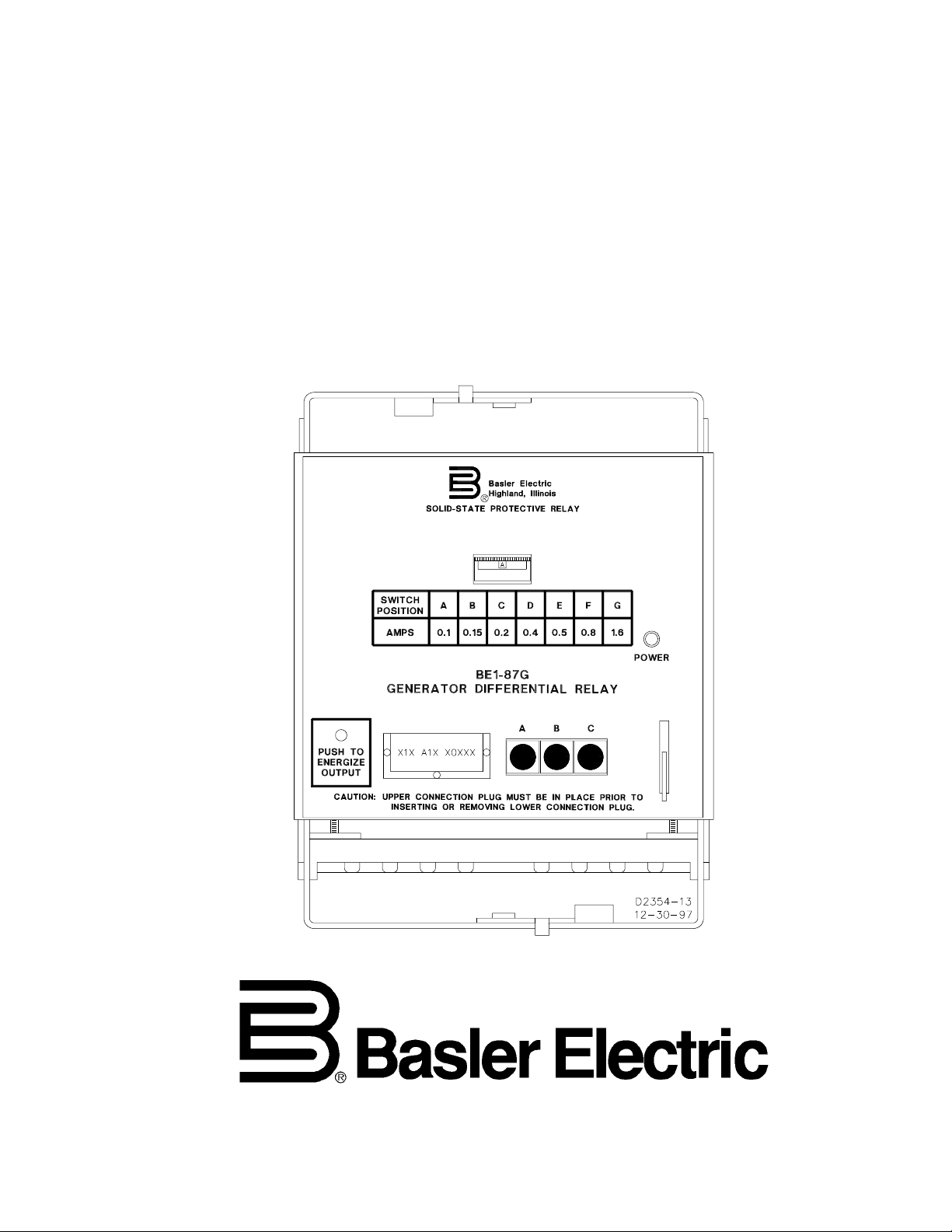

Page 1

+05647%6+10/#07#.

(14

8#4+#$.'2'4%'06#)'&+(('4'06+#.

4'.#;

$')

2WDNKECVKQP

4GXKUKQP ,

Page 2

INTRODUCTION

This manual provides information concerning the operation and installation of the BE1-87G Variable

Percentage Differential Relay. To accomplish this, the following is provided.

Specifications

Functional description

Mounting information

Setting procedure/example.

W A R N I N G !

To avoid personal injury or equipment damage, only

qualified personnel should perform the procedures

presented in this manual.

BE1-87G - Introduction i

Page 3

First Printing: December 1985

Printed in USA

© 1995, 1996, 1999, Basler Electric Co., Highland, IL 62249

May 1999

CONFIDENTIAL INFORMATION

OF BASLER ELECTRIC COMPANY, HIGHLAND, IL. IT IS LOANED FOR

CONFIDENTIAL USE, SUBJECT TO RETURN ON REQUEST, AND WITH THE

MUTUAL UNDERSTANDING THAT IT WILL NOT BE USED IN ANY MANNER

DETRIMENTAL TO THE INTEREST OF BASLER ELECTRIC COMPANY.

It is not the intention of this manual to cover all details and variations in equipment, nor does this

manual provide data for every possible contingency regarding installation or operation. The

availability and design of all features and options are subject to modification without notice. Should

further information be required, contact Basler Electric Company, Highland, Illinois.

