T

R

I

U

T

R

I

U

T

R

I

U

G

A

S

-

F

I

R

E

D

H

I

G

A

S

-

F

I

R

E

G

A

S

-

F

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam & Hot Water

Boilers

Installation Date: _______________________

TRIAD Boiler Systems, Inc.

1099 Atlantic Drive, Unit 2

West Chicago, IL 60185

Phone: 630.562.2700

Fax: 630.562.2800

www.triadboiler.com

Version 1.0 / 1-08-08

ASME Code, Section IV

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam & Hot Water

Boilers

D

I

R

E

D

G

H

I

G

H

I

G

M

M

M

H

H

H

P

H

S

E

R

I

E

S

P

H

S

E

R

P

H

S

-

E

F

F

F

F

F

F

I

I

I

-

E

-

E

E

C

C

C

I

I

I

R

E

E

E

I

I

N

E

E

N

N

S

S

C

C

C

Y

Y

Y

B

O

I

L

E

R

S

B

O

I

L

O

E

I

L

E

B

R

R

S

S

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

TTaabbllee ooff CCoonntteennttss

ATTENTION!!!

WATER:

ÿ The pH of the system must be between 6.0 and 8.5. Periodically check the pH!

ÿ If Glycol is used it must be approved by the chemical manufacturer for aluminum boilers!

VENTING:

ÿ This boiler is Category IV (condensing positive pressure) and is NOT certified for use with

Type “B” vent!

HEAT EXCHANGER:

ÿ Maximum operating pressure is 80 psi and maximum temperature is 200° F!

BURNER:

ÿ If the material surrounding the burner tube is ripped in any way, it MUST be replaced!

ÿ Change the spark iginiter once a year!

MANUAL RESET SERVICE CODES:

ÿ A few of the more common lockout codes: (See page 33 for all of them.)

Code Lockout Description

E 00 False flame. A flame signal is present when it shouldn’t be.

E 02 Flame failure. The burner did not light on startup, or loss of flame during run.

E 03 Gas Valve error. Check all gas valves electrical connections.

E 08 Air pressure switch open Air pressure switch failed to close to indicate sufficient air flow to start the boiler.

E 12 External limit open An external limit has opened. (High/Low Gas Pressure, High Temp, or Low Water)

ÿ If any “Manual Reset” limit device trips, DO NOT reset without determining and correcting

the cause!!

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

TTaabbllee ooff CCoonntteennttss

1.0 INTRODUCTION ................................ .......2

2.0 SAFETY ................................ .................... 2

2.1 General................................ ............................ 2

2.2 Training ................................ ........................... 2

2.3 Safety Features................................................2

2.4 Safety Labels................................ ...................3

2.5 Safety Precautions................................ ...........3

2.5.1 Electrical Hazards................................ ...3

2.5.2 Burn, Fire, and Explosion Hazards..........3

2.5.3 Crush Hazards................................ ........4

2.5.4 Chemical Hazards................................ ...4

2.5.5 Pressure Hazards................................ ...5

2.5.6 Slip, Fall Hazards................................ ....5

3.0 INSTALLATION................................ ......... 6

3.1 Receiving and Storage................................ .....6

3.1.1 Initial Inspection................................ ......6

3.1.2 Storage Prior to Installation..................... 6

3.2 Compliance with Codes................................ ....6

3.3 Setup................................ ............................... 6

3.3.1 Foundation..............................................6

3.3.2 Placement ................................ ..............7

3.3.3 Clearances................................ .............7

3.4 Electrical Connections................................ ......7

3.5 Combustion Air................................................8

3.5.1 Air Inlet Requirements............................. 8

3.6 Flue Venting................................ .....................9

3.6.1 Barometric Damper................................ .9

3.6.2 Flue Connection................................ ......9

3.6.3 Required Clearances.............................. 9

3.6.4 Vent Terminations................................ .10

3.6.5 Venting for Multiple Boilers....................10

3.6.6 Sealed Combustion Air/Venting System11

3.6.7 Removing an Existing Boiler .................11

3.6.8 Intake/Exhaust Layout........................... 11

3.6.9 Intake Duct Materials and Sizes:...........12

3.6.10 Sealing the Intake Duct....................... 13

3.6.11 Intake Duct Connection to Boiler.........13

3.6.12 Intake Duct Terminations ....................13

3.6.13 Vent Elbows................................ ........13

3.7 Gas Piping................................ .....................13

3.7.1 Gas Supply Piping by Installer...............15

3.8 Boiler Water Piping................................ ........15

3.8.1 Piping Design................................ ........15

3.8.2 Boiler Inlet and Outlet Connections.......16

3.8.3 Boiler Water Piping by Installer..............17

3.8.4 Water Quality, Flushing and Filling........17

3.9 Burner and Ignition System............................ 18

3.9.1 Inspection................................ .............18

3.10 Pre-Start Check List................................ .....19

3.11 Safety Checks................................ ..............19

3.11.1 Test of Ignition Safety System.............19

3.11.2 Test of Low Water Cut Off...................19

3.11.3 Test of High-Limit Control....................20

3.11.4 Test of Gas Pressure Switch...............20

3.12 Initial Adjustments................................ ........20

3.12.1 Operating Temperature Controller.......20

3.12.2 Gas Pressure Adjustment ...................25

3.12.3 Air Flow Adjustments .......................... 25

3.12.4 Gas Valve Setup and Adjustment........25

4.0 OPERATION................................ ........... 28

4.1 General................................ .......................... 28

4.1.1 Control Panel Front............................... 28

4.1.2 Tests ................................ .................... 28

4.2 Normal Lighting and Shut-Down Procedures..28

4.2.1 Lighting Procedures.............................. 28

4.2.2 Normal Shut Down Procedures.............28

4.2.3 Emergency Shut-Off.............................. 28

4.3 Typical Boiler Operating Conditions................29

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

TTaabbllee ooff CCoonntteennttss

5.0 MAINTENANCE ................................ ......30

5.1 Maintenance and Inspection Schedule...........30

5.1.1 Daily................................ ..................... 30

5.1.2 Weekly................................ ..................30

5.1.3 Monthly (During Operation)................... 30

5.1.4 Semi-Annually (every 6 months) ...........31

5.1.5 Annually................................ ................31

5.2 Cleaning the Burner................................ .......31

5.3 After All Repairs or Maintenance.................... 31

5.4 Sequence of Operation................................ ..32

5.5 Troubleshooting................................ ............. 32

5.5.1 Manual Reset Service Codes................34

5.5.2 Auto-reset Service Codes.....................35

It is essential to read, understand, and follow

this manual before installing, operating, or

servicing this equipment. Failure to do so

could result in fire or explosion and serious

injury, death, and/or property damage.

The features which permit this boiler to

achieve high-efficiency performance make it

unlike most other boilers of this general size,

so it is important to understand how it

operates.

Do not store or use gasoline or other

flammables in the vicinity of this or any other

appliance. Chemicals, fuels, or other

potentially hazardous or toxic materials must

not be stored in the same room as the boiler.

6.0 PARTS/TECHNICAL SUPPORT............. 36

6.1 Wiring Diagrams................................ ............37

6.1.1 Terminal Block Assignments – High Voltage

Circuit (TB2)................................ .............37

6.1.1a Terminal Block Assignments – Low Voltage

Circuit (TB1)................................ .............38

6.1.2 Wiring Triad Series 750/900/1000.........39

6.2 Boiler Parts List................................ ..............40

6.2.1 Main Assembly ................................ .....40

6.2.2 Control Panel................................ ........41

6.2.3 Display Panel................................ ........42

6.2.4 Triad-750/900/1000 Heat Exchanger.....43

6.2.5 Triad-750/900/1000 Gas Train ..............44

7.0 LIMITED WARRANTY ............................ 45

8.0 APPENDIX................................ .............. 47

Installation and service must be performed by

a qualified installer or service agency that has

been trained on the Triad TRIUMPH Boiler

What to do if you smell gas:

∑ Do not try to light any appliance.

