Page 1

Important: Retain these instructions

1 3

1 3

1234 5678 910

RX

TX

OK

ADD RESS BAUD

SW 4

A

D

DP

C

B

J16

De v B

J15

De v A

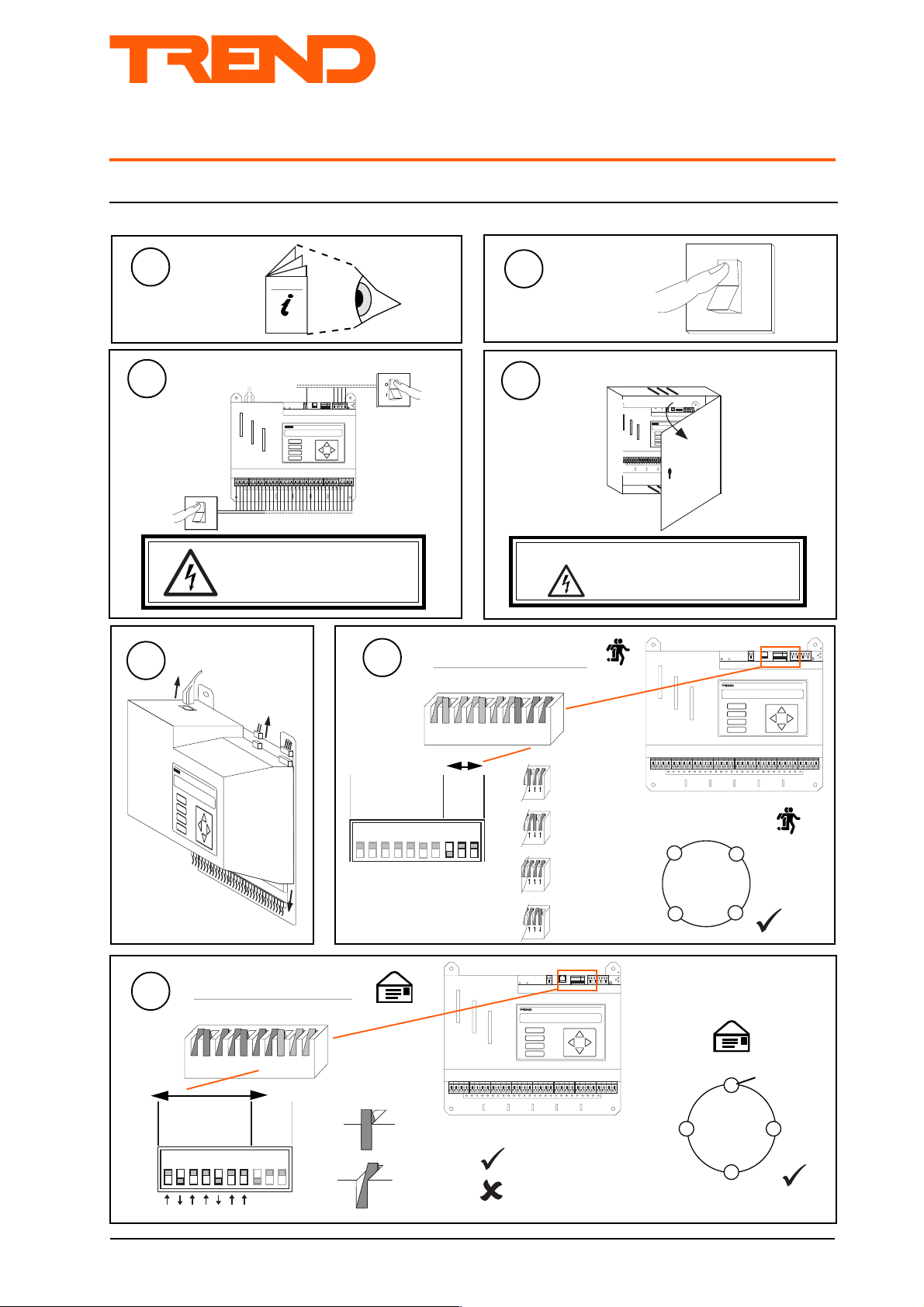

Installation Instructions - Fixing

IQ23x

Series Controllers

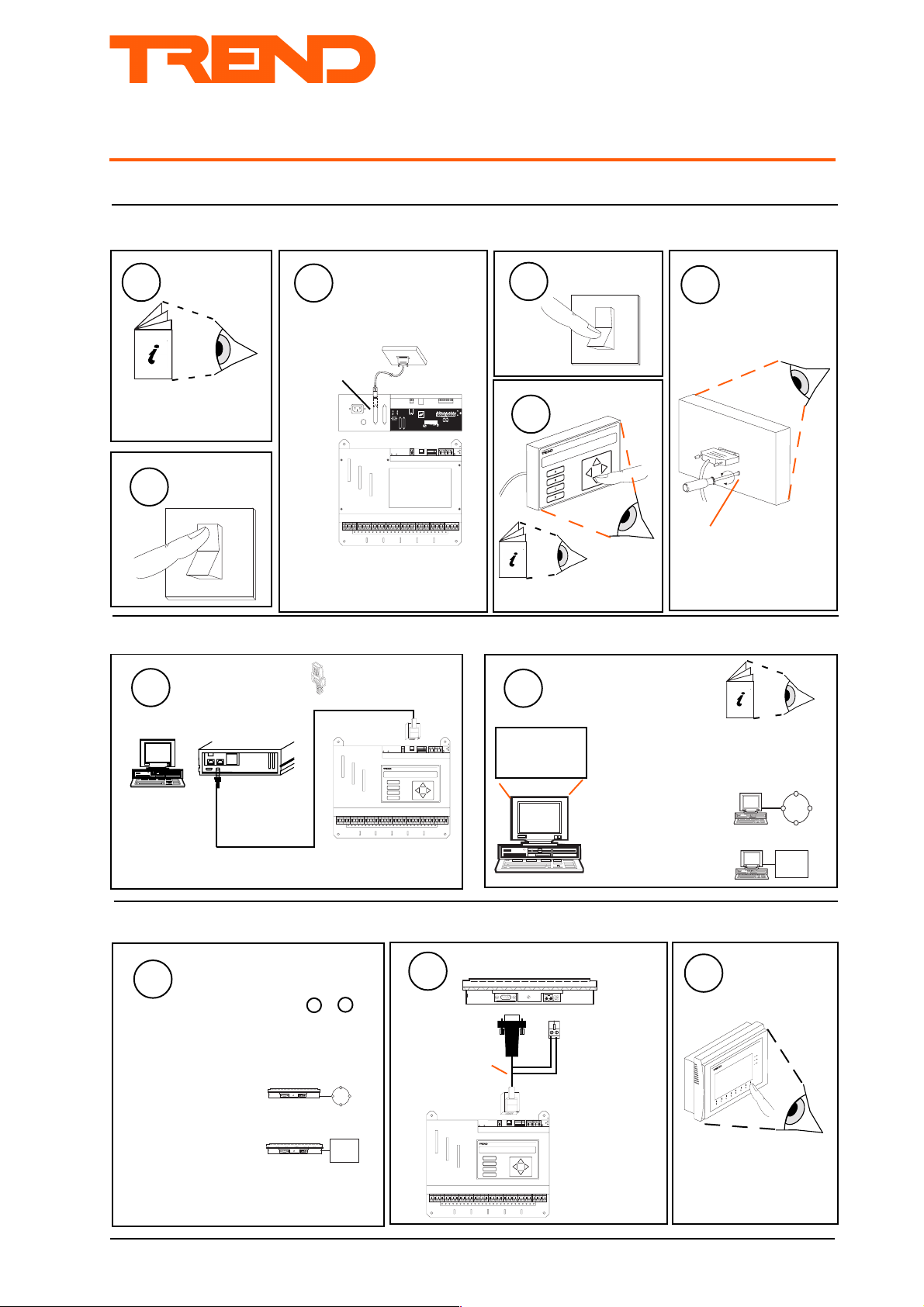

CONTENTS

1.1 Unpacking 1 - 1

1.2 Storing 1 - 1

1.3 Installation - Fixing 1 - 1

2 Installation - Configuration 2 - 1

3.1 Fitting a Remote 2-line Display 3 - 1

3.2 Connecting to a PC via Supervsior Port 3 - 1

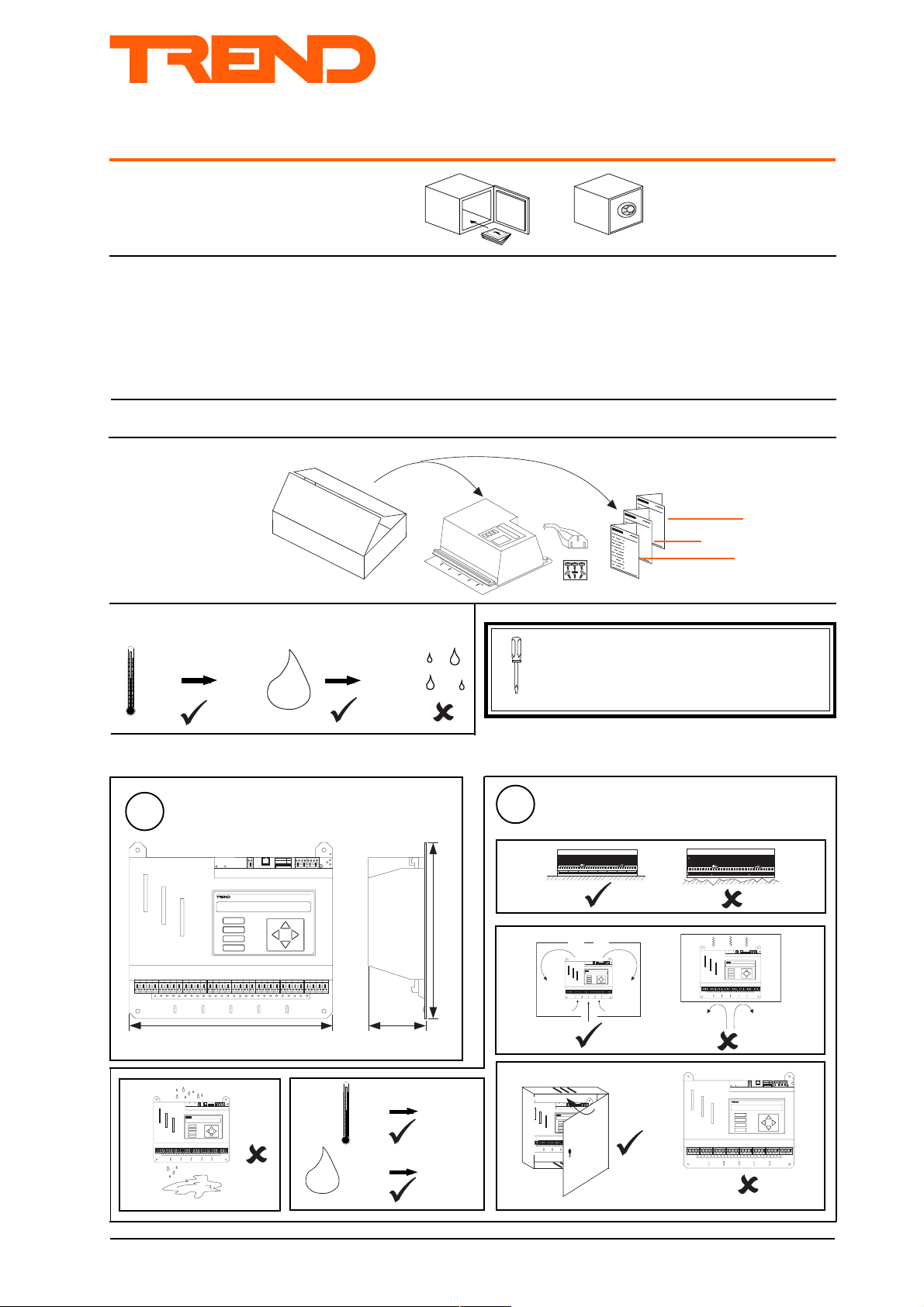

SHEET 1: Installation Instructions - Fixing

1.1 Unpacking

1.2 Storing

-10 °C

+50 °C

0

90 %RH

H2O

3.3 Connecting to an NDP via Supervsior Port 3 - 1

3.4 Mounting in an Enclosure,ENCLS/... 3 - 2

3.5 Replacing the Battery 3 - 2

3.6 Zero Address/Baud Rate Switch Reset 3 - 4

4 Replacing IQ111 4 - 1

5 Replacing IQ111+ 5 - 1

6 Replacing IQ131 6 - 1

7 Replacing IQ131+ 7 - 1

8, 9 Installing a Node Board from a Replaced Controller 8 - 1

1

IQ23x Installation

Instructions TG200539

Sheet 1: Fixing

Sheet 2: Configuration

Sheet 3: Options

It is recommended that the installation should

comply with the HSE Memorandum of Guidance

on Electricity at Work Regulations 1989.