BASLER ELECTRIC

ROUTE 143, BOX 269

HIGHLAND, IL 62249 USA

http://www.basler.com, infor@basler.com

PHONE 618-654-2341 FAX 618-654-2351

ii BE1-87G - Introduction

Page 4

CONTENTS

SECTION 1 GENERAL INFORMATION 1-1

Description ..............................................1-1

Applications .............................................1-1

Variable Restraint Characteristic ..........................1-3

Design Highlights ......................................1-3

Model and Style Number ...................................1-3

Style Number Example .................................1-3

Style Number Identification Chart .........................1-4

Specifications ............................................1-5

SECTION 2 CONTROLS AND INDICATORS 2-1

SECTION 3 FUNCTIONAL DESCRIPTION 3-1

General .................................................3-1

Functional Description .....................................3-1

Current Transformers ...................................3-1

Stabilizing Reactor .....................................3-2

Bandpass Filters ......................................3-3

Comparator ..........................................3-3

Outputs .............................................3-3

Targets (Optional) .....................................3-3

Push-To-Energize (Optional) .............................3-3

Power Supply Status Output (Optional) .....................3-3

Power Supply .........................................3-4

SECTION 4 INSTALLATION 4-1

General .................................................4-1

Dielectric Test ............................................4-1

Mounting ................................................4-1

Relay ...............................................4-1

S1 Case, Outline Dimensions ............................4-1

S1 Case, Double-Ended, Outline Dimensions ................4-2

S1 Case, Panel Drilling Diagram ..........................4-3

Stabilizing Reactor .....................................4-4

S1 Case And Reactor, Outline Dimensions ..................4-5

Connections .............................................4-5

Typical DC Control Connections ..........................4-6

Single-Phase Sensing Input Connections ...................4-6

Three-Phase Sensing Input Connection ....................4-7

Single Phase Internal Connection Diagram ..................4-8

Three Phase Internal Connection Diagram ..................4-9

SECTION 5 TESTING AND SETTING 5-1

General .................................................5-1

Relay Operating Precautions ................................5-1

Dielectric Test ............................................5-1

Equipment Required .......................................5-1

Operational Test Procedure .................................5-2

Operational Test Setup .................................5-2

Location Of Assemblies (Single-Phase Only) ................5-3

TP-1 And TP-2 On Single-Phase Relays ....................5-3

Single-Phase Trip And Dropout Test .......................5-4

BE1-87G - Introduction iii

Page 5

CONTENTS -

Continued

SECTION 5 TESTING AND SETTING -

Sensing Input Range 1, Operating Characteristics ............ 5-5

Sensing Input Range 2, Operating Characteristics ............ 5-6

Extended Restraint Operating Characteristic ................... 5-7

Pickup Response Timing ............................... 5-7

Phases B And C, Trip And Dropout Test ................... 5-8

Target Test .......................................... 5-8

Auxiliary Output Test .................................. 5-8

Push To Energize Output Test ........................... 5-8

Power Supply Status Output Test ......................... 5-8

Setting The Relay ........................................ 5-8

General ............................................. 5-8

Setting Example Number One ........................... 5-10

Setting Example Number Two ........................... 5-11

Continued

SECTION 6 MAINTENANCE 6-1

General ................................................ 6-1

In-House Repair ......................................... 6-1

Storage ................................................ 6-1

SECTION 7 MANUAL CHANGE INFORMATION 7-1

iv BE1-87G - Introduction

Page 6

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

BE1-87G Variable Percentage Differential relays are single- or three-phase solid state devices designed to

provide selective, high-speed, differential protection for generators, motors and shunt reactors.

Differential relaying selectivity is based on the ability of a relay to distinguish between an internal fault (within

the protected zone) and an external fault. Under normal operating conditions the current into the protected

zone equals the current out of the protected zone with a net operating current equal to zero. Internal faults

upset this balance and result in a difference between the input and output currents. External faults have

relatively little effect on the balance because the protected zone input current still equals the output current.

Therefore, by comparing the currents on both sides of the protected element or zone and detecting when

these currents are not equal, a differential relay acts to isol ate the element or zone from the system with

unsurpassed effectiveness.

BE1-87G Variable Percentage Differential relays typically trip a lockout relay (86) which in turn trips the

generator breaker and, when present, the field and/or neutral breakers.

APPLICATION

BE1-87G Variable Percentage Differential relays are recommended for the following specific applications

when used with current transformers (CT) with an accuracy class of either C20 or better or T20 or better.

Generators: any terminal voltage and a rating of 1000 kVA and above.

Generators: any kVA rating and a terminal voltage of 5 kV and above.

Generators: a terminal voltage of 2200 V or higher, and a rating of more than 500 kVA.

Motors: rated 1500 horsepower and above.

As primary protection on shunt reactors for transmission lines.

Generator ground differential

Differential relaying is the most selective form of faul t protection which may be applied to the individual

elements or zones of ac power systems. Various types of differential relays and relaying systems have

evolved to take advantage of the differential principle.

WARNING

Relays manufactured prior to July 22, 1991 (EIA date code symbol 9129 and previous)

NOT

do

applies to three phase relays terminals 7 and 8, terminals 13 and 14, and terminals 17

and 18. Exercise

connected to these terminals.

Typical application schemes are shown in Figures 1-1 and 1-2.

have case jumpers between terminals 7 and 8 (single phase units). This also

CAUTION

when grounding or testing current transformer circuits

BE1-87G - General Information 1-1

Page 7

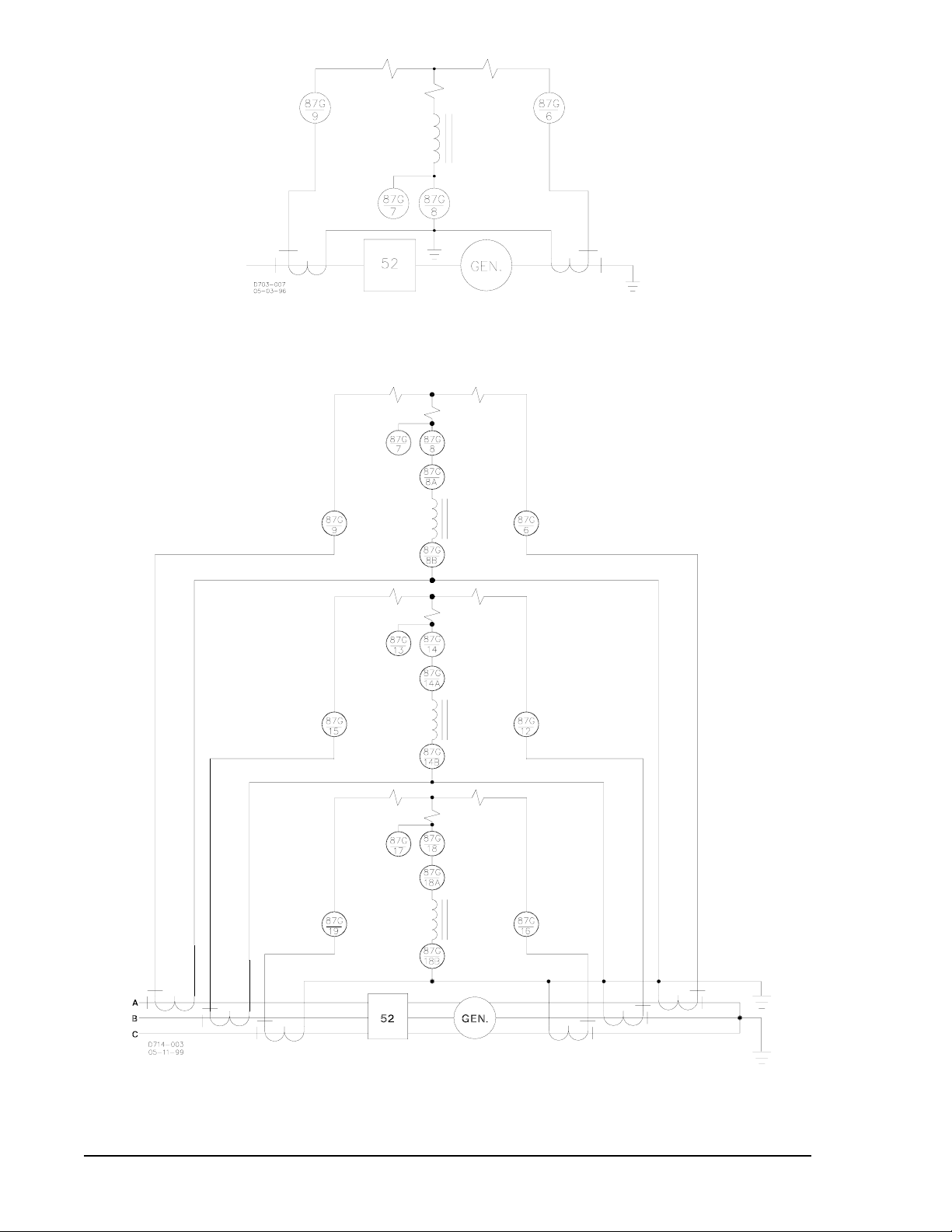

Figure 1-1. Typical Single-Phase Application Scheme

Figure 1-2. Typical Three-Phase Application Scheme

1-2 BE1-87G - General Information

Page 8

Variable Restraint Characteristic

At high current levels, the inevitable difference in the saturation characteristics between current transformers

indicates a need for a compensating decrease in relay sensitivity. The design of the BE1-87G provides a

restraint factor that is proportional to input current when the restraining current (IR) is greater than nominal

(five amperes for sensing input type one or one ampere for sensing input type two). The BE1-87G compares

the protected zone sensed input and output currents. The lesser of the two sensed current levels becomes

the restraining current. The difference between the two sensed currents (the operating current) is compared

to a reference established by the sensitivity setting, and adjusted by an amount proportional to the

restraining current. This makes the BE1-87G more sensitive to low current internal faults, and less sensitive

to external faults with high levels of through current.

