Page 1

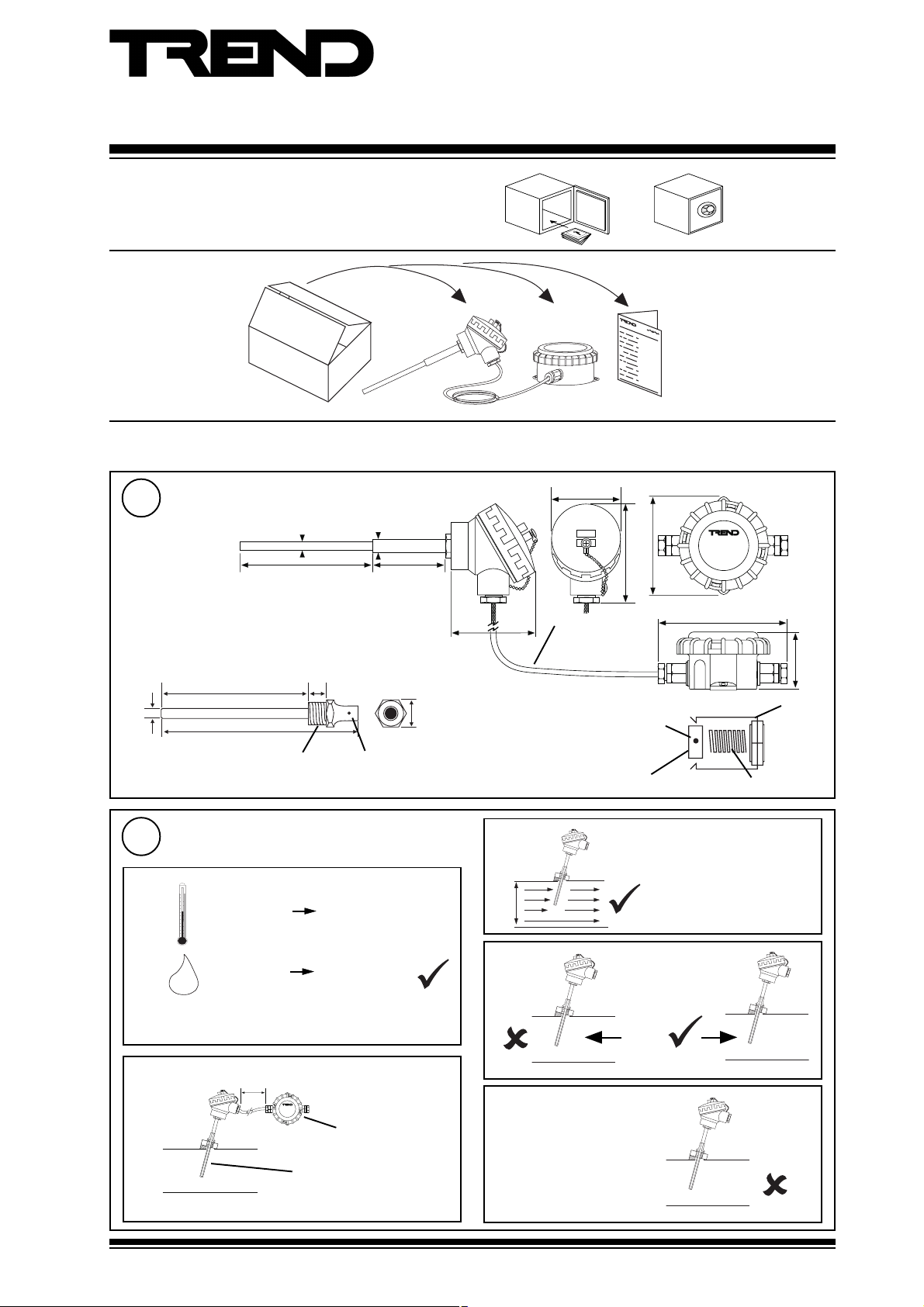

PRT Immersion Temperature Sensor

Important: Retain these instructions

UNPACKING

INSTALLATION

Installation Instructions

T/PI/160

T/PI/160 Installation

Instructions TG100310A

Dimensions

1

6 mm (0.24”)

155 mm (6.1”)

Stainless steel pocket (POC/SS/6)

17mm

(0.67”)

½” BSPT

(0.37”)

9.5 mm

2

a

106 mm (4.17”)

150 mm (5.9”)

Requirements

measurement ranges

-10 °C

+14 °F

H O

2

0 %RH 95 %RH

8 mm (0.31”)

65 mm

(2.56”)

27 mm

(1.1”)