1.3 Installation - Fixing

1

c

Dimensions

A

B

C

D

339 mm

RX

ADD RES S BA UD

OK

123 456 7891 0

TX

SW 4

DP

A

B

C

D

BA U D

AD D R ES S

1284163264

1K 2

9K 6

19 K2

2

R X

O K

T X

D P

299 mm

b

Requirements

a

1

! N

2 3 4 5 6 7 8 9 10 1 1 1 2 13 1 4 1 5 16 17 18 19 20

A

B

C

D

ADDR ESS BA UD

1234 567891 0

SW4

1

2 3 4 5 6 7 8 9 10 1 1 12

RX

OK

TX

DP

V

! N

1

2 3 4 5 6 7 8 9 10 1 1 1 2 1 3 14 15 1 6 1 7 1 8 19 20

V

1

2 3 4 5 6 7 8 9 10 1 1 1 2

RX

ADD RESS BAUD

OK

1234 5678 910

TX

SW4

DP

A

B

C

D

93 mm

RX

BAU D

AD DRE SS

OK

1284163264

1K2

9K6

e

d

0 °C +45 °C

H2O

0 %RH

90 %RH

19K2

TX

D P

A

B

C

D

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 1 - 1

Page 2

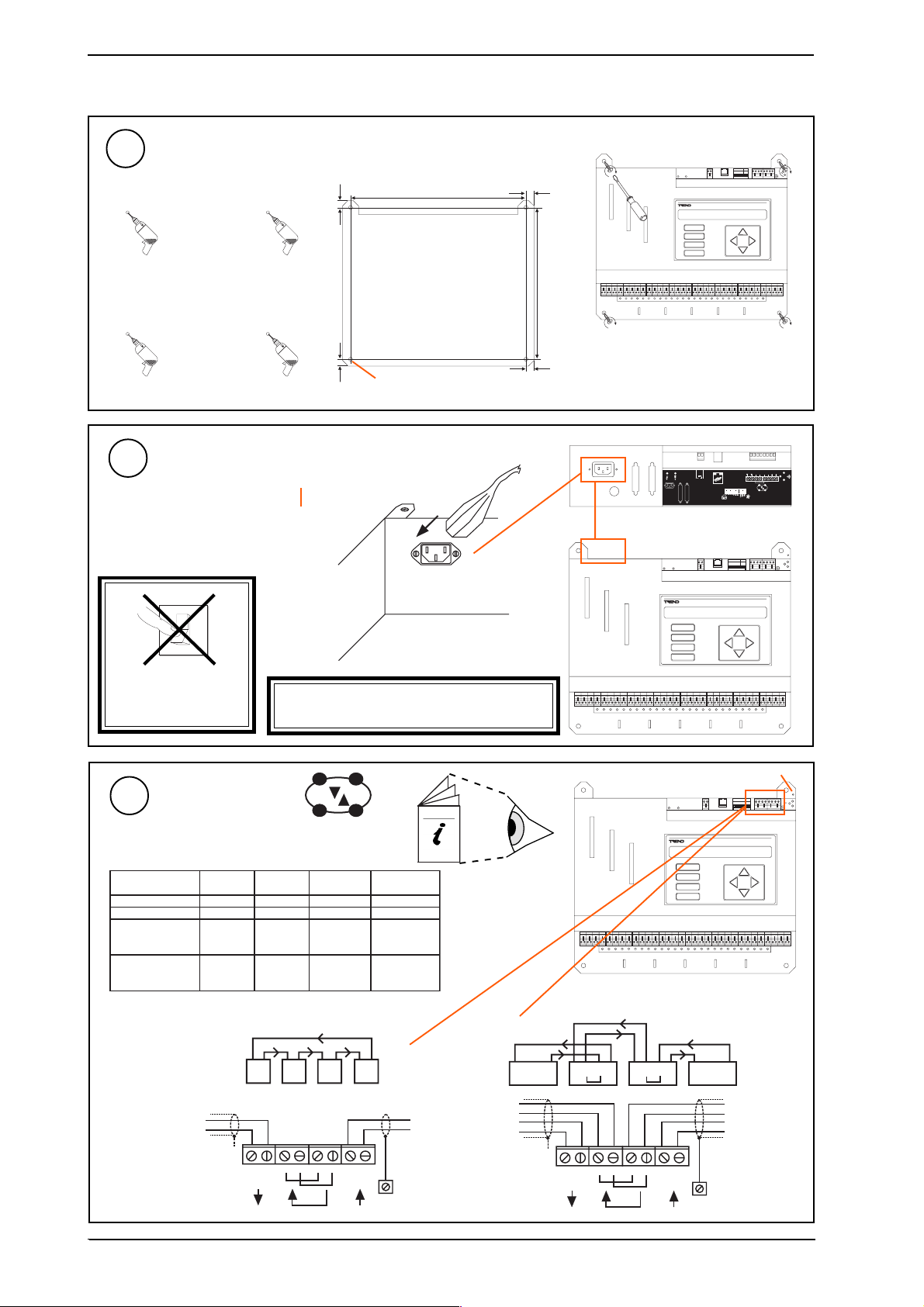

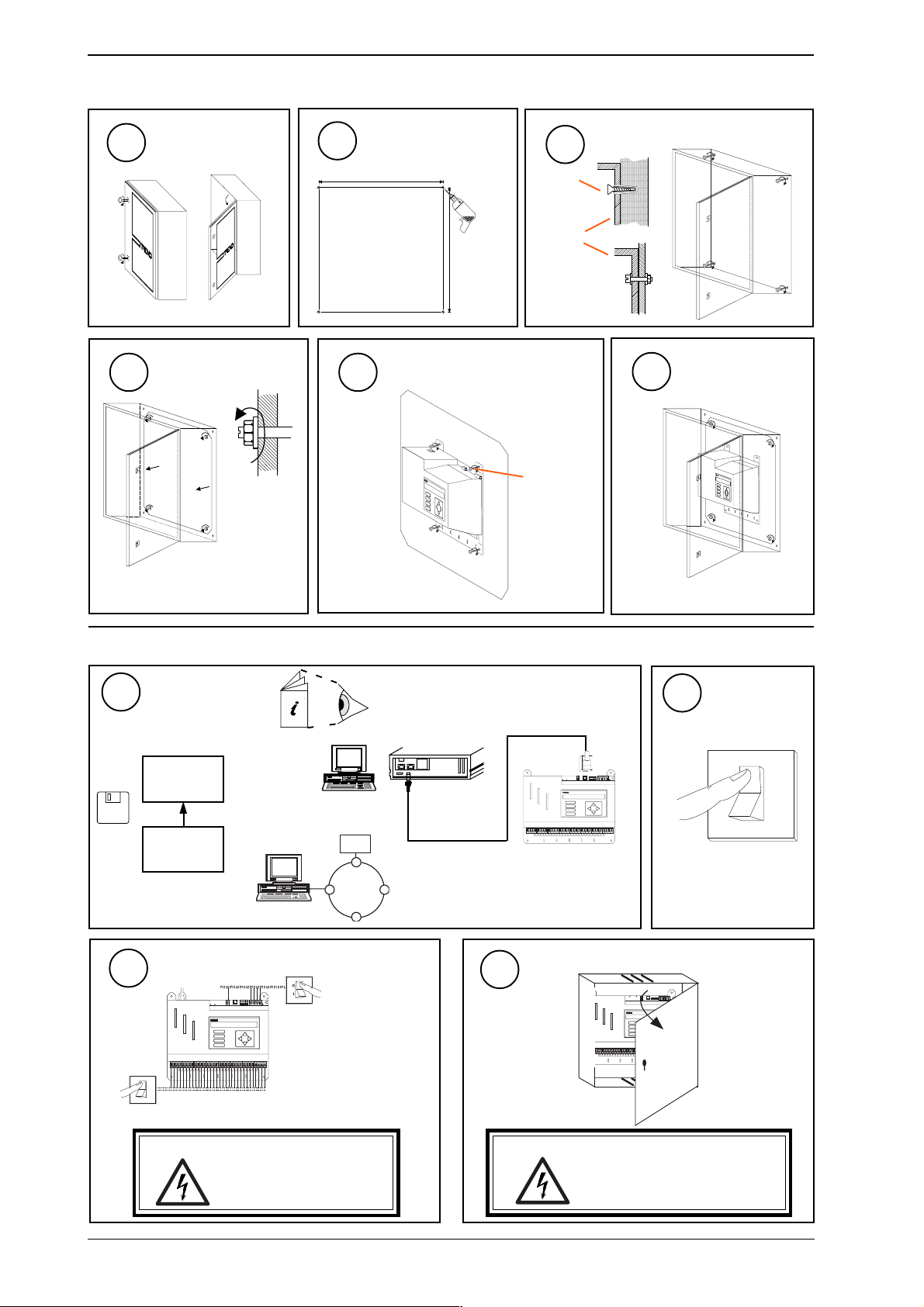

IQ23x Installation Instructions - Fixing

1.3 Installation - Fixing (continued)

3

a

4

Mounting

Connecting Power

IQ Consumption > 60 VA

230 Vac +15% -10%

50 to 60 Hz

b

dimensions in mm

308

14

AD D RE S S

1284163264

12

A

B

C

D

263

12

4 x Ø 6 mm

cable supplied

14

A U X

2 4 V

2 30 V

R D S

R S 2 3 2/ M O D E M

AD D R ES S

1284163264

R X

R X

BA U D

O K

1K 2

9K 6

19K 2

TX

D P

R x

T + T- R + R -

O K

T x

R +

T +

T -

R -

BA U D

R X

O K

1K 2

9K 6

19 K2

T X

O

1

DO NOT APPLY

POWER

5

Terminal size 0.5 to 2.5 mm

Connect Network

elbaCduab2k1duab6k9duab2k91seriWfo.oN

2819nedleBm0001m0001m0072

7029nedleBm0001m0001m0052

dnerT

)1678nedleB(

dnerT

)3278nedleB(

m0001m007m0532

005/FH/22/1/1/PT

m0001m005m0524

005/FH/22/2/2/PT

WARNING: This apparatus must be

earthed (via power lead)