When the restraining current is at nominal (five amperes for sensing input type one or one ampere for

sensing input type two) or less, the relay trips if the differential current exceeds the relay setting (I

). But

S

when the restraining current is greater than nominal, the overall sensitivity is a combination of the front panel

setting and the restraint factor.

Design Highlights

Some of the many advantages of the solid-state BE1-87G Variable Percentage Differential Relay are

summarized as follows.

Seven sensitivity levels on each of the two sensing input ranges. The seven levels allow

compensation for CT mismatch and provide the flexibility and adaptability necessary for many

special applications such as split winding generator protection.

Stabilizing reactor. Minimizes dissimilar performance of system CTs. Reactor can be located on

the back of the relay or remotely from the BE1-87G for flexibility of system installation.

Variable restraint. The variable restraint characteristic allows increased sensitivity to low current

internal faults while providing increased security against high levels of through current caused by

external faults.

Single- or three-phase availability. Either configuration is available in the Basler Electric S1 drawout

case.

High-Speed Operation. The BE1-87G operates in 30 milliseconds for fault levels of 10 times the

sensitivity setting. This high-speed operation minimizes potential damage to the protected

equipment. Response characteristics for sensing input ranges 1 and 2 are shown in Section 5,

Testing And Setting

the relay.

MODEL AND STYLE NUMBER

The electrical characteristics and operational features included in a specific relay are defined by a

combination of letters and numbers which constitutes the device's style number. The style number together

with the model number describe the features and options in a particular device and appear on the front

panel, drawout cradle, and inside the case as sembly. The model number BE1-87G designates the relay

as a Basler Electric Class 100, Variable Percentage Differential Relay.

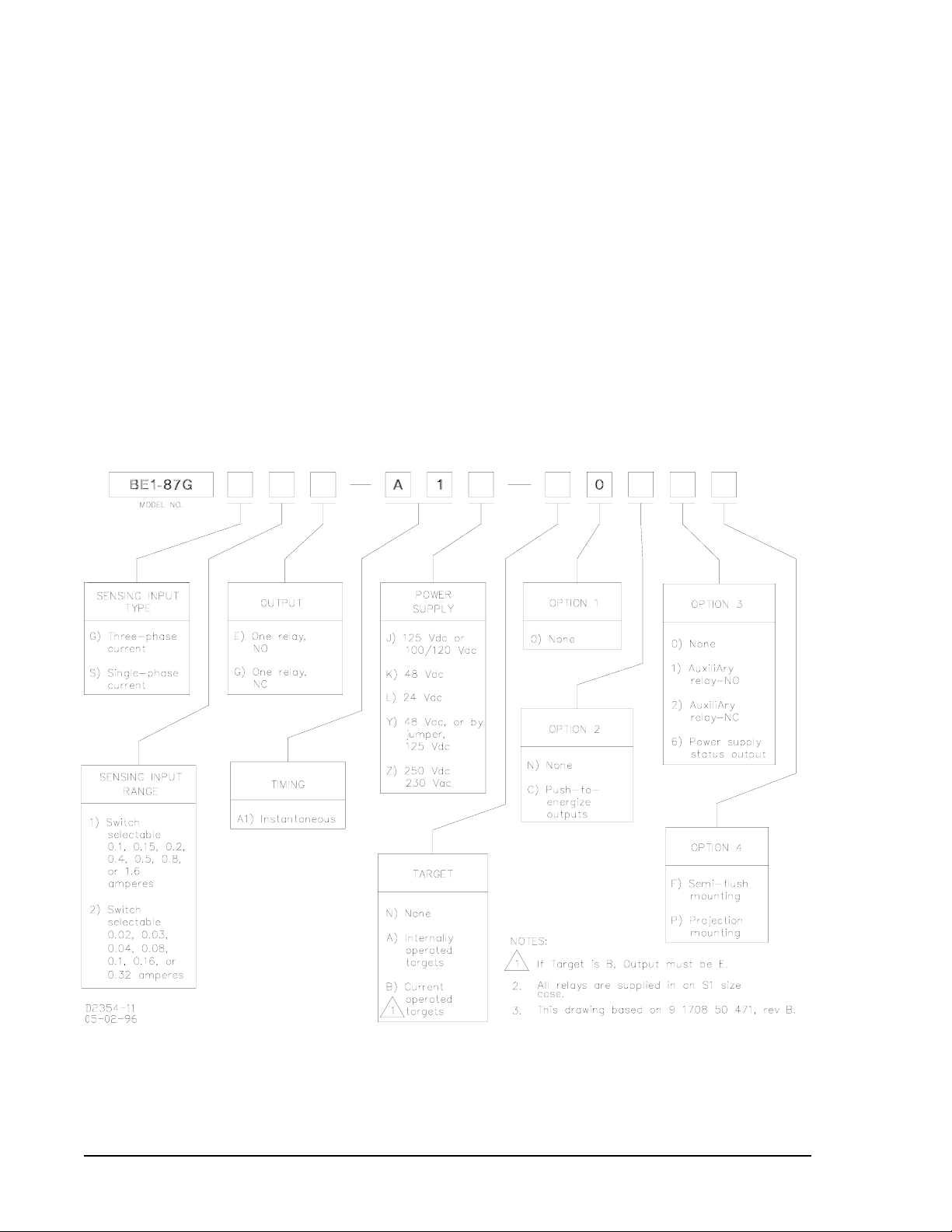

Style Number Example

Figure 1-3 illustrates the style number identification chart with features and options for BE1-87G relays. For

example, if the style number were BE1-87G GlE AlJ AOCOF the device would have the following:

BE1-87G - General Information 1-3

Page 9

BE1-87G

Style Number Identification Chart

Figure 1-3 is the Style Number identification Chart for the BE1-87G Variable Percentage Differential relay.

Model Number

G

Three-phase sensing input

1

Sensing range switch selectable for 0.1, 0.15, 0.2, 0.4, 0.5, 0.8, or 1.6 A

E

Normally open output relay

A1

Instantaneous timing

J

Operating power derived from 125 Vdc or 100/120 Vac

A

Internally operated targets (one per phase)

0

No option 1 available

C

Push-to-energize outputs (pushbuttons)

0

No auxiliary output contacts

F

Semi-flush mounting

Figure 1-3. Style Number Identification Chart

1-4 BE1-87G - General Information

Page 10

SPECIFICATIONS

BE1-87G relays are available in single-phase and three-phase configurations, and with the following features

and capabilities.

