Page 1

SIXpack 2

Manual

6-Axis stepper motor controller / driver module

1.4A RMS (2A peak) / 48V

with CAN, RS485 and RS232 interface

Manual Version: 1.01

May 5

th

, 2006

GmbH & Co KG

Sternstraße 67

D - 20357 Hamburg, Germany

Phone +49-40-51 48 06 - 0

FAX: +49-40-51 48 06 - 60

http://www.trinamic.com

Page 2

SIXpack 2 – manual (V1.01 / May 5th, 2006) 2

Table of Contents:

1 Life support policy.............................................................................................. 4

2 Introduction......................................................................................................... 5

2.1 Brief Description.......................................................................................................... 5

2.2 What do I have to know about my application ............................................................5

2.2.1 The SIXpack 2 does not support............................................................................ 5

2.3 Technical Data............................................................................................................ 6

3 System Start Up.................................................................................................. 7

3.1 System Start Up / Notes .............................................................................................7

3.2 Selecting Motors ......................................................................................................... 7

3.3 Length of Wires........................................................................................................... 7

3.4 Grounding ................................................................................................................... 7

3.5 Improvement of the EMC-Conduction......................................................................... 7

3.6 Further Information: ....................................................................................................7

4 Replacing QUADpack or SIXpack...................................................................... 8

4.1 DIP-switch marking comments ................................................................................... 8

4.2 SIXpack compatible setting......................................................................................... 8

4.3 QUADpack compatible setting.................................................................................... 8

5 Fundamental Functions – First Steps............................................................... 9

5.1 Security Advise ........................................................................................................... 9

5.2 Basic Device Settings ................................................................................................. 9

5.2.1 SIXpack 2 Address................................................................................................. 9

5.2.2 Option RS232/RS485............................................................................................. 9

5.2.3 Baudrate of serial interface ..................................................................................10

5.2.4 Termination of CAN/RS485.................................................................................. 10

5.2.5 Seven-segment display ........................................................................................ 10

5.2.6 Driver enable ........................................................................................................ 10

5.2.7 Adjusting the maximum current............................................................................ 11

5.2.8 Adjusting chopper mode....................................................................................... 12

5.3 Connections.............................................................................................................. 12

5.3.1 Current supply...................................................................................................... 12

5.3.2 Serial interface .....................................................................................................12

5.3.3 Motor connectors.................................................................................................. 12

5.3.4 Connector specifications ...................................................................................... 13

5.4 Start-up with software SQPack ................................................................................. 14

5.4.1 Installation ............................................................................................................ 14

5.4.2 Initiation................................................................................................................ 14

5.4.3 Functional test: Get system information of SIXpack 2.......................................... 14

5.4.4 “First steps”: Movement of motor ......................................................................... 14

5.4.5 Concept of SIXpack 2 interface protocol.............................................................. 14

5.4.6 Macro functions of SQPack.................................................................................. 15

5.5 Operation with reference/ending points .................................................................... 15

5.5.1 Types of reference point definitions .....................................................................16

5.5.2 Hardware installation............................................................................................ 16

5.5.3 Reference search software configuration............................................................. 17

5.6 Basic configurations for operation............................................................................. 18

5.6.1 Adjusting motor current ........................................................................................ 18

5.6.2 Configuration of acceleration and velocity............................................................ 19

5.6.3 Motion control....................................................................................................... 19

6 Full Functionality.............................................................................................. 20

6.1 Inputs and Outputs.................................................................................................... 20

6.1.1 RS232 or RS485 interface ...................................................................................20

6.1.2 CAN interface ....................................................................................................... 20

6.1.3 Ready output ........................................................................................................ 20

6.1.4 Multifunctional connector “RS232” ....................................................................... 20

6.1.5 RS 232-Remote Control via CAN-Interface.......................................................... 21

6.2 Programming ............................................................................................................22

Page 3

SIXpack 2 – manual (V1.01 / May 5th, 2006) 3

6.2.1

Hints for Programming ......................................................................................... 22

6.2.2 Examples.............................................................................................................. 24

6.3 Adjusting SIXpack 2 to motors micro step characteristics ........................................ 27

6.3.1 Calculation of micro step frequency ..................................................................... 27

6.3.2 Adapting the microstep-table to the motor characteristics ................................... 28

6.4 Reference point adjustments .................................................................................... 28

6.4.1 Coordinate plane of an axis.................................................................................. 28

6.4.2 Reference point / reference switch....................................................................... 28

6.4.3 Moving zero-point................................................................................................. 28

6.4.4 Automatic reference search .................................................................................29

6.4.5 Adjusting activity zone of reference switch........................................................... 29

6.4.6 Compensation of reference switch delay .............................................................29

6.4.7 Elimination of glitches........................................................................................... 29

6.4.8 Adjusting reference search velocity...................................................................... 29

6.4.9 Aborting reference search.................................................................................... 29

6.5 End switch configurations ......................................................................................... 30

6.5.1 A_ln as end switch input....................................................................................... 30

6.5.2 Combination of end and reference switches ........................................................ 30

6.5.3 “Security Margin” for combined end/reference switch .......................................... 30

6.6 Commands for axis movements ............................................................................... 31

6.6.1 Basic ramp run ..................................................................................................... 31

6.6.2 Start of constant rotation ...................................................................................... 31

6.6.3 Change target position for ramp run..................................................................... 31

6.6.4 Starting different motors synchronous.................................................................. 31

6.6.5 Starting linear interpolation of multiple axis.......................................................... 32

6.6.6 Configuration for rotating movements .................................................................. 32

6.7 Control of motor current............................................................................................ 33

6.8 Default values ........................................................................................................... 34

7 Instruction Set................................................................................................... 35

7.1 Setting motor parameters .........................................................................................35

7.2 Driving Ramps ..........................................................................................................39

7.3 Additional Inputs / Outputs........................................................................................ 42

7.4 Other Settings........................................................................................................... 43

7.5 Multi-dimensional Movement .................................................................................... 44

7.6 Service-Functions ..................................................................................................... 44

8 Instruction table................................................................................................ 47

9 Test Reports...................................................................................................... 48

Page 4

SIXpack 2 – manual (V1.01 / May 5th, 2006) 4

1 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life support

systems, without the specific written consent of TRINAMIC

Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or

sustain life, and whose failure to perform, when properly

used in accordance with instructions provided, can be

reasonably expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2005

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is assumed

for the consequences of its use nor for any infringement of

patents or other rights of third parties, which may result form

its use.

Specifications subject to change without notice.

Page 5

SIXpack 2 – manual (V1.01 / May 5th, 2006) 5

2 Introduction

2.1 Brief Description

The SIXpack 2 is a highly integrated stepper motor controller for six 2-phase stepper motors with a coil

current of up to 2000 mA each. It is the fully compatible advancement of the QUADpack and SIXpack

with enhanced ratings and functions.

The SIXpack 2 comes in a rugged box package with tested electromagnetic compatibility. It is easy to

use and the ideal solution for stepper motor control in an industrial environment.

A DSP supported by special hardware allows a powerful function set and a wide stepping frequency

range for all motors. The SIXpack 2 is equipped with RS 232, RS 485 and CAN-Interface.

2.2 What do I have to know about my application

Before the SIXpack 2 is set up the demands of the application to the stepper motors should be clearly

defined.

What are the right motors? The SIXpack 2 supports 2-phase stepper motors. The peak motor power is

defined by the modules supply voltage and the coil current of the driver ICs (max. 2000mA).

The actual motor position is not known after power on. Thus a reference search has to be made in order

to find the absolute position. Most applications use switches or photo interrupters to detect the reference

position. In some applications a mechanical limit point without any detector switch is appropriate. The

SIXpack 2 does not support encoders.

To control the SIXpack 2 there are different interfaces (RS232, RS485, CAN). It is not relevant to the

SIXpack 2 if it is controlled by a desktop-PC, another machine operating unit or a set up with

microcontroller. A stand alone operation is not possible.

2.2.1 The SIXpack 2 does not support

Stand alone operation: The SIXpack 2 can not operate without initialization and control by a host

connected to one of its serial interfaces.

Closed loop operation: The SIXpack 2 has no encoder interface and there is no other possibility for

nominal/actual value comparison for motor position. It is possible to

compare the internal position counter with the status of the reference

switch. If an invalid value is detected an automatic reference search can be

started automatically.

External output stages: There is no possibility to connect external power stages to the SIXpack 2 to

increase the maximum motor rating above 2A / 48V.

Page 6

SIXpack 2 – manual (V1.01 / May 5th, 2006) 6

2.3 Technical Data

ramp profile: automatic 3-phase ramps (32 Bit signed position resolution) with

programmable parameters for maximum frequency and acceleration for

each channel; alternatively user defined ramps; automatic reference search

(reference switch)

stepping frequency: full step frequencies from 0.3 Hz 12.5 kHz

step type: microstepping resolution 1/16 with user-programmable motor

characteristics or sine-table

current control: programmable acceleration-dependent motor current; programmable stand-

by timer for current reduction

interfaces: RS 232 or RS 485; CAN

protocols: 9 byte control, barcode-reader interface via RS 232 in CAN-mode possible

