Page 1

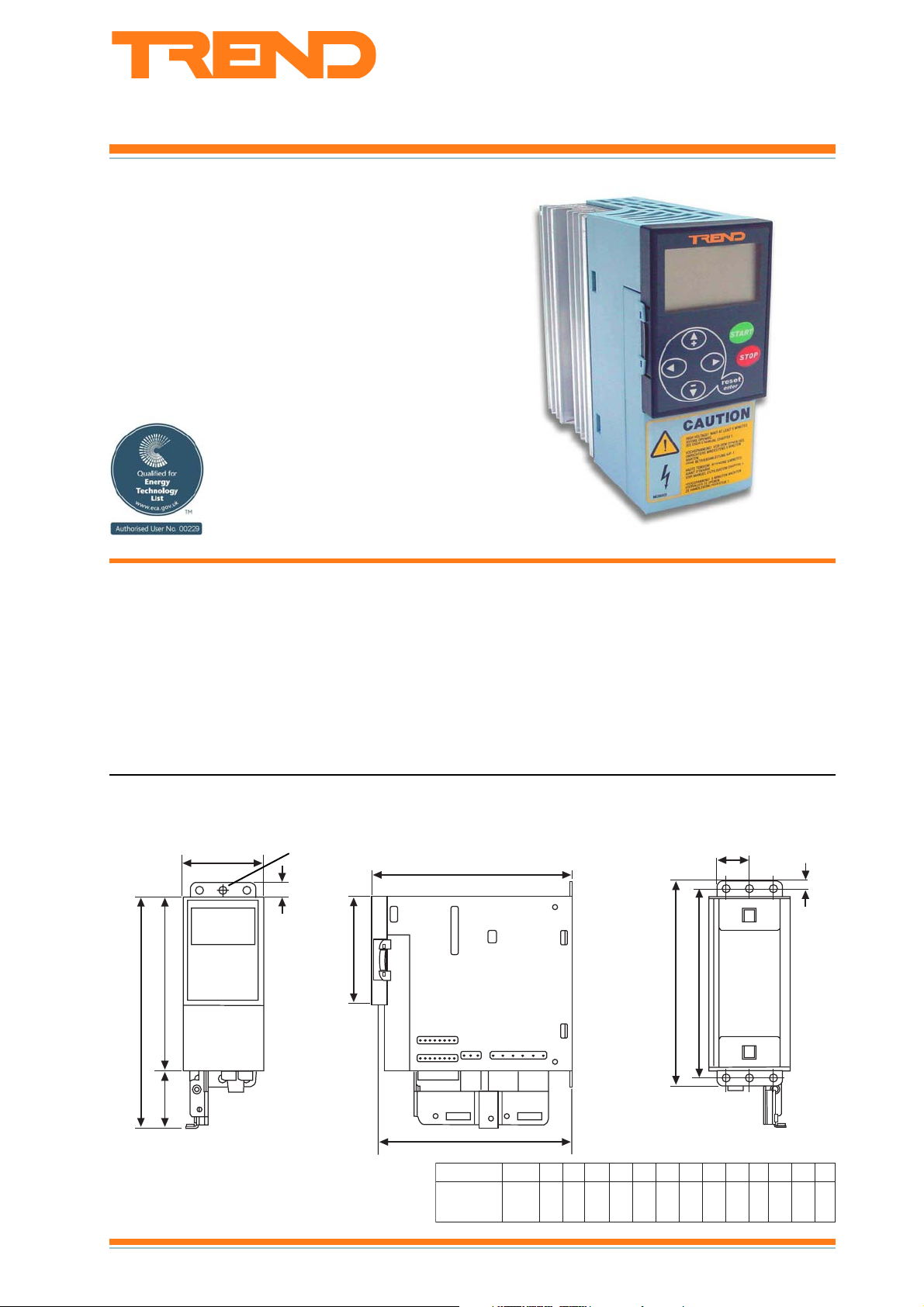

NXL Variable Speed Drives

Data Sheet

NXL

Variable Speed Drives

Description

Variable motor speed drives suitable for a wide range of voltage

and current loads. Convert fixed frequency and voltage from the

mains supply to variable frequency and voltage enabling motors to

be used with maximum efficiency resulting in significant energy

savings. The drive has a built-in PID control application that can be

adjusted from the control keypad.

NXL drives are suitable for mounting in a small space, using back,

side, or DIN rail mounting.

The drives are easily programmed and commissioned by using

the control keypad or PC tools software.

Physical

(dimensions in mm)

Microdrives

H4

H1

W2

Ø

H7

H5

Features

• 380 to 500 Vac 3 phase or 208 to 240Vac single phase supply

• current rating range from 1.9 A to 61 A (0.37 kW to 30 kW)

• built-in multi-control application

• multilingual control panel

• integrated RFI filter for industry strength EMC

• versatile PC tools available

• slim, space-saving, “bookshelf” design

• additional I/O, 3 digital inputs, 2 digital outputs (Ecodrives only)

