Page 1

Important: Retain these instructions

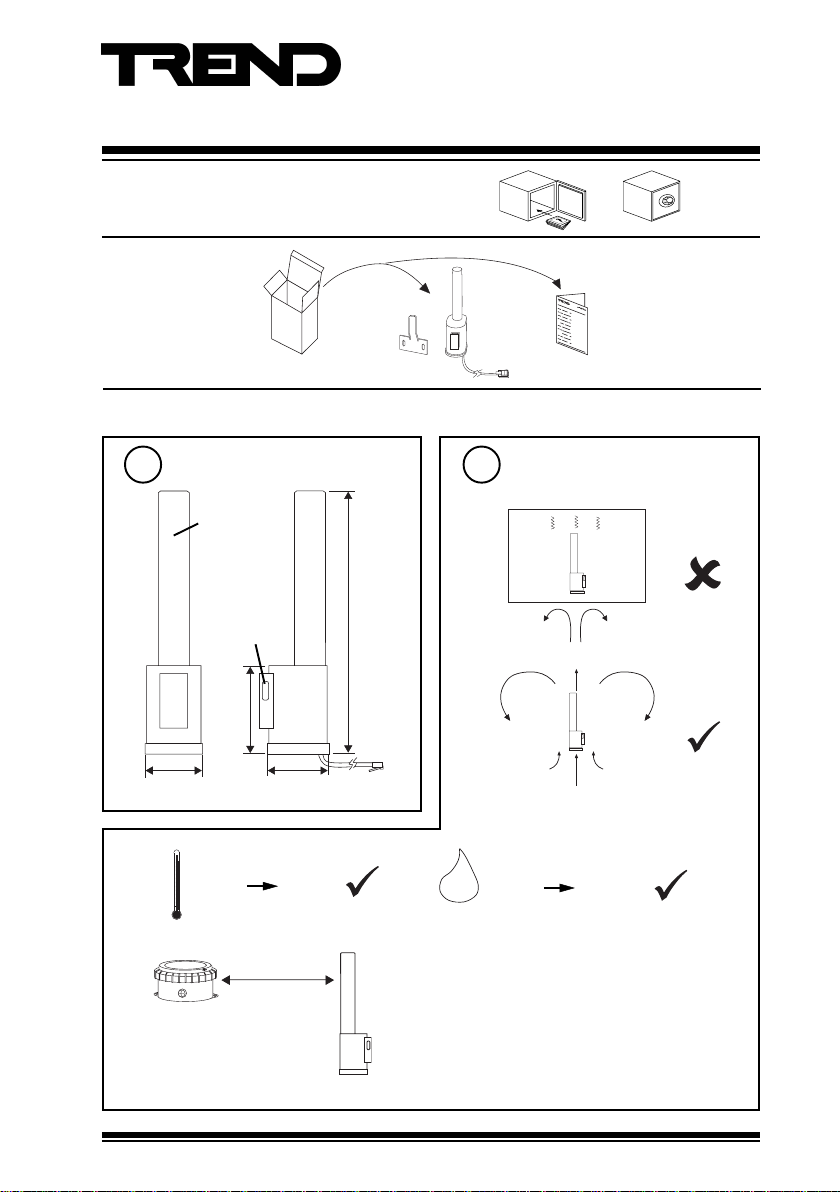

UNPACKING

INSTALLATION

Installation Instructions

XW/R/IQ

Wireless Sensor Receiver

XW/R/IQ Installation

Instructions TG200783

Dimensions

1

Ø 20 mm

(0.78”)

mounting slot

(1.77”)

45 mm

37 mm

(1.46”)

40 mm

(1.57”)

b

-35 °C

(-31 °F) (+158°F)

c

Note that range may be affected

by environmental characteristics,

e.g. partitions, walls, building

structure etc.

+70 °C

75 m, 80 yds

(maximum)

174 mm (6.85”)

RJ11

plug

4 m

(4 yds 1’)

XW/R/IQ

Requirements

2

a

H O

0 %RH

2

100 %RH

Protection IP68+

d

• Avoid using many other devices on frequency

range 433.05 to 434.79 MHz

• Keep away from sources of interference (e.g.

computer >1 m, 1 yd, microwave ovens, switch

mode power supplies).

• Mount above partition height if possible.

