Travis 430 Owner’s Manual

430 Ember-Glo™

GSR2 Insert

Owner’s Manual

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Tested and Listed by

HOT GLASS WILL CAUSE

BURNS

DO NOT TOUCH GLASS

UNTIL COOLED

NEVER ALLOW CHILDREN

TO TOUCH GLASS

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance

and shall be installed for the protection of children

Report# G100518003PRT-002

ANSI Z21.88-2017

CSA 2.33-2017

Direct Vent Fireplace Insert

Masonry or Factory-Built

(Metal) Wood-Burning

Fireplace

Residential or Mobile Home

and other at-risk individuals.

This appliance may be installed in an aftermarket, permanently located, manufactured home

(USA only) or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. A conversion

kit is supplied with the appliance.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Travis Industries, Inc. 12521 Harbour Reach Dr., Mukilteo, WA 98275 www.travisproducts.com

Copyright 2019, T.I. $10.00 1/11/2021 100-01521

2 Introduction

Introduction

We welcome you as a new owner of a 430 GSR2 Insert. In purchasing this fireplace insert you have

joined the growing ranks of concerned individuals whose selection of an energy system reflects both a

concern for the environment and aesthetics. It is one of the finest home heaters the world over. This

manual will explain the installation, operation, and maintenance of this heater. Please familiarize yourself

with the Owner's Manual before operating your heater and save the manual for future reference. Included

are helpful hints and suggestions that will make the operation and maintenance of your new heater an

easier and more enjoyable experience. We offer our continual support and guidance to help you achieve

the maximum benefit and enjoyment from your heater.

Important Information

No other 430 EG GSR2 Insert has the same serial

number as yours. The serial number is below and to

the left of the gas control valve.

This serial number will be needed in case you require

service of any type.

Model: 430 EG GSR2

Serial Number:

Purchase Date:

Purchased From:

Register your warranty online at:

traviswarranty.com

Save Your Bill of Sale.

To receive full warranty coverage, you will

need to show evidence of the date you

purchased your heater.

We suggest that you attach your Bill of Sale

to this page so that you will have all the

information you need in one place should the

need for service or information occur.

Listing Details

This appliance was listed by Intertek. The listing label is attached to the appliance near the gas control

valve. A copy is shown on page 44.

Massachusetts Approval

This manual has been submitted to the Massachusetts Board of State Examiners of Plumbers and Gas Fitters.

National Fireplace Institute

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Table of Contents 3

Introduction ...................................................... 2

Important Information ...................................... 2

Listing Details ................................................... 2

Features ............................................................ 6

Installation Options .......................................... 6

Heating Specifications ..................................... 6

Dimensions ....................................................... 6

Electrical Specifications (for blowers) ........... 6

Fuel .................................................................... 6

Installation Warnings ....................................... 7

Packing List ...................................................... 7

Additional Items Required ............................... 7

Order of Installation ......................................... 7

Fireplace Requirements .................................. 8

Masonry Fireplace Hearth Requirements ...... 8

Factory-Built (Metal) Wood-Burning Fireplace

Requirements ................................................... 9

Factory Built Fireplace Hearth Requirements9

Clearances ...................................................... 10

Mantel Clearances .............................................. 10

Televisions Placed Above the Insert ............ 11

Leveling Bolts ................................................. 12

Electrical Requirements ................................ 13

Gas Line Requirements ................................. 14

Gas Inlet Pressure .............................................. 14

Gas Line Installation ...................................... 15

Vent Requirements ........................................ 16

Vent Installation ............................................. 17

Vent Location ................................................. 18

Altitude Considerations ................................. 18

Vent Attachment – Tight Installations .......... 19

Exhaust Restrictor Settings .......................... 21

Glass Frame Removal and Installation ........ 24

Steps for Finalizing the Installation ............. 25

Before You Begin ........................................... 28

Remote Set-Up ............................................... 29

Starting the Heater for the First Time .......... 30

Location of Controls ...................................... 30

Direct Operation ............................................. 30

Continuous/Intermittent Pilot Switch ........... 31

Remote Operation .......................................... 32

Manual On-Off / Smart Thermostat / Standard

Thermostat ..................................................... 33

Mode Controls (Flame, Blower, Light,

Comfort Control, EmberBed Light) .............. 34

Mode Controls - continued ........................... 35

Display Fahrenheit or Celsius ...................... 35

Low Battery Indicator .................................... 36

Battery Replacement ..................................... 36

Power Outages ............................................... 36

Child-Proof Feature ....................................... 37

Normal Operating Sounds ............................ 37

Normal Operating Odors ............................... 37

Maintaining Your Heater's Appearance ....... 38

Accent Light Replacement ............................ 38

Ember-Glo Bulb Replacement ...................... 39

Yearly Service Procedure ............................. 41

Troubleshooting Table .................................. 42

Wiring Diagram .............................................. 43

Replacement Parts ........................................ 43

CONDITIONS & EXCLUSIONS ...................... 45

IF WARRANTY SERVICE IS NEEDED: ......... 45

LP Conversion Instructions .......................... 46

Fireback Installation ...................................... 49

Oak and Birch Log Set Installation (sku#

94500957, 94500956) ...................................... 53

Log Set Overview – Oak (sku# 94500957) ... 53

Log Set Overview – Birch (sku# 94500956) . 54

Driftwood Log Set Installation (sku#

94500953) ........................................................ 63

Log Set Overview – Driftwood (sku#

94500953) ........................................................ 65

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

4 Safety Precautions

Failure to follow all of the requirements may result in property damage, bodily injury, or even death.