D1

H2

W1

H3

H8

H6

D2

epyTemarF1W2W1H2H3H4H5H6H7H8H1D2DØ

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

&,51000LXN

&,52000LXN

2FM03062712510410310824116 0514416

1C2000LXN

1

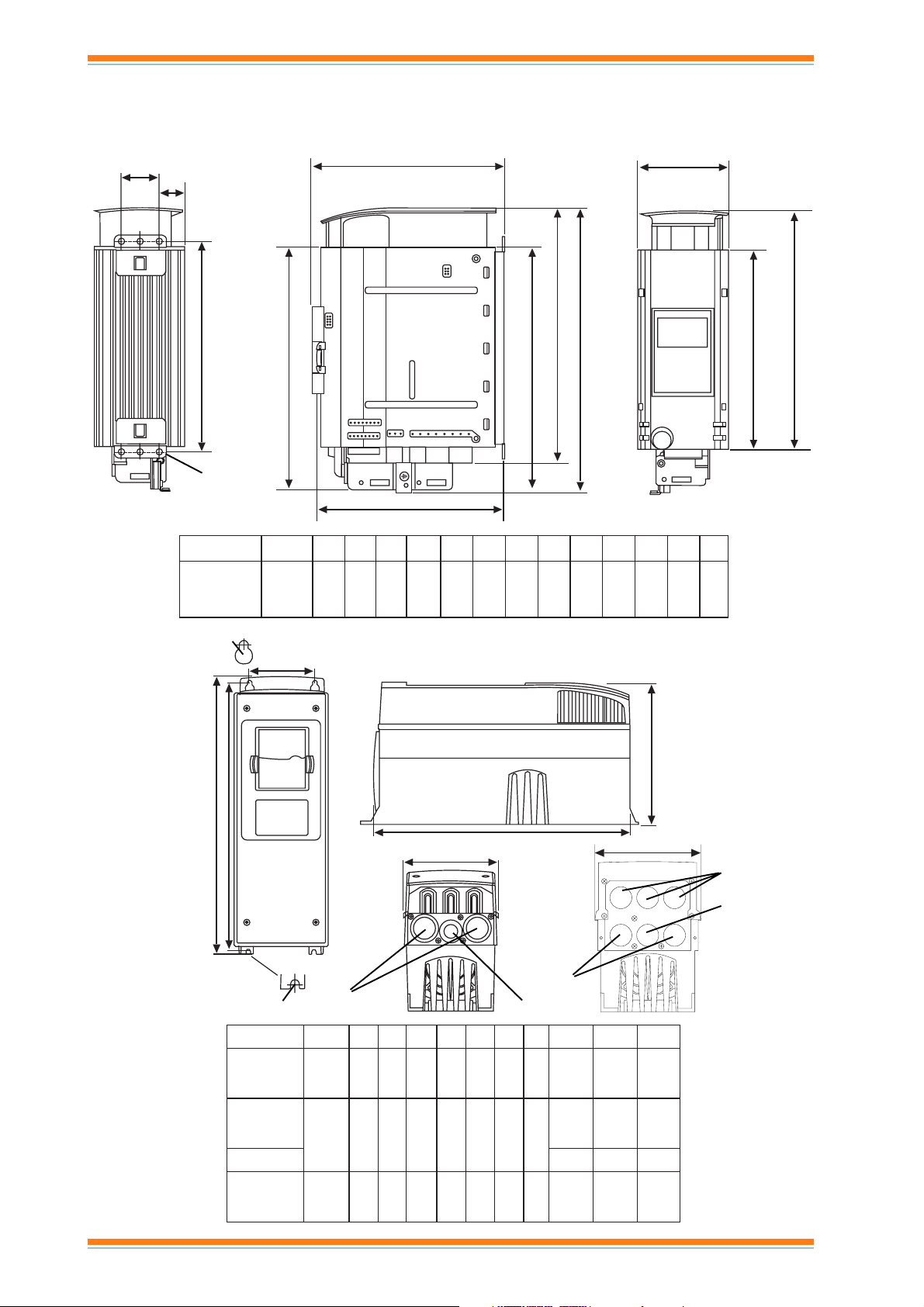

Page 2

NX L Data Sheet

Physical

(dimensions in mm)

