Page 1

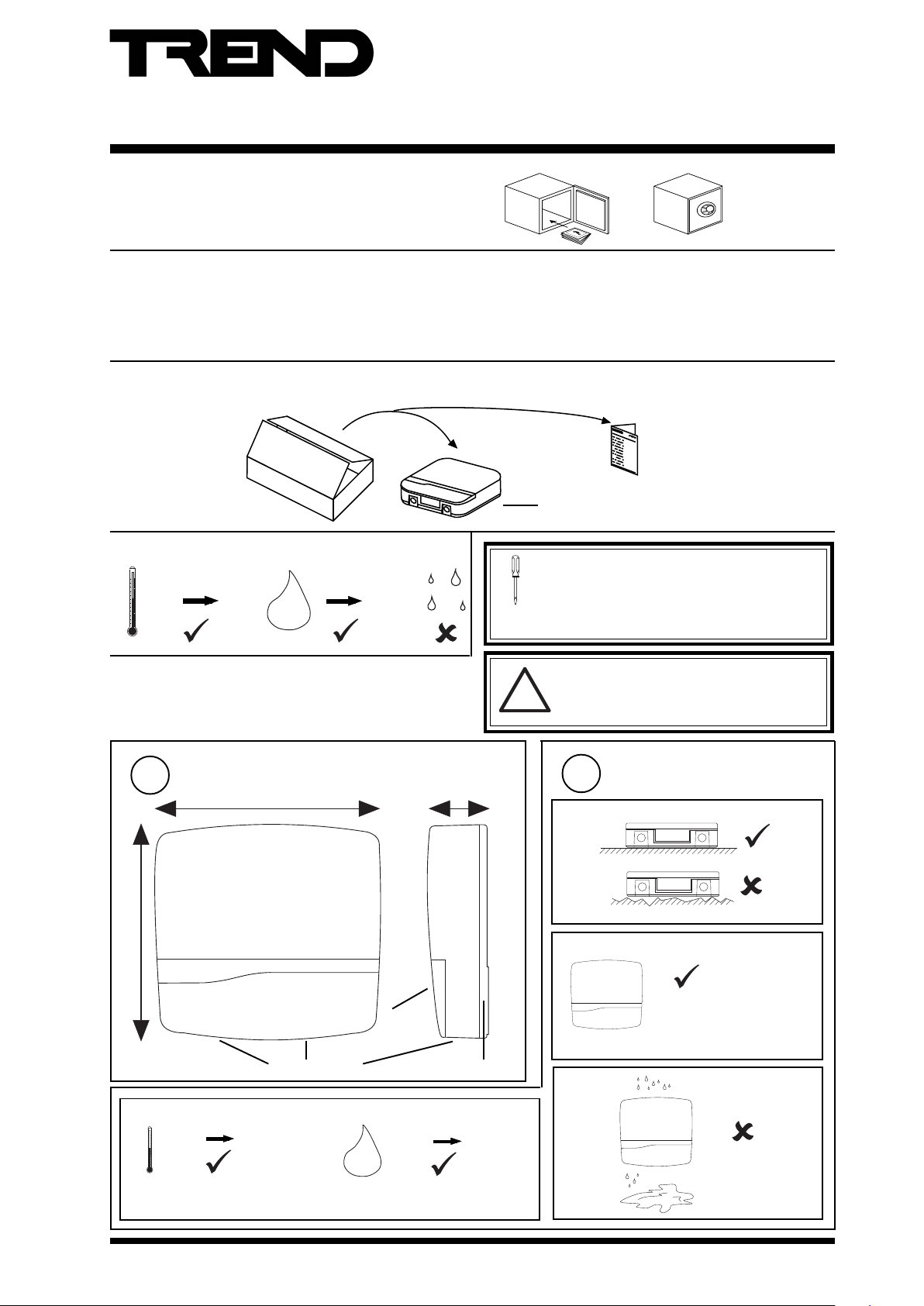

Important: Retain these instructions

Installation Instructions

3xtend/EINC L/24

Node Controller

CONTENTS

1 Installation..................................................................... 1

1.1 Unpacking ..................................................................... 1

1.2 Storing........................................................................... 1

1 INSTALLATION

1.1 UNPACKING

1.2 STORING

-10 °C

(14 °F)

1.3 INSTALLATION - FIXING

+50 °C

(122 °F)

H2O

0

90 %RH

1.3 Installation - Fixing ........................................................ 1

1.4 Installation - Configuration............................................ 6

2 End User Licence Agreement .................................... 14

3 Disposal ...................................................................... 15

3xtend/EINC L/24 Installation

Instructions TG200811

3xtend/EINC L/24 Template TG200813

It is recommended that the installation should

comply with the HSE Memorandum of Guidance

on Electricity at Work Regulations 1989.

For USA install equipment in accordance with

the National Electric Code.

WARNING

Other than removing front covers, do not

!

attempt to open the unit. Failure to comply

may cause damage to the unit.

Dimensions

1

218 mm (8.58")

c

0 °C

(32 °F)

227 mm (8.94")

Bottom cable access

+45 °C

(113 °F)

H2O

60 mm (2.36")

Terminal

access

Rear cable access

0 %RH

Requirements

2

a

b

The unit is UL rated as

'UL916, open energy

management equipment'