2 mm hexagonal socket

grub screw (each side)

+160 °C

+320 °F

70 mm

(2.76”)

Universal Fitting Kit

for use in existing

pocket (ACC/UF)

c

d

d

55 mm (2.17”)

1 m (3’3”)

stainless steel

cable

hexagonal

socket grub

screw

T/PI/160

MANUFACTUREDIN EU

TRENDCONTROL SYSTEMS

LTD UK

97 mm (3.82”)

75 mm (2.95”)

117 mm (4.61”)

brass bush

Ensure no stratification (e.g.

downstream of mixing valves,

junctions)

(minimum distance from

junctions =10xd).

spring

clip

57 mm

(2.24”)

Protection :IP67, NEMA6

b

T/PI/160 PRT Immersion Temperature Sensor Installation Instructions TG100310A Issue 3/C 25/06/07

1 m max

T/PI/160

MANUFACTUREDINEU

TRENDCONTROLSYSTEMS

LTDUK

-40 °C to +50 °C

-40 °F to +122 °F

-10 °C to +160 °C

+14 °F to +320 °F

e

Note that POC/SS/6 is NOT

suitable for use in chlorine

rich environments

Cl

2

1

Page 2

T/PI/160 Installation Instructions

INSTALLATION (Continued)

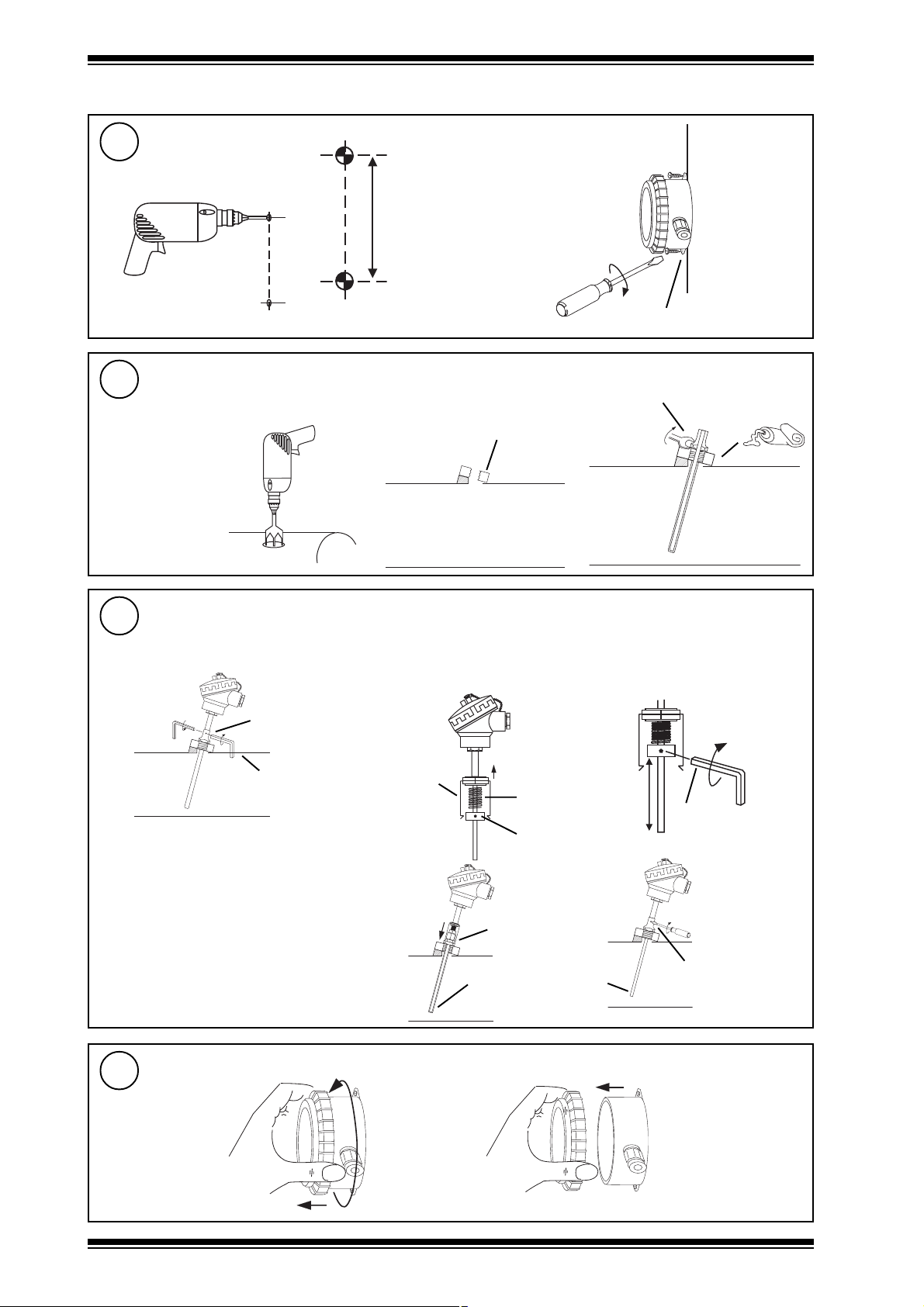

Tighten 2 screws

3

a

Mount on Wall

Drill 2 pilot holes

85 mm (3.35”)

b

2 off No 6 screws

4

a

5

a

Install pocket

(if installing new pocket)

Drill hole for boss

Install sensor into pocket

If using compatible pocket

tighten screws

use 2 mm hexagonal

socket key

(iii) Fix to pocket

b

Fix threaded boss

½” BSPT threaded boss

If using universal adaptor

b

(i) Push adaptor onto probe

clip

spring

brass brush

c

Screw pocket into boss

use M27

spanner

(ii) Adjust probe length

pocket

length

use 2 mm

hexagonal socket key

apply sealent to

boss thread

tighten

6

Remove lid

if pocket has clip retaining

groove, push clip over

pocket

clip engages

in groove

probe is forced against

end of pocket

b

if pocket has grub

screw, discard

spring and clip

tighten screw

over bush

a

2

T/PI/160 PRT Immersion Temperature Sensor Installation Instructions TG100310A Issue 3/C 25/06/07

Page 3

Installation Instructions T/PI/160

INSTALLATION (Continued)

7

8

Remove connector

Insert cable

either use M20 flexible conduit

Caution: This unit contains static sensitive

devices. Suitable anti-static

precautions should be taken

throughtout the operation to prevent

damage to the units.

BS EN100015/1 Basic Specification:

protection of electrostatic sensitive devices.

or use M16 cable gland

9

IQ system TP/I/22/HF/200 (Belden