I/O-lines: 10 bit analogue input for ratiometric measurements or stop functions; digital

input for reference switch; separate analogue input; digital I/O and digital

output; LED-„Interface active“; 7-segment display (number of active motors,

Decimal point indicates reference search); 1 Ready Output (Open

Collector)

power supply: 15 to 48 V DC (absolute max. 58V)

max. ca. 12A, depending on motor type

motor current SIXpack: software configurable ca. 100 - 2000 mA per channel (peak coil current);

constant current (chopper, ca. 36 kHz), motor driver thermally protected

motor type: bipolar 2-phase motors

motor connectors: 8-pin single-in-line (motor, reference switch, A/D, 5V supply (15 mA))

temperature range: up to 85°C with reduced current or forced cooling of board

dimensions: board: W: 126, D: 180, H: 25 mm; housing: W: 152, D: 180, H: 36 mm

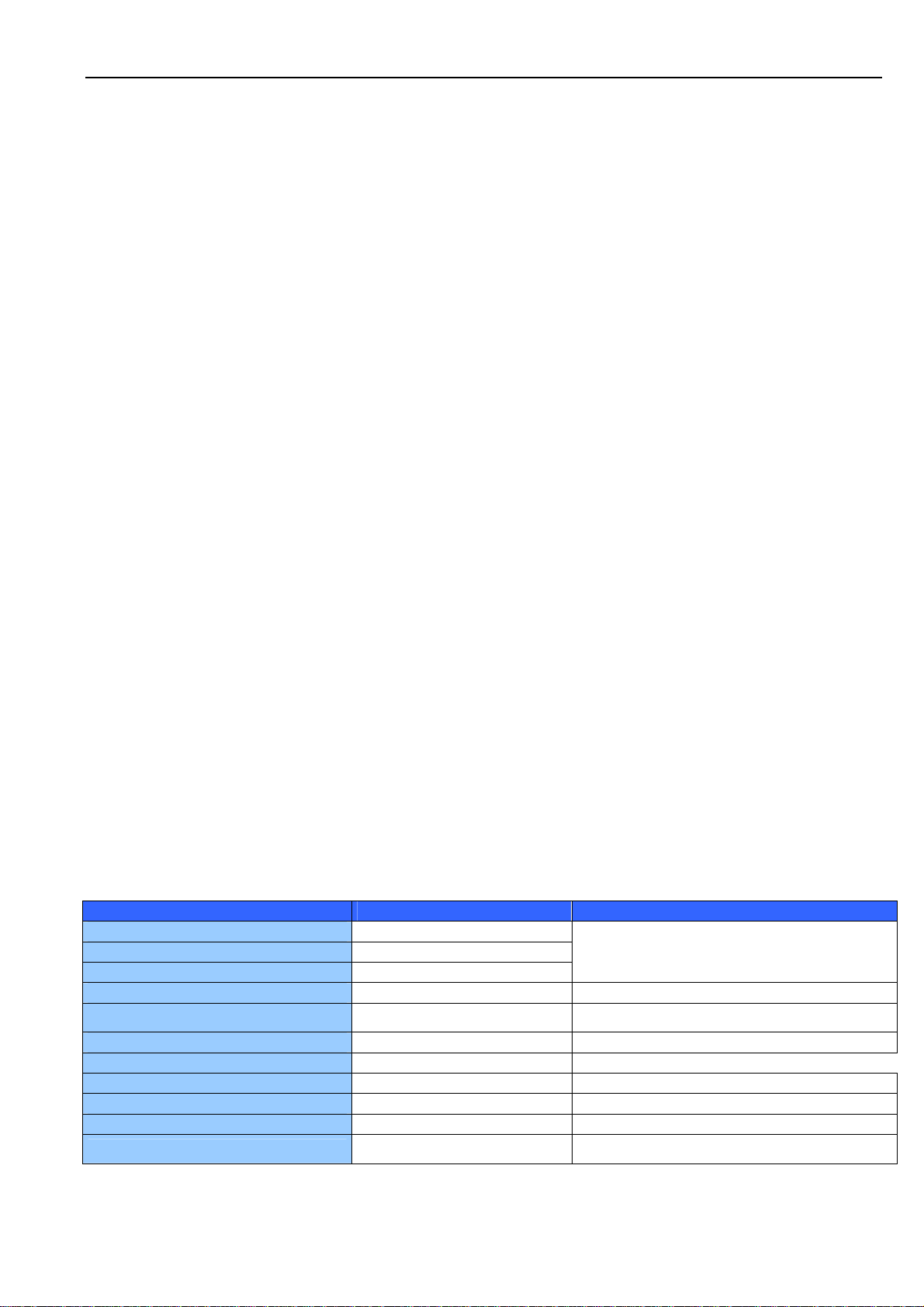

Feature SIXpack 2 data Advantages of new feature

Supply voltage (nominal)

Supply voltage (maximum limit)

Motor current

Numbers of motors

Chopper scheme

Motor drivers

Software

Control LEDs

Reset button

Protection

Hot plugging / emergency off

15 .. 48 VDC

10 .. 58 VDC

Software setting 0.2A to 1.4A RMS

6

Slow Decay / Mixed Decay

TMC239A-LA Very low power dissipation and high reliability

Fully compatible to SIX/QUADpack

Data, Reset, +5V

Yes

Varistor protection for all motors Life plug protection up to some degree

Additional motor off-jumper

High motor dynamics / higher torque

(up to 3x compared to SIXpack)

Reduced motor resonances at medium velocities and

improved microstep exactness when using Mixed Decay

Not visible by software – connect to TTLIO1 if software

readout is desired

Page 7

SIXpack 2 – manual (V1.01 / May 5th, 2006) 7

3 System Start Up

3.1 System Start Up / Notes

When the SIXpack 2 is supplied with power it runs an internal initialization and a self-test of the internal

processor-system starts. If executed successfully a “0“ appears in the LED-display after a second. The

SIXpack 2 is operational now and can receive user commands.

Defective motor drivers can not be detected by the self test. Should the motor turn on and off during

operation, a constant high motor current or insufficient cooling of the drivers could be the problem. The

motor driver chip turns itself off for a short time when overheated. This condition should not occur in a

normal operation condition. If the SIXpack 2 reports a board temperature above or near 85°C, a forced

air cooling or other means to reduce heat dissipation, like reduction of stand by motor current is

proposed to ensure a long product life time.

When an application requires detection of temporarily interrupted power supply of the SIXpack 2, this

can be done for example by signaling via external TTLOUT1 by programming it to a negative level. It will

return to a high level after a reset. The RS 232-interface usually receives a 0-byte after hardware reset.

3.2 Selecting Motors

When selecting motors, consider stepper motors with the lowest inductance possible, i.e. low coil

resistance, to obtain smoothest movements and the maximum possible RPM. On the other hand low coil

resistance increases the required motor current. Therefore you should choose the motor with the lowest

inductance possible which delivers the required torque at a coil current of approx. 1000 to 1400 mA.

Highest possible operating voltage of the SIXpack 2 results in high RPM also. With higher coil resistance

or a too low operating voltage the duty factor of the chopper drivers increases. When exceeding 50% a

chirping noise can occur in the coils.

3.3 Length of Wires

motor wires: typically < 3m (use twisted pair wire)

RS 232: typically < 3m

CAN, RS485: can be > 30m

3.4 Grounding

For a good ESD protection the electronics must be connected effectively with ground. Therefore two

holes are provided on the PCB with ground contacts.

If the electronics is delivered without housing, these two screws must be connected to ground.

If the electronics are built-in in the housing the protection tape must be taken away of the two fixing

drilled holes on the back side. The electronics must now be grounded via these two blank areas.

3.5 Improvement of the EMC-Conduction

To improve the cable-bound conducted emission, a ferrite-clip should be clipped over the supply circuit.

3.6 Further Information:

For further information please view our homepage (www.trinamic.com). You will find help under

“frequently asked questions”. You also have the possibility to send us an e-mail via a contact sheet

located on the same site.

Page 8

SIXpack 2 – manual (V1.01 / May 5th, 2006) 8

4 Replacing QUADpack or SIXpack

The SIXpack 2 is fully compatible to the QUADpack and SIXpack. Adaptation is provided by DIPswitches.

4.1 DIP-switch marking comments

Mx_I0, Mx_I1: Inputs for motor current setting. The index x specifies the motor number

2A_135: Enable of 2A motor current for motor 1, 3 and 5.

2A_246: Enable of 2A motor current for motor 2, 4 and 6.

MD_135: Disable of mixed decay for motor 1, 3 and 5.

MD_246: Disable of mixed decay for motor 2, 4 and 6.

4.2 SIXpack compatible setting

Mx_I0

Mx_I1

2A_135

2A_246

MD_135

MD_246

ON OFF

Motor current: 0.8 A

Chopper

scheme:

"Slow decay"

To use "mixed decay" for all motors switch 'MD_135' and

'MD_246' off.

4.3 QUADpack compatible setting

Mx_I0

Mx_I1

2A_135

2A_246

MD_135

MD_246

Mx_I0

Mx_I1

2A_135

2A_246

MD_135

MD_246

Mx_I0

Mx_I1

2A_135

2A_246

MD_135

MD_246

ON OFF

ON OFF

ON OFF

Motor current: 0.5 A

Chopper

scheme:

Motor current: 1.0 A

Chopper

scheme:

Motor current: 1.5 A

Chopper

scheme:

"Slow decay"

To use "mixed decay" for all motors switch 'MD_135' and

'MD_246' off.

"Slow decay"

To use "mixed decay" for all motors switch 'MD_135' and

'MD_246' off.

"Slow decay"

To use "mixed decay" for all motors switch 'MD_135' and

'MD_246' off.

Page 9

SIXpack 2 – manual (V1.01 / May 5th, 2006) 9

5 Fundamental Functions – First Steps

This part of the documentation describes the use of SIXpack 2 via an example with limited functionality.

For additional functionality please refer to next chapter. In addition to the required steps in hardware set

up you should take into the operation the delivered Windows

5.1 Security Advise

To avoid damage to the SIXpack 2 please be aware that:

• Wrong connector pin assignment may destroy the SIXpack 2. Be extremely accurate at the

installation and when confectioning cables.

• Disconnecting the Motor while operational may destroy the SIXpack 2. Disable the motor current

by pulling the jumper, or better power down the device before connecting / disconnecting motors.

5.2 Basic Device Settings

5.2.1 SIXpack 2 Address

Before the SIXpack 2 is put into operation some adjustments of the device have to be checked,

eminently the address of the serial interface. It is set via the CANHI and CANLO switches and should be

set to zero by default. Refer to Figure 5.1.

RS232-Connector:

2: RXD

3: TXD

5: GND

7: RTS

8: CTS

CAN-Connector:

2: CANL

6: GND

7: CANH

CAN-TERM

6 7

21

12

8 9

54

3

9

8

A

7

6

5

4

3

F

2

0

1

CANLO CANHI

B

C

D

E

SIXpack 2

9 8 7 6

12345

9

8

A

7

B

6

C

5

D

4

E

3

F

2

0

1

123 12

34

12

TM

-Software.

6 5 4 3 2 1 2 11 2

READY:

1: GND

2: OUT

(open collector,

100mA, 35V)

RS485:

1: GND

2: RS485+

3: RS485 4: GND

5: RS485+

6: RS485-

POWER:

1: GND

2: Vcc(+15,40V, 7A)

CAN-Adress setting

Baudrate setting

1-2: JP2

3-4: JP1

RS232/RS485-

Selector

Seven-Segment

Display

RS485-Term.