Microdrives

W2

W3

D1 W1

Ecodrives

H5

H3

Ø

D2

H2

H1

H4

epyTemarF1W2W3W1H2H3H4H5H6H7H1D2DØ

1C3000LXN

ot

3FM4853322625323229913914810222716616

1C6000LXN

Ø

W2

D1

H7

H6

H1

H2

IP21

Ø

P

W1

H3

IP54

P

B

epyTemarF1W2W1H2H3H1DØ P B C

xx30AALXN

ot

4FM8210017233132920917 02x202x152x1

W1

C

B

P= power cable

B= brake cable

C= control cable

xx21AALXN

xx61AALXN

ot

5FM4410019146041934127

xx32AALXN

52x252x152

x1

xx13AALXN23x252x152x1

xx83AALXN

ot

6FM5918418551459157329 23x223x152x1

xx16AALXN

2

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

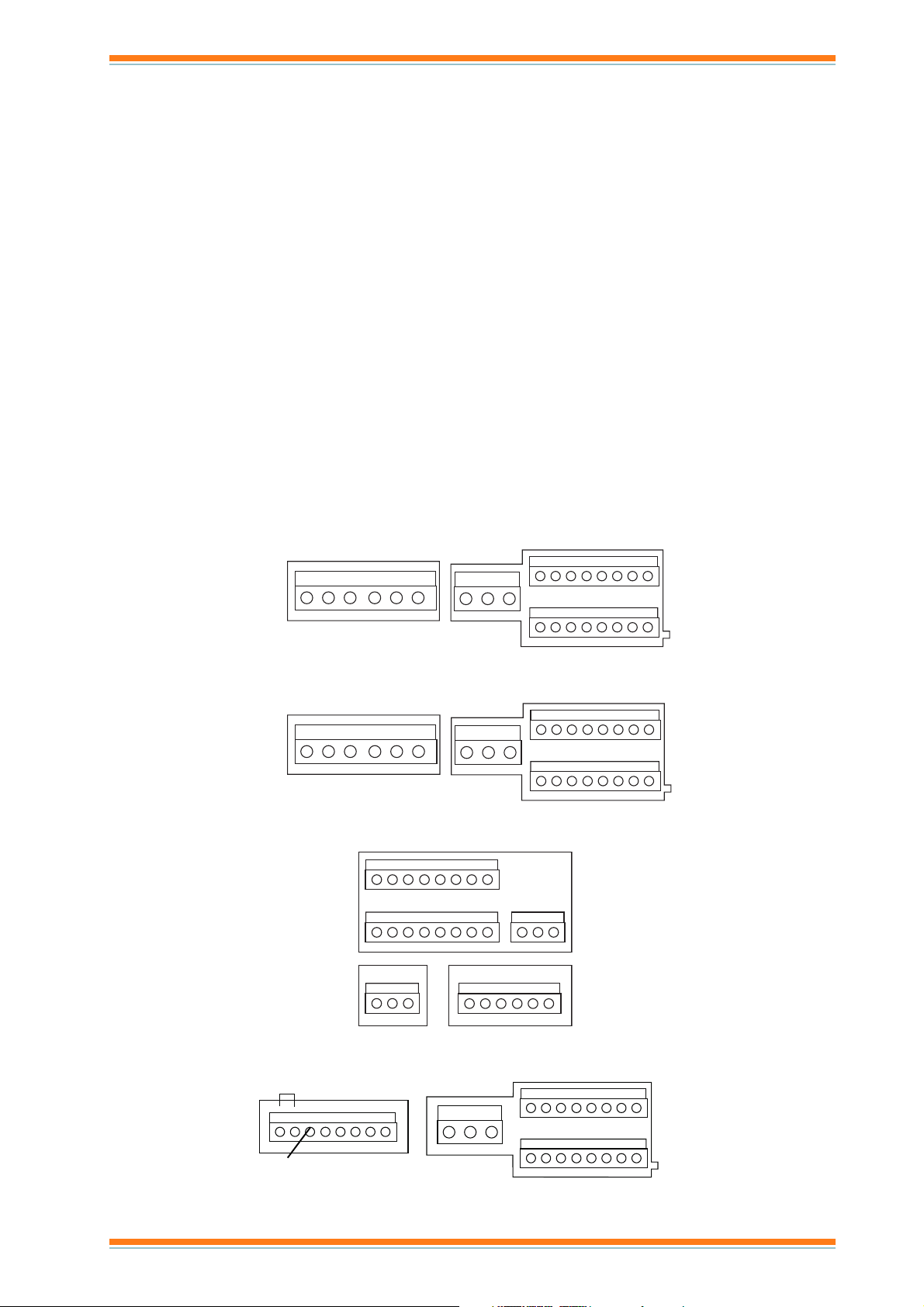

Page 3

Data Sheet NXL

21 22 23

9 10 11 18 19

A B

1 2 3 4 5 6 7 8

L1 L2 L3

U/T1

V/T2

W/T3

BR+

BR-

30

1~

FUNCTIONALITY

The NXL range of variable speed drives provides both three phase to three phase (1 A to 61 A) and single phase to three phase

(2 A to 6A) units. Of particular use in the HVAC environment, they enable fans and motors to regulate delivery of air and water

in variable flow applications. Where flow rates may be reduced, motor energy can be significantly cut as the relationship between

flow rate and power follows a cube law hence reducing flow by 20% reduces power by 50%. The drives also enable saving in

installation costs; switchgear is eliminated, motor cables are reduced from 6 to 3 wires, power factor correction capacitors are

not required, size and cost of cabling and fuses is minimised (as starting current is kept within nominal value).

The sensorless flux vector control gives dynamic precision over most of the speed range. A drive is provided with built-in control

application, which can be set up from the control keypad. It has a slot for an optional I/O expansion board.

HARDWARE

The Trend NXL is an extremely slim, space-saving and

easy-to-use frequency converter for the power range of 0.37

to 30 kW. The installation is flexible and easy using the mounting

components shipped with the unit. Traditional back installation

and side installation, suitable for very limited space, are available,

as well as DIN rail mounting.

An optimal solution is available for most application needs. The

modular design allows the choice of only the functions and

features needed in a specific application. The control keypad is

fitted as standard. The NXOPTAA board (3 x digital inputs, 1 x

digital relay output, and 1 x digital open collector output) is fitted

as standard in the I/O expansion slot of the Ecodrives; it can be

fitted as an optional extra in the Microdrives. At the core of the

Easy programming and commissioning add to overall

user-friendliness. The default control I/O of the Trend NXL includes

the most common control inputs and outputs. For maximum

compatibility, the connector numbers correspond to those of the

Trend NX drives. Parameter setting is carried out in a familiar

NXL is sensorless vector control technology coupled with current

measurements of all three output phases. Fieldbus control using

RS485 Modbus is available as standard. The Trend NXL also

incorporates PID control as standard, enhanced with a host of

special features such as a sleep function.

way, either via the control panel or by means of the PC tools for

the NXL.

Terminals for NXL0002C1 (MF2 single phase to three phase)

L1 L2 L3 U/T1

V/T2

W/T3

21 22 23

Terminals for NXL00015, NXL00025 (MF2 three phase to three phase)

L1 L2 L3 U/T1

V/T2

W/T3

21 22 23

910111819A B

12 3 4 5 6 7 8

910111819A B

30

30

Terminals for NXLAA03xx to NXLAA61xx where xx = C2 or C5 (MF4 to MF6)

910111819A B

123456783021 22 23

L1 L2 L3

B- B+ R-

Terminals for NXL0003C1 to NXL0006C1 (MF3 single phase to three phase)

not used

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

12 3 4 5 6 7 8

U/T1 V/T2 W/T3

3

Page 4

NX L Data Sheet

HARDWARE (continued)

Standard I/O The unit provides basic I/O connections

directly to suit common applications for NXL.

Typical connector for Multicontrol Application

1

2

3

4

5

6

7

8

9

10

11

mA

18

19

A

B

30

21

22

23

I/O Board NXOPTAA Additional control inputs and

outputs are provided by the NXOPTAA I/O board (3 x

digital inputs, 1 x digital relay output, and 1 x digital

open collector output). It is fitted as standard to the

Ecodrives and can be fitted as an optional extra to the

Microdrives.

