Page 1

Page 2

Combi 650

-2-

ITEMS ENCLOSED

Length = 760mm

Width = 360mm

Thickness = 13mm

Weight = 4.2kg

Specification

1 x Solid laminate template

2 x Location bushes

1 x Manual

1 x Guarantee card

1 x Length setting stop

1 x Machine screw csk

1 x Washer

1 x Knob

Page 3

Combi 650

-3-

SAFETY P RECAUT I O N S

■ Always switch off the power and unplug the

router when changing cutters or when making

adjustments.

■ Always wear protective goggles when routing.

■ Wear sound protective ear muffs when routing

for long periods of time.

■ Always wear a dust mask or respirator. Use

dust extraction equipment whenever possible.

■ Do not wear loose clothing. Make sure baggy

sleeves are rolled up and ties are removed.

■ Always remove spanners and hex keys from

the workpiece before switching router on.

■ Keep hands well clear of the router cutter

when routing.

■ Avoid accidental starting of the router. Make

sure the power switch is in the ‘Off’ position

before plugging in and connecting to the

electrical supply.

■ Never leave the router unattended when

running. Always wait until the router comes to

a complete stop before making any

adjustments.

■ Do not switch the router on with the cutter

touching the workpiece.

■ Mount the workpiece securely to a work

bench or to a workboard fitted to a suitable

surface.

■ Periodically check all nuts and bolts to make

sure they are tight and secure.

Cutter Care

■ Do not drop cutters or knock them against

hard objects.

■ Cutters should be kept clean. Resin build-up

should be removed at regular intervals with

Resin Cleaner

®

. The use of a dry lubricant

will act as a preventative such as Trendicote

®

PTFE spray.

■ Cutter shanks should be inserted into the

collet at least

3

/4 of shank length to prevent

distortion. A distorted collet should be

discarded, as it can cause vibration and

damage the shank.

■ Do not over-tighten collet as this will score the

shank and create a weakness there.

■ It is also advisable to periodically check the

router collet nut for wear.

Useful Advice

■ Judge your feed rate by the sound of the

motor. In time, the operator will acquire a

‘feel’ for the router, and a feed speed relative

to the work will come naturally. Too slow a

feed will result in burning.

■ Apply the normal precautions as with any

electric power tool.

■ The main abuse of routing machines is the

inclination for operators to overload them.

The motto is ‘Keep the revs up’. The drop in

revolutions should not exceed, if possible,

more than 20% of full running speed.

■ The motor of a router is susceptible to the

accumulation of sawdust and wood chips, and

should be blown out, or ‘vacuumed’,

frequently to prevent interference with normal

motor ventilation.

■ Refer to the Instruction Manual supplied with

your router for full details of its features and

safety information.

■ Trial cuts should be made on waste material

before starting any project.