100 OHM

Figure 5.1: Jumper and connectors

5.2.2 Option RS232/RS485

The SIXpack 2 shall be controlled with RS232 interface. The jumper RS232/RS485 has to be at RS232

(Refer Figure 5.1).

The use of RS485 is described in chapter 6.1.1.

Page 10

SIXpack 2 – manual (V1.01 / May 5th, 2006) 10

5.2.3 Baudrate of serial interface

The baud rate of the serial interface is set via jumper JP1 and JP2 (refer Figure 5.1).

JP1 JP2 Baud rate RS232/RS485 Baud rate CAN

X X 9600 1 Mbit/s (*)

- X 57600 500 kbit/s (*)

X - 38400 125 kbit/s (*)

- - 19200 250 kbit/s (default)(*)

Table 5.1: Adjustment of baudrate with jumpers

(*): The SIXpack 2 has an internal buffer for 16 CAN commands which need about 2ms execution time

each. This might limit the maximum data throughput.

The command GetInputValues (SQPack-Tab I/O, $30) provides the actual jumper configuration in the

variable AllInputs.

Bit 6 = Jumper1, Bit 7 = Jumper2

The baud rate for RS232/485 can be modified by software also. This setting is not stored permanently.

In order to get the actual jumper-configurations send CMD $30.

5.2.4 Termination of CAN/RS485

Each interface can be terminated by setting the jumpers “TERM CAN” and “TERM RS485” (refer Figure

5.1).

5.2.5 Seven-segment display

The seven segment display shows the number of active motors. With an appropriate power supply a “0”

is shown at start. The decimal point indicates that a reference search at any motor is accomplished.

If a malfunction occurs the display shows “8”, “C” or “F”. Try to restart the SIXpack 2.

5.2.6 Driver enable

The jumper “Driver enable” (close to the motor connectors) enables (jumper set) or disables (jumper

open) the drivers for all motors. If the drivers are disabled, i.e.. jumper open, it is safe to disconnect the

motors while power on and retain the actual settings of the SIXpack 2.

Hint: It is possible to use a switch to enable/disable the drivers.

Driver enable

Multifunctional

"RS232"

DIP-switches:

1: M2 I 1

2: M2 I 0

3: M1 I 1

4: M1 I 0

5: MD246

6: MD135

7: 2A_246

8: 2A_135

1

910

12

2

3

78

4

56

5

34

6

7

12

8

SIXpack 2

Motor connectors

Figure 5.2: Driver enable, DIP switches and motor connectors

1

2

3

4

5

6

7

8

DIP-switches:

1: M6 I 1

2: M6 I 0

3: M5 I 1

4: M5 I 0

5: M4 I 1

6: M4 I 0

7: M3 I 1

8: M3 I 0

Page 11

SIXpack 2 – manual (V1.01 / May 5th, 2006) 11

r

r

r

r

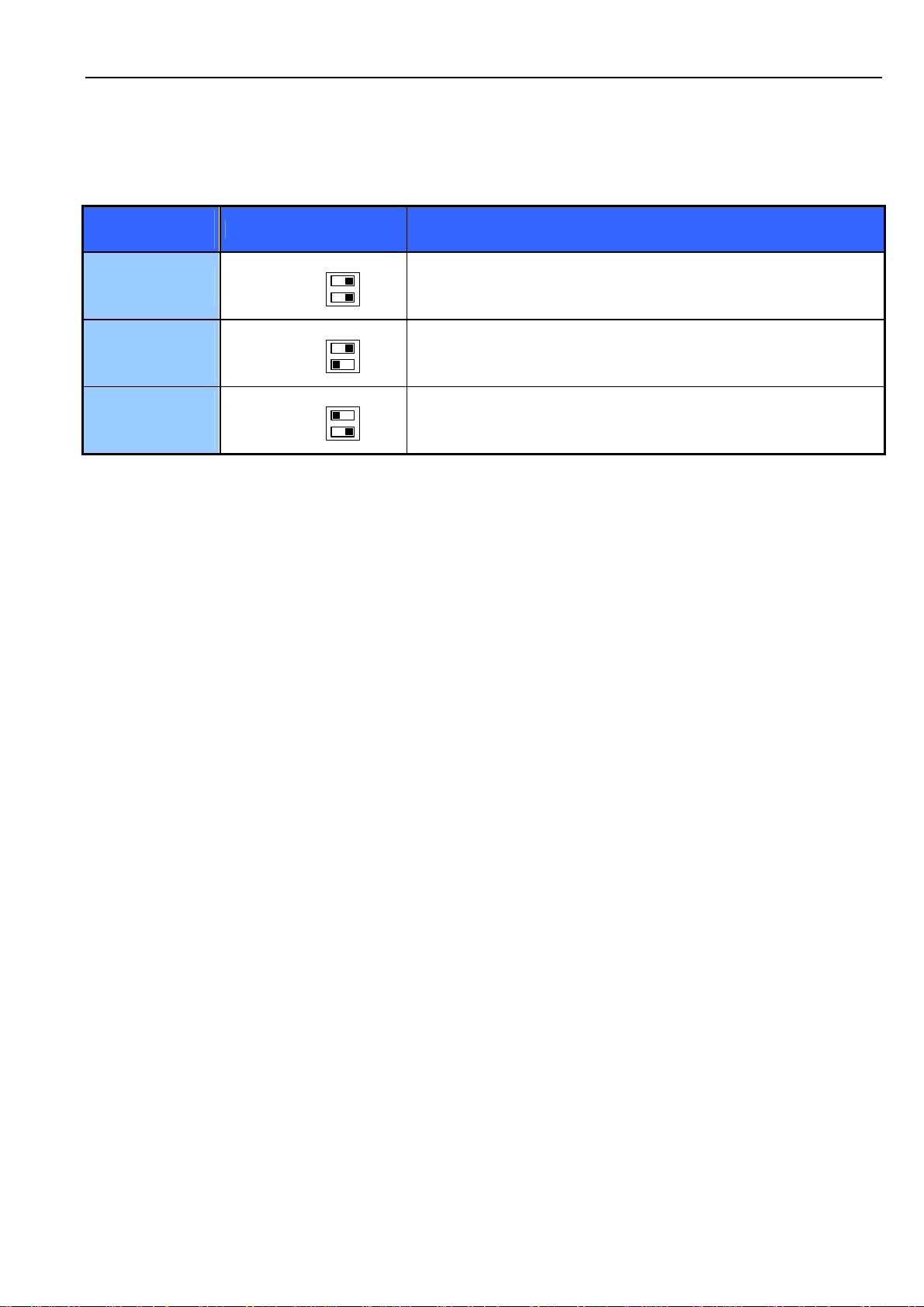

5.2.7 Adjusting the maximum current

The maximum current of the SIXpack 2 can be set via DIP-switches. The switches are close to the motor

connectors. The former QUADpack and SIXpack had different maximum currents. With the appropriate

DIP-switch configuration they are fully compatible.

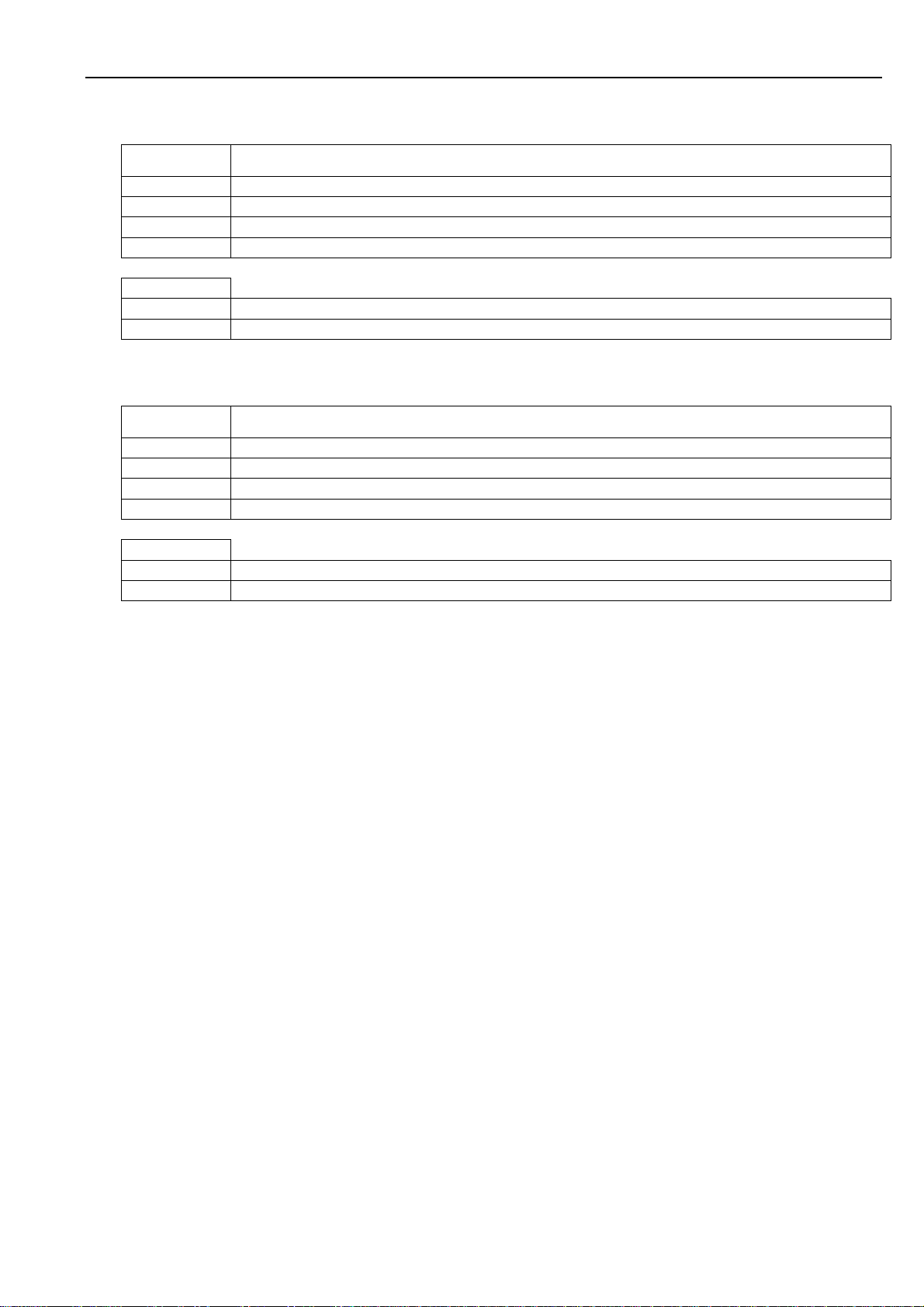

Current DIP-switch position description

ON OFF

0.5 A

0.8 A

1.0 A

1.5 A

2.0 A

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

Mx_I0

Mx_I1

2A_135

2A_246

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

ON OFF

Current setting for each motor (index x specifies the moto

number)

Current setting for each motor (index x specifies the moto

number)

Current setting for each motor (index x specifies the moto

number)

Current setting for each motor (index x specifies the moto

number)

2.0 A maximum current for all motors

2.0 A maximum current for motor 1, 3 and 5.

Current setting for motor 2, 4 and 6 via 'Mx_I0' and 'Mx_I1'.

