Page 1

MONOPACK 2

Manual

Version: 1.04

Jan 29th, 2010

Trinamic Motion Control GmbH & Co KG

Sternstraße 67

D - 20357 Hamburg, Germany

http://www.trinamic.com

Page 2

Monopack 2 Manual V1.04 2

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

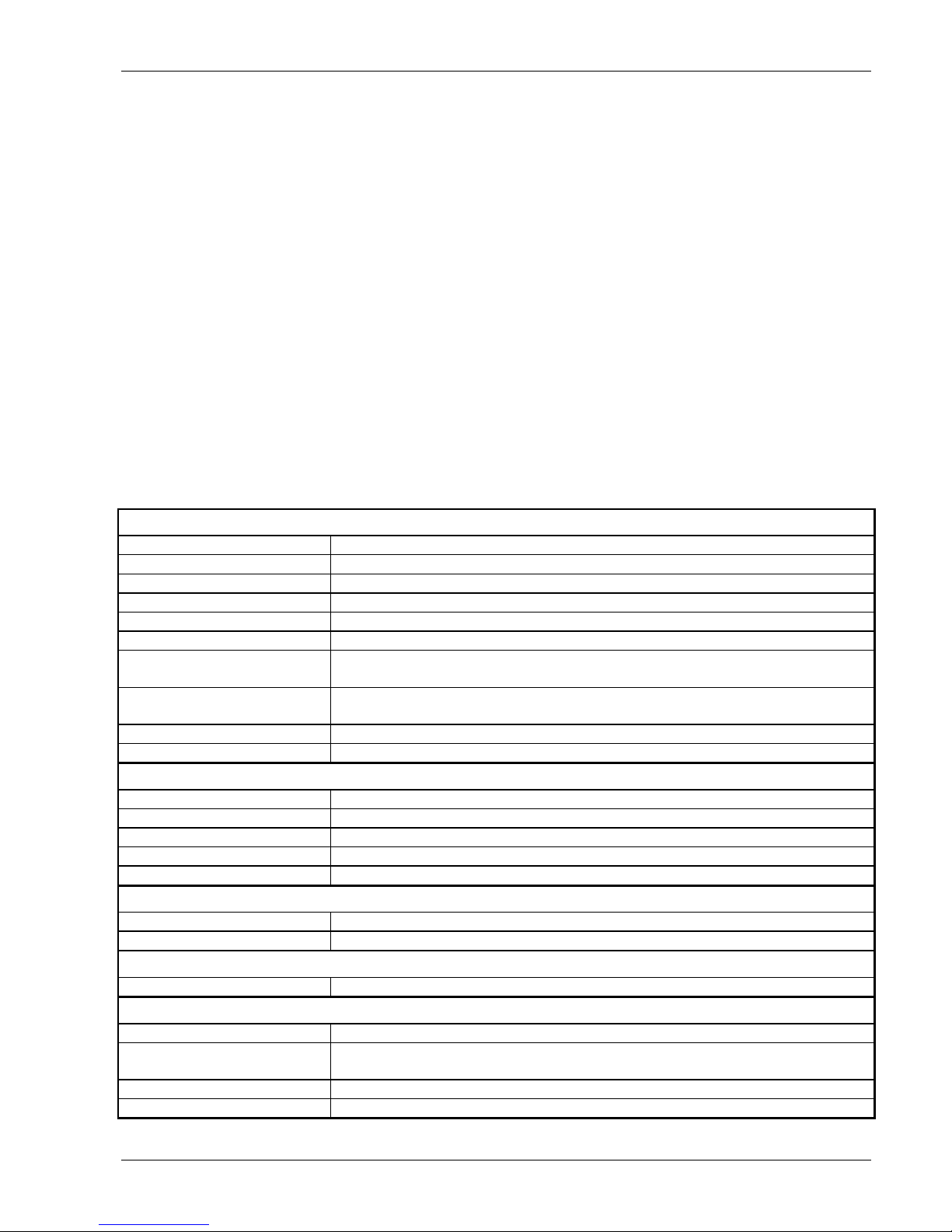

Version

Version

Date

Author

Remarks

1.00

2-Nov-05

OK

Initial version

1.01

18-Aug-06

HC

Added firmware update information

1.01

21-Aug-06

BD

Added Monopack LT frequency incompatibility information

1.02

16-May-2007

HC

Added Mixed Decay information (chapter 4.2.5)

1.03

15-Feb-08

GE

Added V2.0 info

1.04

29-Jan-10

OK

Declaration of Conformity added

Table of Contents

1 Introduction ................................................................................................................................................................... 5

1.1 Brief Description .................................................................................................................................................. 5

1.2 Technical Data ...................................................................................................................................................... 5

2 Connecting the Monopack 2 ..................................................................................................................................... 6

2.1 Pin Assignments .................................................................................................................................................. 6

2.2 Connecting the Motor ........................................................................................................................................ 6

2.3 Stop Switches and Reference Switches........................................................................................................ 7

2.3.1 Linear vs. Circular Drives ........................................................................................................................ 7

2.4 Incremental Encoder .......................................................................................................................................... 7

2.5 Power Supply ....................................................................................................................................................... 7

2.6 The RS232 interface ............................................................................................................................................ 7

2.7 The 25 pin Sub-D Socket ................................................................................................................................... 8

2.7.1 CAN and RS485 Interface ........................................................................................................................ 8

2.7.2 The Step/Direction Interface .................................................................................................................. 8

2.7.3 The Alarm Input ........................................................................................................................................ 8

2.7.4 The Alarm Output ..................................................................................................................................... 8

2.7.5 The Incremental Encoder Output ......................................................................................................... 8

2.7.6 The Stop Switch Outputs ....................................................................................................................... 8

2.8 The Step/Direction input socket...................................................................................................................... 9

2.9 The hexadecimal Switch.................................................................................................................................... 9

2.10 The DIP switches ................................................................................................................................................ 9

3 Controlling the Monopack 2 .................................................................................................................................... 10

3.1 Step/Direction Mode ......................................................................................................................................... 10

3.2 Binary Command Mode ................................................................................................................................... 10

3.2.1 Format of the Data Telegrams............................................................................................................ 10

3.2.2 Unit Addresses ......................................................................................................................................... 10

3.2.3 Parameter Storage .................................................................................................................................. 10

3.3 Monopack LT (ASCII) Command Mode ....................................................................................................... 11

4 Binary Command Reference .................................................................................................................................... 12

4.1 Parameter Storage Control ............................................................................................................................. 12

4.2 Motor Parameters .............................................................................................................................................. 12

4.2.1 Current Limit ($10) .................................................................................................................................. 12

4.2.2 Current Control ($11) ............................................................................................................................. 12

4.2.3 Get Current Control Settings ($53) .................................................................................................... 13

4.2.4 Frequency Range ($12) .......................................................................................................................... 13

4.2.5 Microstep Resolution, Waveform and Mixed Decay ($17) ........................................................... 13

4.3 Driving .................................................................................................................................................................. 14

4.3.1 About the Parameters ........................................................................................................................... 14

4.3.2 Velocity and Maximum Acceleration ($14) ...................................................................................... 14

4.3.3 Bow Value ($63) ...................................................................................................................................... 15

4.3.4 Get Acceleration and Velocity Settings ($52) ................................................................................. 15

Page 3

Monopack 2 Manual V1.04 3

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.3.5 Get actual Position ($20) ...................................................................................................................... 15

4.3.6 Get actual Acceleration and Velocity ($21) ...................................................................................... 15

4.3.7 Drive a Ramp ($23) ................................................................................................................................. 16

4.3.8 Constant Rotation ($25) ........................................................................................................................ 16