∑ Do not touch any electrical switch.

∑ Do not use any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas

supplier's instructions.

∑ If you cannot reach your gas supplier call

the fire department.

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

SSaaffeettyy

1.0 INTRODUCTION

Congratulations on purchasing the highly efficient

TRIUMPH Series Gas-Fired Boilers form Triad

Boiler Systems, Inc. These boilers feature an

aluminum alloy heat exchanger capable of

operating in a fully condensing mode to provide

maximum efficiency in a very small footprint. This

is complemented by a fully modulating burner

with a variable speed combustion blower,

microprocessor controls, and modulating gas

safety shut off & control valves. The high-quality

materials and thoroughly tested design of your

boiler will provide years of trouble-free service if

the instructions in this manual are carefully

followed.

This manual covers installation of the TRIAD

TRIUMPH Series Boilers. The model numbers

may be followed by a prefix or suffix letter in

some cases to indicate special features or

options.

While details may differ slightly, basic operation is

the same for all models. Boilers may be built to

operate with natural gas or propane. Check the

rating plate for correct fuel usage and gas

pressures.

The boiler is only a part of the complete heating

system. It may be fully operational, yet because

of poor circulation, control, or other operating

characteristics, not deliver heat to the desired

location. Additional equipment such as

temperature sensors, pumps, flow switches,

balancing valves, and check valves will be

required for satisfactory operation of any system.

Triad Boiler Systems cannot be responsible for

the design or operation of such systems and a

qualified engineer or contractor must be

consulted.

2.0 SAFETY

2.1 GENERAL

∑ Installed, operated, and serviced in

accordance with instructions contained in this

manual.

∑ Installed by qualified personnel in accordance

with designs prepared by qualified facility

engineers including: structural, mechanical,

electrical, and other applicable disciplines.

∑ Operated and serviced in accordance with a

comprehensive safety program determined

and established by the customer. Do not

attempt to operate or service until such a

program has been established.

∑ Operated and serviced by qualified, properly

trained personnel in accordance with all

applicable codes, laws, and regulations.

Note: Each safety device must be maintained

and checked per the recommended schedule;

refer to Section 5.1 of this manual.

2.2 TRAINING

It is essential to read, understand, and follow the

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to

do so could result in property damage, serious

injury, or death.

Proper training is the best protection against

accidents. Operating and service personnel must

be thoroughly familiar with the basic construction

of the TRIAD TRIUMPH Series boiler, the use

and locations of the controls, the operation of the

boiler, adjustment of its various mechanisms, and

all applicable safety precautions. If any of the

provisions of this manual are not fully and

completely understood, contact Triad Boiler at

630.562.2700 for assistance.

The TRIUMPH Series gas-fired boiler must be:

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

2.3 SAFETY FEATURES

It is the responsibility of the customer to maintain

the safety features, such as: guards, safety

Page 2

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

SSaaffeettyy

labels, safety controls, interlocks, lockout devices,

etc., in place and operable.

2.4 SAFETY LABELS

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

The safety labels shown above are affixed to your

boiler. Although the labels are of high quality,

they may become dislodged or unreadable over

time. Contact Triad Boiler Systems at

630.562.2700 for replacement labels.

2.5 SAFETY PRECAUTIONS

Provide a suitable location for the boiler, away

from normal personnel traffic, with adequate

working space, adequate clearances, proper

ventilation and lighting, with a structure

sufficiently strong and rigid to support the weight

of the boiler, all piping, and accessories.

2.5.1 Electrical Hazards

∑ Shock hazard! Properly lockout/tagout the

electrical service and all other energy sources

before working on or near the boiler.

∑ Shock hazard! Do not spray water directly on

any electrical components.

Reorder No. 8032-01NHPK

2.5.2 Burn, Fire, and Explosion Hazards

General Warning

Hot Surface

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

∑ Burn, fire, and explosion hazards!

Installation must be in strict conformance to

all applicable codes and standards including

NFPA 54, ANSI Z223.1 and CAN/CGA B.149.

Install all required vent lines for gas devices.

Refer to Section 3.7.1.

∑ Hazard from incorrect fuels! Possible fire,

explosion, overheating, and damage. Do not

use any fuels except the design fuels for the

unit.

∑ Overfire hazards! High pressure in gas or

propane supply could result in overfiring of

other devices supplied from the same source.

∑ Fire and explosion hazards! Close the main

gas shutoff before servicing boiler.

∑ Fire and explosion hazards! Do not store or

use gasoline or other flammable vapors or

liquids in the vicinity of this or any other gas

fired appliance.

∑ Burn hazard! Possible hot surfaces. Do not

touch gas vent during firing operation. Use

only factory recommended vent components.

∑ Burn hazard! Pipes, vents, and boiler

components could be hot. Do not touch piping

Reorder No. 8032-01NHPK

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 3

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

or stack surfaces during operation or

immediately after shutdown of the boiler.

∑ Burn hazard! Hot fluids. Use caution when

servicing or draining boiler.

∑ Fire and explosion hazards! Use caution

when servicing burner. Propane (LPG) is

heavier than air and may linger in the

combustion chamber, vent lines, or

elsewhere.

∑ Gas leak hazard! Make sure the burner is

installed correctly and burner hood is securely

fastened following any maintenance

performed on them. These connections

cannot be tested after the burner is

assembled.

∑ Gas leak hazard! All threaded gas

connections must be made using a pipe

compound that is resistant to liquefied

petroleum. Do not use Teflon‰ tape on

threaded gas piping.

∑ Gas leak hazard! Check entire gas train for

leaks after installation. If there is a smell of

gas, shut down the boiler and obtain

immediate assistance from trained service

personnel and/or your local fire department.

General Warning

SSaaffeettyy

∑ Lifting hazards! Use properly rated lifting

equipment to lift and position the boiler. The

load is unbalanced. Test balance before lifting

3 ft. above the floor. Do not allow personnel

beneath the lifted load. Refer to approximate

weights in the table below:

Boiler Size Weight in Pounds

750,000 Btu 650

900,000 Btu 700

1,050,000 Btu 750

∑ Bump hazard from overhead ductwork and

piping. Install components with adequate

vertical clearance.

2.5.4 Chemical Hazards

∑ Overfire hazard! Possible fire and explosion

from excess gas pressure. Make sure that

gas inlet pressure does not exceed 14 inches

W.C. to the regulator.

∑ Overfire hazard! Possible fire and explosion.

Possible malfunction of regulators and/or gas

safety shut off / control valves. Maintain all

gas train components in good condition. Do

not alter wiring connections. Annual

inspection by factory-trained personnel for

proper set-up and operation is recommended.

∑ Overfire and underfire hazards! Possible

fire, explosion, overheating, and component

failure. Do not attempt to adjust firing rate of

the boiler. The firing rate must be adjusted

∑ Chemical hazards from cleaning products.

Use caution when cleaning the system.

Consulting a professional is recommended.

Use safe procedures for the disposal of all

cleaning solutions.

∑ Combustion Condensate – a pH of

approximately 4 to 5 can be expected. Use

PVC or CPVC piping. Collection and disposal

must be in accordance with all applicable

regulations.

only by factory trained personnel.

2.5.3 Crush Hazards

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

General Warning

Page 4

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

SSaaffeettyy

2.5.5 Pressure Hazards

∑ Pressure hazard! Hot fluids. Install isolation

valves on boiler water inlet and outlet. Make

sure isolation valves are closed before

servicing boiler.

∑ Pressure hazard! Hot fluids. Annually test

safety relief valve for proper operation. Do not

operate boiler with faulty relief valve.

2.5.6 Slip, Fall Hazards

∑ Tripping hazard! Do not install piping on floor

surfaces. Maintain clear path around boiler.

