Page 1

MECHATRONIC DRIVES WITH BLDC MOTOR PANdrives

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

V 1.10

HARDWARE MANUAL

+ +

TMCM-170-57

controller / driver module

up to 10A RMS / 12… 48V DC

CAN, RS232/RS485 (optional)

+ +

+ +

PDx-170-57-E

mechatronic device with

57 mm BLDC servo motor

up to 10A RMS / 12… 48V DC

CAN, RS232/RS485 (0ptional)

incremental encoder

hall sensors

+ +

Page 2

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 2

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Contents

1 Life support policy ....................................................................................................................................................... 3

2 Features........................................................................................................................................................................... 4

3 Order codes .................................................................................................................................................................... 5

4 Electrical and mechanical description .................................................................................................................... 6

4.1 Pinning ................................................................................................................................................................... 6

4.2 Application circuit ............................................................................................................................................... 7

4.3 Dimensions ........................................................................................................................................................... 8

4.4 Connectors ............................................................................................................................................................ 9

4.5 PANdrive™ specifications ................................................................................................................................. 9

4.5.1 PANdrive™ motor .................................................................................................................................... 9

5 Operational ratings .................................................................................................................................................... 11

5.1 Power supply requirements........................................................................................................................... 12

5.2 Bus interface ....................................................................................................................................................... 12

5.2.1 Terminating the RS485 network ........................................................................................................ 12

6 Functional description .............................................................................................................................................. 13

6.1 Setting the basic values for operation (using the demonstration application) ............................. 13

6.2 Start-up for encoder based commutation ................................................................................................. 13

6.3 Encoder setting .................................................................................................................................................. 14

6.4 Hall sensor only operation w/o encoder ................................................................................................... 15

6.5 Stop switch ......................................................................................................................................................... 15

6.6 General functions (explore using the Windows based demo software) ......................................... 15

6.7 Temperature, current and voltage monitoring functions ..................................................................... 15

6.8 Programmable motor current limit ............................................................................................................. 16

7 Revision history .......................................................................................................................................................... 17

7.1 Document revision ........................................................................................................................................... 17

7.2 Firmware revision ............................................................................................................................................. 17

8 References .................................................................................................................................................................... 17

9 Appendix ....................................................................................................................................................................... 18

Page 3

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 3

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

1 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 20092011

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility

is assumed for the consequences of its use nor for

any infringement of patents or other rights of third

parties, which may result from its use.

Specifications are subject to change without notice.

Page 4

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 4

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

2 Features

The PD-170-57 is a combination of an intelligent BLDC servo motor controller / driver, an optical

encoder and a 57mm brushless DC motor. As a controller/driver module the TMCM-170 has been

designed for high performance servo drives based on brushless DC motors. It combines the high

resolution known from stepper motors with the high dynamic, high velocity and high reliability of a

BLDC drive. A build-in ramp generator allows parameterized smooth positioning. Its small form factor

allows direct mounting on / into a motor-encoder assembly. The TMCM-170 supports BLDC motors

with nearly any number of poles and incremental encoders with nearly any resolution. The TMCM-170

integrates a position and a velocity regulator.

The module can be remote controlled via an RS232 or RS485 interface (ordering options) and CAN

interface.

Applications

Replacement of servo drive by high reliability / low cost BLDC drive

Fast and precise positioning

Smooth very low to very high constant / variable velocity drives

Very high velocity stability drives

Extremely compact decentralized motor electronics

Motor / Encoder type

Sine (or block) commutated BLDC motors with encoder and with / without additional hall sensors

Hall sensor based motors can be operated without encoder

Motor power from a few watts to 500W

Motor velocity up to 100,000 RPM (electrical field)

Incremental encoder (2 channel with option for N-channel) with resolution from 256 to 30000 /

motor rotation (opt. per electrical field rotation)

12V to 48V nominal motor voltage

Coil current up to 10A nominal (up to 14A current for short time)

PANdrive™ Motor and Encoder data

Motor: TRINAMICs QBL 5704-94-04-032 or QBL 5704-116-04-042, rated torque 0.32 Nm or 0.42 Nm

Encoder: HEDS-5640-A12 with resolution of 2000 per motor rotation

Please refer to the datasheets for detailed motor and encoder information

Highlights

High-efficiency operation, low power-dissipation

CAN interface and RS232 or RS485 integrated

Integrated Protection: reverse polarity and overload / overtemperature / overvoltage

TRINAMIC TMCL™ protocol and TMCL™ software environment for parameterizing and for update

and for programming of standalone mode

1024 entry 10 bit motor sine commutation table

External (stop) switch or encoder N channel can be used for absolute position reference

Different start up modes for automatic commutation calibration

Page 5

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 5

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

3 Order codes

The RS232 and RS485 interfaces are assembly options of one and the same TMCM-170 printed circuit

board.