2.0 A maximum current for motor 2, 4 and 6.

Current setting for motor 1, 3 and 5 via 'Mx_I0' and 'Mx_I1'.

Table 5.2: Adjusting maximum current

Page 12

SIXpack 2 – manual (V1.01 / May 5th, 2006) 12

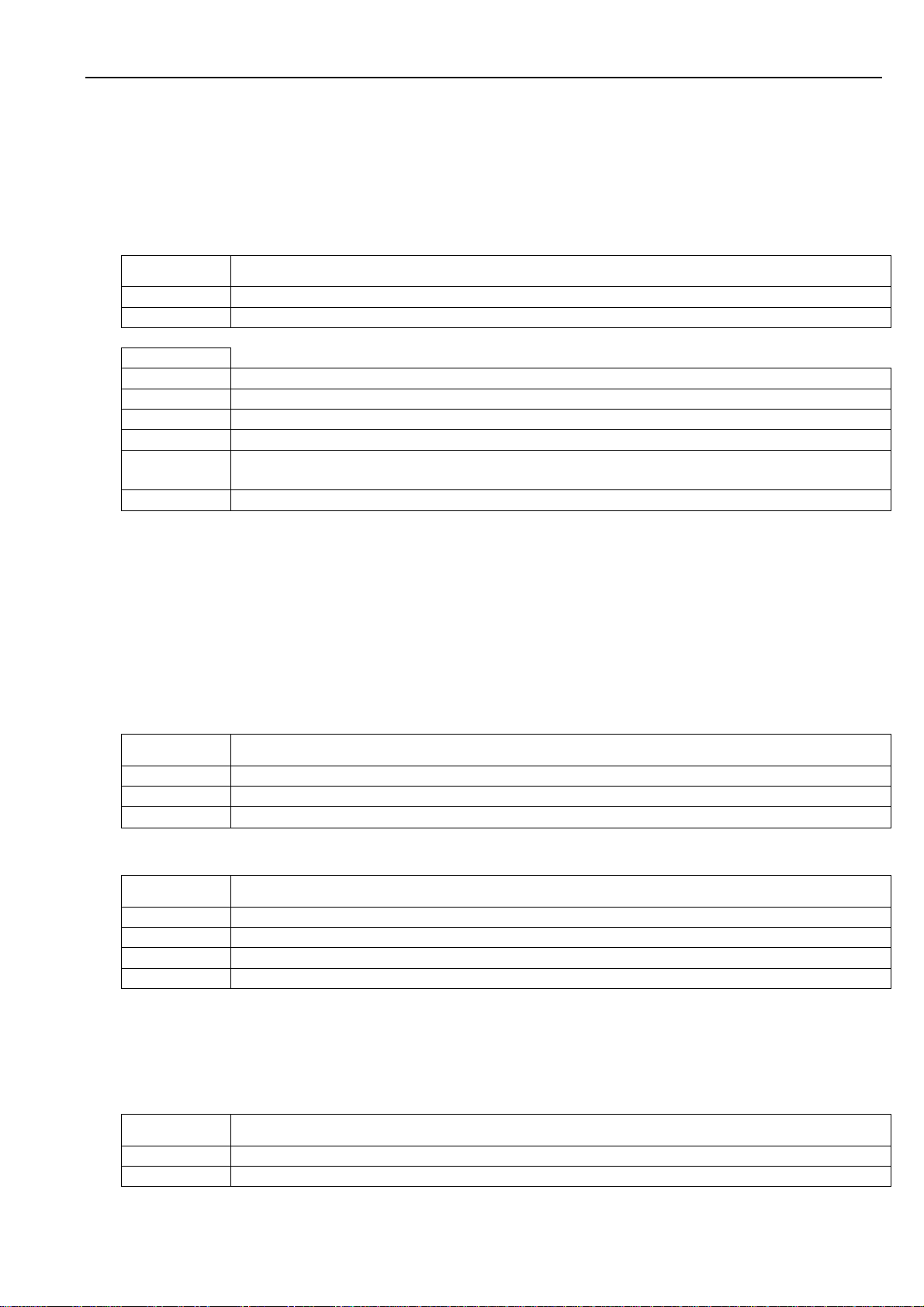

5.2.8 Adjusting chopper mode

The SIXpack 2 supports “Mixed Decay” which provides reduced motor resonance at medium velocities

and improved microstep exactness. This mode can be switched off by the DIP-switches if desired.

Chopper

Scheme

Mixed decay

(all motors)

DIP-switch position description

MD_135

MD_246

ON OFF

Mixed decay for all motors

Mixed decay

(motor 1, 3 and

5)

Mixed decay

(motor 2, 4 and

6)

MD_135

MD_246

MD_135

MD_246

ON OFF

Mixed decay for motor 1, 3 and 5

ON OFF

Mixed decay for motor 2, 4 and 6

Table 5.3: Adjusting chopper mode

5.3 Connections

Initial operation of the SIXpack 2 is possible after installing current supply and serial interface.

5.3.1 Current supply

Any power supply unit with an output voltage of 15-48V may be used. The required current is conform to

the usage and quantity of motors. The connector is labeled POWER. Be aware that the polarity is correct

and make sure that your supply voltage never exceeds the absolute maximum rating.

With an appropriate current supply the LEDs “+5V” and “+24V” light up and the 7-segment-display shows

zero. If the display shows “8”, “C” or “F”, or the unit resets continuously, an internal defect has been

detected. When continuous resets occur, the Flash memory could be erased. You can try to swap flash

with an other device.

5.3.2 Serial interface

The RS232 interface is connected via a null modem cable with one serial interface of the PC.

5.3.3 Motor connectors

CAUTION: Connecting or disconnecting while power on may damage the motor drivers

of the SIXpack 2.

The function “Driver enable” (refer to 5.2.6) provides the possibility to disconnect motors while the

modules power is on. Thereby all actual settings are retained.

The motors are connected with the 8 pin connectors. The pinning of the connectors are as follows:

Page 13

SIXpack 2 – manual (V1.01 / May 5th, 2006) 13

A_ln(analog input 0...5V)

Refln (reference input, 10k

intern pullup resistor, 5V level,

2.5V threshold with hysteresis)

Vcc (5V, 15mA, 33 Ohm)

Ground (for A_ln, Refln)

Phase B, Connector 2

Phase B, Connector 1

Phase A, Connector 2

SIXpack 2

Phase A, Connector 1

Figure 5.3: Pinning of motor connector

For fundamental functions the pin connections for the motor phases are important. Connect the motor

coils indicated in Figure 5.4 with the connector of the pack.

PHB2

M

PHB1

PHA2

PHA1

SIXpack 2

Figure 5.4: Connecting motor coils

5.3.4 Connector specifications

Motor connector: Producer: AMP Connectors (www.amp.com)

Item number: 0-0770602-8 (case)

0-0770666-1 (crimp contacts)

0-0058517-1 (crimping tool)

Power supply/RS485: Producer: Weidmüller (www.weidmueller.com)

Item number: 1716320000 (2-pole, VDC, Ready)

1716360000 (6-pole, RS485)

Page 14

SIXpack 2 – manual (V1.01 / May 5th, 2006) 14

5.4 Start-up with software SQPack

After adjusting the necessary hardware of the SIXpack 2 the first function tests with the WindowsTM

program SQPack can be done.

5.4.1 Installation

The installation of the program SQPack is accomplished by copying the file “SQPack.exe” to any location

on your PCs hard disc. At first start the file “SQPack.ini” is created to save actual settings. To reset the

settings of the software simply remove this file.

5.4.2 Initiation

To initiate the program double click “SQPack.exe”. A window with nine tabs is opened. In front is the tab

“Connection”. To establish a connection to the SIXpack 2 choose the correct COM-Port. The other

settings should be at necessary values.

2. step:

1. step:

choose

COM port

SIXpack II adress

(see Hex switches)

3. step:

establish connection

Figure 5.5: Setup of SQPack

5.4.3 Functional test: Get system information of SIXpack 2

To check the connection the command GetUnitInformation is useful. Choose the tab “Others” and

activate in box “Commands” the line “$43: Get Unit Information”. If the connection settings are done

correctly it is possible to click the button “Send” at the bottom of the window to transfer the command to

the SIXpack 2. If a connection is established the values for “Firmware Revision”, “Reset Flag”,

“Temperature” and “S/N” are displayed in the box “Parameters”.

5.4.4 “First steps”: Movement of motor

The significant advantage of stepper motors is to turn to a specific position. The motor is accelerated by

the SIXpack 2 to an assigned velocity and decelerated in time to reach the specified position.

Therefore choose on the tab “Movement” the command “Ramp”. The variable “Position” represents the

exact target position. By clicking the “Send” button the motor turns to the specified position.

