Trinamic PD1-113-57-SE232, PD2-113-57-SE232, PD3-113-57-SE232, PD4-113-57-SE232, PD1-113-60-SE232 Firmware Manual

...

PDx-113-57/60-SE

TMCM-113-57/60-SE

TMCLTM Firmware Manual

Version: 1.10

2009-OCT-28

Trinamic Motion Control GmbH & Co KG

Sternstraße 67

D – 20 357 Hamburg, Germany

Phone +49-40-51 48 06 - 0

FAX: +49-40-51 48 06 - 60

http://www.trinamic.com

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

2 |

Table of contents

1 |

Life support policy ....................................................................................................................................................... |

4 |

||

2 |

Features........................................................................................................................................................................... |

5 |

||

3 |

Order codes .................................................................................................................................................................... |

6 |

||

4 |

Overview ......................................................................................................................................................................... |

7 |

||

5 Putting the PDx-113-57/60-SE into operation ....................................................................................................... |

8 |

|||

|

5.1 |

Starting up............................................................................................................................................................. |

9 |

|

|

5.2 |

Writing a simple TMCLTM program ................................................................................................................ |

10 |

|

|

5.3 |

Operating the module in direct mode ........................................................................................................ |

11 |

|

6 |

TMCLTM and TMCL-IDE ................................................................................................................................................ |

12 |

||

|

6.1 |

Binary command format.................................................................................................................................. |

12 |

|

|

6.2 |

Reply format........................................................................................................................................................ |

13 |

|

|

6.2.1 |

|

Status codes.................................................................................................................................................. |

14 |

|

6.3 |

Stand-alone applications ................................................................................................................................. |

14 |

|

|

6.4 |

TMCLTM command overview ............................................................................................................................ |

14 |

|

|

6.4.1 |

|

Motion commands ...................................................................................................................................... |

14 |

|

6.4.2 |

|

Parameter commands ................................................................................................................................ |

15 |

|

6.4.3 |

|

I/O port commands..................................................................................................................................... |

15 |

|

6.4.4 |

|

Control commands...................................................................................................................................... |

15 |

|

6.4.5 |

|

Calculation commands............................................................................................................................... |

15 |

|

6.5 |

TMCLTM commands ............................................................................................................................................. |

16 |

|

|

6.6 |

The ASCII interface ........................................................................................................................................... |

18 |

|

|

6.6.1 |

|

Format of the command line................................................................................................................... |

18 |

|

6.6.2 |

|

Format of a reply......................................................................................................................................... |

18 |

|

6.6.3 |

|

Commands that can be used in ASCII mode ..................................................................................... |

18 |

|

6.6.4 |

|

Configuring the ASCII interface .............................................................................................................. |

18 |

|

6.7 |

Commands ........................................................................................................................................................... |

20 |

|

|

6.7.1 |

|

ROR (rotate right)......................................................................................................................................... |

20 |

|

6.7.2 |

|

ROL (rotate left)............................................................................................................................................ |

21 |

|

6.7.3 |

|

MST (motor stop)......................................................................................................................................... |

22 |

|

6.7.4 |

|

MVP (move to position)............................................................................................................................. |

23 |

|

6.7.5 |

|

SAP (set axis parameter) ........................................................................................................................... |

25 |

|

6.7.6 |

|

GAP (get axis parameter)........................................................................................................................... |

29 |

|

6.7.7 |

|

STAP (store axis parameter) ..................................................................................................................... |

33 |

|

6.7.8 |

|

RSAP (restore axis parameter) ................................................................................................................. |

37 |

|

6.7.9 |

|

SGP (set global parameter)....................................................................................................................... |

40 |

|

6.7.10 |

GGP (get global parameter)...................................................................................................................... |

43 |

|

|

6.7.11 |

STGP (store global parameter)................................................................................................................. |

46 |

|

|

6.7.12 |

RSGP (restore global parameter)............................................................................................................. |

48 |

|

|

6.7.13 |

RFS (reference search)................................................................................................................................ |

50 |

|

|

6.7.14 |

SIO (set output) ........................................................................................................................................... |

51 |

|

|

6.7.15 |

GIO (get input/output) ............................................................................................................................... |

52 |

|

|

6.7.16 |

CALC (calculate) ............................................................................................................................................ |

54 |

|

|

6.7.17 |

COMP (compare)........................................................................................................................................... |

55 |

|

|

6.7.18 |

JC (jump conditional).................................................................................................................................. |

56 |

|

|

6.7.19 |

JA (jump always).......................................................................................................................................... |

57 |

|

|

6.7.20 |

CSUB (call subroutine)................................................................................................................................ |

58 |

|

|

6.7.21 |

RSUB (return from subroutine)................................................................................................................ |

59 |

|

|

6.7.22 |

WAIT (wait for an event to occur) ......................................................................................................... |

60 |

|

|

6.7.23 |

STOP (stop TMCLTM program execution) ................................................................................................ |

61 |

|

|

6.7.24 |

SCO (set coordinate) ................................................................................................................................... |

62 |

|

|

6.7.25 |

GCO (get coordinate) .................................................................................................................................. |

63 |

|

|

6.7.26 |

CCO (capture coordinate)........................................................................................................................... |

64 |

|

|

6.7.27 |

CALCX (calculate using the X register) .................................................................................................. |

65 |

|

|

6.7.28 |

AAP (accumulator to axis parameter) .................................................................................................... |

66 |

|

|

6.7.29 |

AGP (accumulator to global parameter) ............................................................................................... |

70 |

|

|

6.7.30 |

CLE (clear error flags) ................................................................................................................................. |

73 |

|

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

3 |

||

|

6.7.31 Customer specific TMCLTM command extension (UF0…UF7/user function)................................... |

74 |

|

|

6.7.32 Request target position reached event................................................................................................. |

75 |

|

|

6.7.33 BIN (return to binary mode) .................................................................................................................... |