4.3.9 Reset Position ($27) ............................................................................................................................... 16

4.3.10 Soft Stop ($2A) ........................................................................................................................................ 16

4.3.11 Emergency Stop ($2B) ........................................................................................................................... 16

4.4 Stop and Reference Switches ........................................................................................................................ 17

4.4.1 Switch Mode ($54) .................................................................................................................................. 17

4.4.2 Deceleration at Stop Switches ($57) ................................................................................................. 17

4.4.3 Reference Search ($22) .......................................................................................................................... 17

4.4.4 Reference Search Velocity ($16).......................................................................................................... 18

4.4.5 Travel Check Tolerance ($59) ............................................................................................................... 18

4.4.6 Number of Microsteps per Revolution ($15) ................................................................................... 18

4.4.7 Get the State of the Stop Switches ($30) ........................................................................................ 18

4.5 Incremental Encoder ........................................................................................................................................ 19

4.5.1 About Incremental Encoders ............................................................................................................... 19

4.5.2 Encoder Configuration ($70) ................................................................................................................ 19

4.5.3 Encoder Counter ($71) ........................................................................................................................... 20

4.5.4 Encoder Holding Register ($72) .......................................................................................................... 20

4.5.5 Deviation Alarm ($73) ............................................................................................................................ 20

4.5.6 Configure Automatic Position Correction ($58) ............................................................................. 20

4.5.7 PID Controller Configuration ($6A, $6B, $6C, $6D, $6F) .............................................................. 21

4.6 Alarms and Errors ............................................................................................................................................. 22

4.6.1 Alarm Mode ($51) ................................................................................................................................... 22

4.6.2 Reset Alarm Output ($74) ..................................................................................................................... 22

4.7 Other Settings .................................................................................................................................................... 22

4.7.1 Enter Step/Direction Mode ($50) ........................................................................................................ 22

4.7.2 Set CAN receive ID and RS485 ID ($55) ........................................................................................... 22

4.7.3 Set CAN send ID ($56) ........................................................................................................................... 23

4.7.4 Set CAN Baud Rate ($C0) ...................................................................................................................... 23

4.7.5 Get Version Number ($43) .................................................................................................................... 23

4.7.6 Hardware Reset ($CC) ............................................................................................................................ 23

4.8 Factory Default Settings ($DD) ...................................................................................................................... 23

5 Monopack LT Command Reference ....................................................................................................................... 24

5.1 Interface selection ............................................................................................................................................ 24

5.2 Command overview ......................................................................................................................................... 24

5.2.1 Set the pre-divider.................................................................................................................................. 25

5.2.2 Set microstep resolution ...................................................................................................................... 25

5.2.3 Acceleration setting ............................................................................................................................... 25

5.2.4 Bow setting .............................................................................................................................................. 25

5.2.5 Velocity setting ........................................................................................................................................ 25

5.2.6 Direction setting ..................................................................................................................................... 25

5.2.7 Drive with fixed velocity ...................................................................................................................... 25

5.2.8 Soft stop .................................................................................................................................................... 25

5.2.9 Hard stop .................................................................................................................................................. 26

5.2.10 Set target position or relative distance ........................................................................................... 26

5.2.11 Drive to target position ........................................................................................................................ 26

5.2.12 Relative move .......................................................................................................................................... 26

5.2.13 Set motor standby current ................................................................................................................... 26

5.2.14 Set motor run current ........................................................................................................................... 26

5.2.15 Set motor acceleration current ........................................................................................................... 26

5.2.16 Set mixed decay mode ......................................................................................................................... 27

5.2.17 Automatic reference search ................................................................................................................. 27

5.2.18 Find reference switch position ........................................................................................................... 27

5.2.19 Set stop switch mode ........................................................................................................................... 27

5.2.20 Change actual position ......................................................................................................................... 27

5.2.21 Query actual position ............................................................................................................................ 27

Page 4

Monopack 2 Manual V1.04 4

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

5.2.22 Query actual velocity ............................................................................................................................. 28

5.2.23 Query status of stop switches ............................................................................................................ 28

5.2.24 Query TMC453 FIFO filling.................................................................................................................... 28

5.2.25 Step/Direction mode selection ........................................................................................................... 28

5.2.26 Display actual ADC values .................................................................................................................... 28

5.2.27 Write all parameters to the EEPROM ................................................................................................ 28

5.2.28 Enable or disable the EEPROM ............................................................................................................ 28

5.2.29 Choose interface and set RS485 delay ............................................................................................. 28

5.2.30 Set the RS485 address........................................................................................................................... 29

5.3 Help screen ......................................................................................................................................................... 29

5.4 Messages sent by the device ......................................................................................................................... 29

6 The Monopack PC Software ..................................................................................................................................... 30

6.1 Using the Program ............................................................................................................................................ 30

6.2 Firmware update / Reset to factory default .............................................................................................. 30

7 Application Notes ....................................................................................................................................................... 31

7.1 Making a simple RS232 to RS485 Converter ............................................................................................. 31

7.2 Setting the Maximum Current ....................................................................................................................... 31

7.3 Using the “ic485-I” RS232 to RS485 Converter ......................................................................................... 32

7.4 Choosing Plugs for the Monopack ............................................................................................................... 32

8 Declaration of Conformity ....................................................................................................................................... 33

TRINAMIC Motion Control GmbH & Co. KG does not authorize or warrant any of its products for use in life support

systems, without the specific written consent of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or sustain life, and whose failure to perform, when

properly used in accordance with instructions provided, can be reasonably expected to result in personal injury or

death.

Trinamic Motion Control GmbH & Co KG, Germany 2005

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the written permission of the publisher. Information given in this data-sheet is believed to be

accurate and reliable. However no responsibility is assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties which may result from its use. Specifications are subject to

change without notice.

Page 5

Monopack 2 Manual V1.04 5

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

1 Introduction

1.1 Brief Description

The Monopack 2 is an intelligent easy-to-use stepper motor driver for two-phase bipolar stepper motors with up to

5A coil current. It comes in a small and robust housing and provides a high motor power and dynamics. It can be

controlled via CAN bus, an RS485, RS232 or a Step/Direction interface and provides the functionality for either

remote controlled or stand alone applications. Its optional encoder feedback and a number of protection features

makes this drives very dependant and reliable. The Monopack 2 can do up to 406 microsteps and needs a power

supply of 12-48 Volts.

A Windows 95/98/ME/NT/2000/XP based PC software is supplied to explore the possibilities of the Monopack 2. To

use this software, the Monopack just has to be connected to the PC via its RS232 interface.

The Monopack 2 replaces the Trinamic products “Monopack” and “Monopack LT” which have been discontinued. It

is fully compatible with the Monopack and offers most features of the Monopack LT. A DIP switch allows to select

either “Monopack” or “Monopack LT” mode. Also the maximum motor current can be either 2.5A like in the old

Monopack and Monopack LT or, in the extended mode, 5A. This can also be selected by a DIP switch. From version

V2.0 on the Monopack 2 is RoHS conform.