Network Engineering

Manual 92-1735

2

2 wire 4 wire

A

B

C

D

A

B

C

D

polarity independent

D P

M3 earth stud

BA U D

AD D R ES S

1284163264

1K 2

9K 6

19 K2

R X

O K

T X

D P

1 - 2

R T R T R T R T

T

T

X

T -T +R -R + T -T +R -R +

-+-+ -+-+

e a r t h

s t u d

R T R T R T R T R T R T R T R T

R

R

T

T

X

T -T +R -R + T -T +R -R +

-+-+ -+-+

e a r t h

s t u d

T

T

R

R

IQ23x Series Controllers Installation Instructions TG200539 Issue1/A 26/3/02

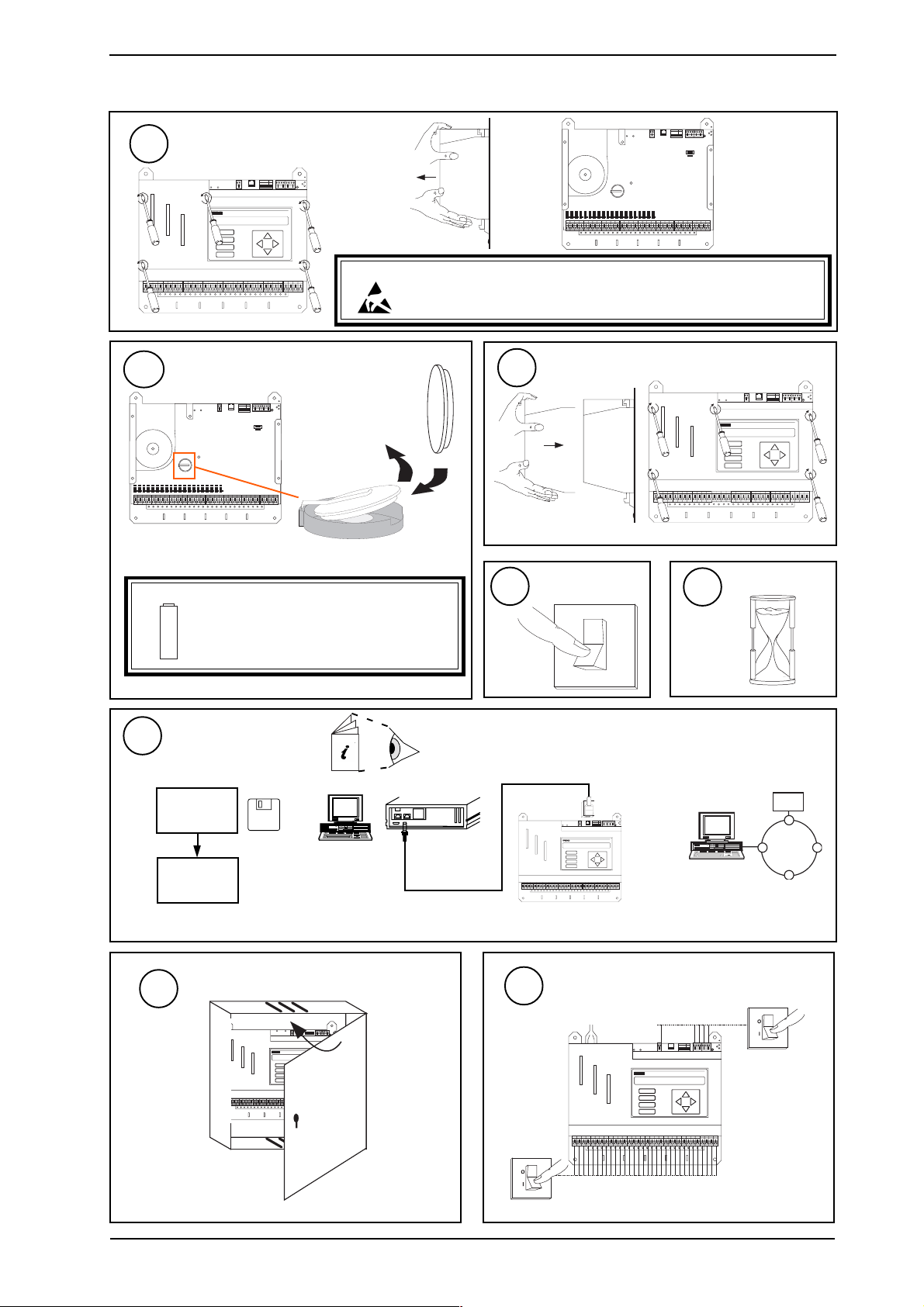

Page 3

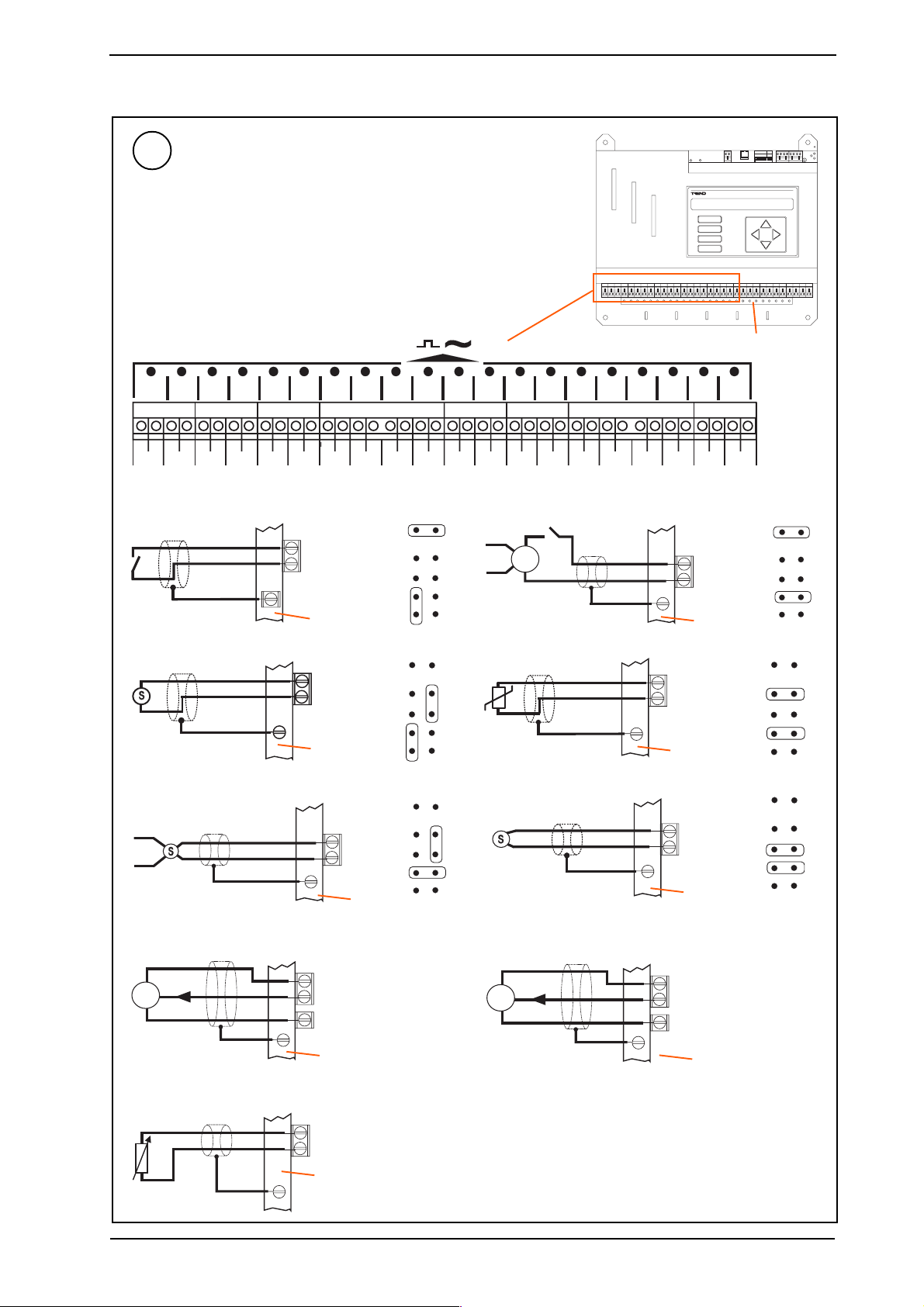

Installation Instructions - Fixing IQ23x

1.3 Installation - Fixing (continued)

R X

BA U D

6

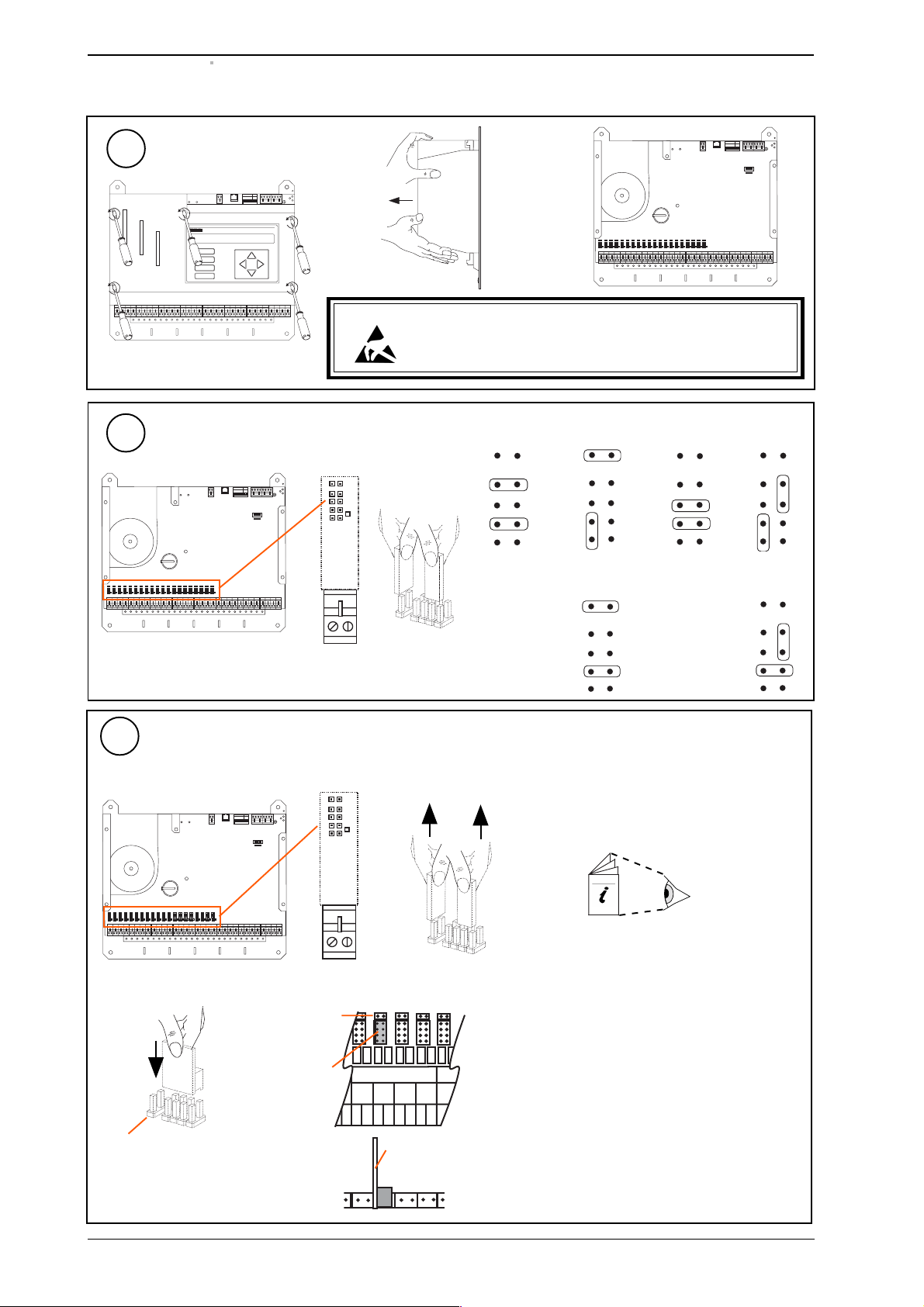

Connect Inputs

Trend TP/1/1/22/HF/500 (Belden 8761) cable

recommended for all inputs

Terminal size 0.5 to 2.5 mm

2

AD D R ES S

1284163264

A

B

C

D

O K

1K 2

9K 6

19 K2

T X

D P

Universal Inputs IN1 to IN20

1 2 3 4 5 6 7 8 9 1 0 1 1 1 2 1 3 1 4 1 5 1 6 1 7 1 8 1 9 2 0

I N 1

C

I N 2CI N 3CI N 4CI N 5

Digital input (loop powered)

Current input (loop powered)

( 0 t o 2 0 m A )

®

1

S I G

2 4 V

C

I N 6CI N 7CI N 8

I N n

C ( 2 4 V )

earth flange

I N n

C ( 2 4 V )

earth flange

C

I N 9

C

C

C

I N 1 1

I N 1 0

I N 1 2CI N 1 3

C

I N 1 4CI N 1 5CI N 1 6

C

I N 1 7

C

C

I N 1 8

Digital input (external powered)

D

+ 2 4 V

2 4 V

D C

-

0 V

Thermistor input

I

0 V

I N n

C ( 0 V )

earth flange

I N 1 9CI N 2 0

I N n

C ( 0 V )

earth flange

earth flange

C

D x

T

Current input (external powered)

( 0 t o 2 0 m A )

®

1

S I G

0 V

S i g n a l

5 V

S

0 V

if LKE/10mA fitted

1 0 m A

¬

0 V

I N n

C ( 0 V )

earth flange

I N n

C ( 5 V )

0 V

earth flange

I N n

C ( 0 V )

earth flange

Voltage input

I x

V ( 0 t o 1 0 V )

I N n

0 V

C ( 0 V )

V

earth flange

if LKE/15V fittedif LKE/5V

S i g n a l

1 5 V

S

0 V

I N n

C ( 1 5 V )

