Page 1

Outside Humidity and Temperature Sensor

HO

2

Important: Retain these instructions

Installation Instructions

HT/O

CONTENTS

1 Unpacking.......................................................................... 1

2 Installation .......................................................................... 1

1 Unpacking

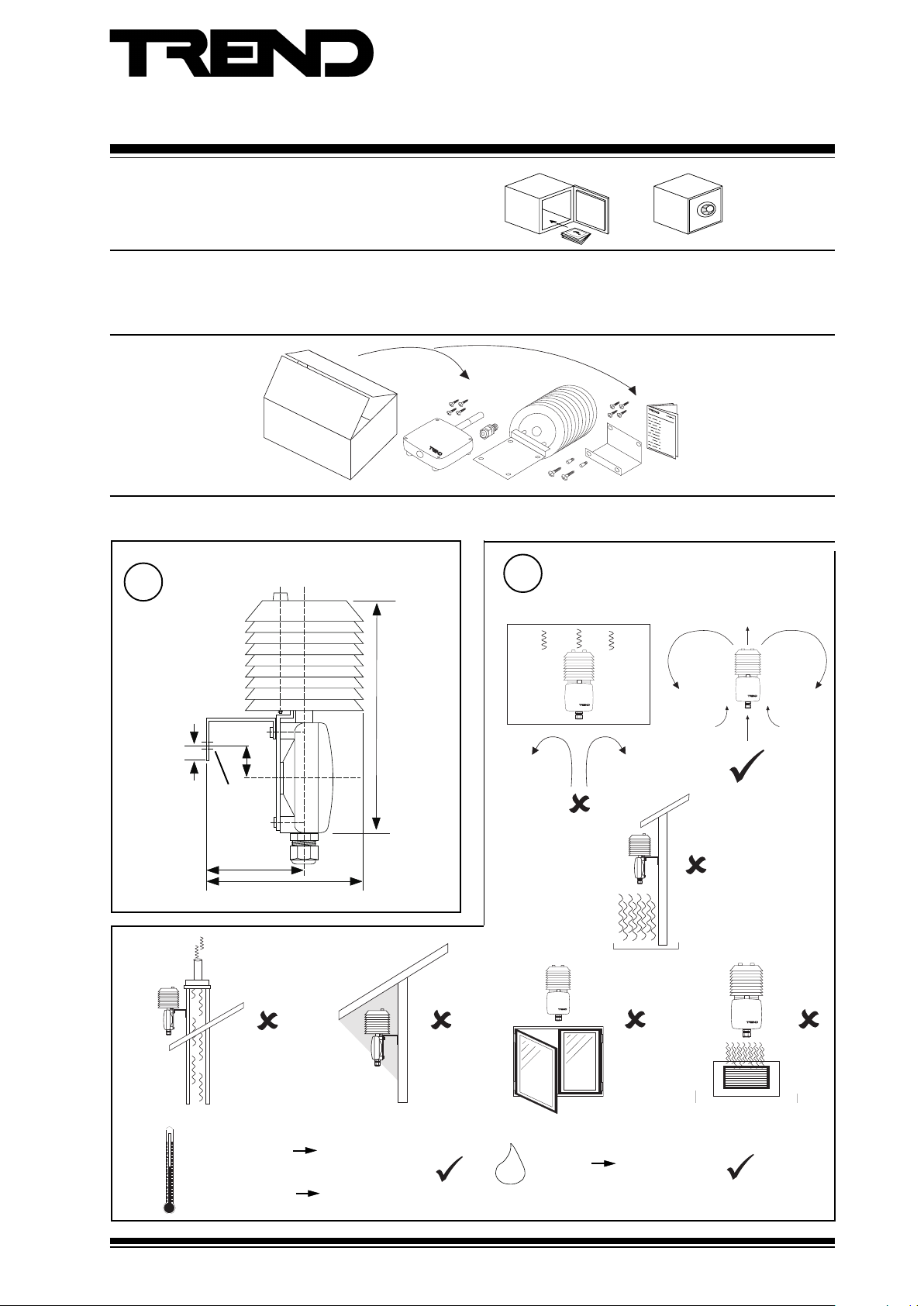

2 Installation

1

Dimensions

3 Fault Finding ...................................................................... 4

4 Maintenance ...................................................................... 5

5 Disposal ............................................................................. 8

HT/O Installation

Instructions TG200992

2

Requirements

a

196 mm, 7.72”