1.2 Technical Data

Features and operational ratings

Ramp profile

S-curve, controlled by a TMC 453

Step type

Microstepping resolution from 1 to 64 or 100.8, 202.125 or 406.5

Power supply

12V - 48 V DC

Motor current

Maximum 5A peak coil current in extended mode or 2.5A in compatible mode

Motor type

Bipolar 2-phase stepper motor

Encoder type

Two channel incremental encoder with optional zero channel and 5V outputs

Inputs

Two stop switches (left and right), one reference switch, one differential alarm

input

Outputs

One differential alarm output, one differential encoder output (channel A, B and

Null)

Temperature range

0-70°C

Dimensions

132mm x 130mm x 45mm (without plugs)

Electrical data of the stop switch, reference switch and encoder inputs

Integrated pull up resistor

10k to internal +5V

Logic level low

0.0V..+1.3V

Logic level high

+3.3V..+5.0V

Continus protection voltage

-8V..+13V

Short time protection voltage

-24V..+24V

Electrical data of the differential inputs:

Common-mode input voltage

-7V to +12V

Differential input voltage

±6V

Electrical data of the differential outputs:

Differential output voltage

1.7V

Interfaces

RS232

9600 or 19200 baud, 8 data bits, 1 stop bit, no parity bit

Rs485

9600 or 19200 baud, 8 data bits, 1 stop bit, no parity bit, 100 Ohms termination

selectable

CAN

CAN 2.0B, 125, 250, 500 kbit/s or 1Mbit/s, 100 Ohms termination selectable

Step-/ Direction

Differential interface

Page 6

Monopack 2 Manual V1.04 6

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

2 Connecting the Monopack 2

2.1 Pin Assignments

The connectors of the Monopack 2 and their pin assignments are shown in Figure 2.1.

Max 45VDC

+ -

Address

CAN/

RS485

8 1

MONOPACK 2

CAN/RS485 Termination

ON = RS485

ON = RS485

ON = CAN

ON = CAN

ON

OFF

ON = Monopack LT mode

ON = Upgrade firmware

OFF= max. 2.5A,

ON=max. 5A

1 13

14 25

CANL/RS485-

CANH/RS485+

EnCHB-

EnCHB+

StopL-

StopL+

AlarmIN-

AlarmIN+

MC1-

MC1+

DIR-

DIR+

GND

EnCHN-

EnCHN+

EnCHA-

EnCHA+

StopR-

StopR+

AlarmOUT-

AlarmOUT+

MC0-

MC0+

STEP-

STEP+

Encoder

+5V A B N GND

SYNC

IN

Stop Switch

R GND L GND

Motor max. 3A

A1 A2 B1 B2

RS232

1 5

6 9

2=TxD

3=RxD

5=GND

+5V

STEP -

STEP+

GND

DIR-

DIR+

Figure 2.1: Connectors and pin assignments

2.2 Connecting the Motor

Connect one phase coil to the “A1” and “A2” connectors and the other phase coil to the “B1 ” and “B2” connectors.

Attention: Do not connect or disconnect the motor while the Monopack 2 is powered on as this could damage the

power drivers!

When using the stop switches, the motor must be connected so that the traveler moves towards the stop switch

connected to the “Stop Switch R” input when the velocity is positive and towards the stop switch connected to

the “Stop Switch L” input when the velocity is negative. Change the polarity of one of the coils if this should not

be the case. Otherwise, some functions of the Monopack 2 can not operate correctly (especially the stop switches

and the reference search algorithm).

Page 7

Monopack 2 Manual V1.04 7

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

2.3 Stop Switches and Reference Switches

For stop and reference switches, only openers can be used. The stop and reference switch inputs can be used in

different ways:

Two stop switches and a separate reference switch: Connect the left stop switch to the “Stop Switch L”

input and the right stop switch to the “Stop Switch R” input. Connect the reference switch to the “Ref

IN” input.

One stop switch and a separate reference switch: Connect the stop switch to the desired stop switch

input and the other stop switch input permanently to ground.

Combining the reference switch with one stop switch: Connect one switch to the reference switch

input and to the desired stop switch input, as shown in Figure 2.1. If only one stop switch is to be

used connect the other stop switch input to ground.

2.3.1 Linear vs. Circular Drives

In a linear drive (Figure 2.2), the traveler moves between two end points. It is not necessarily driven by a linear

stepper motor. In most cases, stop switches are used at the end points, and also a reference switch is used for

finding the reference point. The reference switch can also be combined with one of the end switches (as shown in

Figure 2.1).

Right Stop

Switch

Traveller

Left Stop

Switch

Reference

Switch

Negative

Direction

Positive

Direction

Figure 2.2: A linear drive

In a circular drive (Figure 2.3), the traveler moves around. There are no end points, and for that reason there are

also no stop switches. So the stop switch inputs are disabled in circular mode. A reference switch can be used for

finding the reference point.

Traveller

Reference

Switch

Figure 2.3: A circular drive

2.4 Incremental Encoder

Connect the two channels of the incremental encoder to the inputs “A” and “B”. An optional null channel can be

connected to the “N” input. The incremental encoder connector also provides a 5V power supply.

2.5 Power Supply

The voltage should be between 12 and 48 Volts to operate and must not exceed 49V. When using a regulated

power supply, set the current limit higher than the maximum motor current.

2.6 The RS232 interface

The 9-pin Sub-D socket provides the RS232 interface. This interface can be used in

Monopack mode as well as in Monopack LT mode. The pin assignments are as follows:

Pin

Signal name

2

TxD

3

RxD

5

GND

RS232

1 5

6 9

2=TxD

3=RxD

5=GND

Page 8

Monopack 2 Manual V1.04 8

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

2.7 The 25 pin Sub-D Socket

This socket contains the RS485 interface, the CAN interface, the

STEP/DIRECTION interface and the alarm input and output. The signals

of the incremental encoder input and the stop switch inputs are output

here as differential signals. The following subsections describe those

interfaces.

2.7.1 CAN and RS485 Interface

For the CAN and the RS485 interface, the same pins are used. So the

interface which shall be used must be selected via the DIP switches:

To use the CAN interface, set switch 1 and 2 to ON and

switch 3 and 4 to OFF position.

To use the RS485 interface, set switch 1 and 2 to OFF and

switch 3 and 4 to ON position.

The termination of both interfaces (120 Ohms) can be switched on and

off with switch 6. Switch 5 is not used. Attention: Changing between

RS485 and CAN interface requires a hardware reset (by powering off for

a short time).

2.7.2 The Step/Direction Interface

The Step/Direction interface uses differential signals. After powering on, the Monopack is in Step/Direction mode

so that the Step/Direction interface is usable. After getting the first RS485 or CAN command the Monopack leaves

the Step/Direction mode and enters the command mode where the Step/Direction interface can not be used. It is

possible to switch back to Step/Direction mode by a command.

The motor current control inputs MC0 and MC1 also belong to the Step/Direction interface. Using these inputs, the

motor current can be controlled by hardware in three steps (please see also section 4.2.1):

MC0

MC1

Motor current

0 0 1/3 of configured maximum current

1 0 2/3 of configured maximum current

0 1 2/3 of configured maximum current

1 1 Configured maximum current

In contrast to the old Monopack, these motor current settings can also be controlled by software (please see

section 4.2.1). The step and direction inputs are also provided on the Step/Direction input socket. These are

internally connected to the step/direction inputs of the 25-pin socket.

2.7.3 The Alarm Input

The alarm input is a differential input which can be used to stop the motor in case of emergency. To connect a

key to this input, simply connect it between AlarmIN+ and +5V (from the incremental encoder connector) and

connect the AlarmIN- input to ground.

2.7.4 The Alarm Output

This differential output is set high in case of an alarm or error condition. Alarm and error conditions can be

cleared by command $74 (s. 4.6.2).

2.7.5 The Incremental Encoder Output

The incremental encoder outputs (EnchA+/-, EnchB+/-, EnchN+/-) provide the encoder signals from the encoder input

(s. 2.4) converted to differential signals.

2.7.6 The Stop Switch Outputs

The stop switch outputs (StopL+/- and StopR+/-) provide the signals from the stop switch inputs (s. 2.3) converted

to differential signals.

