Page 1

PANdrive™ for Stepper Motors

+6V..+28V DC

ARM

Cortex-M0+

TM

microcontroller

TMCL™

Memory

Step

Motor

CAN

Energy Efficient

Driver

TMC262

Stepper

motor

controller +

driver

TMCM-1270

I2C

SPI

Input

REFL/REFR

PD42-x-1270

ENC_A/ENC_B

/ENABLE

4

PANDRIVE™

PD42-1270 Hardware Manual

Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

PD42-1270 is an easy to use PANdrive™smart stepper motor. The module is controlled via a CAN bus interface and comes with two firmware options – TMCL and CANopen. PD42-1270 features stealthChop™for

absolute silent motor control, spreadCycle™for high speed stepper motor commutation, a fully integrated

hardware motion controller with sixPoint™ motion ramps, as well as stallGuard2™ and coolStep™.

Features

• PANdrive™ smart motor

• Supply Voltag +6 to +24V DC

• CAN bus interface

• TMCL or CANopen protocol

•

Integrated

controller

• stealthChop™ silent PWM mode

• spreadCycle™ smart mixed decay

• stallGuard2™ load detection

• coolStep™ autom. current scaling

sixPoint™

ramp motion

Applications

• Lab-Automation

• Manufacturing

Simplified Block Diagram

• Robotics

• Factory Automation

• CNC

• Laboratory Automation

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at: www.trinamic.com

Read entire documentation.

Page 2

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

2 / 24

Contents

1 Features 3

1.1 General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 TRINAMIC’s Unique Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 stealthChop™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 spreadCycle™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.3 stallGuard2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.4 coolStep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.5 sixPoint Motion Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Order Codes 7

3 Mechanical and Electrical Interfacing 8

3.1 PD42-1270 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 PD42-1270 Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 PD42-1270 Motor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 PD42-1270 Torque Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Connectors and LEDs 13

4.1 Power supply and I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 CAN Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Motor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Functional Description 17

5.1 Typical Application Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Operational Ratings and Characteristics 18

6.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Electrical Characteristics (Ambient Temperature 25° C) . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 I/O Ratings (Ambient Temperature 25° C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Functional Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.5 Other Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Abbreviations used in this Manual 19

8 Figures Index 20

9 Tables Index 21

10 Supplemental Directives 22

10.1 Producer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.2 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.3 Trademark Designations and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.4 Target User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.5 Disclaimer: Life Support Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.6 Disclaimer: Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.7 Collateral Documents & Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11 Revision History 24

11.1 Hardware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11.2 Document Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 3

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

3 / 24

1 Features

The PANdrive™PD42-1270 is a full mechatronic solution with state of the art feature set. It is highly

integrated and offers convenient handling via CAN interface. The PD42-1270 includes a stepper motor,

driver electronics, and a fully featured hardware motion controller. It can be used in many decentralized

applications and has been designed for 0.20...0.47 Nm maximum holding torque and 24V DC nominal

supply voltage. With stealthChop™, the PD42-1270 offers absolutely silent and smooth motor operation

for lower and medium velocities. With spreadCycle™, the PD42-1270 offers a high performance current

controlled chopper mode for highest velocities with perfect zero crossing performance. With stallGuard2™,

a sensorless load detection feature is provided for automatic end step detection and load monitoring.

stallGuard2 is also used for the automatic current scaling feature coolStep™. The PD42-1270 comes with a

CAN bus interface and four (4) digital IOs.