∑ Slip and fall hazard! Use drip pan to catch

water while draining the boiler. Maintain dry

floor surfaces.

∑ Slip and fall hazard! Do not locate intake or

exhaust terminations directly above a

walkway; dripping of condensation can cause

icing of the walking surface.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 5

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

3.0 INSTALLATION

3.1 RECEIVING AND STORAGE

3.1.1 Initial Inspection

Upon receiving the boiler, inspect it for signs of

shipping damage. Since some damage may be

hidden, we recommend unpacking the boiler and

removing the top cover and inspecting the boiler.

Verify that the total number of pieces shown on

the packing slip agrees with those actually

received.

Important: Note any damage, suspected

potential damage, or shortage of materials on

the freight bill and immediately notify the

carrier. File all claims for shortage or damage

with the carrier. Claims for hidden damages

must be filed with your carrier within 7 days.

The boiler carton is equipped with a “Tip (N)

Tell”. If "Tip (N) Tell” arrow point is blue, that

indicates that the package has been on its

side or tipped over in transit.

3.1.2 Storage Prior to Installation

If the boiler is not installed immediately, it must be

stored in a location adequately protected from the

weather, preferably indoors. If this is not possible,

then it should remain in the shipping container

and be covered by a tarpaulin or other waterproof

covering.

Note: Controls and other equipment that are

damaged or fail due to weather exposure are

not covered by warranty.

3.2 COMPLIANCE WITH CODES

The TRIAD TRIUMPH Series Boiler with standard

components and with many options complies with

American National Standard/CSA Standard ANSI

Z21.13/CSA 4.9, latest edition, Gas-Fired Low

Pressure Steam and Hot Water Boilers.

The heat exchanger is constructed and stamped

in accordance with ASME Boiler and Pressure

Vessel Code, Section IV for 80 psig maximum

operating pressure and/or 200º F maximum

temperature.

Other codes or approvals which apply will be

labeled on the boiler.

Installation of the boiler must conform to all the

requirements of all national, state and local

codes established by the authorities having

jurisdiction or, in the absence of such

requirements, in the U.S. to the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, latest edition.

In Canada, the equipment shall be installed in

accordance with the current Installation Code for

Gas Burning Appliances and Equipment,

CAN/CGA-B.149, and applicable Provincial

Regulations for the class, which should be

carefully followed in all cases. Authorities having

jurisdiction should be consulted before

installations are made.

Where required by local codes, the installation

must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers (ASME

CSD-1).

In the Commonwealth of Massachusetts (a) this

unit must be installed by a licensed pipe fitter /

plumber, (b) field installed gas cocks must be “T”

handle type, and (c) piping of condensate shall

conform with the State Plumbing Code.

3.3 SETUP

3.3.1 Foundation

Provide a firm, level foundation, preferably of

concrete.

Note: The boiler may be installed on a

combustible floor; however, the boiler must

never be installed on carpeting.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 6

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

3.3.2 Placement

The boiler must be level to function properly. To

assist in leveling the boiler, the four (4) adjustable

leg bolts (1/2"- 13 NC) must be installed. The

adjustable legs are also necessary to provide

adequate floor clearance and prevent distortion of

the cabinet, (twisting, etc.) in addition to leveling.

Adjustable

Leg Bolts

Adjustable Legs for Leveling and Clearance

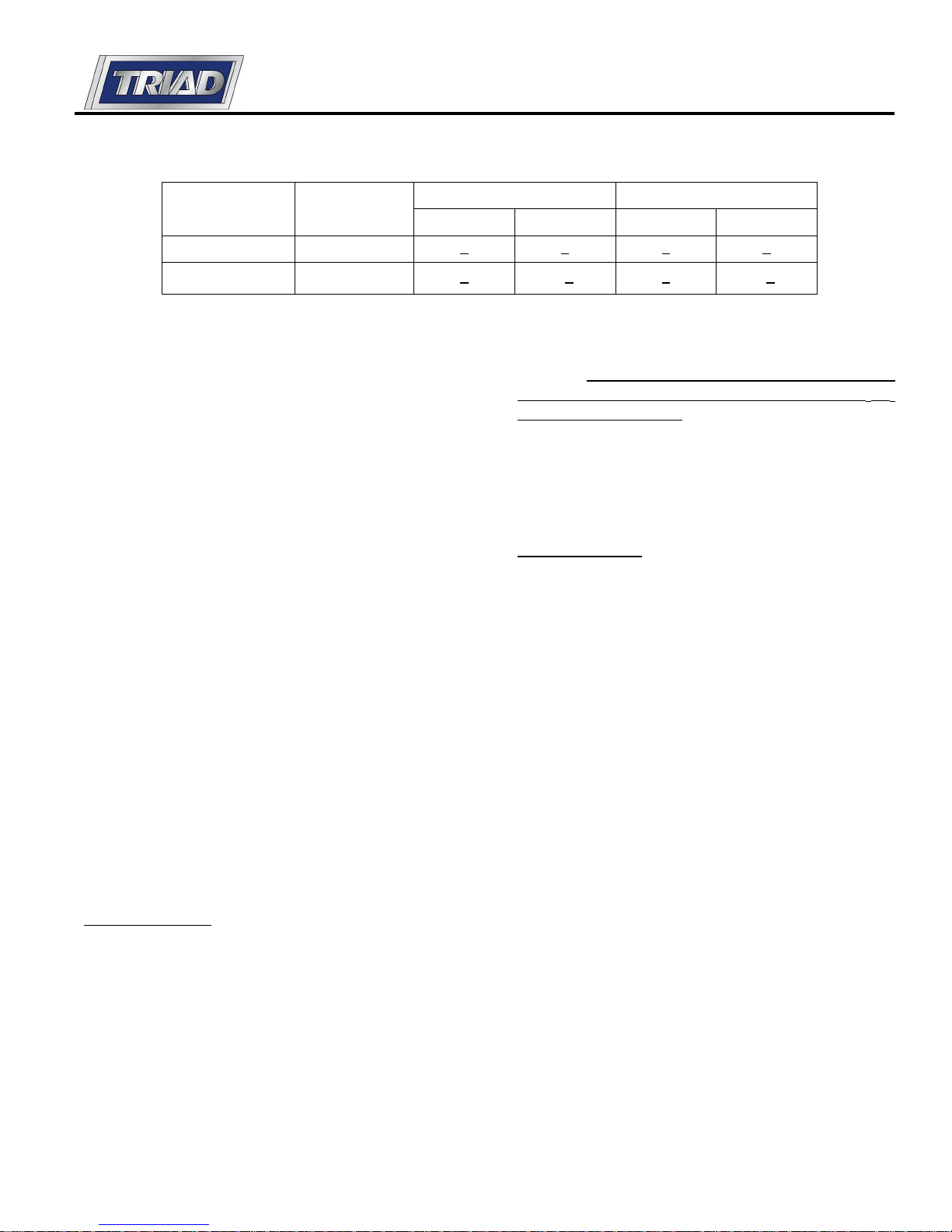

3.3.3 Clearances

D

Minimum Clearances from Adjacent Walls, Ceiling, and

Dimensions (inches) Type of Surface

A B C† D

Combustible Surfaces 24 24 24 24

Non-combustible Surfaces 30 * 24 24**

D

Obstructions

If the boiler is to be installed near combustible

surfaces, the minimum clearances shown in the

table below must be maintained.

Failure to provide for the service access

clearances, even with non-combustible surfaces,

may cause future problems servicing the boiler.

The boiler must be installed in a space large in

comparison to the boiler as described in Section

6.3 of the National Fuel Gas Code, ANSI Z223.1,

latest edition.

No pipes,

ducts, etc. in

this area.

A B

C

† "C" Do not put pipes, ducts, etc. in this area

above the boiler.

CAUTION!

Bumping hazard from overhead ducts! Install all

components with adequate vertical clearances.