Terminals for I/O card NXOPTAA

123 456

24 25 26

slanimretlortnoctuptuOdnatupnILXN

lanimreTlangiStnemmoC

1ferV01+egatlovecnerefeRAm01tnerrucmumixaM

2ro+1IA

4NID

3-1IA/DNGnommoctupnieugolanA;dnuorgotdetcennoctonfitupnilaitnereffiD

4+2IAtnerruc,tupnieugolanA)mho052=iR(Am02ot0

5-2IA/DNGnommoctupnieugolanA;dnuorgotdetcenno

6tuoV42egatlovyrailixuaV42Am001tnerrucmumix

7DNGdnuorgO/IslortnocdnaecnereferrofdnuorG

81NID1tupnilatigiD).nim(mhok5=iR

92NID2tupnilatigiD

013NID3tupni

11DNGdnuorgO/IslortnocdnaecnereferrofdnuorG

81+1OA)tuptuo+(langiseugolanALR,Am02ot)4(0tnerruC:egnarla

91-1OAnommoctuptuoeugolanA

A584SRsublaireSrotsisernoitanimreT

B584

SRsublaireSrotsisernoitanimreT

121/1ORCN1tuptuoyaleRcdV521,caV052egatlovgnihctiwsmumixaM

222/1ORMOC1tuptuoyaleR

323/1ORON1tuptuoyaleR

03V42+egatlovtupnixuAV42pukcabylppusrewoplortnoC

lanimreTretemaraPtnemmoC

3X

1V42+ ,ctesehctiwsrofegatlov;tuptuoegatl

2DNG ODdnaV42+rofg.e,slortnocrofdnuorG

31NID1.x:NIGID1tupnilatigiD

42NID2.x:NIGID2tupnilatigi

53NID3.x:NIGID3tupnilatigiD

61OD1.x:TUOIDV84/Am05,tuptuorotcellocnepO

5X

42CN/1OR2.x:TUOID1tuptuoyaleR

52C/1OR

62ON/1OR

tnerruc

latigiD

roegatlov,tupnieugolanA

ademmargorpebnac

nereffidV02±swollA

am,%01±

ngistuptuO

hctiwsmumixaM

dnuorgO/Iehtmorf

slanimretstuptuOdnatupnIrednapxEAATPOXN

ovlortnoC

Am051.xam

D

A4.0/cdV521

iR(Am02ot0ro)mhok002=iR(cdV01ot0

4NIDs

ctonfitupnilaitnereffiD

cdV521/A4.0,caV052/A8

Am01/V5daolgnihctiws.niM

,A8/cdV42yticapacgnihctiwS

4Xkcolbrepmujhtiwnoitceles)mho052=

DNGotegatlovedomlait

DNGotegatlovedomlaitnereffidV02±swollA

mhok1>LR,V01ot0egatloVromho005xam

,cdV42/A8tnerrucgni

detalosiyllacinavlageraslanimrettuptuoyaleR

,A8/caV052

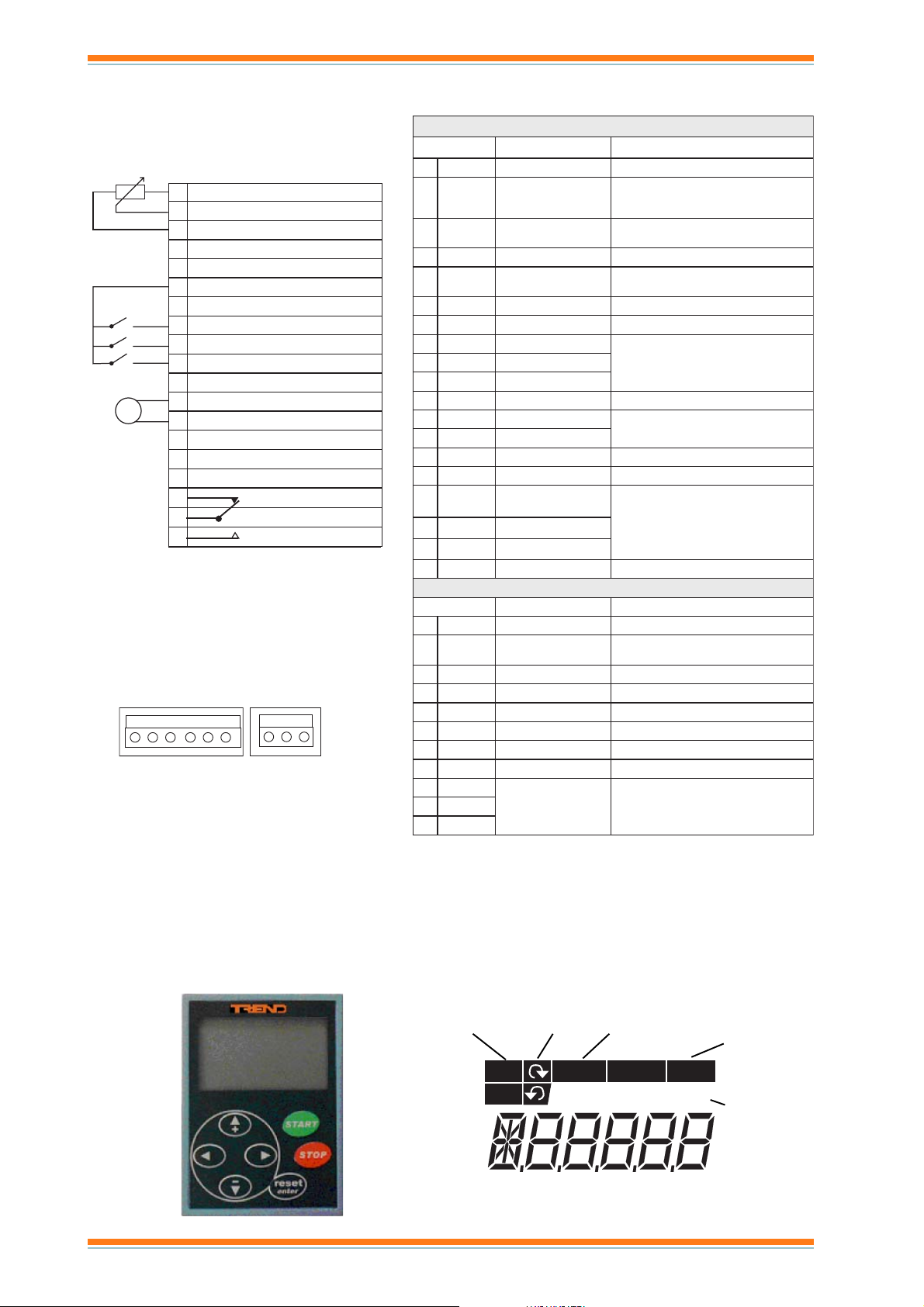

Control Keypad: The control keypad is used for parameter

setting, reading status data, and giving control commands. It is

detachable and can be operated externally being connected via

a cable to the frequency converter. A PC can be connected and

used to control the frequency converter instead of the control

keypad. (A 1.5 m, 9 way D type male to female extension cable

is available, ACC/NXL/RS232PC. A door mounting kit including a

2m cable is available, NXLDRA.)

4

The Trend NXL control keypad features a seven-segment display

with seven indicators for the Run status (RUN, READY, STOP,

ALARM, FAULT) and three indicators for the control place

(I/O term/ Keypad/BusComm). The control information, i.e. the

number of menu, the displayed value and the numeric information

are presented with numeric symbols.