Page 4

Combi 650

-4-

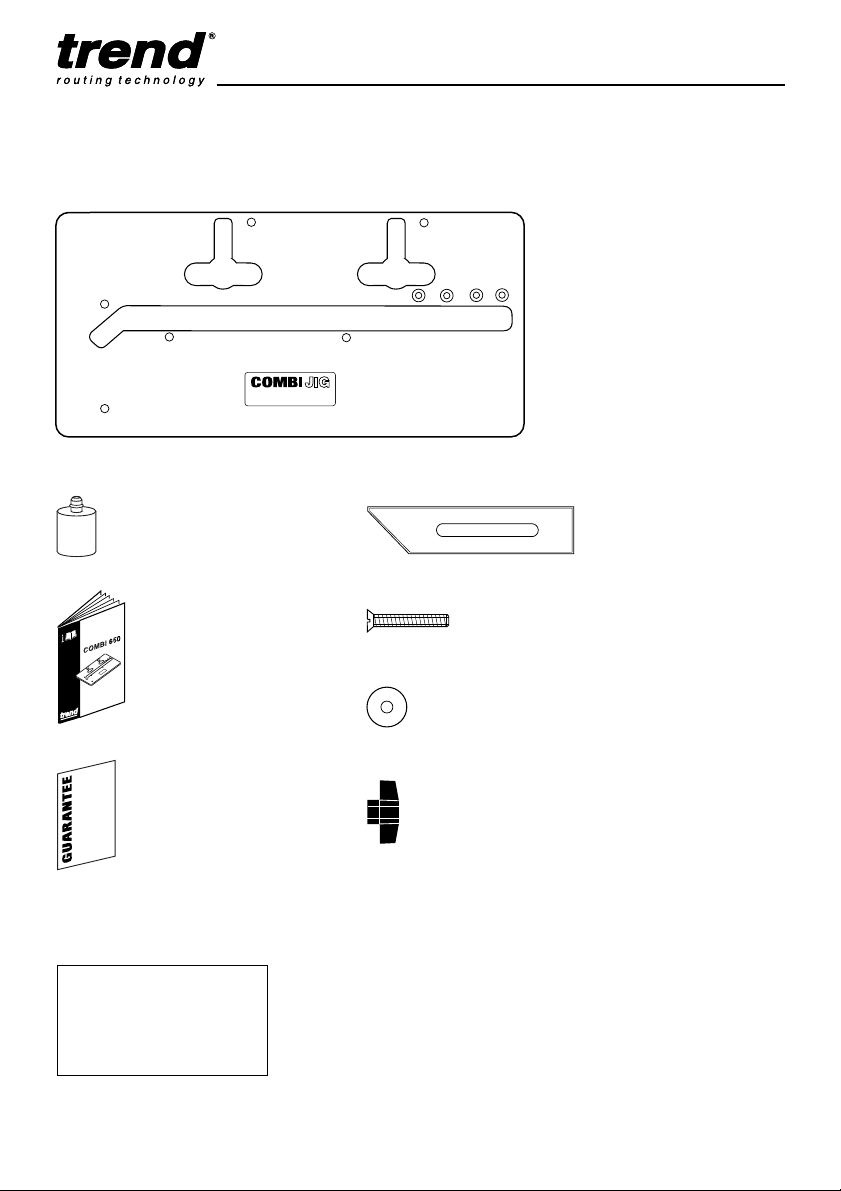

Recommended Cutters

A 12.7mm (1/2”) diameter cutter must be used,

which has a 50mm cutting reach and plunge cut

facility.

Router must be plunged in stages of maximum

8mm in one pass.

Description Order Ref.

Craft Range Cutter C153x1/2TC

As above with TC centre tip C153Dx1/2TC

Trade Range Cutter TR17x1/2TC

As above with TC centre tip TR17Dx1/2TC

Professional Range Cutter 3/83x1/2TC

As above with TC centre tip 3/83Dx1/2TC

As per 3/83 but with shorter shank

for Makita, Ryobi & Hitachi routers 3/83Mx1/2TC

Replaceable tip cutter RT/11x1/2TC*

Above cutter (with shorter shank)

for Makita, Ryobi & Hitachi routers RT/11Mx1/2TC*

Replacement blade (1 off) RB/A

Replacement blade (10 off) RB/A/10

*This cutter has a 30mm tip length but will cut to a

maximum depth of 50mm.