1.1 General Features

Main Characteristics

• Supply Voltage +24V nom. (+6V to +28V DC)

• 1.0A RMS phase current (ca. 1.4A peak phase current)

• Highest micro step resolution, up to 256 micro steps per full step

• Available with enclosure and mounted to NEMA17 / 42mm flange size motor

• Permanent onboard parameter storage

• Advanced sixPoint™ ramp hardware motion controller

• Noiseless stealthChop™ chopper mode for slow to medium velocities

• High performance spreadCycle™ chopper mode

• High-precision sensorless load measurement with stallGuard2™

• Automatic current scaling algorithm coolStep™ to save energy and keep your drive cool

I/Os

• Home and reference switch inputs

• Enable input to power-on/-off driver H-bridges

• Optionally configurable analog input

•

Optionally configurable incremental encoder inputs (quadrature channels A and B only, no N channel)

CAN Bus Interface

• Standard CAN Bus Interface for control and configuration

• CAN bit rate of 20. . . 1000kBit/s

• TMCL-based protocol with TMCL firmware option

• CANopen protocol with DS402 device profile with CANopen firmware option

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 4

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

4 / 24

1.2 TRINAMIC’s Unique Features

1.2.1 stealthChop™

stealthChop is an extremely quiet mode of operation for low and medium velocities. It is based on a voltage

mode PWM. During standstill and at low velocities, the motor is absolutely noiseless. Thus, stealthChop

operated stepper motor applications are very suitable for indoor or home use. The motor operates

absolutely free of vibration at low velocities. With stealthChop, the motor current is applied by driving

a certain effective voltage into the coil, using a voltage mode PWM. There are no more configurations

required except for the regulation of the PWM voltage to yield the motor target current.

Figure 1: Motor coil sine wave current using stealthChop (measured with current probe)

1.2.2 spreadCycle™

The spreadCycle chopper is a high-precision, hysteresis-based, and simple to use chopper mode, which

automatically determines the optimum length for the fast-decay phase. Several parameters are available to

optimize the chopper to the application. spreadCycle offers optimal zero crossing performance compared

to other current controlled chopper algorithms and thereby allows for highest smoothness. The true target

current is powered into the motor coils.

Figure 2: spreadCycle principle

1.2.3 stallGuard2

stallGuard2 is a high-precision sensorless load measurement using the back EMF of the motor coils. It

can be used for stall detection as well as other uses at loads below those which stall the motor. The

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 5

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

Load [Nm]

stallGuard2

Initial stallGuard2 (SG) value: 100%

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

0 50 100 150 200 250 300 350

Velocity [RPM]

Efficiency with coolStep

Efficiency with 50% torque reserve

5 / 24

stallGuard2 measurement value changes linearly over a wide range of load, velocity, and current settings.

At maximum motor load, the value reaches zero or is near zero. This is the most energy-efficient point of

operation for the motor.

Figure 3: stallGuard2 Load Measurement as a Function of Load

1.2.4 coolStep

coolStep is a load-adaptive automatic current scaling based on the load measurement via stallGuard2.

coolStep adapts the required current to the load. Energy consumption can be reduced by as much as 75%.

coolStep allows substantial energy savings, especially for motors which see varying loads or operate at a

high duty cycle. Because a stepper motor application needs to work with a torque reserve of 30% to 50%,

even a constant-load application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler, increases motor

life, and allows for cost reduction.