Current Sensing Inputs

(5 Ampere) Nominally rated at 5 amperes, with a range of 45 to 65 hertz. Maximum

current per input: 10 amperes continuous, 250 amperes for 1 second.

(1 Ampere) Nominally r ated at 1 ampere, with a range of 45 to 65 hertz. Maximum

current per input: 2 amperes continuous, 50 amperes for 1 second.

Current Sensing Burden

(5 Ampere) Burden is less than 0.05 ohms per input.

(1 Ampere) Burden is less than 0.25 ohms per input.

Stabilizing Reactor

2

t Rating

I

(5 Ampere) 65 amperes for 1 second at 70( C ambient, (I

(1 Ampere) 13 amperes for 1 second at 70( C ambient, (I

Pickup Control

Refer to Section 4 for stabilizing reactor impedance characteristic curves.

2

t=4225).

2

t=4225).

A front panel control permits minimum differential (operate) currents to be

selected. This sensitivity is constant for restraint currents less than the

nominal current (5 or 1 amperes). Actual operating characteristics are

shown in graph format in Section 5,

Testing And Setting

the relay.

(5 Ampere) Minimum differential (operate) current = 0.1, 0.15, 0.2, 0.4, 0.5, 0.8, or 1.6

amperes. The ideal operating characteristic is approximated by the

following equations.

where

is the restraint current, defined as the lesser of the input currents.

I

R

is the operate current

I

OP

is the front panel setting

I

S

5 amperes: IOP = I

For I

R

S

For IR > 5 amperes: IOP = IS + 0.5(IR - 5)

(1 Ampere) Minimum differential (operate) current = 0.02, 0.03, 0.04, 0.08, 0.10, 0.16,

or 0.32 ampere. The ideal operating characteristic is approximated by the

following equations.

1 ampere: IOP = I

For I

R

S

For IR > 1 ampere: IOP = IS + 0.5(IR - 1)

Pickup Accuracy

(5 Ampere) For I

5 amperes, ±5% of the operate pickup characteristic or 25

R

milliamperes whichever is greater. Actual operating characteristics are

shown in graph format in Section 5,

5 amperes, up to a maximum of 20 amperes, ±8% of the operate

For I

R

Testing And Setting

the relay.

pickup characteristic or 150 milliamperes, whichever is greater. Actual

operating characteristics for pickup values between 5 and 20 amperes are

shown in graph format in Section 5,

BE1-87G - General Information 1-5

Testing And Setting

the relay.

Page 11

Pickup Accuracy

(1 Ampere) For I

milliamperes whichever is greater. Actual operating characteristics are

shown in graph format in Section 5,

For I

pickup characteristic or 150 milliamperes, whichever is greater. Actual

operating characteristics for pickup values between 1 and 4 amperes are

shown in graph format in Section 5,

1 ampere, ±5% of the operate pickup characteristic or 25

R

Testing And Setting

1 amperes, up to a maximum of 4 amperes, ±8% of the operate

R

Testing And Setting

the relay.

the relay.

Dropout

Timing

Power Supply

Greater than 90% of operate characteristic.

Less than 30 milliseconds at 10 times pickup setting; 70 milliseconds

maximum. See Section 5,

Testing And Setting

the relay, for the pickup

response timing curve.

Power for the internal circuitry may be derived from ac or dc external power

sources as indicated in Table 1-1.

Table 1-1. Power Supplies

Type

Nominal Input

Voltage

Input Voltage

Range

Burden at Nominal

(Maximum)

K (Mid Range) 48 Vdc 24 to 60 Vdc 5.0 W

J (Mid Range) 125 Vdc

120 Vac

L (Low Range)

+

24 Vdc 12 to 32 Vdc 5.5 W

Y (Mid Range) 48 Vdc

125 Vdc

Z (High Range) 250 Vdc

230 Vac

62 to 150 Vdc

90 to 132 Vac

24 to 60 Vdc

62 to 150 Vdc

140 to 280 Vdc

190 to 270 Vac

5.5 W

14.5 VA

5.5 W

6.0 W

7.0 W

20.0 VA

+

Type L power supplies may initially require 14 Vdc to begin operating. Once

operating, the voltage may be reduced to 12 Vdc and operation will continue.

Output Contacts

Output contacts are rated as follows.

Resistive:

120/240 Vac Make and carry 30 amperes for 0.2 seconds, carry 7 amperes

continuously, and break 7 amperes.

125/250 Vdc Make and carry 30 amperes for 0.2 seconds, carry 7 amperes

continuously, and break 0.3 ampere.

Inductive:

120/240 Vac, Make and break 0.1 A (L/R = 0.04).

125/250 Vdc Make and break 0.1 A (L/R = 0.04).

Targets

Magnetically latched, manually reset target indicators may be optionally

selected as either internally operated or current operated. Current

operated targets require a minimum of 0.2 ampere through the output trip

circuit and are rated at 30 amperes for 1 second, 7 amperes for 2 minutes,

and 3 amperes continuously.

1-6 BE1-87G - General Information

Page 12

Isolation

In accordance with ANSI/IEEE C37.90, one minute dielectric (high

potential) tests as follows:

All circuits to ground: 2121 Vdc

Input to output circuits: 1500 Vac or 2121 Vdc

Surge Withstand Capability

Fast Transient

Impulse Test

Radio Frequency

Interference (RFI)

Temperature

Shock

Vibration

Weight

Qualified to ANSI/IEEE C37.90.1-1989

Capability (SWC) Tests for Protective Relays and Relay Systems

Qualified to ANSI/IEEE C37.90.1-1989.

Qualified to IEC 255-5.

Maintains proper operation when tested for interference in accordance

with IEEE C37.90.2, Trial-Use Standard Withstand Capability of Relay

systems to Radiated Electromagnetic Interference from Transceivers.

Operating Range

-40(C (-40(F) to 70(C (158(F)

Recommended Storage Range

-65(C (-85(F) to 100(C (212(F).

15 g in each of three mutually perpendicular planes.

2 g in each of three mutually perpendicular planes swept over the range

of 10 to 500 hertz for a total of six sweeps, 15 minutes each sweep.

3-phase: 19.2 pounds maximum.

1-phase: 14.3 pounds maximum.

Standard Surge Withstand

.

Case Size

All units are supplied in an S1 size case.

BE1-87G - General Information 1-7

Page 13

SECTION 2 •

HUMAN MACHINE INTERFACE

(Controls And Indicators)

DESCRIPTION

Table 2-1 lists and briefly describes the BE1-87G Variable Percentage Differential Relay operator controls

and indicators. Reference the call-out letters to Figure 2-1.

Table 2-1. BE1-87G Controls and Indicators (Refer to Figure 2-1)

Locator Control or Indicator Function

A

B Power

C

D PUSH-TO-ENERGIZE

E

Sensitivity Switch Establishes reference for the operating current. It is a

Indicator LED illuminates to indicate power supply is operating.

Target Reset Lever

(Optional)

(Optional)

Target Indicators

(Optional)

Switch

seven position thumbwheel switch labeled A through G.