The frequency converter is operable through the seven

push-buttons of the control keypad. Furthermore, the buttons

serve the purposes of parameter setting and value monitoring.

run status drive stopped

rotation power on, not tripped

due to fault

RUN

STOP

READY ALARM FAULT

I/O term Keypad Bus/Comm

control signal

value

mA V s % kHz °C °F rpm kWh

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Page 5

Data Sheet NXL

HARDWARE (continued)

The keypad has seven buttons which are used for controlling

the drive, setting parameters, and monitoring values.

nottuBesU

teserstluafevitcasteser

retne)sces3ot2rofdloh(yrotsihtluafteserronoitcelesmrifnoc

+puseulavtide,un

empuesworb

-nwodseulavtide,unemnwodesworb

tfeltidetixe,tfel,unemnidrawkcabevom

thgirtideretne,thgir,unemnid

rawrofevom

tratsecruoslortnocsidapyekfirotomstrats

potsecruoslortnocsidapyekfirotomspots

The Keypad can be made the control source at any time by pressing

the left arrow button for 5 secs. The keypad may then be used to

start and stop the motor and to ramp its speed up and down by

increasing or decreasing the output frequency shown on the

display using the up and down keys. Pressing the left hand arrow

button again for 5 secs will return the drive to remote control.

Note that the motor is stopped as the control changes from

remote to local and vice versa.

The main menu consists of individual items M1 to E7 which are

browsed using up and down buttons, the submenus under these

menus are then browsed by left/right buttons.

M1 Monitoring: This enables the following signals to be

monitored only.

edoCemaNlangiSstinUnoitpircseD

1.1VycneuqerftuptuOzHrotomehtotycneuqerF

2.1VecnereferycneuqerFzH

3.1VdeepsrotoMmprd

4.1VtnerrucrotoMAtnerrucrotomderusaeM

5.1VeuqrotrotoM% tinuehtfoeuqrotlanimon/euqrotdetalu

6.1VrewoprotoM% tinuehtforewoplanimon/rewopdetaluclaC

7.1VegatlovrotoMVegatlovrotomdetaluclaC

il-CDVegatlovknil-CDderusaeM

8.1Vegatlovkn

9.1VerutarepmettinUC°erutarepmetknistaeH

01.1V1tupnieugolana/egatloVV1IA

11.1V2tupni

21.1VtnerructuptuoeugolanAAm1OA

31.1V

41.1V

51.1V3NID,2NID,1NIDsesutatstupnilatigiD

61.1V3EID,2EID,1EID sesutatstupnil

71.1V1ORsutats1tuptuoyaleR

81.1V3EOR,2EOR,1EOR sesutatstuptuoyaleR:draob.pxeO/I

V1EOD sutats1tuptuolatigiD:draob.pxeO/I

91.1

02.1VecnereferDIP% ecnereferssecorpmumixamehtfotnecrepnI

12.1Veulavlau

22.1VeulavrorreDIP% eulavrorremumixamehtfotnecrepnI

32.1VtuptuoDIP% eulav

42.1V3,2,1stuptuoegnahcotuAlortnocnafdnapmupniylnodesU

eugolana/tnerruCAm2IA

,1tnerructuptuoeugolanA

draobrednapxe

ructuptuoeugolanA

,2tner

draobrednapxe

tcaDIP% eulavlautcamumixamehtfotnecrepnI

claC

Am

Am

eepsrotomdetaluclaC

atigiD:draobrednapxeO/I

tuptuomumixamehtfotnecrepnI

P2 Parameters: This enables the parameters to be edited. First

the group of parameters is selected, then the individual

parameter. The parameters below are for the basic group (P2.1),

other groups are used and are described in the NXL Application

Manual :

edoCretemaraPtluafeDetoN

1.1.2Pycneuqerf.niMzH00.0

2.1.2Pycneuqerf.xaMzH00.05

3.1.2PemitnoitareleccAs0.1

4.1.2Pemit

5.1.2PtimiltnerruCAlanimoNx5.1

6.1.2PegatlovrotomlanimoNV004

7.1.2PycneuqerfrotomlanimoNzH00.

8.1.2PdeepsrotomlanimoNmpr0441

9.1.2PtnerrucrotomlanimoN

01.1.2PihpsocrotoM58.0

11.1.2PnoitcnuftratS0

21.1.2PnoitcnufpotS0

31.1.2Pnoitasim

41.1.2PecnereferO/I0

51.1.2Pegnarlangis

61.2PnoitcnuftuptuoeugolanA1

71.1.2Pnoitcnuf2NID1

81.1.2Pnoitcnuf3NID6

1.1.2P1deepsteserPzH00.01

9

02.1.2P2deepsteserPzH00.05

12.1.2PtratsercitamotuA0

22.1.2Plaecnocrete

noitarelecceDs0.1

05

itpof/U0

1IA=0

2IA=1

2IA2

qerF=2

)deeps

)euqrot

)rewop

1

xE=3

desU=1

maraP1

pmaR=0

atsgniylF=1

tr

gnitsaoC=1

pmaR=1

desuton=0

dapyeK=2

subdleiF=3

desuton=0

)tnerrucrotom

rotoM=5

)egatlovrotom

nil-CD=8

desuton=0

luppotS=3

elbanenuR=6

PelbasiD=9

)ecnerefer

1kcolretnI=01

desuton=0

esreveR=1

tesertluaF=4

elbanenuR=5

rotoM=01

)ecnerefer

2kcolretnI=31

desutoN=0

tsaocelbanenuR+pmaR=2

pmarelbanenuR+tsaoC=3

tsoobeuqrotcitamotuA=1

Am02otAm0=1

Am02otAm4=2

)xamfot0(.qerftuptuO=1

)xamfot0(ecnerefer.

lanimonot0(tnerructuptuO=4

lanimonot0(egatlovrotoM=7

)V0001ot0(tlovk

eulavferrellortnocIP=9

eulavlautcarellortnocIP=01

eulavrorrerellortnocIP=11

tuptuorellortnooIP=2

esreveRtratS=1

)drawroftratS=1NID(

)tratS=1NID(esreveR=2

cc,tluaflanretxE=4

co,tluaflanretxE=5

2deepsteserP=7

cc,tluaflanretxE=2

co,tluaflanret

1deepsteserP=6

2deepsteserP=7

)esluptratS=1NID(es

)cc(PU.toprotoM=8

.qerftceriD(DI

dnammocgnikarb-CD=8

)cc(PUtoprotoM=9

)cc(NWODtop

.qerftceriD(DIPelbasiD=11

noitceles2.ferdapyeKDIP=21

tupnirotsimrehT=41

elbisivsretemarapllA=0

elbisiv1.2PpuorgylnO=1

rotomlanimonot0(deepsrotoM=3

rotomlanimonot0(euqrot

rotomlanimonot0(rewoprotoM=6

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

5

Page 6

NX L Data Sheet

HARDWARE (continued)

K3 Keypad Control: This enables changes to control source (I/O terminals, Keypad, or Bus/Comm), frequency reference, and

motor direction of rotation.

edoCretemaraPtluafeDetoN

1.3PecruoslortnoC1

2.3PycneuqerfecnereferdapyeKzHlortn

3.3PnoitceriddapyeK0 lortnocdapyekfinoitceridesreverlliw1

4.3PnottubpotS1

5.3RecnereferDIP0

6.3R2ecnereferDIP0 stupnilatigidhtiwdetceleS

F4 Active Faults: A critical fault which brought the drive to a halt will be displayed, and the history of up to 5 active faults can

be browsed through. For each fault there are sub menu items recording day, time, and motor conditions at the time of the fault.