0 V

earth flange

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 1 - 3

Page 4

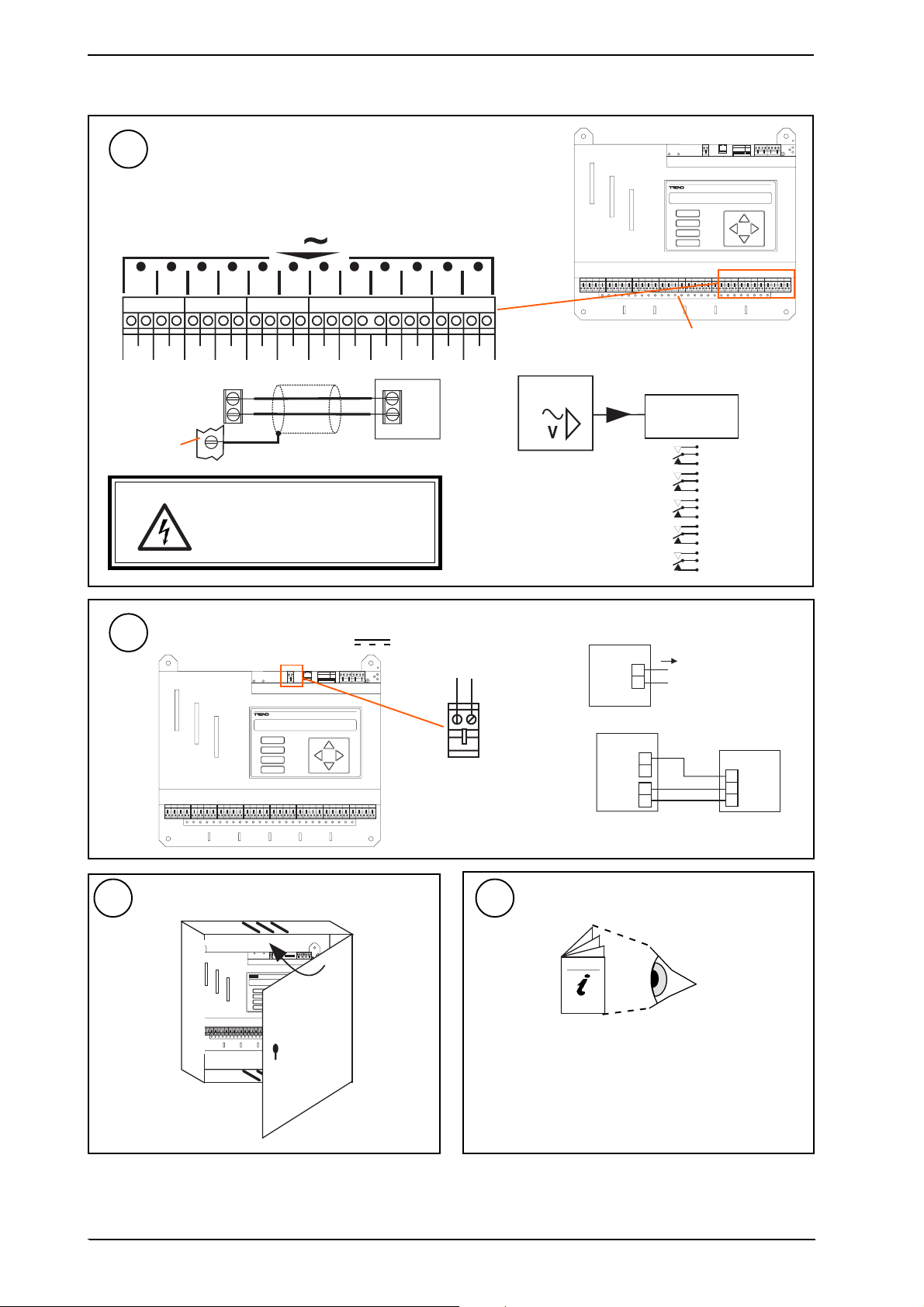

IQ23x Installation Instructions - Fixing

1.3 Installation - Fixing (continuedd

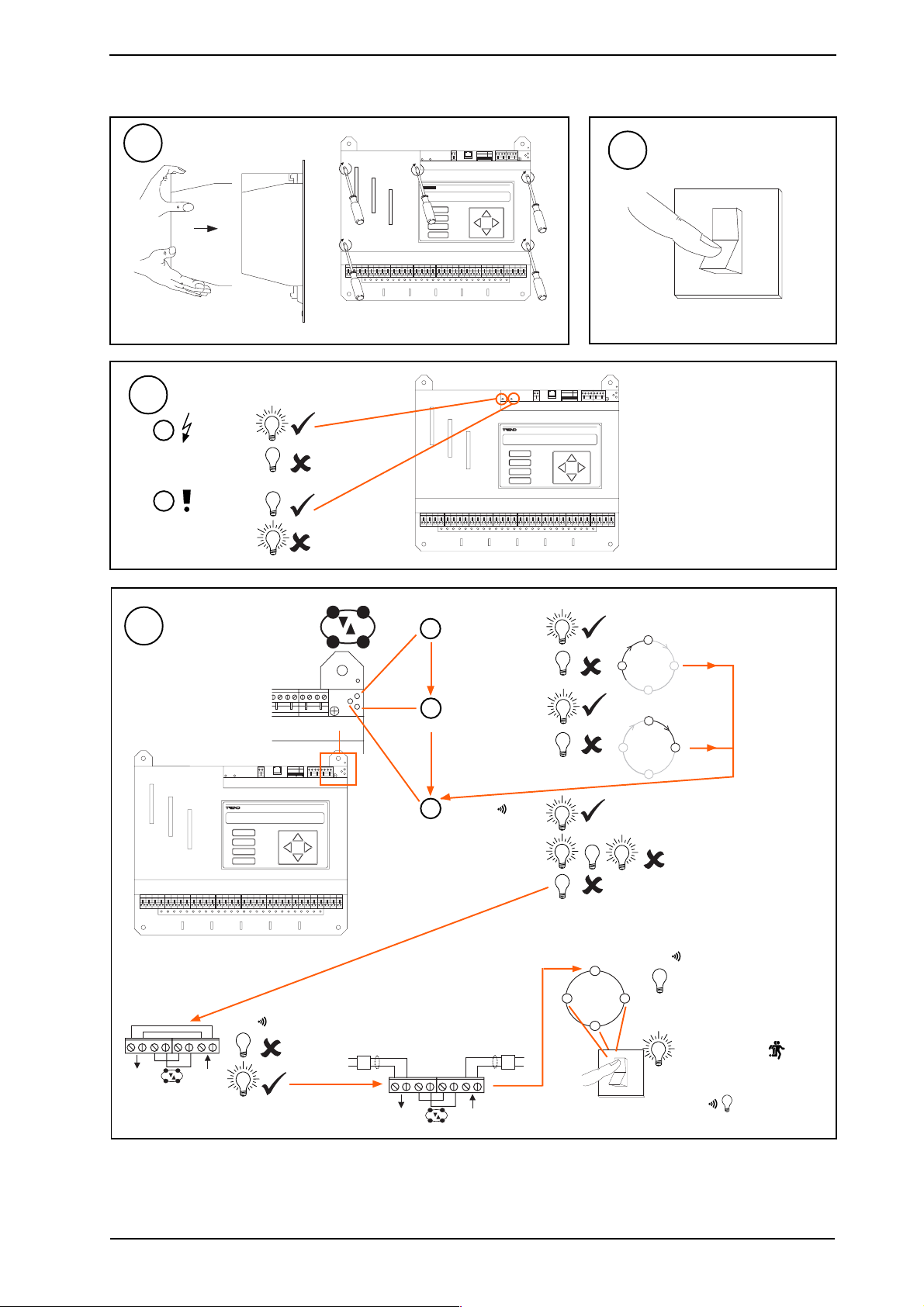

7

Connect Outputs

Trend TP/1/1/22/HF/500 (Belden 8761) cable

recommended for voltage outputs

Terminal size 0.5 to 2.5 mm

2

Analogue Voltage Outputs, B1 to B12

V

1 2 3 4 5 6 7 8 9 1 0 1 1 1 2

B 1

0 V

0 V 0 V 0 V 0 V 0 V 0 V 0 V 0 V 0 V 0 V 0 V

B 2 B 3 B 4 B 5

B 6 B 7 B 8

B n

0 V

earth flange

WARNING: The wires may be connected to hazardous

voltages. Disconnect power before

attempting any wiring.

B 9

l o a d

B 1 0 B 1 1

B 1 2

Additional Relay Modules

I Q 2 3 x

A

B

C

D

R e l a y

M o d u l e

S R M V =

2 S R M =

2 R M =

3 R M = x 3

6 R M = x 6

BA U D

AD D R ES S

1284163264

19 K2

earth flange

n R M

x 1

x 2

x 2

(R/L, H/L)

(HCM/TRM)

R X

O K

1K 2

9K 6

T X

D P

9

Connect Auxiliary Supply 24 V

8

A

B

C

D

Close Panel

AD DR ES S B AU D

12 34 56 78 910

SW 4

A

B

C

D

500 mA

AD D R ES S

1284163264

O K

1K 2

9K 6

19 K2

T X

D P

AUX

R X

BA U D

Terminal size 0.5 to 2.5 mm

0 V 24 V

10

RX

OK

TX

J1 6

D P

D ev B

J1 5

D ev A

Configure/Commission

e.g.

2

I Q 2 3 x

2 4 V

+

-

Imax = 500 mA

I Q 2 3 x

+

2 4 V

-

0 V

B n

2 R M

2 4 V

0 V

I N

2

IQ23x Installation Instructions - Sheet 2: Configuration

1 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue1/A 26/3/02

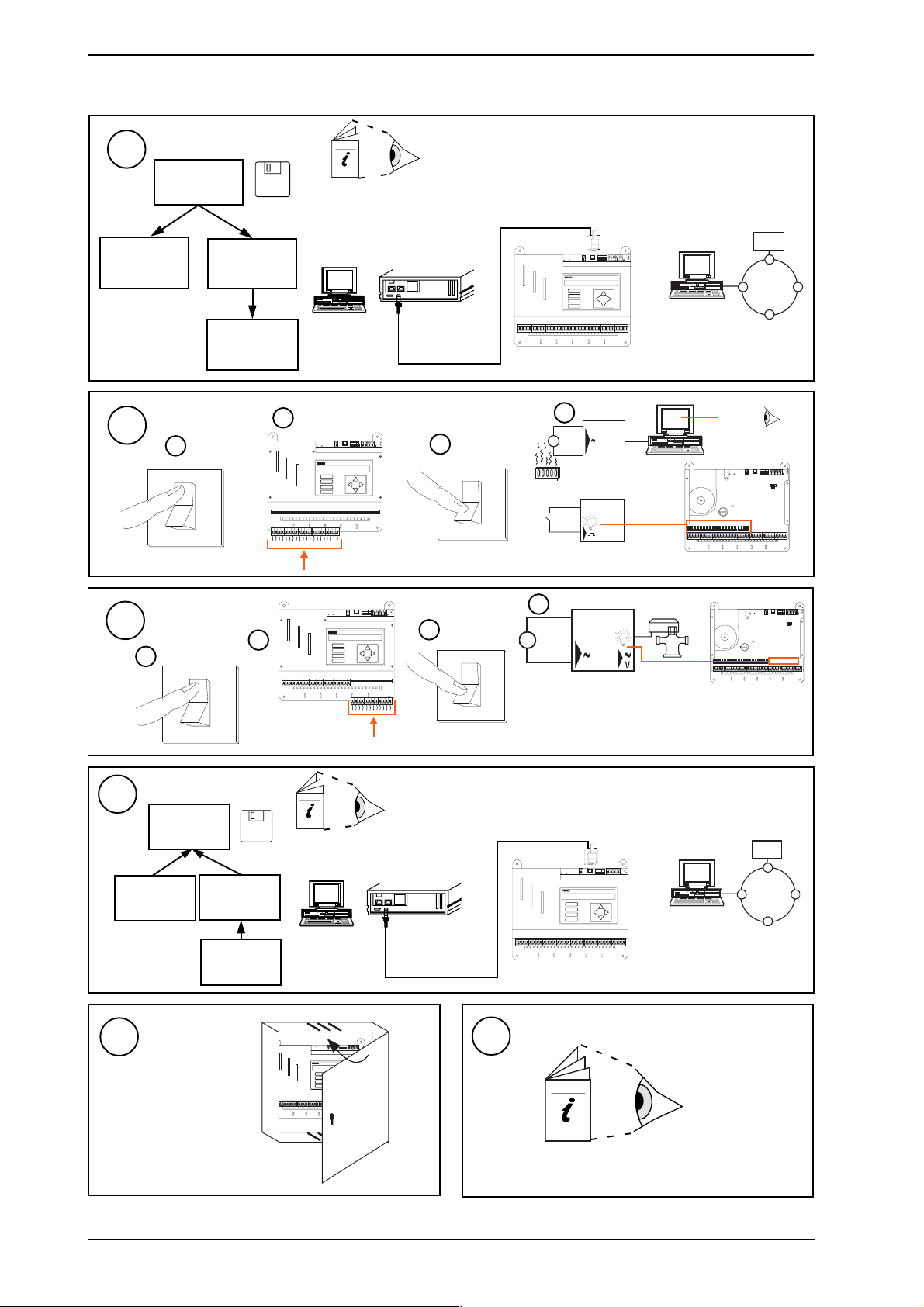

Page 5

Installation Instructions - Configuration

12481 6

3 2

6 4

1 9 K 2

9 K 6

1 K 2

Series Controllers

SHEET 2: Installation Instructions - Configuration

2 Installation - Configuration

IQ23x

Fix Unit

1

IQ23x Installation

Instructions - Sheet 1:

Fixing

Isolate I/O, Network

3

O

I

WARNING: The connecting

leads may be connected to

supplies. Isolate before touching.

Disconnect I/O

5

Switch off

1

2

O

I

Open Panel

4

RX

BA UD

AD DR ESS

OK

1284163264

1K2

9K6

19K 2

TX

D P

A

B

C

D

Set the Network Baud Rate

6

2

RX

ADD RES S B AUD

OK

123 456 789 10

TX

SW 4

J1 6

DP

De v B

J1 5

A

B

C

De v A

D

WARNING: Opening the panel may expose

dangerous voltages.

417-IEC-5036

A

B

C

D

R X

BA U D

AD D RE SS

O K

1284163264

1K2

9K6

19K 2

TX

D P

Set the Network Address

7

e.g.

A D D R E S S

1

284

Address = 2 + 16 = 18

12481 6

1 6

3 2

B A U D

6 4

1 9 K 2

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

= 19k2 baud

= 9k6 baud

= 4k8 baud

= B

Baud Rate = B

= B

= B

A D D R E S S

1

284

B A U D

1 6

3 2

6 4

1 K 2

9 K 6

1 9 K 2

N

1 2 3 4 5 6 7 8 9 1 0

O

ç

= 1k2 baud

= B

R X

BA U D

AD D RE SS

O K

1284163264

1K2

9K6

19K 2

TX

3 2

6 4

1 9 K 2

9 K 6

1 K 2

1 K 2

9 K 6

N

1 2 3 4 5 6 7 8 9 1 0

O

ç

SET

address

NOT SET

A

B

C

D

1, 4 to 9, 11 to 119

0, 2 ,3 ,10 or >119

D P

Address = A

= A

IQ23x

= A

= A

/

= A

/

/

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 2 - 1

Page 6

IQ23x Installation Instructions - Configuration

R X

TX

O K

1284163264

1K 2

9K 6

19K 2

AD D RE SS

BA U D

2 Installation - Configuration (continued)

Remove Cover

8

R X

BA U D

AD D RE SS

O K

1284163264

1K 2

9K 6

19K 2

TX

D P

A

B

C

D

9

10

CAUTION: This unit contains static sensitive devices. Suitable anti-static precautions

Link Input Channels

(unless link header being used on channel)

R X

BA U D

AD D RE SS

O K

19K 2

9K 6

1284163264

1K 2

TX

Fit Link Headers

(if used)

should be taken throughout this operation to prevent damage to the units.

BS EN100115/1 Basic Specification: protection of electrostatic sensitive

devices.

Thermistor

T

Digital loop

powered

D

Digital

externally powered

D x

Voltage

V

Current loop

powered

I

Current

externally powered

I x

(a) Identify set of pins

(d) Push on Link Header

2 pins free

BA U D

AD D RE SS

1284163264

1K 2

9K 6

19K 2

2 pins left free

link header in

position

(b) Remove links

R X

O K

TX

(c) Select Link Header

LKE/5V 5 V supply

LKE/15V 15 V supply

LKE/10mA 10 mA supply

IQ23x Data Sheet TA200538

A I 4

C

view on top of board

A I 4

A n A n + 1

A n - 1

C

C

C C C

A n + 2

board on left

hand side

view on front edge of board

2 - 2

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 7

Installation Instructions - Configuration IQ23x

R X

T X

O K

A

D

D P

C

B

1284163264

1K 2

9K 6

19 K2

AD D R ES S

BA U D

O

I

I Q 2 3 x

?

2 Installation - Configuration (continued)

11

13

a (power)

b (fail)

Replace Cover

Check Controller

(green)

(red)

Check supply

IQ Faulty

A

B

C

D

replace 5 screws

R X

BA U D

AD D RE S S

O K

1284163264

1K 2

9K 6

19K 2

TX

D P

12

Switch on

14

-

+

Check Network

A

B

C

D

OK

-

+

BA U D

AD D R ES S

1284163264

1K 2

9K 6

19 K2

D P

IQ Faulty

aRX

(yellow)

I Q 2 3 x

?

R X

O K

T X

bTX

(yellow)

R X

O K

T X

c OK

(green)

Network Address Invalid

0,2,3 or >119

OK

I Q 2 3 x

Check network cabling for

short circuits with a

multimeter (NOT Megger)

Check baud rate .

O

I

-

+

-

+

Power up other nodes

until faulty node is found

(OK ). Correct fault.

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 2 - 3

Page 8

IQ23x Installation Instructions - Configuration

I Q 2 3 x

S

I Q 2 3 x

S

2 Installation - Configuration (continued)

15

IQ23x

also set time,

day, date

16

Configure

SET

if autodialled

X.IQ2

PowerTool

IQ23x

Test Inputs

Switch off

a

O

I

X.IQ2

IQ Configuration Manual 90-1533

IQ23x Data Sheet TA200538

SET Manual TE200147 or

PowerTool Manual TE200163

I Q 2 3 x

9 Way 'D type'

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

OR

Female

Cable/EJ101442

b

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

Switch on

c

O

I

IQ23x

d

I Q 2 3 x

(yellow)

∆T = X

RX

BAU D

ADD RE SS

OK

19K2

9K6

1284163264

1K2

TX

17

18

IQ23x

19

Test Outputs

Switch off

a

O

I

Backup

SET

(compare)

X.IQ2

PowerTool

Close Panel

b

if autodialled

X.IQ2

IQ23x

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

c

Switch on

O

d

e.g. VB

(yellow)

RX

BAU D

ADD RES S

OK

19K2

9K6

1284163264

1K2

TX

I

SET Manual TE200147

PowerTool Manual TE200163

I Q 2 3 x

9 Way 'D type'

RJ11

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

OR

Female

Cable/EJ101442

RX

AD DRE SS BAU D

OK

123 45 678 910

TX

SW 4

J1 6

DP

De v B

J1 5

A

B

C

De v A

D

20

IQ23x

3

IQ23x Installation Instructions Sheet 3: Options

2 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 9

Installation Instructions - Options

RX

TX

OK

A

D

D P

C

B

1284163264

1K2

9K6

19K2

AD DRE SS

BA UD

Series Controllers

SHEET 3: Installation Instructions - Options

3.1 Connecting a Remote 2-line Display (if KIT/2xx/RDS has been fitted)

IQ23x

Ensure /RDS

1

Installed

KIT/2xx/RDS

Installation Instructions

TG103128

DP

Connector

Connect Display

3

(FPK or HDP)

A UX

24 V

23 0V

RD S

RS 23 2/ MO DE M

R x

T+ T - R + R -

O K

T x

R +

T+

T-

R -

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

Switch Off

2

O

I

3.2 Connecting to PC via Supervisor Port

Connect RS232

1

Switch On

4

O

1

Test

3

Adjust Viewing

Angle

6

5

angle adjust screw

Display Panel

Manual 90-1505

Configure Address

2

if faint

RJ11

RX

BA UD

AD DRE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

9 F'D'

Cable/EJ101442

A

B

C

D

IQ23x

3.3 Connecting to NDP via Supervisor Port

1

Configure Address

See above 'Connecting to PC via

Supervisor port' Steps 1 & 2

Configuration Mode, addRess Module

sUpervisor port addr = 1,4 to 9, 11 to 119

sUpervisor port addr = 0

I Q 2 3 x

Cable/EJ104029

Connect NDP to Controller

2

9 Way

'D' Female

SET or

PowerTool

+

-

RJ11

IQ Configuration Manual 90-1533

IQ23x Data Sheet TA200538

sUpervisor port addr = 1,4 to 9, 11 to 119

sUpervisor port addr = 0

3

I Q 2 3 x

Test

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 3 - 1

Page 10

IQ23x Installation Instructions - Options

123 456 789 10

RX

TX

OK

ADD RE SS B AUD

SW 4

A

D

DP

C

B

J1 6

De v B

J1 5

De v A

3.4 Mounting in an Enclosure, ENCLs/...

Open Door

1

a

b

2

Drill Wall

560 mm

3

No. 12

Fix to Wall

OR

560 mm

Remove Backplate

4

Mount IQ23x on Backplate

5

Replace Backplate

6

M6

3.5 Replacing the Battery

Upload Strategy

1

SET cannot upload

over autodial link

SET or

PowerTool

X.IQ2

IQ23x

Isolate I/O, Network

3

RX

BAU D

ADD RE SS

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

O

I

OR

SET Manual TE200147

PowerTool Manual TE200163

9 'D type'

Female

I Q 2 3 x

Cable/EJ101442

RJ11

BAU D

ADD RESS

1284163264

1K2

9K6

19K2

A

B

C

D

IQ23x

See above, "3.2

Connecting PC via

Supervisor Port"

Open Panel

4

Switch Off

2

RX

OK

TX

DP

O

I

WARNING: The connecting leads may be

3 - 2

connected to supplies. Isolate

before touching.