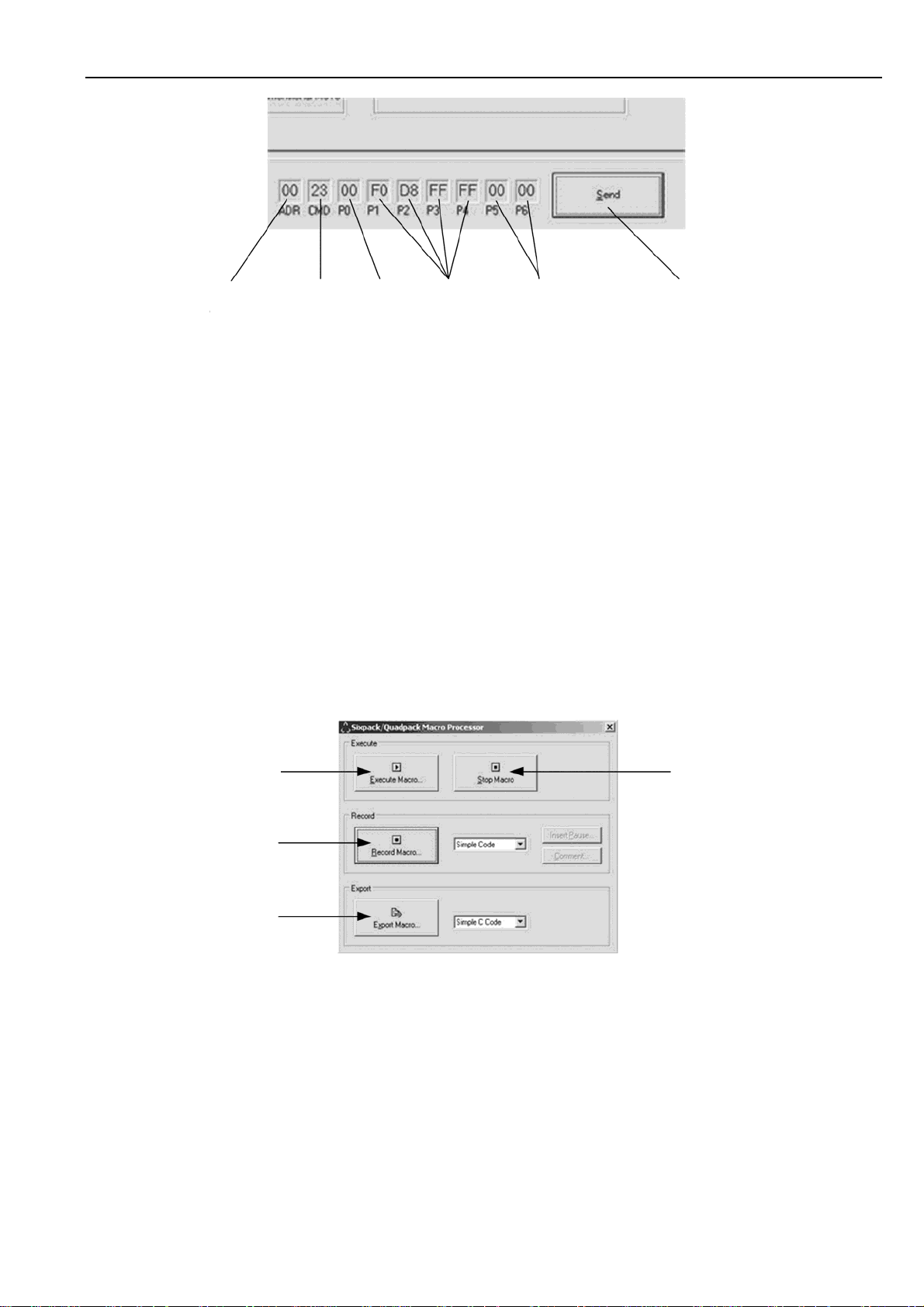

5.4.5 Concept of SIXpack 2 interface protocol

The SIXpack 2 is controlled by frames of 9 byte generally. The software SQPack displays this frames in

the lower part of the window next to the “Send” button. The nine bytes are shown hexadecimal.

At start it is easiest to create the frames by software and add these eventually to an own program.

Page 15

SIXpack 2 – manual (V1.01 / May 5th, 2006) 15

SIXpack II

adress

Command

$23

motor

number

variable

position

not assigned for

this command

Button to send

datagrams

Figure 5.6: Command frames of “SQPack”

5.4.6 Macro functions of SQPack

At the tab “Connection” the software provides the function “Macro Processor Window” to store command

sequences to a file. This file can be opened by an ASCII-Editor and the command sequence is formatted

as follows:

SendToPack ( adr, cmd, p0, p1, p2, p3, p4, p5, p6 )

“SendToPack” stands for the function which sends nine bytes to the SIXpack 2 via the serial interface.

The parameters are hexadecimal.

A Macro is generated by clicking the button “Record Macro” on the tab “Macro Processing Window“. A

dialog box is opened to name the file in which the macro is saved. Afterwards any commands can be

saved to the file until the recording is ended by clicking “EndRecording”.

CAUTION: Some commands are excepted at stopped motor only. According to this refer to the

command description.

open and

execute

stored macro

record

macro

export

macro as

source code

stop macro

execution

Figure 5.7: Macro function of SQPack

5.5 Operation with reference/ending points

Most applications with stepper motors need a reference point to acquire the actual position of the motor.

The reference point of each axis is detected by the SIXpack 2 with a reference search. The positions

scaling determined by type of the application. It is a linear axis if the motor moves a mechanic with

defined end and start point. Every point on the axis is assigned to a position between start and end point.

If there is no end or start point it is a rotating axis. The position values for the axis are defined for one

rotation. The value starts at zero again after full revolution.

Page 16

SIXpack 2 – manual (V1.01 / May 5th, 2006) 16

5.5.1 Types of reference point definitions

The SIXpack 2 provides two completely different types to define the reference point:

• Mechanical stopper for reference point (linear axis only)

At start point or end point a stopper for the mechanic of the axis is build in. At reference search

the SIXpack 2 moves the respective axis in direction of the stopper (defined by the flag

MT_NULLLEFT, SQPack-tab: “Reference search”, CMD $15) for a distance of Poslimit * 5/4.

The multiplication with 5/4 causes the SIXpack 2 to reach the stopper before end of the reference

search. The motor is mechanically stopped, reference point is reached.

• Electrical reference point

At any point of the positioning scale of the axis an electrical switch is implemented which is

activated by the passing motor. The SIXpack 2 catches this for reference point.

A reference switch attached one end of a linear axis can be used as end switch. At activation of

the switch the motor stops.

5.5.2 Hardware installation

5.5.2.1 Connection of electrical reference switch

The reference switch is connected to the pins „Ref_In“ and „GND“. Optionally a series resistance of

about 2.2kOhms can be inserted to match EMC demands. In general using an opener, i.e. a normally

closed switch is advisable. So broken cables can be detected. The reference input is equipped with a

Schmitt-trigger.

Ref_in

opener switch

2k2 Resistor

(optional)

GND

SIXpack 2

Figure 5.8: Connecting reference switch

5.5.2.2 Wiring with stop-switches

To prevent driving beyond the ends of a linear axis stop-switches can be used. They are connected to

pin „A_In“ of the motor connector. Again, openers should be used as stop-switches for the reason

mentioned above.

Page 17

SIXpack 2 – manual (V1.01 / May 5th, 2006) 17

A_ln

Stop_L Stop_R

SIXpack 2

2k2

optional

5V

GND

2k2

optional

Figure 5.9: Connecting two end switches

5.5.2.3 Wiring with combined Stop-/Reference Switch when using Openers

Mounting the reference switch at one of the ends of the axis it can be concurrently used as stop-switch

thus saving the respective stop-switch.

A_ln

optional

2k2

Stop_R

optional

2k2

Ref. switch

optional

2k2

5V

SIXpack 2

GND

Figure 5.10: Combination of reference and end switches

: In this circuit the reference switch is concurrently used as left stop switch if flag StopNull is set.

Note

The flag NullPositive has to be set, to match the opener. Reference search is done in left direction (flag

NullLeft set).. Refer to CMD $15.

5.5.3 Reference search software configuration

Most settings for the reference search are adjusted with the command SetMotorParameters (CMD $15,

SQPack-tab: “Reference search”).

5.5.3.1 Calculation of value range

The positioning is defined by the motors count of micro steps. The pack has 16 micro steps per full step

which angular is defined by the motor standards. Please check the motors datasheet for details.

Calculation of the value range of a linear axis is easiest experimental. Therefore set the axis mechanics

manually to the start position and move it with use of SQPack to the end of the axis. Use the command

“Ramp” (CMD $23, SQPack-tab: “Movement”) and set value of Position higher until the end of the axis is

reached. Position represents now the length of the axis.

Page 18

SIXpack 2 – manual (V1.01 / May 5th, 2006) 18

5.5.3.2 Linear Axis, mechanical reference point

Important parameters for configurations are:

• variable Poslimit,

• Flag MT_NULLLEFT,

• Flag MT_MECHREF.

The value range of the axis is specified in Poslimit. The SIXpack 2 evaluates with this value the length

of the reference search (5/4 * Poslimit). MT_NULLLEFT defines the direction of the reference stopper.

It is on the left side of the axis for NullLeft = 1.

For Poslimit = 10000 the produced dataset by SQPack is:

SendToPack($00, $15, $00, $10, $27, $00, $00, $10, $04).

The reference search is started with command StartReferenceSearch (CMD $23), from the SQPack-tab

“Reference Search”. The dataset is as follows:

SendToPack($00, $22, $00, $00, $00, $00, $00, $00, $00).

5.5.3.3 Linear Axis, reference switch at beginning of axis

The hardware configuration described above is the starting point. For the basic configuration only the

variables Poslimit, MT_NULLLEFT and MT_NULLPOSITIVE are relevant. MT_NULLLEFT and

MT_NULLPOSITIVE are set to 1. The resulting dataset evaluated by SQPack for an axis of the length of

Poslimit = 33333 is:

SendToPack($00, $15, $00, $20, $A1, $07, $00, $10, $40).

Start of reference search as described in 5.5.3.3.

5.5.3.4 Linear axis, combined end/reference switch left, end switch right

Starting point is the same. Additionally to Poslimit, the Flags MT_NULLLEFT and MT_STOPNULL

have to be set. The resulting dataset for Poslimit = 500000 is:

SendToPack($00, $15, $00, $20, $A1, $07, $00, $50, $40).

Start of reference search as described in 5.5.3.3.