d

80 %RH

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 3/9/08

1

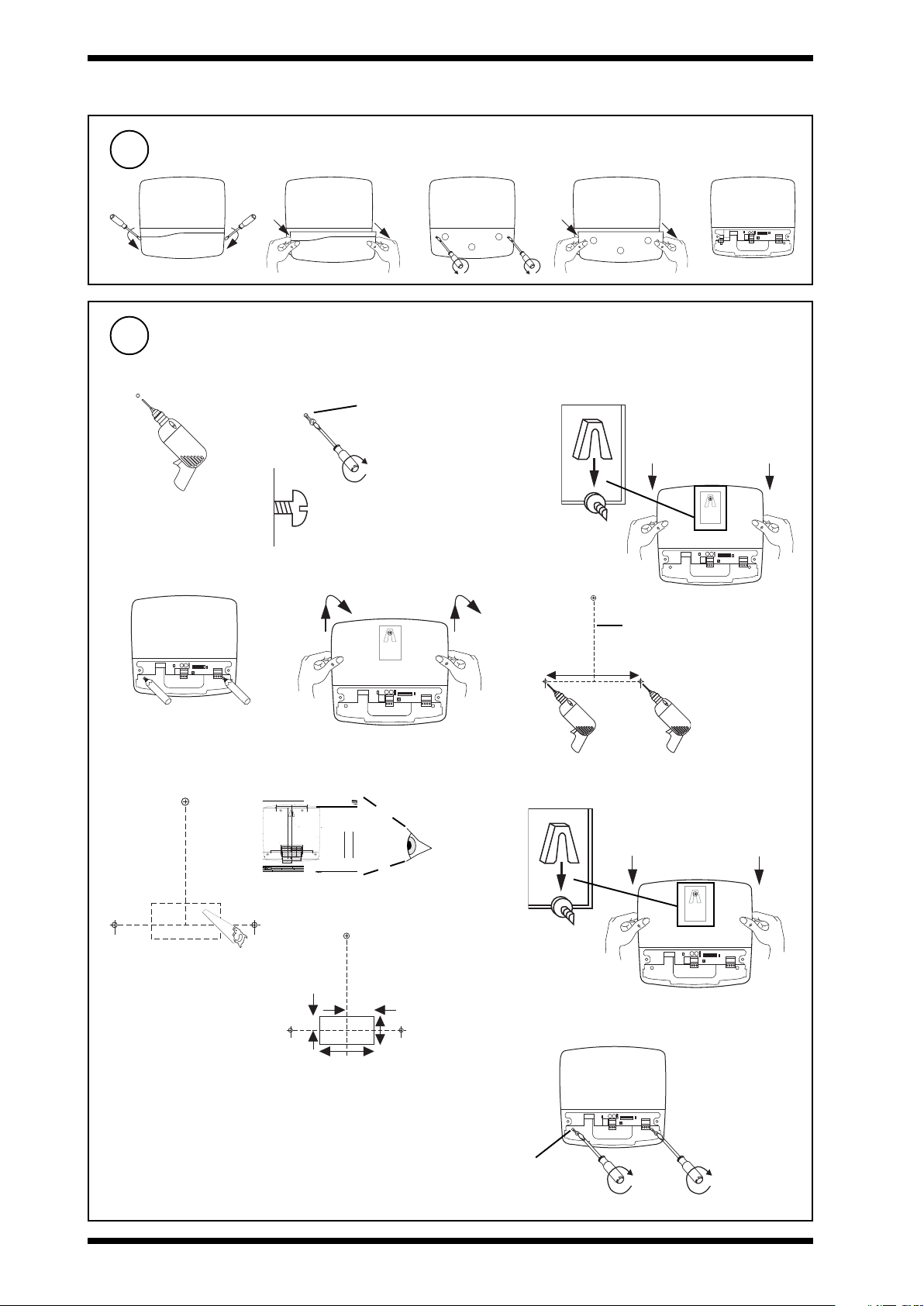

Page 2

3xtend/EINC L/24 Installation Instructions

12345678910

1.3 INSTALLATION - FIXING (Continued)

Remove Covers

3

abcde

12345678910

Mount Unit

4

Either via 3 screw fixing (e.g. for fixing on wall)

ab c

M4, 5, or 6 (pan or CSK)

or No 10 or 12 (CSK)

Rear

view

de

f

Length depends on screw

head projection and screw

type

12345678910

12345678910

170 mm (6.69”)

g Cut rear cable entry hole if required

LERN/24 Installation Instructions - Template

Trend Control Systems Ltd reserves the right to revise this publication from time to time and make changes to the content hereof without

obligation to notify any person of such revisions or changes.

var.com

trendinfo@no

E-mail

Installation Instructions - Template

LERN/24

XXXXXXXXXXXXXXXX

126 mm (4.96”)

88

Novar Hou

A

nternatio

Fax (I

se 24 Queen

B

196 mm (3.78”)

20 mm

(0.78”)

rear cable entry cutout

75 mm (2.95”

37.5 mm (1.48”)

1403 2109

nal) +44 (0)

s Road Weybridge Surrey KT13 9UX Registered in England No 1664519

A 3 hole fixing

A

Screw size 4 off M4 x 16

Hole/drill 5mm

or alternatively

B 3 hole fixing

(Do not use template for 3 hole fixing, see LERN../SM installation instructions, TGxxxxxx sheet 1 step x.)

NOTE: Print to size.

ions below

Check dimens

4"

80 mm (3.15”)

8 mm (0.31”)

)

Website www.trend-controls.com

82

Fax (U

10 cm

40 mm (1.57”)

B

40 mm (1.57”)

A

8

)1403 241 60

K) +44 (0

LERN/24 Installation Instructions TGxxxxxx Issue 1/A dd/mm/yy

1

A

B

170 mm (6.69”)

P.O. Box 34, Horsham, West Sussex, RH12 2YF United Kingdom

0)1403 211 8

one +44 (

Teleph

red office.

Registe

3xtend/EINC L/24 Template TG200813

h

Rear

view

12345678910

40 mm

20 mm

(1.57”)

(0.78”)

80 mm

40 mm

(1.57”)

i

(3.15”)

12345678910

2 x M4, 5, or 6

(No 10 or 12)

2

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

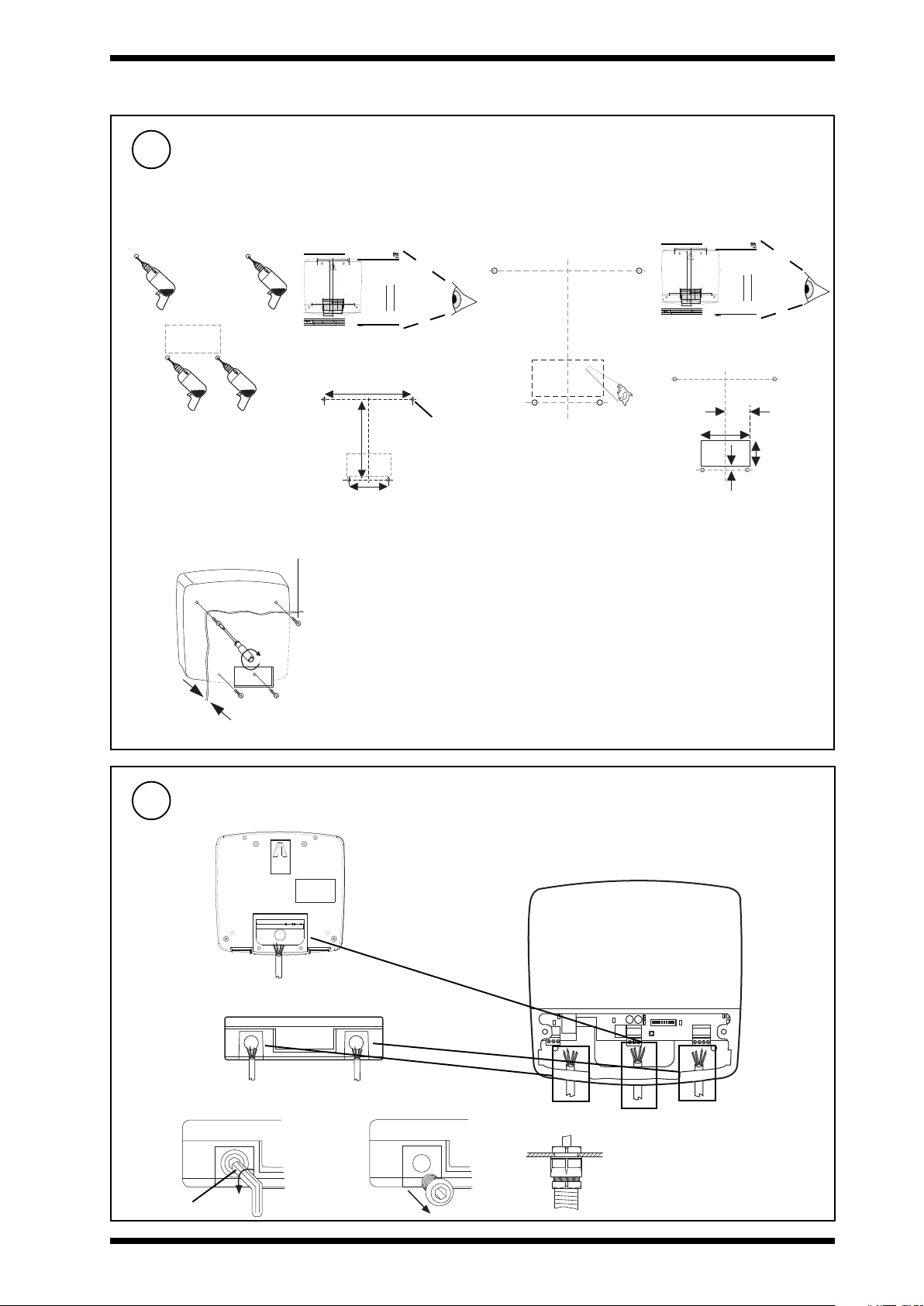

Page 3

Installation Instructions 3xtend/EINC L/24

1.3 INSTALLATION - FIXING (Continued)

Mount Unit (Continued)

4

Or via 4 screw fixing (e.g. fixing on a panel)

Cut rear cable entry hole

a

LERN/24 Installation Instructions - Template

Trend Control Systems Ltd reserves the right to revise this publication from time to time and make changes to the content hereof without

o

bli

gation

to

notify any person of such revisions or changes.