The chart below the switch relates the switch position to

the operating current required for tripping when the

restraint current is nominal (five amperes, sensing input

range one, and one ampere, sensing input range two).

Linkage extends through bottom of front cover to reset

magnetically latching target indicators.

A momentary contact pushbutton switch accessible by

inserting a 1/8" diameter non-conducting rod through the

front panel. Operates the output and auxiliary relays.

Magnetically latching indicators which indicate the

associated phase that has caused a trip.

Above panel for 3

NOTE:

Figure 2-1. Location of Controls and Indicators, BE1-87G, Sensing Input Range 1

BE1-87G - Human Machine Interface (Controls And Indicators) 2-1

L

units only.

Page 14

SECTION 3 • FUNCTIONAL DESCRIPTION

GENERAL

BE1-87G Variable Percentage Differential Relays are static devices that protect motors and generators by

providing an output signal when incoming current does not match outgoing current by a predetermined but

variable limit. The functional block diagram in Figure 3-1 illustrates the overall operation of the BE1-87G

Variable Percentage Differential Relay. Note that it may be configured to monitor either single-phase or threephase. Phases B and C, when present, are functionally identical to Phase A.

Figure 3-1. Functional Block Diagram

FUNCTIONAL DESCRIPTION

The following paragraphs describe the Relay circuit functions illustrated in Figure 3-1.

Current Transformers

Two standard system CTs with secondary windings to match sensing input range one or range two (five ampere

BE1-87G - Functional Description 3-1

Page 15

(

)

(

)

and one ampere nominal), one transformer on each side of the protected machine, supply sensing current for

each monitored phase. The sensing currents are applied to the respective input transformers of the relay which

provide system isolation and determine the differential and sum currents. These CTs are gapped to withstand

DC offset.

Stabilizing Reactor

To minimize dissimilar performance of the system CTs, the stabilizing reactor acts as a stabilizing impedance

during external faults. Stabilizing reactors are current r ated based on time and ambient temperature (refer to

Section 1, Specifications

35

30

25

20

15

VOLTAGE(VOLTS)

10

). See Figures 3-2 and 3-3 for the stabilizing reactor impedance characteristics.

5

0

012345678910

CURRENT

AMPS

Figure 3-2. Sensing Input Range 1 (5 Ampere), Stabilizing Reactor Impedance Characteristics

30

25

20

15

VOLTAGE(VOLTS)

10

5

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

CURRENT

AMPS

3-2 BE1-87G - Functional Description

Page 16

Figure 3-3. Sensing Input Range 2 (1 Ampere),Stabilizing Reactor Impedance Characteristics

Bandpass Filters

Outputs from the relay transformers are filtered to eliminate the third harmonic and to minimize the effect of DC

offset caused by CT saturation (as may occur during synchronization or asymmetrical faults).

The output of the difference bandpass filter is applied to a full wave rectifier. The rectifier scales the differential

and applies the output to the comparator as the operating current (I

) signal .

OP

The output of the sum bandpass filter is also applied to a full wave rectifier. The scaled sum of the two inputs

represents the restraint current (I

). The restraint current is scaled for a 50% slope above nominal input current

R

(five amperes input range one and one ampere input range two).

Comparator

The comparator provides the variable percentage characteristic of the relay as follows:

When I

comparator provides an output signal whenever the operate current (I

sitivity setting I (

When I

front panel sensitivity threshold is increased by adding to it a scaled value representing 1/2 of I

is less than nominal (f ive amperes input range one and one ampere input range two), the

R

).

S

is greater than nominal (five amperes input range one and one ampere input range two), the

R

) exceeds the front panel sen-

OP

minus

R

nominal (five amperes input range one and one ampere input range two).

Outputs

In the three-phase model, the outputs of the comparators are OR'd so that the coil of the output relay is

energized if the current difference of any monitored phase exceeds the variable percentage limit. When the

current difference falls below 90% of the variable percentage threshold, the output relay resets.

Targets (Optional)

If the relay is equipped with targets, the target associated with the phase or phases with excessive differential

current is tripped.

Depending on the style number (TARGET Option A or B), a unit may contain either internally operated or current

operated targets. Internally operated targets are actuated in conjunction with the output relay. Current operated

targets require a minimum of 0.2 ampere in the output circuit for actuation. Both types are magnetically latching

devices and must be manually reset by use of the reset lever.

Push-To-Energize (Optional)

The unit may be equipped (Option 2-C) with a momentary pushbutton that is accessible through the front panel.

To prevent accidental operation of this switch, it is recessed behind the front panel of the relay and is actuated

by inserting a thin non-conducting rod through an access hole in the panel. When pushed, the switch operates

the output relays and internally operated targets. Current operated targets will activate if the required 0.2

ampere of minimum current is present.

Power Supply Status Output (Optional)

The power supply status output relay (Option 3-6) has normally closed (NC) output contacts . This relay is

energized upon power-up and the NC contacts open. Normal relay operating voltage maintains the power

BE1-87G - Functional Description 3-3

Page 17

supply status output relay continually energized and its output contacts open. If the power supply output voltage

falls below the requirements for proper operation, the power supply status output relay de-energizes, closing the

NC output contacts.

Power Supply

Basler Electric enhanced the power supply design for unit case relays. This new design created three, wide

range power supplies that replace the five previous power supplies. Style number identifiers for these power

supplies have not been changed so that customers may order the same style numbers that they ordered

previously. The first newly designed power supplies were installed in unit case relays with EIA date codes 9638

(third week of September 1996). Relays with a serial number that consists of one alpha character followed by

eight numerical characters also have the new wide range power supplies. A benefit of this new design increases

the power supply operating ranges such that the 48/125 volt selector is no longer necessary. Specific voltage

ranges for the three new power supplies and a cross reference to the style number identifiers are shown in the

following table.

Table 3-1. Wide Range Power Supply Voltage Ranges

Power Supply Style Chart Identifier Nominal Voltage Voltage Range

Low Range L 24 Vdc 12† to 32 Vdc

Mid Range J, K, Y 48, 125 Vdc,

120 Vac

High Range Z 125, 250 Vdc,

120, 240 Vac

† 14 Vdc required to start the power supply.

Relay operating power is developed by the wide range, isolated, low burden, flyback switching, solid state power

supply. Nominal +

is not polarity sensitive. A red LED turns ON to indicate that the power supply is functioning properly.

12 Vdc is delivered to the relay internal circuitry. Input (source voltage) for the power supply

24 to 150 Vdc

90 to 132 Vac

62 to 280 Vdc

90 to 270 Vac

3-4 BE1-87G - Functional Description

Page 18

SECTION 4 • INSTALLATION

GENERAL

When not shipped as part of a control or switchgear panel, the relays are shipped in sturdy cartons to prevent

damage during transit. Immediately upon receipt of a relay, check the model and style number against the

requisition and packing list to see that they agree. Visually inspect the relay for damage that may have occurred

during shipment. If there is evidence of damage, immediately file a claim with the carrier and notify the Regional

Sales Office, or contact the Sales Representative at Basler Electric, Highland, Illinois.