Figure 4: Energy Efficiency Example with coolStep

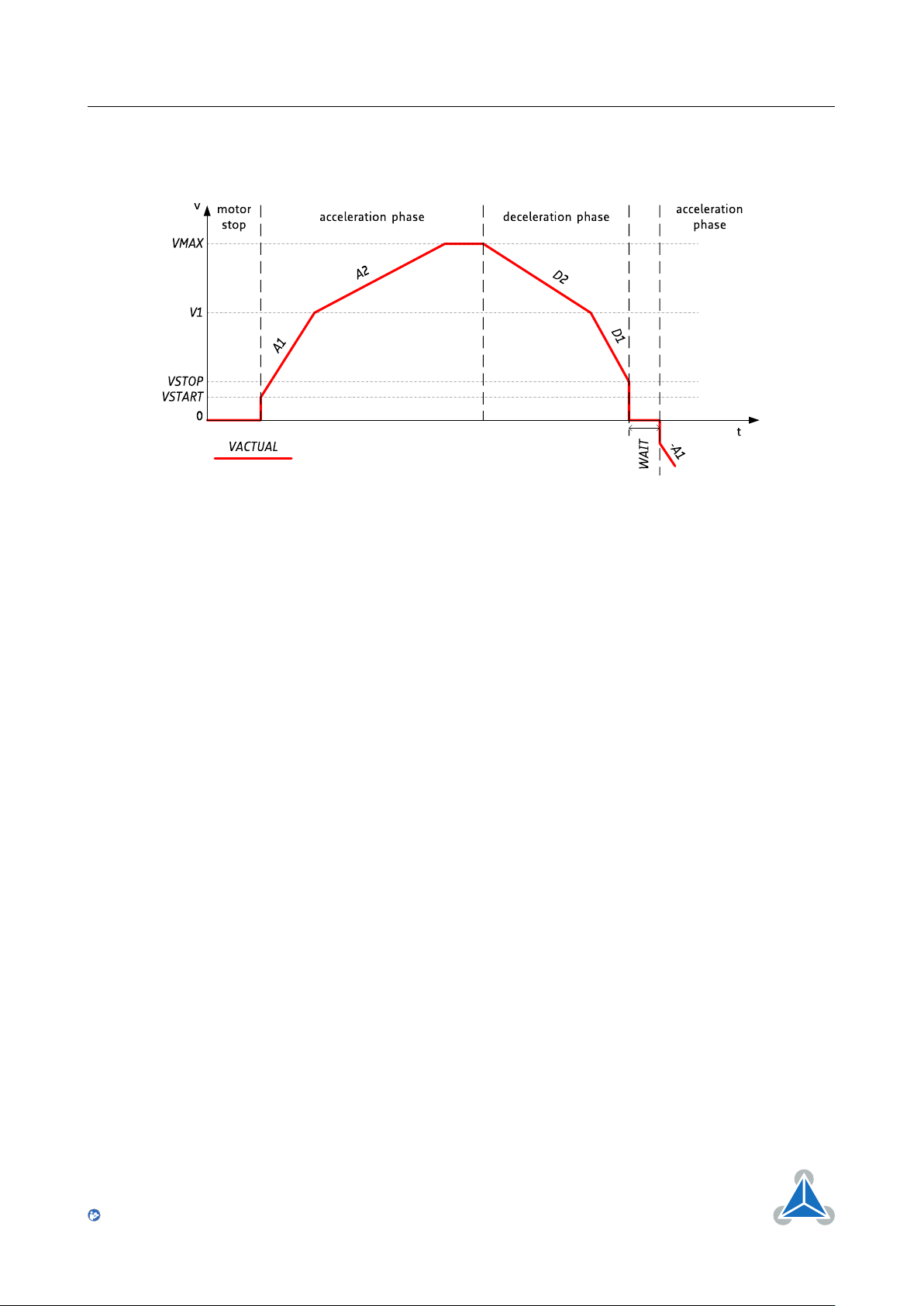

1.2.5 sixPoint Motion Controller

TRINAMIC’s sixPoint motion controller is a new type of ramp generator, which offers faster machine

operation compared to the classical linear acceleration ramps. The sixPoint ramp generator allows adapting

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 6

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

6 / 24

the acceleration ramps to the torque curves of a stepper motor and uses two different acceleration settings

each for the acceleration phase and for the deceleration phase

Figure 5: Typical motion profile with TRINAMIC’s sixPoint motion controller

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 7

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

2 Order Codes

Order Code Description Size (LxWxH)