0.87”

Ø 5 mm

0.2”

112 mm, 4.4”

22 mm

d

+60 °C (+140 °F)

+50 °C (+122 °F)

b

e

0 %RH 100 %RH

Protection: IP65

f

10 mm, 0.39”

69.5 mm, 2.74”

c

g

ambient limit

-40 °C (-40 °F)

measurement

-30 °C (-22 °F)

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

1

Page 2

HT/O Installation Instructions

2 Installation (continued)

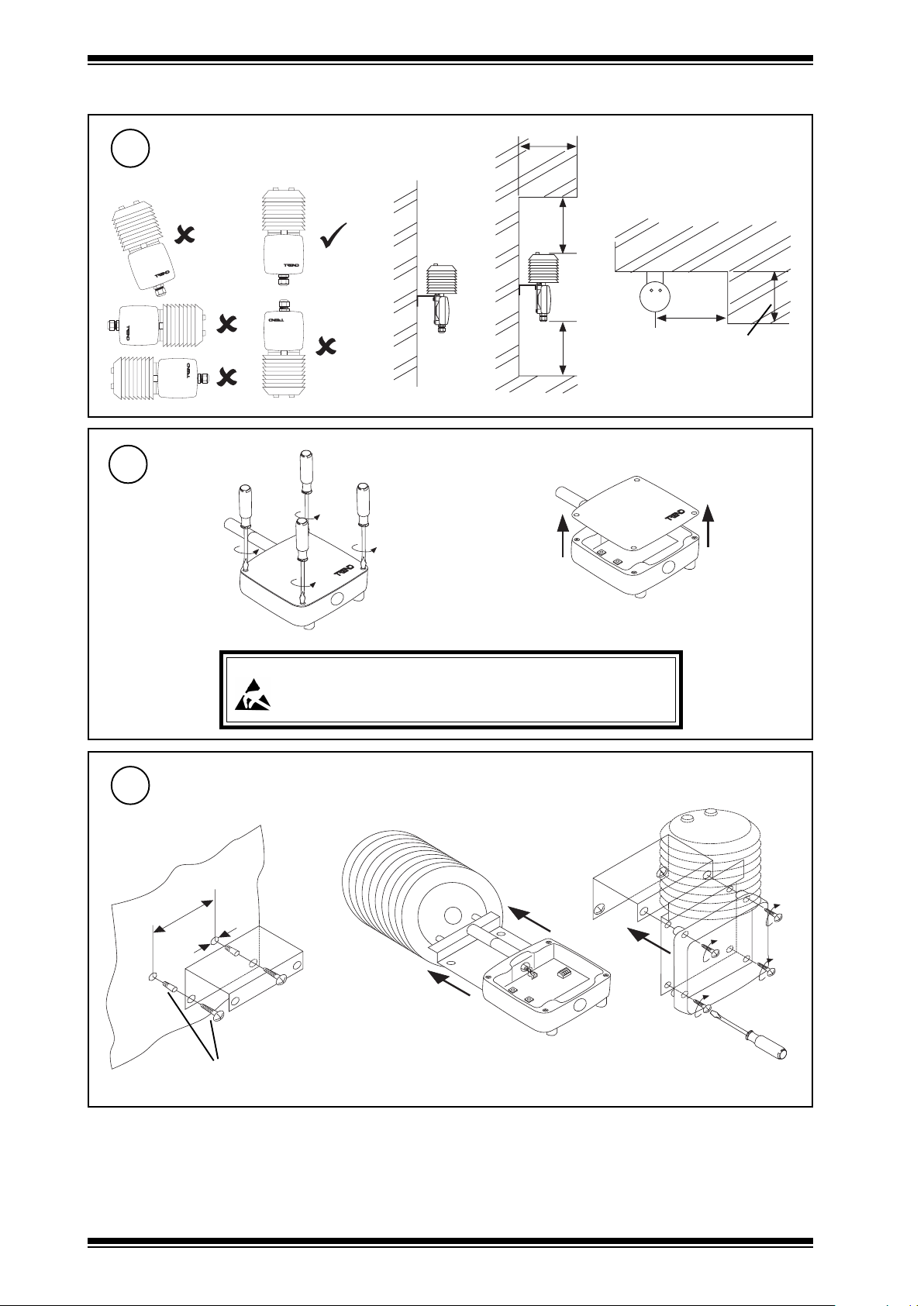

2

h

3

Requirements (continued)

Remove Cover

a

ij k

b

B1 < L1

L1

> 1 m, 1 yd

L2

B2 < L2

Caution: This unit contains static sensitive devices. Suitable anti-static precautions

4

Fit Bracket, Shield and Sensor

a

44 mm (1.73”)

2 wallplugs and screws supplied

Ø 6 mm (0.24”)

should be taken throughtout the operation to prevent damage to the units.

BS EN100015/1 Basic Specification: protection of electrostatic sensitive

devices.

