Page 1

ELECTRONIC/PNEUMATIC-TRANSDUCER

APPLICATION

An E/P Transducer accepts a proportional voltage signal

from an electronic controller and converts it into a proportional pneumatic signal of 0.2 to 1.0 bar to operate

pneumatic actuators or reset pneumatic controllers.

The PN-VPC accepts a 2...10 Vdc / 4...20 mA signal. It

includes a voltage to current converter. The PN-VPC

requires an external 24 Vac power supply.

MAINTENANCE

A full range of maintenance programs is available from your

local registered Trend office.

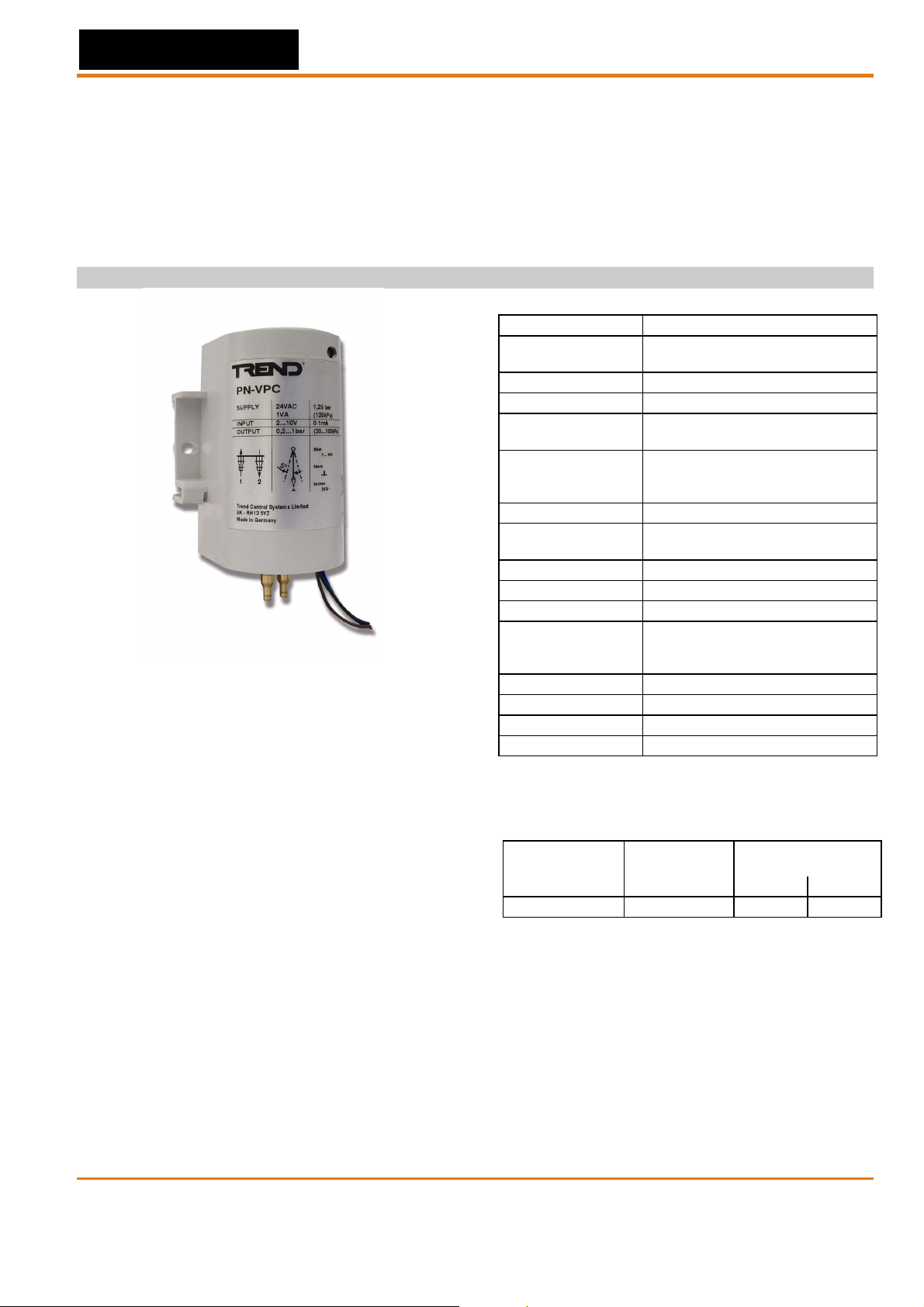

PN-VPC

PRODUCT DATA

SPECIFICATIONS

Type No. PN-VPC

Power supply

Power consumption 1.7 VA

Input signal 2... 10 V

Min. current at

10 Vdc

0.02 bar (2 kPa) max. at 0 Vdc Output pressure at

1.25 bar (125 kPa)

main pressure

Main air pressure 1.25 bar (125 kPa)