Cables are not included. Add the appropriate cable loom to your order if required.

Order code

Description

Dimensions [mm³]

PD4-170-57-E (-option)

PANdrive™ 0.32Nm

132 x 61 x 61 (without motor axis)

PD5-170-57-E (-option)

PANdrive™ 0.42Nm

152 x 61 x 61 (without motor axis)

TMCM-170 (-option)

BLDC servo module

61 x 61 x 28

Table 3.1: PANdrive™ or module order codes

Option

Host interface

-232

RS232 and CAN interface

-485

RS485 and CAN interface

Table 3.2: Options for order codes

Component parts

Description

TMCM-170-CABLE

Cable loom for module and PANdrive™.

Table 3.3: Order codes for component parts

Page 6

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 6

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

4 Electrical and mechanical description

4.1 Pinning

Connectors shown as top view

3

2

1

W

V

U

Motor / power supply

connector on bottom PCB

Hall

sensors

1.5mm

conn.

12345

+5V

GNDH1H2

H3

Inter-

face

5

4

3

2

1

RS485- / TXD

RS485+ / RXD

GND

CANL

CANH

Encoder

5

4

3

2

1

CHB

CHA

CHN/Null

GND

+5V

I/O

8

7

6

5

4

+5V

CUR LED

GND

OVT LED

DIRIN

3

2

1 AIN

N.C.

/STOP

21GND

VS

RS485 Term

CAN Term

Figure 4.1: Pinning

Pin

Function

AIN

Analog input: Can measure 0 - 10V signal.

DIRIN

5V TTL input. Not used in current firmware releases

/STOP

Reference Switch / Emergency stop. Tie this pin to GND to stop the motor or to clear

the position counter. Function / polarity depends on Software setting.

(5V TTL input with integrated 10K pull-up resistor to 5V)

OVT LED

5V TTL output: Toggling with 3Hz when temperature pre-warning threshold is

exceeded, high when module shut down due to overtemperature.

CUR LED

5V TTL output: High, when module goes into current limiting mode or into

overvoltage switch off. Toggling with 3Hz on undervoltage condition.

+5V

5V supply for motor hall sensors and as reference for external purpose

GND

Power GND / GND reference

GND is also connected to the mounting holes on the bottom PCB

RXD /

RS485+

RXD signal of module for RS232 communication (RS232 version)

Non-inverting RS485 signal (RS485 version)

TXD /

RS485-

TXD signal of module for RS232 communication (RS232 version)

Inverting RS485 signal (RS485 version)

CANH / CANL

CAN interface signals

U, V, W

BLDC motor coil outputs

CHN

Encoder null channel (optional use)

(5V TTL input with integrated pull-up resistor to 5V)

CHA, CHB

Incremental encoder channel A / channel B

(5V TTL input with integrated pull-up resistor to 5V)

H1, H2, H3

Hall sensor signals

(5V TTL input with integrated pull-up resistor to 5V)

VS

Positive power supply voltage (reverse polarity protected)

Other pins

Leave all other pins unconnected!

Table 4.1: Pinning

Page 7

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 7

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

I/O board

(top view)

1

2

3

4

5

Interface

1234567

8

I/O

1

2

3

4

5

Hall

sensors

12345

Encoder

Driver board

(top view)

Motor

U V W

Power

+

Interface

EncI/O

Hall

Motor Power

Important note: For the PANdrives™ PD-170, the motor coils, hall sensor signals and encoder signals

are already connected. Nevertheless, in order to connect power supply the upper interface board has

to be removed. Never connect or disconnect the boards while power is switched on!

4.2 Application circuit

The schematic shows a typical application circuit using CAN bus interface. Optionally the unit allows

connection of motor hall sensors and encoder N-channel as well as further digital / analog pins and

different interface options.