76 |

|

|

6.7.34 TMCLTM Control Functions.......................................................................................................................... |

77 |

|

7 |

Axis parameters .......................................................................................................................................................... |

79 |

|

8 |

Global parameters ...................................................................................................................................................... |

83 |

|

8.1 |

Bank 0 ................................................................................................................................................................... |

83 |

|

8.2 |

Bank 1 ................................................................................................................................................................... |

85 |

|

8.3 |

Bank 2 ................................................................................................................................................................... |

86 |

|

9 |

Hints and tips .............................................................................................................................................................. |

87 |

|

9.1 |

Reference search ................................................................................................................................................ |

87 |

|

9.2 |

Changing the prescaler value of an encoder ............................................................................................ |

88 |

|

9.3 |

Stall detection..................................................................................................................................................... |

89 |

|

9.4 |

Fixing microstep errors .................................................................................................................................... |

89 |

|

9.5 |

Using the RS485 interface ............................................................................................................................... |

89 |

|

|

9.5.1 |

Using RS485 with converter ..................................................................................................................... |

89 |

|

9.5.2 Using RS485 with USB-2-X interface converter ................................................................................... |

89 |

|

10 |

Revision history .......................................................................................................................................................... |

90 |

|

10.1 |

Firmware revision.............................................................................................................................................. |

90 |

|

10.2 |

Hardware revision ............................................................................................................................................. |

90 |

|

11 |

References..................................................................................................................................................................... |

90 |

|

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

4 |

1 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not authorize or warrant any of its products for use in life support systems, without the specific written consent of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or sustain life, and whose failure to perform, when properly used in accordance with instructions provided, can be reasonably expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2009

Information given in this data sheet is believed to be accurate and reliable. However neither responsibility is assumed for the consequences of its use nor for any infringement of patents or other rights of third parties, which may result from its use.

Specifications are subject to change without notice.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

5 |

2 Features

The PDx-113-57/60-SE is a full mechatronic device consisting of a NEMA 23 (flange size 57mm) or NEMA 24 (flange size 60mm) stepper motor, controller/driver electronics and integrated encoder. The electronics itself is also available without the motor as TMCM-113-57/60-SE module.

Applications

Compact single-axis stepper motor solutions

Encoder feedback for high reliability operation (-SE option)

Electrical data

Supply voltage: +24V DC nominal (+7V .. +28.5V DC)

Motor current: up-to 2.8A RMS (programmable)

Integrated motor (for PDx-113-57/60-SE only)

Two phase bipolar stepper motor with 2.8A RMS nom. coil current

Holding torque with 57mm motor: 0.55Nm, 1.01Nm, 1.26Nm or 1.89Nm

Holding torque with 60mm motor: 1.1Nm, 1.65Nm, 2.1Nm or 3.1Nm

Integrated encoder (for –SE option only)

Integrated sensOstep™ magnetic encoder (max. 256 increments per rotation) for step-loss detection under all operating conditions

Integrated motion controller

Motion profile calculation in real-time (TMC428 motion controller)

On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

Integrated bipolar stepper motor driver

Up-to 16 microsteps per full step

High-efficient operation, low power dissipation (TMC249 stepper driver with external MOSFETs)

Dynamic current control

Integrated protection

Integrated stallGuard™ for motor stall detection (e.g. elimination of end switches)

Integrated chopSync™ for high velocity operation

Interfaces

2 inputs for reference switches, 2 general purpose inputs and 2 general purpose outputs

either RS-232 or RS-485 serial communication interfaces

Software

Available with TMCL (both interface options)

stand-alone operation or remote controlled operation

program memory (non volatile) for up-to 2048 TMCL commands

PC-based application development software TMCL-IDE available for free

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

6 |

3 Order codes

The PDx-113-57/60-SE is currently available with two different stepper motor series (NEMA23 / 57mm flange size or) with four stepper motors of different length and holding torque each and two interface options:

With NEMA 23 / 57mm flange size motor:

|

Order code |

Description |

Length of unit |

|

PD1-113-57-SE-option |

PANdrive with 0.55Nm max./holding torque |

60mm |

|

PD2-113-57-SE-option |

PANdrive with 1.01Nm max./holding torque |

70mm |

|

PD3-113-57-SE-option |

PANdrive with 1.26Nm max./holding torque |

75mm |

|

PD4-113-57-SE-option |

PANdrive with 1.89Nm max./holding torque |

95mm |

|

|

Table 3.1: Order codes (PDx-113-57-SE) |

|

With NEMA 24 / 60mm flange size motor: |

|

||

|

|

|

|

|

Order code |

Description |

Length of unit |

|

PD1-113-60-SE-option |

PANdrive with 1.10Nm max./holding torque |

64mm |

|

PD2-113-60-SE-option |

PANdrive with 1.65Nm max./holding torque |

75mm |

|

PD3-113-60-SE-option |

PANdrive with 2.10Nm max./holding torque |

84mm |

|

PD4-113-60-SE-option |

PANdrive with 3.10Nm max./holding torque |

105mm |

|

|

Table 3.2: Order codes (PDx-113-60-SE) |

|

The electronic module TMCM-113-57/60-SE itself is also available with two serial interface options: |

|||

|

|

|

|

|

Order code |

Description |

Size of unit |

|

TMCM-113-57/60-SE-option |

Single axis bipolar stepper motor controller / |

board size: 60mm x 60mm |

|

|

driver electronics with integrated encoder |

|

|

|

electronics |

|

|

|

Table 3.3: Order codes (TMCM-113-57/60-SE) |

|

Serial interface options: |

|

|

|

|

|

|

|

|

Interface option |

Communication interface |

|

|

232 |

RS232 interface |

|

|

485 |

RS485 interface |

|

Table 3.4: Options

For cost critical applications and applications with reduced requirements with regard to position feedback both versions - with and without motor - are also available without sensOstep™ encoder as PDx-113-57/60 and TMCM-113-57/60 on request.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

7 |

4 Overview

As with most TRINAMIC modules the software running on the microprocessor of the PDx-113-57/60-SE consists of two parts, a boot loader and the firmware itself. Whereas the boot loader is installed during production and testing at TRINAMIC and remains – normally – untouched throughout the whole lifetime, the firmware can be updated by the user. New versions can be downloaded free of charge from the TRINAMIC website (http://www.trinamic.com).