* Clearance depends upon vent configuration.

** Service access need be only on one side of a

boiler or row of boilers. Boilers may be installed

immediately adjacent to each other. However

Triad recommends this clearance between each

boiler when there is insufficient access at the

rear to allow for service and adjustment.

3.4 ELECTRICAL CONNECTIONS

The boiler is wired for 120 volts, single phase, 60

hertz. The total operating amperage is indicated

on the rating nameplate. All TRIUMPH units

require less than 8 amps. Before starting the

boiler, check to ensure that the proper electrical

service is connected to the boiler.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 7

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

An external electrical disconnect (not supplied

with the boiler) with adequate overload protection

is required. The boiler must be grounded in

accordance with local codes or in the absence of

such requirements, in the U.S. with National

Electrical Codes, ANSI/NFPA No. 70 latest

edition and in Canada to the current Canadian

Electrical Code, Part I, CSA C22.1.

Note: A dedicated earth ground (green wire) is

required to avoid nuisance shutdowns. Do not

ground through the conduit. Make sure that

proper polarity is maintained.

Note: Refer to Terminal Block Assignments

(Section 6.1.1).

120 Volt

Electrical Control

Junction Box

Low Voltage

Control Junction

Box

Electrical Connections at Rear of Boiler

3.5 COMBUSTION AIR

Combustion air must be free from dust, lint, etc.

The presence of such materials in the air supplied

to the burner could cause nuisance "Low Air"

shutdowns, reduced capacity, or premature

burner failure. The boiler should not be operated

during construction while the possibility of drywall

dust, demolition dust, etc. exists.

The combustion air supply must be completely

free of chemical fumes which may be corrosive

when burned in the boiler. Common chemicals

which must be avoided are fluorocarbons and

other halogenated compounds, most commonly

present as refrigerants or solvents, such as freon,

trichlorethylene, perchlorethylene, chlorine, etc.

These chemicals, when burned, form acids which

quickly attack the boiler and the boiler stack.

The result is improper combustion and

premature boiler failure.

Provisions for combustion and ventilation air

must be in accordance with Section 5.3, Air for

Combustion and Ventilation, of the National Fuel

Gas Code, ANSI Z223.1, latest edition, or

applicable provisions of the local building codes.

In Canada, combustion air openings shall

comply with CSA B.149 Installation Code. The

formula is 1 sq. in. per 1,000 Btu/hr of gas input

not less than 100 sq. in. The location shall be

neither more than 18", nor less than 6" above

the floor level.

The boiler room shall be provided with two

openings to ensure adequate combustion air

and proper ventilation. One opening should be 6

to 12 inches above the floor and the other 6 to

12 inches below the ceiling, preferably on

opposite walls. The size of each opening is

determined by whether air is taken from inside or

outside the building. In Canada, ventilation air

openings shall be at least 10% of the cross

sectional area required for combustion air, but

not less than 10 square inches. It is to be

located at the highest practical point

communicating with outdoors.

WARNING!

Under no circumstances shall the boiler room

ever be under a negative pressure. Particular

care should be taken when exhaust fans,

compressors, air-handling units or other

equipment may rob air from the boiler.

3.5.1 Air Inlet Requirements

If air is taken directly from outside the building,

each opening (minimum of two) should have a

net free area of 1 square inch for each 4,000 Btu

per hour of total boiler input. For instance, 112.5

square inches are required for 450,000 Btu per

hour input.

When air is taken from the outdoors through a

vertical duct, 1 square inch per 4,000 Btu per

hour is required. If a horizontal duct is used, 1

square inch per 2,000 Btu per hour is required,

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 8

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

i.e., 225 square inches for 450,000 Btu per hour

input.

If air is taken from another interior space, each

opening should have a net free area of 1 square

inch for each 1,000 Btu per hour of boiler input

(450 square inches for a 450,000 Btu per hour.)

3.6 FLUE VENTING

This boiler requires a special vent system. This

boiler is Category IV (condensing – positive

pressure) as it is defined in ANSI Z21.13/CSA

4.9, latest edition. The vent material must be

listed Category IV vent pipe (316L or AL29-4C

Stainless Steel) and comply with UL 1738 or

UL103. In Canada it must comply with ULCS636. The exhaust vent can be run horizontally

or vertically.

This boiler is NOT certified for use with Type

"B" vent.

Vent installations shall be in accordance with Part

10, Venting of Equipment, of the National Fuel

Gas Code, ANSI Z223.1 or CSA B.149 code, or

applicable provisions of the local building codes.

The venting system and the horizontal portions of

the venting system shall be supported to prevent

sagging.

WARNING!

Do not use a barometric damper with this

boiler. (This is a positive pressure system;

combustion gas may leak into the room.)

3.6.2 Flue Connection

The connection from the boiler to the vent should

be as direct as possible and the upward slope of

any horizontal breaching should be at least 1/4

inch per linear foot. The vent connection

incorporates a slope toward the boiler to

facilitate pitching of the vent for condensate

collection. This boiler should not be connected

into any portion of another mechanical draft

system operating under positive pressure

without consulting your local venting

representative. Provisions must be made for

supports to prevent contact of the vent with

combustible surfaces.

Note: If the vent is erected directly behind the

boiler, make sure that the weight of the duct is

not supported by the boiler vent. The boiler is

not designed to support the weight of the

duct. Structural support and spacing from

combustible surfaces must be in accordance

with the vent manufacturer's requirements.

The vent must be sized according to the vent

manufacturer’s recommendations. Consult your

vent supplier for correct sizing and structural

support requirements. Design calculations should

be based on a maximum of 0.22" W.C. total

frictional resistance in the stack (measured at the

boiler flue gas discharge), with a stack

temperature of 210° F (gross) and a CO

level of

2

9% (natural gas) or 10.4% (propane). These

values are to be used for vent sizing calculations.

The installation of a bird screen on the vent

termination is recommended. Consult your local

vent manufacturer for proper sizing.

3.6.1 Barometric Damper

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Flue Connection at Boiler

3.6.3 Required Clearances

Provide clearances between combustion air

intake, exhaust vent, roof and wall surfaces,

doors and window, and snow line as shown in

the following diagrams. The exhaust vent

termination must be 14 feet above grade when

located adjacent to a public walkway. It must

Page 9

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

also have a minimum 6 foot horizontal and 6 foot

vertical clearance (above or below) any electric

meters, gas meters, regulators, or relief

equipment.

WARNING!

Do not locate intake or exhaust terminations

directly above a walkway; dripping of

condensation can cause icing of the walking

surface.

Mechanical draft vent

12 in.

min.

terminal

Grade

Direct vent terminal

clearance minimum 12 in.

12 in.

min

Mechanical draft

vent terminal

4 ft.

min.

12 in.

min.

4 ft.

min.

Less

than

10 ft.

3 ft min.

3.6.4 Vent Terminations

No rain cap

required,

or Tee.

Centering

Support Plate

Sealant

Outside Plate

Cover Plate

Fastener

Sealant

Recommended

Termination

(see text below)

12" min.

Vent Termination Details

The vent should extend at least three (3) feet

above the roof, or at least two (2) feet above the

highest part of any structure within ten (10) feet

of the vent.

Reference: ANSI Z223.1 - 2002

10' min.

Combustion

Air Inlet

4' min above

4' min.

snow line

Forced

air inlet

Sidewall Installations

Flue Gas

Outlet

Rooftop Installations

To prevent the possible re-circulation of flue

gases, your vent designer must take into

consideration such things as prevailing winds,

eddy zones, building configurations, etc. Triad

cannot be responsible for the effects such

adverse conditions may have on the operation of

the boilers. Dimensions listed above or those

illustrated represent minimum dimensions only

and may or may not be sufficient for conditions

at a specific job site.

A tee must be of approved design and adequate

capacity.

3.6.5 Venting for Multiple Boilers

The venting instructions in this manual apply to a

single boiler.

