Page 1

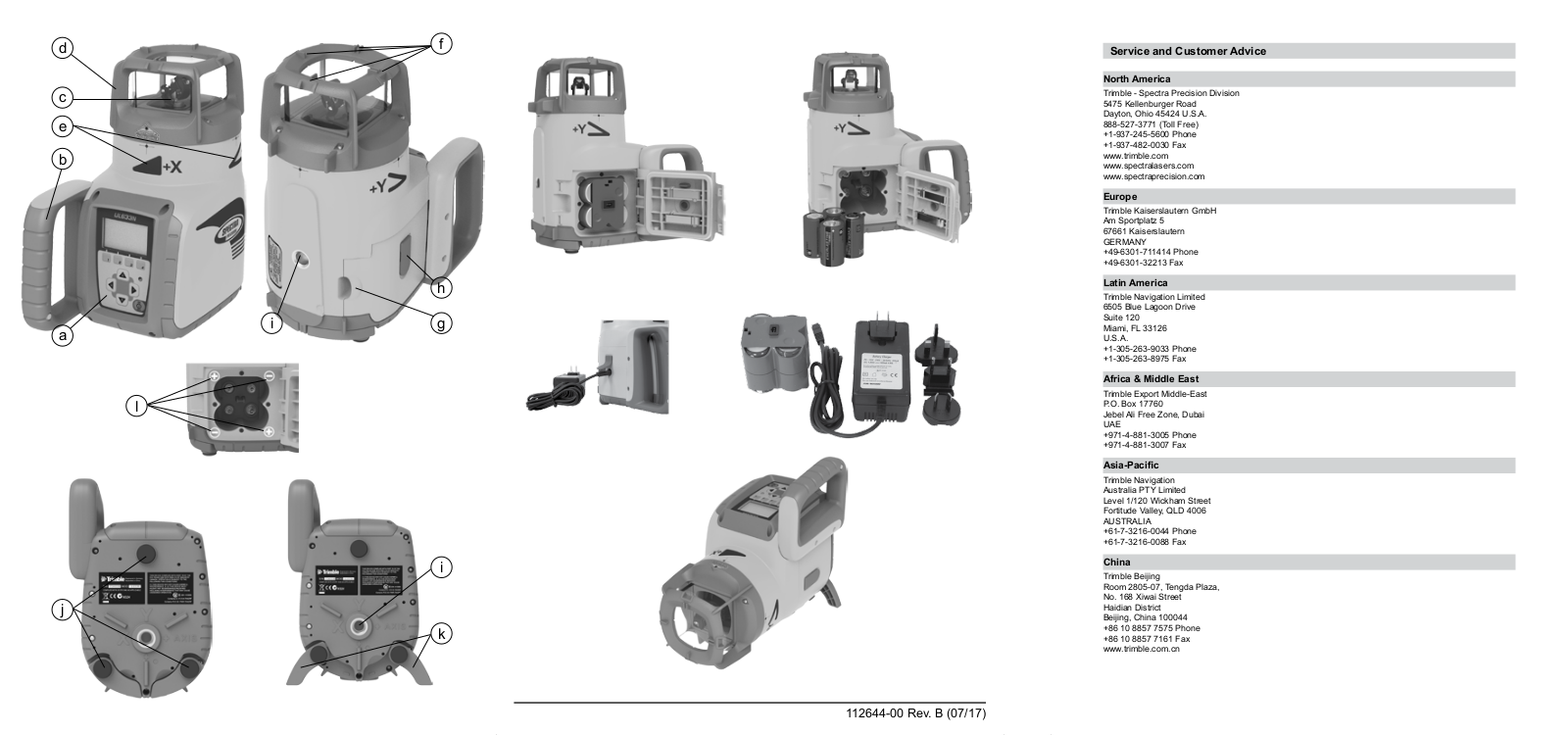

Page 2

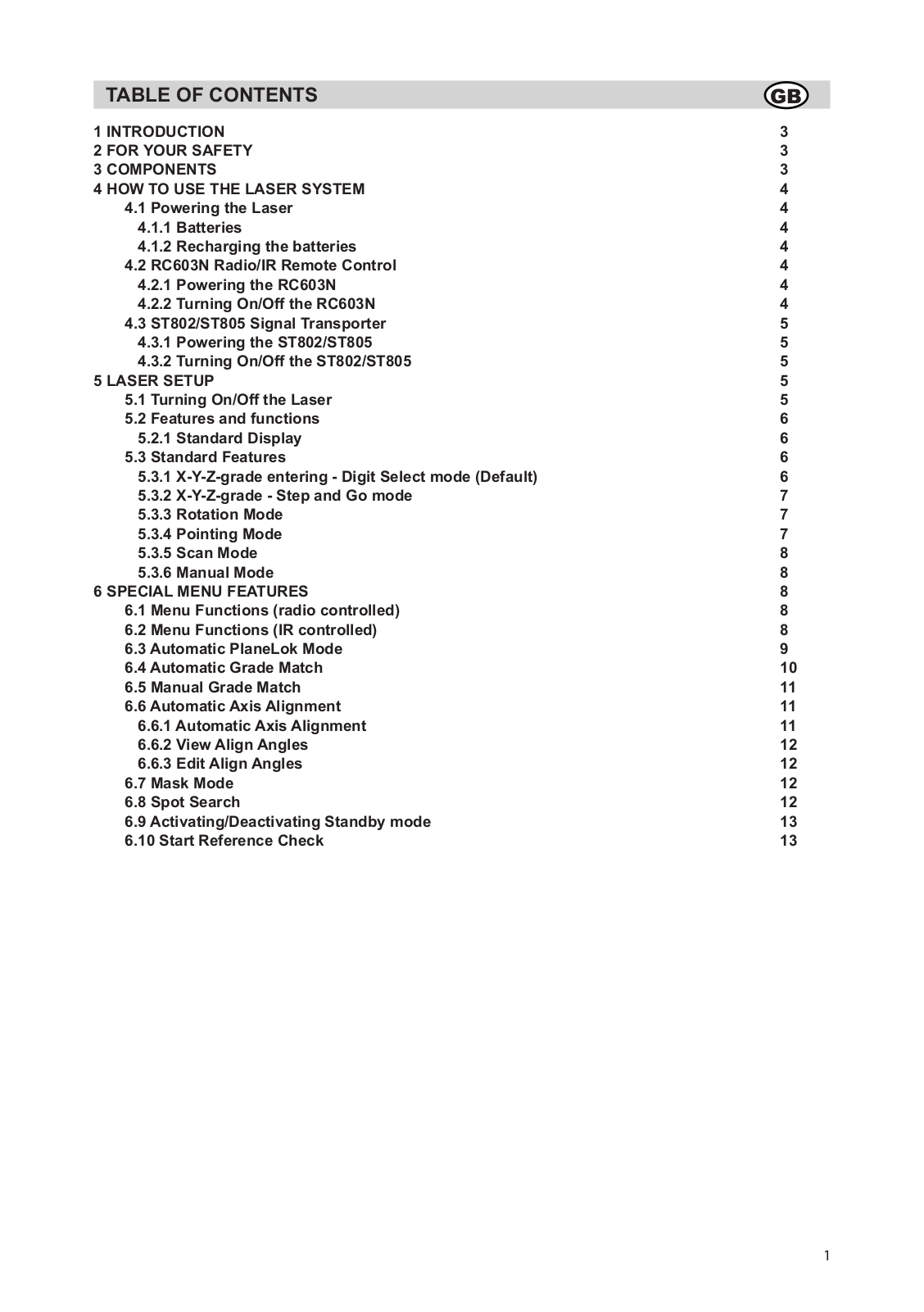