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

WARNING: Opening the panel may expose

dangerous voltages.

417-IEC-5036

Page 11

Installation Instructions - Options IQ23x

3.5 Replacing the Battery (continued)

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

Remove Cover

TX

5

RX

BA UD

AD DR E SS

O K

1284163264

1K2

9K6

19K 2

TX

D P

A

B

C

D

CAUTION: This unit contains static sensitive devices. Suitable anti-static precautions

remove 5 screws

should be taken throughout this operation to prevent damage to the units.

BS EN100015/1 Basic Specification: protection of electrostatic sensitive devices.

Replace Battery

6

RX

BA UD

AD DR ES S

OK

19K 2

9K6

1284163264

1K2

TX

Warning: The lithium battery must not be recharged,

+

10

SET cannot download

over autodial link

Also set time, day, date.

disassembled, burnt or short circuited.

Misuse may cause explosion or fire.

Dispose of carefully. Refer to Health and

Safety Executive Guidance Note GS43.

Download Strategy

SET or

PowerTool

X.IQ2

IQ23x

Varta

CR2032

3V

7

8

SET Manual TE200147

PowerTool Manual TE200163

9 'D type'

Female

Cable/EJ101442

Replace Cover

Switch On

O

I

RJ11

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

TX

D P

A

B

C

D

IQ23x

replace 5 screws

9

10s

OR

A

B

C

D

Wait

RX

BA UD

AD DR E SS

O K

1284163264

1K2

9K6

19K 2

TX

D P

I Q 2 3 x

11

Close Panel

12

RX

AD DR ES S B AU D

OK

12 34 567 89 10

TX

SW 4

J1 6

D P

D ev B

A

B

C

D

J1 5

D ev A

Reconnect Supply to I/O, Network

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

D P

A

B

C

D

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 3 - 3

Page 12

IQ23x Installation Instructions - Options

RX

TX

OK

A

D

D P

C

B

1284163264

1K2

9K6

19K 2

AD DR ES S

BA UD

B A U D

A D D R E S S

12841 6

3 2

6 4

1 K 2

9 K 6

O

N

1 2 3 4 5 6 7 8 9 1 0

ç

1 9 K 2

12481 6

3 2

6 4

1 9 K 2

9 K 6

1 K 2

3.6 Zero Address/Baud Rate Switch Reset

Backup,

Switch Off,

1

Isolate,

Open Panel

Complete 'Replacing

the Battery' steps 1

to 4

Switch On

4

Note the Network Address

2

and Baud Rate

12481 6

3 2

6 4

A D D R E S S

1

284

1 6

3 2

6 4

e.g.

Address = 2 + 16 = 18

SET

NOT SET

5

O

I

1 9 K 2

9 K 6

1 K 2

B A U D

1 K 2

9 K 6

1 9 K 2

N

1 2 3 4 5 6 7 8 9 1 0

O

ç

Wait for Relays

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

9 K 6

1 K 2

1 9 K 2

BAU D

ADD RE SS

1284163264

1K2

9K6

19K2

D P

A

B

C

D

= 19k2 baud

= 9k6 baud

= 4k8 baud

= 1k2 baud

Set all Switch Poles

3

RX

OK

TX

to Zero

Address = 0 Baud = 0

'click'

BA UD

AD DRE SS

1284163264

1K2

9K6

19K2

A

B

C

D

NOT SET

RX

OK

TX

D P

Reset the Network Baud Rate

6

12481 6

19k2 baud

9k6 baud

4k8 baud

1k2 baud

A D D R E S S

12841 6

3 2

6 4

1 9 K 2

9 K 6

1 K 2

B A U D

3 2

6 4

1 K 2

9 K 6

1 9 K 2

N

1 2 3 4 5 6 7 8 9 1 0

O

ç

Baud Rate = B

9 K 6

1 K 2

1 9 K 2

1 9 K 2

9 K 6

1 K 2

= B

1 9 K 2

9 K 6

1 K 2

1 9 K 2

9 K 6

1 K 2

= B

= B

Reset the Network Address

7

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

D P

A

B

C

D

12481 6

3 2

6 4

1 9 K 2

9 K 6

1 K 2

e.g.

A D D R E S S

1

284

B A U D

1 6

3 2

6 4

1 K 2

9 K 6

1 9 K 2

N

1 2 3 4 5 6 7 8 9 1 0

O

ç

Address = A

= A

IQ23x

Address = 2 + 16 = 18

= A

/

SET

NOT SET

= A

/

= B

= A

/

address

Download Strategy,

1, 4 to 9, 11 to 119

Close Panel,

8

Reconnect Power to

0, 2 , 3,10 or >119

I/O

Complete 'Replacing the Battery'

steps 10 to 12

3 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 13

Installation Instructions - Replacing IQ111

Series Controllers

SHEET 4: Installation Instructions - Replacing IQ111

4 Replacing an IQ111 with an IQ231

Survey Unit

1

tcejbuSnoitseuQderiuqeRnoitcAtnempiuqElanoitiddA

gnixiF?desusrabgnixiferAselohgnixifwenllirdtsumONfI

?mm39nahtretaerghtpedlenapsI?deifidomebsihtnac,tonfI

O/I?desustuptuotnerrucerA ro(VMRShtiwIMRSecalperSEYfI

slennahcrehto

PD2lanretxElenapyalpsidenil2lanretxenasI

?dettif

PD2lanretnI?dettiflenapyalpsidenil2lanretnisI/PD/132QIesutsumSEYfInoitpo../PD/132QI

PDNlanetxE?detcennocPDNlanretxesI rof920401JE/ELBACelbacesuSEYfI

rosivrepuSlacoLrehtiedetcennocrosivrepuslacolsI

?emitotemitmorfroyltnenamrep

ylppuSyrailixuAslanimretylppusyrailixuaehterA

?desu

sredaeHkniL?desusredaehkniLerAwolebsredaehknilyfitnediSEYfI

?A/KLV5/EKLesUV5/EKL

?B/KLV51/EKLesUV51/EKL

?C/KLAm01/EKLesUAm01/EKL

?E/KLdetroppuston

?F/KLderiuqerton

?0/KLtnerrucderewopyllanretxerofkniL

)xI(rosnes

edoNlanretnI?dettifedonlanretninasIotdesuCNCsiedondnaSEYfI

wolebkcehc

draobNMTehtnodesabedonehtsI

ecnis,NMT,2CNI,2CNP,2CNC(

?)9991

,CNC(draobredlonaedonehtsI

,CNAdna,9991erofeb,CNI,CNP

,CNM,+CNX,82NX,CNE,DNA

?)CNIL

?2CNP,CNP,2CNC,CNCedonsI tekcosenilninip01100A971001JEesU

?ENMTedonsI tekcosenilninip01718301JEesU

?82NX,DNA,CNAedonsI tekcosenilninip011/3090-87esU

setaRduaB?2k1etarduabrosivrepussI 6k9otetarduabrosivrepusegnahC

rosneSlanretnIlanretninidesurosneslanretnisI

?edomlatigid

Note that KIT/IQ23x/UPGRADE also contains the 2 off 4 wide network extension cables (see step 15).

4

rewopdnalangis

244101JE/ELBACelbac

etalpdraobepytNMTesUnietalpdraobepytNMT

ecivedroretnirpottcennoc

medomottcennoc

medomottcennoc

1,605tibtesSEYfI

noDIV2esu,)slennahc2rofMRS2

SDR/xx2/TIKhtiw132QItiftsumSEYfISDR/xx2/TIK

wenhtiwelbacetelpmocecalperSEYfI

ylppusyrailixua132QIottcennocSEYfI

.elbacnoisnetxeyaw2ybslanimret

ytiraloppowsotrotcennoceriweR

otPDNrorosivrepuslacoltcennoc

,SEYfiesle,draobdracsid,krowten

etalpdraobepytNMT-erpesUnietalpdraobepytNMT-erp

otelbacDelamefyaw52ot)xeloM(

otelbacDelamyaw52ot)xeloM(

otelbacDelamyaw52ot)okcotS(

IQ23x

,IMRShcaerofeno(VMRS

)slennahc2rofMRS2ro

)slennahcowtrofeno(DIV2

920401JE/ELBAC

224101JE/ELBAC

nielbacnoisnetxeyaw2

EDARGPU/x32QI/TIK

x32QI/EDON/TIK

x32/EDON/TIK

ni100A971001JE

x32QI/EDON/TIK

ni718301JE

x32QI/EDON/TIK

ni1/3090/87

x32QI/EDON/TIK

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 4 - 1

Page 14

IQ23x Installation Instructions - Replacing IQ111

I Q 1 1 1

A B

C D

A B

C D

I Q 1 1 1

4 Replacing an IQ111 with an IQ231 (continued)

Upload IQ111 Strategy

2

WupDn or

PowerTool

X.IQF

IQ111

9 'D type'

Female

Cable/58-0750

WupDn Manual TE200162

PowerTool Manual TE200163

Note Network Address

3

Use PowerTool, Lan 0, Address 0

Top Menu

tYpe Sensor difI/p Driver Functn loGic Loop scHedule

seQnc Analog digBit Knob sWitch Time Zone Oss

User addRess intcoN calarM reView Plot calEndar

R

Q

select addRess

module

to Quit module

IQ Configuration Manual 90-1533

Note Local address

to eXit configuration

X

mode

IQ111

25 Way 'D type'

Male

OR

I Q 1 1 1

Switch Off

4

O

I

Isolate I/O, Network

5

I Q 1 1 1

O

I

WARNING: The connecting

leads may be

connected to

supplies. Isolate

before touching.

Remove all Connections

8

I Q 1 1 1

6

I Q 1 1 1

Open Panel

Remove Cover

9

I Q 1 1 1

Check Connections

7

is external 2DP fitted?

Are auxiliary supply

connections used?

is local supervisor

connected?

is external NDP fitted?

is internal 2DP fitted?

is network connected?

4 - 2

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 15

Installation Instructions - Replacing IQ111 IQ23x

V

1

4 Replacing an IQ111 with an IQ231 (continued)

Check Setup

10

Note input link settings

V D T

1

Check for

Link Headers

If Node Fitted Remove Node Card

11

Note Baud Rate Settings

9 K 6

S u p e r v i s o r

1 K 2

1 9 K 2

9 K 6

N e t w o r k

4 K 8

1 K 2

Is a node fitted?

new (TMN type) board or not?

C

CNC, CNC2, PNC, PNC2

MNC, TMN

?

ANC, AND, XN28, XNC

Note that a CNC used to

Link Header type

LK/A, B, C, E, F, 0

Check output link settings

connect a local supervisor or

NDP to the network may be

discarded

Remove IQ111

12

Replace with IQ231

13

Same centres

If mounting bars were not used, redrill - see

Sheet 1 step 3

Connect Network

if used - see step 7 above

15

RX

BA UD

AD DR ESS

OK

1284163264

1K2

9K6

19K 2

TX

see Sheet 1 step 5

A

B

C

D

D P

2 off 4 wide network

extension cables

provided in

KIT/IQ23x/UPGRADE

screen

Connect Outputs

17

Channels previously linked as current (I) will need:

either (a) Replace SRMI by SRMV or (2SRM for pair of channels)

or (b) Add 2VID for each pair of channels

Otherwise signal leads should be plugged in channel for channel

- see Sheet 1 step 7

2VID Data Sheet TA101135A

SRMV Installation Instructions 91-2853

2SRM Installation Instructions TG103210

Connect Power

14

Plug in power lead - see

Sheet 1 step 4

R + R -T + T -

R + R -T + T -

-

-

+

+

-

+-+

Note: Early IQ111s had single part

input connectors so will require

terminals to be wired.