5.6 Basic configurations for operation

5.6.1 Adjusting motor current

Additionally to the possibility to adjust the maximum motor current manually by the DIP switches (refer to

5.2.7) there are different ways to adjust the motor current to the demands of the system with the

software.

The maximum current for the motors has to be determined. You can find it in the motors datasheet.

Commonly the producer provides the current for a full step. This means for the SIXpack 2 that a current

of 1.4 times the peak current is possible. The command PeakCurrent (CMD $10, SQPack-tab „Current“)

configures the maximum current.

CAUTION: The maximum current is always compound for two motors. The current counts for motor n

and also for motor n+1 !!!

Additionally to the motor number a value, functioning as divider for the maximum current of the

SIXpack 2 is transmitted. Value range is 0…255.

Page 19

SIXpack 2 – manual (V1.01 / May 5th, 2006) 19

divider = (maximum current*256) / (2000mA * DIP switches)

5.6.2 Configuration of acceleration and velocity

The exact and calculation and configuration of micro steps and the description of parameters concerning

calculation of micro steps follow in “6 Full Functionality”. In this chapter the detection and configuration of

maximum acceleration and velocity is described, only.

5.6.2.1 Configuration of initial velocity

CAUTION: This value may be changed at motor standstill, only !!!

The initial velocity characterizes velocity at start of motion ramp. Value range is 1…256. The command

StartVelocity (CMD $13, SQPack-Tab „Velocity & Acceleration“) configures the initial velocity in the

variable VStart.

Attention: This command changes the two other values VMin and ClkDiv, also. These functions are

explained in the Instruction Set. The default values VMin = 5 and Div = 2 are sufficient here.

Example dataset: VStart = 100, VMin = 5, Div = 2 for Motor 3:

SendToPack($00, $13, $02, $0A, $00, $0A, $00, $02, $00)

5.6.2.2 Acceleration and maximum velocity

Acceleration and maximum velocity are related closely. Starting from VStart a velocity with fixed

frequency is raised by AMax until VMax is reached. A detailed instruction is provided in the Instruction

Set.

Both values are set with command SetAMaxVMax (CMD $14, SQPack-Tab „Velocity & Acceleration“).

AMax has to be ranged from 1 to (VStart*64), VMax from 1 to 511.

Example dataset: AMax = 200, VMax = 400 for Motor 4:

SendToPack($00, $14, $03, $C8, $00, $90, $01, $00, $00).

5.6.3 Motion control

Divers commands for the movement of the axis are combined in chapter 6.6 “Commands for axis

movements”.

Page 20

SIXpack 2 – manual (V1.01 / May 5th, 2006) 20

6 Full Functionality

6.1 Inputs and Outputs

6.1.1 RS232 or RS485 interface

The RS 485 interface is a bi-directional 2-wire interface and can handle up to 255 slave devices in halfduplex mode. The RS 232 interface can be used accordingly, however it is not possible to connect

multiple transmitters to the receiver input. The baud-rate is pre-configured to 19200 baud. It can be

changed via command.

Instructions consist of a 9 byte word, which in turn consist of the address of the unit, a command byte

and if required parameters with a length of up to 7 bytes.

Address command P0 P1 P2 P3 P4 P5 P6

The command word always has to be completely transmitted during a parameterized timeout

(s. CMD $41). It will be aborted and not interpreted, when a break-code is received. If errors occur the

interface can be newly synchronized via break-code.

The address of the unit can be set via rotary switches (scanned on reset).

During parameter read out an instruction will be transmitted only after an adjustable transmitter switchover time (s. CMD $40; pre-set to 6ms) has passed. This allows the transmitter to switch to receiving

mode. Ditto for the opposite direction: The PACK continues to drive the line for a pre-set time after

transmitting a message. The direction can be checked at the RTS-line of the RS 232-interface (negative

= SIXpack 2 is in sending mode). The CTS-line will be ignored.

When a valid command word is received, the status LED flashes.

6.1.2 CAN interface

The integrated CAN-Controller supports the full-CAN-specifications 2.0A with 11 address bits. Telegrams

with a fixed length of 8 bytes are used. The address of the unit (upper 8 address bits) can be set via

rotary switches (scanned on reset). The lower 3 address bits are fixed to “000“. Take care: According to

the CAN standard 0 is no valid address! Address range: $008 to $7F8 (in increments of 8).

After receiving the first valid instruction via CAN, control via RS 232 or RS 485 will be terminated. The

CAN response address is transferred to SIXpack 2 in a 8 bit format, like at RS 232 / 485. For responding

the address is shifted to the left by 3 bits, resulting in the same address range as defined above. If

continuous error conditions occur, CAN and RS 232 / 485 will be newly initialized.

For a table to configure the Baudrate refer to 5.2.3.

6.1.3 Ready output

The Ready output can be activated (low, open collector, with pullup to 4.3V internally), whenever a motor

is active (velocity above 0) or at reference search. The ready output will be switched within 2ms after

start/end of motor action. The repeatability (Jitter) matches approximately the micro step rate at start or

stop (see command SetVMinVStart, CMD $13, SQPack-Tab „Velocity & Acceleration”).

6.1.4 Multifunctional connector “RS232”

The 10 pin connector “RS232” next to the motor connectors offers divers inputs and outputs for

additional functions of the SIXpack 2.

Page 21

SIXpack 2 – manual (V1.01 / May 5th, 2006) 21

SIXpack 2

1 2

3 4

5 6

7 8

9 10

1: RXD

2: TXD

3: CTS

4: RTS

5: GND

6: GND

7: Analog In (0..5V)

8:TTLOUT1(270 Ohm)

9:TTLIO1 (270 Ohm)

10: 5V (120mA)

Figure 6.1: Pinning of multifunctional connector “RS232”

Pin Use Description

1, 2, 3, 4

connected directly to the

sub-D-connector of the

RS232 interface

electrically identical with the interface at the sub-D connector and

can not operate independent

5, 6 ground

7 analog input (0..5V) value readout with command GetInputValues (CMD $30)

TTL levels, internal resistor 270Ω. Value readout with command

8 digital output (TTL)

SetOutputs (CMD $32) in variable TTLOUT1. Function “Ready

output” is activated if TTLOUT1_READY is set.

TTl levels, internal resistor 270Ω. Command SetOutputs

(CMD $32) :

9 digital I/O port (TTL)

TTLIO_INPUT = 0: Output, set with variable TTLIO1

TTLIO_INPUT = 1: Input, value readout with variable TTLIO1 of

GetInputValues (CMD $30).

10 output, max 5V, 120 mA

Table 6.1: Pin description of multifunctional connector “RS232”

6.1.5 RS 232-Remote Control via CAN-Interface

The RS 232-interface can be controlled via CAN. Therefore the baud-rate is set via command “RS 232change baud-rate“. Only 8 bit, 1 stop bit and no parity is possible. Of course 7 bit and parity could be

simulated by the user. The response address for bytes received via RS 232 and the packet size for

transferring received bytes are configured by a separate instruction.

To forward bytes received via CAN to RS 232, the CAN-address of the PACK is incremented by 1, i.e.

the lower 3 bits are “001“. Every byte which is received with this address will be transferred to the

RS 232-interface. 1 to 8 bytes can be transferred at once. Please note that the RS 232-interface needs

sufficient time before the next block is transmitted. To be sure that the RS 232-cache is empty, it can be

checked via command. There is no CTS-handshake, however the CTS-line can be read-out

(s. CMD $44).

Bytes received via RS 232 will be sent to the pre-set response address, as soon as the pre-set number

of bytes has been received. Incorrect messages will be ignored now. If the configurable RS 232-timeout

has expired, remaining bytes will be sent (→ see CMD $41).

Page 22

SIXpack 2 – manual (V1.01 / May 5th, 2006) 22

6.2 Programming

The concept programming the SIXpack 2 is based on dataset of a fixed length. To allow networks the

datasets have to contain the SIXpack 2 address.

The commands dataset itself contains a command byte and seven bytes to transfer parameters. The

bytes have to be transmitted even if they contain no data.

Figure 6.2: Command dataset

6.2.1 Hints for Programming

6.2.1.1 Strategy for Parameter Setting

The Pack can be parameterized for standard applications with a few commands since it is pre-set with

default values. However these default values should not substitute a thorough configuration of all

parameters in a given application. Normally the following parameters should be configured for your

application:

6.2.1.2 Setting of Motor Current

Configure maximum current (s. CMD $10) and current control (s. CMD $11) as needed. The minimum

current (which provides proper microstepping) selected by current control is 19% (Index 6) for every

parameter.

6.2.1.3 Velocity Configuration (global)

Calculate clkdiv (s. CMD $12, SQPack-Tab “Velocity & Acceleration”) with the step frequency formula (s.

begin of chapter Instruction Set) so that the required maximum step velocity is achieved with v

and small values div

= 0 or 1.

i

= 511

i

6.2.1.4 Setting of starting Velocity, max. Velocity and max. Acceleration

These values (s. CMD $13 and $14) should be adapted to the motor type, mechanical load, and so on.

As a reference value div

should be set so, that the maximum velocity vmax could be set between 256

i

and 511. This way maximum resolution is obtainable. Then the acceleration amax can be configured.

The velocity vstart should not be set too low.

6.2.1.5 Setting of Motor Parameters and Reference Search Parameters

These settings describe the axis type, the reference search, and so on. For time saving purposes both,

fast reference search FastRef (s. CMD $15 P6, Bit1) should be activated and the maximum velocity for

this reference search should be set. To avoid errors caused by vibrations of the motor during fast

reference search, de-bouncing of the reference switch FilterSwitch (s. CMD $15 P5, Bit7) should be

activated, too, and the mask for reference point de-bouncing (s. CMD $16) should be programmed with

an applicable value. vmin (always used with predivider div

the reference switch. The fastest possible vmin will be choosen automatically when its value is set to 0.

set to 3) will be used while exactly locating

i

Page 23

SIXpack 2 – manual (V1.01 / May 5th, 2006) 23

Stop

Left

null position

testnullrange

Reference

null point-offset

reference point

motor

traveller

poslimit

positive

direction

StopR

Stop

Right

Graphic assumes null-left Flag is set and null point offset is positive(s.

In this configuration the reference switch is reliably closed at position null.

Note: testnullrange >= width of reference switch!

settings: null point-offset, poslimit -> CMD $15

testnullrange -> CMD $18

CMD $15

).