1 13

14 25

CANL/RS485-

CANH/RS485+

EnCHB-

EnCHB+

StopL-

StopL+

AlarmIN-

AlarmIN+

MC1-

MC1+

DIR-

DIR+

GND

EnCHN-

EnCHN+

EnCHA-

EnCHA+

StopR-

StopR+

AlarmOUT-

AlarmOUT+

MC0-

MC0+

STEP-

STEP+

Page 9

Monopack 2 Manual V1.04 9

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

2.8 The Step/Direction input socket

The Step/Direction input socket provides the same differential step/direction inputs as the 25-pin Sub-D socket. It is

electrically identical with those inputs.

2.9 The hexadecimal Switch

This switch is used to set the LSN of the CAN receive identifier and the RS485 address. If the switch is set to zero,

the CAN receive identifier and the RS485 address will be reset to 1 and the CAN send identifier will be reset to 2

(please see also section 3.2.2, 4.7.2 and 4.7.3). The position of the hexadecimal switch is only read after a hardware

reset. So it is required to power off the unit when changing the hexadecimal switch setting.

2.10 The DIP switches

The DIP switches allow selecting the interface that is to be used and the operating mode. They have the following

functions:

Switch

Function

1

OFF: Use RS485 interface; ON: Use CAN interface

2

OFF: Use RS485 interface; ON: Use CAN interface

3

OFF: Use CAN interface; ON: Use RS485 interface

4

OFF: Use CAN interface; ON: Use RS485 interface

5

OFF: Use Monopack 2 (binary) command set (compatible with old Monopack)

ON: Use Monopack LT (ASCII) command set (compatible with old Monopack LT)

6

OFF: normal operation

ON: perform a firmware upgrade

7

OFF: No bus termination

ON: 100 Ohms RS485/CAN bus termination

8

OFF: Maximum current is 2.5A (compatible with Monopack / Monopack LT)

ON: Maximum current is 5.7A

Please note that switches 5 and 6 are only read after a hardware reset. So it is necessary to power off the unit

when changing the settings of switch 5 or 6.

Page 10

Monopack 2 Manual V1.04 10

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

3 Controlling the Monopack 2

3.1 Step/Direction Mode

Right after powering on, the device works as a step/direction power module. After getting the first command via

the RS232 interface, the RS485 interface or the CAN interface, it switches from step/direction mode to command

mode. It is possible to switch back to step/direction mode using command $50.

3.2 Binary Command Mode

The binary command mode is selected when DIP switch #6 is in its “off” position. This mode is compatible with

the old “Monopack”, with some extensions. In the binary command mode the Monopack 2 expects data telegrams

via the RS232 interface, the RS485 interface or the CAN interface. With those interfaces the following parameters

can be used:

RS485 interface

19200 baud

8 data bits, no parity bit, 1 stop

bit

RS232 interface

19200 baud

8 data bits, no parity bit, 1 stop

bit

CAN interface

125, 250, 500 or 1000 kbit/s

Default: 250 kbit/s

3.2.1 Format of the Data Telegrams

Every data telegram consists of one command byte and seven parameter bytes. Unused parameter bytes must be

set to zero. It is not allowed to leave out unused parameter bytes. In RS485 mode, every data telegram is

preceded by an address byte which contains the RS485 address of the unit. In CAN mode the identifier field of the

CAN telegram is used to address the unit. So the format of every Monopack data telegram is as follows:

Address

(in RS485 mode only)

Command

P0

P1

P2

P3

P4

P5

P6

Some commands also send back a data telegram of the same format as answer.

3.2.2 Unit Addresses

In RS485 mode, the LSN of the address can be set by the hexadecimal switch. The MSN can be set using command

$55 (s. 4.7.2).

In CAN mode, the LSN of the CAN receive ID is set by the hexadecimal switch. The rest of the CAN receive ID can

be set using command $55. The CAN send ID is set using command $56 (s. 0).

The CAN baud rate can be set using command $C0 (s. 4.7.4).

If the hexadecimal switch is set to zero the RS485 address and the CAN receive ID will be

reset to 1. The CAN send ID will be reset to 2.

3.2.3 Parameter Storage

Most of the parameters which can be set by the commands can be stored in an EEPROM. This makes it possible

that the Monopack is configured only once and can then be used without having to reconfigure it every time it is

powered on again. In firmware versions prior to 2.05, the EEPROM values are always changed whenever a

parameter changing command is given. From version 2.05 on, this can be controlled, so that parameters can also

be changed temporarily without affecting the values stored in the EEPROM and the parameters can also be read

back. These features are controlled by the P0 byte of the command. Please see section 4.1 for further explanation.

Page 11

Monopack 2 Manual V1.04 11

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

3.3 Monopack LT (ASCII) Command Mode

The Monopak LT compatible command mode is selected when DIP switch #6 is in its “on” position. This command

set is compatible with the old “Monopack LT” command set. In LT mode, the communication with the Monopack 2

can either take place via the RS232 interface or via the RS485 interface. The CAN interface can not be used in LT

mode. The baud rate is 9600 bps.

Attention: The Monopack 2 uses a higher clock frequency than the Monopack LT. Thus the velocity and

acceleration settings do not give identical results. To be compatible with the settings required by the

Monopack LT, please multiply your velocity and acceleration settings by 0.691.

Page 12

Monopack 2 Manual V1.04 12

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4 Binary Command Reference

In the description of the commands, hexadecimal values are marked with a leading “$” sign. Numbers which

occupy more than one byte are stored with least significant byte first and are marked with a “#” sign.

To get used to the binary command set we recommend to start with the Monopack Control Panel software. Please

refer to chapter 6.

4.1 Parameter Storage Control

As described in section 3.2.3 it can be controlled whether parameters are to be stored in the EERPOM or not, and

parameters can also be read back. This is done using the P0 parameter. The meaning of this parameter is as

follows:

P0 byte

Function

0

Set value and store the new value in the

EEPROM

1

Set value, but do not alter the EEPROM

2

Read the value from the EEPROM

3

Read the actual value

Whenever a parameter is read, a data telegram of the same format as the command is sent back.

4.2 Motor Parameters

4.2.1 Current Limit ($10)

Set the absolute maximum current. This command is new on the Monopack 2. On the old Monopack, the absolute

maximum current could only be set using the MC0 and MC1 input. On the Monopack 2 this is also possible, but it

is now better to use this command. The absolute maximum motor current also depends on the setting of DIP

switch #8.

CMD

$10

P0

Parameter storage control (s. 4.1)

P1

Current limit

0: Selected by MC0 and MC1 inputs

1: 0.8A when DIP switch #8 is OFF and 4.15A when switch #8 is ON

2: 1.6A when DIP switch #8 is OFF and 5.0A when switch #8 is ON

3: 2.5A when DIP switch #8 is OFF and 5.7A when switch #8 if ON

4.2.2 Current Control ($11)

Set up the motor current control. The current is separately controlled for the standby phase (v=0), the acceleration

phase and the constant velocity phase. All three values with this command have a range of 0..255, where 255

means 100% of the selected absolute maximum current. Please see also section 4.2.1 for selecting the absolute

maximum current.

CMD

$11

P0

Parameter storage control (s. 4.1)

P1

Standby current (motor standing still) (0..255)

P2

Active current (motor rotating with constant velocity)

(0..255)

P3

Acceleration phase current (0..255)

Page 13

Monopack 2 Manual V1.04 13

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.2.3 Get Current Control Settings ($53)

Get the current control settings from the internal EEPROM (as set up using command $11).