R +R -T +T - R +R -T +T -

Connect Auxiliary Supply

18

if used - see step 7 above

see Sheet 1 step 8

2 wide extension cable

provided in

KIT/IQ23x/UPGRADE

Rewire connector to swop polarity

Connect Inputs

16

Signal leads should plug

in channel for channel see Sheet 1 step 6

024

AD DR ES S

1284163264

A

B

C

D

0 24

RX

BA UD

OK

1K2

9K6

19K 2

TX

D P

24

0

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 4 - 3

Page 16

IQ23x Installation Instructions - Replacing IQ111

123 4567 8910

RX

TX

OK

ADD RES S BAU D

SW 4

A

D

DP

C

B

J1 6

De v B

J1 5

De v A

4 Replacing an IQ111 with an IQ231 (continued)

Set Network Baud Rate to previous

19

as noted in step 10 above - see Sheet 2 step 6

Remove Cover

21

see Sheet 2 step 6

Fit Link Headers

23

to channels as noted in step 10 above

- see Sheet 2 step 10

Download Strategy file

previously saved in step 2 above

25

WupDn or

PowerTool

X.IQF

IQ231

set time, date, day of week

9 'D type'

Female

Cable/EJ101442

Set Network Address to previous

20

as noted in step 3 above - see Sheet 2 step 9

Link Input Channels

22

as noted in step 10 above - see Sheet 2 step 9

Replace Cover, Switch On,

24

Check Controller, Check Network

- see Sheet 2 steps 11 to 14

WupDn Manual TE200162

PowerTool Manual TE200163

RJ11

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

A

B

C

D

IQ231

TX

DP

OR

I Q 2 3 1

Make IQ2xx Changes

either upload to SET and make changes,

26

or change in configuration mode - see Sheet 2 step 15 .

Loop Reschedule Time: Multiply by 5 and re-enter

Sensor Scaling Mode 1: If sensor outputs a voltage signal, and scaling mode 0, linear is being used, multipy T and B by 2 and re-enter.

Sensor Scaling Mode 2: If scaling mode 2 (linearise thermistor volts) is used, change it to sensor scaling mode 3 (linearise volts).

Shared Labels: Set up digital input labels. (Copy from sensor channel of same number if appropriate).

Internal Sensors: If an internal sensor is used in internal digital mode, bit 506,1 should be set to one

Test Inputs, Test Outputs, Backup

27

see Sheet 2 step 16 17 18

Connect Local Supervisor

29

if noted in step 7 - see Sheet 3 section 3.2

Set Baud Rate of Supervisor

if 1k2 supervisor baud rate noted in step 10 , and

31

supervisor connected in step 29 above, set baud rate

Connect External Display Panel

if noted in step 7 - see Sheet 3 section 3.1

28

Connect External NDP

30

if noted in step 7 - see Sheet 3 section 3.3

Close Panel

33

of supervisor to 9k6

Connect Internal Node

32

if noted in step 10 - see Sheets 8, 9

4 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 17

Installation Instructions - Replacing IQ111+

Series Controllers

SHEET 5: Installation Instructions - Replacing IQ111+

5 Replacing an IQ111+ with an IQ231

Survey Unit

1

tcejbuSnoitseuQderiuqeRnoitcAtnempiuqElanoitiddA

IQ23x

gnixiF08x083x083(xobllamsanidexiftisI

rewoPgniylppusfoelbapacylppussniamsI

?AV06

PD2lanretxE?dettiflenapyalpsidenil2lanretxenasI SDR/xx2/TIKhtiw132QItiftsumSEYfISDR/xx2/TIK

PD2lanretnI?dettiflenapyalpsidenil2lanretnisI/PD/132QIesutsumSEYfInoitpo../PD/132QI

PDNlanetxE?detcennocPDNlanretxesI rof920401JE/ELBACelbacesuSEYfI

rosivrepuSlacoLrehtiedetcennocrosivrepuslacolsI

ylppuSyrailixuA?desuslanimretylppusyrailixuaehterA ylppusyrailixua132QIottcennocSEYfI

sredaeHkniL?desusredaehknilerA wolebsredaehknilyfitnediSEYfI

V5/KLV5/EKLesUV5/EKL

V51/KLV51/EKLesUV51/EKL

Am01/KLAm01/EKLesUAm01/EKL

edoNlanretnI?dettifedonlanretninasI otdesuCNCsiedondnaSEYfI

?)CNIL,CNM,+CNX,82NX

?ENMTedonsI tekcosenilninip01718301JEesU

?82NX,DNA,CNAedonsI tekcosenilninip011/3090-87esU

rosneSlanretnIlatigidlanretninidesurosneslanretnisI

?edom

?sgnixiftuotucralucricimesgnisu)mm

?mm39nahtretaerghtpedlenapsI?deifidomebsihtnac,tonfI

?emitotemitmorfroyltnenamrep

draobNMTehtnodesabedonehtsI

?)9991ecnis,NMT,2CNI,2CNP,2CNC(

,CNP,CNC(draobredlonaedonehtsI

,CNE,DNA,CNAdna,9991erofeb,CNI

?2CNP,CNP,2CNC,CNCedonsI tekcosenilninip01100A971001JEesU

5

ylppusrewopesaercni,tonfI

rewopdnalangis

244101JE/ELBACelbac

wolebkcehc

etalpdraobepytNMTesUnietalpdraobepytNMT

ecivedroretnirpottcennoc

medomottcennoc

medomottcennoc

1,605tibtesSEYfI

selohgnixifwenllirdtsum,SEYfI

wenhtiwelbacetelpmocecalperSEYfI

elbacnoisnetxeyaw2ybslanimret

otPDNrorosivrepuslacoltcennoc

,SEYfiesle,draobdracsid,krowten

etalpdraobepytNMT-erpesUnietalpdraobepytNMT-erp

otelbacDelamefyaw52ot)xeloM(

otelbacDelamyaw52ot)xeloM(

otelbacDelamyaw52ot)okcotS(

920401JE/ELBAC

224101JE/ELBAC

nielbacnoisnetxeyaw2

EDARGPU/x32QI/TIK

x32QI/EDON/TIK

x32QI/EDON/TIK

ni100A971001JE

x32QI/EDON/TIK

ni718301JE

x32QI/EDON/TIK

ni1/3090/87

x32QI/EDON/TIK

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 5 - 1

Page 18

IQ23x Installation Instructions - Replacing IQ111+

5 Replacing an IQ111+ with an IQ231 (continued)

Upload IQ111+ Strategy

2

WupDn or

PowerTool

X.IQF

IQ111+

Switch Off

3

O

I

WupDn Manual TE200162

PowerTool Manual TE200163

CABLE/78-1172

9 'D type'

Female

Cable/58-0750

IQ111+

Isolate I/O, Network

4

12 34 56 78 910

I Q 1 1 1 +

O

I

WARNING: The connecting leads may be

connected to supplies. Isolate

before touching.

O

I

25 way 'D type' Female

5 in line Stocko

Female

12 345 67 891 0

OR

I Q 1 1 1 +

5

I Q 1 1 1 +

Open Panel

12 34 567 89 10

I Q 1 1 1 +

Check Connections

6

is external 2DP fitted?

Remove Cover

8

is local supervisor connected?

is external NDP fitted?

A B

C D

1 23 4 5 6 7 89 1 0

is network connected?

is internal 2DP fitted?

A B

C D

I Q 1 1 1 +

Is auxiliary supply

connection used?

1 2 3 45 6 7 8 9 10

Remove all Connections

7

1 2 3 45 6 7 8 9 10

I Q 1 1 1 +

5 - 2

I Q 1 1 1 +

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 19

Installation Instructions - Replacing IQ111+ IQ23x

5 Replacing an IQ111+ with an IQ231 (continued)

Check Setup

9

Note input link settings

V DT

1

Check for

Link Headers

Link Header type

5V, 15V, 10mA

If Node Fitted Remove Node Card

10

Note address

Note baud rate settings

O N

1

284

1 6

3 2

6 4

1 K 2

1 2 3 4 5 6 7 8 9 10

9 K 6

1 9 K 2

B A U DA D D R E S S

e.g.

Address = 2 + 16 = 18

19k2 baud

SET

9k6 baud

1k2 baud

Is a node fitted?

new (TMN type) board or not?

1 5 V

CNC, CNC2, PNC, PNC2

MNC, TMN

ANC, AND, XN28, XNC

NOT SET

Note that a CNC used to

connect a local supervisor or

?

NDP to the network may be

discarded

Remove IQ111+

11

1 2 3 4 5 6 7 8 91 0

1 23 4 5 6 7 89 1 0

Replace with IQ231

12

Same centres

If mounted in small box (380 x 380 x 80 mm) using

semi-circular cutout fixings, redrill - see

Sheet 1 step 3

Connect Network

14

if used - see step 6 above

Network connections should plug in directly - see Sheet 1

step 5

Connect Outputs

16

Signal leads should be plugged in channel for channel - see

Sheet 1 step 7

Connect Power

13

Check mains supply can provide 60 VA.

Plug in power lead - see

Sheet 1 step 4

Connect Inputs

15

Signal leads should plug in channel for channel - see

Sheet 1 step 6

Connect Auxiliary Supply

17

if used - see step 6 above

24

0

BA UD

AD DR ES S

1284163264

19K 2

see Sheet 1 step 8

A

B

C

2 wide extension cable

provided in

KIT/IQ23x/UPGRADE

D

RX

OK

1K2

9K6

TX

D P

0

24

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 5 - 3

Page 20

IQ23x Installation Instructions - Replacing IQ111+

123 4567 8910

RX

TX

OK

ADD RES S BA UD

SW 4

A

D

DP

C

B

J1 6

De v B

J1 5

De v A

5 Replacing an IQ111+ with an IQ231 (continued)

Set Node Baud Rate to previous

18

as noted in step 9 above - see Sheet 2 step 6

Remove Cover

20

see Sheet 2 step 6

Fit Link Headers

22

to channels as noted in step 9 above

- see Sheet 2 step 10

Download Strategy file

previously saved in step 2 above

24

WupDn or

PowerTool

X.IQF

IQ231

set time, date, day of week

9 'D type'

Female

Cable/EJ101442

Set Network Address to previous

19

as noted in step 9 above - see Sheet 2 step 9

Link Input Channels

21

as noted in step 9 above - see Sheet 2 step 9

Replace Cover, Switch On,

23

Check Controller, Check Network

- see Sheet 2 steps 11 to 14

WupDn Manual TE200162

PowerTool Manual TE200163

RJ11

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

A

B

C

D

IQ231

TX

DP

OR

I Q 2 3 1

Make IQ2xx Changes

either upload to SET and make changes,

25

or change in configuration mode - see Sheet 2 step 15 .

Loop Reschedule Time: Multiply by 5 and re-enter

Sensor Scaling Mode 1: If sensor outputs a voltage signal, and scaling mode 0, linear is being used, multipy T and B by 2 and re-enter.

Sensor Scaling Mode 2: If scaling mode 2 (linearise thermistor volts) is used, change it to sensor scaling mode 3 (linearise volts).

Shared Labels: Set up digital input labels. (Copy from sensor channel of same number if appropriate).

Internal Sensors: If an internal sensor is used in internal digital mode, bit 506,1 should be set to one

Test Inputs, Test Outputs, Backup

26

see Sheet 2 step 16 17 18

Connect Local Supervisor

28

if noted in step 6 - see Sheet 3 section 3.2

Connect Internal Node

30

if noted in step 9 - see Sheets 8, 9

Connect External Display Panel

if noted in step 6 - see Sheet 3 section 3.1

27

Connect External NDP

29

if noted in step 6 - see Sheet 3 section 3.3

Close Panel

31

5 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 21

Installation Instructions - Replacing IQ131

Series Controllers

SHEET 6: Installation Instructions - Replacing IQ131

6 Replacing an IQ131 with an IQ233

Survey Unit

1

tcejbuSnoitseuQderiuqeRnoitcAtnempiuqElanoitiddA

gnixiF?desusrabgnixiferAselohgnixifwenllirdtsumONfI

IQ23x

?mm39nahtretaerghtpedlenapsI?deifidomebsihtnac,tonfI

O/I?desustuptuotnerrucerA rofMRS2ro(VMRShtiwIMRSecalperSEYfI

PD2lanretxE?dettiflenapyalpsidenil2lanretxenasI SDR/xx2/TIKhtiw332QItiftsumSEYfISDR/xx2/TIK

PD2lanretnI?dettiflenapyalpsidenil2lanretnisI/PD/332QIesutsumSEYfInoitpo../PD/332QI

PDNlanetxE?detcennocPDNlanretxesI langisrof920401JE/ELBACelbacesuSEYfI

rosivrepuSlacoLrehtiedetcennocrosivrepuslacolsI

?emitotemitmorfroyltnenamrep

ylppuSyrailixuA?desuslanimretylppusyrailixuaehterA ylppusyrailixua132QIottcennocSEYfI

sredaeHkniL?desusredaehkniLerA wolebsredaehknilyfitnediSEYfI

?A/KLV5/EKLesUV5/EKL

?B/KLV51/EKLesUV51/EKL

?C/KLAm01/EKLesUAm01/EKL

?D/KL)T(rotsimrehtrofkniL

?E/KLdetroppuston

?F/KLderiuqerton

?0/KL )xI(rosnestnerrucderewopyllanretxerofkniL

edoNlanretnI?dettifedonlanretninasI tcennocotdesuCNCsiedondnaSEYfI

draobNMTehtnodesabedonehtsI

?)9991ecnis,NMT,2CNI,2CNP,2CNC(

,CNP,CNC(draobredlonaedonehtsI

,CNE,DNA,CNAdna,9991erofeb,CNI

?)CNIL,CNM,+CNX,82NX

?2CNP,CNP,2CNC,CNCedonsI tekcosenilninip01100A971001JEesU

?ENMTedonsI ot)xeloM(tekcosenilninip01718301JEesU

?82NX,DNA,CNAedonsI )okcotS(tekcosenilninip011/3090-87esU

setaRduaB?2k1etarduabrosivrepussI 6k9otetarduabrosivrepusegnahC

6

slennahcrehtonoDIV2esu,)slennahc2

rewopdna

elbacwenhtiwelbacetelpmocecalperSEYfI

244101JE/ELBAC

elbacnoisnetxeyaw2otgniriwerybslanimret

,SEYfiesle,draobdracsid,krowtenot131QI

wolebkcehc

etalpdraobepytNMTesUnietalpdraobepytNMT

etalpdraobepytNMT-erpesU nietalpdraobepytNMT-erp

tcennocotelbacDelamefyaw52ot)xeloM(

ecivedroretnirpot

medomottcennocotelbacDelamyaw52

medomottcennocotelbacDelamyaw52ot

920401JE/ELBAC

224101JE/ELBAC

x32QI/EDON/TIK

x32QI/EDON/TIK

ni100A971001JE

x32QI/EDON/TIK

ni718301JE

x32QI/EDON/TIK

ni1/3090/87

x32QI/EDON/TIK

,IMRShcaerofeno(VMRS

)slennahc2rofMRS2ro

)slennahcowtrofeno(DIV2

nielbacnoisnetxeyaw2

EDARGPU/x32QI/TIK

rosneSlanretnIlatigidlanretninidesurosneslanretnisI

?edom

slatigiDlanretnIlennahctupniehtnilatigidlanretninasI

?desu02ot71egnar

Note that KIT/IQ23x/UPGRADE also contains the 2 off 2 wide network extension cables (see step 14).