8761) cable recommended.

Terminal size 0.5 to 2.5 mm2 (14 to 20

AWG)

Note that if connecting to an IQ22x controller (including /ADL or /OC), do not connect directly to C (+24V), instead

connect to AUX+ (+24V).

10

Wire to controller

polarity independent

Replace Connector

Sensor

Sensor

IQ1xx, IQ2xx

24 Vdc

IN

Terminate screen at IQ end only

0 (0 V)

N (in)

+ (24 V)

I

Analogue input channel

linked for current (I)

IQ3

T/PI/160 PRT Immersion Temperature Sensor Installation Instructions TG100310A Issue 3/C 25/06/07

3

Page 4

T/PI/160 Installation Instructions

INSTALLATION (Continued)

11

Replace lid

b

a

Note that IP67 (NEMA6) rating is only achieved if the sensor is correctly installed with cable or conduit connection fully

tightened.

12

13

It is recommended to use SET (Software Tool) for the setting of the sensor type module. For all IQ2 series controllers with

firmware version 2.1 or greater, or IQ3 series controllers, the following SET Unique Sensor Reference should be used:

Configure IQ

or

I Q

Set up IQ sensor type

I Q

IQ Configuration Manual 90-1533

PRT Sensor -10+160 (°C)

PRT Sensor +14+320 (°F)

Alternatively set scaling mode to 5 (characterise) and enter scaling manually as defined in table below. Note that for IQ3

the scaling mode and exponent do not need to be set up.

For all other IQ controllers see Sensor Scaling Reference Card TB100521A

PRT Sensor (-10 °C +160 °C, +14 °F +320 °F)

14

Test system

T/PI/160

MANUFACTUREDIN EU

TRENDCONTROLSYSTEMS

LTDUK

Δ T

IQ

Y

E

U

L

P

x

1

2

DISPOSAL

Do not dispose of with normal household

waste. Do not burn.

epyttupni)tnerruc(2

tnenopxE3

stinUC°F°

reppU061023

rewoL01-41

stnioP22

xIxOxO

401-41

02061023

WEEE Directive :

At the end of their useful life

the packaging and product,

should be disposed of by a

suitable recycling centre.

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37,Switzerland by its Authorized Representative, Trend Control Systems Limited.

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content

hereof without obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)867-3900, Fax: (425)869-8445 www.trend-controls.com

4

T/PI/160 PRT Immersion Temperature Sensor Installation Instructions TG100310A Issue 3/C 25/06/07

Loading...

Loading...