Young children should be carefully supervised when they are in the same room

as the appliance. Toddlers, young children, and others may be susceptible to

accidental contact burns. A physical barrier is recommended if there are at-risk

individuals in the house. To restrict access to a fireplace or stove, install an

adjustable safety gate to keep toddlers, young children, and other at-risk

individuals out of the room and away from hot surfaces.

Children and adults should be alerted to the hazards of high surface temperature

and should stay away to avoid burns or clothing ignition. Do not touch the hot

surfaces of the heater. Educate all children of the danger of a high-temperature

heater.

Due to the high temperature, the heater should be located out of traffic and away

from furniture and draperies.

This unit must be installed by a qualified installer to prevent the possibility of an explosion.

This appliance must be installed in accordance with all local codes if any; if not, in U.S.A. follow ANSI

Z223.1 and NFPA 54(88), in Canada follow CSA B149.1.

A manufactured home (USA only) or mobile home OEM installation must conform with the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or, when such a

standard is not applicable, the Standard for Manufactured Home Installations, ANSI/NCSBCS

A225.1, or Standard for Gas Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4. This

appliance may be installed in Manufactured Housing only after the home is site located.

All exhaust gases must be vented outside the structure of the living area. Combustion air is drawn

from outside the living-area structure. The venting must not be connected to a chimney flue serving a

separate solid-fuel burning appliance.

Notify your insurance company before hooking up this fireplace.

The instructions in this manual must be strictly adhered to. Do not use makeshift methods or

compromise in the installation. Improper installation will void the warranty and safety listing.

This heater is approved for use with natural gas (NG) or propane (LP). Burning the incorrect fuel will

void the warranty and safety listing and may cause an extreme safety hazard. Direct questions about

the type of fuel used to your dealer.

Contact your local building officials to obtain a permit and information on any installation restrictions

or inspection requirements in your area.

If the flame becomes sooty, dark orange in color, or extremely tall, do not operate the heater. Call

your dealer and arrange for proper servicing.

It is imperative that control compartments, screens, or circulating air passageways of the heater be

kept clean and free of obstructions. These areas provide the air necessary for safe operation.

Do not operate the heater if it is not operating properly in any fashion or if you are uncertain. Call

your dealer for a full explanation of your heater and what to expect.

Do not store or use gasoline or other flammable liquids in the vicinity of this heater.

Do not operate if any portion of the heater was submerged in water or if any corrosion occurs.

Immediately call a qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control which has been underwater.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Safety Precautions 5

Safety Warnings (continued)

Because this heater can be controlled by a thermostat there is a possibility of the heater turning on

and igniting any items placed on or near the appliance.

Light the heater using the built-in igniter. Do not use matches or any other external device to light

your heater.

Never remove, replace, modify, or substitute any part of the heater unless instructions are given in

this manual. All other work must be done by a trained technician. Don't modify or replace orifices.

The viewing glass should be opened only for conducting service.

Allow the heater to cool before carrying out any maintenance or cleaning.

Operate the heater according to the instructions included in this manual.

If the main burners do not start correctly turn the gas off and call your dealer for service.

This unit is not for use with solid fuel.

Do not place anything inside the firebox (except the optional artwork).

Warning: Do not operate appliance with the glass front removed, cracked, or broken. Replacement

of the glass should be done by a licensed or qualified service person.

Do not throw this manual away. This manual has important operating and maintenance instructions

that you will need at a later time. Always follow the instructions in this manual.

Instruct everyone in the house how to shut the gas off to the appliance and at the gas main shutoff

valve. The gas main shutoff valve is usually next to the gas meter or propane tank and requires a

wrench to shut off.

A barrier designed to reduce the risk of burns from the hot viewing glass is provided with this

appliance and shall be installed for the protection of children and other at-risk individuals.

If the barrier becomes damaged, the barrier shall be replaced with the manufacturer’s barrier for this

appliance.

Clothing or other flammable material should not be placed on or near the appliance.

Any safety screen, guard, or barrier removed for servicing an appliance must be replaced prior to

operating the appliance.

Installation and repair should be done by a qualified service person. The appliance should be

inspected before use and at least annually by a professional service person. More frequent cleaning

might be required due to excessive lint from carpeting, bedding material, et cetera. It is imperative

that control compartments, burners, and circulating air passageways of the appliance be kept clean.

Travis Industries, Inc. grants no warranty, implied or stated, for the installation or

maintenance of your heater, and assumes no responsibility of any consequential damage(s).

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

6 Features and Specifications

Features

- Works During Power Outages (battery backup system)

- Blowers and Remote Control Included

- Continuous or Intermittent (GreenSmart) Pilot

- Convenient Operating Controls

- Variable-Rate Heat Output

- Accent Lights

Installation Options

Residential or Mobile Home

Fireplace Insert

Existing Masonry or Factory Built (Metal)

Wood-Burning Fireplace

Heating Specifications

Approximate Heating Capacity (in square feet)* 500 to 1,600 500 to 1,600

Maximum BTU Input Per Hour 31,000 31,000

* Heating capacity will vary with floor plan, insulation, and outside temperature.