• The reference switch defines the zero position. The zero position can be moved further into the

switch using the nulloffset setting. If testnullbit is set it must be active at the end of T0 and the

delay time of the filter.

• Activation of the switch is only allowed in the testnullrange to testnull around the zero position. If

you reference to the edge of the switch and never exceed the zero position the testnull range can

be choosen around 1-2 fullsteps * 16. In all other cases you must choose it at least slightly larger

than the active area of the reference switch or half of this for nullcenter motors.

• The reference search requires proper poslimit (0..0x7FFFFFFF) settings! For cyclic axis you must

set poslimit to the number of microsteps per revolution, for linear axis it should cover at least your

whole intended driving range to avoid unintended or interrupted reference drives.

6.2.1.6 Problems with fast Search for Reference

The fast search for reference will function properly only if CMD $15 and $16 are set correctly, especially

those for the reference switch. Also is it sensitive to noise pulses in the wiring of the reference switch –

should the fast reference search stop abruptly, anti-noise measures have to be taken for the reference

switch input.

6.2.1.7 Interlacing of Requests

Requests must not be interlaced. Each request should wait for the response of the SIXpack 2 before

transmitting a new command. However a delayed response with RS 232 may be outstanding in parallel.

6.2.1.8 Default Values

For testing purposes here is a list of default values for motor parameters:

clkdiv=5; div=2; // 26 kHz microstep-frequency

vstart=5; // starting with 254 Hz (should be >=8)

amax=128; vmax=511; // increments v by 128/16=8 each 2 ms

vmin=4; vrefmax=100; // 102 Hz / 5086 Hz for reference drive

poslimit=400*16; // 400 full- = 6400 microsteps/revolution

testnullrange=15*16; // ignore switch in range –240 ... 240

Peak current=128; // define 100% curr. control as 400 mA

T0=500; // wait 1000 ms before standby

I0=00%(!); // waste no energy for unused motors

I1=50%; // power stopped motors with 200 mA

I2=75%; // power v const. motors with 300 mA

Page 24

SIXpack 2 – manual (V1.01 / May 5th, 2006) 24

I3=100%; // power accelerat. motors with 400 mA

motortype= Delayedtest0 | NullCenter | Filterswitch | FastRef;

De-bounce mask=$0FFF; // Filter delay 12-1 cycles = 22 ms

Readymask=$3F; // check any active motor

Refer.-Readymask=$3F; // check any referencing motor

propdiv=8; // v = position-difference / 8

intdiv=129; // v += pos-difference integral / 129

intclip=129; // clip pos-difference integrals > 129

intinpclip=1; // integrate pos-difference of max. 1

All other values are set to 0, i.e. the functions are disabled.

6.2.2 Examples

Attention:

command and waits for the missing bytes.

$ indicates that the value is in hexadecimal notation!

All 9 Bytes must be sent to the interface, otherwise the SIXpack 2 does not recognize the

6.2.2.1 Setting motor parameters

CMD $15 contains information about the motor and settings for the reference drive.

For more details see Hints for Programming and CMD $15 in the Instruction set!

Bit 7

P

0

0

0

0

0

MotorNr.1

Pseudocode:

SendToPack(address); // Address of the Pack(Sixpack2)

SendToPack($15); // Command in hexadecimal notation

SendToPack(P0); // Motor number (0...5)

SendToPack(P1); // poslimit LSB

SendToPack(P2);

SendToPack(P3);

SendToPack(P4); // poslimit MSB

SendToPack(P5); // further settings, for more information read the instruction set

SendToPack(P6);

=

0

0

0

(0...5)

Bit 0

0

0

1

0

0

LSB

( = 90 hex

= 144 dez)

0

0

0

0

1

,

,

3

P

P

P

1

,

P

2

0

0

0

3rdSB 2rdSB

( = 1 hex

= 1 dez )

4

1

0

0

0

0

(

=

0

0

4

0

0

0

0

)

!

s

t

r

i

f

L

B

S

0

0

0

0

-> poslimit = 00000190 hex ( = 400 decimal)

NOTE: P5, Bit1=0 -> linear motor -> poslimit=whole intended driving range

0

0

2

=

P

5

MSB

0

1

1

StopNull

FilterSwitch

0

1

0

TestNull

0

0

+ 64

+128

0

0

0

0

0

0

0

0

200

( = C8 hex )

P6 = 90

0 1 0 1 1 0 1 0

8

DelayTestNull

StopSoft

NullPositive

FastRef

+ 8

+16

+64

90

( = 5A hex )

2

Page 25

SIXpack 2 – manual (V1.01 / May 5th, 2006) 25

6.2.2.2 Navigating the motor

CMD $23 prompts the concerned motor to drive to the position, which stands in P1 ... P4.

Pseudocode:

sendToPack(address); // Address of the SIXpack2

sendToPack($23); // Command for starting a trapezoidal Ramp

sendToPack(motno); // Number of the concerned motor (0...5)

sendToPack(destinationLSB); // Least significant Byte of the target position

sendToPack(destination3rdSB);

sendToPack(destination2ndSB);

sendToPack(destinationMSB); // Most significant Byte

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

6.2.2.3 Inquiring the actual position of a motor

CMD $20 returns the 4-byte value with the actual position and status of the concerned motor. In addition

P6 specifies whether a stop-switch was active. This is e.g. when the motor has lost steps and if during

driving back to the real null-point the switch is found too early.

Pseudocode:

sendToPack(address); // Address of the SIXpack

sendToPack($20); // Command for inquiring actual position and action of one motor

sendToPack(motno); // Number of the concerned motor (0...5)

sendToPack(receiver); // address of the receiver

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

cmd = receiveFromPack(); // should be $20

motno = receiveFromPack(); // should be the same number as the sent

posakt_byte1 = receiveFromPack(); // LSB of the actual Position

posakt_byte2 = receiveFromPack();

posakt_byte3 = receiveFromPack();

posakt_byte4 = receiveFromPack(); // MSB of the actual Position

act_action = receiveFromPack(); // Information about the actual action of the motor

stop = receiveFromPack(); // is 1 when null-switch is active

Page 26

SIXpack 2 – manual (V1.01 / May 5th, 2006) 26

6.2.2.4 Starting a two axis interpolated movement

Linear motions with multiple axes can be driven. For this, the destinations have to be set via CMD $26

and then the trapezoidal Ramp can be started via CMD $50. In the example the axis 1 is navigated to

position 10000 and in parallel the axis 2 to position 2000.

Pseudocode:

sendToPack(address); // Address of the Sixpack2

sendToPack(0$26); // Command for setting the destination

sendToPack(0); // Motor 1

sendToPack($E8); // 232

sendToPack($03); // 3*256=768

sendToPack($00);

sendToPack($00);

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(address); // Address of the Sixpack2

sendToPack($26); // Command for setting the destination

sendToPack(1); // Motor 2

sendToPack($D0); // 208

sendToPack($07); // 7*256=1792

sendToPack($00);

sendToPack($00);

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(address); // Address of the SIXpack2

sendToPack($50); // Command for multi-axis Interpolation

sendToPack($03); // 0000 0011=3, e.g. Mask for motor 1 and 2

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

sendToPack(0); // fill 9 bytes

Page 27

SIXpack 2 – manual (V1.01 / May 5th, 2006) 27

6.3 Adjusting SIXpack 2 to motors micro step characteristics

6.3.1 Calculation of micro step frequency

The SIXpack 2 operates with a fixed micro step frequency of 16 micro steps every full step. The

programming positions are specified in micro steps in relation to zero. Following formula calculates the

given motors micro steps for a whole rotation:

Number of micro steps / rotation = 360° / Full step angle * 16

The full step angle is specified in the motors datasheet.

The absolute micro step frequency, the number of steps per second, in relation of the motors actual

velocity settings is described with following formula:

f

f

stepmicro

−

=

clkdiv

clk

v

⋅

i

+

1

• Full step frequency = 1/16micro step frequency

• f

is 20MHz

clk

• Clkdiv (ClockDivider, $12, SQPack-Tab “Velocity & Acceleration”) is the same for all motors

(value range 0…31)

respectively vakt is the velocity of each motor (range: –511..+511)

• v

i

• div

(Div, SQPack-Tab “Velocity & Acceleration”) can be parameterized for each motor (range

i

0…3)

Note: The micro step frequency must not exceed 200 kHz.

div

+

14

2

i

6.3.1.1 Example

The starting position (get with GetPositionAndActivity, CMD $20, set with SetActualPosition, CMD $27)

is zero, target position is 116666 (refer to command StartRamp, CMD $23).

Actual full step frequency (f

) is calculated with given formula for f

full-step

micro-step

by multiplication with 16.

VAkt for accelerations is:

AMax/64

+VStart VAkt =

ms 2 t /

This formula is not valid for decelerations. To realize the actual function the SIXpack 2 decelerates more

slowly than it accelerates.

Parameter:

ClockDivider = 5,

Div = 2,

VStart = 16,

VMax = 128,

AMax = 5

Page 28

SIXpack 2 – manual (V1.01 / May 5th, 2006) 28

π

π

π

π

ϕ

π

π

6.3.2 Adapting the microstep-table to the motor characteristics

)(ϕf

2

1

1

2

0

0

2

up to 16 micro steps

1 full step

3

4

alternative motor characteristics (s. CMD $17)

A

(1)

0

( 16 val ues for gener ati ng t he curr ent)

0

(2)

(3)

(default) sinus (2)

triangle(3)

)(ϕf

2

y

1

6

micro s

t

eps within a

1 f

u

ll st

q

e

uadrant

c

b

m

o

h

2

r

box

p

ir

cle

x

Most motors have varying microstep lengths, due

to this the motor would drive discontinuously for a

sin -/ cos -current. In order to reach a smoother

step full / rectangle (1)

run, you can drive the motor with an adjusted

current, so that the motor’s characteristics can be

compensated. This current curves are generated

with the 16 values in the table set via CMD $17,

which describe a quarter period.

(s. left)

6.4 Reference point adjustments

Additionally to the standard configurations for end and reference switches described in chapter 5.5 there

are many possibilities to adept these settings to an individual configuration.

6.4.1 Coordinate plane of an axis

In standard configuration the position counter for each axis is zero. The target position value for a

movement is the absolute number of micro steps from zero to target position. The maximum value of

micro steps per axis is adjusted by variable Poslimit in command SetMotorParameters (CMD $15,

SQPack-Tab “Reference search”.