E-mail trendinfo@novar.com

Installation Instructions - Template

LERN/24

XXXXXXXXXXXXXXXX

126 mm (4.96”)

A 3 hole fixing

B

A

A

Screw size 4 off M4 x 16

Hole/drill 5mm

or alternatively

B 3 hole fixing

(Do not use template for 3 hole fixing, see LERN../SM installation instructions, TGxxxxxx sheet 1 step x.)

NO

TE: P

rin

t to size.

Check dimensions below

4"

10 cm

40

mm (1

.57”

)

B

40 mm (1.57”)

A

.trend-controls.com

LERN/24 Installation Instructions TGxxxxxx Issue 1/A dd/mm/yy

1

B

170 mm (6.69”)

A

P.O

. B

ox 34

, Horsham, West Sussex, RH12 2YF United Kingdom

Fax (International) +44 (0)1403 210982

Telephone +44 (0)1403 211 888

Registered office. Novar House 24 Queens Road Weybridge Surrey KT13 9UX Registered in England No 1664519

196 mm (3.78”)

80 mm (3.15”)

20 mm

(0.78”)

rear cable entry cutout

8 mm (0.31”)

75 mm (2.95”)

37.5 mm (1.48”)

Web

sit

e www

Fax (UK) +44 (0)1403 241 608

3xtend/EINC L/24 Template TG200813

126 mm (4.96”)

4 holes Ø 5 mm

(3.78”)

196 mm

75 mm

(2.95”)

b

if required

LERN/24 Installation Instructions - Template

Trend Control Systems Ltd reserves the right to revise this publication from time to time and make changes to the content hereof without

obl

iga

tion

to

notify any person of such revisions or changes.

E-mail trendinfo@novar.com

A

B

170 mm (6.69”)

A

37.5 mm (1.48”)

P.O.

Bo

x 34,

Horsham, West Sussex, RH12 2YF United Kingdom

Fax (International) +44 (0)1403 210982

Telephone +44 (0)1403 211 888

Registered office. Novar House 24 Queens Road Weybridge Surrey KT13 9UX Registered in England No 1664519

Installation Instructions - Template

LERN/24

XXXXXXXXXXXXXXXX

126 mm (4.96”)

A 3 hole fixing

B

A

Screw size 4 off M4 x 16

Hole/drill 5mm

or alternatively

B 3 hole fixing

(Do not use template for 3 hole fixing, see LERN../SM installation instructions, TGxxxxxx sheet 1 step x.)

NOTE: Print to size.

196 mm (3.78”)

80 mm (3.15”)

40

mm

20 mm

(0.78”)

rear cable entry cutout

8 mm (0.31”)

75 mm (2.95”)

Webs

ite

www.t

Fax (UK) +44 (0)1403 241 608

Check dimensions below

4"

10

cm

(1.5

7”)

B

40 mm (1.57”)

A

rend-controls.com

LERN/24 Installation Instructions TGxxxxxx Issue 1/A dd/mm/yy

1

3xtend/EINC L/24 Template TG200813

40 mm (1.57”)

80 mm (3.15”)

40 mm

(1.57”)

8 mm

(0.31”)

c

10 mm

5

4 x M4 x 16 mm

Max

Route Cables

Rear entry

Bottom entry

Fit M20 (¾”) cable

glands

ab

c

8 mm Allen key

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

12345678910

3

Page 4

3xtend/EINC L/24 Installation Instructions

0

I

1.3 INSTALLATION - FIXING (Continued)

Connect Power

28 to 36 Vdc or 24 Vac ±10 %, 50/60 Hz, Consumption <= 8VA

6

12345678910

28 - 36 V

24 V ~

Terminal size 0.14 to

2.5 mm2 (25 to 14

AWG). For UL rated

units use 22 to 14

AWG cable.

24 Vac

~

28 Vdc

CAUTION: Do not apply mains power to

this connector.

24 Vac

+28V 0V

E

E

WARNING: This apparatus must be earthed (via

supply earth/ground terminal).

DO NOT

SWITCH ON

Using a 230V/24 Vac transformer

Some transformers (as in typical plant room

installions) are earthed on one side of the

secondary; therefore care must be taken to

E

ensure that the earthed side of the transformer

24Vac

LN

Using the ACC/24VAC transformer Using the PSR/230/24-2.5 power supply

secondary is connected to the middle terminal

of the power connector. If the polarity of the

connection is incorrect the unit will not power

up. If this happens you should swap the left

most and center connections over and the

unit should power up unless there is another

fault.

Connect Ethernet

7

Connect to an Ethernet hub

Use Ethernet cable.

12345678910

Maximum Cable distance

100 m (109 yds)

Ethernet

24Vac

E

ACC/24VAC

LNE

230 Vac

3xtend/EINC L

100 m (109 yds)

