Page 1

Stepper Motor with

Controller / Driver

0.55 - 3.1 Nm / 48 V

sensOstep™ Encoder

USB, RS485, and CAN

Step/Dir Interface

MECHATRONIC DRIVES WITH STEPPER MOTOR PANdrive

Hardware Version V1.1

HARDWARE MANUAL

+

+ +

+

PD-1160

UNIQUE FEATURES

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

Page 2

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 2

Table of Contents

1 Features ........................................................................................................................................................................... 3

2 Order Codes ................................................................................................................................................................... 5

3 Mechanical and Electrical Interfacing ..................................................................................................................... 6

3.1 PD57-1160 and PD60-1160 Dimensions ......................................................................................................... 6

3.1.1 PD57-1160 Dimensions ................................................................................................................................ 6

3.1.2 PD60-1160 Dimensions ................................................................................................................................ 7

3.2 Connectors of PD-1160 ....................................................................................................................................... 8

3.2.1 Power Connector ........................................................................................................................................... 9

3.2.1.1 Power Supply .......................................................................................................................................... 9

3.2.2 Serial Communication Connector ........................................................................................................... 10

3.2.2.1 RS485 ....................................................................................................................................................... 11

3.2.2.2 CAN ........................................................................................................................................................... 12

3.2.3 Multipurpose I/O Connector ..................................................................................................................... 13

3.2.3.1 Digital Inputs STOP_L, STOP_R, and HOME ................................................................................... 13

3.2.3.2 General Purpose Inputs IN_0 and IN_1 ......................................................................................... 14

3.2.3.3 Outputs OUT_0, OUT_1 ........................................................................................................................ 14

3.2.4 Step/Direction Connector .......................................................................................................................... 15

3.2.4.1 Step / Direction / Enable Inputs ...................................................................................................... 15

3.2.5 Encoder Connector ...................................................................................................................................... 16

3.2.5.1 Encoder Inputs ...................................................................................................................................... 16

3.2.6 Motor Connector .......................................................................................................................................... 17

3.2.7 Mini-USB Connector .................................................................................................................................... 18

4 Jumpers ......................................................................................................................................................................... 19

4.1 RS485 Bus Termination .................................................................................................................................... 19

4.2 CAN Bus Termination ....................................................................................................................................... 19

5 Reset to Factory Defaults ......................................................................................................................................... 20

6 On-board LEDs ............................................................................................................................................................. 21

7 Operational Ratings ................................................................................................................................................... 22

8 Torque Curves ............................................................................................................................................................. 24

8.1 Curves of PD57-1160 ......................................................................................................................................... 24

8.1.1 PD57-1-1160 Torque Curves ...................................................................................................................... 24

8.1.2 PD57-2-1160 Torque Curves ...................................................................................................................... 26

8.2 Curves of PD60-1160 ......................................................................................................................................... 28

8.2.1 PD60-3-1160 Torque Curves ...................................................................................................................... 28

8.2.2 PD60-4-1160 Torque Curves ...................................................................................................................... 29

9 Functional Description .............................................................................................................................................. 30

10 PD-1160 Operational Description ........................................................................................................................... 31

10.1 Calculation: Velocity and Acceleration vs. Microstep and Fullstep Frequency ................................ 31

11 Life Support Policy ..................................................................................................................................................... 33

12 Revision History .......................................................................................................................................................... 34

12.1 Document Revision ........................................................................................................................................... 34

12.2 Hardware Revision ............................................................................................................................................ 34

13 References .................................................................................................................................................................... 34

www.trinamic.com

Page 3

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 3

1 Features

The PANdrive™ PD-1160 is a full mechatronic solution with state of the art feature set. It is highly

integrated and offers a convenient handling. The PD-1160 includes a stepper motor, controller/driver

electronics, and TRINAMICs sensOstep™ encoder. It can be used in many decentralized applications and

has been designed for 0.55… 3.1Nm max. holding torque and 24 or 48 V DC nominal supply voltage. With

its high energy efficiency from TRINAMIC’s coolStep technology cost for power consumption is kept

down. The TMCL™ firmware allows for standalone operation and direct mode.

MAIN CHARACTERISTICS

Motion controller

- Motion profile calculation in real-time

- On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

- High performance microcontroller for overall system control and serial communication protocol

handling

Bipolar stepper motor driver

- Up to 256 microsteps per full step

- High-efficient operation, low power dissipation

- Dynamic current control

- Integrated protection

- stallGuard2 feature for stall detection

- coolStep feature for reduced power consumption and heat dissipation

Encoder

- sensOstep magnetic encoder (1024 increments per rotation) e.g. for step-loss detection under all

operating conditions and positioning supervision

- Interface for connection of external incremental a/b/n encoder

Interfaces

- RS485 interface

- CAN (2.0B up to 1Mbit/s) interface

- USB full speed (12Mbit/s) interface

- Step/Direction interface (optically isolated)

- 3 inputs for stop switches and home switch (+24V compatible) with programmable pull-up

- 2 general purpose inputs (+24V compatible) and 2 general purpose outputs (open collector)

- Incremental a/b/n encoder interface (TTL and open-collector signals supported directly)

Safety features

- Shutdown input – driver will be disabled in hardware as long as this pin is left open or shorted to

ground

- Separate supply voltage inputs for driver and digital logic – driver supply voltage may be switched

off externally while supply for digital logic and therefore digital logic remains active

Software

- TMCL: standalone operation or remote controlled operation,

program memory (non volatile) for up to 2048 TMCL commands, and

PC-based application development software TMCL-IDE available for free.

- Ready for CANopen

Electrical and mechanical data

- Supply voltage: common supply voltages +12 V DC / +24 V DC / +48 V DC supported (+9 V… +51 V DC)

- Motor current: up to 2.8 A RMS (programmable)

- 0.55… 3.1Nm max. holding torque (depends on motor)

- With NEMA23 (57mm motor flange size) or NEMA24 (60mm motor flange size) stepper motor

Refer to separate TMCL Firmware Manual, too.

www.trinamic.com

Page 4

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 4

Load

[Nm]

stallGuard2

Initial stallGuard2

(SG) value: 100%

Max. load

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

0 50 100 150 200 250 300 350

Efficiency

Velocity [RPM]

Efficiency with coolStep

Efficiency with 50% torque reserve

TRINAMICS UNIQUE FEATURES – EASY TO USE WITH TMCL

stallGuard2™ stallGuard2 is a high-precision sensorless load measurement using the back EMF on the

coils. It can be used for stall detection as well as other uses at loads below those which

stall the motor. The stallGuard2 measurement value changes linearly over a wide range

of load, velocity, and current settings. At maximum motor load, the value goes to zero or

near to zero. This is the most energy-efficient point of operation for the motor.