Venting systems for multiple boilers must be

designed by qualified professionals and

verified by the stack manufacturer. The

venting system must prevent backflow of

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 10

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

exhaust gas through idle boilers which are

not operating.

3.6.6 Sealed Combustion Air/Venting System

The TRIUMPH Series Boilers are also certified for

operation with a sealed combustion air and

pressurized venting system. Such a system

employs a sealed combustion air intake duct

leading from outdoors and a sealed exhaust vent

terminating outdoors. Air flow through the system

is maintained by the fan inside the boiler

assembly.

Vent Installation Details

Installation must conform to the vent

manufacturer's instructions in all respects

including joining, clearances, fastening, firestopping, and other matters.

Vent ductwork may be run horizontally or

vertically if so certified.

3.6.7 Removing an Existing Boiler

(from a common venting system)

When an existing boiler is removed from a

common venting system, the venting system will

now probably be too large for proper venting of

any remaining appliances that are still connected.

When an existing boiler is removed, complete the

following steps with each appliance remaining

connected to the common venting system (when

they are not in operation):

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine that

there is no blockage or restriction, leakage,

corrosion or other deficiency which could

cause an unsafe condition.

3. Insofar as is practical, close all building

doors and windows and all doors between

the space in which the appliances remaining

connected to the common venting system

are located and other spaces of the building.

Turn on clothes dryers and any appliances

not connected to the common venting

system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not

operate a summer exhaust fan. Close

fireplace dampers.

4. Place the appliance being inspected in

operation. Follow the lighting instructions.

Adjust the thermostat so that the appliance

will operate continuously.

5. Test for spillage at the draft hood relief

opening after 5 minutes of main burner

operation. Use the flame of a match or

candle or smoke from a cigarette.

6. After it has been determined that each

appliance connected to the common venting

system properly vents, return windows,

doors, exhaust fans, fireplace dampers and

any other gas-burning appliance to their

previous conditions of use.

Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1 and CSA B149 Installation Code. When

resizing any portion of the common venting

system, the common vent system should be

resized to approach the minimum size as

determined using the appropriate tables.

3.6.8 Intake/Exhaust Layout

Four basic configurations for the intake/exhaust

may be used. Refer to Section 3.6.3 for

required clearances for all terminations

shown in the four following figures:

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 11

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

Basic Air Inlet/Vent Configurations

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 12

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

3.6.9 Intake Duct Materials and Sizes:

Material: PVC, CPVC (Schedule 40), single wall

galvanized steel, or other suitable materials.

The intake duct must be sized for a maximum

pressure drop of 0.22 inches W.C., for the SCFM

as specified below.

Btu Size Required SCFM

1050 245

900 210

750 175

The installation of a bird screen on the intake

termination is recommended.

3.6.10 Sealing the Intake Duct

Proper sealing of the intake ductwork is

necessary to prevent infiltration of air from

conditioned space. Joints in PVC or CPVC must

be cemented. For galvanized duct, wrap each

joint and seam with adhesive aluminum tape.

3.6.11 Intake Duct Connection to Boiler

Connect the air supply duct to the collar on the

back of the boiler. Fasten the duct to the collar

with sheet metal screws at 90º angles. Seal the

joint.

3.6.12 Intake Duct Terminations

No rain cap -

Unrestricted

The roof intake termination must be an

unrestrictive type, as shown above.

Support Plate

Centering

Sealant

Recommended

Outside Plate

Cover Plate

Fastener

Sealant

Termination

12" min.

Intake Termination Details

Field Provided

Inlet Screens

3.6.13 Vent Elbows

The turn from horizontal to vertical should be

made with two 45º ells or with one long radius

90º ell for best operation. Do not use "short

radius" ells.

3.7 GAS PIPING

Before making the gas hook-up, make sure the

boiler is being supplied with the type of fuel

shown on the boiler nameplate.

The boiler shall be installed such that the gas

ignition system components are protected from

water (dripping, spraying, rain, etc.) during

appliance operation and service (circulator

replacement, control replacement, etc.)

The boiler is factory fire-tested and adjusted for

proper combustion with natural gas supply

pressure of 7” W.C. Typical gas pressure

supply for natural gas is 7" W.C. (11" W.C. for

propane). The gas train components are

certified to handle a maximum inlet pressure of

14" W.C. (1/2 psig.). If the available gas

pressure exceeds 14" W.C., a suitable additional

intermediate gas pressure regulator of the "lock

up" type must be provided to reduce the

pressure to less than 14" W.C.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 13

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

WARNING!

All threaded connections must be made using a

pipe compound that is resistant to the action of

liquefied petroleum gases. Do not use Teflon

tape on gas line threads.

Natural Gas

Supply

Gas Piping

Drip Leg

Meter

(not supplied)

Remote Gas Shutoff

(not supplied)

By Installer

Union

Shutoff

(on boiler)

In the Commonwealth of Massachusetts, the gas

cock must be a “T-handle type.”

Note: Install a sediment trap (drip leg) and a

union connection ahead of the primary

manual shutoff valve on the boiler. Gas

piping should be installed in accordance with

National Fuel Gas Code, ANSI Z223.1, latest

edition, and any other local codes which may

apply; in Canada see CAN/CGA-B.149.

Note: See Pipe Capacity for Natural Gas chart

on the following page for required pipe size,

based on overall length of pipe from meter plus

equivalent length of all fittings. Approximate

sizing may be based on 1 cubic foot of natural

gas per 1,000 Btu per hour input, i.e., 500,000

Btu per hour requires about 500 cubic feet per

hour. (See "Typical Boiler Operating Conditions,"

Section 4.3, for more information.)

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 14

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

Pipe Capacity for Natural Gas

Nominal

Iron Pipe

Size

(Inches)

1/2 0.622 1.55 3.1 120 82 66 57 50 40 35

3/4 0.824 2.06 4.12 250 170 138 118 103 84 72

1 1.049 2.62 5.24 465 320 260 220 195 160 135

1- 1/4 1.380 3.45 6.9 950 660 530 460 400 325 280

1- 1/2 1.610 4.02 8.04 1460 990 810 690 620 500 430

2 2.067 5.17 10.3 2750 1900 1520 1300 1150 950 800

2- 1/2 2.469 6.16 12.3 4350 3000 2400 2050 1850 1500 1280

3 3.068 7.67 15.3 7700 5300 4300 3700 3250 2650 2280

4 4.026 10.1 20.2 15800 10900 8800 7500 6700 5500 4600

Internal

Diameter

(Inches)

Equivalent Pipe Length

90º Ell

(Feet)

Tee

(Feet)

3.7.1 Gas Supply Piping by Installer

Maximum Capacity in Cubic Feet of Natural Gas per Hour

Pressure Drop of 0.5 inch Water Column/Equivalent Length of Pipe

(in feet)

20

40

60

80

100

150

3.8 BOILER WATER PIPING

200

The boiler and all gas piping connections should

be pressure-tested and must be checked for

leaks before being placed into service. Test with

compressed air or inert gas if possible.

The boiler must be disconnected at the boiler

manual shut-off valve (located at the end of the

supplied gas train) from the gas supply piping

system during any pressure testing of the system

at pressures in excess of 1/2 psig (14" W.C.).

During any pressure testing of the gas supply

piping system at pressures equal to or less than

1/2 psig (14" W.C.), the boiler should be isolated

from the gas supply piping system by closing the

manual shut-off.

Some leak test solutions, including soap and

water, may cause corrosion. These solutions

should be rinsed-off with water after testing.

3.8.1 Piping Design

Water Flow in System

For proper water flow requirements see below.

Incorrect flow may result in eventual damage or

premature failure of the equipment.