Page 3

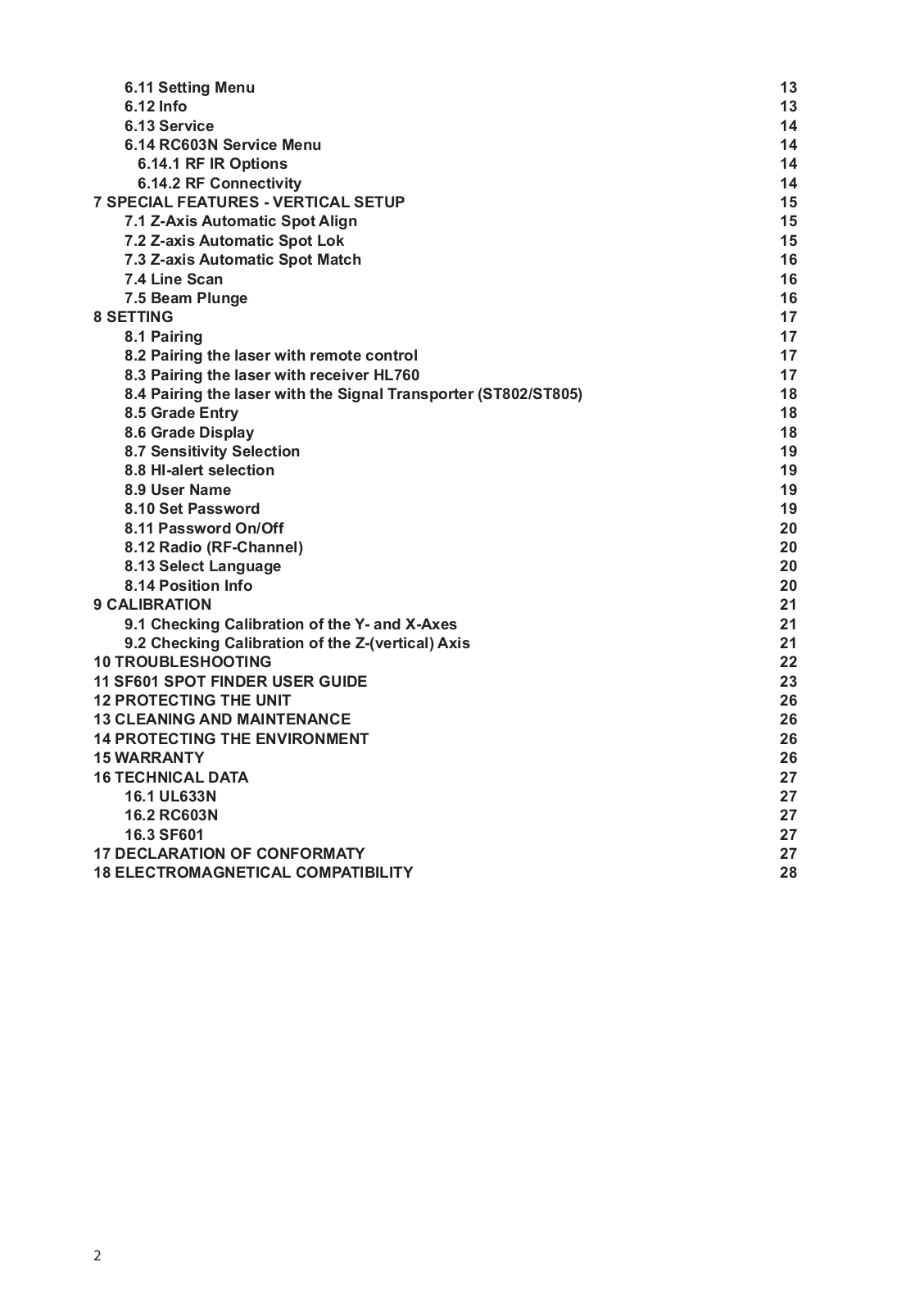

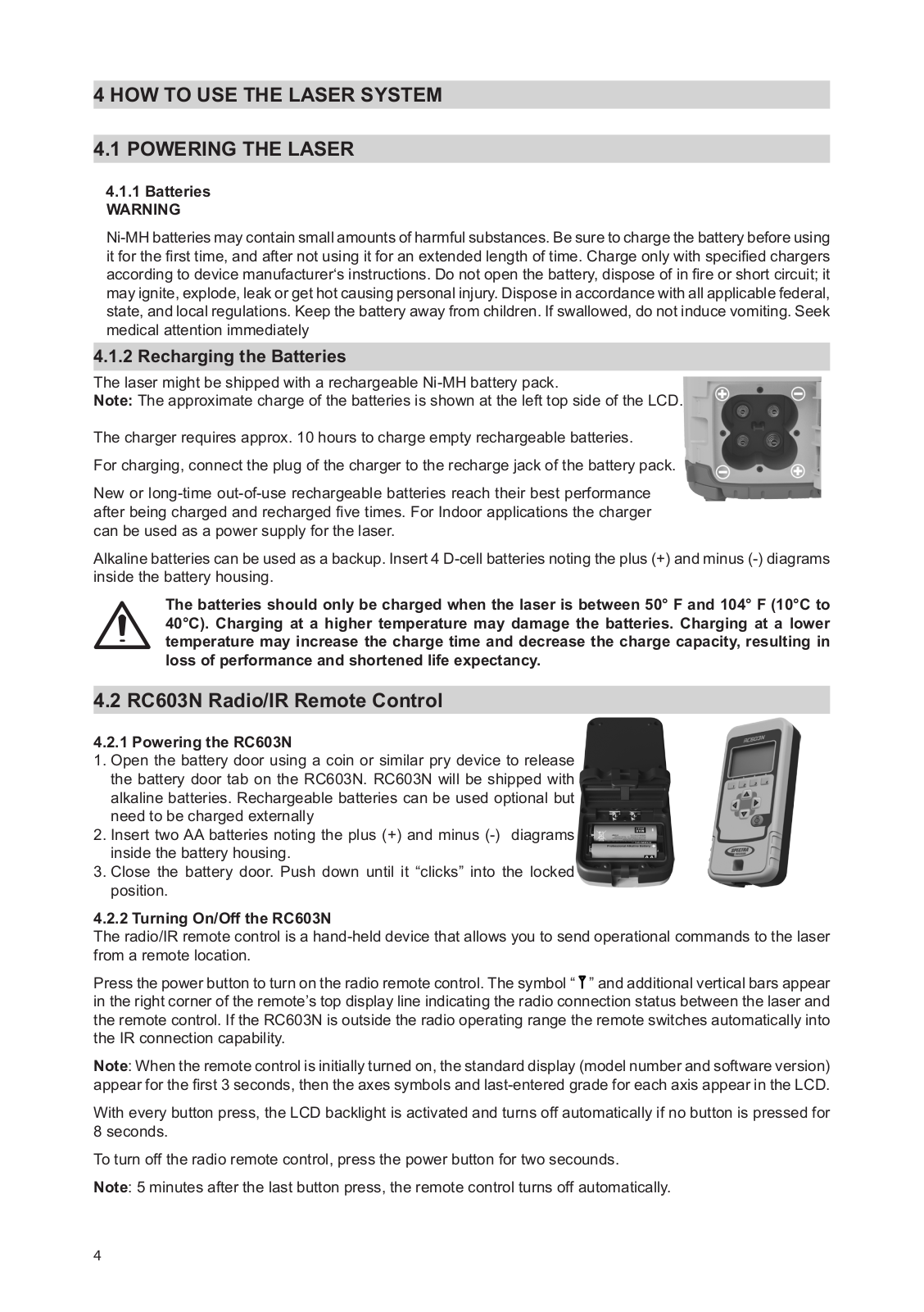