The firmware shipped with this PANdriveTM is related to the standard TMCLTM firmware shipped with most of TRINAMIC modules with regard to protocol and commands. Corresponding, the module of the PANdriveTM is based on the TMC428 motion controller for stepper motors and the TMC249 high power driver and supports the standard TMCLTM with a special range of values. All commands and parameters available with this unit are explained on the following pages.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

8 |

5 Putting the PDx-113-57/60-SE into operation

Here you can find basic information for putting your PANdrive into operation. The text contains a simple example for a TMCLTM program and a short description of operating the module in direct mode.

The things you need:

PDx-113-57/60-SE

Interface (RS232 or RS485) suitable to your PDx-113-57/60-SE version with cables

Power supply for 24V

TMCL-IDE program and PC

Precautions:

Do not connect or disconnect the motor while powered!

Do not mix up connections or short-circuit pins.

Avoid bounding IO wires with motor power wires as this may cause noise picked up from the motor supply.

Do not exceed the maximum power supply of 28.5V.

Start with power supply OFF!

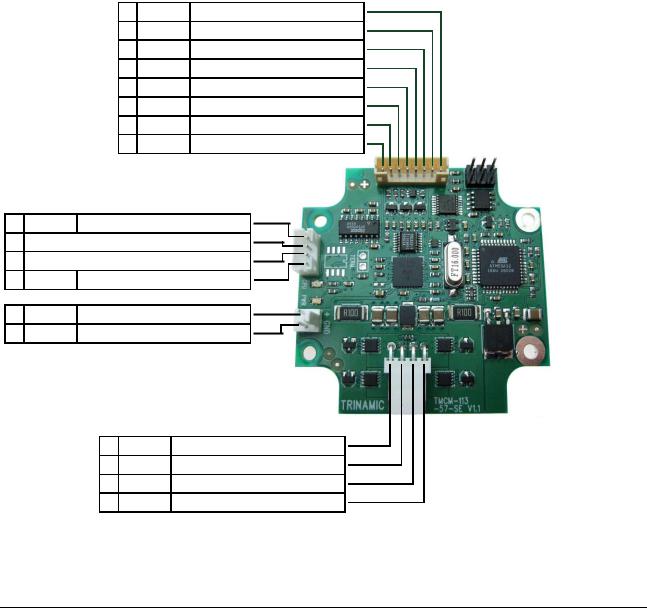

1 |

STOPL |

Left reference switch input |

2 |

STOPR |

Right reference switch input |

3 |

GND |

Supply and signal ground |

4 |

VDD |

Power supply output |

|

|

|

5GPO_0 General purpose output 0

6GPO_1 General purpose output 1

7IN_0 General purpose input 0

8 IN_1 General purpose input 1

1 |

GND |

Supply and signal ground |

2 |

RS232_RxD or RS485A / RS485+ |

|

3 |

RS232_TxD or RS485B / RS485- |

|

4 |

GND |

Supply and system ground |

|

|

|

2 |

VDD |

Power supply input |

1 |

GND |

Supply and system ground |

4 |

B- |

Motor coil B |

3 |

B+ |

Motor coil B |

2 |

A- |

Motor coil A |

|

|

|

1 |

A+ |

Motor coil A |

|

|

|

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

9 |

5.1 Starting up

Here we show you, how to connect the RS232 interface. Use the RS485 interface similarly please.

1.Connect the interface:

Please keep in mind that the RS232 transmit signal wire of the master has to be connected to the RS232 receive signal wire of the board and vice versa.

|

|

|

|

PC |

|

|

|

|

PDx-113-57/60-SE |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

(D-SUB 9pin) |

|

(Serial communication connector) |

|

1 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin |

|

|

Label |

|

Pin |

|

|

Label |

|

|

|

2 |

|

|

RS232_RxD |

|

3 |

|

|

RS232_TxD |

|

|

|

3 |

|

|

RS232_TxD |

|

2 |

|

|

RS232_RxD |

4 |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

GND |

|

|

|

|

GND |

|

||

|

5 |

|

|

|

1, 4 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

2.Connect power supply:

|

|

|

|

PDx-113-57/60-SE |

|

|

|

|

|

|

|

|

|

|

|

|

|

(Power connector) |

|

2 |

|

|

|

|

|

|

1 |

|

Pin |

|

|

Label |

|

|

|

2 |

|

|

Power supply |

|

|

|

1 |

|

|

Ground |

|

|

|

|

|

|

|

|

|

3.Turn power ON. The green LED of the module glows and gives notice that the module is powered with its supply voltage. If this does not occur, switch power OFF and check your connections as well as the power supply.

4.Start the TMCL-IDE software development environment (available on the TechLibCD and www.trinamic.com).

Installing the TMCL-IDE:

Make sure the COM port you intend to use is not blocked by another program.

Open TMCL-IDE by clicking TMCL.exe.

Choose Setup and Options and thereafter the Connection tab.

Choose COM port and type with the parameters shown below (baud rate 9600). Click OK.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

10 |

||

|

|

|

|

|

|

|

|

5.2Writing a simple TMCLTM program

1.Type the following text in the open window.