Ethernet hub/switch

E0V+28V

PSR/230/24-2.5

LNE

RJ45 Connector

IQ System

Products

Engineering

Guide TE200369

RJ45 Connector

4

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

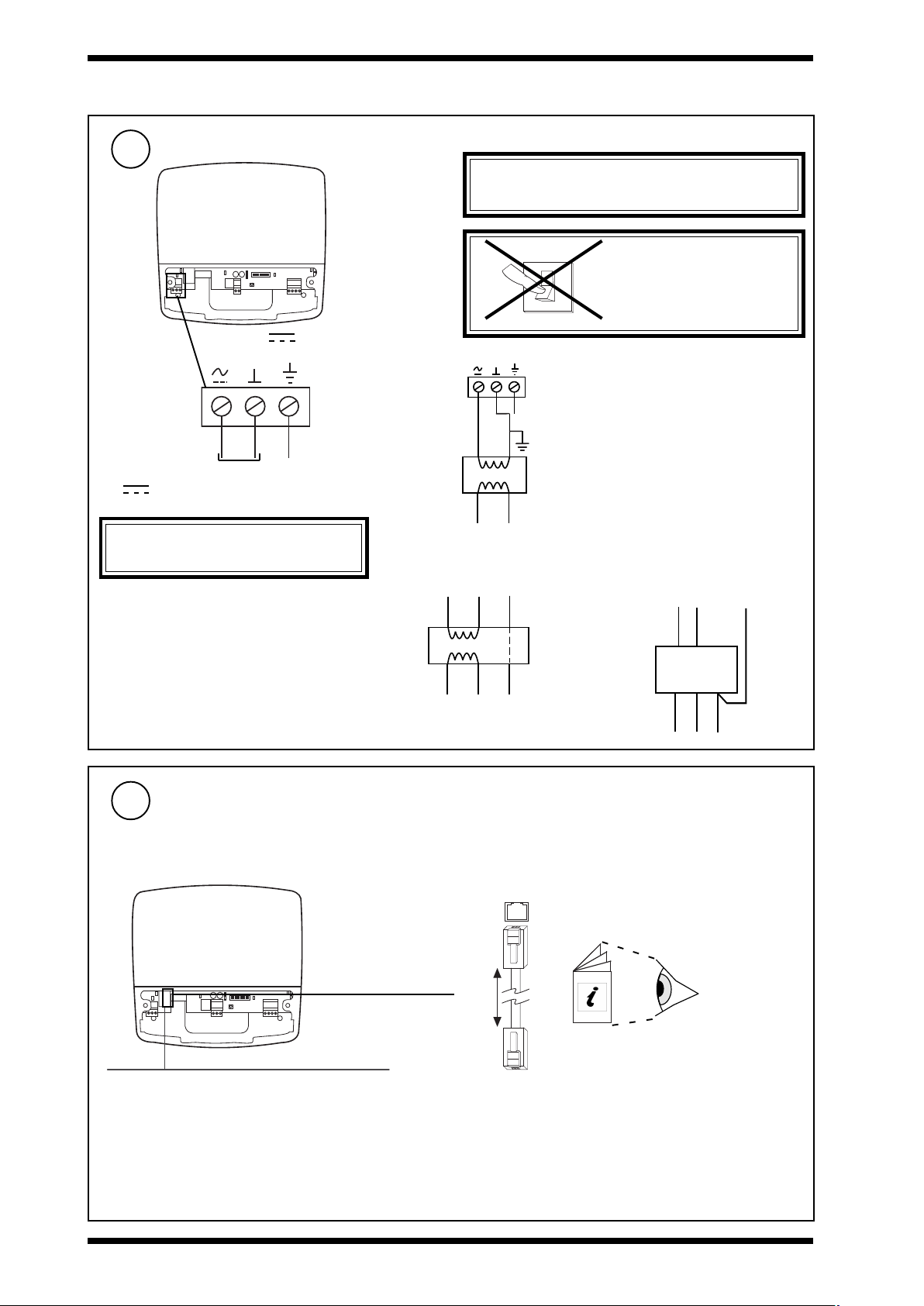

Page 5

Installation Instructions 3xtend/EINC L/24

T R

T R

T R

T R

X

T

T

R

R

1 2 3 4

T- T+ R- R+

X

T

T

R

R

T

T

R

R

+

LON

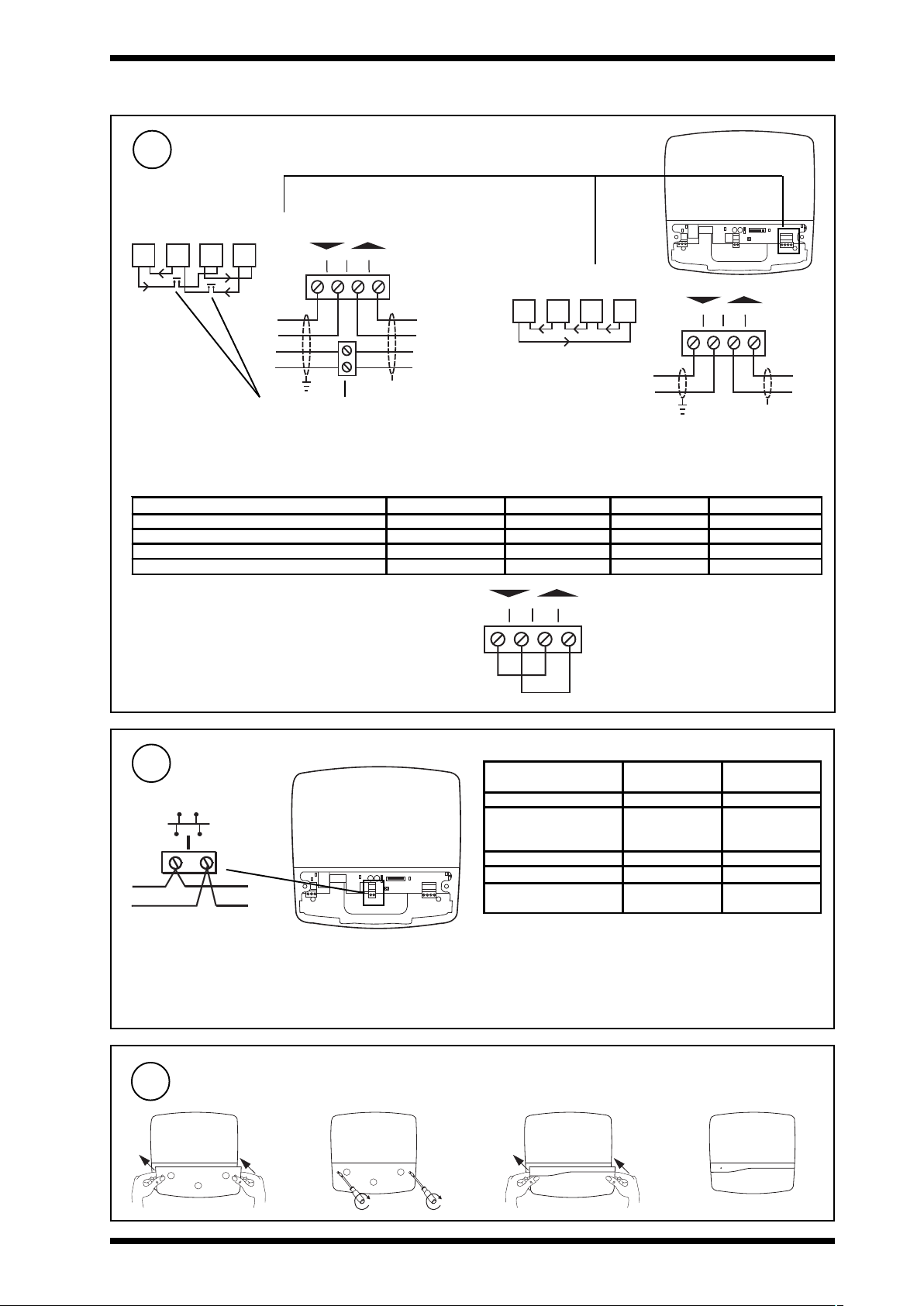

1.3 INSTALLATION - FIXING (Continued)

Connect Current Loop

8

4 wire

T- T+ R- R+

1 2 3 4

Additional terminals

Maximum Cable distance

Belden 9182 1000 m (1090 yds) 700 m (765 yds) 500 m (545 yds) 2

Belden 9207 1000 m (1090 yds) 500 m (545 yds) 350 m (380 yds) 2

IQ System TP/1/1/22/HF/200 (Belden 8761)

IQSystem TP/2/2/22/HF/200 (Belden 8723)

IMPORTANT

If the 3xtend/EINC L’s current loop is not to be connected (i.e

3xtend/EINC L is only to interface between Ethernet and

LONWORKS network) a loop back should be fitted as shown

Cable 9k6 baud 19k2 baud 38k4 baud * No. of Wires

Terminal size 0.14 to 2.5

mm2 (25 to 14 AWG). For UL

rated units use 22 to 14

AWG cable.

700 m (765 yds) 350 m (380 yds) 250 m (270 yds) 2

500 m (545 yds) 250 m (270 yds) 125 m (135 yds) 4

T R

Terminal size 0.14 to 2.5

mm2 (25 to 14 AWG). For UL

rated units use 22 to 14

AWG cable.

Note only 1 INC type node on a single Lan.

T- T+ R- R

1 2 3 4

T R

2 wire

T R T R

12345678910

Connect LONWORKS® Bus

9

1 2

12345678910

Polarity independent

Terminal size 0.14 to 2.5 mm2 (25 to 14 AWG).

For UL rated units use 22 to 14 AWG cable.

Normal current loop Lan cable is not recommended.

Do not use screened cable.

Maximum Cable distance

Recommended

Cables

Belden 85102 500 m (545 yds) 500 m (545 yds)

Trend

TP/1/0/16/HF/200

(Belden 8471)

UL Level IV, 22 AWG 500 m (545 yds) 400 m (430 yds)

JY(St) Y2 x 2 x 0.8 500 m (545 yds) 320 m (350 yds)

TIA568A Cat. 5, 24

AWG

If used with LPT-10 (powered bus), cable lengths differ - see

‘Link Power Transceiver User’s Guide (078-0105-01C)’.

Available from Echelon.

Note that the 3xtend/EINC L is not compatible with LONC.

The LONC must be bound on a LONWORKS network, and the

3xtend/EINC L cannot be bound.

Max bus length

500 m (545 yds) 400 m (430 yds)

450 m (490 yds) 250 m (270 yds)

Max node to

node

Replace Covers

10

ab c d

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

5

Page 6

3xtend/EINC L/24 Installation Instructions

12345678910

O

I

ADDRESS

O

1.4 INSTALLATION - CONFIGURATION

1

Fix Unit

1

Note that this product may involve

LONWORKS system integration. This

procedure should only be performed by

!

an installer with LONWORKS expertise.

Section 1.3

Switch off

2

Remove Covers

3

abcde

12345678910

Set Internetwork Address (Lan number)

4

address

1, 4 to 9, 11 to 119

0, 2, 3, 10 or >119

ON

N

e.g.

Address = 2 + 16 + 64 = 82

If address < 100, INC Mode If address = > 100, Internetwork Extension Mode

Internetwork

(on Ethernet)

Note that only one internetwork device is allowed on a Lan therefore ensure that the 3xtend/EINC L’s LAN number is not

used by another INC type device.