H5 Fault History: The fault history of up to 5 faults with submenus as for active faults.

S6 System: This enables the following system settings to be changed and monitored:

edoCretemaraPunem-buSretemaraPnoitpircseD

3.6SsretemarapypoC1.3.6PstesretemaraP retemaraperotserrostesretemara

5.6SytiruceS2.5.6PkcolretemaraPsretemaraptsniaga'dekcol'teS

6.6SsgnittesdapyeK1.6.6Peg

.6PemittuoemiTnwohssiegaptluafederofebtuoemiT

3.6

7.6SsgnitteserawdraH1.7.6ProtsiserekarblanretnI

2.7.6PlortnocnaF3dna2sezisemarfnosuounitnoC=0

3.7.6Pt

4.7.6SseirterforebmunIMH

8.6SnoitamrofnImetsyS

1.8.6SuneMsretnuoC1.1.8.6PretnuochwM e

2.1.8.6PretnuocsyadgnitarepO

3.1.8.6Pretnuo

2.8.6SsretnuoCpirT1.2.8.6PretnuocpirthWM

2.2.8.6PretnuocpirthWMraelC

3.2.8.6Pretnuocpirtsyadg

4.2.8.6PretnuocpirtsruohgnitarepO

5.2.8.6PretnuocemitgnitareporaelC

3.8.6SofnIerawtfoS1.3.8.6Pegakca

2.3.8.6PnoisrevWSmetsyS

3.3.8.6PecafretnierawmriF

4.3.8.6PdaolmetsyS

4.8.6SofninoitacilppA1.1.4.8.6Pd

2.1.4.8.6PnoisrevnoitacilppA

3.1.4.8.6PecafretnierawmriF

5.8.6SofnierawraH2.5.8.6PegatlovtinU

.8.6PreppohcekarB

3.5

6.8.6SsnoitpO1.6.8.6PtpoXNnoisrevemmargorpdnasutatS

9.6SedomIA1.9.6Pedom1AIAtupnitnerruc=1,tup

2.9.6Pedom2AIAtupnitnerruc=1,tupniegatlov=0

01.6SsretemarapsubdleiF1.01.6PsutatsnoitacinummoC

1.6PlocotorpsubdleiF

2.0

3.01.6PsserddaevalS

4.01.6PetarduaB

5.01.6PstibpotS

6.01.6PepytytiraP

7.01.6Ptuoemitnoitaci

aptluafeD emittuoemitnehwdapyeknodeyalpsidegaptluafeD

noitcennoc

nitarepO

perawtfoS

inoitacilppA

nummoC

slanimretO/I=1

dapyeK=2

subdleiF=3

ocdapyekfI

tubpots=0

delbanesyawlanottubpots=1

)egap

uoemittnemegdelwonkcaIMH

csruohgnitarepO

lortnocdapyekfidelbanenot

stluafed

powtdaolroerotS

tsal=0(dapyekotnodehctiwssirewoproseripxe

sezisemarfnoelbaliavatoN

6ot3

5,4sezisemarfnoerutarepmeT=1

.elbatteser;tinuLXN

niegatlov=0

htrofdessapsruohdnasyaddna,hWMfotnuoclatoT

E7 Expander Board: This enables the user to see whether the expander board is connected to the control board, and to monitor

and edit parameters associated with the board.

6

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Page 7

Data Sheet NXL

FIRMWARE

Applications

The Multicontrol Application for Vacon NXL uses direct frequency

reference from the analogue input 1 as a default. However, a PID

controller can be used e.g. in pump and fan applications, which

offers versatile internal measuring and adjusting functions. This

means that external devices are not necessary. When the drive

is commissioned, the only visible parameter group is B2.1 (Basic

parameters). The special parameters can be browsed and edited

after changing the value of par. 2.1.22 (Parameter conceal).

The direct frequency reference can be used for the control

without the PID controller and it can be selected from the analogue

inputs, fieldbus, keypad, preset speeds or motor potentiometer.

The PID controller reference can be selected from the analogue

inputs, fieldbus, PID keypad reference 1 or by enabling the PID

keypad reference 2 via digital input. The PID controller actual

value can be selected from the analogue inputs, fieldbus or the

actual values of the motor. PID controller can also be used when

the frequency converter is controlled via fieldbus or the control

keypad.

· Digital inputs DIN2, DIN3, (DIN4) and optional dig. inputs DIE1,

DIE2, DIE3 are freely programmable.

· Internal and optional digital/relay and analogue outputs are

freely programmable.

· Analogue input 1 can be programmed as current input, voltage

input or digital input DIN

Additional functions:

· The PID controller can additionally be used from control places

I/O, keypad and fieldbus

· Sleep function

· Actual value supervision function: fully programmable; off,

warning, fault

· Programmable Start/Stop and Reverse signal logic

· Reference scaling

· 2 Preset speeds

· Analogue input range selection, signal scaling, inversion and

filtering

· Frequency limit supervision

· Programmable start and stop functions

· DC-brake at start and stop

· Prohibit frequency area

· Programmable U/f curve and U/f optimisation

· Adjustable switching frequency

· Autorestart function after fault

· Protections and supervisions (all fully programmable; off,

warning, fault):

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

7

Page 8

NX L Data Sheet

SOFTWARE

Windows based PC utility tools are available for making the use

of the Trend NXL as easy and convenient as possible. The

software is intended for tasks such as commissioning, loading

of various applications, and block programming. The built-in Help

is available in all software. The minimum requirement for using

the software is a PC and the ACC/NXL/RS232PC serial cable, to

be connected to the RS232C terminal behind the control panel.