//A simple example for using TMCL and the TMCL-IDE

SAP 4, 0, 1000 |

//Set the maximum speed |

|

Loop: MVP ABS, 0, |

150000 |

//Move to position 150000 |

WAIT POS, 0, 0 |

|

|

WAIT TICKS, |

0, 200 |

|

MVP ABS, 0, |

0 |

//Move back to position 0 |

WAIT POS, 0, 0 |

|

|

WAIT TICKS, |

0, 100 |

|

JA Loop |

|

// Infinite Loop |

Assemble |

|

|

|

|

|

|

Stop |

|

|

||||||

|

|

|

Download |

|

Run |

||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

2.Click the Assemble icon.

3.Thereafter click the Download icon to download the code into the TMCM-113-57/60-SE.

4.Click the Run icon. The downloaded program will now be executed.

5.Click Stop button to stop the program.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

11 |

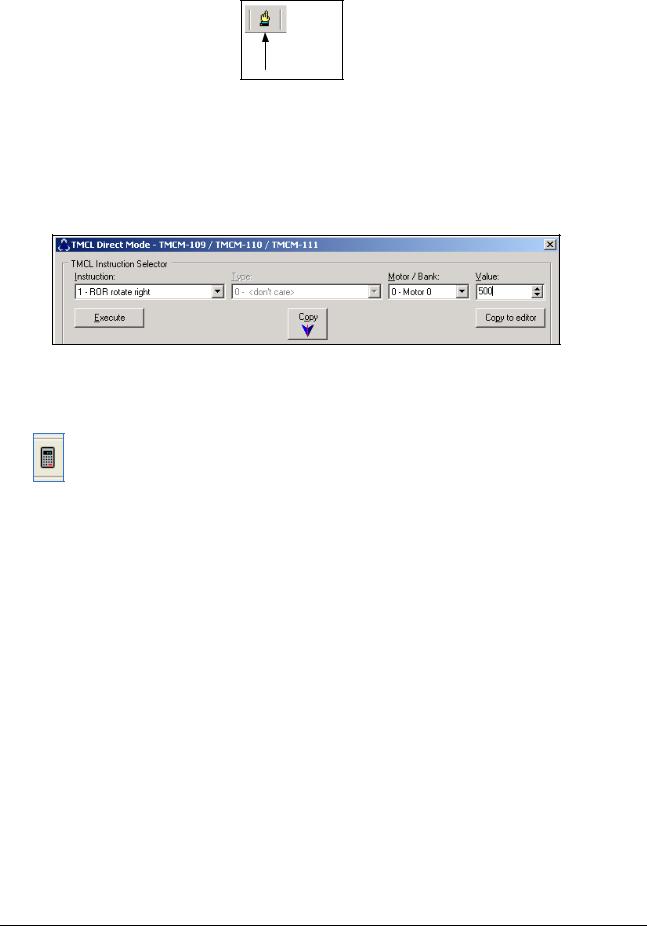

5.3Operating the module in direct mode

1.Start TMCL Direct Mode.

Direct Mode

2.If the communication is established the TMCM-113-57/60-SE is automatically detected. If the module is not detected, please check all points above (cables, interface, power supply, COM port, baud rate).

3.Issue a command by choosing instruction, type (if necessary), motor, and value and click Execute to send it to the module. As the TMCM-113 controls and drives only one motor, always choose 0 for the motor number.

Examples:

ROR rotate right, motor 0, value 500 -> Click Execute. The motor is rotating now.

MST motor stop, motor 0 |

-> Click Execute. The motor stops now. |

Please use the TMCL-IDE axis parameter calculation tool for getting best values.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

12 |

6 TMCLTM and TMCL-IDE

The PDx-113-57/60-SE supports TMCLTM direct mode (binary commands or ASCII interface) and stand-alone TMCLTM program execution. You can store up to 2048 TMCLTM instructions on it.

In direct mode the TMCLTM communication over RS485 or RS232 follows a strict master/slave relationship. That is, a host computer (e.g. PC/PLC) acting as the interface bus master will send a command to the PDx- 113-57/60-SE. The TMCLTM interpreter on the module will then interpret this command, do the initialization of the motion controller, read inputs and write outputs or whatever is necessary according to the specified command. As soon as this step has been done, the module will send a reply back over RS485/RS232 to the bus master. The master should not transfer the next command till then. Normally, the module will just switch to transmission and occupy the bus for a reply, otherwise it will stay in receive mode. It will not send any data over the interface without receiving a command first. This way, any collision on the bus will be avoided when there are more than two nodes connected to a single bus.

The Trinamic Motion Control Language (TMCLTM) provides a set of structured motion control commands. Every motion control command can be given by a host computer or can be stored in an EEPROM on the TMCMTM module to form programs that run stand-alone on the module. For this purpose there are not only motion control commands but also commands to control the program structure (like conditional jumps, compare and calculating).

Every command has a binary representation and a mnemonic. The binary format is used to send commands from the host to a module in direct mode, whereas the mnemonic format is used for easy usage of the commands when developing stand-alone TMCLTM applications using the TMCL-IDE (Integrated Development Environment).

There is also a set of configuration variables for the axis and for global parameters which allow individual configuration of nearly every function of a module. This manual gives a detailed description of all TMCLTM commands and their usage.

6.1 Binary command format

Every command has a mnemonic and a binary representation. When commands are sent from a host to a module, the binary format has to be used. Every command consists of a one-byte command field, a one-byte type field, a one-byte motor/bank field and a four-byte value field. So the binary representation of a command always has seven bytes. When a command is to be sent via RS232 or RS485 interface, it has to be enclosed by an address byte at the beginning and a checksum byte at the end. In this case it consists of nine bytes.