Note that it is recommended that the LONWORKS network is not used where a high level of communication traffic is expected,

e.g. joining internetworks or where there are many IQ System devices on many IQ System Lans being accessed across

an internetwork routed through the LONWORKS network. An alternative topology should be used, such as an Ethernet

internetwork.

6

3xtend/

EINC L

Lan

(on current loop)

Internetwork

(on LONWORKS)

NOT SET

SET

Address = A

Lan

= A

/

Internetwork

(on Ethernet)

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

= A

3xtend/EINC L

Lan

Lan

= A

/

Lan

= A

/

3xtend/

EINC L

Internetwork

(on current loop)

Internetwork

(on LONWORKS)

Page 7

Installation Instructions 3xtend/EINC L/24

O F F F R E E

1.4 INSTALLATION - CONFIGURATION (Continued)

Set Current Loop Baud Rate

5

5

12345678910

NOT SET

Baud Rate = C

SET

=C

38k4 baud

3xtend/EINC L

=C

19k2 baud

9k6 baud

SET LONWORKS Terminator Link

6

*

T e r m in a t o r

12345678910

Lon - FTT (free topology)

*

T e r m in a t o r

=C

=C

Note 1: 38k4 Lan not available with IQ2xx, IQ1xx, INC, LINC,

CNC, CNC2, INC2,and TMN.

Note 2: 38k4 Internetwork not available with INC, and LINC.

O F F F R E E

OFF

No terminator, LONWORKS

bus must be terminated

FREE

Use to terminate LONWORKS

bus at 3xtend/EINC L

elsewhere.

*

T e r m i n a t o r

Star topology Bus topologyLoop topology

Do not allow wires to

cross on a loop

*Terminate LONWORKS bus at one end only

Terminated using IQLRouter’s LONWORKS terminator link

IQL

IQL

IQL

y

z

x

xyzw

IQL

xyzw

xyzw

3xtend/

EINC L

SCN

Recommend terminate at 3xtend/EINC L using LONWORKS terminator link

Otherwise terminate elsewhere using LONTERMINATOR. Terminate

LONWORKS bus at one end only.

Terminator

100 mF, 50 V min

LonA

LonB

IQLROUTER

A

4

3

1

2

IQLROUTER

A

4

3

1

2

B

4

3

1

w

2

Maximum 64 nodes per LONWORKS

network segment.

Maximum 40 IQLs (and LONCs)

per virtual Lan

B

4

3

1

2

Terminated using IQLRouter’s LONWORKS terminator link

100 mF, 50 V min

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

7

Page 8

3xtend/EINC L/24 Installation Instructions

1.4 INSTALLATION - CONFIGURATION (Continued)

Install DHCP Server

7

If the IP address settings (IP address, subnet mask,

default router, and WINs server) are to be supplied by

a DHCP server install one on the same network segment.

8

Read Licence

9

Read and agree to End User

3

Licence Agreement (these

instructions Section 2).

10

The 3xtend/EINC L will attempt to obtain its

IP settings from a DHCP server if one does

not exist it will go into link/local mode.

Check Status LEDs

11

Ethernet OK LED

Power LED

Ethernet Link LED

Normal Operation Indication (shown after 2 minutes)

+ ++

Power LED Ethernet OK LED Lon OK LED Current Loop OK LED

If LEDs are not as above after 2 minutes check table below.

12345678910

Install WINS Server

If host names are to be used for IP addressing

across a router install a WINS server on the system

if one is not already installed.

Switch On

0

I

Lon OK LED

TX LED

RX LED

Current Loop OK LED

Ethernet Data LED

Note that if connecting using a

24Vac transformer and the unit

does not power up check the

polarity of the power connections

(see page 1-4 step (6)).

DELylsuounitnoCgnihsalFylsuounitnoCffO

)eulB(rewoPyhtlaeHtinUyldetaepereciwtgnihsalF

KOtenrehtE

)neerG(

KOnoL

)neerG(

)neerG(

)wolleY(

pooLtnerruC

)neerG(KO

)wolleY(XR=rekcilfthgils,KOtiucricrevieceR

)wolleY(XT.lamron-rekcilfthgilS

kniLtenrehtE

ataDtenrehtE

wtenretninoL:rofsdnoces42yrevetuobagnihsalF

.lamron

.detrohseb

tluafelbaC.deviecergniebataD ebyamelbaC(

KOtliubkro

dnuofecivedtenrehtE.)ytluafelbaC(tluaF ebyamelbaC(

snoitacinummoc

03>

KOtliubkrowtenretnitenrehtE tenrehtEoN-DELrew

rO

rO

NOWSKRO

L-s021<

NOWSKRO

L-s021>

rO

NOWSKRO

LrehtooN

rO

NOWSKRO

L

KOtliubnaL/krowtenretninoL:rofsdnoces21yrev

rO

FtiucricrevieceR

ricrettimsnarT-gnirekcilFoN

yamtiuc

etuobagnihsalF

etnihsalflliW

lbaliavatonsisserddaPI

.)erehweslestluafrofkcehC(

laerasDELneerg3llafI

oPhtiwyletanretlagnihsalF

:rofs21yrevetuobagnihsalF

iubkrowtenretnitenrehtE-s09<

.)erehweslestluafrofkcehC(

.)erehweslestluafrofkcehC(

.dnuofsecived

rehweslestluafrofkcehC(ylreporp

.deviecergniebatad-tsafsrekcil

.sgnittestenrehtEgniniatbO-s003<

sgnittestenrehtEniatbootelbanU-s0

.gnidl

rebmuntropPDUemastasecivedrehtooN

.

.tluafadepolevedsahrotcennoC/elbaC

.gnidliubkrowtenretni

yltcerrocdetanimrettonkrowten

.)e

.)sDELXRdnaXTkcehC(detcennoctoN

.dettimsnartgniebsiatad-tsafsrekcilF

tenrehtEoneblliwereht,e

.sDELrehtokcehctluafasahtinuyldetaepergnihsalF

.sserddadilavni-gnihsalfos

.).rotcennocro/dnaelbackcehC(.dnuofnoitcennoc

ylreporpgnidliubtonkrowtenretnitenrehtE-s09>

ylreporpgnidliubtonkrowtenretni

.gnidliubnaL/krowtenretnipooLtnerruC-s06<

gnidliubtonkrowtenretni/naLpooLtnerruC-s06>

.gnitacinummocsitinuehtnehwyltnettimr

.detcennocsidtiucricrettimsnarT-s21yrevetuobasehsalF

tluaFrewoP

ytluaFtinU

ytluaFtinU

ytluaFtinU

ytluaFtinU

nekorb/detcennocsid

ytluaFtinU

ytluaFtinU

detrohsseriwrevieceR

.dnuofecivedtenrehtEoN

)ytluafrodetcennocsid

.dnuofecivedtenrehtEoN

)ytluafrodetcennocsid

8

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

Page 9

Installation Instructions 3xtend/EINC L/24

1.4 INSTALLATION - CONFIGURATION (Continued)

Connect to 3xtend/EINC L with IP Tool

12

Either over Ethernet or Local PC Ethernet Connection

XCITE/XA crossover adaptor

order separately (XCITE/XA/5 pack

of 5)

Router

3xtend/

EINC L

Initially access EINC L via its MAC address (written on label)

Router

SET v6

(including IP Tool)

Local PC (Ethernet) connection can be either to adjacent Ethernet

hub using standard cable only, or directly to EINC L using

standard cable and crossover adaptor, XCITE/XA.