Figure 1.1 stallGuard2 load measurement SG as a function of load

coolStep™ coolStep is a load-adaptive automatic current scaling based on the load measurement via

stallGuard2 adapting the required current to the load. Energy consumption can be

reduced by as much as 75%. coolStep allows substantial energy savings, especially for

motors which see varying loads or operate at a high duty cycle. Because a stepper motor

application needs to work with a torque reserve of 30% to 50%, even a constant-load

application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler,

increases motor life, and allows reducing cost.

www.trinamic.com

Figure 1.2 Energy efficiency example with coolStep

Page 5

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 5

Order code

Description

Size (mm3)

PD57-1-1160

PANdrive with 0.55Nm max./holding torque

60 x 60 x 58

PD57-2-1160

PANdrive with 1.01Nm max./holding torque

60 x 60 x 68

Order code

Description

Size (mm3)

PD60-3-1160

PANdrive with 2.10Nm max./holding torque

60 x 60 x 82

PD60-4-1160

PANdrive with 3.10Nm max./holding torque

60 x 60 x 103

Order code

Description

PD-1160-CABLE

Cable loom for PD-1160:

- 1x cable loom for power connector (length 200mm)

- 1x cable loom for communication connector (length 200mm)

- 1x cable loom for multipurpose I/O connector (length 200mm)

- 1x cable loom for S/D connector (length 200mm)

- 1x cable loom for encoder connector (length 200mm)

- 1x USB type A connector to mini-USB type B connector cable (length 1.5m)

2 Order Codes

The PD-1160 is currently available with two different stepper motor series (NEMA23 / 57mm flange size or

NEMA24 / 60mm flange size):

With NEMA 23 / 57mm flange size motor:

The length of the PANdrives is specified without the length of the axis. For the overall length of the

product please add 24mm.

Table 2.1 Order codes (PD57-1160)

With NEMA 24 / 60mm flange size motor:

The length of the PANdrives is specified without the length of the axis. For the total length of the

product add 24mm.

Table 2.2 Order codes (PD60-1160)

A cable loom set is available for this module:

Table 2.3 Cable loom order codes

www.trinamic.com

Page 6

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 6

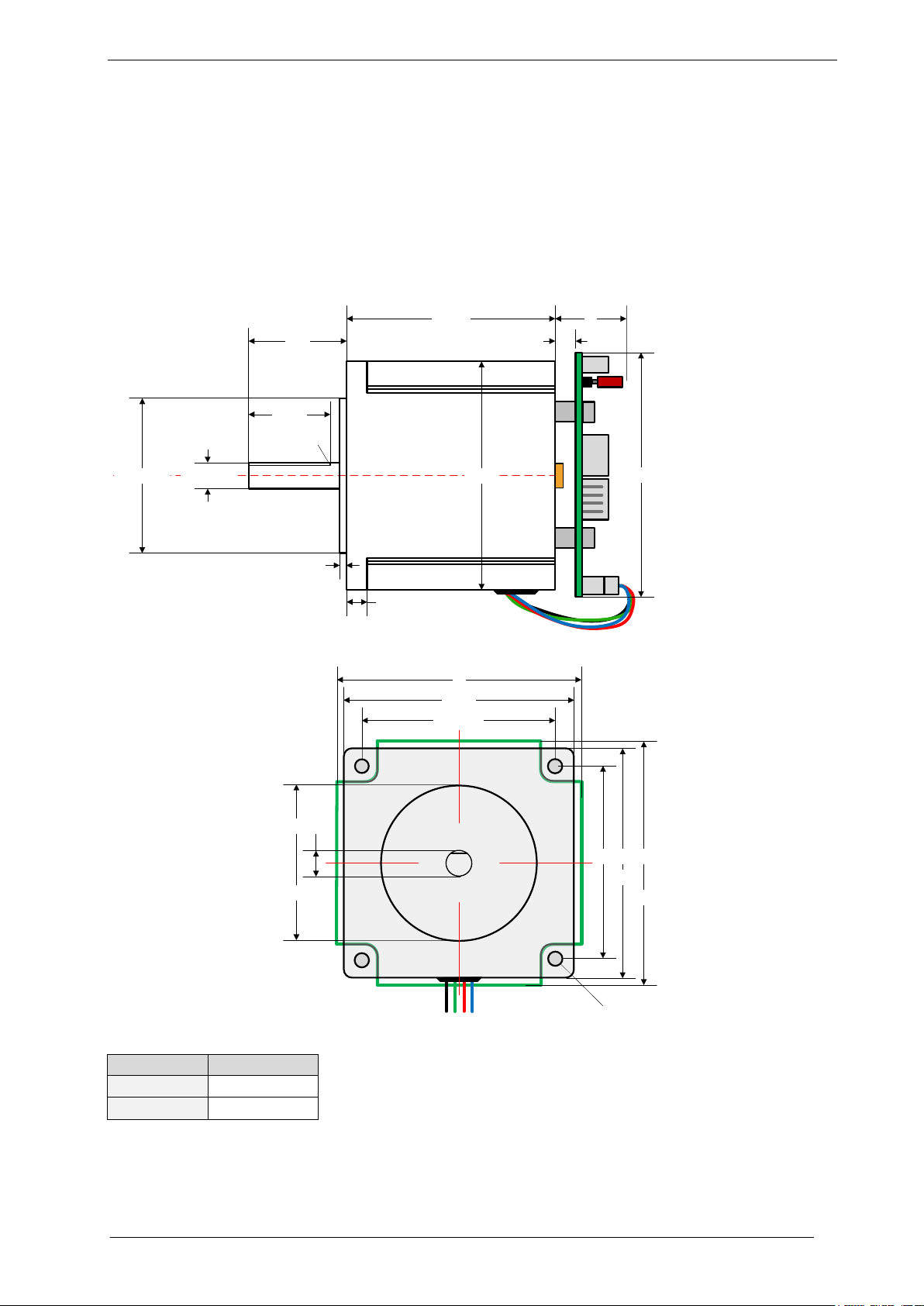

Length

56.4±138.1±0.025

1.6

5

6,35-0.013

24±1

20±0.5

R 0.5

38.1±0.025

47.14±0.2

4-ø4.6

56.4±1

56.4±1

6.35-0.013

60

60

47.14±0.2

17

60

4.5

Model

Length (mm)

PD57-1-1160

41

PD57-2-1160

51

3 Mechanical and Electrical Interfacing

3.1 PD57-1160 and PD60-1160 Dimensions

3.1.1 PD57-1160 Dimensions

The PD57-1160 includes the TMCM-1160 stepper motor controller/driver module, the magnetic encoder

based on sensOstep technology and a NEMA23 bipolar stepper motor. Currently, there is a choice

between two NEMA 23/57mm bipolar stepper motors with different lengths and different holding

torques.