CMD

$53

P0

0 Answer

CMD

$53

P0

0

P1

Standby current

P2

Active current

P3

Acceleration current

4.2.4 Frequency Range ($12)

Set the frequency range for all ramp operations. The following formula defines the microstep frequency. Fclk is the

clock frequency of the device, which is 16MHz.

f

clkstep

vff

15

2

CMD

$12

P0

Parameter storage control (s. 4.1)

P1

pre-divider value (f) (0..15)

4.2.5 Microstep Resolution, Waveform and Mixed Decay ($17)

This command allows setting the microstep resolution and the waveform which is used to generate the

microsteps.

The number of microsteps can either be set between 1 and 64 or to 65, 66 or 67. Setting it to 65, 66 or 67 results

in the following numbers of microsteps:

Parameter

Resolution

65

100.8

66

202.125

67

406.5

The second parameter controls the waveform. It is a sine wave when set to zero, a triangular wave when set to

-1.0 and a trapezoid wave when set to +1.0. Please note that the waveform can only be set when the microstep

resolution is set to a value between 1 and 64. If other microstep resolutions are used, the waveform parameter

will be ignored and a sine wave will be used.

CMD

$17

P0

Parameter storage control (s. 4.1)

P1

Microstep resolution (1..64 or 65, 66, 67)

P2

Waveform (-1..+1)*127 (signed byte)

(-127 (0x81) means –1.0, +127 (0x7F) means +1.0)

P5

0: Mixed Decay disabled

1: Mixed Decay enabled

The mixed decay setting especially at rotation velocities in the range of a few 10 steps per seconds to several 100

steps per second improves motor behavior (less resonance). However, the actual performance depends on the

motor and mechanics. For supply voltages above 24V and for low inductivity motors, best microstep behavior is

reached when mixed decay setting is continuously on.

Page 14

Monopack 2 Manual V1.04 14

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

The figure above shows differences in chopper cycles with fast and slow decay. Fast decay is better at high

velocities, while slow decay shows better performances at low velocities. With the mixed decay feature activated

the modes will be switched automatically for best motor performances. Mixed decay should be switched off in

standstill to avoid possible chirping noise.

4.3 Driving

4.3.1 About the Parameters

Driving is controlled by the bow, acceleration, velocity and pre-divider parameters. See section 4.2.4 for calculating

the step frequency for a given velocity. When driving linear ramps by using command $25 (s. 4.3.8), the microstep

acceleration rate can be calculated as follows:

f

clk

afa

224

2

2max

f

clk

is 16MHz

f is the pre-divider setting (s. 4.2.4)

amax is the acceleration setting (to be set up using command $14)

Command $23 (s. 4.3.7) uses S-shaped ramps. With these ramps, the bow parameter is used: a high bow value

increases the positioning speed, while a low bow value smoothens the acceleration ramp. The duration of the

bow phase can be calculated as follows (compare to the acceleration and velocity formula):

)2/(1max/256

15 f

clkbow

fbowat

Attention: The following limitations apply: Do not set the bow higher than about 20 times the acceleration, and

do not set the acceleration higher than about 20 times the minimum required velocity value.

4.3.2 Velocity and Maximum Acceleration ($14)

Set the acceleration and the maximum velocity.

CMD

$14

P0

Parameter storage control (s. 4.1)

P1,P2

Maximum Acceleration (1..8191) #

P3,P4

Maximum Velocity (1..8191) #

Page 15

Monopack 2 Manual V1.04 15

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.3.3 Bow Value ($63)

Set the bow value for the ramp generation. This value must not be set to zero.

CMD

$63

P0

Parameter storage control (s. 4.1)

P1,P2

Bow (1..8191)#

4.3.4 Get Acceleration and Velocity Settings ($52)

Get the acceleration and velocity settings from the internal EEPROM.

CMD

$52

P0

0

Answer

CMD

$52

P0 0 P1,P2

Maximum Acceleration #

P3,P4

Reference Search Velocity #

P5,P6

Maximum Velocity #

4.3.5 Get actual Position ($20)

Get the actual position of the motor.

CMD

$20

P0

0

Answer

CMD

$20

P0

0

P1 – P4

Actual position (signed 24 bit)#

4.3.6 Get actual Acceleration and Velocity ($21)

Get the actual acceleration and velocity of the motor and if a reference search is just being executed. Please note

that during a reference search or an automatic position correction, the returned acceleration and velocity values

are invalid.

CMD

$21

P0

0

Answer

CMD

$21

P0 0 P1,P2

Velocity (signed 12 bit)#

P3,P4

Acceleration (signed 12 bit)#

P5

0 – reference search not active

1 – reference search active (acc./vel. values are invalid!)

P6

0 – automatic correction not active

1 – automatic correction active (acc./vel. values are

invalid!)

Page 16

Monopack 2 Manual V1.04 16

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.3.7 Drive a Ramp ($23)

Drive an S-shaped ramp to the given position. The maximum acceleration, maximum velocity and bow settings (s.

4.3.1, 4.3.3) are used. If this command is given while a ramp is active, it will be queued and executed after the

currently active ramp has terminated.

CMD

$23

P0

0

P1 – P4

Position (32 bit signed long) # (-8388608..+16777215)

4.3.8 Constant Rotation ($25)

Constant rotation of the motor using the given velocity. The maximum acceleration setting (s. 4.3.1) is used to

accelerate or to decelerate the motor.

CMD

$25

P0

P1,P2

Velocity (-8191..8191)#

4.3.9 Reset Position ($27)

Set the position counter and the encoder counter to zero. If the PID controller is switched on you will have to

turn it off before using this command (s. 4.5.7, command $6F).

CMD

$27

P0

0

4.3.10 Soft Stop ($2A)

Terminate a ramp and stop the motor softly. The maximum acceleration (s. 4.3.1) parameter is used to decelerate

the motor.

CMD

$2A

P0

0

4.3.11 Emergency Stop ($2B)

Stop the motor immediately. This command has the same functionality as setting the external alarm input high.

CMD

$2B

P0

0

Page 17

Monopack 2 Manual V1.04 17

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.4 Stop and Reference Switches

4.4.1 Switch Mode ($54)

P2 defines if the reference switch is also used as an end switch. The switch must be connected to both the

reference input and to one stop switch input then (P3 defines if the left or the right stop switch input is used for

this purpose). If the reference switch is not used as a stop switch connect it to the reference input only.

P3 defines the direction of the calibration. Either the left or the right stop switch will be used for calibration

purposes.

P4 defines the movement mode. In circular mode, only the reference switch (connected to the reference input) is

used and the stop switch inputs are disabled. Also, P2 is ignored in circular mode. In linear mode, the end switch

inputs are enabled and P2 is used (please see also section 2.3.1).

P6 enables the travel check function together with command $59 (travel check tolerance, 4.4.5). In this function the

reference switch is also used as a travel check switch. If the travel check switch is found at a position out of the

travel check tolerance, the alarm output will be set high.

CMD

$54

P0

Parameter storage control (s. 4.1)

P1

0 Reserved; always set to zero

P2

0/1 0: separate reference and stop switches

1: stop switch also used as reference switch

P3

0/1 0: use left stop switch for calibration

1: use right stop switch for calibration

P4

0/1 0: circular movement 1: linear movement

P5

0 Reserved; always set to zero

P6

0/1 0:travel check disabled

1: use the reference switch also as a travel check switch (see also

4.4.5)

4.4.2 Deceleration at Stop Switches ($57)

Set the deceleration which is used to decelerate the velocity to zero when a stop switch is reached. If this value is

set to zero, a hard stop will be used (the motor stops abruptly when a stop switch is reached). If set to a value

other than zero, a soft stop will be used.