6.4.2 Reference point / reference switch

The reference point is defined by a mechanic stopper or a reference switch. If an active reference switch

is used, in opposition to the recommended passive switch (refer to chapter 5.5.2), the Flag

MT_NULLPOSITIVE (command SetMotorParameters, CMD $15) has to be set to zero

(MT_NULLPOSITIVE = 0).

6.4.3 Moving zero-point

In basic configuration the reference point is the zero-point, also. With the command SetNullPointOffset

(CMD $18)an offset of the zero-point is possible. This can be important if for example the reference

switch is at the center of the axis but the programming allows positive values, only.

Page 29

SIXpack 2 – manual (V1.01 / May 5th, 2006) 29

6.4.4 Automatic reference search

The SIXpack 2 provides the possibility to start an automatic reference search at identified lost of steps.

To activate this function set the Flag MT_TESTNULL (command SetMotorParameters, CMD $15). The

intern position counter will be compared with the status of the reference switch. If the reference switch

reacts at wrong position or does not react at internally logic position, a reference search is started and

the flag STOPFLAG (command GetPositionAndActivity, CMD $20) set.

6.4.5 Adjusting activity zone of reference switch

Mechanical inaccuracy may lead to reaction of the reference switch a few steps too early or too late. If

an automatic reference search (MT_TESTNULL) is used this may start unintended reference searches.

It is possible to define a zone around the zero-point in which the status of the reference switch is not

checked using the commands SetNullPointOffset, (CMD $18) variable TestNullRange.

Figure 6.3: Coordinate transformation using „NullPointOffset“

6.4.6 Compensation of reference switch delay

At use of mechanic reference switches the problem of a delay time problem between mechanic and

electronic status change occurs often. To avoid dysfunction it is possible to delay the request of the

reference switch signal with PowerDownDelay. It is set and used in SetCurrentControl, CMD $11.

MT_DELAYTESTNULL is set and PowerDownDelay is 500 in basic configuration.

NOTE: PowerDownDelay is used for “power down”- delay (command SetCurrentControl, CMD $11),

also.

6.4.7 Elimination of glitches

In standard configuration the input signal at Refln is debounced for 22 ms. The change of levels has to

be constant in this time to be interpreted. This value is set with variable DebouncingTime (command

SetRefSearchParameters, CMD $16).

6.4.8 Adjusting reference search velocity

Fast reference search is activated in standard configuration (Flag MT_FASTREF of command

SetMotorParameters, CMD $15). At this configuration the axis is moved at reference search with the

velocity set in variable VRefMax (default VrefMax=100).

CAUTION: If MT_FASTREF is used the length of the axis has to be defined in the variable Poslimit.

Otherwise no correct reference search is possible. If MT_FASTREF is not set Poslimit is not

imperative. The reference search will be with a fixed velocity of 1.

6.4.9 Aborting reference search

A reference search is aborted with CMD $2B, SQPack-Tab “Reference search”.

Page 30

SIXpack 2 – manual (V1.01 / May 5th, 2006) 30

6.5 End switch configurations

To recognize a lost of steps and to avoid a possible mechanic damage it is reasonable to limit linear axis

as described in 5.5.

6.5.1 A_ln as end switch input

End switches to limit the axis can be connected to the input A_ln. Additionally to the in 5.5 described

setup with two opening end switches other configurations are possible:

A_ln is an analog input. In use as end switch voltage levels below a defined level are interpreted as the

left and above an other level as right end switch. These levels are defined with the command

SetStopSwitchLimits, CMD $30, SQPack-tab “I/O” in the variables MinLeft bzw. MaxRight.

6.5.2 Combination of end and reference switches

If the reference switch is at the end of the axis it can be used as en switch also. This function is activated

by setting the flag MT_STOPNULL (command SetMotorParameters, CMD $15). The flag

MT_NULLLEFT (command SetMotorParameters) defines, on which side of the axis the combined

end/reference switch is located.

MT_NULLLEFT = 0 Æ end/reference switch is on the right.

6.5.3 “Security Margin” for combined end/reference switch

As described in chapter 6.4.5 errors can occur if a switch reacts too late or too early. It is recommended

to provide the combined end/reference switch with a “security margin”.

The value set with the command SetMargin, CMD $1A, SQPack-tab “Reference search”, defines the

number of steps the SIXpack 2 runs into the reference switch (see Figure 6.3 also).

Figure 6.4: Adjustments for reference switch function

Page 31

SIXpack 2 – manual (V1.01 / May 5th, 2006) 31

6.6 Commands for axis movements

The SIXpack 2 provides different possibilities to move the axis. Which one to choose is related to the

demands of the application.

Basically there is the possibility to move the motor on the axis from a to b (ramps run) or with a fixed

velocity (rotation) until the next velocity command.

6.6.1 Basic ramp run

The ramp run requires the configuration of a reference run with the values for Poslimit, acceleration

and velocity (see CMD $15).

Through the command StartRamp, CMD $23 every position, defined by Poslimit can be achieved.

The target is defined by the variable TargetPosition (CMD $24, SQPack-tab “PI Controller”). The

motor is decelerated before it reaches the target position to stop at the exact target.

Figure 6.5: Schema of ramp generation

6.6.2 Start of constant rotation

For a rotation with a constant velocity the command ConstantRotation (CMD $25) transmits the variable

Velocity which defines the velocity for the constant move (calculation in 6.3).

After receiving the command the motor is accelerated with the maximum acceleration AMax until the

speed defined in Velocity is reached. To stop the axis the command ConstantRotation is used again

and Velocity is set to 0.

6.6.3 Change target position for ramp run

To change the target position of an active ramp run use the command SetTargetPosition (CMD $24,

SQPack-tab “PI Controller”) to transmit the variable TargetPosition with the new target of the

movement.

If the motor already reached its defined target SetTargetPosition takes no effect. To avoid failures and to

be sure the desired position is reached it is recommended to send the command StartRamp (CMD $23)

with the actual target position in addition afterwards. If the mode ConstantRotation (CMD $25) was

active, before, the motor is stopped and than moved to the target position.

6.6.4 Starting different motors synchronous

The command StartRampParallel (CMD $29) is used to start multiple ramp runs. Before this command is

sent each target position should be set with the command SetTargetPosition (CMD $24). When all

motors are inactive the parallel ramp run can be started.

Page 32

SIXpack 2 – manual (V1.01 / May 5th, 2006) 32

Example: In a parallel started ramp run of Motor 1 and Motor 2 is demonstrated. The parameters for

velocity and acceleration (refer to 6.6.1) are identical for both motors but the distance for motor 1 is

longer. Both motors start at the same time, accelerate synchronous and have the same maximum

velocity. Motor 2 reaches its target position earlier and therefore finishes the ramp earlier than motor 1.

6.6.5 Starting linear interpolation of multiple axis

A linear interpolated movement of different axis is possible with the command StartInterpolation (CMD

$50). All motors reach the target at the same time. The target has to be set previously at motor standstill

with the command SetTargetPosition (CMD $24).

The axis with the longest distance, i.e. the longest movement time at maximum velocity, is the leading

axis. The velocities of the other axis rely on this leading axis. A small inhomogeneity may occur,

nevertheless. Therefore the status of all moved motors should be checked before the next command.

Example: In Figure 6.6: Synchronous start of motors Figure 6.7 a linear interpolated ramp

run is demonstrated. Motor 1 has a longer distance to move than motor 2. Therefore Motor 1 is

accelerated to the velocity defined in VMax. For motor 2 a lower maximum velocity has been calculated.

Both motors reach their target simultaneously. The values for the acceleration are still valid, so the slope

of both ramps is identical.

Figure 6.6: Synchronous start of motors Figure 6.7: Linear interpolated ramp

6.6.6 Configuration for rotating movements

The SIXpack 2 differentiates between linear and rotating movements. The active mode is defined by the

flag MT_ROTARY (command SetMotorParameters, CMD $24).

Most important is the interpretation and definition of the positioning values. In linear mode the difference

between actual and target position is interpreted as absolute value for the micro steps to run. Target

positions may be out of the value range defined by Poslimit.

The value range is strictly limited by the value of Poslimit. Positions above this value are adjusted with

a modulo operator to a multiple value. The flag MT_NULLLEFT (command SetMotorParameters) defines

in rotating mode if the positioning values are in positive or negative area:

Page 33

SIXpack 2 – manual (V1.01 / May 5th, 2006) 33

MT_NULLLEFT = 0: 0 ≤ position value < Poslimit

MT_NULLLEFT = 1: - ( Poslimit ) < position value ≤ 0

The direction of the motors rotation is in standard configuration identical to the linear mode. Movements

with rising coordinates lead to clockwise rotation and with falling coordinates to counter clockwise

rotation.

If the flag MT_OPTIMIZEWAY = 1 (command SetMotorParameters) is set the SIXpack 2 chooses the

shortest way to get to the target position from the starting position.

6.7 Control of motor current

To provide an always sufficient torque or holding torque with the lowest use of power an individual

configuration of the motor currents is possible.

The maximum coil current IMax is set with the command SetMaxCurrent (CMD $10). Please check the

DIP-switches of the SIXpack 2, also (refer to 5.2.7).

Also the command SetCurrentControl (CMD $11) provides the possibility to adept to the actual

movement. In the variables a percentage grading can be defined.

EXAMPLE:

Current % of max current Variable setting

while acceleration

while at constant velocity

at target position

after expiration of PowerDownDelay

To lower the current consumption unused motors should be set to the value of a power down current of

zero (PowerDownCurrent = 8).

100

75

38

9

AccelerationCurrent = 0

RunningCurrent = 1

StandigCurrent = 3

PowerDownCurrent = 7

Figure 6.8: Ramp depending current setting

Page 34

SIXpack 2 – manual (V1.01 / May 5th, 2006) 34

6.8 Default values

For testing purposes here is a list of default values for motor parameters:

clkdiv=5; div=2; // 26 kHz microstep-frequency

vstart=5; // starting with 254 Hz (should be >=8)

amax=128; vmax=511; // increments v by 128/16=8 each 2 ms

vmin=4; vrefmax=100; // 102 Hz / 5086 Hz for reference drive