Figure 3.1 Dimensions of PD57-1160

www.trinamic.com

Page 7

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 7

Length

5

9

38.1±0.025

1.6

24±1

8-0.013

20±0.5

7.5±0.2

60±0.5

17

60

4.5

60

47.14±0.2

60

38.1±0.025

8

47.14±0.2

4-ø4.5

Model

Length (mm)

PD60-3-1160

65

PD60-4-1160

86

3.1.2 PD60-1160 Dimensions

Currently, there is a choice between two NEMA 24/60mm bipolar stepper motors with different lengths

and different holding torques.

Figure 3.2 Dimensions of PD60-1160

www.trinamic.com

Page 8

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 8

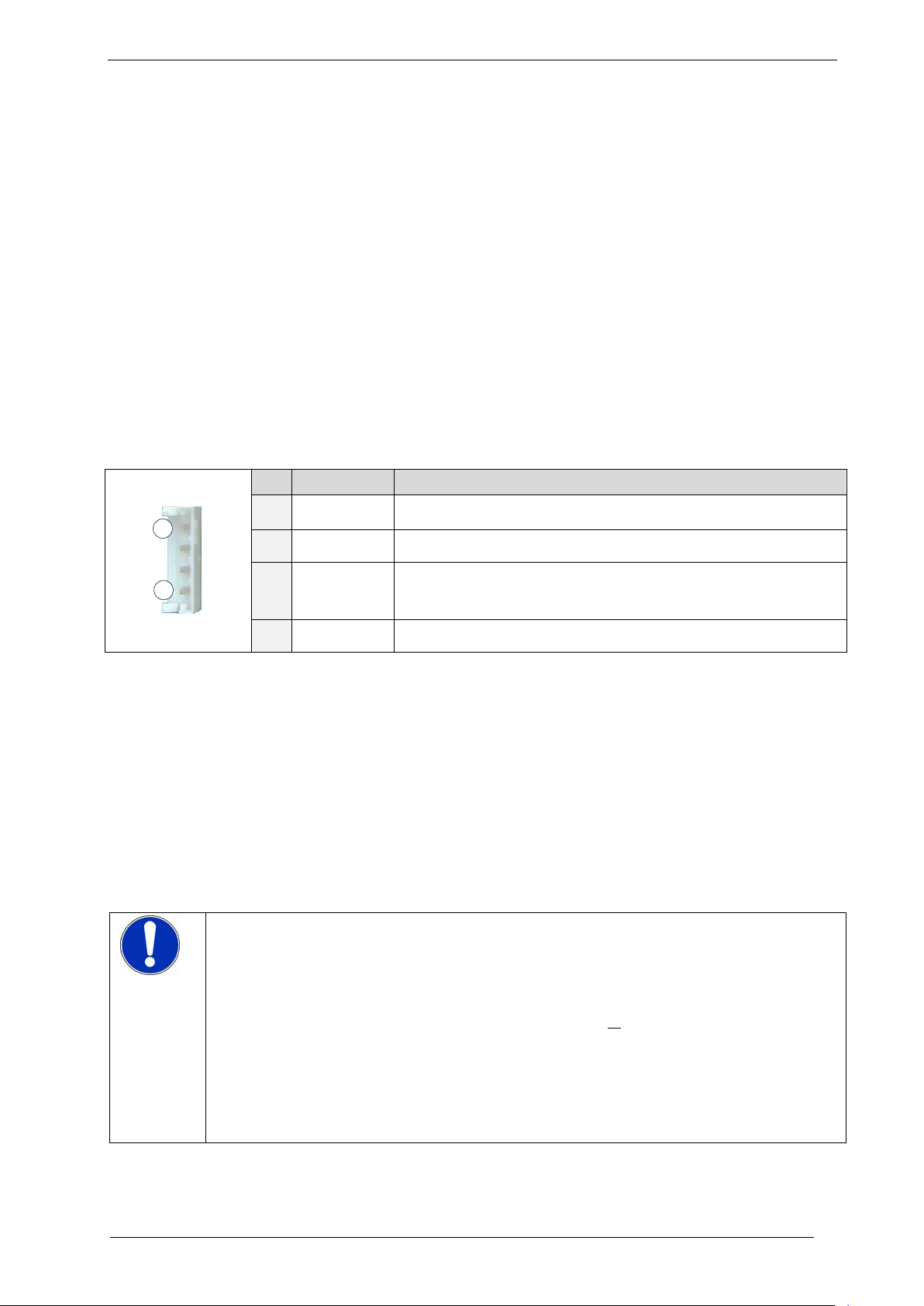

USB

Serial

communication

Multi-purpose

I/O

Motor

Power

Encoder

14

1

8

1

4

1

5

1

5

1

4

Step /

Direction

Label

Connector type

Mating connector type

Power

Connector

JST B4B-EH-A

(JST EH series, 4pins, 2.5mm pitch)

Connector housing: JST EHR-4

Contacts: JST SEH-001T-P0.6

Wire: 0.33mm2, AWG 22

Serial

communication

Connector

JST B5B-PH-K-S

(JST PH series, 5pins, 2mm pitch)

Connector housing: JST PHR-5

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

Multi-purpose

I/O Connector

JST B8B-PH-K-S

(JST PH series, 8pins, 2mm pitch)

Connector housing: JST PHR-8

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

Step/Direction

Connector

JST B4B-PH-K-S

(JST EH series, 4pins, 2mm pitch)

Connector housing: JST PHR-4

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

Encoder

Connector

JST B5B-PH-K-S

(JST EH series, 5pins, 2mm pitch)

Connector housing: JST PHR-5

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

Motor

Connector

JST B4B-EH-A

(JST PH series, 4pins, 2.5mm pitch)

Connector housing: JST EHR-4

Contacts: JST SEH-001T-P0.6

Wire: 0.33mm2, AWG 22

Mini-USB

Connector

Molex 500075-1517

Mini USB Type B vertical receptacle

Any standard mini-USB plug

3.2 Connectors of PD-1160

The PD-1160 offers seven connectors including the motor connector which is used for attaching the

motor coils to the electronics. In addition to the power connector there are two connectors for serial

communication (mini-USB connector and 5pin connector for RS485 and CAN) and three connectors for

Step/Direction, multipurpose input/output signals, and for an external encoder.