Order Ref. C153, TR17D, TR17, 3/83D, 3/83M

Order Ref. RT/11, RT/11M

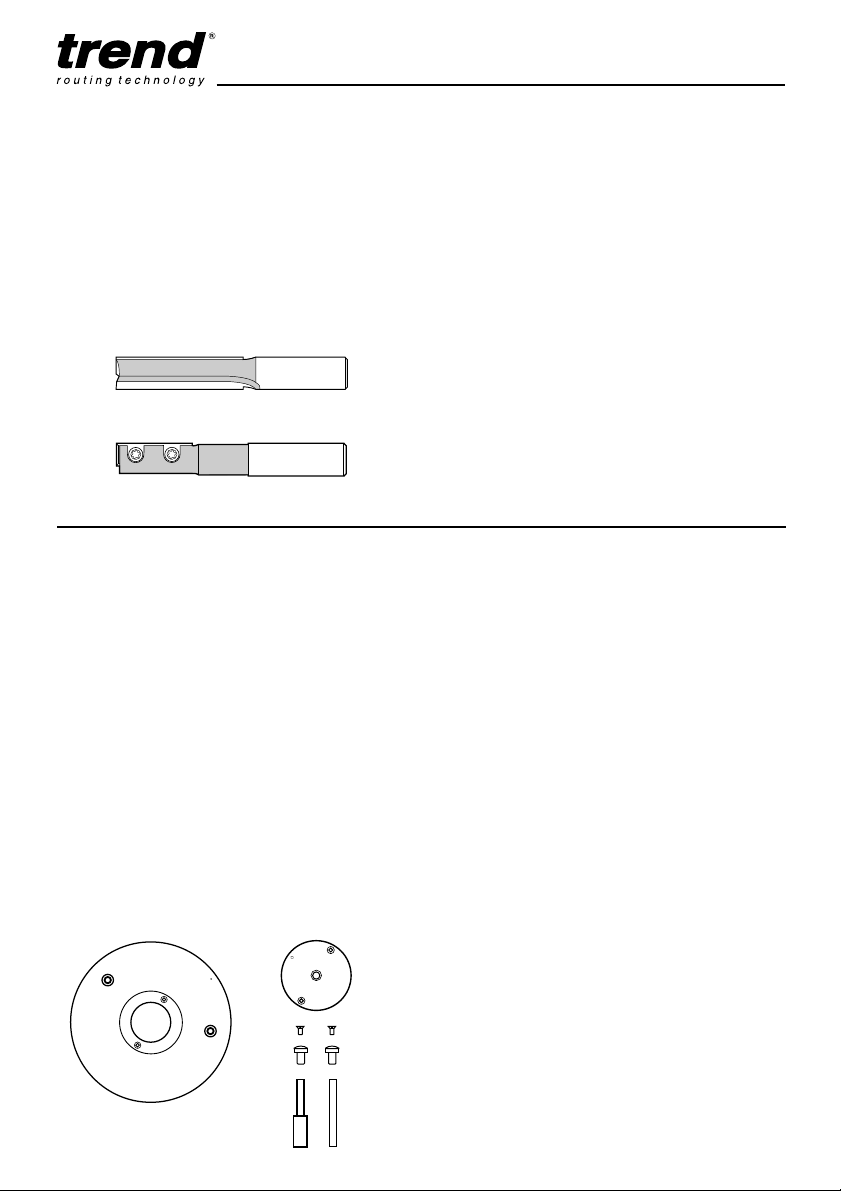

Sub-base Sets

To obtain a perfect accurate close fitting joint, a

30mm guide bush must be used. The guide bush

must always be fitted concentric with the cutter.

This can be achieved using Trend sub-bases and

30mm outside diameter guide bush ref. GB30.

Trend sub-bases have a central recess to allow

fitting of the Trend guide bush to most makes of

routers and are available ready to fit the most

popular makes.

Two types are offered GB/5 and UNIBASE.

All sub-bases contain screws, a line-up bush and

two line-up pins. The line-up pins and bush

ensure exact alignment of sub-base with router

spindle, when fitted with the relevant collet.

r o u t i n g t e c h n o l o g y

R

trendtrend

GB/5 SUB-BASE

Fits following Router Models

Description Order Ref.

Elu MOF31,77,98,131,177(E),

Bosch GOF1600A & 1700ACE

DeWalt DW625EK

Felisatti R346EC

GB/5

Makita 3612BR & 3600B

Ryobi RE600N & R600N, RE601

GB/5/A

Hitachi M12V, M12SA & TR12

GB/5/D

Makita 3612C & 3612

GB/5/J

Bosch 1300ACE

GB/5/K

Freud FT2000E

AEG OFSE2000

Casals FT2000VCE

GB/5/L

Flex OFT3121VV,

Portercable 7539, 7519

GB/5/M

Felisatti TP246(E), Festo OF2000E,

Kinzo 25C46, Mafell L065E,

Metabo OF1612 & OFE1812,

Performance PRO1250,

Ryobi R500 & R502, Skil 1875U1,

Triton TRB001, Wadkin R500

GB/5/S*

*Please state model when ordering.

GB/5 Set comprises the following

Sub-base

GB10

170mm Ø x 8mm

1

/2” shank

line-up pin

1

/4” shank

line-up pin

t

r

e

n

d

1

0

m

m

R

ACCESSORIES

Page 5

Combi 650

-5-

General instructions for fitting

sub-bases to Router

1. Fit line-up guide bush onto sub-base, with

screws supplied.

