Page 1

DPIA

2-WIRE DIFFERENTIAL PRESSURE TRANSMITTERS

CURRENT OUTPUT

SPECIFICATION DATA & MOUNTING INSTRUCTIONS

FEATURES

Monitoring gaseous, non-aggressive media

Piezo-resistive pressure transducer

Up to 40 kPa overload capacity

Rugged design; protection class IP54

Easy installation and wiring connection

Measurement range adjustable by jumper

Response time adjustable by jumper

Pushbutton zero adjustment

GENERAL

The differential pressure transmitters of the DPIA series are

used for measuring differential pressure, positive pressure,

and vacuum. The transmitters are suitable for:

air-conditioning,

building automation,

environmental protection,

valve and damper control,

filter and blower monitoring,

control of air flows.

Models

order no.

DPIA-100-250 0...100 Pa1) 0...250 Pa 20 kPa 40 kPa

DPIA-250-500 0...250 Pa1) 0...500 Pa 20 kPa 40 kPa

DPIA-500-1000 0...500 Pa1) 0...1 kPa 20 kPa 40 kPa

DPIA-1000-2500 0...1 kPa2) 0...2.5 kPa 40 kPa 70 kPa

1)

5% of FS; 2) 2.5% of FS

Supplied complete with connection kit comprising 2 m (2yds

7”) tubing, 2 connection tubes, and 4 screws

pressure range

1 2

overload

capacity

bursting

pressure

SPECIFICATION

Supply voltage 15 to 30 Vdc

Output signal 4...20 mA, two-wire

Maximum load 500 Ω

Pressure medium Air and non-aggressive

gases

Working temperature 0...50 °C

Linearity and hysteresis error 1.0% of FS

Temperature error at 0...50°C 1.0% of FS

Storage temperature -10 to 70 C (14 to 158 °F)

Humidity 0...95% rh, non-condensing

Long-term stability, typical

DPIA-100-250 to DPIA-500-1000

2.5% of FS per year

DPIA-1000-2500 1.5% of FS per year

Repetition accuracy 0.2% of FS

Position dependence 0.02% of FS per g

Response time 1s (switchable to 100 ms)

Process connection 6 mm (0.24”) hose pipe

Electrical connection Screw terminal block for wire

up to 1.5 mm² (16 AWG)

Housing material ABS and POM

Cable entry M20x1.5 (polyamide)

Protection class IP54 as per EN60529

EMC EN60770, EN61326

Weight approx. 130 g (4.57ozs)

1)

5.0% of FS

2)

2.5% of FS

DPIA Data Sheet TA200879 Issue 2, 3/03/2009 1

EN0B-0467GE51 R0707

Page 2

DPIA Data Sheet

FUNCTION

The DPIA Two-Wire Differential Pressure Transmitters are

equipped with an integrated piezo-resistive pressure

transducer designed so that the pressure to be measured is

applied to a thin membrane made of monosilicon, thus

deflecting it. The semiconductor resistors on the membrane

detect this mechanical deflection and generate an electrical

output signal. The arrangement of the resistors

simultaneously compensates for the temperature response.

The signal of the pressure transducer is converted into the

output signal by high-gain operation amplifiers.

The electrical output signal changes within the specified error

limits in proportion to the applied pressure.

NOTE: All DPIA Two-Wire Differential Pressure

Transmitters are factory pre-set to a response time

of 1s (slow).

NOTE: All DPIA Two-Wire Differential Pressure

Transmitters are factory pre-set to the lower

pressure range 1.