In the event the relay is not to be installed immediately, store the relay in its original shipping carton in a moisture

and dust free environment. When relay is to be placed in service, it is recommended that the operational test

procedure in Section 5,

Testing And Setting

DIELECTRIC TEST

In accordance with IEC 255-5 and ANSI/IEEE C37.90-1989, one-minute dielectric (high potential) tests may be

performed as follows:

All circuits to ground: 2828 Vdc

Input to output circuits: 2000 Vac or 2828 Vdc

, be performed prior to installation.

MOUNTING

Relay

Because the relay is of solid state design, it

does not have to be mounted vertically. Any

convenient mounting angle may be chosen.

Relay outline dimensions and panel drilling

diagrams are shown in Figures 4-1 through 4-

7. Numbers in parentheses indicate metric

dimensions (millimeters). All other dimensions

are in inches.

Figure 4-1. S1 Case, Outline Dimensions, Front View

BE1-87B - Installation 4-1

Page 19

Figure 4-2. S1 Case, Double-Ended, Outline Dimensions, Semi-Flush Mounting, Side View

Figure 4-3. S1 Case, Double-Ended, Outline Dimensions, Projection Mounting, Side View

4-2 BE1-87B - Installation

Page 20

Figure 4-4. S1 Case, Double-Ended, Panel Drilling Diagram, Semi-Flush Mounting

Figure 4-5. S1 Case, Double-Ended, Panel Drilling Diagram, Projection Mounting, Rear View

BE1-87B - Installation 4-3

Page 21

Stabilizing Reactor

The stabilizing reactor for a three-phase relay is mounted on the rear of the relay. For projection mounting

or convenience, the stabilizing reactor can be removed and relocated. Rewire i n accordance with the

procedures and illustrations in this section. To remove the stabilizing reactor, remove four screws holding

the reactor to the mounting plate. To remove the mounting plate, remove two five-sixteenths by eighteen,

hex head bolts. The stabilizing reactor outline dimensions and panel drilling diagrams are shown in

Figures 4-6 and 4-7.

Figure 4-6. Outline Dimensions for External Reactor Chassis 9 1708 18 100

4-4 BE1-87B - Installation

Page 22

Figure 4-7. S1 Case And Reactor, Outline Dimensions (Semi-Flush Mounting)

CONNECTIONS

Incorrect wiring may result in damage to the relay. Be sure to check model and style number against the

options listed in the Style Number Identification Chart before connecting and energizing a particular relay.

WARNING

Relays manufactured prior to July 22, 1991 (EIA date code symbol 9129 and previous)

NOT

do

applies to three phase relays terminals 7 and 8, terminals 13 and 14, and terminals 17

and 18. Exercise

connected to these terminals.

Be sure the relay case is hard-wired to earth ground with no smaller than 12 AWG copper

wire attached to the ground terminal on the rear of the relay c ase. When the relay is

configured in a system with other protective devices, it is recommended to use a

separate lead to the ground bus from each relay.

have case jumpers between terminals 7 and 8 (single phase units). This also

CAUTION

when grounding or testing current transformer circuits

NOTE

Except as noted above, connections should be made with minimum wire size of 14 AWG. Typical dc control

connections are shown in Figure 4-8. Sensing input connections are shown in Figures 4-9 and 4-10.

Terminals 7, 13, and 17 are provided for convenience and to insure compatibility with earlier versions of the

relay. Figures 4-11 and 4-12 are typical internal connection diagrams.

BE1-87B - Installation 4-5

Page 23

Figure 4-8. Typical DC Control Connections

Figure 4-9. Single-Phase Sensing Input Connections

4-6 BE1-87B - Installation

Page 24

Figure 4-10. Three-Phase Sensing Input Connection

BE1-87B - Installation 4-7

Page 25

Figure 4-11. Single-Phase Internal Connection Diagram

4-8 BE1-87B - Installation

Page 26

Figure 4-12. Three-Phase Internal Connection Diagram

BE1-87B - Installation 4-9

Page 27

SECTION 5 • TESTING AND SETTING

GENERAL

Proper operation of the relay may be confirmed by performing the operational test procedures in this Section.

In the event the relay is not to be installed immediately, store the relay in its original shipping carton in a moisture

and dust free environment.

RELAY OPERATING PRECAUTIONS

Before installation or operation of the relay, note the following precautions:

1. A minimum of 0.2 ampere in the output circuit is required to ensure operation of current

operated targets.

2. The relay is a solid-state device. If a wiring insulation test is required, remove the connection

plugs and withdraw the cradle from its case.

CAUTION

To avoid false tripping on three phase units, upper connection plug must be in place

prior to inserting or removing lower connection plug.

3. When the connection plugs are removed the relay is disconnected from the operating circuit and

will not provide system protection. Always be sure that external operating (monitored)

conditions are stable before removing a relay for inspection, test, or service.

4. Be sure the relay case is hard wired to ear th ground using the ground terminal on the rear of

the unit. It is recommended to use a separate ground lead to the ground bus for each relay.

DIELECTRIC TEST

In accordance with and ANSI/IEEE C37.90, one minute dielectric (high potential) tests as follows.

All circuits to ground: 2121 Vdc

Input to output circuits: 1500 Vac or 2121 Vdc

EQUIPMENT REQUIRED

Because of the speed and sensitivity of this relay, it is necessary that the accuracy and stability of the test

equipment be appropriate to test the sensitivity switch settings. For example, this switch at the most sensitive

setting (0.1 ampere) is monitoring a current difference that is only 1% for a sensing input of 10 amperes.

Two Multi-Amp SSR-78, or one Doble F2500, or suitable substitute

Digital voltmeter accurate to within 1% or better

Digital ammeter accurate to within 1% or better

Variable AC/DC ()-250 V) power supply (operating power input)

DC power supply (for current operated targets)

BE1-87G - Testing And Setting 5-1

Page 28

OPERATIONAL TEST PROCEDURE

The following procedure verifies operation of the relay. Terminal numbers are referenced to the operational test

setup in Figure 5-1. Three-phase units may be tested one phase at a time because all phases are OR'd together

at the output.

WARNING

During testing, do

amperes. If the operate current is greater than three amperes, a temperature increase

in the reactor may result and cause insulation breakdown.

NOT

apply or generate continuous operate current greater than three

NOTE

Because of the reactance of the stabilizing reactors, the burden may be too high for large

values of operate current with solid state test sets. Stabilizing reactor L1 may be shorted

out in single-phase relays by placing a jumper on TP-1 and TP-2 on the lower magnetics

shield board. The jumper should be capable of carrying five amperes of operate current.

Figure 5-2 shows the location of the lower magnetics shield board assembly and Figure

5-3 shows test point locations. In three-phase relays, current sources may be connected

directly to the upper and lower terminals (6-9 and 12-19) to bypass the external reactor

chassis.

Restraint current supplied to any one relay input must not exceed either of the following conditions.

10 amperes continuous or 250 amperes for 1 second (sensing input range one)

2 amperes continuous or 50 amperes for 1 second (sensing input range two)

Whenever this current level is exceeded, provisions must be made to cut off the sensing current as the relay

trips.