CMD

$57

P0

Parameter storage control (s. 4.1)

P1,P2

Deceleration (0..8191)#

4.4.3 Reference Search ($22)

This command starts a reference search. During the reference search also other commands can be given and they

are processed. Especially use the command $21 to see if the reference search has already finished. Any driving

command will abort the reference search.

Attention: The motor has to be connected correctly to make this command work correctly (s. 2.2)!

The behavior of the reference search depends on the switch mode setting (command $54, s. 4.4.1) and is as

follows:

Circular mode: The reference switch (connected to the reference switch input) is searched at first from one

and then form the other side. The zero position is then set to the middle of the reference switch.

Linear mode:

Reference switch is also end switch: A move into the reference switch and then out of the reference

switch is executed. The zero position is then set to the beginning of the switch.

Separate reference switch and end switch: First, the left or the right stop switch (as configured) is

searched. After that, the reference switch is searched at first from one, then from the other side. The

zero position is then set to the middle of the reference switch.

Page 18

Monopack 2 Manual V1.04 18

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

CMD

$22

P0

0

4.4.4 Reference Search Velocity ($16)

Set the velocity which is used for reference searches.

CMD

$16

P0

Parameter storage control (s. 4.1)

P1,P2

Velocity (1..8191) #

4.4.5 Travel Check Tolerance ($59)

Set the tolerance of the travel check (see also command $54, section 4.4.1). The travel checking can be enabled or

disabled using command $54. If the travel check (reference switch) is found out of the travel check tolerance the

alarm output will be set high.

CMD

$59

P0

Parameter storage control (s. 4.1)

P1

Tolerance

4.4.6 Number of Microsteps per Revolution ($15)

Set the number of microsteps per revolution. This is needed for travel checking in the circular movement mode.

The number of microsteps per revolution can be calculated from the number of full steps per revolution multiplied

by the number of microsteps set using command $17 (s. 4.2.5).

CMD

$15

P0

Parameter storage control (s. 4.1)

P1,P2,P3,P4

Microsteps per revolution (max. 16777215)#

4.4.7 Get the State of the Stop Switches ($30)

This command reads out the actual state of the stop and reference switch inputs of the Monopack.

CMD

$30

P0

0

Answer

CMD

$30

P0 0 P1

State of left stop switch input (0 or 1)

P2

State of right stop switch input (0 or 1)

P3

State of reference switch input (0 or 1)

Page 19

Monopack 2 Manual V1.04 19

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.5 Incremental Encoder

4.5.1 About Incremental Encoders

Using an incremental encoder allows exact position control, as it feeds back the steps of the motor into the

Monopack. The Monopack can then detect deviations and can also try to correct such deviations automatically (see

sections 4.5.5 and 4.5.6). If this does not solve the problems, a PID controller can also be used for highly exact

positioning, but the deviation detection and the automatic position correction after a deviation has occurred are

much easier to use than the PID controller.

The resolution of the encoder (pulses per revolution) must match the resolution of the motor to make deviation

detection and automatic position correction function correctly. If the resolutions do not match, they can be

adapted by changing one or more of the following parameters:

Microstep resolution: This parameter changes the resolution of the motor and can be set using

command $17 (see section 4.2.5).

Encoder pre-divider: This can be used if the resolution of the encoder is higher than the resolution of

the motor. When for example the pre-divider is set to 4, only every 4th pulse of the encoder will be

used to increment or decrement the encoder counter register.

Encoder multiplier: This can be used if the resolution of the encoder is lower than the resolution of

the motor. When for example the multiplier is set to 5, every encoder pulse will increment or

decrement the encoder counter register by 5.

The encoder pre-divider and multiplier are set up using command $70. To find the right combination of the

parameters you can just let the motor run for example 10000 steps (using command $23 (s. 4.3.7), with deviation

detection and automatic position correction switched off) and then watch the encoder counter register (using

command $71). Before doing that, use command $27 (s. 4.3.9) to set all position registers to zero.

4.5.2 Encoder Configuration ($70)

Configure the behavior of the incremental encoder input.

CMD

$70

P0

Parameter storage control (s. 4.1)

P1

Encoder configuration. See the table below for an

explanation of the configuration bits.

P2

Encoder pre-divider (0..255)

P3,P4

Maximum deviation between ramp position and

encoder position counter (11 Bit unsigned #)

P5

Encoder multiplier (0..255). (Available since

firmware version 2.09.)

Explanation of the encoder configuration bits:

Bit

Description

0

Polarity of the encoder N input (1=positive, 0=negative)

1

The next N signal clears the encoder counter register when

set 2 Reserved. Always set to zero.

3

Reserved. Always set to zero.

4

Set this bit to copy the actual ramp position to the encoder

counter register. The bit will be reset automatically.

5

Reserved. Always set to zero.

6

Direction of the encoder signals. 1: A->B, 0: B->A

Page 20

Monopack 2 Manual V1.04 20

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.5.3 Encoder Counter ($71)

Get the value of the incremental encoder counter register.

CMD

$71

Answer

CMD

$71

P1

0

P2,P3,P4

Encoder counter value (signed 24 bit #)

4.5.4 Encoder Holding Register ($72)

This command has been removed in version 2.09 of the Monopack firmware.

4.5.5 Deviation Alarm ($73)

Enables or disables the deviation alarm. This alarm occurs when the maximum deviation is exceeded. The alarm

output will then be set high. Set the maximum deviation using command $70. The motor can also be stopped

immediately or softly when the alarm occurs. Furthermore, the automatic position correction (see 4.5.6) can be

started n/200 sec (n=1..65535) after a deviation has been detected. In this case, the alarm output will only be set

when the maximum number of retries for automatic position correction has been exceeded. The maximum

deviation has to be set up using command $70 (s. 4.5.1) first. The automatic position correction has to be set up

using command $58 (s. 4.5.6).

CMD

$73

P0

Parameter storage control (s. 4.1)

P1

0: disable deviation alarm

1: enable deviation alarm

P2

0: do not stop when deviation alarm occurs

1: soft stop when deviation alarm occurs

2: hard stop when deviation alarm occurs

P3,P4

0: no automatic position correction after

deviation

1-65535: start automatic position correction n/200

sec after a deviation has been detected (available

since firmware V2.09)

4.5.6 Configure Automatic Position Correction ($58)

Configure if an automatic position correction shall be done at the end of each ramp or when a deviation has been

detected. Automatic position correction can only be used in conjunction with an incremental encoder which has to

be configured correctly first.

When this function is turned on, the Monopack checks if the position counter of the incremental encoder matches

the desired end position at the end of every ramp (since firmware V2.09, the tolerance value defines a tolerance

window around the end position). If this is not the case, the Monopack will try to correct the position of the

motor using the reference search velocity. The maximum number of retries after each ramp can also be configured.

The alarm output will be set high and the position correction will be aborted if this number is exceeded.

This function is an easy to use alternative to the PID controller.

CMD

$58

P0

Parameter storage control (s. 4.1)

P1

0: automatic correction turned off

1-255: maximum number of retries for position

correction after each ramp.

P3,P4

end position tolerance (16 bit unsigned #)

(available since firmware V2.09)

Page 21

Monopack 2 Manual V1.04 21

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.5.7 PID Controller Configuration ($6A, $6B, $6C, $6D, $6F)

The following commands ($6A, $6B, $6C, $6D, $6F) are to be used for setting up the PID controller configuration

registers of the TMC453. Please see the TMC453 manual for further explanation of the PID controller registers.