7 / 24

PD42-1-1270-TMCL

PD42-2-1270-TMCL

PD42-3-1270-TMCL

PD42-1-1270-CANOpen

PD42-2-1270-CANOpen

PD42-3-1270-CANOpen

TMCM-1270-TMCL

TMCM-1270-CANOpen

Table 1: Order codes modules (electronics + enclosure) and PANdrives™

PANdrive, 0.27Nm, 1.0A RMS, +24V DC, CAN Bus

interface, TMCL firmware

PANdrive, 0.35Nm, 1.0A RMS, +24V DC, CAN Bus

interface, TMCL firmware

PANdrive, 0.49Nm, 1.0A RMS, +24V DC, CAN Bus

interface, TMCL firmware

PANdrive, 0.27Nm, 1.0A RMS, +24V DC, CAN Bus

interface, CANopen firmware

PANdrive, 0.35Nm, 1.0A RMS, +24V DC, CAN Bus

interface, CANopen firmware

PANdrive, 0.49Nm, 1.0A RMS, +24V DC, CAN Bus

interface, CANopen firmware

Controller/Driver Module without motor, +24V

DC, CAN Bus interface, TMCL firmware

Controller/Driver Module without motor, +24V

DC, CAN Bus interface, CANopen firmware

42mm x 42mm x 45,5mm

42mm x 42mm x 50mm

42mm x 42mm x 59mm

42mm x 42mm x 45,5mm

42mm x 42mm x 50mm

42mm x 42mm x 59mm

42mm x 42mm x 12mm

42mm x 42mm x 12mm

Order Code Description

TMCM-1270-CABLE Cable loom for TMCM-1270:

• 1x cable loom for motor connector with 4-pin JST PH series connector

•

1x cable loom for Power supply and I/O connector with 10-pin JST PH series

connector

PD42-1270-CABLE Cable loom for PD42-x-1270:

•

1x cable loom for Power supply and I/O connector with 10-pin JST PH series

connector

Table 2: Order codes cable loom

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 8

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

8 / 24

3 Mechanical and Electrical Interfacing

3.1 PD42-1270 Dimensions

The PD42-1270 includes the TMCM-1270 stepper motor controller/driver module (electronics + encapsulating enclosure) and a NEMA17 / 42mm flange size bipolar stepper motor. Currently, there is a choice

between three NEMA17 / 42mm flange size stepper motors with different lengths and different holding

torques. All three stepper motors are rated for 1A RMS coil current - perfectly fitting to the TMCM-1270

electronics.

The dimensions of the controller/driver unit are approx. 42mm x 42mm x 12mm (TMCM-1270 electronics +

encapsulating enclosure). There are two mounting holes for M3 screws for mounting on the back bell of a

NEMA17 / 42mm flange size stepper motor (screw/thread length depends on motor size).

Figure 6: PD42-1270 top view mechanical dimensions

3.2 PD42-1270 Dimensions and Weight

When mounted to the stepper motor the overall size of the PANdrive is the housing height plus motor

body size.

Order Code L in mm Weight in g

TMCM-1270 12 ±0,2 ≈ 32

PD42-1-1270 45,5 ±1 ≈ 260

PD42-2-1270 50 ±1 ≈ 320

PD42-3-1270 59 ±1 ≈ 395

Table 3: Length and weight

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 9

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

9 / 24

Figure 7: PD42-3-1270 mechanical dimensions with motor

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 10

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

3.3 PD42-1270 Motor Parameters

Specifications Parameter Unit PD42-1-1270 PD42-2-1270 PD42-3-1270

Step angle

Step angle accuracy % ±5 ±5 ±5

Ambient temperature T

Max. motor temperature T

amb

motor

max

Shaft radial play (450g load) mm 0,02 0,02 0,02

Shaft axial play (450g load) mm 0,08 0,08 0,08

◦

◦

C -20...+50 -20...+50 -20...+50

◦

C 80 80 80

1.8 1.8 1.8

10 / 24

Max radial force (20mm from

N 28 28 28

front flange)