The binary command format for RS232 and RS485 is as follows:

|

Bytes |

|

|

Meaning |

|

|

|

|

|

||

|

1 |

|

Module address |

||

|

1 |

|

Command number |

||

|

1 |

|

Type number |

||

|

1 |

|

Motor or Bank number |

||

|

4 |

|

Value (MSB first!) |

||

|

1 |

|

Checksum |

||

The checksum is calculated by adding up all the other bytes using an 8-bit addition.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

13 |

Checksum calculation

As mentioned above, the checksum is calculated by adding up all bytes (including the module address byte) using an 8-bit addition. Here are two examples to show how to do this:

in C:

unsigned char i, Checksum; unsigned char Command[9];

//Set the “Command” array to the desired command

Checksum = Command[0]; for(i=1; i<8; i++)

Checksum+=Command[i];

Command[8]=Checksum; //insert checksum as last byte of the command //Now, send it to the module

in Delphi:

var

i, Checksum: byte;

Command: array[0..8] of byte;

//Set the “Command” array to the desired command

//Calculate the Checksum: Checksum:=Command[0];

for i:=1 to 7 do Checksum:=Checksum+Command[i]; Command[8]:=Checksum;

//Now, send the “Command” array (9 bytes) to the module

6.2 Reply format

Every time a command has been sent to a module, the module sends a reply.

The reply format for RS485 and RS232 is as follows:

|

Bytes |

|

|

Meaning |

|

|

|

|

|

||

|

1 |

|

Reply address |

||

|

1 |

|

Module address |

||

|

1 |

|

Status (e.g. 100 means “no error”) |

||

|

1 |

|

Command number |

||

|

4 |

|

Value (MSB first!) |

||

|

1 |

|

Checksum |

||

The checksum is also calculated by adding up all the other bytes using an 8-bit addition.

Do not send the next command before you have received the reply!

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

14 |

6.2.1 Status codes

The reply contains a status code.

The status code can have one of the following values:

|

Code |

|

|

Meaning |

|

|

|

|

|

||

|

100 |

|

Successfully executed, no error |

||

|

101 |

|

Command loaded into TMCLTM |

||

|

|

|

program EEPROM |

||

|

1 |

|

Wrong checksum |

||

|

2 |

|

Invalid command |

||

|

3 |

|

Wrong type |

||

|

4 |

|

Invalid value |

||

|

5 |

|

Configuration EEPROM locked |

||

|

6 |

|

Command not available |

||

6.3 Stand-alone applications

The module is equipped with an EEPROM for storing TMCLTM applications. You can use the TMCL-IDE for developing stand-alone TMCLTM applications. You can load your program down into the EEPROM and then it will run on the module. The TMCL-IDE contains an editor and a TMCLTM assembler where the commands can be entered using their mnemonic format. They will be assembled automatically into their binary representations. Afterwards this code can be downloaded into the module to be executed there.

6.4 TMCLTM command overview

In this section a short overview of the TMCLTM commands is given.

6.4.1 Motion commands

These commands control the motion of the motor. They are the most important commands and can be used in direct mode or in stand-alone mode.

|

Mnemonic |

|

|

Command |

|

|

Meaning |

|

|

|

|

number |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

ROL |

|

2 |

|

|

Rotate left |

||

|

ROR |

|

1 |

|

|

Rotate right |

||

|

MVP |

|

4 |

|

|

Move to position |

||

|

MST |

|

3 |

|

|

Motor stop |

||

|

RFS |

|

13 |

|

|

Reference search |

||

|

SCO |

|

30 |

|

|

Store coordinate |

||

|

CCO |

|

32 |

|

|

Capture coordinate |

||

|

GCO |

|

31 |

|

|

Get coordinate |

||

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

15 |

6.4.2 Parameter commands

These commands are used to set, read and store axis parameters or global parameters. Axis parameters can be set independently for the axis, whereas global parameters control the behavior of the module itself. These commands can also be used in direct mode and in stand-alone mode.

|

Mnemonic |

|

|

Command |

|

|

Meaning |

|

|

|

|

number |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

SAP |

|

5 |

|

|

Set axis parameter |

||

|

GAP |

|

6 |

|

|

Get axis parameter |

||

|

STAP |

|

7 |

|

|

Store axis parameter into EEPROM |

||

|

RSAP |

|

8 |

|

|

Restore axis parameter from EEPROM |

||

|

SGP |

|

9 |

|

|

Set global parameter |

||

|

GGP |

|

10 |

|

|

Get global parameter |

||

|

STGP |

|

11 |

|

|

Store global parameter into EEPROM |

||

|

RSGP |

|

12 |

|

|

Restore global parameter from EEPROM |

||

6.4.3 I/O port commands

These commands control the external I/O ports and can be used in direct mode and in stand-alone mode.

|

Mnemonic |

|

|

Command |

|

|

Meaning |

|

|

|

|

number |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

SIO |

|

14 |

|

|

Set output |

||

|

GIO |

|

15 |

|

|

Get input |

||

|

SAC |

|

29 |

|

|

Access to external SPI device |

||

6.4.4 Control commands

These commands are used to control the program flow (loops, conditions, jumps etc.). It does not make sense to use them in direct mode. They are intended for stand-alone mode only.

|

Mnemonic |

|

|

Command |

|

|

Meaning |

|

|

|

|

number |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

JA |

|

22 |

|

|

Jump always |

||

|

JC |

|

21 |

|

|

Jump conditional |

||

|

COMP |

|

20 |

|

|

Compare accumulator with constant |

||

|

|

|

|

|

|

|

value |

|

|

CLE |

|

36 |

|

|

Clear error flags |

||

|

CSUB |

|

23 |

|

|

Call subroutine |

||

|

RSUB |

|

24 |

|

|

Return from subroutine |

||

|

WAIT |

|

27 |

|

|

Wait for a specified event |

||

|

STOP |

|

28 |

|

|

End of a TMCLTM program |

||

6.4.5 Calculation commands

These commands are intended to be used for calculations within TMCLTM applications. Although they could also be used in direct mode it does not make much sense to do so.