2. Fit 12.7mm (

1

/2”) shank line-up pin into collet

of router. Plunge router until pin projects

through base and lock plunge.

3. Locate guide bush and sub-base assembly

over protruding pin.

4. Line up fixing holes and fit screws.

5. Now tighten up screws.

6. Remove line-up bush and line-up pin.

Alignment should now be correct. Fit 30mm

guide bush and cutter.

7. Per iodically check the sub-base is concentric

to the spindle of the router.

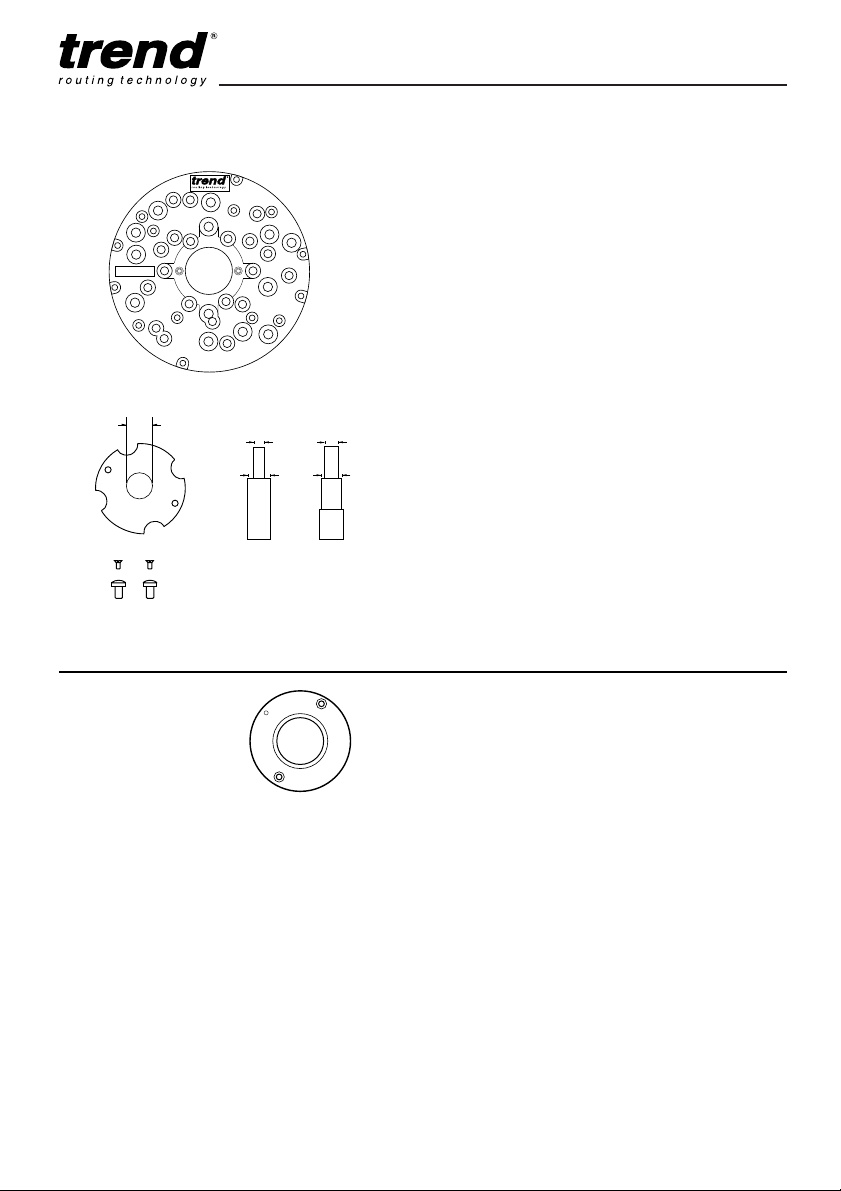

UNIBASE comprises the following

Fits following Router Models

Atlas Copco OFSE2000

Bosch GOF 1300ACE, 1600A, 1700ACE

Casals FT2000VCE

DeWalt DW625EK, 629

Draper R1900V

Elu MOF 31, 77, 98, 131, 177(E)

Faithful FPPR2000E

Felisatti TP246(E), R346EC

Festo OF2000E

Freud FT2000E

Hitachi MI12V, M12SA, TR12

Metabo OF1612, OFE1812

Ryobi RE600N, R600N, RE601, R500, R502

Skil 1875U1

Wadkin R500

Description Order Ref.