c

b

2

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

Page 3

Installation Instructions HT/O

I Q

2 Installation (continued)

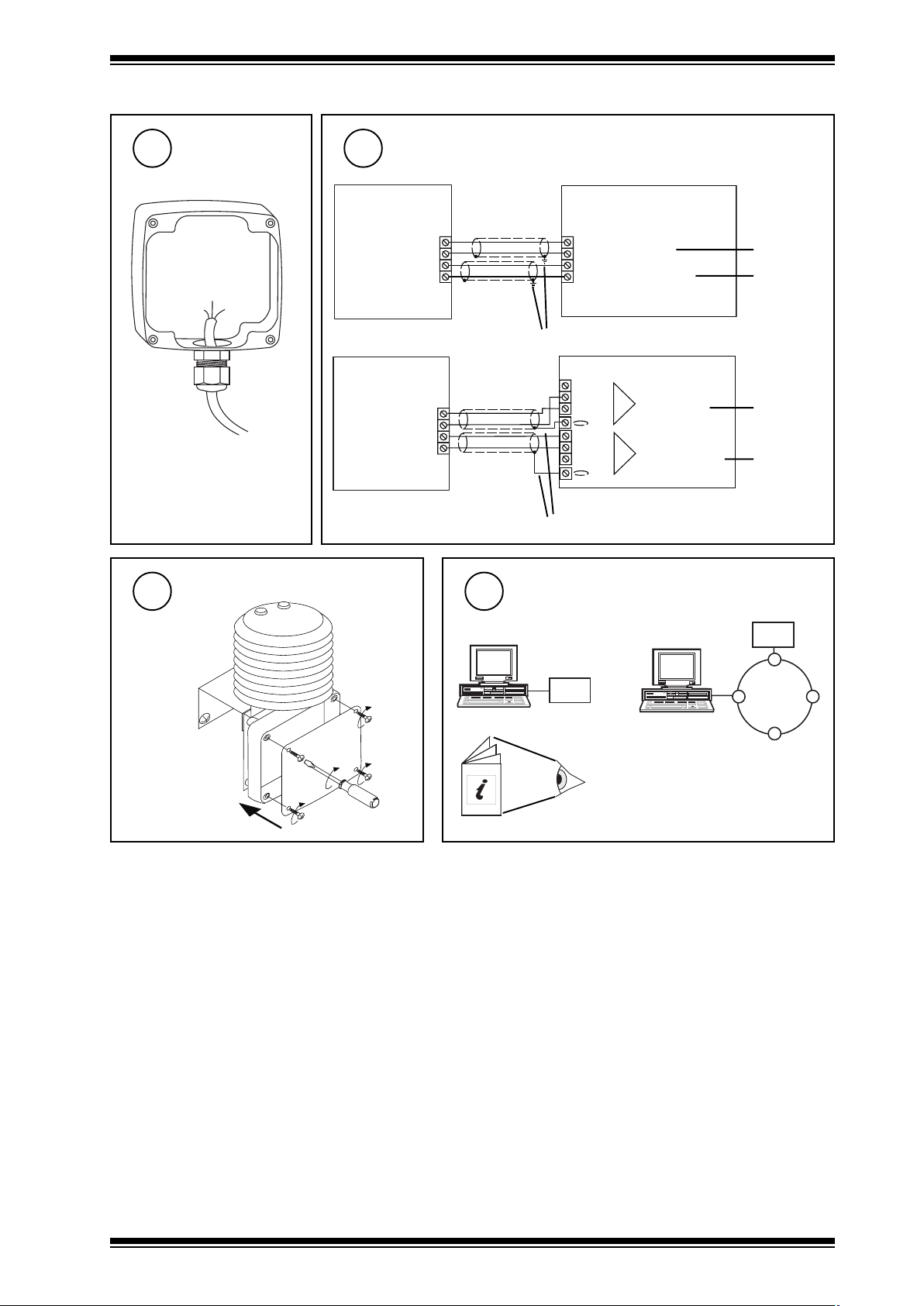

5

7

Insert Cable

through gland

M16 gland

Fit Cover

6

Wire to Controller

V+

RH

T

Tp

V+

RH

T

Tp

8

IQ1 & IQ2

C (+24V)

} humidity

IN

C

} temperature

IN

earth (ground) screens at IQ end

N

N+1

IQ3

humidity

temperature

0 (0V)

N (in)

+ (+24V)

0 (0V)

N+1 (in)

+ (+24V)

earth (ground) screens at IQ end

Configure IQ

2 analog input

channels

linked for

current (I)

linked for

thermistor

(T)

linked for

current (I)

linked for

thermistor

(T)

or

I Q

IQ Configuration Manual 90-1533

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

3

Page 4

HT/O Installation Instructions

2 Installation (continued)

9

Set up IQ Sensor types

It is recommended to use SET (Software Tool) for the setting of the sensor type module. For all IQ2 series controllers with

firmware version 2.1 or greater, or IQ3 series controllers, the following SET Unique Sensor References should be used:

Humidity :Humidity I

Temperature :Thermistor HTOT (°C)

Thermistor HTOT F (°F)

Alternatively enter scaling manually as defined in tables below.

For all other IQ contriollers see Sensor Scaling Reference Card TB100521A

Temperature (thermistor)

(-30 to +50 °C, -22 t0 122 °F)

10

Test System

:stinUC°F°

Y