Max axial force N 10 10 10

Rated voltage V

Rated phase current I

Phase resistance at 20◦C R

Phase inductance (typ.) L

RAT ED

RMSRAT ED

COIL

COIL

V 2.0 2.4 2.4

A 1.0 1.0 1.0

Ω 1.0 1.2 1.4

mH 1.6 2.2 2.1

Holding torque Nm 0.22 0.36 0.44

Insulation class B B B

Rotor inertia g cm2 35 57 68

Weight M kg 0.22 0.24 0.35

Table 4: PD42-1270 Motor Parameters

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 11

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

11 / 24

3.4 PD42-1270 Torque Curves

The following diagrams show the torque vs. speed curves for the PD42-1-1270, the PD42-2-1270, and

the PD42-3-1270 at three different typical conditions. All measurements have been done in spreadCycle

chopper mode. The measurement conditions are:

1. V DD =+24V, I

2. V DD =+24V, I

3. V DD =+12V, I

COILRM S

COILRM S

COILRM S

=1A, 1/256 microstepping

=1A, half stepping

=1A, half stepping

Figure 8: PD42-1-1270 torque vs. speed

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 12

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

12 / 24

Figure 9: PD42-2-1270 torque vs. speed

Figure 10: PD42-3-1270 torque vs. speed

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 13

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

10

1

1

4

Power Supply and I/O

connector

Motor connector

13 / 24

4 Connectors and LEDs

The PD42-1270 offers two connectors - one 10-pin connector for power supply, communication (CAN) and

four Inputs and one four pin connector for connecting the motor.

Figure 11: PD42-1270 connectors

Overview of connector and mating connector types:

Label Connector type Mating connector type

Power supply and I/O connector

Motor connector

JST B10B-PH-K-S (JST PH series,

10pins, 2mm pitch)

JST B4B-PH-K-S (JST PH series,

4pins, 2mm pitch)

Table 5: Connector and mating connectors

4.1 Power supply and I/O Connector

Pin no. Pin name Description

1 GND Supply and signal ground connection

2 +24V Supply voltage input (+6V to +28V DC)

Connector housing: JST PHR-10

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

Connector housing: JST PHR-4

Contacts: JST SPH-002T-P0.5S

Wire: 0.22mm2, AWG 24

3 CAN_H Differential CAN bus signal (non-inverting)

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 14

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

Pin no. Pin name Description

4 CAN_L Differential CAN bus signal (inverting)

5 GND Signal ground connection

14 / 24

6 +5V

7 HOME (GPI0)

8 REFL (GPI1)

9 REFR (GPI2)

10 ENN (GPI3)

Table 6: PD42-1270 Power supply and I/O connector pin assignment

NOTICE

5V output, 100mA maximum load, e.g. for end / home switch circuit or

external encoder supply

General purpose input 0, can be used as HOME switch input, also. Configurable as analog input AIN0 via software (+5V compatible, internal 10k pull-up

to +5V)

General purpose input 1, can be used as left reference / stop switch input

REFL / STOP_L, also. Configurable as incremental encoder input channel A via

software (+5V TTL compatible, internal 10k pull-up to +5V)

General purpose input 2, can be used as right reference / stop switch input

REFR / STOP_R, also. Configurable as incremental encoder input channel B

via software (+5V TTL compatible, internal 10k pull-up to +5V)

ENABLE NOT input (active low) for driver stage, 0 = enabled, 1 = disabled (+5V

TTL compatible, internal 10k pull-up to +5V)

Always keep the power supply voltage below the upper limit of 28V!

Otherwise the driver electronics will be seriously damaged. Especially, when the

selected operating voltage is near the upper limit a regulated power supply is

highly recommended.

NOTICE

Add external power supply capacitors!

It is recommended to connect an electrolytic capacitor of significant size (e.g. 470µF/35V) to the power supply lines next

to the PD42-1270!