Mnemonic |

Command |

Meaning |

|

number |

|

CALC |

19 |

Calculate using the accumulator and a |

|

|

constant value |

CALCX |

33 |

Calculate using the accumulator and the |

|

|

X register |

AAP |

34 |

Copy accumulator to an axis parameter |

AGP |

35 |

Copy accumulator to a global parameter |

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

16 |

For calculating purposes there is an accumulator (or accu or A register) and an X register. When executed in a TMCLTM program (in stand-alone mode), all TMCLTM commands that read a value store the result in the accumulator. The X register can be used as an additional memory when doing calculations. It can be loaded from the accumulator.

When a command that reads a value is executed in direct mode the accumulator will not be affected. This means that while a TMCLTM program is running on the module (stand-alone mode), a host can still send commands like GAP, GGP or GIO to the module (e.g. to query the actual position of the motor) without affecting the flow of the TMCLTM program running on the module.

6.5 TMCLTM commands

The following TMCLTM commands are currently supported:

Command |

Number |

Parameter |

Description |

ROR |

1 |

<motor number>, <velocity> |

Rotate right with specified velocity |

ROL |

2 |

<motor number>, <velocity> |

Rotate left with specified velocity |

MST |

3 |

<motor number> |

Stop motor movement |

MVP |

4 |

ABS|REL|COORD, <motor number>, |

Move to position (absolute or relative) |

|

|

<position|offset> |

|

SAP |

5 |

<parameter>, <motor number>, <value> |

Set axis parameter (motion control |

|

|

|

specific settings) |

GAP |

6 |

<parameter>, <motor number> |

Get axis parameter (read out motion |

|

|

|

control specific settings) |

STAP |

7 |

<parameter>, <motor number> |

Store axis parameter permanently (non |

|

|

|

volatile) |

RSAP |

8 |

<parameter>, <motor number> |

Restore axis parameter |

SGP |

9 |

<parameter>, <bank number>, value |

Set global parameter (module specific |

|

|

|

settings e.g. communication settings or |

|

|

|

TMCL™ user variables) |

GGP |

10 |

<parameter>, <bank number> |

Get global parameter (read out module |

|

|

|

specific settings e.g. communication |

|

|

|

settings or TMCL™ user variables) |

STGP |

11 |

<parameter>, <bank number> |

Store global parameter (TMCL™ user |

|

|

|

variables only) |

RSGP |

12 |

<parameter>, <bank number> |

Restore global parameter (TMCL™ user |

|

|

|

variable only) |

RFS |

13 |

START|STOP|STATUS, <motor number> |

Reference search |

SIO |

14 |

<port number>, <bank number>, <value> |

Set digital output to specified value |

GIO |

15 |

<port number>, <bank number> |

Get value of analogue/digital input |

CALC |

19 |

<operation>, <value> |

Process accumulator & value |

COMP |

20 |

<value> |

Compare accumulator <-> value |

JC |

21 |

<condition>, <jump address> |

Jump conditional |

JA |

22 |

<jump address> |

Jump absolute |

CSUB |

23 |

<subroutine address> |

Call subroutine |

RSUB |

24 |

|

Return from subroutine |

WAIT |

27 |

<condition>, <motor number>, <ticks> |

Wait with further program execution |

STOP |

28 |

|

Stop program execution |

SCO |

30 |

<coordinate number>, <motor number>, |

Set coordinate |

|

|

<position> |

|

GCO |

31 |

<coordinate number>, <motor number> |

Get coordinate |

CCO |

32 |

<coordinate number>, <motor number> |

Capture coordinate |

CALCX |

33 |

<operation> |

Process accumulator & X-register |

AAP |

34 |

<parameter>, <motor number> |

Accumulator to axis parameter |

AGP |

35 |

<parameter>, <bank number> |

Accumulator to global parameter |

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

|

17 |

|

||||||||||||

TMCLTM control commands: |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Instruction |

Description |

|

|

|

|

|

Type |

Mot/Bank |

|

Value |

||||

|

128 |

– stop application |

a running |

|

TMCL™ |

standalone |

(don't care) |

(don't care) |

|

(don't care) |

|||||

|

|

|

application is stopped |

|

|

|

|

|

|

|

|||||

|

129 |

– run application |

TMCL™ execution is started (or |

0 - run from |

(don't care) |

|

(don't care) |

||||||||

|

|

|

continued) |

|

|

|

|

|

|

current address |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 - run from |

|

|

starting address |

|

|

|

|

|

|

|

|

|

|

|

|

specified address |

|

|

|

|

|

130 |

– step application |

only the next command of a |

(don't care) |

(don't care) |

|

(don't care) |

||||||||

|

|

|

TMCL™ application is executed |

|

|

|

|

|

|||||||

|

131 |

– reset application |

the program counter is set to |

(don't care) |

(don't care) |

|

(don't care) |

||||||||

|

|

|

zero, |

and |

the |

standalone |

|

|

|

|

|

||||

|

|

|

application |

is |

stopped |

(when |

|

|

|

|

|

||||

|

|

|

running or stepped) |

|

|

|

|

|

|

|

|

||||

|

132 |

– start download |

target |

command execution |

is |

(don't care) |

(don't care) |

|

starting address |

||||||

|

|

mode |

stopped |

and |

all |

following |

|

|

|

of the application |

|||||

|

|

|

commands |

are |

transferred |

to |

|

|

|

|

|

||||

|

|

|

the TMCL™ memory |

|

|

|

|

|

|

|

|

||||

|

133 |

– quit download |

target |

command execution |

is |

(don't care) |

(don't care) |

|

(don't care) |

||||||

|

|

mode |

resumed |

|

|

|

|

|

|

|

|

|

|

|

|

|

134 – read TMCL™ |

the specified program memory |

(don't care) |

(don't care) |

|

<memory |

|||||||||

|

|

memory |

location is read |

|

|

|

|

|

|

|

address> |

||||

|

135 |

– get application |

one of these values is |

(don't care) |

(don't care) |

|

(don't care) |

||||||||

|

|

status |

returned: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 – stop |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 – run |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 – step |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 – reset |