CMD

$6A

P0

Parameter storage control (s. 4.1)

P1,P2

Pid_control register

P3,P4

Pid_vcalc_factor register

CMD

$6B

P0

Parameter storage control (s. 4.1)

P1

Pid_pcof register

P2

Pid_p_range register

P3

Pid_icof register

P4

Pid_i_range register

P5

Pid_dcof register

P6

Pid_d_range register

CMD

$6C

P0

Parameter storage control (s. 4.1)

P1

Pid_clip_p register

P2

Pid_clip_i register

P3

Pid_clip_d register

CMD

$6D

P0

Parameter storage control (s. 4.1)

P1

Pid_clip_int_sum register

P2

Pid_clip_int_input register

P3,P4

Pid_clip_sum register

CMD

$6F

P0

0

P1

0:turn off the PID controller

1:turn on the PID controller

Page 22

Monopack 2 Manual V1.04 22

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.6 Alarms and Errors

4.6.1 Alarm Mode ($51)

Set up the alarm mode. The alarm mode determines if the motor is to be powered off when an external alarm

(alarm input set high) or a driver error occurs. The motor can be powered on again by resetting the alarm using

command $74 (s. 4.6.2).

CMD

$51

P0

Parameter storage control (s. 4.1)

P1

0: only stop motor in case of external alarm

1: stop and power off in case of external alarm

P2

0: do not stop motor in case of driver error

1: stop and power off in case of driver error

4.6.2 Reset Alarm Output ($74)

Reset the alarm output and return the alarm reason as answer.

CMD

$74

P0

0

Answer

CMD

$74

P0

0

P1

Driver error (0=no/1=yes) (short circuit, overload, etc.)

P2

Deviation error (0=no/1=yes) (s. 4.5.5)

P3

External alarm input (0=no/1=yes)

P4

Travel check tolerance error (0=no/1=yes) (s. 4.4.5)

P5

Position correction error (0=no/1=yes) (s. 4.5.6)

4.7 Other Settings

4.7.1 Enter Step/Direction Mode ($50)

This command can be used to switch the Monopack back to step-/direction mode (e.g. after changing parameters

or resetting an alarm).

CMD

$50

P0

0

P1

0: step/direction mode

1: command mode (any other command will also

switch to command mode)

4.7.2 Set CAN receive ID and RS485 ID ($55)

Set the CAN identifier which will be used for receiving data from the CAN bus and the RS485 address. Please note

that the LSN of the CAN receive ID and the LSN of the RS485 address are set by the hexadecimal switch and not by

command. Please see also section 3.2.2 and 2.8.

CMD

$55

P0

Parameter storage control (s. 4.1)

P1 – P4

32 bit unsigned long ID # (only 11 bits are used)

Page 23

Monopack 2 Manual V1.04 23

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.7.3 Set CAN send ID ($56)

Set the CAN identifier which will be used for sending data on the CAN bus. Please see also section 3.2.2 and 2.8.

CMD

$56

P0

Parameter storage control (s. 4.1)

P1-P4

32 bit unsigned long ID # (only 11 bits are used)

4.7.4 Set CAN Baud Rate ($C0)

Change the baud rate of the CAN interface. After executing this command, a hardware reset is required to make

the change take effect.

CMD

$C0

P0

0

P1

1: 125 kBit/s

2: 250 kBit/s

3: 500 kBit/s

4: 1 Mbit/s

4.7.5 Get Version Number ($43)

Get the firmware version number and the reset flag. The reset flag is 1 if a reset occurred before the last $43

command was given.

CMD

$43

P0

0

Answer

CMD

$43

P0

Firmware revision (decimal 203 means V2.03)

P1

Reset Flag: 1 after a reset

P2

Not used

P3, P4

Temperature (16 bit #) (units: TBD)

On the old Monopack this command also returned the serial number of the device. This is no longer supported on

the Monopack 2. Instead, the Monopack 2 returns the actual temperature of the device.

4.7.6 Hardware Reset ($CC)

Reset the microcontroller of the MONOPACK so that all parameters are re-read from the EEPROM. This command

can be used to make parameter changes which need a hardware reset take effect.

CMD

$CC

P0

0

4.8 Factory Default Settings ($DD)

Set all parameters which are stored in the EEPROM (including the CAN and RS485 addresses and the CAN baud

rate) to their factory default settings. After executing this command, a hardware reset has to be issued to make all

the changes take effect.

CMD

$DD

P0

0

P1

Must be $31

P2

Must be $41

Page 24

Monopack 2 Manual V1.04 24

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

5 Monopack LT Command Reference

When the DIP switch #5 is in its “ON” position, the ASCII command set of the former Monopack LT will be used.

This chapter provides a reference of the Monopack LT command set. The commands can simply be entered using a

terminal program, for example HyperTerminal.

5.1 Interface selection

In LT mode, the Monopack 2 can either communicate via RS232 or via RS485 interface. The default interface is the

RS232 interface. To use the RS485 interface it must be selected by using the Y command. This setting can then be

stored in the EEPROM to make it the default setting after next power-on.

5.2 Command overview

The table given here is an overview of all possible commands. Every command is described in detail in the

following sections. Commands without parameters do not need to be terminated by a CR. They are executed as

soon as they are entered. Commands with parameters must be terminated with a CR. The value must follow the

command letter without any additional spaces. The command will be executed as soon as the CR has been sent.

Some commands also send back one or more messages. Each message is terminated by a CR and LF.

Command

Short description

See section

A<value>

Set acceleration (<value>=1..8191)

5.2.3

B<value>

Set bow (<value>=1..8191)

5.2.4

C<value>

Select Step/Direction mode (<value>= 0 or 2)

5.2.25

D

Driver with constant velocity

5.2.7

d

Display voltage and temperature

5.2.26

E

Enable / disable EEPROM

5.2.28

F

Set operating frequency range

5.2.1

f

Query FIFO filling

5.2.24

G

Automatic reference search

5.2.17

H

Soft stop

5.2.8

I

Set standby current

5.2.13

J

Set constant speed current

5.2.14

K

Set acceleration current

5.2.15

M<value>

Set stop switch mode (<value>=0..2)

5.2.19

N

Find reference switch closing position

5.2.18

O

Find reference switch opening position

5.2.18

P<value>

Change position counter

5.2.20

p

Query actual position

5.2.21

Q

Mixed decay setting

5.2.16

R

Relative move

5.2.12

S

Set target position, relative distance or reference switch offset

5.2.10

s

Query stop and reference switches

5.2.23

T

Move to target position

5.2.11

U<value>

Set microstep resolution

5.2.2

V<value>

Set velocity (<value>=1..8191)

5.2.5

v

Query actual velocity

5.2.22

W

Write settings to EEPROM

5.2.27

X

Hard stop

5.2.9

Y<value>

Choose interface and set RS485 delay (<value>=0..9)

5.2.29

Z<value>

Set RS485 address (<value>=33..255)

5.2.30

+

Set direction CW

5.2.6

-

Set direction CCW

5.2.6

Page 25

Monopack 2 Manual V1.04 25

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

5.2.1 Set the pre-divider

Command: F<value>

The command “F” sets the pre-divider and thus the operation frequency range of the motor. It must be followed

by a value between 0 and 15. This command can only be used when the motor is standing!

Example: F9 sets the pre-divider to 9.

5.2.2 Set microstep resolution

Command: U<value>

The “U” command sets the microstep resolution. It must be followed by the value 0, 1, 2 or 3, where 0 means 25

microsteps, 1 means 50 microsteps, 2 means 32 microsteps and 3 means 64 microsteps. Do not use this command

while the motor is moving!

Example: U3 sets the microstep resolution to 64 microsteps.

5.2.3 Acceleration setting

Command: A<value>

The command “A” sets the acceleration and deceleration of the motor. It must be followed by a value between 1

and 8191. Do not set this value to 0.