Rule of thumb for size of electrolytic capacitor: C =

1000µF

A

× I

SU P P LY

In addition to power stabilization (buffer) and filtering this added capacitor will

also reduce any voltage spikes which might otherwise occur from a combination

of high inductance power supply wires and the ceramic capacitors. In addition

it will limit slew-rate of power supply voltage at the module. The low ESR of

ceramic-only filter capacitors may cause stability problems with some switching

power supplies.

NOTICE

Tie ENN to GND in order to enable driver stage!

Please note that pin 10 of the

Power supply and I/O connector is a hardware driver stage enable input (active

low) with an internal pull-up resistor. In order to enable motor driver stage and

be able to move the motor using appropriate software commands it is necessary

to tie this input to GND.

4.2 CAN Connection

For remote control and communication with a host system the PD42-1270 provides a CAN bus interface.

For proper operation the following items should be taken into account when setting up a CAN network:

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 15

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

15 / 24

Bus Structure

The network topology should follow a bus structure as closely as possible. That is, the

connection between each node and the bus itself should be as short as possible. Basically, it should be

short compared to the length of the bus.

Figure 12: CAN bus strcuture

Bus Termination

Especially for longer busses and/or multiple nodes connected to the bus and/or high

communication speeds, the bus should be properly terminated at both ends. The PD42-1270 does not

integrate any termination resistor. Therefore, 120 Ohm termination resistors at both ends of the bus have

to be added externally.

Number of Nodes

The bus transceiver used on the PD42-1270 (TJA1051) supports at least 100 nodes

under optimum conditions. Practically achievable number of nodes per CAN bus highly depend on bus

length (longer bus → less nodes) and communication speed (higher speed → less nodes).

CAN Bus Adapters

To quickly connect to the PD42-1270 a PC based intergated development environment TMCL-IDE is available. Latest release can be downloaded for free from our web site: www.trinamic.com

A number of common CAN interface adapters from different manufactures is supported from within this

software. Please make sure to check our web site from time to time for the latest version of the software!

4.3 Motor Connector

Pin no. Pin name Description

1 A1 Motor phase A pin 1

2 A2 Motor phase A pin 2

3 B1 Motor phase B pin 1

4 B2 Motor phase B pin 2

Table 7: Motor connector pinning

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 16

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

Green LED

Red LED

16 / 24

NOTICE

Do not connect or disconnect motor during operation!

Motor cable and motor inductivity might lead to voltage spikes when the motor is connected / disconnected while energized. These voltage spikes might exceed voltage limits of the

driver MOSFETs and might permanently damage them. Therefore, always switch

off or disconnect power supply before connecting or disconnecting the motor.

4.4 LEDs

The PD42-1270 includes two LEDs: one green status LED and one red error LED. See figure 13 for LED

location.

Figure 13: PD42-1270 LED colors and loacation

Depending on the firmware option (TMCL or CANopen), these LEDs have different functionality. Main

states for TMCL:

State green LED State red LED Description TMCL Firmware

Flashing off Firmware running (normal operation mode)

Permanent on Permanent on Bootloader mode, firmware update supported

Table 8: LED functionality description

For CANopen firmware LED functionality has been implemented based on CANopen standard.

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 17

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

Power supply

USB-CAN

c:>

Host

5 Functional Description

5.1 Typical Application Wiring

The PD42-1270 driver/controller’s wiring is straightforward as shown in the following figure.

• Power supply must be connected to V+ and GND.

• CAN - use appropriate CAN interface adapter

• ENN - connect ENN signal to GND in order to enable driver stage

17 / 24

Figure 14: Typical application scenario for remote control of PD42-1270

5.2 Inputs

The four inputs of the PD42-1270 are +5V TTL compatible with internal pull-ups (10k) to +5V and

optically isolated.

not

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 18

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

6 Operational Ratings and Characteristics

6.1 Absolute Maximum Ratings

Parameter Min Max Unit

Supply voltage +6 +28 V

Working temperature -30 +40 ° C

Motor coil current / sine wave peak 1.4 A

Continuous motor current (RMS) 1.0 A

18 / 24

NOTICE

Stresses above those listed under "‘Absolute Maximum Ratings"’ may cause permanent damage to the device. This is a stress rating only and functional operation

of the device at those or any other conditions above those indicated in the operation listings of this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