Page 4

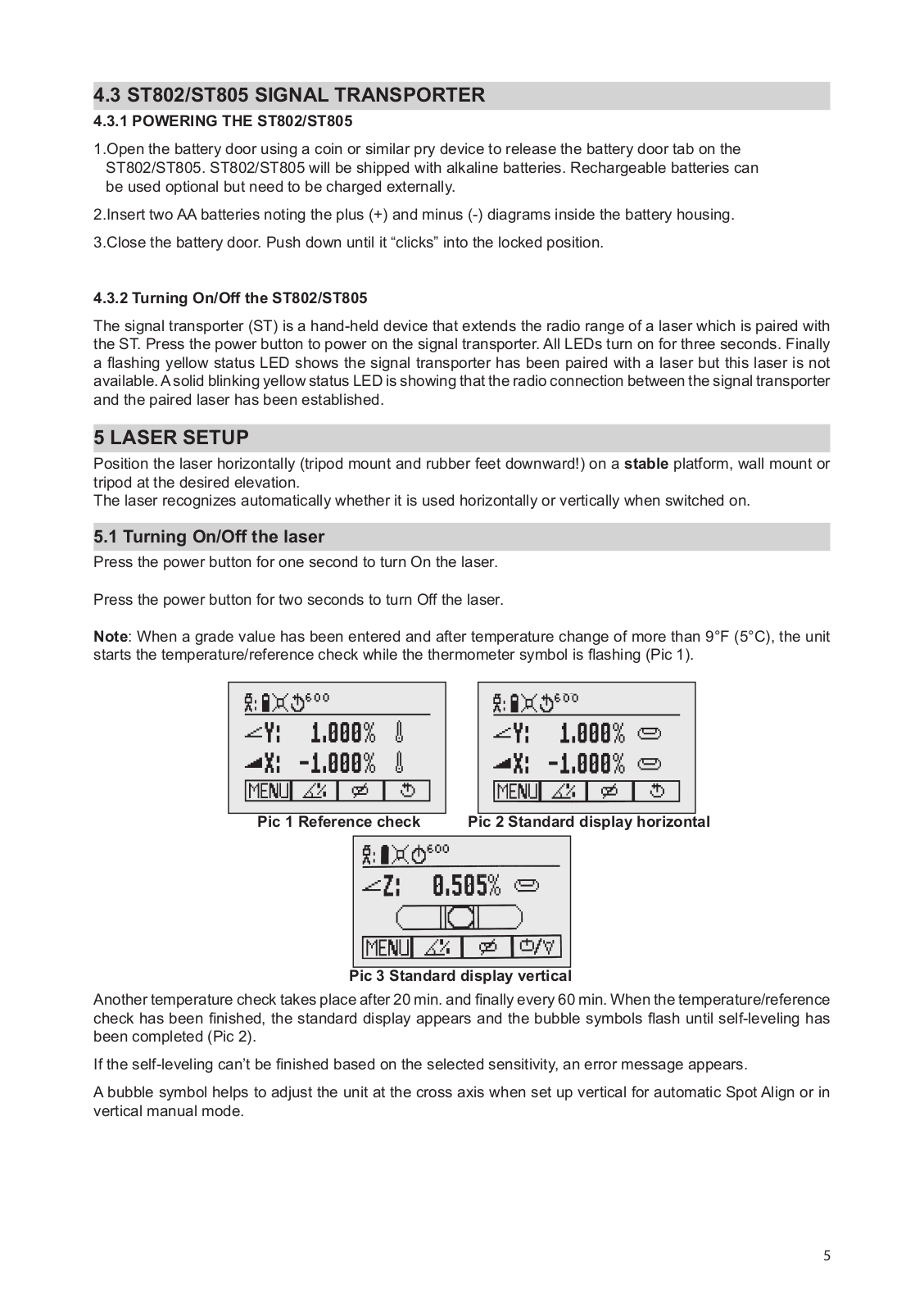

Page 5