Universal sub-base UNIBASE

t

r

e

n

d

3

0

m

m

R

GB30 30mm Guide Bush

Description Order Ref.

30mm guide bush to fit sub-bases GB30

UNIBASE

UNIBASE

170mm Ø

x 8mm

1

/4”+ 1/2”

shank

line-up pin

8mm +

12mm shank

line-up pin

1/2"

12mm

1/4"

8mm

16mm

Page 6

Combi 650

-6-

100mm (4”) min.

throat depth

Panel Butt Connectors

Panel butt connectors are essential for

connecting worktops. They fit into the recess on

the underside of the worktop and are tightened

with a 10mm spanner. The jig has integral bolt

recess slots to allow the bolt recess to be cut in

the underside of the worktop, using the cutter.

The recess is elongated to allow easy access for

the spanner. Two types are offered, plastic

ended or metal ended. Plastic ended offer better

grip.

See the latest Trend Routing Catalogue for

details.

Description Order Ref.

Panel Butt Connectors plastic ends

(pack of 10) PC/10

(pack of 50) PC/50

(pack of 100) PC/100

(pack of 1000) PC/1000

Panel Butt Connectors metal ends

(pack of 10) PC/10/M

(pack of 50) PC/50/M

(pack of 100) PC/100/M

(pack of 1000) PC/1000/M

Biscuit Jointer for the Router

Worktops with inadequate support below them

need additional stability by biscuit jointing the

edges. The Trend biscuit jointing set for the

router together with the No.20 biscuits will

ensure worktops do not sag or warp in time, see

the latest Trend Routing Catalogue for details.

Description Order Ref.

Craft Range Biscuit Jointer Set C152x1/2TC

Trade Range Biscuit Jointer Set TR35x1/2TC

Professional Range Biscuit Jointer Set 342x1/2TC

No.20 Biscuits –

Quantity 100 BSC/20/100

1000 BSC/20/1000

IMPORTANT!

Two heavy duty quick action or

gripper clamps with throats of

at least 100mm (4”) are

required to secure the jig to the

worktop. Whenever fast action

clamps are used, ensure they

do not foul the router path and

that they are securely tightened.

Gripper Clamp

Description Order Ref.

Gripper Clamps 6003010

(Two off required)

Page 7

Combi 650

-7-

Carry Case

Hard wearing carry case to protect and allow

ease of carrying of the COMBI650 Jig.

Description Order Ref.

Carry Case for COMBI650 CASE/650

Fill and Seal

A solvent and silicone free coloured bonding

sealant used to seal worktop joints to prevent

moisture reaching the core material. Available

in nine colours, Fill and Seal can be intermixed

to match all laminate colour variations.

Sufficient to join four 700mm worktops, it is

supplied in 100ml flexible tubes, allowing it to

be squeezed into the joint prior to closing the

joint faces. Low odour and mould resistant the

sealant has a fast curing time of around 20

minutes.

Description Order Ref.

Black Ash FS/100/BA

China Blue FS/100/CB

Champagne FS/100/CH

Deep Buff FS/100/DB

Empire Green FS/100/EG

Oyster White FS/100/OW

Pastel Grey FS/100/PG

Polar White FS/100/PW

Terracotta FS/100/TE

Pack of 9 colours FS/100/PACK

Page 8

Combi 650

-8-

ASSEMBLY

Location Bush Identification

Two location bushes are used in different holes

in the jig to align the correct template aperture

for the application.

The holes are colour coded for easy

identification with dots as follows:

Green dot – Female Joint

Red dot – Male Joint

Yellow dot – Connector Recess

The jig has a colour coded key on its label for

quick reference.

Setting out the Joints

When cutting a joint ensure location bushes

contact the postformed edge of the worktop. For

certain joints the worktop will need to be inverted

so that all cuts are made into the postformed

edge, never out through it. When routing wor ktop

the balancing paper on the underside may feather

edge – this feather edge should be removed with

abrasive paper.