Natural Gas Propane

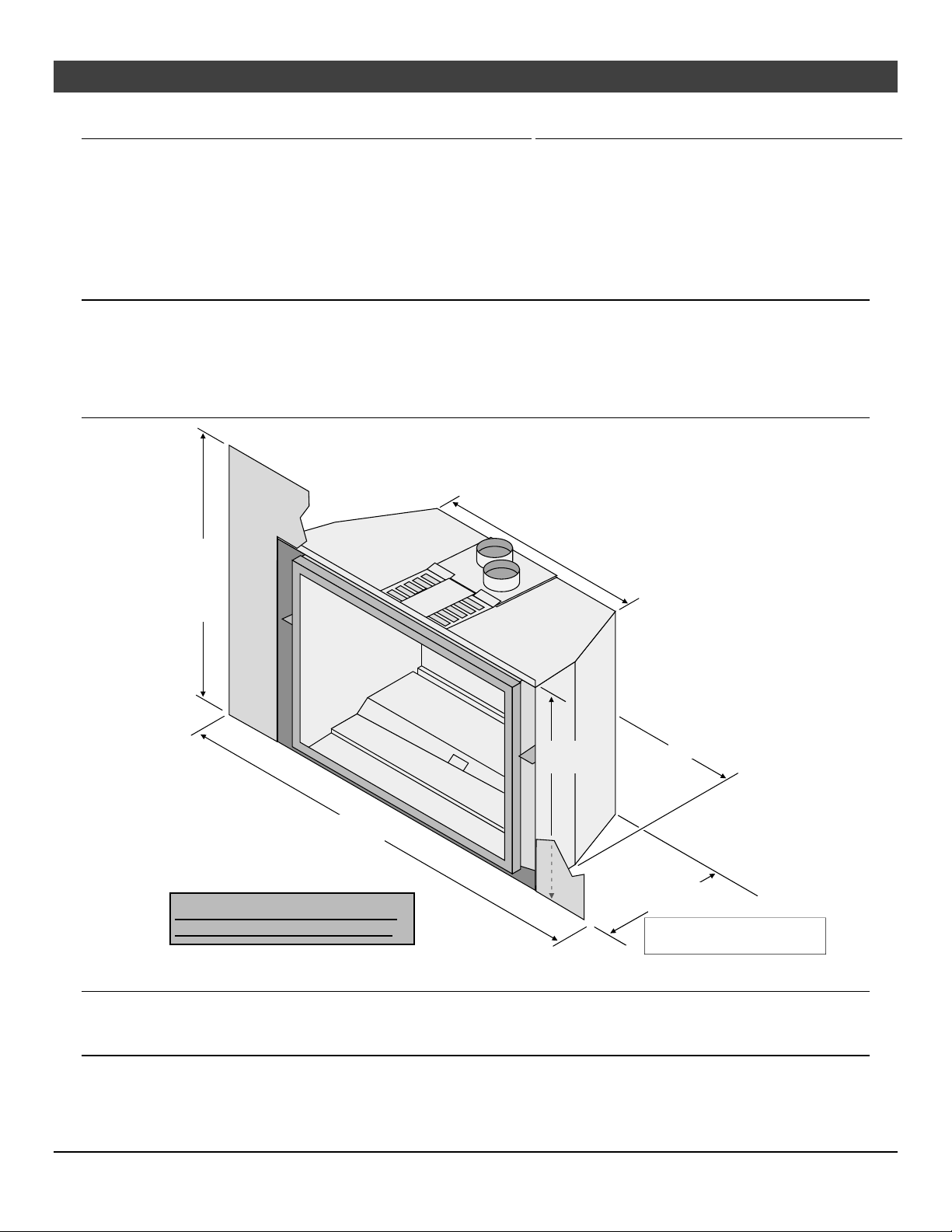

Dimensions

21" *

Small 25"

(63 5 mm)

(534mm) *

Large 28-1/2"

(72 4 mm)

19-1/2" *

(496mm) *

Small 38" (966mm)

Large 40" (1016mm)

* See "Fireplace Requirements"

for minimum fireplace sizing.

IDB1005

Electrical Specifications (for blowers)

Electrical Rating 120 Volts, 1.8 Amps, 60 Hz (205 watts) (typical max amps: 5).

Fuel

29-1/2" *

(750mm) *

15" *

(381mm) *

13-3/4"* if using panel trim.

(350mm) *

This heater is shipped in natural gas (NG) configuration but may be converted to propane (LP) using

the LP Conversion Kit (included) and the LP stepper motor (SKU 250-01463, sold separately). The

sticker on top of the gas control valve will verify the correct fuel.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Installation (for qualified installers only) 7

Installation Warnings

Failure to follow all of the requirements may result in property damage, bodily injury, or even death.

This heater must be installed by a qualified installer who has gone through a training program

for the installation of direct vent gas appliances.

The installation must conform with local codes or, in the absence of local codes, the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the National Gas and Propane Installation Code, CSA

B149.1.

In Manufactured or Mobile Homes must conform with Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280, or, when such a standard is not applicable, the

Standard for Manufactured Home Installations, ANSI/NCSBCS A225.1. This appliance may be

installed in Manufactured Housing only after the home is site located.

The heater is designed to operate on natural gas, or propane (LP).

All exhaust gases must be vented outside the structure of the living area. Combustion air is

drawn from outside the living-area structure.

Notify your insurance company before hooking up this heater.

The requirements listed below are divided into sections. All requirements must be met

simultaneously. The order of installation is not rigid – the qualified installer should follow the

procedure best suited for the installation.

Packing List

Propane (LP) Conversion Kit

Remote Control

"Fireplace Altered" tag (attach to the fireplace)

46” Flex Line with Adapter and Shutoff Valve

Additional Items Required

Faceplate

3" Diameter Gas Liner with Termination (Kit – sku# 96200339)

Gas Line Equipment (shutoff valve, pipe, etc.)

Panel Kit

Fireback Kit

Media

If using LP (propane) a conversion kit is required (sku# 250-01463 – GSR Stepper Motor Kit).

Order of Installation

1. Run gas line to the fireplace.

2. Remove the glass frame.

3. Run vent through fireplace chimney. On larger fireplaces, the vent connector may be left in place. For

smaller fireplaces, remove the vent connector. See “Vent Connector Removal and Installation” for details.

4. Place insert into position and attach the gas line and vent.

5. Remove the burner.

NOTE: If using propane (LP), convert the appliance at this time.