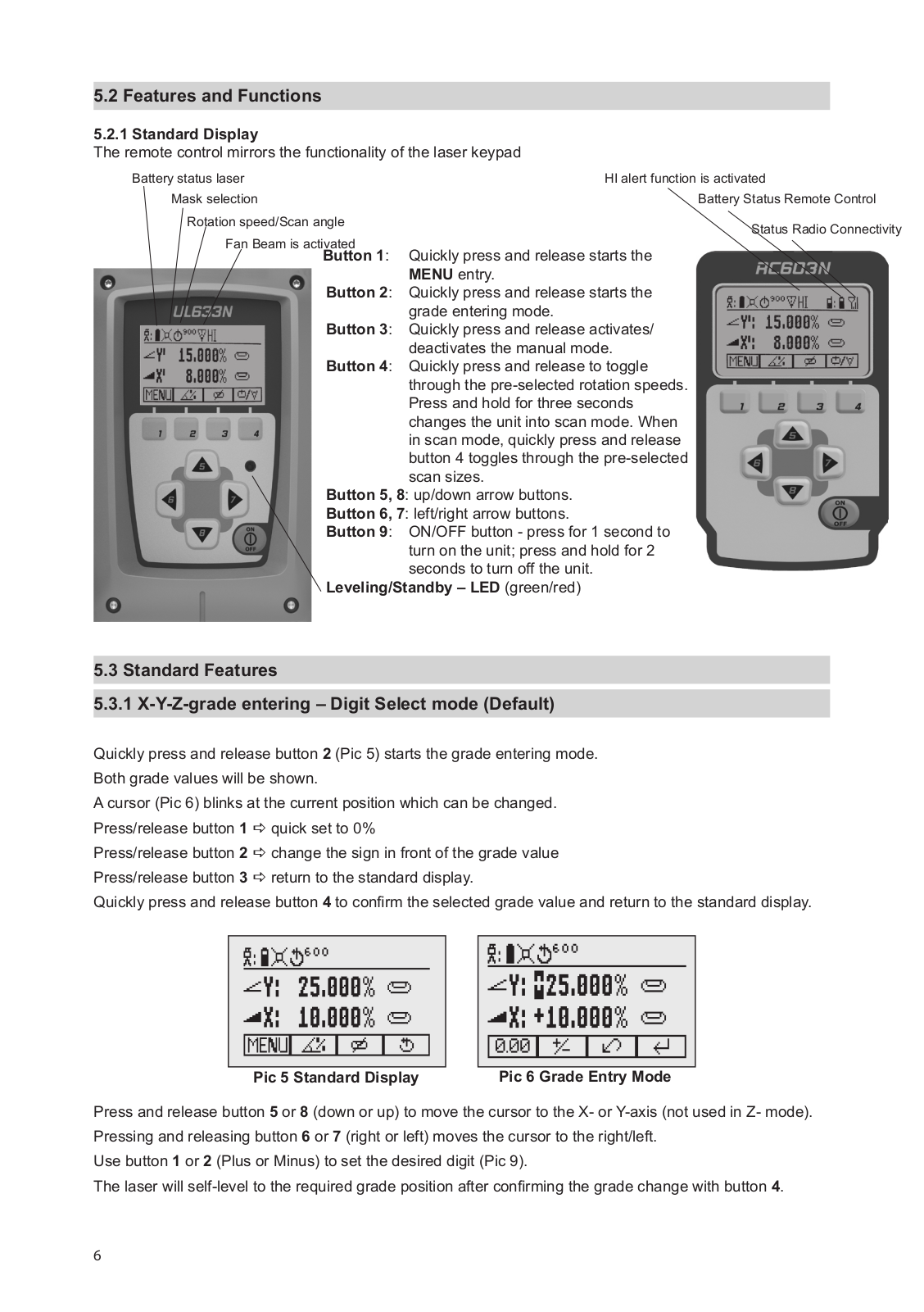

Page 6

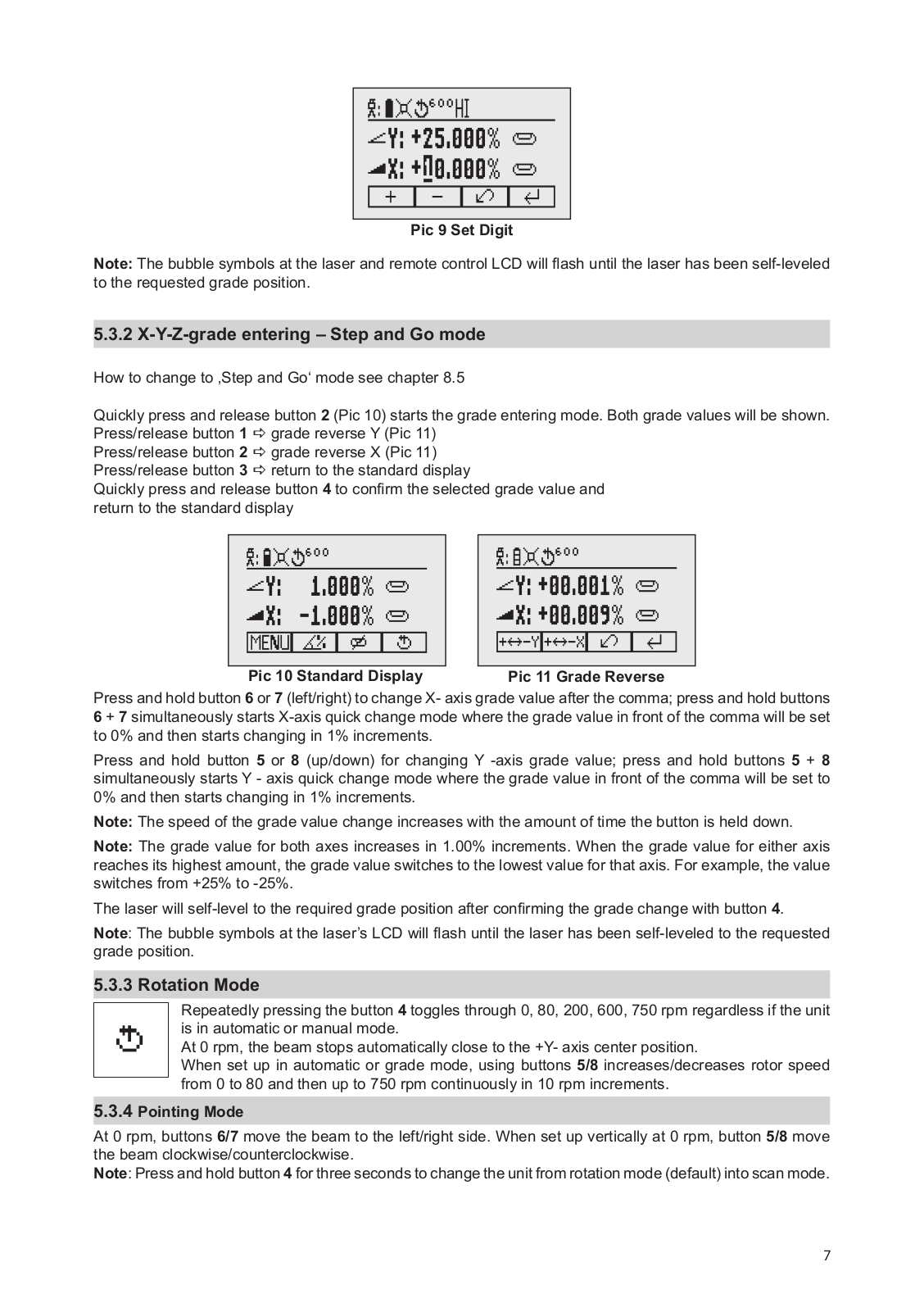