SET Manual TE200147

IP Tool Manual TE200638

Configure Addressing Details with IP Tool

13

3xtend/EINC L Data Sheet TA200800

IP Tool Manual TE200638

The 3xtend/EINC L’s addressing information can be set up automatically (automatic addressing) or manually (manual

addressing). When set up automatically the addressing details are obtained from a DHCP server, if a DHCP server is not being

used or fails the 3xtend/EINC L enters link/local mode where it autonegotiates its IP address with other devices on its Ethernet

segment. Alternatively the settings can be specified manually. When automatic addressing is used the 3xtend/EINC L’s IP

address may vary, with manual addressing the IP address is fixed. The addressing details can be viewed or configured using

IPTool. The table below describes the options that must be set up for each addressing mode.

Addressing Method

Automatic Manual

DHCP Link/Local

DHCP Server Required Ye s Must not be i nsta lle d No

WINS Server Required Yes No if all devices on same

DHCP Set to Yes. This is the default. Set to Yes. This is the default. Set to No using IPTool

IP Address Set by DHCP server Autonegotiated with other

Subnet Mask Set by DHCP server Uses 255.255.0.0 Must be specified using IPTool

Default Router Set by DHCP server N/A Must be specified using IPTool

WINS Server Set by DHCP server N/A Must be specified using IPTool

HostName De fa ult value us ed . Ca n be

specified using IPTool.

UDP Port De fa ult value us ed . Ca n be

specified using IPTool.

Identifier D efa ult value us ed . Ca n be

specified using IPTool.

Internetwork Across Routers S e t up hos t nam e a nd sub ne t

mask of remote devi ces using

IPTool.

Virtual CNCs Required Set C NC ad dress and port

number of required vCNCs with

IPTool. For vCNCs in alarm

mode also set up the host name

of devi ce to which alarms are to

be sent.

subnet, otherwise requi red.

devices on same subnet.

Default value used. Can be

specified using IPTool.

Default value used. Can be

specified using IPTool.

Default value used. Can be

specified using IPTool.

Not available Set up host name/IP address,

Set C NC address and port

number of required vCNCs with

IPTo ol. For vC NCs in alarm

mode als o set up the h ost name

of device to which alarms are to

be sent.

Only required if connection to

de vi ce s i s to b e ma d e usi ng

host na mes.

Must be specified using IPTool.

It is possible to use a fixed IP

address on a DHCP system

providing the DHCP server is

set not to allocate the address.

Default value used. Can be

specified using IPTool.

Default value used. Can be

specified using IPTool.

Default value used. Can be

specified using IPTool.

and subnet mask of remote

devices using IPTool.

Set CNC address and port

number of required vCNCs with

IPTool. For vCNCs in alarm

mode al so set u p t h e I P add ress

of host name of device to which

alarms are to be sent

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

9

Page 10

3xtend/EINC L/24 Installation Instructions

1.4 INSTALLATION - CONFIGURATION (Continued)

Configure Addressing Details with IP Tool (Continued)

13

3xtend/EINC L Data Sheet TA200800

IP Tool Manual TE200638

The table below describes the addressing parameters that need to be set up.

retemaraPnoitpircseD egnahcotnehW

sserddA

eludoM

--renrehtE

pi

eludoM

reifitnedI otstluafedtI.naLehtyfitnediotdesulebalretcarahc

retuoRtluafeD ehtfitneserasegassem

PCHD .desusignisserddalaunamrocitamotuarehtehwseificepS

emantsoH emankrowtenehthtiwderetsigersitahtgnirtsretcar

*sserddAPI ehtnoecivedhcaerofsserddaPIeht,sserddaPIehT)etirw/daer(

revreSSNIW.revreSSNIWehtfosserddaPIehtseificepS)etirw/daer(

*ksaMtenbuS tonsecivedllarofemasehtebtsumtiksamtenbusehT)etirw/daer(

troPPDU otdesutrop)locotorPmargataDresU(P

-04A

ehtni.sserddaCAM

=egnaRsretcarahc*?;{(\/ton

pseb

.0.0.0.0otstluafedti

.0.0=egnaR

ortluafed

toehthtiwdetaitogenotua

alaunamfI

=egnaR

ahc-51A)ylno/daer(

x_DNERTotstluafedtI

ehtnisrebmunfo.sserddaCAM

=egnaRsretcarahc*?;{(\/ton-sretcarahcciremunahpla51

.0.0.0.0otstluafedti

.0.0.0.0otstluafedti

yehttahtserusne

ehtfI.revres

.0.552.552.552otstluafedti

DUehT)etirw/daer(

.21675ot

53556ot0=egnaR

srebmunfospuorg3tsalehterazzdna,yy,xxerehW.zz_yy_xx_DNERT

-sretcarahcciremunahpla04

hcihwotretuorehtfosserddaPIehT

E/dnetx3ehtsatenbusemasehtnoretuorafosserdda

.retuorafoedisrehtoehttenbustenrehtE

552.552.552.552ot0.0

0.0.552.552ottessiksamtenbus

trehtaremanybgnitcennocrofrevresserddaPInah

aoteuqinuebtsumkrowtentenrehtE

.tenbusemasehtnoseivedrehtohtiw

amebtsumtidetcelessignisserddalaunamfI

552.552.552.552ot0.0.0.0=egnaR

ficepssignisserddacitamotuanehW

mtidetcelessignisserddalaunamfI

552.552.552.552ot0.0.0.0=egnaR

.tenbusemasehtnoera

52.552.552.552ot0.0.0.0=egnaR

5

owtenretninaetaercotdesusecivedllA

eniatbositideificepssignisserddacitamotuanehW

.seY=tluafeD,desuPCHD=seY,oNroseY

.sehsalcsserddadiov

tignitarepotonsitirorevresPCHDonerehtfI.revres

.testonsitirorevresPCHDonerehtfI.revres

.0.0.0.0ottessitirevresPCHDoner

PIehtottesebdluohstI.tenbuslacolehtnotonsisserddanoitanitsed

tsumtI.LCNI

,sretuorsnapstahtkrowtenretninadliubotsiLCNIEehtfideifice

naotdetcennocCPaybdesuebotsisCNClautrivehtfoenofiro

PCHDamorfd

.testonsitignitarepotonsitirorevresPCHDonerehtfI.revres

sacsihtni,denifedyllaunamebtsumtidetcelessignisserddalaunamfI

e

,ksam

tenbus,sserddaPIehtdeificepssignisserddacitamotuanehW

PCHDamorfdeniatboerasretemaraprevresSNIWdna,retu

sisserddaPIehtgnitarepotonsitirorevresPCHDonerehtfI.revres

PIehtdna,tenbusemasehtnosecivedreh

,ksamtenbus,sserddaPIs'LCNIEehtdetcelessignisserdd

.denifedyllaunamebtsumsretemaraprevresSNIWdna,retuortluafed

spuorg3tsalehterazzdna,yy,xxerehW.zz_yy_x

PCHDamorfdeniatbositideificepssignisserddacitamotuanehW

detaitogenotuasi

esacsihtni,denifedyllaun

hW

PCHDamorfdeniatbositidei

esacsihtni,denifedyllaunamebtsu

sihT.krowtenretninarosnaLdliuboteratahtsretuorybdetarapes

PCHDamorfdeniatbositideificepssignisserddacitamotuanehW

esacsihtni,denifedyllaunamebtsumtidetcelessignisserddalaunamfI

.krowtentenrehtEehtrevosecivedmetsysQIrehtohtiwetacinummoc

stluafeD.tropemasesutsumkr

.desugnieb

.degnahceb

revres

aunamnehW

.desugnieb

.deriuqer

.desugnieb

pg.e

.elbatiustonsitluafednehW

signisserddalaunamnehW

otsiedomgnisserddanehW

ebnacgnisserddalaunaM

ahtiwmetsysanodesu

ehtgedivorprevresPCHD

edi

stuosisserddas'LCNIE

ehtybdengissaegnareht

stonsitluafednehW

.elbatiu

signisserddal

signisserddalaunamne

otnoitcennocdna,desugnieb

sisemantsohgnisusecived

signisserddalaunamnehW

elbatiustonsitluafednehW

rodesugniebydaerlatro

)setis(skrowtenretnielpitlum

.tenbusemasehtnoderiuqer

*Note that when setting up the Ethernet addressing ensure that there is only one subnet on a network segment.