XW/R/IQ Wireless Sensor Receiver Installation Instructions TG200783 Issue 1/B 16/01/07

1

Page 2

XW/R/IQ Installation Instructions

INSTALLATION (continued)

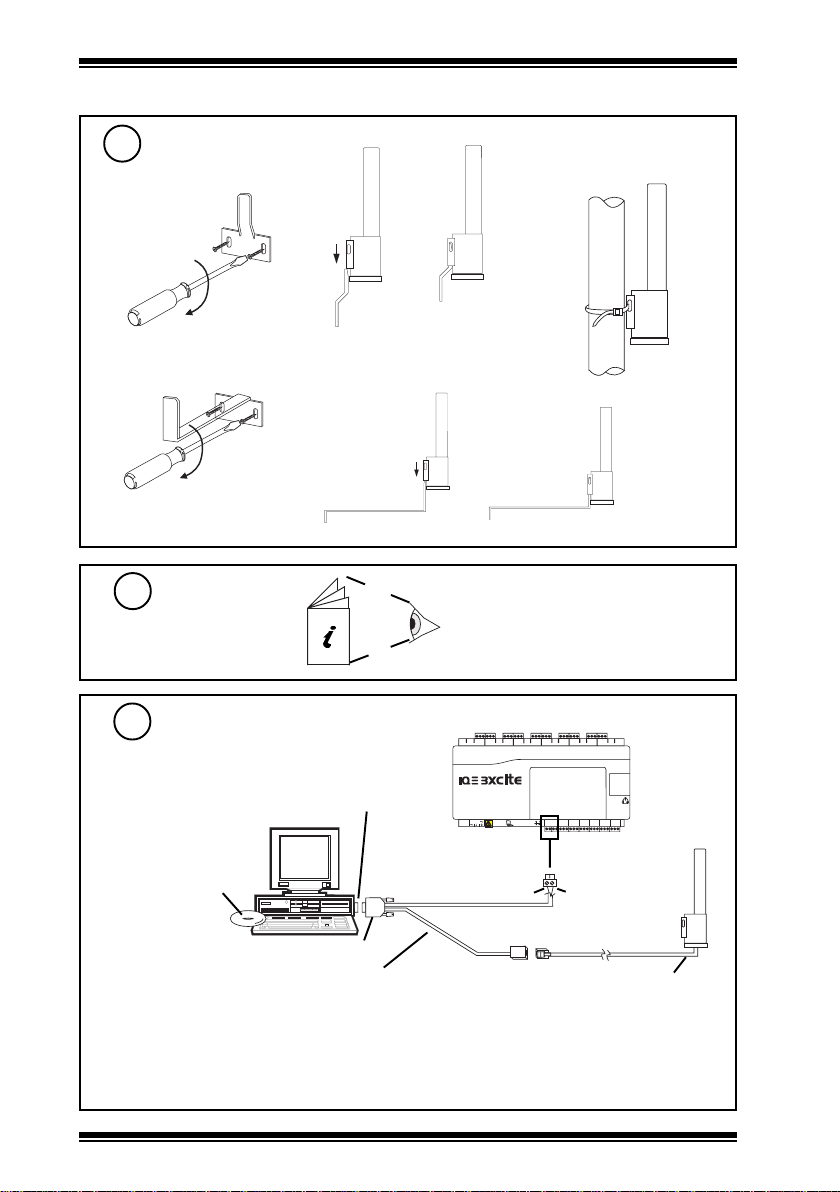

Mount Unit

3

(1) Using plastic bracket supplied

(a) fix bracket (b) (c)

use screws

and rawl plugs

(2) Using stainless steel bracket accessory ACCW/FK/SS

(2) Using cable tie to pipe

(a) (b)

use screws and rawl plugs

Install Sensor(s)

4

Configure Receiver

5

(a) Connect to PC and 24 Vac

RS232 port

XW/R/IQ Configuration

Tool CD (part of

ACCW/CONFIGKIT)

9 way D type female

configuration cable (part of ACCW/CONFIGKIT)

24 Vdc Aux supply out

(c)

TW/S Installation Instructions TG200781

TW/P Installation Instructions TG200782

100-240 V

2 screw terminal

(+24 V) Red Blue (0 V)

RJ11

socket

OK RX

ensure correct

polarity

<=50 mA

RJ11 plug

XW/R/IQ

(b) Check the following settings in XW/R/IQ Configuration Tool:

b1: Port is set to appropriate port number

b2: Protocol is set to Trend Protocol

b3: Read Channels 1-16 (if some channels already set up)