TMCM-170

Reference

Sw.

BLDC-

Motor

Encoder

Mech. Axis

GND

/STOP

GND

I/OInterface

CANL

CANH

System's

CAN bus

keep distance

short for CAN

110R

Termination

resistor at bus end

U

V

W

GND

Encoder

+5V

CHA

CHB

VS

GND

Place unit near

encoder / motor

4700µ,

63V

48V system

power

supply

optional overvoltage

suppressor:

high power zener /

zener transistor

circuit

+

-

optional

capacitor if > 2m

CHN

Figure 4.2: Application circuit

Page 8

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 8

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

4.3 Dimensions

Diameter 61mm, TMCM-170 height 28mm (16mm + highest part), mounting holes diameter is 2.8mm

Figure 4.3: Dimensions of TMCM-170 and PD-170

32,00

25,97

14,50

2

7

,

0

0

13,50

2

7

,

0

0

27,00

30,50

46,77

61,00

Top view of

Driver board

All values are in

millimeters

Gap pad

Metal plate

BLDC

Motor

Encoder

I/O-Board

Driver-Board

PD-170

132,00 (PD4) or 152,00 (PD5)

15,00

1,00

16,00

20,00

39,00

Page 9

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 9

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

4.4 Connectors

Hall sensor: JST1.5mm type: S5B-ZR-SM2-TF

Other interfaces: JST-PHR – 8 and JST PHR – 5 2.00 mm

4.5 PANdrive™ specifications

This chapter describes the additional components of the PD-170.

4.5.1 PANdrive™ motor

The PD-170 comes either with the QBL 5704-94-04-032 or QBL 5704-116-04-042 motor (ordering option).

For further information refer to the QBL 5704 motor manual, also.

Main characteristics:

Hall Effect Angle: 120° electric angle

Shaft run out: 0,025 mm

Insulation Class: B

Radial Play: 0,02 mm 450G load

Max Radial Force: 75N (10mm from flange)

Max Axial Force: 15N

Dielectric Strength: 500 VDC For One Minute

Insulation Resistance: 100M Ohm min. 500VDC

Recommended Ambient Temp.: -20 to +40°C

Bearing: Brushless motors fitted with ball bearings

Specifications

QBL 5704

-94-04-032

-116-04-042

No. of Pole

4 4

No. of Phase

3 3

Rated Voltage

V

36

36

Rated Phase Current

A

5.08

6.67

Rated Speed

RPM

4000

4000

Rated Torque

Nm

0.32

0.42

Max Peak Torque

Nm

0.98

1.3

Torque Constant

Nm/A

0.063

0.063

Line to Line Resistance

Ohm

0.45

0.35

Line to Line Inductance

mH

1.4

1

Max Peak Current

A

16.5

20.5

Lenth (L

MAX

)

mm

94

116

Rotor Inertia

kgm² x 10-6

17,3

23

Mass

kg 1 1,25

Related TRINAMIC PANdrive™

PD4-170-57

PD5-170-57

Table 4.2: Motor technical data

Page 10

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 10

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Adjustments for QBL5704-116-04-042

Switch the reverse hall sensor polarity on and the reverse encoder direction off. Use the basic control

and diagnostics software or TMCL-IDE.

Adjustments for QBL5704-94-04-032

Switch the reverse hall sensor polarity off and the reverse encoder direction on. Use the basic control

and diagnostics software or TMCL-IDE.

Figure 4.4: Motor dimensions

Page 11

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 11

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

5 Operational ratings

The operational ratings show the intended / the characteristic range for the values and should be

used as design values. An operation within the limiting values is possible, but shall not be used for

extended periods, because the unit life time may be shortened. In no case shall the limiting values be

exceeded.