10

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

Page 11

Installation Instructions 3xtend/EINC L/24

1.4 INSTALLATION - CONFIGURATION (Continued)

Configure Addressing Details with IP Tool (Continued)

13

Para me te r Des c r ip tio n When to cha nge

Remote

EINC

Modules

Virtual

CNC

Modules

I P Address (read/write) T he IP address/host n ame of th e r emote dev ice on Eth ern et.

Subnet mask (read/write) The subnet mask for the remote device.Range = 0.0.0.0 to

At least two devices from each each subnet should be specifed. For increased reliabili ty details of additio nal devi ces

sho uld be specified . If automatic ad dr e ss ing is bein g used th e de vices must be specified u sing hostnames, and if manual

addressing is being used the li st should contai n the devices with the lowest IP addresses. The table must be placed in

all devices on the network.

Alarm IP

Address

CNC Address The device address of the virtual CNC on EINC L’s Lan. It is set to

Port Address The TCP port used by the virtual CNC. It is set unused by default and

The host name or IP address of the remote device on Ethernet.

Range = 0.0.0.0 to 255.255.255.255. Default=0.0.0.0

255.255.255.255 Default=0.0.0.0

The host name or IP address of the alarm target supervisor that is

connected to the Ethernet network if operating in alarm mode. Setting

this u p switch es the v irtu al CNC into alar m mode, an d preven ts th e virt ual

CNC being used as a CNC by a supervisor . 0 w ill sw itch t h e virtu al CNC

back into supervi s or mode. Default=Unus ed

unused by default, and the virtual CNC will not operate until its address

is set up. It can be set to any valid address (1 to 119 excluding

addresses 2, 3, and 10). 0 will disable the vi rtual CNC.

then defaults to 10000 plus the cnc address when the cnc address is

set up, but can subsequently be changed.Range = 1 to 32767.

If internetwo rk is to be bui lt

across routers.

If the virtual CNC is to be u sed

to send alarms to a supervisor

over Ethernet.

I f the virt u al CNC is t o be u s ed.

I f the virt u al CNC is t o be u s ed.

Configure Optional Settings Using SET

14

Parameter Description

Address

Module

Remote

Devices

Enter configuration mode using SET. The top level

a

prompt will be displayed as below.

Lan Alarm

Address

Lan Alarm

Lan

Alarm

Language

Internetwork

Alarm

Address

Internetwork

Alarm Lan

Disable

vCNC A live

Alarms

Send

Remote

Broadcasts

The alarm target device address for alarms generated by the current loop network when it is operating

as a Lan. It can be set to any valid address (1 to 119 excluding addresses 2, 3, and 10). 0 stops the

alarms being transmitted.

The target Lan number for alarms generated by the current loop network when it is operating as a Lan.

It can be set to any valid address (1 to 1 19 excluding addr esses 2, 3, and 10). 0 stops the alarms being

transmitted.

The langu age used for the networ k al ar m s. 0 =English, 1= S pa nish, 2= Fin nish, 3=Sw edish, 4= N or w egian,

5=Danish, 6=German, 7=Italian, 8=Portuguese, 9=French.

The alarm target device address for internetwork alarms. It can be set to any valid address (1 to 119

excluding addresses 2, 3, and 10). 0 stops the alarms being transmitted.

Th e al ar m t arget Lan n u m ber f or in ter n etw ork al arms . It can be set to an y v al id address (1 t o 1 19 ex c luding

addresses 2, 3, and 10). 0 stops the alarms being transmitted.

Enabl es/ disabl es device on- l in e, an d dev ice dead al ar ms generated by virtual CNCs. R an ge= Yes or N o,

Yes = alarms disabled. Default = No.

Specif ies w hether r em ot e br oadc ast m ess ages or dir ect ed m ess ages a re used to buil d t he int er network

across routers.

If set to use broadcast messages (Yes) the messages used to build the internetwork across routers

will be sent to the default router requesting a broadcast message to all devices on the remote

device’s subnet as well as the remote device specified in the module.

If set not to use broadcast messages (No) the messages used to build the i nternetwork across routers

will only be sent (by di rect messaging) to the device specified in the module.

Thi s option should only be turned off if the routers have remote broadcast messaging disabled.

I f broadcasting is turned off , details of as m any dev ice’s as poss ibl e f r om ea ch su bnet should be entered

in the remote devices table to enable the internetwork to be built in the event of a failure.

SET Manual TE200147

3xtend/EINC L Data Sheet TA200800

b

Note that it may be necessary to set up a virtual CNC in the

3xtend/EINC L if one is not available elsewhere on the network.

Configure the optional settings the relevant upper

case letter and pressing ENTER. If a value has been

changed X+ENTER will confirm it and return to the

top menu, whereas Q+ENTER will quit and return

with the value unchanged. The table below describes

the settings.

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

11

Page 12

3xtend/EINC L/24 Installation Instructions

XTEND -400007096

3 X t r e a m

L A N

M A C A d d r

00.10.70.00.UD.BB

O / S

S/No:

I P A d d r

Location

M A C A d d r

00.10.70.00.UD.BB

S/No:

Q3B____X73010003

I P A d d r

3

3

SET, or 963

963

1.4 INSTALLATION - CONFIGURATION (Continued)

Configure Optional Settings Using SET (Continued)

14

retemaraPnoitpircseD

pi-tenrehtE

eludom

klatnoL

eludom

etadpU

etomeR

seciveD

gnikrowteN

delbasiD

klatnoL

delbanE

ruoyypoC

CNIEetomer

rehtoottsil

)N/Y(sCNIE

resU

NIP aybtnesebtsumro,yalpsidamorfnogolot

seludoM

Note that if required the parameters configured using IP Tool can also be configured in the same way.

lliwecivedehtrehtehwseificepS

Ls'ecivedehtselbasid/selbanE

NO

W

SKRO

.snoitacinummoc

iwstenbuslladnatenbuslacolottsilscniEetomerehtseipoC

.krowtentenrehtEehtnoseciveddnerTrehtorofhcraes

tsilniCNIEdnasLCNIE/dnetx3ht

resuehtybderetneebtsumtahtrebmuntigid-4ehT

.egnahcaesirohtuaotrosivrepus/loot

Tear off Label Strip

M A C A d d r

00.10.70.00.UD.BB

IP A d d r

S/No:

Location

Q3B____X73010003

15

Write on Label

M A C A d d r

00.10.70.00.UD.BB

I P A d d r

3 X t r e a m

XTND -400007096

M A C A d d r

00.10.70.00.UD.BB

I P A d d r

S/No:

Q3B____X7301000

Location

S/No:

Q3B____X7301000

L A N

O / S

e.g. location/identifier

recommended

S/No:

M A C A d d r

00.10.70.00.UD.BB

Q3B____X73010003

Location

IP A d d r

S/No:

3X tre a m

XTND -400007096

Q3B____X73010003

LA N

O /S

M A C A d d r

00.10.70.00.UD.BB

IP A d d r

16

IP Address, Location, Lan, address

Replace Covers

17

ab c d

Check Virtual CNCs

Virtual CNCs in Alarm Mode

18

Virtual CNCs in Supervisor Mode

using temporary

connection

12

CNC in

Supervisor mode

EINC L

using permanent

connection

E t h e r n e t

CNCA

CNCB

CNCFCNCE

CNCDCNCC

CNCHCNCG

EINC L

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

E t h e r n e t

CNCA

CNCFCNCE

CNC in

Alarm mode

CNCB

Alarm from system sent to VCNC

CNCDCNCC

CNCHCNCG

Page 13

Installation Instructions 3xtend/EINC L/24

EINC

456

2

789

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

123

1

+ 0

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

EINC

45 6

2

78 9

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

12 3

1

+ 0

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

EINC

456

2

789

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

123

1

+ 0

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

EINC

456

2

789

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

123

1

+ 0

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

EINC

45 6

2

78 9

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

12 3

1

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

EINC

45 6

2

78 9

3

101112

4

131415

5

161718

6

192021

7

222324

8

252627

9

282930

10

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

12 3

1

+ 0

343536

12

373839

13

404142

14

A

313233

P

11

434445

15

464748

16

100-240V

OKRX

P0

P0

P0

P0

P0

P0

1.4 INSTALLATION - CONFIGURATION (Continued)

Check Communications

19

If address <100

Lan

(on current loop)