6. Install the firebacks.

7. Replace the burner.

8. Install the media (logs, stones - see instructions included with the media).

9. Install the surround panel (see instructions included with surround panel).

10. Follow the instructions under “Finalizing the Installation.”

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

8 Installation (for qualified installers only)

Fireplace Requirements

Insert must be placed within a code-conforming masonry fireplace or tested and listed factory-built

(metal) wood-burning fireplace. Repair any fireplace damage prior to installation.

Because the insert uses a circulation blower, clean the fireplace, smoke shelf, and chimney prior to

installation.

This heater may be placed in a bedroom. Please be aware of the large amount of heat this appliance

produces when determining a location.

Do not place insulation or any other material on top of the insert. This may block the upper accent

light ventilation, leading to premature bulb failure.

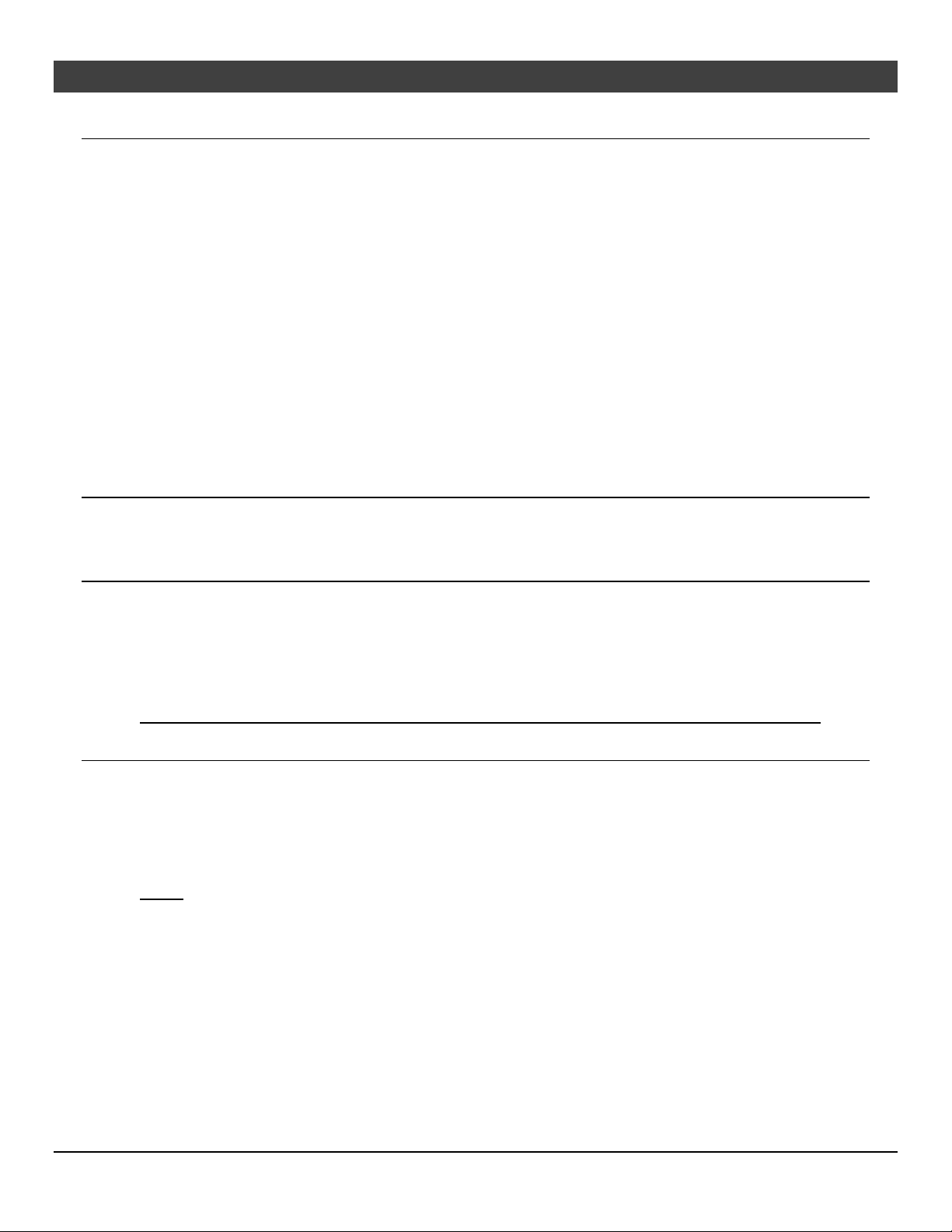

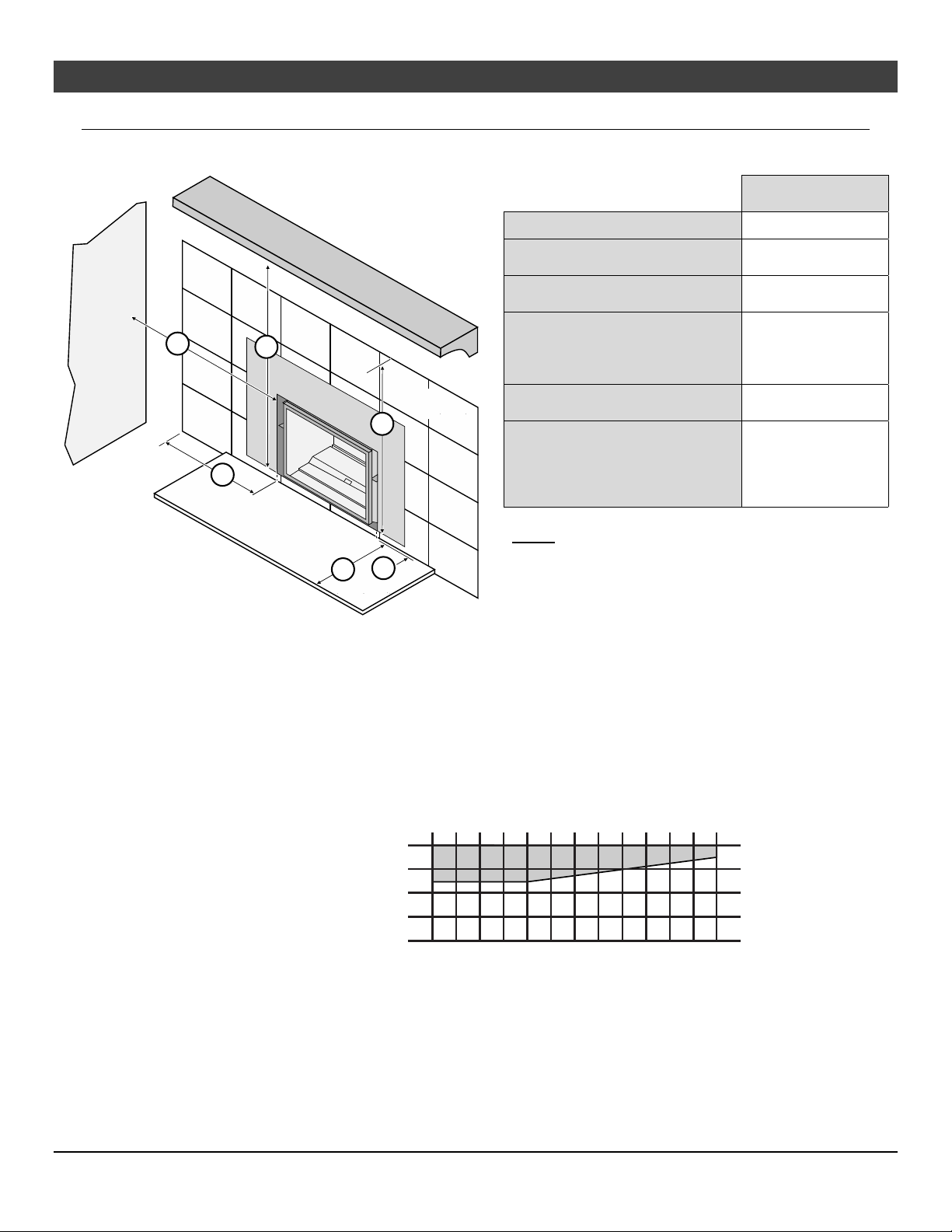

Fireplace Sizing 1-Piece Panel 1-Piece Panel w/ Trim

a

Minimum Height

b

g

a

I

h

f

e

I Attach the “This fireplace has been altered…” plate to the fireplace (use two screws or other suitable method). You may