Symbol

Parameter

Min

Typ

Max

Unit

VS

Power supply voltage for operation

12.5

14 - 48

52

V

V

SMAX

Maximum power supply voltage (for surge)

60

V

V

SLOOFF

Under voltage switch off trip point

9.5

10

10.5

V

V

SON

Under voltage switch on trip point

10.5

12

12.5

V

V

SOFF

Over voltage switch off trip point (Feature can be

switched off, then V

SMAX

limit applies)

52

55

58

V

VSD

Power supply voltage for module operation with motor

disabled

7 8 9.5

V

IS

Power supply current

0.04

(P

Motor

+3..10W)

/ VS

I

MOT

A

PID

Module idle power consumption without encoder / hall

sensor

2.4 W

V5

5 Volt (+-4%) output external load (encoder plus hall

sensors plus other load)

0 200

mA

IMC

Continuous Motor RMS current

(module surface at maximum 85°C)

10

A

IMP

Short time Motor current in acceleration periods

It is not recommended to set motor current above 12A!

14

A

I

MPP

Peak coil output current for 100ms

40

A

f

CHOP

Chopper frequency

20

kHz

T

SL

Motor output slope (U, V, W)

100 ns

VI

Logic input voltage on digital inputs, encoder and hall

sensor inputs

-0.3 VCC+

0.3

V

II

Pull-up resistor current for hall and encoder inputs

50

250

400

µA

VO

Logic output current on digital outputs (5V CMOS output)

10

mA

VIA

Analog input voltage

-24

0 – 10

24

V

EV

Exactness of voltage measurement

-5 +5

%

EC

Exactness of current measurement (the measured coil

current value might not correspond to the RMS current,

but is repeatable within the given exactness)

-10 +10

%

f

ENC

Encoder count rate (signals 50% duty cycle)

13.3

MHz

TO

Environment temperature operating

-25 +85

°C

T

board

Temperature of the bottom (driver) PCB, as measured by

the integrated sensor.

<105

115

°C

Table 5.1: Operational ratings

Page 12

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 12

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

5.1 Power supply requirements

The power supply should be designed in a way, that it supplies the nominal motor voltage at the

desired maximum motor power. In no case shall the supply value exceed the upper / lower voltage

limit. The BLDC motor unit uses a chopper principle, i.e. the power supply to the motor is pulsed at a

frequency of 20kHz. To ensure reliable operation of the unit, the power supply has to have a sufficient

output capacitor and the supply cables should have a low resistance, so that the chopper operation

does not lead to an increased power supply ripple directly at the unit. Power supply ripple due to the

chopper operation should be kept at a maximum of a few 100mV.

Therefore we recommend to

˗ keep power supply cables as short as possible

˗ use large diameter for power supply cables

˗ if the distance to the power supply is large (i.e. more than 2-3m), use a robust 4700µF or

larger additional filtering capacitor located near to the motor driver unit.

An effect the power supply has to cope with, is, that the motor can feed back substantial current into

the power supply whenever it is actively braked! While this generally is a positive effect (because it

saves energy), precautions have to be taken, to limit the supply voltage to within the operational

limits. The TMCM-170 contains an overvoltage protection circuit, which disables braking whenever the

upper supply voltage limit is exceeded. This automatic function may lead to an unwanted behavior,

i.e. overshooting the target position, and thus can be disabled. Disabling the overvoltage protection

should only be done, provided that the user takes additional precautions to limit the voltage:

It is recommended to use

a) a large capacitor on the power supply lines able to store substantial part of feed back energy

b) a zener / suppressor diode circuitry, limiting the power supply voltage to a maximum of 52-

60V

5.2 Bus interface

The TMCM-170 supports an optional CAN interface. It can be operated via CAN or RS232 / RS485 in the

same way. CAN bus and RS485 require a termination resistor at both ends of the cable (but not at

every unit). This resistor is integrated and can be activated on the TMCM-170 by shorting a soldering

bridge (dotted line in the connector drawing), but for most purposes it is more elegant to provide

this resistor external to the unit.

5.2.1 Terminating the RS485 network

For RS485 in addition to the termination resistor a termination network is required, which forces an

“inactive” level to the line, when no driver is on. Typically, use a 1K resistor to + 5V for RS485+ line

and a 1K resistor to GND for the RS485- line at some point of the network.

Page 13

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 13

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

6 Functional description

6.1 Setting the basic values for operation (using the

demonstration application)

The TMCM-170 can use nearly any BLDC motor and encoder type. However, care has to be taken to

correctly set the motor pole count (default: 8) and encoder resolution (default: 4096) and direction

(default: Encoder gives same direction as motor) before trying to operate the motor! Using a

PANdrive™ motor please refer to chapter 3.5.1. This motor comes normally with the encoder HEDS5640-A12, in this case the encoder resolution is 2000. Please note the TMCL-code in the appendix at

the end of this document.