Main air pressure

independence

Maximum safe air 2.0 bar (200 kPa)

Air consumption 42 NL/h (700 sccm) at 0.6 bar

Air capacity 720 NL/h (12000 sccm)

Air connections

Calibration Factory calibrated

Ambient temperature 5...55ºC

Storage -30...+70ºC

Humidity 5...95% RH

All E/P-Transducers supplied with 1 m cable

1.12 bar (112 kPa) min. at 11.5 Vdc

1% per 0.1 bar main air pressure

Dual-barb-fittings for either 6 x

1 mm (1/4“ O.D.) or 4 x 0.75 mm

(5/32“ O.D.) polyethylene tubing.

WIRING

Distance

E/P-Transducer

to ... 100 m 150 m

Controller local standard 1.0 mm21.5 mm

See also

NOTE: The E/P Transducer connection wire 24 V ⊥

Fig. 3.

(black) must be connected to the same potential

0 V level as the controller.

Type of wire length max.

+10% / -15%

24 V, 50/60Hz

(0.1 mA)

2

PN-VPC Data Sheet TA200855 Issue 1/B 28/03/07 1

EN0B-0505GE51 R0307B

Page 2

PN-VPC Data Sheet

OPERATION

The input signal 2...10 V is fed into a voltage to current

converter in the PN-VPC.

The current through the coil produces a magnetic force on

the flapper. This force is balanced by the feedback force

developed by the nozzles pressure on the opposite side of

the flapper.

When the magnetic force on the flapper changes due to a

change in current, the position of the flapper over the

nozzle changes, and a new pressure is established. This

pressure is used to pilot the pneumatic amplifier, which

converts the low capacity pilot pressure to a high capacity

branch line. The operation span is fixed and the startpoint

of the output signal is factory calibrated.

Both transducers are compensated to eliminate ambient

temperature influence. The transducers are protected by a

rigid plastic cover.

38

diameter

4.1

4.5

5°

7

47

51.5

62

Fig. 1. PN-VPC dimensions (in mm)

MOUNTING

Wall mounting with two screws 4 mm diameter (see Fig. 1).

Rail mounting using the European Standard Rail 35 x 7.5

(EN 50022) (see

Mount the transducer in the vertical position ONLY with a

maximum of 5 angular degree tolerance to the

perpendicular line (see

Fig. 2).

Fig. 1).

78

13.5

1. For test or indication gauge

2. Additional length to dismount from rail

Fig. 2. Mounting

START-UP INSTRUCTIONS

Before starting up the system, the following checks should

be made on the transducer:

1. Check that main line pressure is available and input

voltage is at maximum i.e. 12 Vdc.

2. Check that output pressure is at minimum i.e 120 kPa

(1.2 bar).

3a. If the output pressure is within the transducer rating, the

system can be started up.

3b. If not, short out the contact pins with a screwdriver.

When this is done, the sound of discharging air should be

heard.

4. Check for correct output pressure build-up and repeat

step 3(b) if transducer does not function correctly.

BLUE

PN-VPC

c

o

n

v

e

r

t

e

r

BROWN

BLACK

Y = 2...10 Vdc

24 V~

24 V

Fig. 3. Wiring and connections

DISPOSAL

WEEE Directive

At the end of their useful life the packaging

and product should be disposed of by a suitable

recycling centre.

Do not dispose of with normal household waste.

Do not burn.

:

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37,Switzerland by its Authorized Representative.

Trend Control Systems Ltd reserves the right to revise this publication from time to time and make changes to the content hereof without obligation to

notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34 Horsham, West Sussex, RH12 2YF, UK. Tel: +44 (0)1403 211888, Fax: +44 (0)1403 241608, www.trend-controls.com

2 PN-VPC Data Sheet TA200855 Issue 1/B 28/03/07

EN0B-0505GE51 R0307B

Loading...

Loading...