Page 7

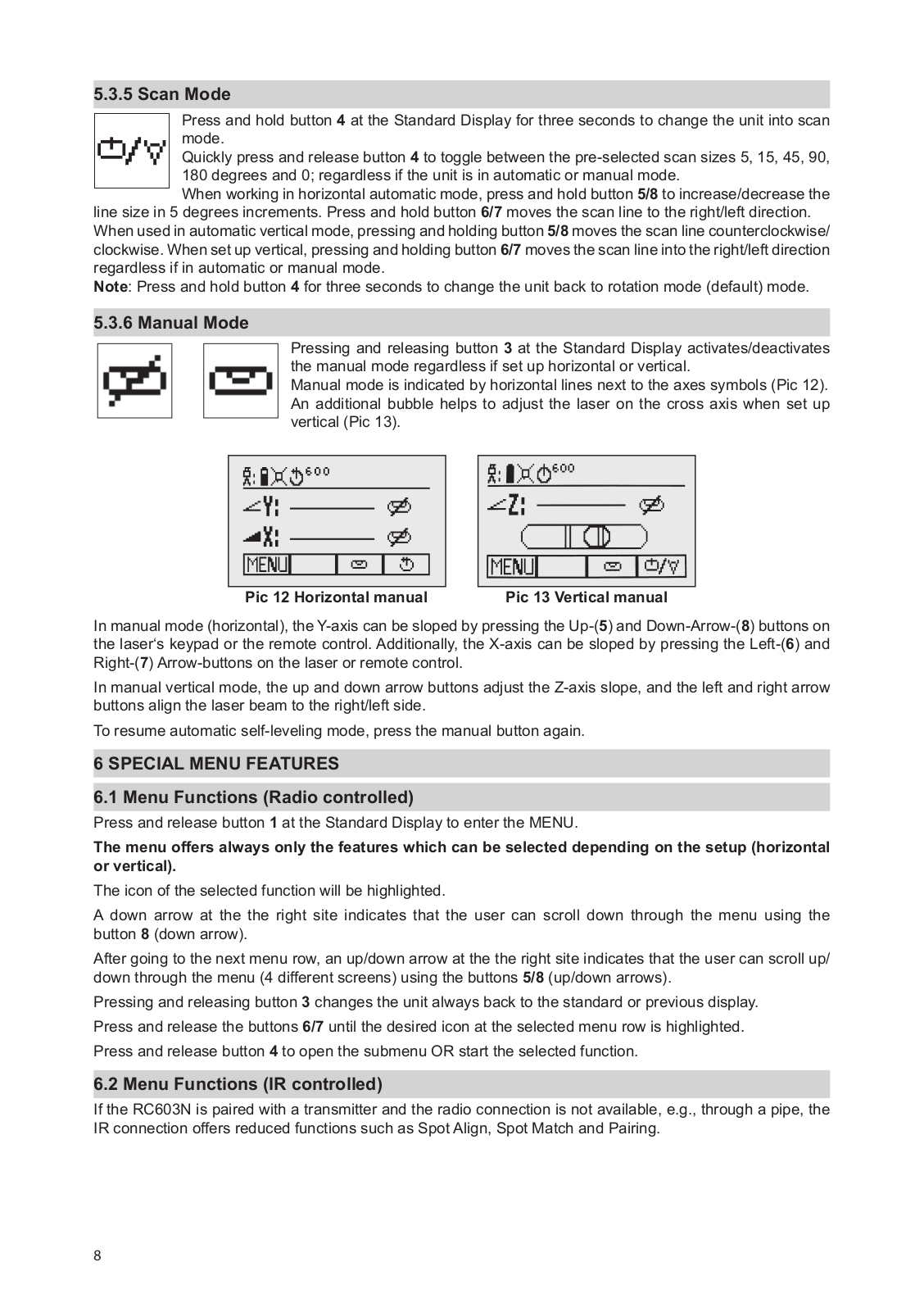

Page 8

Page 9

Page 10

Page 11