|

|

|

|

|

|

|

|

|

|

|

|

|

136 |

– get firmware |

return the module type and |

0 – string |

(don’t care) |

|

(don’t care) |

||||||||

|

|

version |

firmware revision either as a |

1 – binary |

|

|

|

|

|||||||

|

|

|

string or in binary format |

|

|

|

|

|

|

||||||

|

137 |

– restore factory |

reset all settings stored in the |

(don’t care) |

(don’t care) |

|

must be 1234 |

||||||||

|

|

settings |

EEPROM |

to |

their |

factory |

|

|

|

|

|

||||

|

|

|

defaults |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This command does not send |

|

|

|

|

|

|||||||

|

|

|

back a reply. |

|

|

|

|

|

|

|

|

|

|||

|

138 |

– reserved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

139 |

– enter ASCII |

Enter ASCII command line (see |

(don’t care) |

(don’t care) |

|

(don’t care) |

||||||||

|

|

mode |

chapter 6.6) |

|

|

|

|

|

|

|

|

|

|

||

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

18 |

6.6 The ASCII interface

TMCLTM also offers an ASCII interface that can be used to communicate with the module and to send some commands as text strings.

The ASCII command line interface is entered by sending the binary command 139 (enter ASCII mode).

Afterwards the commands are entered like in the TMCL-IDE. Please note that only those commands, which can be used in direct mode, also can be entered in ASCII mode.

For leaving the ASCII mode and re-enter the binary mode enter the command BIN.

6.6.1 Format of the command line

As the first character, the address character has to be sent. The address character is A when the module address is 1, B for modules with address 2 and so on. After the address character there may be spaces (but this is not necessary). Then, send the command with its parameters. At the end of a command line a <CR> character has to be sent.

Here are some examples for valid command lines:

AMVP ABS, 1, 50000

A MVP ABS, 1, 50000

AROL 2, 500

A MST 1

ABIN

These command lines would address the module with address 1. To address e.g. module 3, use address character C instead of A. The last command line shown above will make the module return to binary mode.

6.6.2 Format of a reply

After executing the command the module sends back a reply in ASCII format. This reply consists of:

the address character of the host (host address that can be set in the module)

the address character of the module

the status code as a decimal number

the return value of the command as a decimal number

a <CR> character

So, after sending AGAP 0, 1 the reply would be BA 100 –5000 if the actual position of axis 1 is –5000, the host address is set to 2 and the module address is 1. The value 100 is the status code 100 that means command successfully executed.

6.6.3 Commands that can be used in ASCII mode

The following commands can be used in ASCII mode: ROL, ROR, MST, MVP, SAP, GAP, STAP, RSAP, SGP, GGP, STGP, RSGP, RFS, SIO, GIO, SAC, SCO, GCO, CCO, UF0, UF1, UF2, UF3, UF4, UF5, UF6, and UF7.

There are also special commands that are only available in ASCII mode:

BIN: This command quits ASCII mode and returns to binary TMCLTM mode.

RUN: This command can be used to start a TMCLTM program in memory.

STOP: Stops a running TMCLTM application.

6.6.4 Configuring the ASCII interface

The module can be configured so that it starts up either in binary mode or in ASCII mode. Global parameter 67 is used for this purpose (please see also chapter 8.1). Bit 0 determines the startup mode: If this bit is set, the module starts up in ASCII mode, else it will start up in binary mode (default). Bit 4 and Bit 5 determine how the characters that are entered are echoed back. Normally, both bits are set to zero. In

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

19 |

this case every character that is entered is echoed back when the module is addressed. A Character can also be erased using the backspace character (press the backspace key in a terminal program). When bit 4 is set and bit 5 is clear the characters that are entered are not echoed back immediately but the entire line will be echoed back after the <CR> character has been sent. When bit 5 is set and bit 4 is clear there will be no echo, only the reply will be sent. This may be useful in RS485 systems.

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

20 |

6.7 Commands

The module specific commands are explained in more detail on the following pages. They are listed according to their command number.

6.7.1 ROR (rotate right)

With this command the motor will be instructed to rotate with a specified velocity in right direction (increasing the position counter).

Internal function: First, velocity mode is selected. Then, the velocity value is transferred to axis parameter #0 (target velocity).

The module is based on the TMC428 motor controller and the TMC249 power driver. This makes possible choosing a velocity between 0 and 2047.

Related commands: ROL, MST, SAP, GAP

Mnemonic: ROR 0, <velocity>

|

Binary representation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

INSTRUCTION NO. |

|

|

TYPE |

|

|

MOT/BANK |

|

|

|

VALUE |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

1 |

|

|

|

|

(don't care) |

|

0* |

|

|

|

|

|

<velocity> |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0… 2047 |

|

|

|

|

|

|

|

||||

|

|

*motor number is always O as only one motor is involved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

Reply in direct mode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

STATUS |

|

|

|

|

|

VALUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

100 – OK |

|

|

|

(don't care) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotate right, motor 0, velocity = 350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

Mnemonic: ROR 0, 350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

Binary: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Byte Index |

|

|

0 |

|

|

1 |

|

|

|

2 |

|

|

|

3 |

|

|

4 |

|

|

|

5 |

|

|

6 |

|

|

7 |

|

|

8 |

|

||||

|

Function |

|

|

Target- |

|

Instruction |

|

|

Type |

|

|

Motor/ |

|

Operand |

|

Operand |

|

Operand |

|

Operand |

|

Checksum |

||||||||||||||

|

|

|

|

|

address |

|

Number |

|

|

|

|

|

|

Bank |

|

Byte3 |

|

Byte2 |

|

Byte1 |

|

|

Byte0 |

|

|

|

||||||||||

|

Value (hex) |

|

$01 |

|

$01 |

|

$00 |

|

|

$02 |

|

$00 |

|

|

$00 |

|

$01 |

|

|

|

$5e |

$62 |

|

|||||||||||||

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

21 |

6.7.2 ROL (rotate left)

With this command the motor will be instructed to rotate with a specified velocity (opposite direction compared to ROR, decreasing the position counter).