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 6 - 1

1,605tibtesSEYfI

lanretnignivomybygetartsegnahcSEYfI

noslatigidlanretnidesunufoaeraotlatigid

)sdrawno12tupnilatigid(332QI

Page 22

IQ23x Installation Instructions - Replacing IQ131

I Q 1 3 1

I Q 1 3 1

6 Replacing an IQ131 with an IQ233 (continued)

Upload IQ131 Strategy

2

WupDn or

PowerTool

X.IQF

IQ131

Switch Off

3

O

I

WupDn Manual TE200162

PowerTool Manual TE200163

9 'D type'

Female

Cable/58-0750

IQ131

Isolate I/O, Network

4

I Q 1 3 1

O

I

WARNING: The connecting leads may be connected

to supplies. Isolate before touching.

25 Way 'D type'

Male

OR

5

I Q 1 3 1

Open Panel

Check Connections

6

is external 2DP fitted?

I Q 1 3 1

Is auxiliary supply

connection used?

Remove Cover

8

I Q 1 3 1

Remove all Connections

is local supervisor

connected?

A B

C D

is external NDP fitted?

is internal 2DP fitted?

A B

C D

is network connected?

7

I Q 1 3 1

6 - 2

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 23

Installation Instructions - Replacing IQ131 IQ23x

V

1

O F F

1 2 3 4 5 6 7 8

D U M B

N O R M

12481 6

3 2

6 4

6 Replacing an IQ131 with an IQ233 (continued)

Check Setup

9

Note input link settings

V D

1

Check for

Link Headers

Link Header type

LK/A, B, C, D,

E, F, 0

If Node Fitted Remove Node Card

10

C

Check output link settings

1 2 3 4 5 6 7 8

OF F

12481 6

3 2

Note network baud rate

settings on integral CNC

D U M B

N O R M

6 4

1 9 K 2

Note supervisor

baud rate settings

BAUD

1k2 9k6

after removing node

1 2 3 4 5 6 7 8

O FF

12481 6

card step 10

D U M B

N O RM

6 4

3 2

Check network address on integral CNC

e.g Address = 2 + 16 = 18

Node

L

L

H

H

N

S

Supervisor

1

O F F

SET

1

O F F

NOT

SET

Is a node fitted?

new (TMN type) board or not?

CNC, CNC2, PNC, PNC2

MNC, TMN

?

ANC, AND, XN28, XNC

9 K 6

N e t w o r k

4 K 8

1 K 2

Note that a CNC used to connect a local supervisor or

NDP to the network may be discarded

Remove IQ111

11

Replace with IQ233

12

Same centres

If mounting bars were not used, redrill - see

Sheet 1 step 3

Connect Network

if used - see step 6 above

14

RX

BA UD

AD DR ESS

OK

1284163264

1K2

9K6

19K 2

TX

see Sheet 1 step 5

A

B

C

D

D P

2 off 2 wide network

extension cables

provided in

KIT/IQ23x/UPGRADE

screen

Connect Outputs

16

Channels previously linked as current (I) will need:

either (a) Replace SRMI by SRMV or (2SRM for pair of

channels)

or (b) Add 2VID for each pair of channels

Otherwise signal leads should be plugged in channel for

channel - see Sheet 1 step 7

2VID Data Sheet TA101135A

SRMV Installation Instructions 91-2853

2SRM Installation Instructions TG103210

Connect Power

13

Plug in power lead - see

Sheet 1 step 4

R + R - T + T -

R + R - T + T -

-

-

+

+

-

+-+

R +R -T +T -

Connect Auxiliary Supply

17

if used - see step 7 above

Note: Rewire +24 Vdc from

24 Vdc terminal on IQ131 into one

terminal of 2 way extension

connector and rewire 0 V from

adjacent 0 V terminal on IQ131 to

other terminal of 2 way extension

connector.

see Sheet 1 step 8

2 wide extension cable provided

in KIT/IQ23x/UPGRADE

Note: Early IQ131s had single part input

connectors so will require terminals to

be wired.

Connect Inputs

15

Signal leads should plug in

channel for channel - see

Sheet 1 step 6

24

0

A

B

C

D

0 24

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

D P

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 6 - 3

Page 24

IQ23x Installation Instructions - Replacing IQ131

123 4567 8910

RX

TX

OK

ADD RES S BAU D

SW 4

A

D

DP

C

B

J1 6

De v B

J1 5

De v A

6 Replacing an IQ131 with an IQ233 (continued)

Set Network Baud Rate to previous

18

as noted in step 9 above - see Sheet 2 step 6

Remove Cover

20

see Sheet 2 step 6

Fit Link Headers

22

to channels as noted in step 9 above

- see Sheet 2 step 10

Download Strategy file

previously saved in step 2 above

24

WupDn or

PowerTool

X.IQF

IQ233

set time, date, day of week

9 'D type'

Female

Cable/EJ101442

Set Network Address to previous

19

as noted in step 9 above - see Sheet 2 step 9

Link Input Channels

21

as noted in step 9 above - see Sheet 2 step 9

Replace Cover, Switch On,

23

Check Controller, Check Network

- see Sheet 2 steps 11 to 14

WupDn Manual TE200162

PowerTool Manual TE200163

RJ11

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

A

B

C

D

IQ233

TX

DP

OR

I Q 2 3 3

Make IQ2xx Changes

either upload to SET and make changes,

25

or change in configuration mode - see Sheet 2 step 15 .

Loop Reschedule Time: Multiply by 5 and re-enter

Sensor Scaling Mode 1: If sensor outputs a voltage signal, and scaling mode 0, linear is being used, multipy T and B by 2 and re-enter.

Sensor Scaling Mode 2: If scaling mode 2 (linearise thermistor volts) is used, change it to sensor scaling mode 3 (linearise volts).

Shared Labels: Set up digital input labels. (Copy from sensor channel of same number if appropriate).

Internal Sensors: If an internal sensor is used in internal digital mode, bit 506,1 should be set to one

Internal Digitals: If internal digitals in the range 17 to 20 are used, the strategy should changed bymoving them to

an area of unused internal digitals on IQ233 (digital input 21 onwards).

Test Inputs, Test Outputs, Backup

26

see Sheet 2 step 16 17 18

Connect Local Supervisor

28

if noted in step 6 - see Sheet 3 section 3.2

Connect External Display Panel

if noted in step 6 - see Sheet 3 section 3.1

27

Connect External NDP

29

if noted in step 6 - see Sheet 3 section 3.3

Set Baud Rate of Supervisor

if 1k2 supervisor baud rate noted in step 9 , and

30

supervisor connected in step 29 above, set baud rate

of supervisor to 9k6

Close Panel

32

Connect Internal Node

31

if noted in step 9 - see Sheets 8, 9

6 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 25

Installation Instructions - Replacing IQ131+

Series Controllers

SHEET 7: Installation Instructions - Replacing IQ131+

7 Replacing an IQ131+ with an IQ233

Survey Unit

1

tcejbuSnoitseuQderiuqeRnoitcAtnempiuqElanoitiddA

IQ23x

gnixiF08x083x083(xobllamsanidexiftisI

rewoPgniylppusfoelbapacylppussniamsI

?AV06

PD2lanretxE?dettiflenapyalpsidenil2lanretxenasI SDR/xx2/TIKhtiw332QItiftsumSEYfISDR/xx2/TIK

PD2lanretnI?dettiflenapyalpsidenil2lanretnisI/PD/332QIesutsumSEYfInoitpo../PD/332QI

PDNlanetxE?detcennocPDNlanretxesI rof920401JE/ELBACelbacesuSEYfI

rosivrepuSlacoLrehtiedetcennocrosivrepuslacolsI

ylppuSyrailixuA?desuslanimretylppusyrailixuaehterA ylppusyrailixua332QIottcennocSEYfI

sredaeHkniL?desusredaehknilerA wolebsredaehknilyfitnediSEYfI

V5/KLV5/EKLesUV5/EKL

V51/KLV51/EKLesUV51/EKL

Am01/KLAm01/EKLesUAm01/EKL

edoNlanretnI?dettifedonlanretninasI otdesuCNCsiedondnaSEYfI

?)CNIL,CNM,+CNX,82NX

?ENMTedonsI tekcosenilninip01718301JEesU

?82NX,DNA,CNAedonsI tekcosenilninip011/3090-87esU

rosneSlanretnIlatigidlanretninidesurosneslanretnisI

?edom

decneuqeStsaF

stupnIlatigiD

?emitotemitmorfroyltnenamrep

?desu02ot71egnarlennahc

?sgnixiftuotucralucricimesgnisu)mm

?mm39nahtretaerghtpedlenapsI?deifidomebsihtnac,tonfI

draobNMTehtnodesabedonehtsI

?)9991ecnis,NMT,2CNI,2CNP,2CNC(

,CNP,CNC(draobredlonaedonehtsI

,CNE,DNA,CNAdna,9991erofeb,CNI

?2CNP,CNP,2CNC,CNCedonsI tekcosenilninip01100A971001JEesU

tupninitupnilatigiddecneuqestsafasI

7

ylppusrewopesaercni,tonfI

rewopdnalangis

244101JE/ELBACelbac

wolebkcehc

etalpdraobepytNMTesUnietalpdraobepytNMT

ecivedroretnirpottcennoc

medomottcennoc

medomottcennoc

1,605tibtesSEYfI

4ot1slennahcotstupni

selohgnixifwenllirdtsum,SEYfI

wenhtiwelbacetelpmocecalperSEYfI

elbacnoisnetxeyaw2ybslanimret

otPDNrorosivrepuslacoltcennoc

,SEYfiesle,draobdracsid,krowten

etalpdraobepytNMT-erpesUnietalpdraobepytNMT-erp

otelbacDelamefyaw52ot)xeloM(

otelbacDelamyaw52ot)xeloM(

otelbacDelamyaw52ot)okcotS(

egnahcdnastupnieriwerSEYfI

latigiddecneuqestsafevomotygetarts

920401JE/ELBAC

224101JE/ELBAC

nielbacnoisnetxeyaw2

EDARGPU/x32QI/TIK

x32QI/EDON/TIK

x32QI/EDON/TIK

ni100A971001JE

x32QI/EDON/TIK

ni718301JE

x32QI/EDON/TIK

ni1/3090/87

x32QI/EDON/TIK

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 7 - 1

Page 26

IQ23x Installation Instructions - Replacing IQ131+

7 Replacing an IQ131+ with an IQ233 (continued)

Upload IQ111+ Strategy

2

WupDn or

PowerTool

X.IQF

IQ131+

Switch Off

3

O

I

WupDn Manual TE200162

PowerTool Manual TE200163

CABLE/78-1172

9 'D type'

Female

Cable/58-0750

IQ131+

Isolate I/O, Network

4

12 34 56 78 910

I Q 1 3 1 +

O

I

WARNING: The connecting leads may be

connected to supplies. Isolate

before touching.

O

I

25 way 'D type' Female

5 in line Stocko

Female

12 345 67 891 0

OR

I Q 1 3 1 +

5

I Q 1 3 1 +

Open Panel

12 34 567 89 10

I Q 1 3 1 +

Check Connections

6

is external 2DP fitted?

Remove Cover

8

is local supervisor connected?

is external NDP fitted?

A B

C D

1 23 4 5 6 7 89 1 0

is network connected?

is internal 2DP fitted?

A B

C D

I Q 1 3 1 +

Is auxiliary supply

connection used?

1 2 3 45 6 7 8 9 10

Remove all Connections

7

1 23 4 5 6 7 89 1 0

I Q 1 3 1 +

7 - 2

I Q 1 3 1 +

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 27

Installation Instructions - Replacing IQ131+ IQ23x

7 Replacing an IQ131+ with an IQ233 (continued)

Check Setup

9

Note input link settings

V DT

1

Check for

Link Headers

Input channels

1 to 4 (T, I, V)

5 to 16 (T, I , V, D)

17 to 20 (D only, no links)

If Node Fitted Remove Node Card

10

Note address

Note baud rate settings

O N

1

284

1 6

3 2

6 4

1 K 2

1 2 3 4 5 6 7 8 9 10

9 K 6

1 9 K 2

B A U DA D D R E S S

e.g.

Address = 2 + 16 = 18

19k2 baud

SET

9k6 baud

1k2 baud

Is a node fitted?

new (TMN type) board or not?

1 5 V

Link Header type

5V, 15V, 10mA

CNC, CNC2, PNC, PNC2

MNC, TMN

ANC, AND, XN28, XNC

NOT SET

Note that a CNC used to

connect a local supervisor or

?

NDP to the network may be

discarded

Remove IQ131+

11

1 2 3 4 5 6 7 8 91 0

1 23 4 5 6 7 89 1 0

Replace with IQ231

12

Same centres

If mounted in small box (380 x 380 x 80 mm) using

semi-circular cutout fixings, redrill - see

Sheet 1 step 3

Connect Network

14

if used - see step 6 above

Network connections should plug in directly - see Sheet 1

step 5

Connect Outputs

16

Signal leads should be plugged in channel for channel - see

Sheet 1 step 7

Connect Power

13

Check mains supply can provide 60 VA.

Plug in power lead - see

Sheet 1 step 4

Connect Inputs

15

If fast sequenced digital inputs were connected

to IQ131+ input chaqnnels 17 to 20, they should

be rewired to input channels 1 to 4 and strategy modified

accordingly.