Figure 5-1. Operational Test Setup

5-2 BE1-87G - Testing And Setting

Page 29

Figure 5-2. Location of Assemblies (Single Phase Only)

NON-COMPONENT SIDE OF LOWER MAGNETICS/SHIELD BOARD

Figure 5-3. TP-1 and TP-2 on Single Phase Relays

BE1-87G - Testing And Setting 5-3

Page 30

Single-Phase Trip And Dropout Test

Step 1. Connect the test setup for phase A in accordance with Figure 5-1.

Step 2. Set the sensitivity switch to A.

Step 3. Apply appropriate power input voltage to terminals 3 and 4.

Step 4. Using a regulated current source that is independently adjustable, apply the restraint current (0.1

ampere, sensing input range 1 or 0.02 ampere, sensing input range 2) to phase A terminals 6 and 9.

Step 5. Slowly increase the operate current source to phase A terminals 6 and 8 until the relay trips. Trip

should occur at (0.1 ampere, sensing input range 1 or 0.02 ampere, sensing input range 2), ±(5% or

25 milliamperes), whichever is greater.

NOTE

Output contacts may be NC or NO, depending on style of relay. Check continuity at

terminals 1 and 10 with relay tripped and not tripped to assure correct response for the

type of contacts specified.

Step 6. Slowly decrease the operate current source until dropout. Reset must occur at a value of current that

is greater than or equal to 90% of I

(sensitivity switch setting value).

s

Step 7. Repeat steps 2 through 6 for the other sensitivity switch settings. If desired, a sufficient number of trip

points may be taken to verify any or all of the performance curves shown in Figure 5-4. For I

R

nominal (5 amperes, sensing input range 1 or 1 ampere, sensing input range 2), the tolerance is

±(0.05 I

(sensing input range 1) or 4 amperes (sensing input range 2), the tolerance is ±0.08 I

or 25 milliamperes, whichever is greater.) For IR nominal up to a maximum of 20 amperes

OP

on the

OP

characteristic curve or 150 milliamperes, whichever is greater. See Figures 5-4 through 5-7 for the

operating characteristic curves and trip response timing curve.

5-4 BE1-87G - Testing And Setting

Page 31

Figure 5-4. Sensing Input Range 1, Operating Characteristics

BE1-87G - Testing And Setting 5-5

Page 32

Figure 5-5. Sensing Input Range 2, Operating Characteristics

5-6 BE1-87G - Testing And Setting

Page 33

)

20

g

18

16

14

12

10

8

6

RESTRAINT CURRENT (AMPERES)

4

2

0

Range 1

Ran

e 2

0

0

5 10152025303540

1 2345678

RESTRAINT CURRENT (AMPERES

D2354-14

04-30-96

Figure 5-6. Extended Restraint Operating Characteristic

45

40

35

30

25

RESPONSE TIME (MSEC)

20

15

0 102030405060708090

MULTIPLES OF PICKUP

Figure 5-7. Pickup Response Timing

BE1-87G - Testing And Setting 5-7

Page 34

Terms for Calculations

I"

Subtransient current

d

N

Total number of CT turns

N

Number of CT turns in use (for multi-ratio type)

a

R

One-way lead resistance, in ohms

l

R

Relay restraint circuit resistance, in ohms

r

R

CT winding resistance, in ohms.

w

Sensing Input Range 1: If R

Sensing Input Range 2: If R w is unknown, assume R w = 0.01 * N

R

Total CT burden = R l + R r + R w (for phase faults and switching)

t

= 2R

SFR

Saturation factor ratio = [(Vce)

Vc

CT accuracy-class voltage rating

NOTE

is unknown, assume R w = 0.003 * N

w

+ 2R r + R w (for external ground faults)

l

/(Vce) 2]*[(R t) 2/(R t) 1] (If SFR is < 1, use 1/SFR)

1

a

a

Vce

Effective CT accuracy-class voltage rating = Vc (N

X"

Subtransient reactance

d

a

/N)

CT Quality

CTs should have an accuracy class of either C20 or better or T20 or better.

Burden Limit

The CTs should be operating below the knee point under symmetrical current conditions --i.e. no "ac saturation".

For a generator, ac saturation should not occur for the maximum external fault current. For a motor, ac

saturation should not occur during starting. For a shunt reactor, high current fundamental-frequency currents

won't flow unless the reactor becomes faulted.

< 0.007Vce (1)

Assuming a maximum current of 20 times CT rating:

where V

= 70% of Vce and 20 X 5 A nominal rating = 100 A so that

knee

R

= V

t

/ I max = 0.7 Vce/ 100 A = 0.007 Vce

knee

R

t

Relative CT Performance

Table 5-1 lists the recommended minimum pickup settings to provide security during external faults and

switching.

BE1-87G - Testing And Setting 5-9

Page 35

Phases B And C, Trip And Dropout Test

Step 1. If the relay is a 3-phase relay, repeat steps 1 through 7 for phases B and C.

Target Test

If relay is equipped with targets, check for correct operation of each phase when relay is tripped, and for manual

reset.

NOTE

If option B (current operated) targets are specified, the target is only operable when a

minimum of 0.2 ampere is present in the output circuit (terminals 1 and 10).

Auxiliary Output Test

If an Auxiliary output (Option 3-2 or 3-3) is present, check outputs at terminals 2 and 5 (either NC or NO as

specified) when relay is tripped.

Push To Energize Output Test

If a PUSH TO ENERGIZE switch (Option 2-C) is present, verify correct operation by depressing the switch and

observing that the output and auxiliary relays cycle (terminals 1 and 10 and terminals 2 and 5 respectively.)

Power Supply Status Output Test

Step 1. If power supply status output (Option 3-6) is present, verify correct operation by applying appropriate

voltage to the power input, placing the unit in a powered-up condition, verifying that the power supply

status output contacts are energized open (terminals 2 and 5).

Step 2. Remove input power and verify that the power supply status output contacts close.

SETTING THE RELAY

General

This paragraph provides recommendations for selecting the current sensitivity switch setting. Figures 5-4 and

5-5 show how this setting corresponds to the operating current pickup over the restraint current range.

Assuming that the CTs on both sides of the zone (generator, motor or reactor) perform identically, operating

current will be equal to zero. The sensitivity setting serves to accommodate dissimilar CT performance, resulting

from differences in CT quality, burden, and core remanence.

During normal operation, the pickup on the flat part of the operating characteristics (refer to Figures 5-4 and 5-5)

must exceed the difference in steady-state CT errors. The relay must also override the error differences in the

presence of dc components developed by external faults or switching. Currents will be offset during external

faults on generator applications, during motor starting, and during switching of shunt reactors.

Out-of-phase synchronizing of machines will also produce offset components. These so-called dc components

will produce significant CT saturation. For high-current faults, the relay relies on the 50% slope characteristic

to override large operating currents. Significant operating current can also be developed at restraint levels that

fall on the flat part of the characteristic if the offset component persists. The sensitivity setting needs to be above

this operating current.

5-8 BE1-87G - Testing And Setting

Page 36

Table 5-1. Recommended Pickup Settings

Vce

(Lower Value)

1 1.5 2 3 4

SFR

20 0.2 0.4 0.5 0.8 1.6

50 0.2 0.4 0.4 0.5 0.8

100 0.2 0.2 0.4 0.4 0.5

200 0.1 0.1 0.2 0.4 0.5

>200 0.1 0.1 0.2 0.4 0.5

Note:

Use next higher setting if CTs are a mix of C classification and T classification.