EINC

Internetwork

(on Ethernet)

161718

456

131415

192021

123

252627

222324

101112

282930

789

+0

+0

+0

+0

+0

+0

+0

+0

+0

+0

100-240V

OKRX

343536

313233

373839

434445

464748

404142

24V

24V

0V

OK

Tx

Rx

24VAC24VAC24V

24V

230V

12345

6

7

AC

91011

8

345

If address =>100

Lan

(on current loop)

Internetwork

(on Ethernet)

EINC

161718

456

131415

192021

123

252627

222324

101112

282930

789

+0

+0

+0

+0

+0

+0

+0

+0

+0

+0

100-240V

OKRX

343536

313233

373839

434445

464748

404142

24V

24V

0V

OK

Tx

Rx

24VAC24VAC24V

24V

230V

12345

7

6

AC

91011

8

345

EINC L

Lan

(on current loop)

EINC L

Internetwork

(on current loop)

INC

Lan

(on current loop)

IQL

Internetwork

(on L W

ON ORKS

network)

IQL

Internetwork

(on L W

ON ORKS

network)

Internetwork

(on Ethernet)

Internetwork

(on Ethernet)

(on current loop)

456

131415

123

101112

789

+0

+0

+0

+0

+0

100-240V

OKRX

(on current loop)

161718

456

131415

123

101112

789

+0

+0

+0

+0

+0

100-240V

OKRX

24V

0V

Lan

EINC

EINC L

161718

192021

252627

222324

282930

+0

+0

+0

+0

+0

343536

313233

373839

434445

464748

404142

24V

24V

0V

Tx

24VAC24VAC24V

24V

230V

12345

6

7

AC

91011

8

345

OK

Rx

Lan

(on current loop)

Internetwork

(on L W

ON ORKS

network)

IQL

Internetwork

(on Ethernet)

Lan

EINC

EINC L

192021

252627

222324

282930

+0

+0

+0

+0

343536

313233

373839

434445

464748

404142

24V

Internetwork

(on current loop)

IQL

Internetwork

ON ORKS

(on L W

network)

Internetwork

(on Ethernet)

INC

OK

Tx

Rx

24VAC24VAC24V

24V

230V

12345

7

6

91011

8

AC

345

Lan

(on current loop)

(on current loop)

161718

456

131415

123

101112

789

+0

+0

+0

+0

+0

+0

100-240V

OKRX

(on current loop)

161718

456

131415

192021

123

101112

789

+0

+0

+0

+0

+0

+0

+0

100-240V

V

V

V

OKRX

313233

24

24

0

12345

Lan

EINC

EINC L

192021

252627

222324

282930

+0

+0

+0

+0

343536

313233

373839

434445

464748

404142

24V

24V

0V

OK

Tx

24VAC24VAC24V

24V

230V

12345

7

6

AC

91011

8

345

Rx

Lan

(on current loop)

IQL

Internetwork

(on L W

ON ORKS

network)

Lan

EINC

IQL

EINC L

252627

222324

282930

+0

+0

+0

343536

373839

434445

464748

404142

Internetwork

(on current loop)

Internetwork

(on L W

ON ORKS

network)

INC

OK

Tx

Rx

24VAC24VAC24V

24V

230V

7

6

AC

91011

8

345

Lan

(on current loop)

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

13

Page 14

3xtend/EINC L/24 Installation Instructions

2 END USER LICENCE AGREEMENT

EULA Terms

• You have acquired a 3xtend/EINC L (“Device”) that includes software licensed by Trend Control Systems Ltd from one or more

software licensors (“Trend Control Systems Ltd Software Suppliers”). Such software products, as well as associated media

printed materials and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property

laws and treaties. The SOFTWARE is licensed, not sold. All rights reserved.”

• IF YOU DO NOT AGREE TO THIS END USER LICENSE AGREEMENT (“EULA”), DO NOT USE THE DEVICE OR COPY THE

SOFTWARE. INSTEAD, PROMPTLY CONTACT TREND CONTROL SYSTEMS LTD FOR INSTRUCTIONS ON RETURN OF THE

UNUSED DEVICE(S) FOR A REFUND. ANY USE OF THE SOFTWARE INCLUDING BUT NOT LIMITED TO USE ON THE DEVICE

WILL CONSTITUTE YOUR AGREEMENT TO THE EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

• You may use the SOFTWARE only on the DEVICE

• NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. TREND CONTROL SYSTEMS LTD HAS

INDEPENDENTLY DETERMINED HOW TO USE THE SOFTWARE IN THE DEVICE, AND TREND CONTROL SYSTEMS LTD’S

SOFTWARE SUPPLIERS HAS RELIED UPON TREND CONTROL SYSTEMS LTD TO CONDUCT SUFFICIENT TESTING TO

DETERMINE THAT THE SOFTWARE IS SUITABLE FOR SUCH USE.

• NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS” and with all faults. THE ENTIRE RISK

AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE)

IS WITH YOU. ALSO, THERE IS NO WARRANTY AGAINST INTERFERENCE WITH YOUR ENJOYMENT OF THE SOFTWARE

OR AGAINST INFRINGEMENT. IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR THE SOFTWARE,

THOSE WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT BINDING ON, TREND CONTROL SYSTEMS LTD’S

SOFTWARE SUPPLIERS.

• Note on Java Support. The SOFTWARE may contain support for programs written in Java. Java technology is not fault

tolerant and is not designed, manufactured, or intended for use or resale as online control equipment in hazardous

environments requiring fail-safe performance, such as in the operation of nuclear facilities, aircraft navigation or

communication systems, air traffic control, direct life support machines, or weapons systems, in which the failure of Java

technology could lead directly to death, personal injury, or severe physical or environmental damage. Sun Microsystems,

Inc. has contractually obligated Trend Control Systems Ltd’s software suppliers to make this disclaimer.

• No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, TREND CONTROL SYSTEMS LTD’S SOFTWARE

SUPPLIERS SHALL HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES

ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL

APPLY EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN NO EVENT SHALL TREND CONTROL SYSTEMS

LTD’S SOFTWARE SUPPLIERS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS

(U.S.$250.00).

• Limitations on Reverse Engineering, Decompilation, and Disassembly. You may not reverse engineer, decompile,

or disassemble the SOFTWARE, except and only to the extent that such activity is expressly permitted by applicable law

notwithstanding this limitation.

• SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. You may permanently transfer rights under this EULA

only as part of a permanent sale or transfer of the Device, and only if the recipient agrees to this EULA. If the SOFTWARE

is an upgrade, any transfer must also include all prior versions of the SOFTWARE.

14

3xtend/EINC L/24 Installation Instructions TG20081 1 Issue 3 3/9/08

Page 15

Installation Instructions 3xtend/EINC L/24

3 DISPOSAL

WEEE Directive :

At the end of their useful life the packaging and

product should be disposed of via a suitable

Do not dispose of with normal household waste. Do not burn.

recycling centre.

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 Issue 3 3/9/08

15

Page 16

3xtend/EINC L/24 Installation Instructions

Please send any comments about this or any other Trend technical publication to techpubs@trendcontrols.com

© 2008 Honeywell Technologies Sàrl, ECC Division. All rights reserved. Manufactured for and on behalf of the Environmental and Combustion Controls

Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 3, Switzerland by its Authorized Representative, Trend Control Systems Limited.

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content hereof without

obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www. trend-controls.com

Trend Controls Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www. trend-controls.com

16

3xtend/EINC L/24 Installation Instructions TG200811 Issue 3 3/9/08

Loading...

Loading...