6.2 Electrical Characteristics (Ambient Temperature 25° C)

Parameter Symbol Min Typ Max Unit

Supply voltage V DD 6 24 28 V

Motor coil current / sine wave

peak

(chopper regu-

I

COILpeak

0 1.4 A

lated, adjustable via TTL UART interface)

Continuous motor current (RMS) I

Power supply current I

COILRM S

DD

0 1.0 A

I

COIL

1.4∗I

COIL

Table 10: Electrical Characteristics

6.3 I/O Ratings (Ambient Temperature 25° C)

A

Parameter Symbol Min Typ Max Unit

Input voltage V

Low level voltage V

High level voltage V

IN

L

H

0 1.75 V

3.25 5 V

5 5.5 V

Table 11: I/O ratings

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 19

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

6.4 Functional Characteristics

Parameter Description / Value

19 / 24

Control

CAN bus interface and four digital inputs for referencing, incremental encoder,

and NOT_ENABLE

Communication CAN bus interface for control and configuration, 20. . . 1000kBit/s

Driving Mode

spreadCycle, stealthChop, and constant

T

chopper, adaptive current control

off

via stallGuard2 and coolstep

Stepping Resolution Full, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128, 1/256 step

Table 12: Functional Characteristics

6.5 Other Requirements

Specifications Description or Value

Cooling Free air

Working environment Avoid dust, water, oil mist and corrosive gases, no condensation, no frosting

Working temperature -30° C to +40° C

Table 13: Other Requirements and Characteristics

7 Abbreviations used in this Manual

Abbreviation Description

CAN Controller Area Network

IDE Integrated Development Environment

LED Light Emmitting Diode

RMS Root Mean Square value

TMCL TRINAMIC Motion Control Language

TTL Transistor Transistor Logic

UART Universal Asynchronous Receiver Transmitter

USB Universal Serial Bus

Table 14: Abbreviations used in this Manual

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 20

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

8 Figures Index

1

Motor coil sine wave current using

stealthChop (measured with current

probe) . . . . . . . . . . . . . . . . . . . 4

2 spreadCycle principle . . . . . . . . . . 4

3

stallGuard2 Load Measurement as a

Function of Load . . . . . . . . . . . . 5

4

Energy Efficiency Example with coolStep

5

Typical motion profile with TRINAMIC’s

sixPoint motion controller . . . . . . . 6

6

PD42-1270 top view mechanical di-

mensions . . . . . . . . . . . . . . . . . 8

5

7

PD42-3-1270 mechanical dimensions

with motor . . . . . . . . . . . . . . . . 9

8 PD42-1-1270 torque vs. speed . . . . 11

9 PD42-2-1270 torque vs. speed . . . . 12

10 PD42-3-1270 torque vs. speed . . . . 12

11 PD42-1270 connectors . . . . . . . . . 13

12 CAN bus strcuture . . . . . . . . . . . 15

13 PD42-1270 LED colors and loacation . 16

14

Typical application scenario for re-

mote control of PD42-1270 . . . . . . 17

20 / 24

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 21

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

9 Tables Index

1

Order codes modules (electronics +

enclosure) and PANdrives™ . . . . . . 7

2 Order codes cable loom . . . . . . . . 7

3 Length and weight . . . . . . . . . . . 8

4 PD42-1270 Motor Parameters . . . . 10

5 Connector and mating connectors . . 13

6

PD42-1270 Power supply and I/O con-

nector pin assignment . . . . . . . . . 14

7 Motor connector pinning . . . . . . . 15

8 LED functionality description . . . . . 16

10 Electrical Characteristics . . . . . . . . 18

11 I/O ratings . . . . . . . . . . . . . . . . 18

12 Functional Characteristics . . . . . . . 19

13

Other Requirements and Characteristics

14 Abbreviations used in this Manual . . 19

15 Hardware Revision . . . . . . . . . . . 24

16 Document Revision . . . . . . . . . . . 24

21 / 24

19

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 22

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

22 / 24

10 Supplemental Directives

10.1 Producer Information

10.2 Copyright

TRINAMIC owns the content of this user manual in its entirety, including but not limited to pictures, logos,