wish to place it in a location where it will be covered by the surround panels.

c

d

b

Minimum Width

c

Minimum Depth

d

Minimum Hearth

Depth (see “Hearth

Requirements” on

the following page

for full details)

e

Extension onto

Hearth

The gas and electrical line should be installed prior to installing

f

the heater.

For tight fits (under 24”) see the section “Removing the Vent

g

Connector”.

See “Leveling Legs” for details on leveling the heater.

h

20-1/4” (515mm)

30-1/2” (775mm)

15-1/2” (394mm)

19-3/4” (502mm)

30-1/4” (768mm)

14-1/4” (357mm)

0” (0mm) 0” (0mm)

0” (0mm) 1-1/4”(32mm)

Fireplace Clearances to Gas Insert

Side of Insert to Inside of Fireplace ½” (13mm)

Back of Insert to Inside of Fireplace ½” (13mm)

Top of Insert to Inside of Fireplace 3/4” (20mm)

Masonry Fireplace Hearth Requirements

A panel trim kit is available for this appliance. When using the kit, the appliance will sit forward of the fireplace

opening 1-1/4” (32mm).

WARNING:Anon‐combustiblehearthisnotrequiredinfrontoftheappliance.However,iftheheaterisinstallednextto

thefloor,werecommendahearthtoprotecttheflooringsurfacefromdiscolorationorothernegativeimpacts

fromtheheater.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Installation (for qualified installers only) 9