Model Max Flow

GPM

105 52 12

90 45 12

75 37 12

T-

TT-

1000

900

750

Min Flow

GPM

DP ft. at

max flow

Contact Triad for minimum flow at other than

maximum firing rate.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 15

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

14

12

10

8

DP (ft)

6

4

2

0

0 20 40 60 80 100 120

Flow vs . DP

750 900 1000

Flow (g pm)

Proper flow rates may be achieved through a

combination of primary and secondary flow loops.

Multiple zones and pumps may result in different

flow rates at different times. Consideration must

be given to all possible conditions and their

consequences.

Piping With Refrigeration Machines

When installed in a two-pipe system that provides

both chilled and hot water, the control system

should be configured so as to limit the time rate of

change of temperature at the boiler. Consult your

authorized Triad boiler representative for

application guidance.

Piping With Air Handling Units

3.8.2 Boiler Inlet and Outlet Connections

Make water connections as the application

warrants, or at a minimum as shown, but always

in compliance with the local requirements.

Note: The boiler is furnished with 2” grooved

connections for Victaulic Style 75 Couplings.

These coupling must be used with the EPDM

Victaulic seals. Isolating valves must be

installed in both water connections for ease

of service.

The boiler piping system of a hot water heating

boiler connected to heating coils located in air

handling units, where they may be exposed to

refrigerated air circulation, must be equipped with

flow control valves or other automatic means to

prevent gravity circulation of the boiler water

during the cooling cycle.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

The bottom connection to the boiler is the INLET

and must be used for the return from the system.

The top connection to the boiler is the OUTLET

and must be connected as the supply to the

system.

* Note: Condensate Trap must be piped to drain

in accordance with all state and local codes.

Page 16

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

3.8.3 Boiler Water Piping by Installer

Strainer

To avoid possible contamination of the boiler with

dirt, rust or sediment from the system, a strainer

near the boiler inlet is strongly recommended.

Even new systems may contain sufficient foreign

material to eventually reduce the performance of

the heat exchanger. Adequate circulation of good

clean water is essential to maximum efficiency

and long life of the boiler.

Relief Valve and Piping

Each boiler is supplied with a pressure-relief

valve sized in accordance with ASME

requirements. The relief valve should be piped to

a suitable floor drain. Reducing couplings or other

restrictions are not permitted in the discharge

line.

Low Water Cut-off

The boiler is furnished with a probe-type low

water cut-off; no field piping is required. If the

water level in the boiler drops below the probe,

the boiler will shut down and a flashing E 12

service code will be displayed on the control

panel. The low water cutoff circuit will

automatically reset when the low water condition

clears; however the boiler controls will retain the

lockout condition until the reset button on the

display is depressed.

IMPORTANT!

The low water cutout probe only prevents boiler

operation when the water level in the boiler is

insufficient. It does not detect low water

conditions in other parts of the system.

Installation of high point vents or additional low

water safety devices to protect the system should

be considered.

Installation of external limit controls may be

required by certain codes or in certain

installations. Review applicable local codes for

details.

Drain Valve and Piping

A drain valve is installed in the inlet (system

return) header connection to the boiler. Prior to

draining the boiler for maintenance or testing,

electrical power and gas supply must be turned

off to the boiler. The boiler must then be isolated

from the system at the supply and return

connections prior to draining water from the

boiler.

Note: This drain valve is installed for draining

of the boiler water only, not the entire

system. Draining of the system through the

boiler will result in depositing sediment from

the system in the boiler which will result in

poor heat transfer characteristics of the

boiler and early boiler failure.

Condensate Drain

The condensate can be slightly acidic (pH

between 3.0 and 5.0). This may be corrosive to

some building drain systems. A condensate

neutralization system may be required.

Disposal of condensate must comply with all

state and local codes.

3.8.4 Flushing and Filling

Water Quality

Because the TRIUMPH Series boiler heat

exchanger is made of an aluminum alloy it

requires special water conditions to retain

efficiency and function properly.

IMPORTANT!

Chemicals added to the system must be

approved by the chemical manufacturer for use

in aluminum boilers.

IMPORTANT!

Under no circumstances should petroleum

based cleaning or sealing compounds be used in

the boiler system.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 17

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

The boiler is designed to operate in a closed-loop

system. As such, the system should be tight and

not require make-up water. A high percentage of

untreated make-up water will cause premature

failure due to buildup of scale; such failure is not

covered by warranty.

Scale can also reduce efficiency. A scale

thickness of 1/16" will result in a 12.5% loss of

efficiency.

Water pH

The pH of the hydronic system fluid must be

between 6.0 and 8.5. A periodic check of the

system pH should be conducted to ensure these

pH levels are maintained.

IMPORTANT!

Glycol and other additives must be approved by

the chemical manufacturer for use in aluminum

boilers and must meet the required pH levels

listed above to prevent damaging the boiler.

The water quality should be within the guidelines

established by the American Boiler Manufacturers

Association, as follows:

Total solids:........................... 2,500 ppm

Total hardness:........................ 150 ppm

The amount of oils, fats, grease, and other

organic matter should be limited to 10 ppm.

Consult your water conditioning or chemical

treatment supplier for the best recommendation.

IMPORTANT!

If the piping system attached to this unit will be

chemically cleaned, the boiler must be

disconnected from the system and a bypass

installed so that the chemical cleaning solution

does not circulate through the boiler. Following

chemical cleaning, the system should be

thoroughly rinsed to remove cleaning agents

prior to reconnecting the boiler to the system.

Filling

To be sure that the boiler is not air-bound, open

the pressure-relief valve located at the rear of

the boiler. Leave the relief valve open until a

steady flow of water is observed. Close the valve

and finish filling the system.

3.9 BURNER AND IGNITION SYSTEM

3.9.1 Inspection

Inspect the unit to be sure nothing was damaged

or knocked loose during shipment. Since some

damage may be hidden, remove the top cover

and inspect the boiler.

Inspect the gas train, blower, ignition electrode

and boiler in general to be sure there was no

damage during shipment or installation.

Flushing the System

Before filling the boiler, flush the system to

remove any debris. Clean and flush old piping

thoroughly before installing the boiler.

IMPORTANT!

Never flush the hydronic system while the boiler

is attached to the system since the debris or

corrosion products could accumulate in the boiler

and plug the boiler heat exchanger.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 18

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

3.10 PRE-START CHECK LIST

Before attempting to start the boiler, make sure

the following items have been completed.

1. Inspect unit as per Section 3.9.1.

2. Flue gas from the boiler is properly vented;

(refer to Section 3.6)

3. Gas connection has been made, pressure

tested for leakage, and the line purged of air.

Make sure all required vents have been

installed.

4. Water connections are complete, and the

boiler and system have been filled and

purged of air.

5. The boiler is connected to a 120 volt power

source with a disconnect having adequate

overload protection.

6. Combustion air openings are not obstructed

in any way and have adequate capacity.

7. The boiler is placed the proper distance from

any combustible walls, in accordance with

Section 3.3.3.

8. Relief valves have been piped to floor drains.

9. Condensate piping is properly connected.

10. Verify system fluid pH level is within

specification.

3.11 SAFETY CHECKS

The following checks of safety systems must be

made before putting the boiler into normal

operation.

Before firing the boiler refer to Sections 4.1 and

4.2 for information on the use of the controls,

lighting, and shut-down procedures.

WARNING!

Never attempt to operate a boiler that has failed

to pass all the safety checks described below.

WARNING!

After checking controls by manual adjustment,

make sure they are always reset to their proper

settings.

3.11.1 Test of Ignition Safety System

TRIUMPH Models T-750, T-900 & T-1000

Test the ignition system safety shutdown as

follows:

1. Cycle the boiler on by generating a heat

request. (The method for this will depend on

your boiler configuration. See Section

3.12.1.2)

2. Place the boiler in operation at the high fire

setting. See section 3.12.4 Gas Valve Setup

and Adjustment , Test Mode High

3. Smoothly close the downstream manual

isolation valve to reduce the gas flow and

cause flame failure.