If a hall sensor is used, please check if the hall sensor polarity is to be reversed (try operating the

motor in block commutation mode, first). Also choose a fitting initialization mode (2 is most

universal) and set the corresponding parameters (please see chapter on start up).

The motor behavior afterwards may still give unsatisfactory results: The next step is to tune the PID

parameters.

For these basic settings, the Windows based demonstration application can be used. It requires

connection to the RS232 interface or via an RS485 converter to the RS485 interface. For RS485, as a

first step use the TMCL-IDE to set the parameter “Telegram pause time” to a value of about 20. Further

basic settings are required for motor start up (see next chapter).

To avoid motor operation or damage before the unit is completely parameterized, use a supply

voltage of only 8V! This disables the motor.

6.2 Start-up for encoder based commutation

The TMCM-170 uses an incremental encoder for motor commutation. Incremental means, that the

encoder does not give an absolute position reference. Thus, the unit needs an internal start up

procedure, which determines the encoder position with respect to the actual pole motor orientation.

The TMCM-170 provides basically two modes for encoder initialization:

Mode 0 uses additional motor hall sensors for the start up phase. Therefore, the motor can not do a

precise positioning until it has done at least one electrical rotation. This can be perceived

by a somehow rough behavior on the first positioning run.

We recommend using this mode, when the motor has hall sensors and mode 1 does not

give reliable results.

However, the motor hall sensors typically are not as precise, as this would be desired for

sine commutation. To accomplish with the hall sensor error and hysteresis, you can set the

corresponding parameters “Init Sine Block Offset CW” and CCW.

Mode 1 drives the motor field into a known position and then evaluates the encoder position.

While this is a very precise scheme, it is susceptible to external force applied to the rotor:

The rotor is not to be blocked in any direction. Additionally external mechanical torque

applied to the axis should be kept low. To use this mode, it is important to set the “Sine

Initialization Current A” as high as possible (within the 14A limit). Default value is 11A. You

can set Sine Initialization Current B to a somewhat lower value (at least ½ of Current A) to

give optimum results. The best setting has do be determined for a given motor. To allow

for minimum motor movement upon initialization, this mode also checks the hall sensor

positions.

Mode 2 is the same as mode 1, but does not check if the motor has hall sensors.

Mode 3 is the most precise and reliable initialization mode: It uses the encoder N-channel for

initialization. To first find the N-channel reference position, the motor is turned by up to

one rotation, until the N-channel is found positive. The velocity and direction can be

specified using the parameter “Sine Init Velocity”. After finding the reference position, the

Page 14

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 14

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

“Actual Commutation Offset” gives the angular relationship between motor and encoder.

Therefore this parameter has to be stored correctly in EEPROM before power on! Do not

enable this mode, before the parameter has been set correctly. Mode 4 helps for the very

first initialization of this mode.

Mode 4 helps to do a first initialization and tuning of mode 3. It searches for the N-channel

reference point first, and then does a mode 2 initialization to determine the correct setting

for the “Actual Commutation Offset”. The encoder N-channel polarity has to be high active

for this mode (the actual setting of the encoder null polarity has no influence in this mode),

and, additionally, you have to specify the polarity of the encoder A- and B-channel upon N-

channel activity using the setting “Encoder Null Polarity”, bits 1 and 2. The correct setting of

this depends on the encoder. If the N-channel referencing fails, the motor does two full

rotations and then stops. Try again with reversing the “Encoder Null Polarity”. After

successfully initializing the “Actual Commutation Offset”, you can try moving the motor and

tune the offset, if desired. Then store the offset and switch to mode 3. If any encoder errors

are flagged during operation of the motor, retry with a modified setting for A- and Bchannel polarity.

Attention: Initialization modes 1 to 4 apply a high current to the motor for a few seconds. Be sure

to parameterize the initialization current correctly (i.e. not more than 2* the maximum

rated motor current) before first powering on the unit.

The quality of the initialization phase result can be checked by rotating the motor left and right at the

maximum velocity (use a velocity setting slightly higher than the motor can follow). Maximum velocity

for left and right direction shall not differ by more than a few percent. Also make some checks if

results are reproducible.