The multipurpose connector offers two general purpose outputs, two general purpose inputs, two inputs

for stop switches and one for an additional home switch.

The power supply connector offers separate inputs for driver and for logic power supply plus hardware

shutdown input. Leaving the shutdown input open or tying it to ground will disable the motor driver

stage in hardware. For operation, this input should be tied to supply voltage.

Figure 3.3 Overview connectors

Table 3.1 Connectors and mating connectors, contacts and applicable wire

www.trinamic.com

Page 9

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 9

4

1

Pin

Label

Description

1

+V

Driver

Module + driver stage power supply input

2

+V

Logic

(Optional) separate digital logic power supply input

3

/SHUTDOWN

Shutdown input. Connect this input to +V

Driver

or +V

Logic

in order

to activate driver stage. Leaving this input open or connecting it

to ground will disable driver stage

4

GND

Module ground (power supply and signal ground)

Add external power supply capacitors!

It is recommended to connect an electrolytic capacitor of significant size (e.g. 2200 µF /

63V) to the power supply lines next to the PD-1160 especially if the distance to the power

supply is large (i.e. more than 2-3m)!

Rule of thumb for size of electrolytic capacitor:

In addition to power stabilization (buffer) and filtering this added capacitor will also

reduce any voltage spikes which might otherwise occur from a combination of high

inductance power supply wires and the ceramic capacitors. In addition it will limit slewrate of power supply voltage at the module. The low ESR of ceramic-only filter capacitors

may cause stability problems with some switching power supplies.

3.2.1 Power Connector

This PANdrive offers separate power supply inputs for digital logic (pin 2) and driver/power stage (pin 1).

Both supply inputs use common ground connections (pin 4). This way, power supply for the driver stage

may be switched off while still maintaining position and status information when keeping digital logic

supply active. Due to internal diode the digital logic supply has to be equal or higher than the

driver/power stage supply. Otherwise the diode between driver/power stage supply and digital logic

supply might short the separate supplies.

+U

In case power supply is provided only to the power section (pin 1) an internal diode will distribute

power to the logic section. So, when separate power supplies are not required it is possible to just use

pin 1 and 4 for powering the module. If so, pin 2 (logic supply) and pin 3 (/SHUTDOWN input) can be

connected together in order to enable the driver stage.

ENABLING THE DRIVER STAGE

Connect /SHUTDOWN input to +U

open or connecting it to ground will disable driver stage.

A 4-pin JST EH series B4B-EH connector is used as power connector on-board.

SUPPLY ONLY

DRIVER

Driver

or +U

in order to activate the driver stage. Leaving this input

Logic

Table 3.2 Connector for power supply

3.2.1.1 Power Supply

For proper operation care has to be taken with regard to the power supply concept and design. Due to

space restrictions the TMCM-1160 module includes about 20 µF / 100 V of supply filter capacitors. These

are ceramic capacitors which have been selected for high reliability and long life time.

HINTS FOR POWER SUPPLY CABLES

- Keep power supply cables as short as possible.

- Use large diameters for power supply cables.

CAUTION!

www.trinamic.com

Page 10

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 10

Do not connect or disconnect motor during operation!

Motor cable and motor inductivity might lead to voltage spikes when the motor is

disconnected / connected while energized. These voltage spikes might exceed voltage

limits of the driver MOSFETs and might permanently damage them. Therefore, always

disconnect power supply before connecting / disconnecting the motor.

Keep the power supply voltage below the upper limit of 51V!

Otherwise the driver electronics will seriously be damaged! Especially, when the selected

operating voltage is near the upper limit a regulated power supply is highly

recommended. Please see also chapter 7 (operating values).

There is no reverse polarity protection!

The module will short any reversed supply voltage due to internal diodes of the driver

transistors.

1

5

Pin

Label

Description

1

CAN_H

CAN bus signal (dominant high)

2

CAN_L

CAN bus signal (dominant low)

3

GND

Module ground (system and signal ground)

4

RS485+

RS485 bus signal (non inverted)

5

RS485-

RS485 bus signal (inverted)

3.2.2 Serial Communication Connector

The module supports RS485 and CAN communication via this connector.

CAN interface will be de-activated in case USB is connected due to internal sharing of hardware

resources.

A 2mm pitch 5-pin JST B5B-PH-K connector is used for serial communication.

Table 3.3 Connector for serial communication

www.trinamic.com

Page 11

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 11

c:>

node

1

node

n

- 1

node

n

Host

Slave Slave Slave

RS485

termination

resistor

(120 Ohm)

termination

resistor

(120 Ohm)

}

keep distance as

short as possible

node

n - 1

node

n

Slave Slave

termination

resistor

(120 Ohm)

+5V

GND

pull-up (1k)

pull-down (1k)

RS485- / RS485B

RS485+ / RS485A

3.2.2.1 RS485

For remote control and communication with a host system the PD-1160 provides a two wire RS485 bus

interface. For proper operation the following items should be taken into account when setting up an

RS485 network:

1. BUS STRUCTURE:

The network topology should follow a bus structure as closely as possible. That is, the

connection between each node and the bus itself should be as short as possible. Basically, it

should be short compared to the length of the bus.

Figure 6.4: Bus structure

2. BUS TERMINATION:

Especially for longer busses and/or multiple nodes connected to the bus and/or high

communication speeds, the bus should be properly terminated at both ends. The PD-1160 does

offer on-board termination resistors which can be activated with the help of a jumper. The

jumper has to be removed for units not connected to one end of the bus!