Location bushes are held in position by ‘O’ rings.

Insert the smallest end of the bush into the hole

by lightly pushing and turning at the same time.

If the bushes are tight use a lubricant on the ‘O’

ring. Ensure bushes are fully home before use.

When using jig ensure location bushes do not

foul workbench.

23mm

IMPORTANT!

In order to prevent breakout of

the laminate, rotation of the

cutter and feed direction must

always be into the postform

edge of the worktop.

Margin Distance

Allow 8.5mm when cutting joints. Measure or

use a batten of this

thickness to aid

setting out.

Plan view

of joints

O ring

Location bush

Cutter

Sub base

Guide bush

30mm Ø

Location

bush

Worktop

Template

8.5mm

Right hand joint

Male

Female

Male

Female

Cut male with laminate down

Cut female with laminate up

Postform edge

The joint takes up 23mm, this should

be allowed for with extra material in the

length of the male worktop.

Male

Female

Postform edge

PENINSULA

Postform edge

Postform edge

Male

Female

Left hand joint

Cut male with laminate up

Cut female with laminate down

Page 9

Combi 650

-9-

Length Stop Arrangement

OPE RATION

Setting the Length Stop for the

Female Joint

Carry out the setting operation first:

■ Fit bushes into Red dot location holes and

offer the jig to the worktop as shown. The

Green dot location holes will be

uppermost.

■ Position the jig across the width of the

worktop. Loosely fit the length stop.

■ Fasten length stop to template so that it

traps the template across the worktop

between the Red dot location bushes and

the stop. Tighten up the knob.

■ Remove the bushes from Red dot location

hole. The template is now set to cut the

correct length of joint.

Female Joint

■ Fit two location bushes in Green dot holes.

(The Green dots must be upper most.)

Leave the length stop bush in position.

■ Place the template onto the worktop to be

cut, ensuring the location bushes are

touching the worktop. Now cramp securely

in position using two quick action clamps

ensuring they will not foul the router path.

■ Set cutter depth.

■ Plunge router and cut joint in a series of

passes, feeding left to right.

IM P ORTANT!

When cutting a joint, hold the

router guide bush hard against the

template and cut from left to right.

It is recommended that the depth

stops of the router are used to set

the depths of cut. Several shallow

passes of the router should be

made and it is not necessary to

lean heavily on the router or the

jig. Allow the weight of the router

to rest on the part of the template

which is resting on the worktop.

Ensure router remains parallel and

upright at all times.

Routing the female part of the Joint

Setting the Length Stop

Location

bushes

(Red dot)

Postform edge

Length stop on

underside.

Retained with

screw & knob

Location bushes

(Green dot)

Postform

edge

Length stop

Page 10

Combi 650

-10-

Male Joint

Depending on accessibility lay female worktop

into position on units. Lay male worktop on top

and support other end. Using a pencil draw

round the female cut onto the male. If

inaccessible lay female onto male. Depending

on a right or left hand joint, the pencil line may

need to be transferred on to the other side. Due

to the difference between the cutter and the

guide bush diameters, the cutter path will be

8.5mm over from the edge of the template,

therefore either measure 8.5mm or use a

packing piece of this size to offset the template

by this amount to ensure the cutter cuts along

the pencil line.

The postformed edge of the worktop must

always be in contact with the location bushes,

this means that to cut a male right hand joint, the

worktop must be inverted. Remembering to cut

into the postformed edge.

■ Insert two location bushes into holes marked

Red dot. Face marked Red dot must be

uppermost.

■ Place template across the width of the

worktop. Clamp jig securely to worktop.

■ Cut the male joint before finally cutting the

worktop to length. All cuts must be fed left

to right.

Out of square Joints (max. 3°)*

It may not be possible to position all joints at 90°,

in this case it is the male part of the joint that

has to be adjusted.

The length stop has a mitred end which is used

to set up for an out-of-square joint up to 3°.