4 The display will flash E-02 indicating a flame

failure. The E-02 lockout will remain until

reset on the display.

After completing this test, turn off the boiler and

open the downstream manual isolation valve.

3.11.2 Test of Low Water Cut Off

The boiler is furnished with a probe-type Low

Water Cut Off in the outlet nozzle. Test as

follows:

Check the operation of the switch by first turning

the boiler off and then turning the system pump

off. Isolate the boiler from the system pressure.

Then drain the water level below the low water

cut off probe. Turn the boiler back on. It should

not operate, and a manual reset lockout

displaying E 12 on the display panel will occur.

The red light indicator for Low Water Cut Off will

NOT be illuminated. When the water level is

normal, the red light stays illuminated.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 19

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

Return the system to normal operation and restart

the boiler. Refer to Section 4.2.1.

3.11.3 Test of High-Limit Control

Fire the boiler and test the high limit control as

follows:

With the main burner operating, turn down the

temperature setting on the "high-limit" thermostat

until the main burner shuts off. A manual reset

lockout displaying E 12 on the display panel will

occur. The high-limit switch must be manually

reset prior to resetting the boiler at the display

panel. Readjust the high-limit thermostat to the

desired setpoint.

3.11.4 Test of Gas Pressure Switch

Low Gas Pressure Switch

The boiler is furnished with a low gas pressure

switch. The operation of this switch must be

checked by slowly closing the main gas cock

while the burner is operating. The switch should

shut down the main burner. When the gas

pressure switch opens, a manual reset lockout

displaying E 12 on the display panel will occur.

Upon re-opening the main gas cock, the E 12

indicator will remain on until the display panel is

manually reset.

High Gas Pressure Switch

TRIUMPH Series T-750, T-900 and T-1000 units

equipped with a high pressure switch must be

checked by closing the downstream gas cock

with the boiler off. When the boiler is started, it

should enter its normal starting cycle and fail on

high gas pressure when the gas safety valves

open. The high gas pressure switch actuation is

evident when a manual reset lockout displaying E

12 on the display panel occurs. Upon re-opening

the gas cock, the E 12 indicator will remain on

until the display panel is manually reset.

3.12 INITIAL ADJUSTMENTS

3.12.1 Operating Temperature Controller

The TRIUMPH boiler is equipped with a

combination combustion and temperature

control. This control monitors combustion and

lighting of the boiler, as well as maintaining

temperature of the supply water. The

temperature control portion modulates the boiler

to maintain the desired outlet temperature based

on the selected operating configuration.

CAUTION!

The user should become thoroughly familiar with

the operation of the boiler and controls before

attempting to make any adjustments.

3.12.1.1 Operation of the Control

The boiler is operated through the control/display

panel. The display has 3 modes of standard

operating menus. The modes are:

∑ Standby mode will display (Stby)

∑ Parameter mode will display (PArA)

∑ Information mode will display (InFo)

At each level the keys and the display have

different functions. To ascertain which mode you

are in, the displayed information will be shown

as indicated under “display”.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 20

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

Mode Description Display Example

Standby

(

Stby)

Parameter

(

PArA

Information

(

InFo

Normal display

Parameter

)

Display boiler

)

mode

settings

sensors

1st digit

without a dot 0 180

1st digit with

a dot

1st digit with a

blinking dot * 1.180*

1.125

Standby Mode:

The display defaults to this mode at startup or

reset of the control. If no key is pressed for 20

minutes the display will return to this mode. The

function of the keys may be two-fold as shown

below.

Key(s) Duration Function

Mode momentary Change to next mode

Reset momentary Reset the control

Show the comfort heat

setpoint, or max setpoint

Plus momentary

Plus long*

Minus momentary

Minus long*

(outdoor reset only)

Turn the comfort heat system

on or off

Show the domestic hot water

setpoint

Turn the domestic hot water

system on or off

*Note: Long duration is greater than 2 seconds.

When in the Standby Mode the control indicates

boiler status with the first digit of the display. The

remaining digits indicate the boiler's actual

temperature or lockout code. The following table

indicates the meaning of the display digits when

in the standby level.

First Digit

0 Burner off - No call for heat

1 Pre purge or post purge

2 Ignition

3 Burner on in Comfort Heat mode

4 Burner on in Domestic Hot Water mode

5 Checking the airflow switch

Burner off - An internal setpoint has been

6

reached. System is still calling for heat.

Boiler Status

First Digit

Burner off - Comfort Heat pump running on

7

8

9 and b

flashing

A Adjusting the 3 way valve if used

H Burner on in manual high fire

L

delay. No system call for heat.

Burner off - Domestic Hot Water pump

running on delay. No system call for heat.

Burner off – auto reset lockout. A code is

displayed indicating the reason for the

lockout. (See Troubleshooting Section

5.5.)

Burner on in manual low fire

Boiler Status

Parameter Mode:

The Parameter Mode is used to change the

boiler settings and is accessed by pressing the

MODE key several times until PArA is shown.

Parameters are selected with the STEP key, and

changed with the plus “+” and minus “-“ keys.

Once the desired value is reached, pressing the

STORE key accepts the new setting.

Parameters 1 through 4 are accessible directly

at the parameter level. Parameters higher than 4

are only accessible by authorized service

personnel trained on the TRIAD TRIUMPH

Series Boiler.

Upper

Parameter Description Lower Limit

DHW setpoint

1

2

3

4

if used 68° 158°

DHW system

ON/OFF

Comfort heat

system

ON/OFF

Setpoint or

max boiler

temp outdoor

air mode

0=OFF

1=ON

2=OFF +pump

continuous

3=ON + pump

continuous

0=OFF

1=ON

2=OFF +pump

continuous

3=ON + pump

continuous

68° 182°

Limit

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 21

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

Information Mode:

The information mode is used to display the

values of the various sensors such as inlet water

temp, outlet water temp etc. The information

mode is accessed by pressing the MODE key

several times until InFo is displayed. The desired

sensor is selected with the STEP key. The

following table indicates the displayed value:

Step Value

1 Outlet water temp

2 Inlet water temp

3 Domestic Hot Water temp *

4 Outdoor air temp *

5 Flue gas temp

6 Boiler outlet setpoint

7 Rate of change outlet temp °F/second

8 Rate of change inlet temp °F/second

Rate of change Domestic Hot Water

9

A

°F/second

Second Comfort Heat system

temperature

* If the sensors for these functions are not

installed, the display will indicate -22.

3.12.1.2 Operating Configurations

The boiler has several different operating

configurations. These are:

∑ Internal Setpoint

∑ Domestic Priority

∑ Outdoor Air Reset

∑ Analog Input Setpoint

∑ Analog Input Direct Drive

CAUTION!

Do not modify any parameters other than those

specifically mentioned.

Internal Setpoint:

The internal setpoint is set with parameter 4. The

boiler temperature control modulates the boiler

to maintain this internal setpoint. The upper and

lower temperature differentials are used to

instruct the boiler at what temperature to turn on

and at what temperature to turn off.

Item Parameter Value Allowable

Range

Setpoint 4 160 68-185

Low Temp. Differential 22 10 0-36

High Temp. Differential 23 9 0-36

Low Temp. Setpoint 5 68 59-140

The boiler will modulate to try to maintain 160°

F. If the temperature increases above 169° F

which is the setpoint 160° F + High Temp

Differential 9°F the boiler will shut off. Once it

shuts off it will not restart until the temperature

drops below 150° F which is the setpoint – Low

Temp Differential. The Low Temp Set Point will

not permit the operator to adjust the setpoint

below 68° F. (See graph below.)