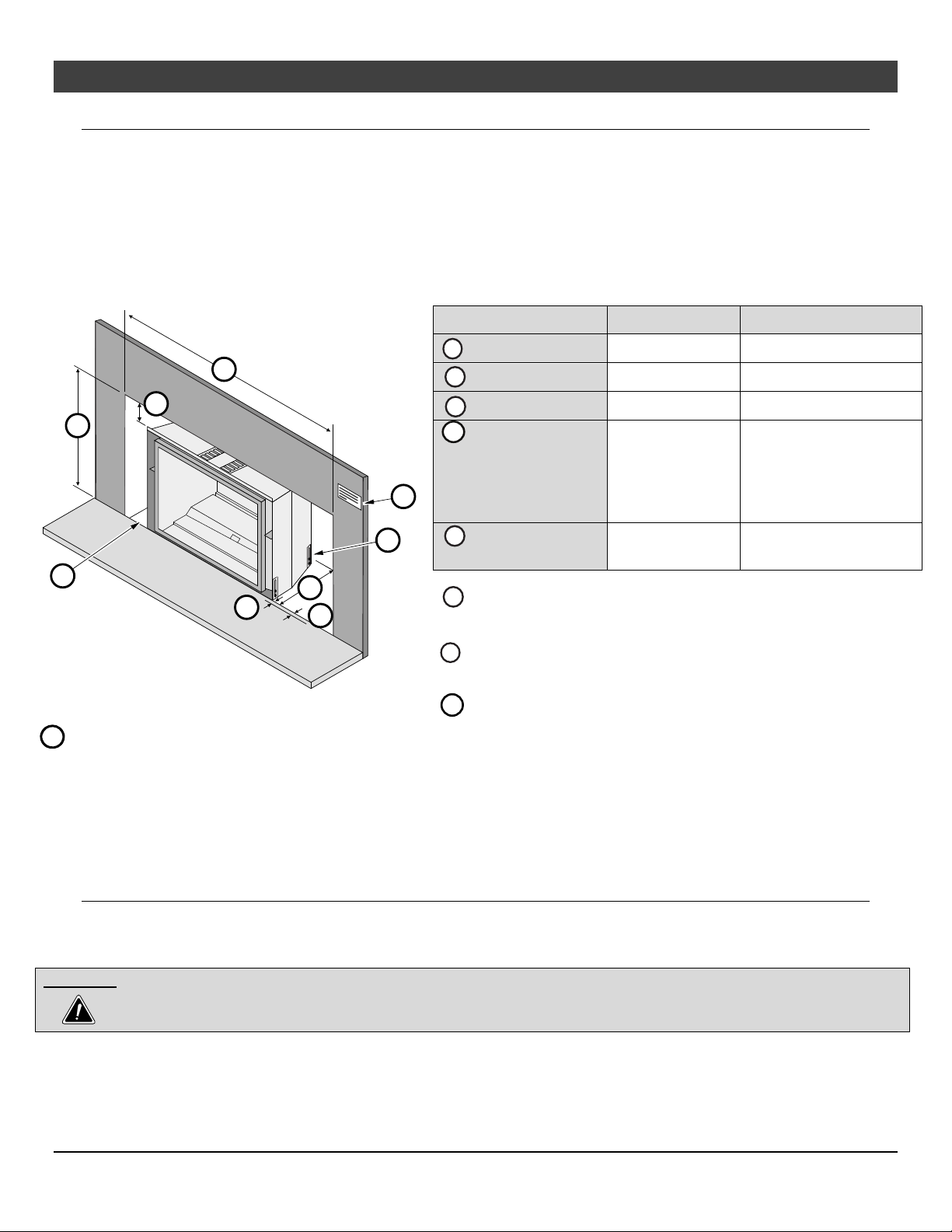

Factory-Built (Metal) Wood-Burning Fireplace Requirements

The damper ("A") and grate (with log set) ("B") must be removed (see the illustration below)

The smoke shelf ("C"), internal baffles ("D"), screen ("E"), masonry lining or refractory ("G" & "I"), and

metal or glass doors ("F") may be removed (if applicable)

The fireplace must be permanently marked to

indicate that it has been altered and is no longer

suitable for burning solid fuel (wood) unless the

removed parts are re-installed. Cutting of any

sheet metal parts is prohibited.

The metal floor (“J”) of the firebox may be removed

in certain cases*.

The insulation ("H"), and any structured rigid frame

members must not be removed or altered (side and

top of door frame, side, and top of the face of the

fireplace, metal sides, etc.).

H

F

E

C

I

A

D

B

G

J

*CAUTION – Removal of the firebox floor of a factory-built solid fuel fireplace in order to accommodate the

installation of a gas-fired fireplace insert is not covered under (ANSI Z21.88 – CSA 2.22 or ANSI Z21.50 – CSA

2.33) standard(s) used to certify the gas-fired fireplace insert or UL 127 and ULC S627 standards used to

certify solid fuel factory-built fireplaces. The Intertek safety certification will not apply to this installation method.

This installation method must be deemed acceptable by the Authority Having Jurisdiction (AHJ) prior to the gasfired fireplace insert being installed. The sheet metal base (or metal wrap) of the fireplace must be left in place

and a minimum ½” cement board sheet placed under the entire length and width of the appliance.

If the factory-built fireplace has no gas access hole(s) provided, an access hole of 1-1/2 inch (37.5 mm) or

less may be drilled through the lower sides or bottom of the firebox in proper workmanship like

manner. This access hole must be plugged with non-combustible insulation after the gas supply line has

been installed.

Factory Built Fireplace Hearth Requirements

½” of non-combustible material is required underneath the entire footprint of the insert.

WARNING:A non-combustible hearth is not required in front of the appliance. However, if the heater is installed next to the

floor, we recommend a hearth to protect the flooring surface from discoloration or other negative impacts from

the heater.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

10 Installation (for qualified installers only)

(

)

)

Maxi

th

Clearances

Due to the high temperature of the heater, it should be located out of traffic and away from furniture and

draperies.