To mark out an out-of square joint, first lay the

female worktop on the cupboard carcass in its

correct position. Next lay the male section of the

worktop on the carcass and on top of the female

section of the worktop. Support the other end of

the male worktop. Using a pencil and from

underneath the worktop mark around the female

joint onto the male section of the worktop, if

access is difficult lay the female worktop onto the

male worktop, support other end and mark with

pencil from above. This drawn line is the male

cut line.

Routing the male part of the Joint

IMPORTANT!

Test fit the joints together,

abrasive paper may be required

to clean up the chipboard core.

Quick action

clamp here

Direction of

router travel

Postform edge

Location bushes

(Red dot)

*Please Note:

Out-of-square joints are possible, but the

finished joint will not be as good as a 90° joint.

Page 11

Combi 650

-11-

■ Insert both location bushes into Red dot

holes. Red dot face uppermost.

■ Lay jig across the worktop, ensure the

location bushes touch the postform edge.

Clamp jig in position with quick action clamps.

Draw a line 8.5mm away from the jig slot

edge.

■ With the mitred end of the length stop facing

towards the back of the worktop, as shown.

Fit the length stop onto underside of jig by

using the countersunk bolt, washer and knob

into one of the holes in the jig. The bolt

should be put into the jig from above, do not

tighten. Carefully position the point of the

length stop so that it lines up with the 8.5mm

margin pencil line. When the correct position

has been obtained tighten bolt and knob

sufficiently to prevent length stop from

moving.

■ Remove location bushes.

■ Lay jig with length stop set onto male work

top that is to be cut. Allowing for the 8.5mm

margin and using the length stop as a pivot

point (pivot point on cut line), position the jig

so the jig slot edge is parallel to the drawn

pencil line. Re-check positioning.

■ Clamp jig to worktop securely using quick

action clamps.

■ Remove length stop and bolt assembly as

these are for setting up only and are not

required when routing.

■ Set cutter depth.

■ Plunge router and cut the male joint, feeding

left to right in a series of shallow passes,

feeding left to right.

Cutting male

joint on out-ofsquare joints

Direction of

router travel

Postform edge

Quick action

clamp here

Shown

exaggerated

Male joint

cut line

Direction of

router travel

Postform edge

Quick action

clamp here

Setting up length stop for out-ofsquare joints

Location bushes

(Red dot)

Parallel pencil line

8.5mm from jig slot edge

IMPORTANT!

After setting for out-of-square

joint the length stop must be

removed or it could come in

contact with the router cutter.

8.5mm margin

pencil line

Male joint

cut line

Pivot point on

male joint cut line

Jig slot edge 8.5mm away

from male joint cut line

Page 12

Combi 650

-12-

Cutting the Bolt Recesses

When the joint has been tested, proceed as

follows to cut the recess for panel butt

connectors on the underside of the worktop.

The same cutter and guide bush are retained

and used with the integral bolt recess slots in the

jig to produce the recesses for the panel butt

connectors. The bolt recess position can be

gauged approximately 150mm from the edge of

the postform edge, or where access is possible

with kitchen units. Mark with pencil both

positions on the underside of the worktop.

Insert the location bushes into the Yellow dot

holes as shown.

■ The template may need to be inverted

when cutting some bolt recesses.

■ Securely clamp jig to worktop.

■ The bolt recesses should be

approximately 20mm deep although

this will depend upon the thickness

of worktop.

■ Once one bolt recess is cut move jig

over to the remaining pencil lines and repeat.

■ Repeat the procedure for the male joint.

IM P ORTANT!

Best results are achieved

when the centre line of the

bolt corresponds to the

centre line of the worktop.

Clamp jig securely to

worktop.

Routing the bolt recess in the

female part of the joint

Quick action

clamp here

150mm

Location bushes

(Yellow dot)

Pencil

mark

Direction of

router travel

Underside of worktop

Quick action

clamp here

Pencil

mark

Routing the bolt recess in the

male part of the joint

150mm

Location bushes

(Yellow dot)

Pencil

mark

Direction of

router travel

Quick action clamp here

Underside of

worktop

Postform edge

Pencil

mark

Page 13

Combi 650

-13-

Strengthening the Joint

If the joint between the worktops is not

supported underneath, after some time the joint

may ‘sag’ and become misaligned; to reduce this

the joint should be reinforced with a loose

tongue or biscuit dowels. The biscuit jointing

cutter set Trend Ref. 342 can be used with a

portable router. The size of biscuit used should

be No. 20.