3. NUMBER OF NODES:

The RS485 electrical interface standard (EIA-485) allows up to 32 nodes to be connected to a

single bus. The bus transceiver used on the PD-1160 units (SN65HVD485ED) has 1/2 of the

standard bus load and allows a maximum of 64 units to be connected to a single RS485 bus.

4. NO FLOATING BUS LINES:

Avoid floating bus lines while neither the host/master nor one of the slaves along the bus line is

transmitting data (all bus nodes switched to receive mode). Floating bus lines may lead to

communication errors. In order to ensure valid signals on the bus it is recommended to use a

resistor network connecting both bus lines to well defined logic levels. In contrast to the

termination resistors this network is normally required just once per bus. Certain RS485 interface

converters available for PCs already include these additional resistors (e.g. USB-2-485).

Figure 3.5 Bus lines with resistor network

www.trinamic.com

Page 12

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 12

c:>

node

1

node

n

- 1

node

n

Host

Slave Slave Slave

CAN

termination

resistor

(120 Ohm)

termination

resistor

(120 Ohm)

}

keep distance as

short as possible

3.2.2.2 CAN

For remote control and communication with a host system the PD-1160 provides a CAN bus interface.

Please note that the CAN interface is not available in case USB is connected. For proper operation the

following items should be taken into account when setting up a CAN network:

1. BUS STRUCTURE:

The network topology should follow a bus structure as closely as possible. That is, the

connection between each node and the bus itself should be as short as possible. Basically, it

should be short compared to the length of the bus.

Figure 3.6 CAN bus structure

2. BUS TERMINATION:

Especially for longer busses and/or multiple nodes connected to the bus and/or high

communication speeds, the bus should be properly terminated at both ends. The PD-1160 does

offer on-board termination resistors which can be activated with the help of a jumper (see

chapter 7). The jumper has to be removed for units not connected to one end of the bus!

3. NUMBER OF NODES:

The bus transceiver used on the PD-1160 units (TJA1050T or similar) supports at least 110 nodes

under optimum conditions. Practically achievable number of nodes per CAN bus highly depends

on bus length (longer bus -> less nodes) and communication speed (higher speed -> less nodes).

www.trinamic.com

Page 13

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 13

1

8

Pin

Label

Description

1

OUT_0

General purpose output, open drain (max. 1A)

Integrated freewheeling diode connected to +V

Logic

2

OUT_1

General purpose output, open drain (max. 1A)

Integrated freewheeling diode connected to +V

Logic

3

IN_0

General purpose input (analog and digital), +24V compatible

Resolution when used as analog input: 12bit (0..4095)

4

IN_1

General purpose input (analog and digital), +24V compatible

Resolution when used as analog input: 12bit (0..4095)

5

STOP_L

Left stop switch input (digital input), +24V compatible,

programmable internal pull-up to +5V

6

STOP_R

Right stop switch input (digital input), +24V compatible,

programmable internal pull-up to +5V

7

HOME

Home switch input (digital input), +24V compatible, programmable

internal pull-up to +5V

8

GND

Module ground (system and signal ground)

+3.3V

STOP_L

STOP_R

HOME

microcontroller (all)

and TMC429 (STOP_L, STOP_R)

10k

22k

100nf

GND

GND GND

programmable in software

1k

+5V

3.2.3 Multipurpose I/O Connector

A 2mm pitch 8-pin JST B8B-PH-K connector is used for connecting general purpose inputs, home and stop

switches and outputs to the unit:

Table 3.4 Multipurpose I/O connector

Note:

All inputs have resistor based voltage dividers with protection diodes. These resistors also ensure a valid

GND level when left unconnected.

For reference switch inputs (STOP_L, STOP_R, HOME) a 1k pull-up resistor to +5V can be activated

(separately for each input). Then these inputs have a default (unconnected) logic level of “1” and an

external switch to GND can be connected.

3.2.3.1 Digital Inputs STOP_L, STOP_R, and HOME

The eight pin connector of the PD-1160 provides three reference switch digital inputs STOP_L, STOP_R and

HOME. All three inputs accept up to +24 V input signals. They are protected against these higher voltages

using voltage resistor dividers together with limiting diodes against voltages below 0 V (GND) and above

+3.3 V DC.

Figure 3.6 STOP_L, STOP_R and HOME inputs (simplified input circuit)

All three digital inputs are connected to the on-board processor and can be used as general purpose

digital inputs!

www.trinamic.com

Page 14

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 14

+3.3V

IN_0,

IN_1

ADC input

(microcontroller)

22k

10k

100nF

GND

GND GND

+V

Logic

microcontroller

GND

3.2.3.2 General Purpose Inputs IN_0 and IN_1

The eight pin connector of the PD-1160 provides two general purpose inputs which may be used as

either digital or analog inputs.

GENERAL PURPOSE INPUTS AS ANALOG INPUTS

As analog input they offer a full scale input range of 0… +10 V with a resolution of the internal analog-to-

digital converter of the microcontroller of 12bit (0… 4095). The input is protected against higher voltages

up to +24 V using voltage resistor dividers together with limiting diodes against voltages below 0 V

(GND) and above +3.3 V DC.

Figure 3.7 General purpose inputs (simplified input circuit)

3.2.3.3 Outputs OUT_0, OUT_1

The eight pin connector of the PD-1160 offers two general purpose outputs OUT_0 and OUT_1. These two

outputs are open-drain outputs and can sink up to 1 A each. The outputs of the N-channel MOSFET

transistors are connected to freewheeling diodes each for protection against voltage spikes especially

from inductive loads (relays etc.) above supply voltage.

- In case free-wheeling diodes are connected to VDD supply voltage:

None of the two outputs should be connected to any voltage above supply voltage of the module.

- It is recommended to connect +V

outputs OUT_0/1 are used to switch inductive loads (e.g. relays etc.).

of the power connector to the power supply output in case the

logic

Figure 3.8 General purpose outputs

www.trinamic.com

Page 15

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 15

1

4

Pin

Label

Description

1

COM

Common supply for the opto-coupler inputs (+5V… +24V)

2

ENABLE

Enable signal input

(function depends on firmware)

3

STEP

Step signal input

(connected to step input of TMC262 driver IC)

4

DIRECTION

Direction signal

(connected to direction input of TMC262 driver IC)

8mA

8mA

8mA

+3.3V

GND

Enable

Direction

Step

Common

(5… 24V)

microcontroller

TMC262

TMC262

3.2.4 Step/Direction Connector

A 2mm pitch 4-pin JST B4B-PH-K connector is used for step and direction input signals. This is an option

in case the on-board controller is used for configuration of the driver stage, only. The Step/Direction

input is optically isolated and will allow direct control of the driver stage.