IDB1007

Side

Wall

k

C

o

m

b

u

s

t

i

b

l

e

o

r

N

o

n

-

C

o

m

b

u

C

o

m

n

s

t

i

b

l

e

b

u

s

t

i

b

M

a

n

t

l

e

T

o

p

e

l

F

a

c

i

n

g

No

n

-

C

o

m

b

F

u

a

s

c

t

i

i

n

b

g

l

m

e

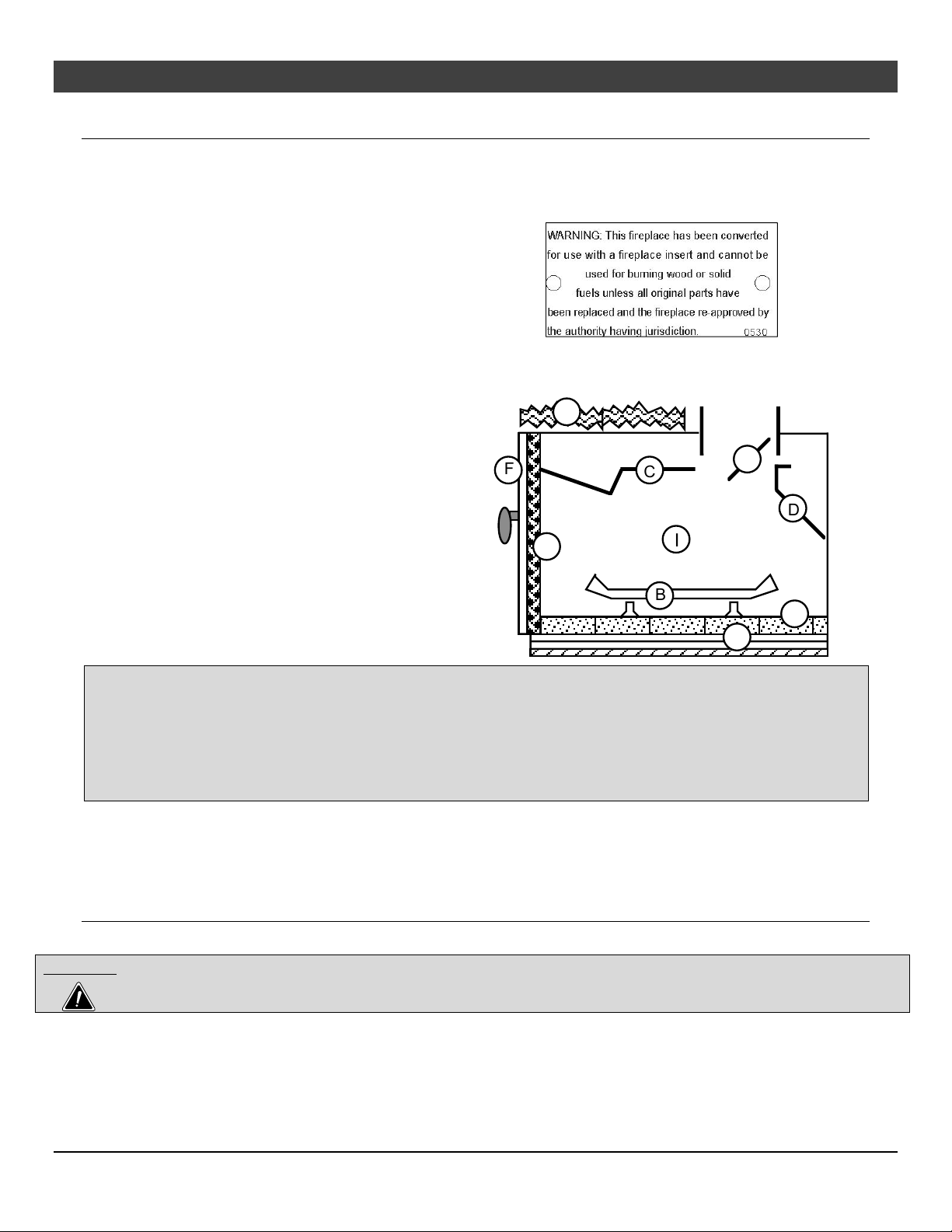

k Sidewall to Insert

l Side Facing

(non-combustible)

m Top Facing*

(non-combustible)

n 12” Mantel* (combustible

or non-combustible)

n 4” Mantel* (combustible

or non-combustible)

p Hearth Extension to the

Front of Insert

x Extension onto Hearth

Minimum

Clearances

5" (127mm)

3-3/8 " (86mm)

32-3/8" (823mm)

34-1/2" (877mm)

33-1/2" (851mm)

0" (0mm)

1 Piece Panel

l

1 Piece Panel w/Trim Kit

1-1/4” (32mm)

* Measured from the base of the insert.

NOTE: the non-combustible top facing must extend

32-3/8” (823mm) above the base of the insert or to

p

x

the bottom of the mantel (whichever is less).

Mantel Clearances

The maximum mantel depth is 12” (305mm).

NOTE: The combustible area above the facing must not protrude more than 3/4" (20mm) from the facing.

If it does, it is considered a mantel and must meet the mantel requirements listed in this manual.

mum Mantel Dep

)

)

)

)

)

m

m

m

6

2

(

"

"

"

0

2

1

m

m

m

1

7

5

(

0

7

1

(

(

"

"

3

4

35"+(889mm+)

antel Height

Above Base

of Fireplace

34"(864mm)

33"(839mm)

32"(813mm)

788mm

31"

)

m

m

2

2

1

(

"

5

)

)

m

m

7

(

"

6

m

m

m

m

8

3

0

7

5

2

1

1

(

(

"

"

7

8

)

)

)

m

m

4

2

(

"

9

m

m

m

m

4

9

5

2

2

(

"

"

1

0

1

1

m

m

m

m

5

0

0

8

3

2

(

(

"

2

1

0" (0mm)

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Installation (for qualified installers only) 11