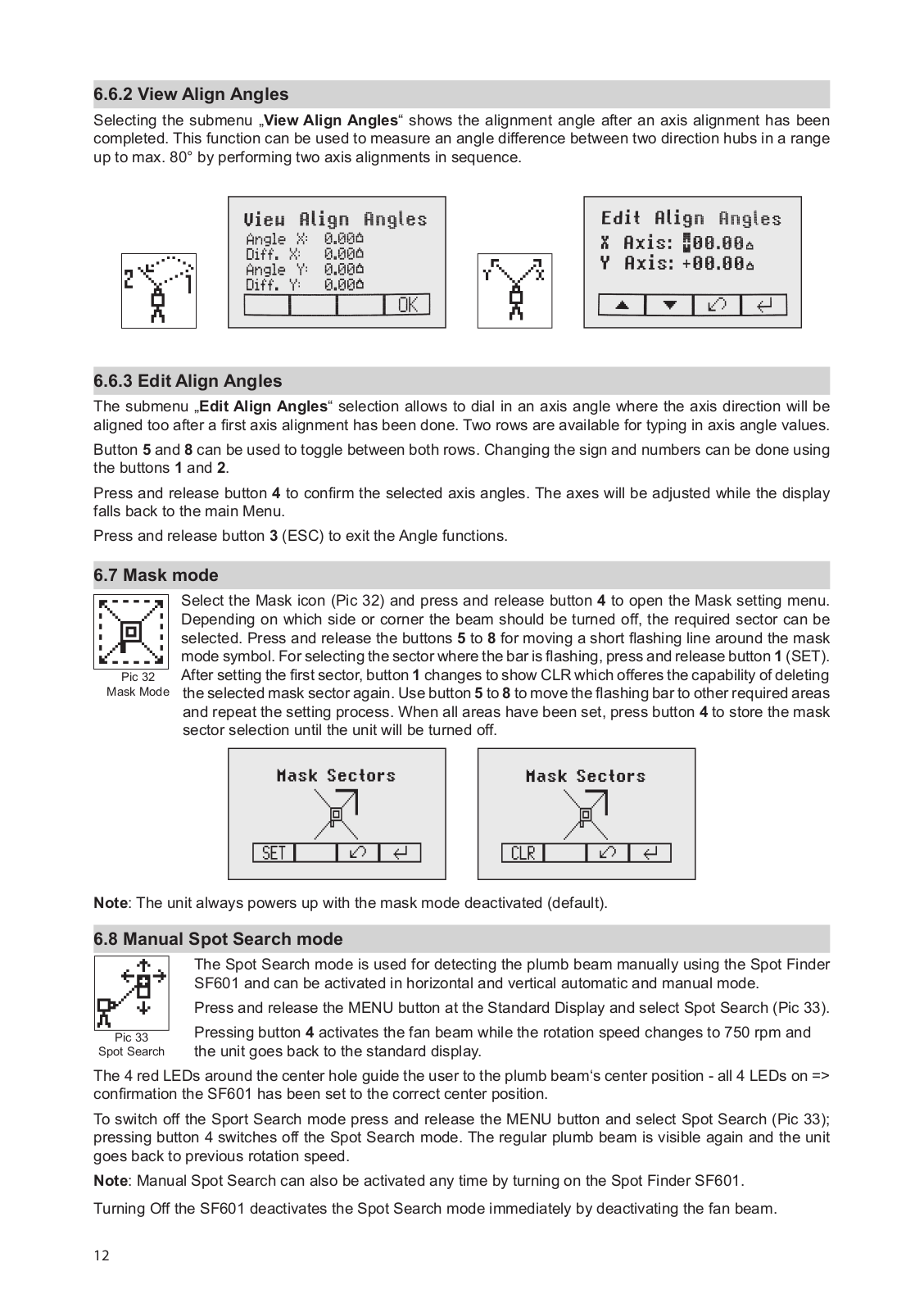

Page 12

Page 13

Page 14

Page 15