A standard RS232 cable should not be used.

NCDrive: NCDrive is an easy-to-use commissioning software

for the control of the NXL. NCDrive allows you to load parameters

from the drive, change them, save them in a file or load them back

to the drive, print the parameters on paper or to a file, set

references, start and stop the motor, monitor signals on a graphical

display and to monitor the actual values. You can also compare

sets of drive parameters in order to identify changed values.

In the PARAMETER window you can view, set and store

parameters as well as compare them to user-stored or default

values so that changed values are easily identified.

In the MONITOR window you can monitor a total of eight freely

user-specified variables simultaneously.

NCDrive requires a PC equipped with a Pentium II processor, 32

MB free RAM, 10 MB free disk space and Windows 95/98 or

2000.

NCLoad: This is a tool for loading the following software to the

drive:

a) system software (the operating system)

b) application software

c) option card software

NCLoad is mainly intended for use by variable speed drive

professionals and service personnel. In addition to the system

software, NCLoad is also suitable for loading custom-made

applications to the drive. The minimum hardware requirements

are those of NCDrive.

NC1131-3: A graphical design tool for custom applications using

block diagrams, ladder logic, or structured text to define the

application

8

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Page 9

Data Sheet NXL

INSTALLATION

The Trend NXL drive must be installed in a vertical position. It can

be mounted on a wall or in an enclosure using four screws or

bolts. The cooling method for NXL00015, NXL00025, and

NXL0002C1 is convection type. Forced air cooling is used for

NXL0003C1 to NXL0006C1 and NXLAA03 (C2 or C5) to

NXLAA061(C2 or C5). The cooling airflow to the drive must not

be blocked in any way, recirculation of air inside the enclosure

should be avoided.

Enough free space should be left above and below the frequency

converter to ensure sufficient circulation and cooling.The

following table gives the required clearance dimensions.

emarFepyT)mm(A)mm(B)mm(C)mm(D

2FM1C2000LXN,52000LXN,51000LXN010100105

3FM1C6000LXNot1C3000LXN010100105

4FM

30AALXN

5FM

6FM

ALXN

2C21AALXNot2C

5C21AALXNot5C30AALXN

2C13AALXNot2C61AALXN

5C13AALXNot5C61AALXN

2C16AALXNot2C83A

5C16AALXNot5C83AALXN

020200105

020202106

030206108

C

B

AA

D

B

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

9

Page 10

NX L Data Sheet

INSTALLATION (continued)

Overload protection of the supply cable should be considered (e.g. fuses). The use of shielded motor cables is recommended; they

should be routed as far away from other cables as possible, and cross other cables at right angles. The motor cable shield should

be grounded at both the NXL drive and at the motor.

The installation involves:

mount the controller in position

connect mains cable

connect motor cable

check mains and motor cable insulation

connect control cable

check quality and quantity of cooling air

check inside of drive for condensation

set up links on basic board

check all start/stop switches connected to I/O are at stop

switch on power to drive

configure the drive (e.g. using the keypad)

perform run test without motor

commission with motor connected

This installation procedure, is covered by the Trend NXL Installation Instructions, TG200620, and NXL Ecodrives Quick Guide

TG200975.

CONNECTIONS

Power Connections

L1 L2 L3

External RFI filter

(MF2 Option)

PE

L1 L2 L3

U/T1 V/T2 W/T3

motor connection

3 phase mains supply

External RFI filter

(MF2 or MF3 Option)

PE

L1 L2

single phase mains supply

DISPOSAL

NXL

RS232

(connection to keypad or PC)

*cable ACC/NXL/RS232PC

(B+) (R-)

BR+ BR-

9 Way D type male

9 Way D type Female

* a standard RS232 cable must not be used

Brake

resistor

(not MF2)

M3

3~

Control Connections

Connect according to application

e.g connections to IQ Controller for Multicontrol

application

Analogue Output

0 to 10V

Digital

DO NO

Output

DO COM

Digital

Input

IQ Controller

AO SIG

Speed

AO 0V

On/off

Fault

DI SIG

DI COM

2 AIA1+

3 AIA1-

8 DIN1

6 +24V

23 RO1 NO

22 RO1 COM

NXL Drive

10

WEEE Directive :

At the end of their useful life the packaging and

product should be disposed of by a suitable

recycling centre.

Do not dispose of with normal household waste.

Do not burn.

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Page 11

Data Sheet NXL

ORDER CODES

Microdrives (Three phase 380 to 500 Vac to three phase)

NXL00015 Rated load overload IL = 1.9 A, IP20, frame size MF2

NXL00025 Rated load overload IL = 2.4 A, IP20, frame size MF2

These units have no EMC emissions protection and no internal brake chopper. An external filter is available (see below).

Ecodrives (Three phase 380 to 520 Vac to three phase)

NXL [current] [IP]

[current]

[current]

]PI[

2C12PI

5C45PI

e.g. NXLAA16C2 Rated load overload IL = 16 A, IP21, frame size MF5

These units have an internal RF1 filter and internal brake chopper. The additional I/O board, NXOPTAA, is fitted as standard.

Microdrives (Single phase 208 to 240 Vac to three phase)

NXL0002C1 Rated load overload IL = 2.4 A, IP20, frame size MF2

NXL0003C1 Rated load overload IL = 3.7 A, IP20, frame size MF3

NXL0004C1 Rated load overload IL = 4.8 A, IP20, frame size MF3

NXL0006C1 Rated load overload IL = 6.6 A, IP20, frame size MF3

These units have no EMC emissions protection and no internal brake chopper. An external filter is available (see below).

AA03 3.3 MF4

AA04 4.3 MF4

AA05 5.6 MF4

AA07 7.6 MF4

AA09 9 MF4

AA12 12 MF4

AA16 16 MF5

AA23 23 MF5

AA31 31 MF5

AA38 38 MF6

AA45 46 MF6

AA61 61 MF6

Rated

Rated

Overload I

Frame Size

L

Note that neither the NXNI, IQ system current loop Lan interface, or the NXIP, the Ethernet network interface are compatible with

the NXL range of Variable Speed Drives (they are compatible with the NX range).

ACC/NXL/FILTER/FR2-3 :Filter for frame sizes MF2 or MF3

ACC/NXL/MF2DIN :Kit to mount NXL frame size MF2 on DIN rail.