trademarks, and resources.©Copyright 2017 TRINAMIC. All rights reserved. Electronically published by

TRINAMIC, Germany.

Redistributions of source or derived format (for example, Portable Document Format or Hypertext Markup

Language) must retain the above copyright notice, and the complete Datasheet User Manual documentation of this product including associated Application Notes; and a reference to other available

product-related documentation.

10.3 Trademark Designations and Symbols

Trademark designations and symbols used in this documentation indicate that a product or feature is

owned and registered as trademark and/or patent either by TRINAMIC or by other manufacturers, whose

products are used or referred to in combination with TRINAMIC’s products and TRINAMIC’s product documentation.

This Hardware Manual is a non-commercial publication that seeks to provide concise scientific and technical

user information to the target user. Thus, trademark designations and symbols are only entered in the

Short Spec of this document that introduces the product at a quick glance. The trademark designation

/symbol is also entered when the product or feature name occurs for the first time in the document. All

trademarks and brand names used are property of their respective owners.

10.4 Target User

The documentation provided here, is for programmers and engineers only, who are equipped with the

necessary skills and have been trained to work with this type of product.

The Target User knows how to responsibly make use of this product without causing harm to himself or

others, and without causing damage to systems or devices, in which the user incorporates the product.

10.5 Disclaimer: Life Support Systems

TRINAMIC Motion Control GmbH & Co. KG does not authorize or warrant any of its products for use in life

support systems, without the specific written consent of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or sustain life, and whose failure to perform,

when properly used in accordance with instructions provided, can be reasonably expected to result in

personal injury or death.

Information given in this document is believed to be accurate and reliable. However, no responsibility

is assumed for the consequences of its use nor for any infringement of patents or other rights of third

parties which may result from its use. Specifications are subject to change without notice.

10.6 Disclaimer: Intended Use

The data specified in this user manual is intended solely for the purpose of product description. No representations or warranties, either express or implied, of merchantability, fitness for a particular purpose

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 23

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

23 / 24

or of any other nature are made hereunder with respect to information/specification or the products to

which information refers and no guarantee with respect to compliance to the intended use is given.

In particular, this also applies to the stated possible applications or areas of applications of the product.

TRINAMIC products are not designed for and must not be used in connection with any applications where

the failure of such products would reasonably be expected to result in significant personal injury or death

(safety-Critical Applications) without TRINAMIC’s specific written consent.

TRINAMIC products are not designed nor intended for use in military or aerospace applications or environments or in automotive applications unless specifically designated for such use by TRINAMIC. TRINAMIC

conveys no patent, copyright, mask work right or other trade mark right to this product. TRINAMIC assumes

no liability for any patent and/or other trade mark rights of a third party resulting from processing or

handling of the product and/or any other use of the product.

10.7 Collateral Documents & Tools

This product documentation is related and/or associated with additional tool kits, firmware and other

items, as provided on the product page at: www.trinamic.com.

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Page 24

PD42-1270 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2017-Mar-02

11 Revision History

11.1 Hardware Revision

Version Date Author Description

1.00 2016-09-27 TMC Series version.

Table 15: Hardware Revision

11.2 Document Revision

Version Date Author Description

1.00 2016-06-26 BS Initial release.

1.10 2016-02-20 GE Update for series version V1.0

Table 16: Document Revision

24 / 24

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.

Loading...

Loading...