The saturation factor ratio, SFR, represents an index of the relative performance of the two sets of CTs. This

performance is a function of the relative quality of the CTs (Vce), the relative burdens (R

remanence.

If SFR is < 1, then use 1/SFR for SFR.

), and neglecting the

t

Setting Example Number One

Select the pick-up setting for the motor application in Figure 5-8. In this application, the settings need to be

based on the probability of significant dissimilar CT saturation due to the very slowly decaying dc component

of the starting current. Since the motor is not grounded, no ground current can flow during starting of an

unfaulted motor. Therefore, one-way lead burden is used to determine the total CT burden. Each phase CT

carries just the burden for the lead for that phase.

Figure 5-8. Motor Differential Application

(R t) 1 = R l + R w = 0.22 + 0.14 = 0.36 ; (Vce) 1 = 50 ; R t < 0.007(Vce) 1 = 0.35

= 0.09 + 0.10 = 0.19 ; (Vce) 2 = 100 ; R t < 0.007(Vce) 2 = 0.7

(R

t) 2

5-10 BE1-87G - Testing And Setting

Page 37

Inequality

CT rating [vs. the assumption of 20 times rated for inequality

Using the SFR 4 column of Table 5-1, a 0.8 ampere setting is indicated. However, based on the note

accompanying this table, choose the next higher setting of 1.6, because CT #1 has a T classification, and CT

#2 has a C classification. The T classification indicates that the CT has significant secondary leakage

inductance which somew hat degrades the transient performance. This is a concern during motor starting

because a slowly decaying offset component develops in at least one phase.

Setting Example Number Two

Select the pick-up setting for the generator application in Figure 5-9. In this application, the settings need to be

based on the probability of significant dissimilar CT saturation during an external fault. Since the generator is

resistance grounded, the three-phase fault current will be much larger than the ground fault level. Moreover,

the resistor will rapidly dampen any offset-current component. Accordingly, determine the subtransient current

).

(I"

d

(1)

is met with CT #2, but not with CT #1. However, since the locked rotor current is only 4.8 times

SFR = (100/50)*(0.36/0.19) = 3.8

(1)

], the application is suitable.

1000

Id

4.16×

3

0.15×200

138.8

30

4.6 × CT rating

Figure 5-9. Generator Differential Application

Since the three-phase fault is involved, one-way lead burden is used to determine the total CT burden. Each

phase CT carries just the burden for the lead for that phase.

= R l + R w = 0.22 + 0.14 = 0.36 ; (Vce) 1 = 50 ; R t < 0.007(Vce) 1 = 0.35

(R

t) 1

= 0.09 + 0.10 = 0.19 ; (Vce) 2 = 100 ; R t < 0.007(Vce) 2 = 0.7

(R

t) 2

BE1-87G - Testing And Setting 5-11

Page 38

Inequality

4.6 times CT rating [vs. the assumption of 20 times rated for inequality

Using the SFR 4 column of Table 5-1, a 0.8 ampere setting is indicated. However, based on the note

accompanying this table, choose the next higher setting of 1.6, because CT #1 has a T classification, and CT

#2 has a C classification. The T classification indicates that the CT has significant secondary leakage

inductance which somewhat degrades the transient performance. This is a concern during motor starting

because a slowly decaying offset component develops in at least one phase.

(1)

is met with CT #2, but not with CT #1. However, since the maximum external fault current is only

SFR = (100/50)*(0.36/0.19) = 3.8

(1)

], the application is suitable.

5-12 BE1-87G - Testing And Setting

Page 39

SECTION 6 • MAINTENANCE

GENERAL

BE1-87G Variable Percentage Differential Relays require no preventive maintenance other than a periodic

operational test (refer to Section 5 for the operational test procedures). If factory repair is desired, contact the

Customer Service Department of the Power Systems Group, Basler Electric, for a return authorization number

prior to shipping.

IN-HOUSE REPAIR

In-house replacement of individual components may be difficult and should not be attempted unless appropriate

equipment and qualified personnel are available.

CAUTION

Substitution of printed circuit boards or individual components does not necessarily mean

the relay will operate properly. Always test the relay before placing it in operation.

Where special components are involved, Basler Electric part numbers may be obtained from the number

stamped on the component or assembly, the schematic, or parts list. These parts may be ordered directly from

Basler Electric. When complete boards or assemblies are needed, the following information is required.

1. Relay model and style number

2. Relay serial number

3. Board or assembly

a) Part number

b) Serial number

c) Revision letter

4. The name of the board or assembly.

STORAGE

This protective relay contains aluminum electrolytic capacitors which generally have a life expectancy in excess

of 10 years at storage temperatures less than 40C. Typically, the life expectancy of the capacitor is cut in half

for every 10C rise in temperature. Storage life can be extended if, at one-year intervals, power is applied to

the relay for a period of thirty minutes.

BE1-87G - Maintenance 6-1

Page 40

SECTION 7 • MANUAL CHANGE INFORMATION

SUMMARY AND CROSS REFERENCE GUIDE

This section contains information concerning the previous editions of the manual. The substantive changes

to date are summarized in Table 7-1.

Table 7-1. BE1-87G Changes

Revision Summary Of Changes ECA/ECO/Date

A

B

C

D

E

F

G

H

Added qualifications to specifications listing, revised isolation test and

dielectric test.

Grammatical changes to specifications, changed comparator

functional description and operational test procedure.

Added Power Supply Status Output Option 3-6 03-13-87/8485

Physically removed Power ON/OFF switch and added stabilizing

reactor. Added illustrations for typical connections, sensing input

connections, test setup, extended operational characteristics, and

pickup response timing. Added table for current sensing burden and

functional description of stabilizing reactor, setting the relay, and

setting the relay example.

Changed Figure 1-1 and 1-2, and added Warning pages 1-1 and 4-2. 07-17-

Changed pickup accuracy for I

the operate pickup characteristic or 150 mA, whichever is greater.

2

Added I

Reactor Impedance Characteristics.

Added sensing input range 2 (one ampere nominal) to the available

models. Changed high speed operation from 20 milliseconds to 30

milliseconds. Changed all connection diagrams to include ground

connections where applicable. Added internal connection diagrams.

Corrected Table 1-1 Clarified

application, and added

differential application. Divided

Section 5

t rating of Stabilizing Reactor and new Figure 4-1, Stabilizing

Setting Example Number Two

, is

Testing And Setting

> 5 A from 30 A, ±5% to 20 A, ±8% of

R

Setting Example

Section 4

the relay.

for motor differential

, generator

into two sections. The new

05-12-86/7820

10-07-86/8199

03-06-

91/11227

91/12091

07-30-

91/12100

10-17-

91/12223

05-03-

96/15555

J

BE1-87G - Manual Change Information 7-1

Reformatted manual to current standards. Page 1-2, corrected Figure

1-2. Page 1-4, last paragraph, changed “Terminals 7, 13, and 14 are

provided for convenience . . .” to “Terminals 7, 13, and 17 are provided

for convenience . . .”. Corrected Figures 4-11 and 4-12. Updated this

section to show changes.

05-12-99/4392

Loading...

Loading...