Internal Setpoint

175

170

165

Boiler Temperature

160

155

150

145

0 10 20 30 40

Boiler Turns On

Boiler Turns Off

Boiler Set Point

Time

Domestic Priority:

If an indirect domestic hot water (DHW) tank is

connected, the DHW function of the boiler will

activate when the DHW temperature controller

(supplied by others) closes (Terminal 5 to 8 TB

1, refer to Section 6.1.1), indicating a call for

heat from the DHW system.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 22

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

The parameters should be set as follows:

Item Parameter Value

DHW Setpoint 1 140

DHW Setpoint Addition 33 30

DHW Status 2 1

DHW High Temp. Differential 25 6

DHW Low Temp. Differential 24 6

DHW Options 35 13

In the above example, the boiler temperature will

be set to the DHW Setpoint + the DHW Setpoint

Addition (140ºF + 30ºF = 170ºF) when the DHW

temperature controller indicates a call for heat

from the DHW system. When the DHW system

calls for heat, the central heat pump output

(Terminal 10 TB2) de-energizes and the DHW

pump output (Terminal 11 TB2) energizes

providing 120 VAC power is provided to energize

a relay coil for the DHW pump. The DHW status

should be set to 1 (DHW system ON).

CAUTION!

Terminal 10 and 11 on TB2 are for pilot duty

only. they should not be connected directly to the

pump.

Outdoor Air Reset (optional):

OUT D O O R A I R vs B O ILER SE TPO IN T

190

180

170

160

150

140

130

120

110

100

90

BOILER SETPOINT °F

80

70

0 10 20 30 40 50 60 70 80 90

OUT DOO R A IR TE MP ° F

The control automatically detects the presence

of the outdoor air sensor. If an outdoor air sensor

is present, the boiler automatically defaults to

outdoor air reset for setting boiler temp. The

parameters should be set according to the

following table:

Item Parameter Value

°F

Maximum Setpoint 4 180 68-185

Minimum Setpoint 5 80 60-140

Outdoor Air

Minimum Temp.

Outdoor Air

Maximum Temp.

Boiler Shutoff Temp. 10 90

Outdoor Air Offset 12 0 0-144

Boiler Configuration 34 01

6 20 4-50

7 70 59-77

Allowable

Range °F

32-140

(32=off)

The set point of the boiler is controlled by an

outdoor temperature sensor. As the outdoor

temperature falls the setpoint of the boiler is

increased. The boiler modulates to maintain this

setpoint.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 23

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

The setpoint is adjusted according to the above

parameters. The boiler setpoint will be the

maximum value (180° F) when the outdoor air is

at or below a minimum temperature value (20° F).

The boiler setpoint will be at the minimum value

(80° F), when outdoor air is at or above a

maximum temperature value (70° F). The setpoint

for “in between“ values of outdoor air

temperature, is linearly proportional to the above

settings. Using the values in the table above, the

boiler setpoint will be 80° F when the outdoor air

temperature is 70° F. As the outdoor air

temperature drops, the boiler setpoint will be

increased until the outdoor air temperature is 20°

F. At this point the boiler will reach its maximum

setpoint of 180° F. If the outdoor air temp drops

further, the boiler setpoint remains at 180° F.

The boiler shutoff temperature can be used to

turn the boiler off at a given setpoint. For example

if you wanted to shut the boiler off when the

outdoor air temperature was above 65° F you

would set the boiler shutoff temp to 90° F since

this is the setpoint that is called for at 65° F

outside air temp.

Analog Input to Adjust Setpoint:

Analog Inpu t S etpoin t

200

150

Bo iler Setpoint

100

Boiler Setpoint

50

0

0 1 2 3 4 5 6 7 8 9 10

V oltage

Non adjustable Curve

Item Parameter

Maximum Setpoint 4 180 68-185

Minimum Setpoint 5 80 60-140

Boiler Configuration 34 03

Value

°F

Allowable

Range °F

The setpoint of the boiler is controlled by an

external 0-10 VDC signal. A signal of at least 0.5

VDC is required to start the boiler. At 0 VDC the

setpoint is 32° F; at 10 VDC the setpoint is 212°

F. This setpoint is low and high limited by

maximum and minimum setpoint parameters.

The controlled setpoint voltage range narrows

when these limits are used. If the above tables

values are used the boiler setpoint will be 80° F

when the voltage is anything less than

approximately 3 VDC. It will then increase

linearly with voltage until approximately 8.5 VDC

when it will be 180° F. The setpoint will remain at

180° F even if voltage is increased further.

Analog Input to Control Firing Rate:

Analog Inp ut F iring Rate

100

90

80

70

60

50

40

Firing Rate

30

20

10

0

0 1 2 3 4 5 6 7 8 9 10

V olta ge

The control must be configured for analog input

direct drive by setting parameter 34 to 02.

The control must be configured for a remote

analog input setpoint according to the following

table:

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

The firing rate of the boiler is controlled by an

external 0 to 10 VDC signal. At a voltage greater

than 0.5 VDC the boiler turns on and runs at low

fire until 1.8 VDC is reached. The firing rate

increases linearly with voltage until high fire is

reached at 10 VDC. The boiler setpoint

Parameter 4 remains active to shut down the

Page 24

TTRRIIUUMMPPHH SSeerriiees

s

GGaass--FFiirreedd BBooiilleerr

IInnssttaallllaattiioonn

boiler when the temperature in the boiler exceeds

this value plus the high temp differential. These

voltage levels, as explained above, are all “nonadjustable”.

3.12.2 Gas Pressure Adjustment

Note: Adjustments shall only be performed

by service representative specifically trained

and certified to perform maintenance on the

Triad TRIUMPH Series boiler.

See rating plate for the minimum and maximum

gas pressure of the boiler. Each boiler is

furnished with a manual shut-off valve which has

an integrated test port.

This gas pressure port is located on the upstream

side of the valve body for measuring supply

pressure. (See figure below.)

(See instructions below). Adjust the carbon

dioxide (CO2) or oxygen (O2) reading to achieve

conditions as listed in the following Table 3-1.

3.12.4 Gas Valve Setup and Adjustment

Verify gas pressure at inlet to boiler is in

accordance with Table 3-1 on the following

page. Gas flow is dependent primarily on fan

speed not upstream gas pressure. When set

up for natural gas operation, the boiler is capable

of operating with gas supply pressure as low as

3.5” W C.

Boiler Test Mode:

The test mode should be used when checking

and setting the gas safety shut off / control

valves on the TRIUMPH Series boilers. In this

mode an automatic heat request is simulated as

follows:

Test Mode High:

Test Port

The supply pressure during main burner

operation must be greater than the minimum

indicated on the rating plate (3.5". W.C. for

natural gas, 7" W.C. for propane).

3.12.3 Air Flow Adjustments

The air flow is pre-set at the factory prior to

shipment. In unusual situations the air/gas ratio

may have to be adjusted to obtain proper

combustion readings for specific local conditions.

Combustion measurement instrumentation must

be used to adjust the boiler for local conditions

Simultaneously pressing the “Mode” button and

the “+” button for 3 seconds activates the “Test

Mode High” function to drive the boiler output to

maximum. The display will blink and indicate “H”

in the first digit of the display to indicate the

boiler is being driven to the maximum output

rating. This test mode will automatically

terminate after 15 minutes or can be terminated

from the control/display panel by simultaneously

pressing the “+” and “-“ buttons for three

seconds.

Test Mode Low:

Simultaneously pressing the “Mode” button and

the “-” button for 3 seconds activates the “Test

Mode Low” function to drive the boiler output to

minimum. The display will blink and indicate “L”

in the first digit of the display to indicate the

boiler is being driven to the minimum output

rating. This test mode will automatically

terminate after 15 minutes or can be terminated

from the control/display panel by simultaneously

pressing the “+” and “-“ buttons for three

seconds.

Triad Boiler Systems, Inc – TRIUMPH Series Hot Water Boiler

Page 25

TTRRIIUUMMPPHH SSeerriiees

Table 3-1 Combustion Reading For Setting Gas Safety Shut Off / Control Valves

Nominal High Fire Setting Low Fire Setting