Whenever changing one of these parameters, re-power the unit to restart initialization phase!

6.3 Encoder setting

The N-channel (index channel) of the encoder is not required for motor operation, but it is very good

for motor initialization, because it gives an absolute and exact reference point. So, the motor

initialization modes 3 and 4 use the N-channel for motor initialization. Behavior of the N-channel

signal is very dependent on the encoder type and has to be taken into account for the setting of the

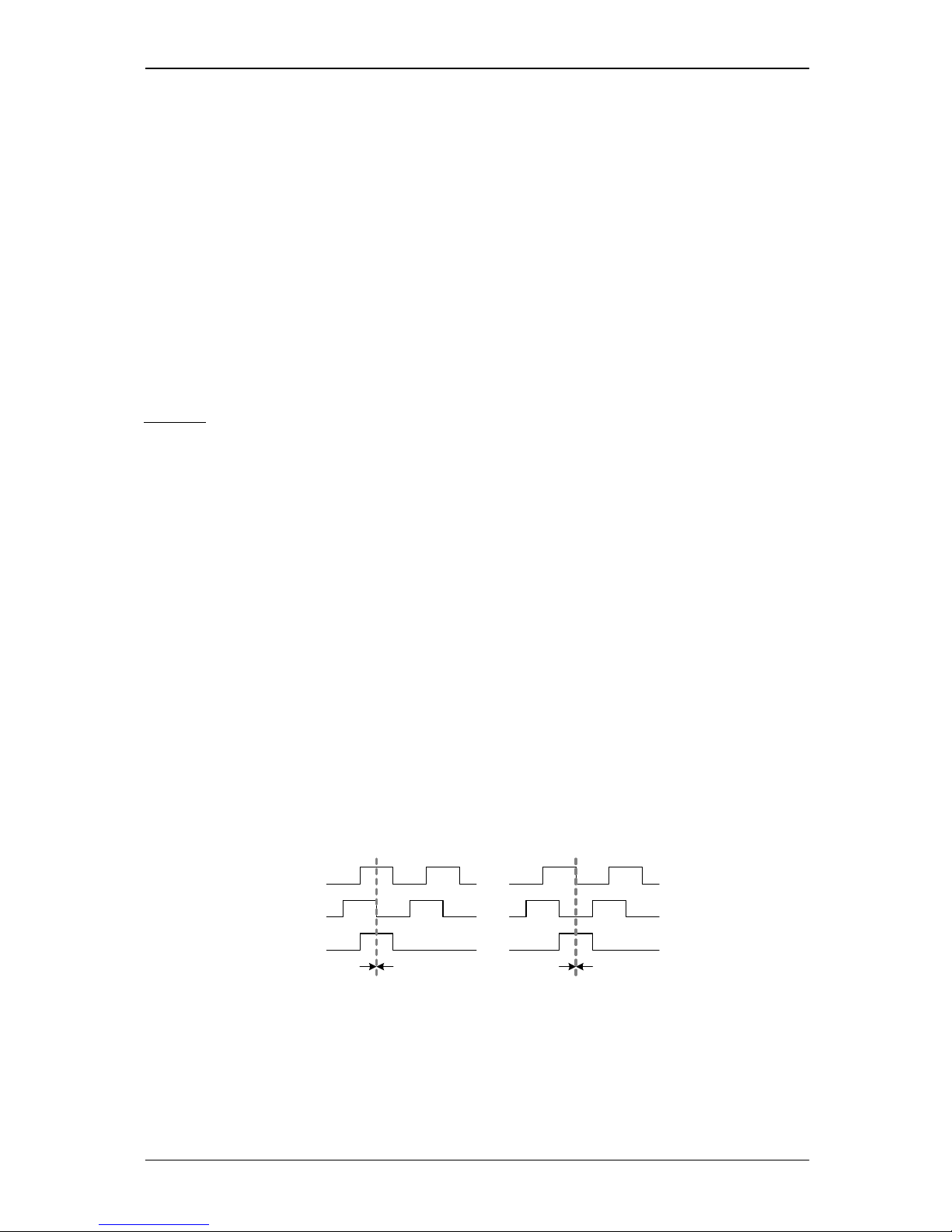

TMCM170 encoder interface. Please refer to the following figure for correct setting of the Encoder Null

Polarity flag.