Please do not attach any signal to this input if the on-board motion controller is used! Otherwise step or

direction signal connected here might interfere with signals generated on-board.

Table 3.4 Connector for step/direction signals

3.2.4.1 Step / Direction / Enable Inputs

The inputs Step, Direction and Enable are electrically (optically) isolated from the power supply and all

other signals of the module. These inputs have one common reference input COMMON.

The COMMON input should be connected to a positive supply voltage between +5 V and +24 V. Step /

Direction / Enable signals might be driven either by open-collector / open-drain outputs or by push-pull

outputs.

In case of push-pull outputs the COMMON supply voltage should be equal / similar to the high signal

voltage level of the push-pull drivers.

Figure 3.9 Step / Direction / Enable inputs

www.trinamic.com

Page 16

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 16

1

5

Pin

Label

Description

1

GND

Module ground (system and signal ground)

2

+5V

+5V supply output for external encoder circuit (100 mA max.)

3

ENC_A

Encoder a channel input (internal pull-up)

4

ENC_B

Encoder b channel input (internal pull-up)

5

ENC_N

Optional encoder n / index channel input (internal pull-up)

ENC_A microcontroller

2k7

1

+5V

ENC_B

ENC_N

2k7 2k7

1

1

microcontroller

microcontroller

3.2.5 Encoder Connector

The module supports an external incremental a/b/n encoder via this connector. The external encoder may

be used in addition or as an alternative to the internal / on-board sensOstep encoder.

A 2mm pitch 5-pin JST B5B-PH-K connector is used for connecting an external encoder with TTL (+5 V

push-pull) or open-collector signals directly:

Table 3.5 Connector for an external incremental encoder

3.2.5.1 Encoder Inputs

The PD-1160 offers a dedicated encoder input for incremental a/b encoders with optional n / indexchannel.

Encoders with +5 V push-pull (TTL) signals or open-collector signals (on-board pull-ups) might be

connected directly. This connector offers a +5 V supply output for supply of the encoder circuit. Up to

100mA might be drawn from this output.

Connecting an external encoder is an option. An external encoder might be used in addition or as

alternative to the internal sensOstep encoder.

Figure 3.9 Encoder a/b/n inputs

www.trinamic.com

Page 17

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 17

4

1

Pin

Label

Description

1

OA1

Motor coil A

2

OA2

Motor coil A

3

OB1

Motor coil B

4

OB2

Motor coil B

M

A

green

B

blue

red

black

TMCM-1160

Q5718 motor

Motor connector pin

Cable colour

Coil

Description

1

Black

A

Motor coil A pin 1

2

Green

A-

Motor coil A pin 2

3

Red B Motor coil B pin 1

4

Blue

B-

Motor coil B pin 2

Keep the electronics free of (metal) particles!

The integrated sensOstep™ encoder uses a magnet at the end of the motor axis in order

to monitor position. The magnet naturally attracts especially tiny metal particles. These

particles might be held on the top side of the PCB and even worse – start moving in

accordance with the rotating magnetic field as soon as the motor starts moving. This

might lead to shorts of electronic contacts / wires on the board and totally erratic

behavior of the module! Use compressed air for cleaning the module if necessary.

3.2.6 Motor Connector

Both motor coil windings (bipolar stepper motor) are connected to the motor connector.

Figure 3.4 Motor connector

CAUTION!

www.trinamic.com

Page 18

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 18

1

5

Pin

Label

Description

1

VBUS

+5V supply from host

2

D-

Data –

3

D+

Data +

4

ID

Not connected

5

GND

Module ground (system and signal ground)

3.2.7 Mini-USB Connector

A 5-pin standard mini-USB connector is available on board. This module supports USB 2.0 full-speed

(12Mbit/s) connections.

Please note:

- On-board digital core logic (mainly processor and EEPROM) will be powered via USB in case no

other supply is connected. The USB connection might be used to set parameters / download

TMCL programs or perform firmware updates while power supply for the module (and the rest of

the machine) has been switched off or is not connected.

- CAN interface will be de-activated as soon as USB is connected due to internal sharing of

hardware resources.

Table 3.6 Mini USB connector

For remote control and communication with a host system the PD-1160 provides a USB 2.0 full-speed

(12Mbit/s) interface (mini-USB connector). As soon as a USB-Host is connected the module will accept

commands via USB.

USB BUS POWERED OPERATION MODE

The PD-1160 supports both, USB self powered operation (when an external power is supplied via the

power supply connector) and USB bus powered operation, (no external power supply via power supply

connector).

On-board digital core logic will be powered via USB in case no other supply is connected (USB bus

powered operation). The digital core logic comprehends the microcontroller itself and also the EEPROM.

The USB bus powered operation mode has been implemented to enable configuration, parameter

settings, read-outs, firmware updates, etc. by just connecting an USB cable between module and host PC.

No additional cabling or external devices (e.g. power supply) are required.

Please note that the module might draw current from the USB +5 V bus supply even in USB self powered

operation depending on the voltage level of this supply.

Motor movements are not possible in this operation mode. Therefore, connect the power connector and

change to USB self powered operation mode.

www.trinamic.com

Page 19

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 19

RS485 bus

termination

CAN bus

termination

4 Jumpers

Most settings of the board are done through the software. Nevertheless, two jumpers are available for

configuration.

Figure 4.1 RS485 and CAN bus termination

4.1 RS485 Bus Termination

The board includes a 120 Ohm resistor for proper bus termination of the RS485 interface. When this

jumper is closed, the resistor will be placed between the two differential bus lines RS485+ and RS485-.

4.2 CAN Bus Termination

The board includes a 120 Ohm resistor for proper bus termination of the CAN interface. When this

jumper is closed, the resistor will be placed between the two differential bus lines CAN_H and CAN_L.

www.trinamic.com

Page 20

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 20

Short these two pads.

PERFORM THE FOLLOWING STEPS:

1. Power supply off and USB cable disconnected

2. Short two pads as marked in Figure 5.1

3. Power up board (power via USB is sufficient for this

purpose)

4. Wait until the on-board red and green LEDs start

flashing fast (this might take a while)

5. Power-off board (disconnect USB cable)

6. Remove short between pads

7. After switching on power-supply / connecting USB

cable all permanent settings have been restored to

factory defaults

5 Reset to Factory Defaults

It is possible to reset the PD-1160 to factory default settings without establishing a communication link.