Otherwise signal leads should plug in channel for channel

- see Sheet 1 step 6

Connect Auxiliary Supply

17

if used - see step 6 above

24

0

BA UD

AD DR ES S

19K 2

9K6

1284163264

1K2

see Sheet 1 step 8

2 wide extension cable

provided in

KIT/IQ23x/UPGRADE

A

B

C

D

D P

RX

OK

TX

0

24

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 7 - 3

Page 28

IQ23x Installation Instructions - Replacing IQ131+

123 4567 8910

RX

TX

OK

ADD RES S BAU D

SW 4

A

D

DP

C

B

J1 6

De v B

J1 5

De v A

7 Replacing an IQ131+ with an IQ233 (continued)

Set Node Baud Rate to previous

18

as noted in step 9 above - see Sheet 2 step 6

Remove Cover

20

see Sheet 2 step 6

Fit Link Headers

22

to channels as noted in step 9 above

- see Sheet 2 step 10

Download Strategy file

previously saved in step 2 above

24

WupDn or

PowerTool

X.IQF

IQ233

set time, date, day of week

9 'D type'

Female

Cable/EJ101442

Set Network Address to previous

19

as noted in step 9 above - see Sheet 2 step 9

Link Input Channels

21

as noted in step 9 above - see Sheet 2 step 9

Replace Cover, Switch On,

23

Check Controller, Check Network

- see Sheet 2 steps 11 to 14

WupDn Manual TE200162

PowerTool Manual TE200163

RJ11

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

A

B

C

D

IQ233

TX

DP

OR

I Q 2 3 3

Make IQ2xx Changes

either upload to SET and make changes,

25

or change in configuration mode - see Sheet 2 step 15 .

Loop Reschedule Time: Multiply by 5 and re-enter

Sensor Scaling Mode 1: If sensor outputs a voltage signal, and scaling mode 0, linear is being used, multipy T and B by 2 and re-enter.

Sensor Scaling Mode 2: If scaling mode 2 (linearise thermistor volts) is used, change it to sensor scaling mode 3 (linearise volts).

Shared Labels: Set up digital input labels. (Copy from sensor channel of same number if appropriate).

Internal Sensors: If an internal sensor is used in internal digital mode, bit 506,1 should be set to one.

Fast Sequencing: If fast sequenced digital inputs in the input channel range 17 to 20 are used, they should be rewired

Test Inputs, Test Outputs, Backup

26

see Sheet 2 step 16 17 18

Connect Local Supervisor

28

if noted in step 6 - see Sheet 3 section 3.2

Connect Internal Node

30

if noted in step 9 - see Sheets 8, 9

and the strategy modified to move them to input channels 1 to 4.

Connect External Display Panel

if noted in step 6 - see Sheet 3 section 3.1

27

Connect External NDP

29

if noted in step 6 - see Sheet 3 section 3.3

Close Panel

31

7 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 29

Installation Instructions - Node Part 1

IQ23x

Series Controllers

SHEET 8: Installation Instructions - Node Part 1

8 Installing an auxiliary internal node board from a replaced controller - part 1

KIT/NODE/IQ23x

1

All the parts required to install

a node into the IQ23x are

included in KIT/NODE/IQ23x.

Switch Off

4

O

I

Remove Cover

7

BA UD

AD DR E SS

1284163264

1K2

9K6

19K 2

A

B

C

D

IQ131 internal

CNC board

2

The IQ131 auxiliary internal CNC

node board is replaced by the

IQ233 firmware node, so the CNC

board can be discarded.

Isolate I/O

5

A

B

C

D

O

I

WARNING: The connecting leads

may be connected to

supplies. Isolate before

touching.

RX

BAU D

ADD RES S

OK

1284163264

1K2

9K6

19K2

TX

D P

8

RX

O K

TX

D P

IQ1xx Supervisor CNC board

3

If an auxiliary internal CNC board was fitted to allow

a local supervisor or NDP to communicate over the

network, this can now be achieved by setting the local

supervisor port address in the range 1, 4 to 119 (excluding

address 10, see Sheet 3, Section 3.2) and the CNC board

can be discarded.

8

Open Panel

6

WARNING: Opening the panel

may expose

dangerous voltages.

417-IEC-5036

Remove Network Links

J47

pull off links

J48

J47

J48

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

RX

ADD RESS BAU D

OK

123 4567 8910

TX

SW 4

J1 6

DP

De v B

J1 5

A

B

C

De v A

D

remove 5 screws

RX

BA UD

AD DR ES S

OK

19K 2

9K6

1284163264

1K2

TX

CAUTION: This unit contains static sensitive devices.

Suitable anti-static precautions should be

taken throughout this operation to prevent

damage to the unit.

BS EN100115/1 Basic Specification: protection of

electrostatic sensitive devices.

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 8 - 1

9

Not ANC, AND, MNC, TMN if on internetwork.

Not INC2 if used as internetwork repeater (dumb/normal =

normal, address >= 100).

AD DR ES S

1284163264

Install Support Pillar

10

BA UD

AD DRE SS

1284163264

1K2

9K6

19K2

RX

BA UD

OK

19K 2

9K6

1K2

TX

CABLE/EJ103086

polarized

connector

J47

J48

Select Board Plate

If the node board is of

11

RX

OK

TX

PNC2, INC2, TMN) then select

the TMN type board plate, else

(CNC, PNC. INC, ANC, AND,

ENC, XN28, XNC+, MNC,

LINC) select the pre-TMN type

board plate.

TMN type (CNC2,

Connect Local Network Cable

Page 30

IQ23x Installation Instructions - Node Part 1

~

0 V

~

8 Installing an auxiliary internal node board from a replaced controller - part 1 (continued)

Screw on Plate

12

3 screws provided

Fix Node to Plate

14

4 screws provided

Place Node on Plate

13

Ensure correct orientation of node board

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

Pre-TMN type boards

J 1

P O W E R

J 2

R S 2 32 A

J 5

power connector top left

hand corner

Connect Earth Cable

15

to IQ23x

R X

BA UD

AD D RE SS

O K

1284163264

1K2

9K6

19K 2

TX

EJ101835

16

Pre-TMN type boards

J1

P O W E R

EJ101835

TMN type boards

J 7

D e v A

J 15

M o d em

D e v B

J 16

E T 1

L an B L a n A

J 9J 8

power connector top right

hand corner

Connect Earth to Node Board

TMN type boards

L an B L a n A

J7

J9J8

D ev A

J1 5

M o de m

D ev B

J2

R S 23 2 A

J5

J1 6

E T1

Connect Power Cable to Node Board

17

CABLE/EJ103087

POWER

Pre-TMN type boards

J 1

P O W E R

~

~O+

-

J 2

R S 2 3 2 A

D e v A

M o d e m

D e v B

J 5

TMN type boards

L a n B L an A

J 7

J 9J8

J 15

J 16

E T 1

CABLE/EJ103087

Ensure socket is connected to correct terminal pins (+, -, or , 0V)

Connect Local Network to Node Board (4 wide)

19

Note: ANC, AND, MNC, TMN if on internetwork

Note: INC2 if used as internetwork repeater (dumb/normal = normal,

address >=100). For LINC see step 21

CABLE/EJ103086

T T +

Lan A

R -

R +

INC, ANC, ENC, XN28,

XNC+ (circa 1988)

CNC, PNC (circa 1988)

CNC, PNC (circa 1997)

J2

Connect Power

18

Cable to IQ23x

CABLE/EJ103087

polarized connector

J2

1

SWITCH ON

DO NOT

O

INC, ANC, AND, ENC,

XN28 (circa 1997)

RX

BA UD

AD DR ES S

OK

1284163264

1K2

9K6

19K 2

TX

P O W E R

J 1

P O W E R

J 2

J 1

P O W E R

(ENC only)

J 2

R S 2 3 2 A

J 5

local network (J5)

8 - 2

J 3

L A N

local network (LAN)

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

J 7

J 2

R S 2 3 2 A R S 23 2 B

L a n BL a n A

J 4

J 5

J 3

local network (Lan A) local network (Lan A)

P O W E R

J 2

(ENC only)

J 3

J 4

J 1 3

J 1 2

R S2 3 2 A

R S2 3 2 B

L a n BL a n A

Page 31

Installation Instructions - Node Part 1 IQ23x

J 7

E T 1

J 1 6

D e v B

J 1 5

D e v A

J 9J 8

L a n B L a n A

M o d e m

8 Installing an auxiliary internal node board from a replaced controller - part 1 (continued)

Connect Local Network to Node Board (4 wide) (continued)

20

local network (Lan)

Connect Local Network to Node Board (8 wide)

21

For LINC only (if not used as internetwork Lan extension node (address >=100))

J 1

P O W E R

MNC (circa 1989)

P O W E R

J 1

J 4

L a n

1 0

9

local network (Lan A)

(a) Rewire cable EJ103086 (b) Connect cable

CABLE/EJ103086

TT+

RR+

CNC2, PNC2, INC2, TMN (circa 1999)

L a n B L a n A

J 7

J 9J 8

D e v A

J 1 5

M o d e m

D e v B

J 1 6

E T 1

Remove

4 way

T - R - R +T + T - R - R +T +

Integral modem

(TMNH only)

plug

S C N

S C N

J 1 5

J 1 1

J 1 2

Connect Internetwork and Internetwork Segment A to Node Board

22

For ANC, AND, XN28, MNC, or LINC on internetwork (for LINC connection see next page, step 22d)

For INC2 if used as internetwork repeater (dumb/normal = normal, address >=100)

(a)

(c) connect 4 wide

internetwork cable

ANC, XN28 (circa 1986)

J 1

P O W E R

L A N

J 9 J 17

CABLE/EJ103086

local network

R X

BA UD

AD DR E SS

O K

1284163264

1K2

9K6

19K 2

TX

ANC, AND, XN28 (circa 1997)

P O W E R

J 2

TT+

RR+

Wire

2 x 2 way

plugs

Ensure sockets are connected to correct terminal pins

(b)

T T +

Lan A

R -

R +

MNC INC2, TMN

P O W E R

J 1

CABLE/EJ103086

R X

BA U D

AD D RE SS

O K

1284163264

1K 2

9K 6

19K 2

TX

J 3

J 4

J 1 3

R S 2 3 2 A R S 2 3 2 B

Internetwork (Lan A)

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 8 - 3

L a n BL a n A

Internetwork (Lan A)

J 4

J 5

J 3

J 2

J 1 2

R S2 3 2 A

R S2 3 2 B

L a n BL a n A

J 4

L a n

Internetwork (Lan)

(Lan A)

Internetwork Segment A (INC2)

Internetwork (TMN)

Page 32

IQ23x Installation Instructions - Node Part 1

T -

R -

R +

T +

T -

R -

R +

T +

8 Installing an auxiliary internal node board from a replaced controller - part 1 (continued)

Connect Internetwork and Internetwork Segment A to Node Board (continued)

22

(d) connect 8 wide

LINC

J 1

P O W E R

10

9

L A N

J 9 J 1 7

J 1 5

J 1 1

Connect Internetwork and Internetwork Segment B to Node Board

23

Internetwork for INC, INC2

Internetwork Segment B for INC2 if used as internetwork repeater (dumb/normal = normal, address >=100)

J 1 2

Internetwork

internetwork cable

(a)

(d) Insert Gland into Box

(e) Connect internetwork

internetwork cable

R X

BA U D

AD D RE S S

O K

1284163264

1K 2

9K 6

19K 2

TX

(b) Place Cable in Gland

(c) Close Gland

strain relief

gland

(supplied)

R X

BA U D

AD D RE S S

O K

1284163264

1K 2

9K 6

19K 2

TX

T T +

Lan B

R -

R +

INC (circa 1988)

J 1

P O W E R

INC (circa 1997)

P O W E R

J 2

(Lan B)

Internetwork

Internetwork Segment B if

J 3

J 2

R S 2 3 2 A R S 2 3 2 B

Internetwork

(Lan B)

J 3

J 4

J 1 3

J 4

J 5

L a n BL a n A

J 1 2

R S2 3 2 A

R S2 3 2 B

L a n BL a n A

Internetwork

(Lan B)

INC2 used as

internetwork repeater

INC2 (circa 1999)

L a n B L a n A

J 7

J 9J 8

D e v A

J 1 5

M o d e m

D e v B

J 1 6

E T 1

Internetwork

8 - 4

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02

Page 33

Installation Instructions - Node Part 2

IQ23x

Series Controllers

SHEET 9: Installation Instructions - Node Part 2

9 Installing an auxiliary internal node board from a replaced controller - part 2

Connect RS232 to Node Board

24

for CNC, PNC, ANC, XNC+, XN28, AND, CNC2, PNC2, TMNE

(a) Knock out RS232/modem hole

RX

BA UD

AD DR E SS

O K

1284163264

1K2

9K6

19K 2

TX

(b) Fit appropriate cable's connector to hole

BA UD

AD DR E SS

O K

1284163264

1K2

9K6

19K 2

25 Way D

9

type

R X

TX

for CNC, CNC2, PNC,

PNC2, cable EJ100179A001

for TMNE, cable EJ103817

for ANC, AND, XN28,

cable EJ100022A003

(c) Connect RS232 to board

CNC, PNC (circa 1988)

J 1

P O W E R

J 2

R S 2 3 2 A

J 5

RS232

25 Way D type

female

1

ANC, XN28 (circa 1988)

J 1

P O W E R

J 4

J 5

J 3

J 2

R S 2 3 2 A R S 2 3 2 B

L a n BL a n A

RS232 (RS232 B)

CNC, PNC (circa 1997)

P O W E R

J 2

J 3

L A N

J 7

RS232

black sheath

CABLE/EJ100179A001

10 Way Molex Socket

(pins 2-4, 3-5 linked)

check polarity

ANC, AND, XN28 (circa 1997)

P O W E R

J 2

J 3

J 4

J 1 3

J 1 2

R S2 3 2 A

R S2 3 2 B

L a n BL a n A

RS232 (RS232 B)

CABLE/78-0903/1

RS232

(Dev B Modem)

25 Way D type

female

RS232

(Dev B Modem)

CNC2, PNC2 (circa 1999)

L a n B L a n A

J 7

J 9J 8

D e v A

J 1 5

M o d e m

D e v B

J 1 6

E T 1

black sheath

CABLE/EJ100179A001

10 Way Molex Socket

(pins 2-4, 3-5 linked)

polarized

1

TMNE (circa 1999)

L a n B L a n A

J 7

J 9J 8

D e v A

J 1 5

M o d e m

D e v B

J 1 6

E T 1

red sheath

CABLE/EJ103817

10 Way Molex Socket

polarized

25 Way D type

male

10 Way Stocko Socket

(pins 2-4 linked)

25 Way D type

male

check polarity

1

1

IQ23x Series Controllers Installation Instructions TG200539 Issue 1/A 26/3/02 9 - 1

Page 34

IQ23x Installation Instructions - Node Part 2

J 7

E T 1

J 1 6

D e v B

J 1 5

D e v A

J 9J 8

L a n B L a n A

M o d e m

E

9 Installing an auxiliary internal node board from a replaced controller - part 2 (continued)

Connect Device to IQ23x RS232/Modem Connector

25