A wrong setting may either hinder the module from initializing the sine mode, or might lead to the

Encoder Error flag being set, in spite of correct encoder function.

zero event

Enc-A

Enc-B

Enc-N

(index)

Set Encoder Null

Polarity to

binary 011

Set Encoder Null

Polarity to

binary 001

zero event

CW turn CCW turn CW turn CCW turn

0

1 0

0

Page 15

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 15

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

6.4 Hall sensor only operation w/o encoder

The module can be used without an encoder. In this case, set the encoder resolution parameter (SGP

250) to the hall sensor resolution, i.e. 3 times the number of motor poles. Example: For a 4 pole

motor set the encoder resolution to 12. To avoid oscillations in positioning mode, the algorithm in

this mode stops regulation, as soon as the target distance is below the setting as determined by

“MVP target reached distance”. Adapt this setting to your needs. Switch the module to hall sensor

based commutation permanently in order to skip encoder initialization procedure in this configuration.

Please be aware, that the hall sensor resolution is very low, when compared to an encoder, and thus,

the PID regulator parameterization values have to be set much higher than the default setting.

Without encoder, the velocity measurement is not available. You may want to set a lower value than

the default for the “PWM Hysteresis” setting to get a softer response upon target reaching.

6.5 Stop switch

For positioning applications, typically some kind of global initialization is required. This can either be

done via a central unit operating the motor via its bus interface, or a reference switch can be

connected to the stop input (pull down to 0V at reference point). The position counter can be

automatically cleared when this point is reached. Be careful not to apply a voltage different from GND

to this digital input!

6.6 General functions (explore using the Windows based

demo software)

The TMCM-170 module can either be remote controlled via the PC demonstration software or a user

specific program. The function of the standalone mode can be modified by the user by writing

initialization values to the on-board EEPROM, e.g. a maximum rotation velocity, motor current limit

and rotation direction.

For more detailed software information refer to the TMCM-170 Module – Reference and

Programming Manual.

6.7 Temperature, current and voltage monitoring functions

LED output

Action

Meaning

Current limit

Blink

The current limit LED blinks upon under voltage switch off

Current limit

On / Flicker

Motor PWM is reduced due to exceeding the set motor current limit

or overvoltage threshold is exceeded

Temperature

warning

Blink

The power stage on the module has exceeded a critical temperature

of 85°C. (Pre-warning)

Temperature

warning

On

The power stage on the module has exceeded a critical temperature

of 115°C. The motor becomes switched off, until temperature falls

below 105°C. The measurement is correct to about +/-10°C

Table 6.1: LED outputs

Page 16

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 16

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

6.8 Programmable motor current limit

The motor current limiting function is meant as a function for torque limiting, and for protection of

motor, power supply and mechanical load.

Whenever the pre-programmed motor current is exceeded in a chopper cycle, the TMCM-170 calculates

a reduced PWM value for the next chopper cycle. New values are calculated 1000 times a second. The

response time of the current regulation can be set using the parameter “current regulation loop

delay”:

A value of zero means, that in every 1kHz period, the current correction calculation is directly executed

and the resulting PWM value is taken. A higher current loop delay acts like a filter for the current. The

higher the value of the delay the slower is the current loop response time. A value of 10 (default)

leads to a current regulation response time of about 10 ms for an 1/e response. On the mechanical

side a higher value simulates a higher dynamic mass of the motor.

The actual current regulation time may differ depending on the PID settings.

Attention: Please be careful, when programming a high value into the current regulation loop delay

register: The motor current could reach a very high peak value upon mechanical blocking

of the motor. The same goes for the motor current limit value: do not set higher than

12A if you are not sure about this.

If the short time motor coil current is not limited to a maximum of about 40A, this could

destroy the unit.

There are a number of aspects when using the current limiting function:

The current measurement is done at a point of the chopper cycle, where just one coil is switched

on. When using sine commutation, the effective coil current is about 88% of the measured current

respectively of the current limit setting.

The current measurement cannot detect currents below about 200-300mA. If the current limit is

set to a too low value, the motor may operate spuriously or become continuously switched off.

The current limiting function is not meant as a protection against a hard short circuit.