2

XW/R/IQ Wireless Sensor Receiver Installation Instructions TG200783 Issue 1/B 16/01/07

Page 3

Installation Instructions XW/R/IQ

INSTALLATION (continued)

Configure Receiver (continued)

5

TW/.., XW/R/IQ data sheet

TA200780

XW/R/IQ Configuration

Tool Manual TE200793

(c) c1: Select Configuration/Output Mode 0 - All transmitters [Binary]

(configuration software communications window will show communications from sensors)

communications window

configuration software

c2: Select appropriate sensor identification no. from window

e.g. Thermistor Temperature TX.: 16946 Temperature: 26.8

ADC: 367 f/w V4 $---- etc.

sensor’s identification number

Note: if no reception from sensor, see step 6 below.

c3: Type sensor ident ification number into Transmitter Address

slot, and type its Analogue Node Number, and O/S

(outstation) Address into adjacent slots in table

sensor table

(d) Configure Table and PIN (if required) (repeat steps c2, c3 for all sensors)

metItluafeDfiegnahCotegnahCetoN

rebmunNIP4321

rettimsnarT

woRrettimsnarT

0rettimsnartwenputesot

sserddA

eugolanA

000rettimsnartwenputesot

.oNedoN

S/O

0rettimsnartwenputesot

sserddA

evah)s(rellortnoC

putes)s(sdrowssap

'4321'ottnereffid

eS

anA

ocnidesuNIP

)s(rellortn

59=>levelytiroirpfo

noitacifitnedirosn

rosnesmorfrebmun

)stigid

eulav

8(lebalnoitacifitnedi

nirebmunedoneugol

rosneserotsotrellortnoc

nosserddarellortnoC

ebnac(krowtenlacol

htonarorellortnoclacol

re

)krowtennorellortnoc

Notes:

1 If the values from the XW are to be sent to more than one controller, check if passwords (PINs)

set up in any of them. One PIN must be the same in all controllers and of priority level >=95.

2 If sensor value is to be sent to another controller (other than the local controller) the local

supervisor port address must be greater than zero.

PIN

1

1

2

(e) Configure Table into XW

e1 Change Configuration/Output Mode to ‘5 Programmed Transmitter Trend Protocol (ASCII)’

e2 Select Configuration/Programme Channels 1-16

e3 Select Configuration (Read Channels 1-16) and check table is correct

Note that to program channels 17-32 select:

Read Channels 17-32 step b3

Program Channels 17/32 step e2

Read Channels 17-32 step e3

CAUTION

Ensure that the menu item Configuration/Output Mode is set back to ‘5 Programmed Transmitters Trend Protocol (ASCII)’ or the receiver will not operate.

!

(f) Unplug XW/R/IQ receiver from adaptor cable

XW/R/IQ Wireless Sensor Receiver Installation Instructions TG200783 Issue 1/B 16/01/07

3

Page 4

XW/R/IQ Installation Instructions

INSTALLATION (continued)

If there is reception failure of sensor

6

1 Check compliance with step 2 sections C & D

2 Move sensor or receiver slightly in case of a standing wave null position

Configure IQ controller strategy

7

For IQ3 the sensor’s target analogue node must be created

using SET. An example strategy including decoding of

alarm bits is given in the TW/.., XW/R/IQ data sheet

Connect receiver to controller

8

Note XW/R/IQ current consumption <= 50 mA

either for IQ3 or current IQ2xx (excluding IQ251)

current IQ2xx (not IQ251)

or IQ3

TW/.., XW/R/IQ

Data Sheet

TA200780

RJ11

or IQ251 and older IQ2xx’s without 24 V on local supervisor port

cable: RD/SDU-ADAPTOR IQ2xx

Test System

9

e.g. TB/TI/..

XW/R/IQ

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37,Switzerland by its Authorized Representative.

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content hereof

without obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 21888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www.trend-controls.com

100-240 V

RJ11

Δ T

IQ

OK RX

local supervisor port

24 Vdc Aux

local

supervisor

port

DISPOSAL

Do not dispose of with normal household waste.

Do not burn.

IQ251

or older IQ2xx’s

WEEE Directive:

At the end of their useful life

the packaging, product, and

batteries should be disposed

of by a suitable recycling

centre.

4

XW/R/IQ Wireless Sensor Receiver Installation Instructions TG200783 Issue 1/B 16/01/07

Loading...

Loading...