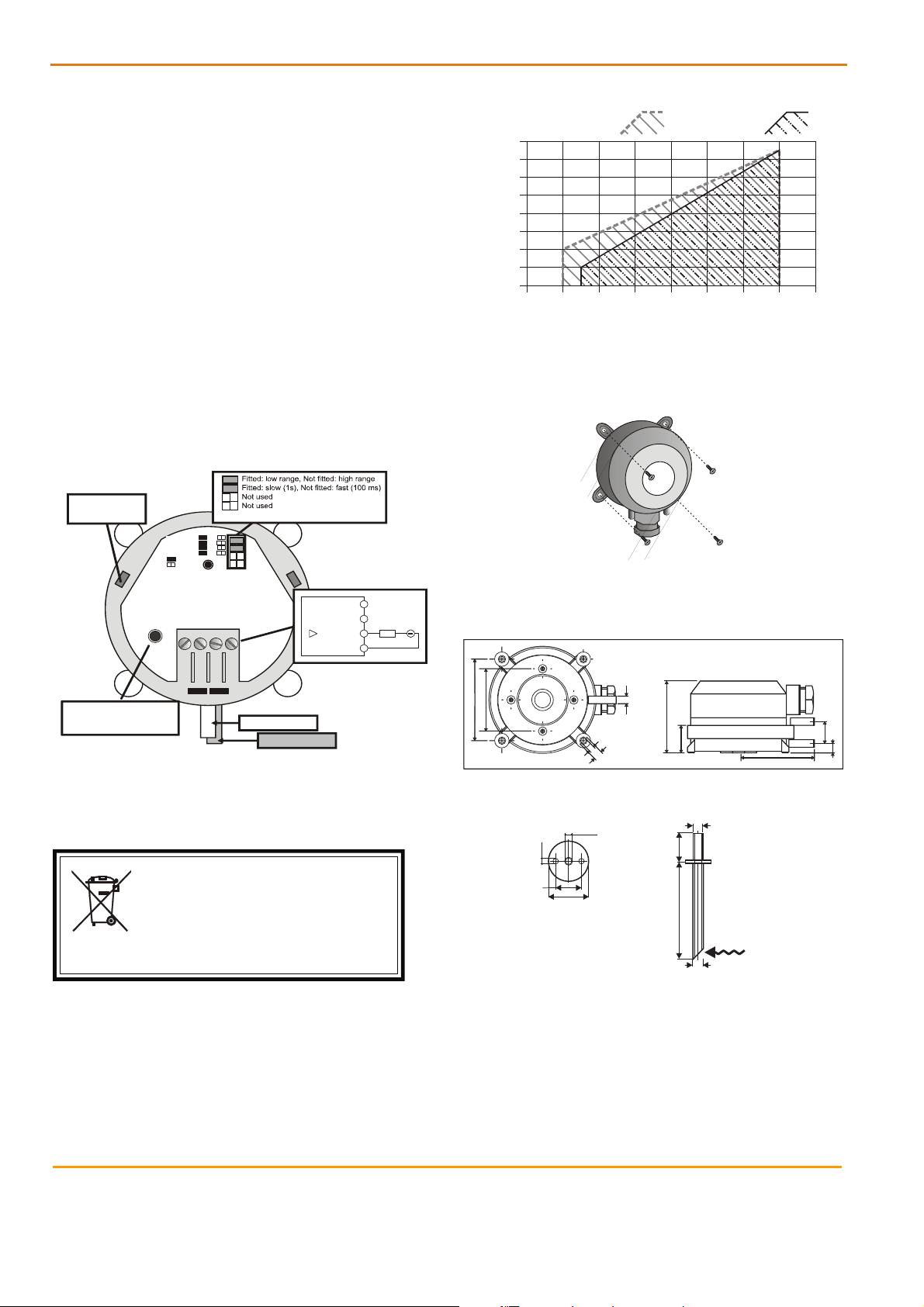

WIRING

storage positions

for pin plugs

Range

Response

Differential Pressure Transmitter

Pressure range 0 ... 100 Pa / 0 ... 250 Pa

Overload capacity 25 kPa

Linearity and hyst. Error <= +-1 % FS

Input 15 ... 30 V DC

Output 4 ... 20 mA

low

slow fast

Jumper yes

Jumper no

DPIA-100-250

Input

24 VDC

1

Default: links fitted

high

Output

4...20 mA

Do not

use

23

(Do not use)

4

(Do not use)

Do not

use

15 to 30 Vdc

4

...20 mA

4

3

load

2

1

permissible Vdc load permissible Vac load

800

600

400

200

resistive load (ohms)

0

201816

supply voltage (2-wire versions: Vdc, only)

Fig. 2. Permissible load vs. supply voltage

2422

MOUNTING

Fig. 3. Mounting

It is sufficient to use two screws to mount the unit.

DIMENSIONS

Ø6 (0.24”)

32302826

Zero Point Deviation:

Disconnect hoses and press

for 5 s to correct zero offset

P2 (low pressure)

P1 (high pressure)

50 (1.97”)

65.05 (2.56”)

Fig. 1. Wiring details

Fig. 4. Dimensions in mm (inches)

DISPOSAL

(0.13”)

WEEE Directive

At the end of their useful life the packa

and product should be disposed of by a

:

ging

suitable

recycling centre.

Do not dispose of with normal household waste.

Do not burn.

Please send any comments about this or any other Trend technical publication to techpubs@trendcontrols.com

© 2009 Honeywell

Technologies Sàrl, ECC Division. All rights rese

Honeywell Technologies Sàrl, Z.A. La Pièce, 16, 1180 Rolle, Sw

Trend Control Systems Limited reserves the right to revise this publi

person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44

rved. Manufactured for and on behalf of the Environmental and Combustion Controls Division of

itzerland by its Authorized Representative.

cation from time to time and make changes to the content hereof without obligation to notify any

(0)1403 211888 Fax:+44 (0)1403 241608 www.trendcontrols.com

Trend Control Systems USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. T

2

EN0B-0467GE51 R0707

el: (425)897-3900, Fax: (425)869-8445 www.trendcontrols.com

3.4 mm

16 mm, (0.63”)

25 mm, (0.98”)

Ø4.5 (0.18”)

8.5 (0.33”)

4 mm, (0.16”)

Ø6.5 mm, (0.26”)

57.5 (2.26”)

18 mm

60 mm

6.5

22 (0.86”)

59 (2.33”)

Ø6 mm, (0.24”)

(0.73”)

(2.36”)

Fig. 5 Connection tube

DPIA Data Sheet TA200879 Issue 2, 3/03/2009

18 (0.70”)

7.5 (0.29”)

Loading...

Loading...