ACC/NXL/RS232PC :NXL to PC cable (also requires use of RS232 adaptor below)

ACC/RS232/ADAPTOR :NXL RS232 adaptor for use with NXL to PC cable

NXLDRA :Door mounting kit for control keypad including 2 m cable

NXOPTAA :I/O expander card with 3x Digital Input, 1x Digital Output (open collector) and 1x Digital Output

Additionally software tools are available:

NCDrive: Commissioning software tool

NCLoad: Tool for loading software to drive

NC1131-3: Tool for creating customised applications

(changeover relay). Fitted as standard to the Ecodrives and available as an optional extra for the

Microdrives

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

11

Page 12

NX L Data Sheet

SPECIFICATIONS

Electrical

Supply voltage

Three phase units :380 to 500 Vac -15% +10% 3 phase, 45

to 66 Hz

Single phase units :208 to 240 Vac -15% +10% 1 phase, 45

to 66 Hz

Motor voltage :0 to supply voltage

Motor current

Rated output :IL, 1.9 A to 61 A dependent on option

(continuous current under low overload,

10% for 1 minute every 10 minutes, 150%

starting torque requirement, 40 °C

ambient temperature e.g. fans, pumps)

High overload :IH, see table (continuous current under

high overload, 50% for 1 minute every

10 minutes, 200% starting torque

requirement, 50 °C ambient temperature

e.g. cranes, hoists, lifts)

Starting Current :2xIH, (maximum current required for 2 secs

every 20 secs if output frequency <30 Hz,

and heat sink temperature <+60 °C )

Output frequency :0 to 320 Hz

Frequency resolution :0.01 Hz

Control method :Frequency control, Open loop

sensorless vector control

Switching frequency :1 to 16 kHz (factory default 6 kHz)

Frequency reference

Analogue input :Resolution 0.1% (10 bit), accuracy ±1%

Keypad reference :Resolution 0.01 Hz

Field weakening point :30 to 320 Hz

Environmental

Operating Temperature:-10 °C (no frost) to +50 °C: (IH)

-10 °C (no frost) to +40 °C: (IL)

Storage temperature :-40 °C to +70 °C

Relative humidity :0 to 95 %RH non-condensing,

non-corrosive, no dripping water

Air quality

chemical vapours :IEC721-3-3, unit in operation class 3C2

mechanical particles :IEC721-3-3, unit in operation

class 3S2

Altitude 100% load capacity (no derating) up to

1000 m. 1% derating for each 100 m

above 1000 m (max. 3000 m)

Vibration :EN50178 and EN60068-2-6

Shock :EN50178 IEC 68-2-27. UPS drop test

(for applicable UPS weights)

Enclosure class :IP20, IP21, IP54 (see codes p9)

EMC Immunity :EN50082-1, -2, EN61800-3

EMC Emissions

MF2, MF3 :EMC level N. Can have external filter to

achieve level H.

MF4 to MF6 :EMC level H:EN61800-3(1996) + A11

(2000) (1st environment, restricted use,

2nd environment), EN61000-4.

Safety :Fulfils EN50178, EN60204-1, CE, UL,

cUL, FI, GOST R , IEC 61800-5 (check

nameplate for details)

Acceleration time :0.1 to 3000 secs

Deceleration time :0.1 to 3000 secs

Braking torque

DC brake :30% TN (nominal torque)

Protective Functions

without brake option

Overcurrent :Trip limit 4.0 x IH instantaneously

Overvoltage protection :911 Vdc

Undervoltage protection:333 Vdc

Earth fault protection :In case of earth fault in motor or

motor cable, only the frequency

converter is protected

Other :Unit overtemperature

protection, motor overload

protection, motor stall

protection, motor underload

protection, short circuit

protection of +24 V and +10 V

reference voltages

Inputs and Outputs

Analogue voltage input:0 to +10 V, Rin = 200 kΩ, single

ended. Resolution 12 bit,

accuracy ±1%

Analogue current input :0 (4) to 20 mA, Rin= 250 Ω,

differential

Digital inputs :3 off (Ecodrives have 6).

Positive or negative logic, 18 to

24 Vdc

Auxiliary voltage out :+24 V ±15 %, 100 mA max.

Reference voltage out :+10 V, +3% 10 mA max.

Analogue output :1 off. 0(4) to 20 mA, RL <500Ω,

resolution 16 bit, accuracy

±1 %

Digital Output (relay) :1 off (Ecodrives have 2).

Programmable changeover

relay max. switching capacity:

24 Vdc/8 A, 250 Vac/8 A, 125

Vdc/0.4 A.

Digital Output (open collector) :1 off (Ecodrives only).

50 mA, 48 V

redrO

edoC

51000LXN9.11.23.12 55.073.00.1

52000LXN4.26.29.19.257.055.00.1

5C/2C30AALXN3.36.32.23.31.157

5C/2C40AAXN3.47.43.35 5.11.15

5C/2C50AALXN6.59.53.45.62.25.15

5C/2C70AALXN6.74.86.54.80.32.25

5C/2C90AALXN99.96.74.110.40.35

5C/2C21

AALXN212.319 5.315.50.45

5C/2C61AALXN616.7121815.75.51.8

5C/2C32AALXN323.526142115.71.8

5C/2C13AALXN1343325351111.8

5C/2C83AALXN832413745.8

5C/2C54AALXN64158375225.815.81

5C/2C16AALXN1676649603225.81

1C2000LXN4.26.27.16.273.052.00.1

1C3000LXN7.31.48.22.

1C4000LXN8.43.57.36.51.157.09.1

1C6000LXN6.63.78.42.75.12,10.2

ytilibadaoL rewoPtfahSrotoM

woLhgiHcaV083

detaR

)A(

%01

suounitnoC

ItnerruC

tnerruc

L

)A(

detaR

daolrevo

)A(

%05

suounitnoC

ItnerruC

H

)A(

457.055.09.1

woL

daolrevO

ItnerruC

S

1515.81

)Wk(P

hgiH

Cged04

)Wk(P

.05

)gk(

Cged05

)Wk(P

caV042ot802

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37,Switzerland by its Authorized Representative, Trend Control Systems Limited.

thgieW

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content

hereof without obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www.trend-controls.com

12

NXL Variable Speed Drives Data Sheet TA200620 Issue 1/G 13/06/07

Loading...

Loading...