Ref. BSC/20/100 (100 biscuits)

Ref. BSC/20/1000 (1000 biscuits)

A 650mm worktop should have at least 5

biscuits.

Sealing the Joint

The cut edges of the joint should be coated with

a water-resistant adhesive, or sealant before

assembly, to prevent moisture seeping into the

core of the worktops, which would swell and

disfigure the worktop.

Use a fine grit abrasive paper to clean up the

torn wood chips of both mating surfaces. Lightly

run the abrasive paper along the edges to de-nib

the cut chipboard edge. This will ensure a tidy

joint is achieved.

Cutter Ref. 342

No.20

PVA

SEALANT

Waterproof

Biscuit

Underside View

Guarantee

■ The jig carries a manufacturers guarantee in

accordance with the conditions on the

enclosed guarantee registration card.

Recycling

■ Jig, accessories and packaging should be

sorted for environmentally friendly recycling.

Page 14

Combi 650

-14-

COMBI 650

SPARE PARTS DIAG RAM

1

2

7

3

8

54 6

COMBI 650 - SPARE PARTS LIST v1.0 10/1999

Item Qty Description Ref.

1 1 Combi 650 Jig COMBI/650

2 2 Alloy Bush BUSH/650

3 1 Length Setting Stop CJ/LSK

4 0 Machine Screw Csk M8 x 50mm Slot WP-SCW/41

5 0 Washer 8.5mm x 32mm x 1.0mm WP-WASH/17

6 0 Knob M8 WP-KNOB/10

7 0 Combi Jig ‘O’ Ring Pack for Bushes (pack of 5) CJ/ORS

8 1 Manual MANU/650

Page 15

Combi 650

-15-

Fault Cause Remedy

■ Joint does not fit correctly Cutter or guide bush is the Check concentricity of cutter

at the radius. incorrect diameter or location with guide bush. Cutter 12.7mm

bushes are not against diameter with 30mm diameter

worktop edge. guide bush. Ensure location

bushes touch worktop.

■ The back edge of the joint Either the length stop or Check position of length stop

does not line up. template was in the incorrect and re-cut joints.

position, or the worktop has

not pushed up against the

length stop when the joint

was cut.

■ When clamped together the The guide bush has drifted away Check with a straight edge

joint has irregular gaps. from the edge of the template which par t of the joint is uneven

whilst cutting either part of the and re-cut (this can only be

joint, or wood chips in particle done on the male cut) ensuring

board have torn slightly. that the guide bush is kept

against the template by

machining from left to right. Use

abrasive paper to remove torn

wood chips.

■ Chipped laminate Can be caused by a blunt cutter Always use sharp cutters and

or removing too much material when cutting through the

at one pass or exiting out of laminate cut 3–4mm of material.

postform edge. Maintain correct feed direction,

to ensure cutter enters

postform edge.

■ Jig slipping on material Clamps not secure or too deep Check clamps for wear. Clamp

a cut being made or cutter is securely, take shallow passes,

blunt. use a sharp cutter.

■ Cut joints not square Router has tilted or operator Ensure jig is supported and do

has leaned heavily on router not push hard on router taking

causing jig flex. shallow passes. Ensure weight

of router is on supported part

of jig and that the router is

upright.

■ Assembled joint not flush Worktop different thickness or Ensure worktop is same

or bowed worktop not flat (cupped). thickness and flat.

TROU BLE S H O OTI N G

Page 16

MANU/650 v6.0

Trend Machinery & Cutting Tools Ltd.

Odhams Trading Estate St Albans Road

Watford WD24 7TR England

Enquiries: _____________0800 487363

Technical Support:_____01923 224681

Fax: _________________01923 236879

Email: ______mailserver@trendm.co.uk

WWW: _____www.trendmachinery.co.uk

© Copyright Trend 2002. No part of this publication may be reproduced, stored or transmitted in any form without prior permission.

Our policy of continuous improvement means that specifications may change without notice. Trend Machinery and Cutting Tools

cannot be held liable for any material rendered unusable or any for m of consequential loss. E&OE

RECYCLABLE

Loading...

Loading...