This might be helpful in case communication parameters of the preferred interface have been set to

unknown values or got accidentally lost.

For this procedure two pads on the bottom side of the board have to be shortened (see Figure 5.1).

Figure 5.1 Reset to factory default settings

www.trinamic.com

Page 21

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 21

Red LED

Green LED

BEHAVIOR OF LEDS WITH STANDARD TMCL FIRMWARE

Status

Label

Description

Heartbeat

Run

The green LED flashes during operation.

Error

Error

The red LED lights up if an error occurs.

6 On-board LEDs

The board offers two LEDs in order to indicate board status. The function of both LEDs is dependent on

the firmware version. With standard TMCL firmware the green LED should be flashing during operation

and the red LED should be off.

When there is no valid firmware programmed into the board or during firmware update the red and

green LEDs are permanently on.

Figure 6.1 on-board LEDs

www.trinamic.com

Page 22

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 22

Symbol

Parameter

Min

Typ

Max

Unit

+V

Driver

/ +V

Logic

Power supply voltage for operation

9

12, 24, 48

51

V DC *)

I

USB

USB supply current when USB bus powered

(+5V USB supply)

70 mA

I

COIL_peak

Motor coil current for sine wave peak

(chopper regulated, adjustable via software)

0 4

A

I

COIL_RMS

Continuous motor current (RMS)

0 2.8

A

I

SUPPLY

Power supply current

<< I

COIL

1.4 * I

COIL

A

T

ENV

Environment temperature at +48V supply and

rated current (100% duty-cycle, no forced

cooling required)

40

°C

T

ENV

Environment temperature at +24V supply and

rated current (100% duty-cycle, no forced

cooling required)

50

°C

Symbol

Parameter

Min

Type

Max

Unit

V

COMMON

Supply voltage for common supply input for

step, direction and enable (inputs have

negative logic)

5… 24

27

V

V

STEP/DIR/ENABLE_ON

Signal voltage at step, direction and enable

input (active, opto-coupler on)

3.5

4.5… 24

30

V

V

STEP/DIR/ENABLE_OFF

Signal voltage at step, direction and enable

input (inactive, opto-coupler off)

-5.5 0 2

V

V

STEP/DIR/ENABLE_ON

Opto-coupler current when switched on

(internally regulated)

6… 8 mA

f

STEP

Step frequency

1 *)

MHz

7 Operational Ratings

The operational ratings show the intended or the characteristic ranges and should be used as design

values.

In no case shall the maximum values be exceeded!

GENERAL OPERATIONAL RATINGS OF THE MODULE

Table 7.1 General operational ratings of module

*) Attention: due to the internal diode between V

than V

Driver

.

Driver

and V

Logic VLogic

should be always equal or higher

GENERAL OPERATIONAL RATINGS OF STEP/DIRECTION INPUT

Table 7.2 Operational ratings of Step/Dir input

*) Maximum frequency for +5 V TTL level step signals is with 50 % duty cycle.

www.trinamic.com

Page 23

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 23

Symbol

Parameter

Min

Type

Max

Unit

V

STOP_L/R/HOME

Input voltage for STOP_L/R/HOME

0 24

V

V

STOP_L/R/HOME_L

Low level voltage for STOP_L/R/HOME

0 1.3

V

V

STOPL/R/HOME_H

High level voltage for STOP_L/R/HOME

(internal programmable 1k pull-up to +5V)

3 24

V

V

IN_0/1_digital

Input voltage for IN_0 and IN_1 when used

as digital input

0 24

V

V

IN_0/1_analog

Full range input voltage for IN_0 and IN_1

when used as analog input

0 10

V

V

IN_0/1_L

Low level voltage for IN_0 and IN_1 when

used as digital input

(internal 10k pull-down)

0 1.3 *)

V

V

IN_0/1_H

High level voltage for IN_0 and IN_1 when

used as digital input

3 *) 24

V

V

OUT_0/1

Voltage at open collector output

0

V

LOGIC

+

0.5 **)

V

I

OUT_0/1

Output sink current at open collector

outputs

1

A

OPERATIONAL RATINGS OF THE GENERAL PURPOSE INPUTS/OUTPUTS

Table 7.3 Operational ratings of the general purpose inputs/outputs

*) this voltage is programmable (internal 12bit ADC)

**) limited to module supply voltage + 0.5V due to integrated freewheeling diode between general

purpose output and module supply voltage

www.trinamic.com

Page 24

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 24

TMCM-1160 – QSH5718-41-28-055 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]; 256 Microsteps

TMCM-1160 – QSH5718-41-28-055 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]; 256 Microsteps

8 Torque Curves

TRINAMIC offers the TMCM-1160 in combination with two different stepper motor series: QSH5718 and

QSH6018. The following paragraphs will show you the curves of each PANdrive.

8.1 Curves of PD57-1160

8.1.1 PD57-1-1160 Torque Curves

www.trinamic.com

Figure 8.1 Torque curves PD57-1-1160, V

= 24 V DC

S

Page 25

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 25

TMCM-1160 – QSH5718-41-28-055 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]; 256 Microsteps

TMCM-1160 – QSH5718-41-28-055 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]; 256 Microsteps

www.trinamic.com

Figure 8.2 Torque curves PD57-1-1160, V

= 48 V DC

S

Page 26

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 26

TMCM-1160 – QSH5718-51-28-101 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]; 256 Microsteps

TMCM-1160 – QSH5718-51-28-101 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]; 256 Microsteps

8.1.2 PD57-2-1160 Torque Curves

www.trinamic.com

Figure 8.3 Torque curves PD57-2-1160, V

= 24 V DC

S

Page 27

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 27

TMCM-1160 – QSH5718-51-28-101 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]; 256 Microsteps

TMCM-1160 – QSH5718-51-28-101 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]; 256 Microsteps

Figure 8.4 Torque curves PD57-2-1160, V

www.trinamic.com

= 48 V DC

S

Page 28

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 28

TMCM-1160 – QSH6018-65-28-210 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]

TMCM-1160 – QSH6018-65-28-210 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]

