cause damage to the

AMAX CS-190!

8.4.2 Adjusting the PC Temperature Display

The adjustment is carried out on the PH-TF (D06801) board.

The actual temperature of the measuring block can

be queried with the service program.

The displayed value can be altered (adjusted) with

the potentiometer R7.

1¬ = approx. - 0.5°C / 1« = approx. + 0.5°C

The temperature of the side surface of the aluminium-ring should be measured with a

contact thermometer. Then it should be adjusted to this value: ca. 16.5°C.

5.4

11.4

June, 98 8 – 25

8

IMPORTANT!

The temperature displayed by the PC in the service program

should always be equivalent to the actual temperature.

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.4.3 Adjusting the Cutoff Voltage of the Servo Power Amplifier

In order to carry out the adjustment, the following instrument casings have to be

removed:

Side casing left (123289)

Subassemblies

The voltage is measured at PIN 2 of IC 7 (IC LM 311) on the AM-RPB (D00301) board

against ground with a multimeter. A voltage of approx. 1.1 volts is adjusted with the

potentiometer R19.

1¬ = approx. + 200mV / 1« = approx. - 200mV

In order to make a function check, the rotor is moved manually. Resistance can be felt

and the operating noise of the motor becomes audible. When the pressure is

increased, the rotor movement must be effortless.

The cutoff has been activated. The LED V5 has gone out and the relay REL1 has

opened.

The adjustment can be checked in the service

program by running the test routine for the reagent-

plasma-tray (the connection: Reagent-plasma-tray

and commander PC must be established).

Here, the cutoff must not activated, otherwise the voltage at PIN 2 of IC 7 must be

increased.

8.4.4 Adjusting the Mixer Voltage

The measured and adjusted voltage is proportional to the mixer voltage. Therefore the

voltage is measured at PIN 15 of IC 10 (L297) with a digital multimeter. The voltage

value is adjusted to a max. of 0.200 volts with potentiometer R24.

1¬ = + 120mV / 1« = - 120mV

11.4

8 – 26 June, 98

Subassemblies

8

To check the mixer vials each containing a magnetic flea is placed in the reagent tray

on positions 9, 17 and 18. The magnetic flea must rotate on all a.m. positions.

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

8.4.5 Mechanical Reset Adjustments at the RPB

In order to carry out the adjustments, the instrument

must be switched on and connected to the

7.5

commander PC.

The reset position must be adjusted so that the indent at rotor

Pic. 8.4.5.1

(2) (plasma ring) coincides with the indent of the ALU-ring (4)

(cooling) after the reset operation.

1

First the reagent tray (3) is taken out of the reagent-plasmacavity in order to unscrew the set-screws which are screwed

2

into the core (6). Now the tray (5) can be turned on its axis so

that the position can be changed. After each change, the setscrews have to be tightened again. The reagent plasma tray

must carry out a reset so the new reset position will be

obtained.

When the indents coincide, the adjustment is complete.

3

4

5

6

8.4.6 Adjusting the Barcode Scanner Position

The lateral position of the barcode scanner can be altered by loosing the plate angle

fastening screws. The scanner can now be positioned facing or opposing the ALU-ring

after the barcode scanner fastening screws have been unscrewed.

A scanning operation can be started with the service

program. Position a monovette in the outer plasma

11.4

ring. The position of the scanner has

to be adjusted so that the laser beam moves centrally across the

Pic. 8.4.6.1

monovette (1). The operation then has to be repeated, this time

with a monovette in the second plasma ring.

Finally, a monovette with a barcode label is placed in the plasma

ring and a new scanning operation is started. When the barcode

is read successfully, the adjustment is complete. The screws have

1

to be tightened again.

June, 98 8 – 27

8

ATTENTION!

Disregard can lead to malfunction of and cause damage to the

AMAX CS-190!

Subassemblies

8 – 28 June, 98

Subassemblies

8.5 Photometer

8

Pic. 8.5.1

Photometer (9)

Tab. 8.5.1 Structure photometer (Q10010)

mechanical subassemblies

Amplifier (Q10050)

Lamp casing (D10085)

Measuring unit (D10087)

Light voltage regulator (Q10015)

67 891011

12345

The module address is adjusted on the PH-O-RK board. It is positioned in the

subassembly: computer board unit (Q10082).

There are two dip-switches for adjusting the module adress on the PH-O-RK board. It

also holds the program-IC (integrated chip) IC1, which can be replaced to update to a

new program version.

The following dip-switch adjustments have to be carried out so that the module can be

identified:

Tab. 8.5.2

Dip-switch S1 Position Dip-switch S2 Position

switch no. 1 on switch no. 1 off

switch no. 2 on switch no. 2 off

switch no. 3 on switch no. 3 off

switch no. 4 off switch no. 4 off

Module address: 7

ATTENTION!

Disregard can lead to malfunction of the AMAX CS-190!

June, 98 8 – 29

8