Internal function: First, velocity mode is selected. Then, the velocity value is transferred to axis parameter #0 (target velocity).

The module is based on the TMC428 motor controller and the TMC249 power driver. This makes possible choosing a velocity between 0 and 2047.

Related commands: ROR, MST, SAP, GAP

Mnemonic: ROL 0, <velocity>

|

Binary representation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

INSTRUCTION NO. |

|

|

TYPE |

|

|

MOT/BANK |

|

|

|

VALUE |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

2 |

|

|

|

|

(don't care) |

|

0* |

|

|

|

|

|

<velocity> |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0… 2047 |

|

|

|

|

|

|

|

||||

|

|

*motor number is always O as only one motor is involved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

Reply in direct mode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

STATUS |

|

|

|

|

|

VALUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

100 – OK |

|

|

|

(don't care) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotate left, motor 0, velocity = 1200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

Mnemonic: ROL 0, 1200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

Binary: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Byte Index |

|

|

0 |

|

|

1 |

|

|

|

2 |

|

|

|

3 |

|

|

4 |

|

|

|

5 |

|

|

6 |

|

|

7 |

|

|

8 |

|

||||

|

Function |

|

|

Target- |

|

Instruction |

|

|

Type |

|

|

Motor/ |

|

Operand |

|

Operand |

|

Operand |

|

Operand |

|

Checksum |

||||||||||||||

|

|

|

|

|

address |

|

Number |

|

|

|

|

|

|

Bank |

|

Byte3 |

|

Byte2 |

|

Byte1 |

|

|

Byte0 |

|

|

|

||||||||||

|

Value (hex) |

|

$01 |

|

$02 |

|

$00 |

|

|

$00 |

|

$00 |

|

|

$00 |

|

$04 |

|

|

|

$b0 |

|

$b8 |

|||||||||||||

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

22 |

6.7.3 MST (motor stop)

With this command the motor will be instructed to stop with deceleration ramp (soft stop). For information about hard stops refer to chapter 9 (hints and tips) please.

Internal function: The axis parameter target velocity is set to zero.

|

Related commands: ROL, ROR, SAP, GAP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

Mnemonic: MST 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Binary representation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

INSTRUCTION NO. |

|

|

TYPE |

|

|

MOT/BANK |

|

|

|

VALUE |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

3 |

|

|

|

|

(don't care) |

|

0* |

|

|

|

|

|

(don't care) |

|

|

|

|

|

|

|

|||||||||||||

|

|

*motor number is always O as only one motor is involved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

Reply in direct mode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

STATUS |

|

|

|

|

VALUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

100 – OK |

|

|

(don't care) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stop motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Mnemonic: MST 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Binary: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Byte Index |

|

|

0 |

|

|

1 |

|

|

|

2 |

|

|

|

3 |

|

|

4 |

|

|

|

5 |

|

|

6 |

|

|

7 |

|

|

8 |

|

||||

|

Function |

|

|

Target- |

|

Instruction |

|

|

Type |

|

|

Motor/ |

|

Operand |

|

Operand |

|

Operand |

|

Operand |

|

Checksum |

||||||||||||||

|

|

|

|

|

address |

|

Number |

|

|

|

|

|

|

Bank |

|

Byte3 |

|

Byte2 |

|

Byte1 |

|

|

Byte0 |

|

|

|

||||||||||

|

Value (hex) |

|

$01 |

|

|

$03 |

|

$00 |

|

|

$00 |

|

$00 |

|

|

$00 |

|

$00 |

|

$00 |

|

$05 |

|

|||||||||||||

Copyright © 2009, TRINAMIC Motion Control GmbH & Co. KG

PDx-113-57/60-SE / TMCM-113-57/60-SE Firmware Manual (V1.10 / 2009-OCT-28) |

23 |

6.7.4 MVP (move to position)

With this command the motor will be instructed to move to a specified relative or absolute position or a pre-programmed coordinate. It will use the acceleration/deceleration ramp and the positioning speed programmed into the unit. This command is non-blocking – that is, a reply will be sent immediately after command interpretation and initialization of the motion controller. Further commands may follow without waiting for the motor reaching its end position. The maximum velocity and acceleration are defined by axis parameters #4 and #5.

Three operation types are available:

Moving to an absolute position in the range from - 8388608 to +8388607 (-223 to+223-1).

Starting a relative movement by means of an offset to the actual position. In this case, the new resulting position value must not exceed the above mentioned limits, too.

Moving the motor to a (previously stored) coordinate (refer to SCO for details).

Please note, that the distance between the actual position and the new one should not be more than 8388607 microsteps. Otherwise the motor will run in the wrong direction for taking a shorter way. If the value is exactly 8388608 the motor maybe stops.

Internal function: A new position value is transferred to the axis parameter #2 target position.

Related commands: SAP, GAP, SCO, CCO, GCO, MST

Mnemonic: MVP <ABS|REL|COORD>, 0, <position|offset|coordinate number>

|

Binary representation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

INSTRUCTION NO. |

|

|

TYPE |

|

|

|

|

|

|

|

MOT/BANK |

|

|

VALUE |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

4 |

|

|

|

|

0 ABS – absolute |

|

|

|

|

0* |

|

|

<position> |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 REL – relative |

|

|

|

|

0 |

|

|

|

<offset> |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

2 COORD – coordinate |

|

0 |

|

|

|

<coordinate number (0..20) |

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

*motor number is always O as only one motor is involved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

Reply in direct mode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|