E

U

L

P

xxIxO

1 146.205221

2 074.304401

3 064.40368

4 366.60105

5 866.7023

6 201.85-32

7 284.801-41

8 708.851-5

9 870.902-4-

epyttupnI

tnenopxE

reppU

rewoL

stnioP

01 992.952-31-

11 674.903-22

)Vmreht(1

3

55131

53-13-

11

-

Humidity (current)

(0 to 100 %RH)

Y

E

U

L

P

xxIxO

1 40

2 02001

epyttupnI

tnenopxE

reppU

rewoL

stnioP

)Amrruc(2

3

001

0

2

3 Fault Finding

stluaFsesuaCelbissoPseidemeR

emitesnopsergnoLdetullopretliFretlifecalpeR

eruliafetelpmoCylppusrewopoN elbacdn

hgihootgnidaerytidimuHeborprosnesnonoitasnednoC yrassecenfiretlifecalperdnaeborpyrD

IQ

Δ H

aylppusrewopkcehC

Δ T

4

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

Page 5

Installation Instructions HT/O

U P

D O W N

4 Maintenance

Over time, the sensing element may become covered in dust. The dust can be removed using compressed air. Under no

circumstances should water or cleansing agents be used on the sensing elements.

It is recommended that the accuracy of the sensor is verified every 12 months. If the sensor falls outside the quoted accuracy,

replace the filter and recalibrate as shown below:

1

2

Remove Cover

Caution: This unit contains static sensitive devices.

Suitable anti-static precautions should be taken

throughtout the operation to prevent damage to

the units.

BS EN100015/1 Basic Specification: protection of

electrostatic sensitive devices.