The performance of the current limiting depends on the motor and on the commutation mode.

Especially in sine commutation mode, the measured current and thus current limiting may be

quite instable. The current limit should be programmed to a value high enough, in order to

achieve good positioning and acceleration performance.

Operation of the current limiter and the PID regulator may result in instable behavior, if the

motor gets into a resonance area. Try adapting the current regulation loop delay parameter.

If the motor is blocked and the ramp generator is not stopped, the motor will speed up and try

to catch up with the ramp generator position after removal of the blocking. To control this effect,

you can set the parameter Clear Target Distance in order to stop the ramp generator, when the

deviation between the positions becomes too large. The effect of this may look somehow weird

if the user does not expect it.

Page 17

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 17

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

7 Revision history

7.1 Document revision

Version

Comment

Author

Description

1.00

2005 – 2007

Dw

Initial Versions

1.05

05-09-2007

HC

Added Documentation Revision and PANdrive™ information

1.06

10-09-2007

GE

Update of dimensions and pictures

1.07

30-10-2007

HC

Encoder graphics added (chapter 6.3)

1.08

21-11-2007

HC

PANdrive™ encoder resolution info corrected to 2000 per

rotation

1.09

10-12-2007

MJ

Chapter v5.1 extended; Appendix with TMCL-code

1.10

2011-NOV-24

SD

New order codes, new front page, minor changes

Table 7.1: Document revision

7.2 Firmware revision

Version

Comment

Description

0.90

Initial Version

Attention: Use Documentation V0.90 or later for connector pinning!!!

0.92

First release

Added encoder N-channel initialization

0.93 Added encoder N-channel for automatic correction and encoder error

flag

0.94 Allows specifying of CHA and CHB polarity for nulling of encoder –

uses higher bits of Encoder Null Polarity

1.00

Release 1.0

Added operation mode with hall sensors only.

1.01 Corrected RS485 behavior

1.02 Added standalone mode feature

1.03 Fixed RS485 delay problem (master had to wait for timeout time before

sending new command), when multiple units share a bus

1.07

TMCL

Added TMCL™ standalone program capability, extended command set

for TMCL™. Up to 64 commands can be stored in EEPROM.

Table 7.2: Firmware revision

8 References

[TMCL]

TMCL™ Manual, www.trinamic.com

[TMCM –170]

Reference and Programming Manual, www.trinamic.com

QBL5704 Manual

QBL5704 BLDC servo motor manual, www.trinamic.com

HEDS-5640#A12 info

HEDS-5640#A12 encoder information http://www.avagotech.com

Page 18

PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 18

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

9 Appendix

// Initialization PANdrive PD4/PD5-170

// --> Start this initialization procedure, when the initialization

// parameters have been lost, e.g. due to Firmware upgrade <-// please see manual, if values have to be modified, e.g. due to power supply

// current limitation

// Set Parameter

MST 0

SGP 247, 0, 40 //Initialization Sinus Current A

SGP 248, 0, 35 //Initialization Sinus Current B

SGP 253, 0, 4 //Motor Pole = 4

SGP 254, 0, 0 //Hall Sensor Invert PD4

// SGP 254, 0, 1 //Hall Sensor Invert PD5

SGP 250, 0, 2000 //Encoder Steps per Rotation

SGP 252, 0, 1 //Reverse Encoder Null Polarity

SGP 251, 0, 1 //Reverse Encoder Direction PD4

// SGP 251, 0, 0 //Reverse Encoder Direction PD5

SGP 249, 0, 4 //Init Mode 4

SAP 159, 0, 1 //Commutation Mode 1 = Sinus / 0 = Block

SAP 160, 0, 1 //Start Initialization

SAP 4, 0, 3000 //max. Pos. Velocity

ROR 0, 0

A: GAP 160, 0 //Ready

COMP 1

JC NE, A

SAP 6, 0, 100 //Max. Current

SAP 11, 0, 2000 //Acceleration

SAP 146, 0, 1 //Use Velocity PID

// Store Parameter

STAP 6, 0 //Store Max Current

STAP 4, 0 //Store Max Pos. Velocity

STAP 165, 0 //Store Commutation Offset !

SGP 249, 0, 3 //Init Mode 3 ( N-Kanal )

STOP

Loading...

Loading...