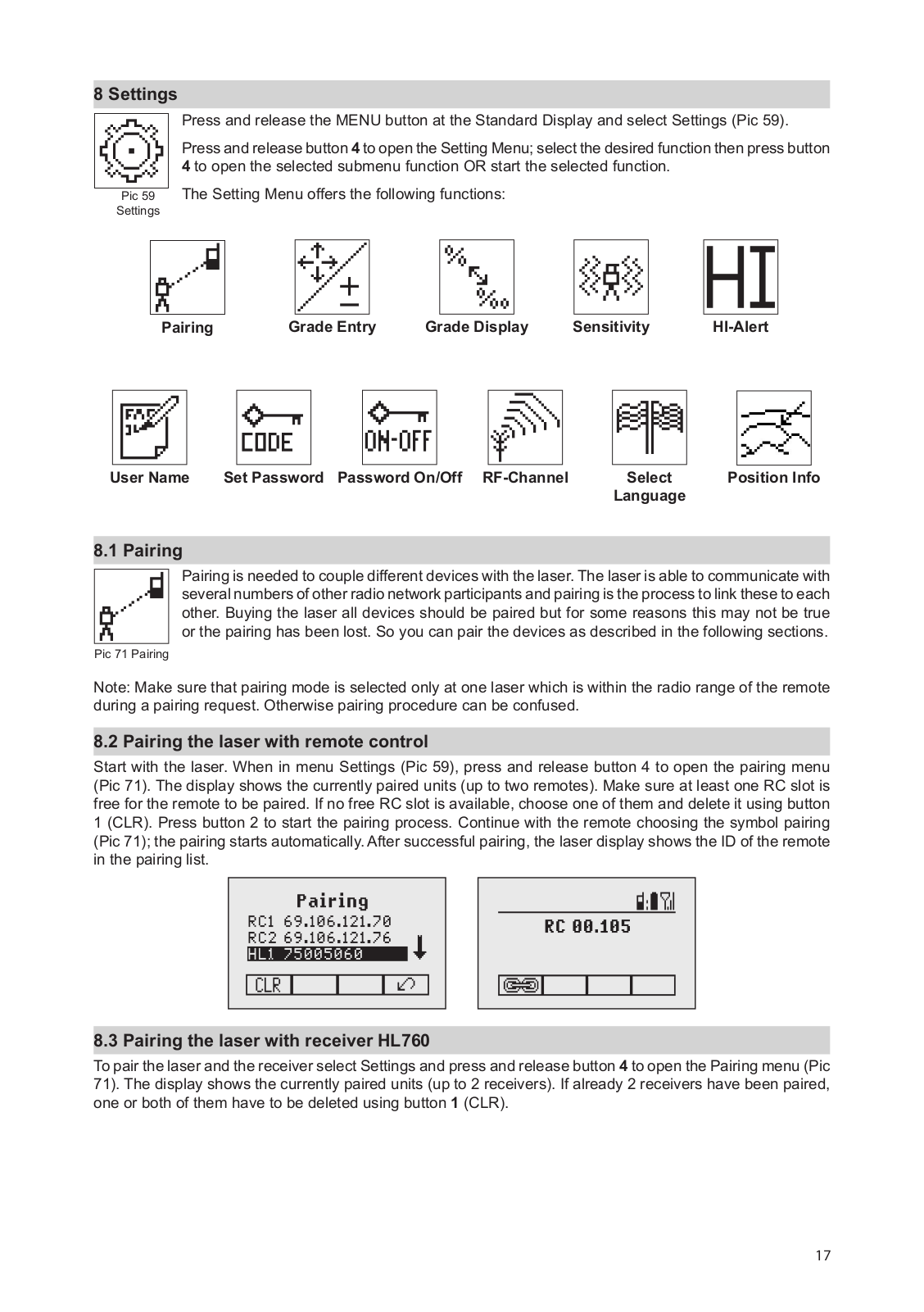

Page 16

Page 17

Page 18

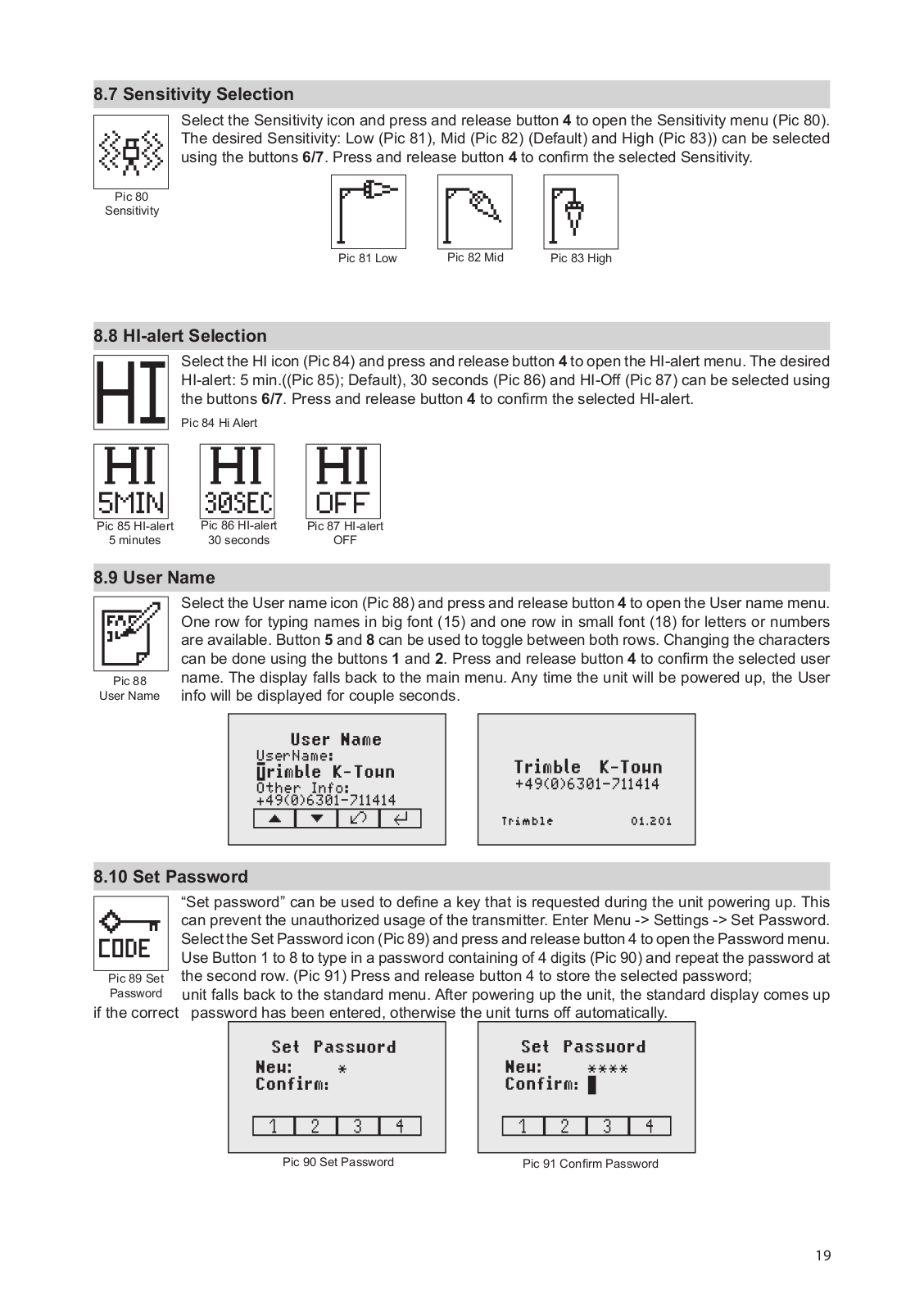

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Loading...

Loading...