Detach Sensor

3

Remove from Radiation Shield

4

Replace filter

a unscrew

See Section 5, Disposal

b

d

c ACC/HTO/FILTER

Caution: Do not touch humidity sensing element

Preparation

5

• Keep sensor and humidity chamber in same room for

4 hours before.

• Place probe in humidity chamber 30 mins before.

• Keep temperature constant during calibration.

Locate buttons

6

push

buttons

U P

D O W N

calibration

LED

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

5

Page 6

HT/O Installation Instructions

4 Maintenance (continued)

7

• Start calibration at lower humidity point.

• Difference between the two points should be >30%RH

Low Humidity Calibration

1 Remove lid from the calibration chamber (ACC/CAL/HT)

and clean chamber thoroughly.

2 Insert one of the cloths provided with the calibrating

liquid. Pour calibrating liquid (ACC/CAL/HT/35%) onto

the fabric. Refit lid and screw tightly.

3 Insert probe into sensor aperture of chamber and tighten

collar to provide air tight seal around the probe. Wait

30 min.

4 Press Down pushbutton for 3 s to start. LED will illuminate.

5 Press Up or Down pushbutton to adjust measured value

in 0.1% steps.

6 Either: Press Up pushbutton for 3 s to stop. Calibrated

value is stored. LED is extinguished.

Or: Press Down pushbutton for 3 s to exit calibration

without storing value. LED is extinguished.

8

• This calibration decreases accuracy over remainder of

working range

Single Point Humidity Calibration

1 Remove lid from the calibration chamber (ACC/CAL/HT)

and clean chamber thoroughly.

2 Insert one of the cloths provided with the calibrating

liquid. Pour calibrating liquid (ACC/CAL/HT/35% or /

80%) onto the fabric. Refit lid and screw tightly.

3 Insert probe into sensor aperture of chamber and tighten

collar to provide air tight seal around the probe. Wait

30 min.

4 Either: (If chamber humidity >50%RH.) Press Up

pushbutton for 3 s to start. LED will illuminate.

Or: (If chamber humidity <50%RH.) Press Down

pushbutton for 3 s to start. LED will illuminate.

5 Press Up or Down pushbutton to adjust measured value

in 0.1% steps

6 Either: Press Up pushbutton for 3 s to stop. Calibrated

value is stored. LED is extinguished.

Or: Press Down pushbutton for 3 s to exit calibration

without storing value. LED is extinguished.

For calibration over whole working range

One point calibration

For calibration over limited range about single point

Two point calibration

High Humidity calibration

7 Remove lid from the calibration chamber (ACC/CAL/HT)

and clean chamber thoroughly.

8 Insert one of the cloths provided with the calibrating

liquid. Pour calibrating liquid (ACC/CAL/HT/80%) onto

the fabric. Refit lid and screw tightly.

9 Insert probe into sensor aperture of chamber and tighten

collar to provide air tight seal around the probe. Wait

30 min.

10 Press Up pushbutton for 3 s to start. LED will illuminate.

11 Press Up or Down pushbutton to adjust measured value in

0.1% steps

12 Either: Press Up pushbutton for 3 s to stop. Calibrated

value is stored. LED is extinguished.

Or: Press Down pushbutton for 3 s to exit calibration

without storing value. LED is extinguished.

9

Replace Radiation Shield

10

6

Re-attach Sensor

11

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

Replace Cover

Page 7

Installation Instructions HT/O

4 Maintenance (continued)

12

Test System

IQ

Δ T

Δ H

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

7

Page 8

HT/O Installation Instructions

5 Disposal

WEEE Directive :

At the end of their useful life the packaging and

product should be disposed of by a suitable

Do not dispose of with normal household waste.

Do not burn.

recycling centre.

Please send any comments on this or any other Trend technical publication to techpubs@trendcontrols.com

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du

Bois 37,Switzerland by its Authorized Representative, Trend Control Systems Limited.

©Trend Control Systems Limited 2007. Trend Control Systems Limited reserves the right to revise this publication from time to time and make

changes to the content hereof without obligation to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www.trend-controls.com

8

HT/O Installation Instructions TG200992 Issue 1/A 30/01/08

Loading...

Loading...