8.2 Curves of PD60-1160

8.2.1 PD60-3-1160 Torque Curves

Figure 8.5 Torque curves PD60-3-1160, V

= 24 V DC

S

Figure 8.6 Torque curves PD60-3-1160, V

www.trinamic.com

= 48 V DC

S

Page 29

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 29

TMCM-1160 – QSH6018-86-28-310 – Torque versus Velocity

VS = 24V; I

coil

= 2.8A [RMS]

TMCM-1160 – QSH6018-86-28-310 – Torque versus Velocity

VS = 48V; I

coil

= 2.8A [RMS]; Fullsteps

8.2.2 PD60-4-1160 Torque Curves

Figure 8.7 Torque curves PD60-4-1160, V

= 24 V DC

S

Figure 8.8 Torque curves PD60-4-1160, V

www.trinamic.com

= 48 V DC

S

Page 30

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 30

9… 51V DC

RS485

USB

µC

TMCL

Memory

7

I/Os

Step

Motor

MOSFET

Driver

Stage

SPI

PD-1160

SPI

SPI

S/D

TMC429

Motion

Controller

Energy Efficient

Driver

TMC262

Power

Driver

TMC262

with

coolStep™

S/D

S/D

CAN

Encoder

a/b/n

TMCM-1160

+5V

Stop

switches

sensOstep™

Encoder

SPI

9 Functional Description

The PD-1160 is a highly integrated mechatronic device which can be controlled via several serial

interfaces. Communication traffic is kept low since all time critical operations, e.g. ramp calculations are

performed on board. Common supply voltages are +12VDC / +24VDC / +48VDC. The PANdrive is designed

for both: direct mode and standalone operation. Full remote control of device with feedback is possible.

The firmware of the module can be updated via any of the serial interfaces.

In Figure 9.1 the main parts of the PD-1160 are shown:

- the microprocessor, which runs the TMCL operating system (connected to TMCL memory),

- the motion controller, which calculates ramps and speed profiles internally by hardware,

- the power driver with stallGuard2 and its energy efficient coolStep feature,

- the MOSFET driver stage,

- the QSH stepper motor, and

- the sensOstep encoder with resolutions of 10bit (1024 steps) per revolution.

Figure 9.1 Main parts of the PD-1160

The PD-1160 comes with the PC based software development environment TMCL-IDE for the Trinamic

Motion Control Language (TMCL). Using predefined TMCL high level commands like move to position a

rapid and fast development of motion control applications is guaranteed.

Please refer to the PD-1160 Firmware Manual for more information about TMCL commands.

www.trinamic.com

Page 31

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 31

Signal

Description

Range

f

CLK

clock-frequency

16 MHz

velocity

-

0… 2047

a_max

maximum acceleration

0… 2047

pulse_div

divider for the velocity. The higher the value is, the less is

the maximum velocity

default value = 0

0… 13

ramp_div

divider for the acceleration. The higher the value is, the

less is the maximum acceleration

default value = 0

0… 13

Usrs

microstep-resolution (microsteps per fullstep = 2

usrs

)

0… 8

3220482

][

][

_

divpulse

CLK

velocityHzf

Hzusf

usrs

Hzusf

Hzfsf

2

][

][

29__

max

2

2

divrampdivpulse

CLK

af

a

usrs

a

af

2

10 PD-1160 Operational Description

10.1 Calculation: Velocity and Acceleration vs. Microstep and

Fullstep Frequency

The values of the parameters sent to the TMC429 do not have typical motor values like rotations per

second as velocity. But these values can be calculated from the TMC429 parameters as shown in this

section.

PARAMETERS OF TMC429

Table 10.1 TMC429 velocity parameters

MICROSTEP FREQUENCY

The microstep frequency of the stepper motor is calculated with

with usf: microstep-frequency

FULLSTEP FREQUENCY

To calculate the fullstep frequency from the microstep frequency, the microstep frequency must be

divided by the number of microsteps per fullstep.

with fsf: fullstep-frequency

The change in the pulse rate per time unit (pulse frequency change per second – the acceleration a) is

given by

This results in acceleration in fullsteps of:

with af: acceleration in fullsteps

www.trinamic.com

Page 32

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 32

Signal

value

f_

CLK

16 MHz

velocity

1000

a_max

1000

pulse_div

1

ramp_div

1

usrs

6

Hz

MHz

msf 31.122070

3220482

100016

1

HzHzfsf 34.1907

2

31.122070

][

6

s

MHz

Mhz

a 21.119

2

1000)16(

2911

2

s

MHz

s

MHz

af 863.1

2

21.119

6

49.26

72

34.1907

rotationperfullsteps

fsf

RPS

46.1589

72

6034.190760

rotationperfullsteps

fsf

RPM

EXAMPLE:

CALCULATION OF THE NUMBER OF ROTATIONS

A stepper motor has e.g. 72 fullsteps per rotation.

www.trinamic.com

Page 33

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 33

11 Life Support Policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent of

TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support

or sustain life, and whose failure to perform, when

properly used in accordance with instructions provided,

can be reasonably expected to result in personal injury

or death.

© TRINAMIC Motion Control GmbH & Co. KG 2013

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties,

which may result from its use.

Specifications are subject to change without notice.

All trademarks used are property of their respective

owners.

www.trinamic.com

Page 34

PD-1160 V1.1 Hardware Manual (Rev. 1.02 / 2013-JUL-23) 34

Version

Date

Author

GE - Göran Eggers

SD - Sonja Dwersteg

Description

0.91

2012-MAY-03

GE

Initial version

1.00

2012-JUN-12

SD

First complete version including the following chapters:

- Reset to factory defaults,

- LEDs

1.01

2012-JUL-30

SD

General purpose inputs corrected.

1.02

2013-JUL-23

SD

Chapter 3.2.1 updated.

Version

Date

Description

TMCM-1160_V10

2011-JUL-20

Initial version

TMCM-1160_V11

2012-JAN-24

- Inputs IN_0 and IN_1 can be used as analog

inputs, also

12 Revision History

12.1 Document Revision

Table 12.1 Document revision

12.2 Hardware Revision

Table 12.2 Hardware revision

13 References

[PD-1160 TMCL] PD-1160 TMCL Firmware Manual

[TMCL-IDE] TMCL-IDE User Manual

[QSH5718] QSH5718 Manual

[QSH6018] QSH6018 Manual

Please refer to www.trinamic.com.

www.trinamic.com

Loading...

Loading...