Please see section 4.3.1 for the calculation of the actual motor acceleration and bow setting.

Example: A250 sets the acceleration to 250.

5.2.4 Bow setting

Command: B<value>

This command sets the bow value of the S-shaped ramp. It must be followed by a vlaue between 1 and 8191. Do

not set this value to 0.

Example: B10 sets the bow value to 10.

5.2.5 Velocity setting

Command: V<value>

The command “V” sets the maximum velocity of the motor. It must be followed by a value between 1 and 8191.

Please see section 4.2.4 for the calculation of the actual motor velocity.

Example: V2000 sets the velocity to 2000.

Attention: The Monopack 2 uses a higher clock frequency than the Monopack LT. Thus the velocity and

acceleration settings do not give identical results. To be compatible with the settings required by the

Monopack LT, please multiply your velocity and acceleration settings by 0.691.

5.2.6 Direction setting

Command: + or –

The commands “+” and “-“ select the direction in which the motor will be running. Entering “+” selects clockwise

rotation (the position counter will be incremented when the motor is moving), and entering “-“ selects counter

clockwise rotation (the position counter will be decremented when the motor is moving).

5.2.7 Drive with fixed velocity

Command: D

The command “D” accelerates (or decelerates) the motor to the velocity that has been set by a previous “V”

command. After the command has been sent, the message “<v_old> to <v_new>” will be sent back, where

“v_old” is replaced by the actual velocity value and “v_new” by the new velocity value.

5.2.8 Soft stop

Command: H

Page 26

Monopack 2 Manual V1.04 26

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

This command stops the motor. The acceleration value that has been set by a previous “A” command will be used

for the deceleration ramp. The message “<v_act> to 0” (with <v_act> replaced by the actual velocity) will be

sent back after the command has been entered.

5.2.9 Hard stop

Command: X

Entering the “X” command stops the motor immediately, without any deceleration ramp. The message “Motor

stop” will be sent back after the command has been entered. Be careful when driving at high speeds as a hard

stop can cause a voltage overshoot on the power supply then.

5.2.10 Set target position or relative distance

Command: S<value>

The command “S” is used to set the target position for the “T” command or the relative distance for the “R”

command. It must be followed by a value between –8388608 and 16777215.

Example: S50000

5.2.11 Drive to target position

Command: T

After entering the command “T” the motor drives to the target position that has been set by the last “S” command,

using the velocity, acceleration, bow and direction that have been set by the last commands. Please be sure that

you have set the direction appropriately, i.e. when the actual position is lower than the new position the direction

should be set to “+”, and when the actual position is higher than the target position the direction should be set to

“-“. Otherwise the motor will run until the position counter wraps around.

The Monopack 2 sends back the message “to <pos_targ>” (with <pos_targ> = target position) after the

command has been entered.

The motor must be standing before this command is entered.

5.2.12 Relative move

Command: R

This command makes the motor drive a number of microsteps into the actual direction. The number of microsteps

to drive can be set using the “S” command, and the direction can be set using the “+” or “-“ command.

Acceleration, velocity and bow can also be set by the appropriate commands.

After entering this command the message “<pos_act> to <pos_targ>” (with <pos_act> = actual position and

<pos_targ> = new position) will be sent back.

The motor must be standing before this command is entered.

5.2.13 Set motor standby current

Command: I<value>

This command sets the maximum motor current that is used when the motor is standing. It must be followed by

a value between 0 and 255, where 0 means 0% and 255 means 100% of the absolute maximum current (2.5A when

DIP switch #8 is off, 5.7A when DIP switch #8 is on).

5.2.14 Set motor run current

Command: K<value>

The “K” command sets the motor current that is used when the motor is running at constant velocity. It must be

followed by a value between 0 and 255, where 0 means 0% and 255 means 100% of the absolute maximum

current (2.5A when DIP switch #8 is off, 5.7A when DIP switch #8 is on).

5.2.15 Set motor acceleration current

Command: J<value>

The “J” command sets the motor current that is used when the motor is accelerating or decelerating. It must be

followed by a value between 0 and 255, where 0 means 0% and 255 means 100% of the absolute maximum

current (2.5A when DIP switch #8 is off, 5.7A when DIP switch #8 is on).

Page 27

Monopack 2 Manual V1.04 27

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

5.2.16 Set mixed decay mode

Command: Q0 or Q1

The command “Q” command turns mixed decay on or off. Q0 turns off mixed decay, and Q1 turns on mixed decay.

This command is new on the Monopack 2.

5.2.17 Automatic reference search

Command: G

Entering this command starts an automatic reference search. A reference point offset can be specified by a

previous “S” command (use “S0” for no reference point offset). The reference switch must be connected between

the reference switch input and ground as a normally closed switch. During the reference search, the following

messages will be sent back:

“>0 to <v>” right after the command has been entered (with <v>= maximum velocity).

“>n=<pos_1>” when the reference switch is open (where <pos_1> is the microstep position where the

switch opened).

“<v> to <-v>” when the motor turns back into the opposite direction (with <v>= maximum velocity).

“>n=<pos_2>” when the switch is closed again (where <pos_2> is the microstep position where the

switch closed).

“<-v> to 0” when the motor being decelerated.

“>OK” at the end of the automatic reference search.

The velocity, bow, acceleration and direction can be set by the appropriate commands (V, B, A, +, -) before starting

the reference search.

5.2.18 Find reference switch position

Commands: N and O

These two commands can be used to find the reference switch manually. Normally there is no need to use them,

instead use the “G” command.

Entering the “N” command makes the motor run. When the switch gets closed, the microstep position of this point

will be sent back (message “n= <position>”). The motor will not be stopped automatically (use the “H” or “X”

command to do this).

Entering the “O” command also makes the motor run. When the switch gets opened, the microstep position of this

point will be sent back (message “n= <position>”). The motor will not be stopped automatically (use the “H” or

“X” command to do this).

5.2.19 Set stop switch mode

Command: M<value>

This command sets the stop switch mode. The value can be one of the following numbers:

0 for no stop switches.

1 for hard stop when a stop switch opens.

2 for soft stop if the motor is in velocity mode (“D” command) and hard stop if the motor is in positioning

mode (“T” or “R” command) when the stop switch opens.

Example: M2

5.2.20 Change actual position

Command: P<value>

This command changes the actual position, without moving the motor. It must be followed by a value between 8388608 and 16777215. The motor must be standing before using this command.

Example: P-50000

5.2.21 Query actual position

Command: p

After entering this command the actual position will be sent back as a message of the form “p=<position>”,

where <position> is the actual position of the motor.

Page 28

Monopack 2 Manual V1.04 28

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

5.2.22 Query actual velocity

Command: v

The “v” command queries the actual velocity and sends this value back. The velocity is sent back in the form

“v=<velocity>”, where <velocity> is the actual velocity of the motor.

5.2.23 Query status of stop switches

Command: s

The “s” command queries the actual status of the stop switches and the reference switch. The status is sent back

in the form “s=<value>”, where bit 0 represents the status of the left stop switch, bit 1 represents the status of

the right stop switch and bit 2 represents the status of the reference switch.

5.2.24 Query TMC453 FIFO filling

Command: f

This command queries the actual number of entries in the TMC453 command FIFO.

5.2.25 Step/Direction mode selection

Command: C0 or C2

Entering the command “C0” selects the normal command mode, and entering “C2” selects the step/direction mode.

5.2.26 Display actual ADC values

Command: d

Entering the command “d” displays the actual ADC values that represent the actual temperature in the pack and

the actual supply voltage. After the command has been sent, the message “TEMP = <t> VOLT = <v>” will be

sent back.