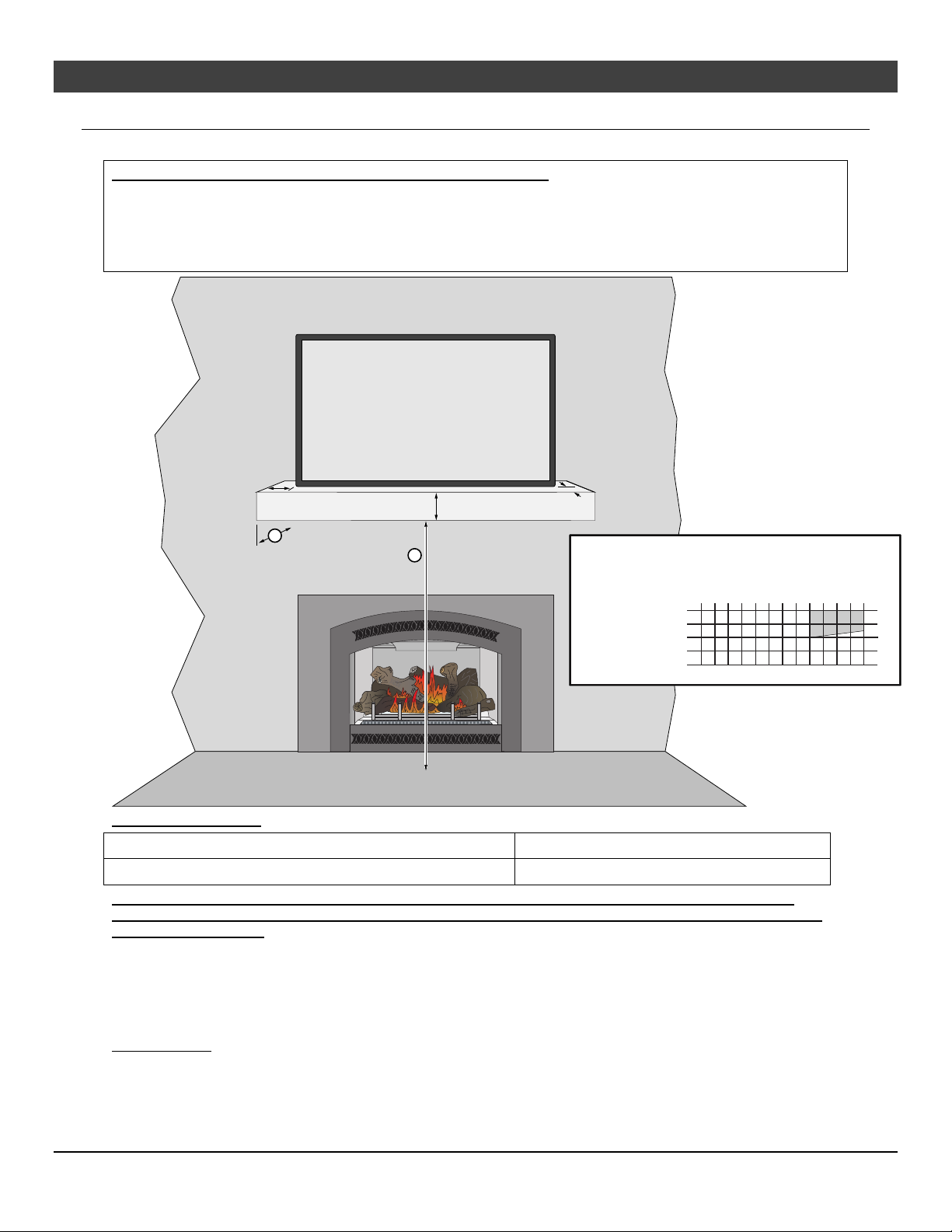

Televisions Placed Above the Insert

The following section gives guidelines to place a television above the insert.

IMPORTANT NOTE REGARDING TELEVISIONS AND THIS INSERT

Most television manufacturers instruct the homeowner not to place the television above a heat source like this insert.

Doing so may decrease the longevity of the television and negate the warranty. If you do place a television above the

insert, you should place a mantel between the insert and television. Follow the guidelines below to reduce the

amount of heat reaching the television. Travis Industries does not take responsibility for any negative impact on

televisions placed near this insert.

Television (TV)

Min. 1" (26mm)

Min. 2" (51mm)

Min. 1" (152mm)

b

a

(a)

Heig ht

36"+(915mm+)

Above

Base of

Fireplace

(4) AA Batteries

F

U

S

E

TOP

F

E

U

S

S

U

E

F

35"(889mm)

34"(864mm)

(

"

"

0

1

(b) Depth

)

)

)

m

)

1

(

m

2

0

"

5

430 EG

)

m

m

2

1

(

m

m

m

m

m

m

m

7

3

8

2

0

5

7

2

1

1

(

(

(

(

"

"

"

"

8

9

6

7

)

)

m

m

m

m

m

1

6

5

5

7

2

(

(

"

"

"

2

3

4

Minimum Dimensions:

(a) Minimum Mantel Height above Base of Insert* 34” (864mm) with 8” (204mm) mantel depth

(b) Minimum Mantel Depth* 8” (204mm)*

* Minimum mantel depth must be 8”(204mm) to allow heat to dissipate. If using a mantel larger than 8”

(204mm), make sure to adjust the mantel height (a) to meet the mantel clearance (see mantel requirements

on page 10 for details).

The mantel must extend 2” in front of the television and 1” to both sides.

If you have a television that is greater than 6” deep (including the 1” gap behind), you will need to alter the

mantel depth and height (see the example below).

The television must have a 1” gap to the wall to allow for proper cooling.

WIRING NOTE: If running wiring into the enclosure, use thermal insulating wrap around the wiring. Secure the wiring

to protect from contact with hot surfaces.

)

)

)

m

m

9

2

2

"

0

1

)

)

m

m

m

m

m

m

9

4

5

7

5

0

2

2

3

(

(

(

"

"

1

2

1

1

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

12

Installation (for qualified installers only)

Leveling Bolts

This heater includes front and rear leveling legs to accommodate fireplaces with a step-down firebox.

Loosen the (4) bolts and adjust the legs down until the insert is properly supported and level.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Installation (for qualified installers only) 13

Electrical Requirements

Travis Industries manufactures a wiring kit specifically for inserts (sku 97200315). This kit allows installers to

wire 120 volt AC power into a fireplace directly to the insert, eliminating the need for an external power cord.

Plug the power cord into a grounded 120 Volt outlet (do not remove the grounding pin).

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1.

Do not route the power over the appliance or near any hot or moving components.

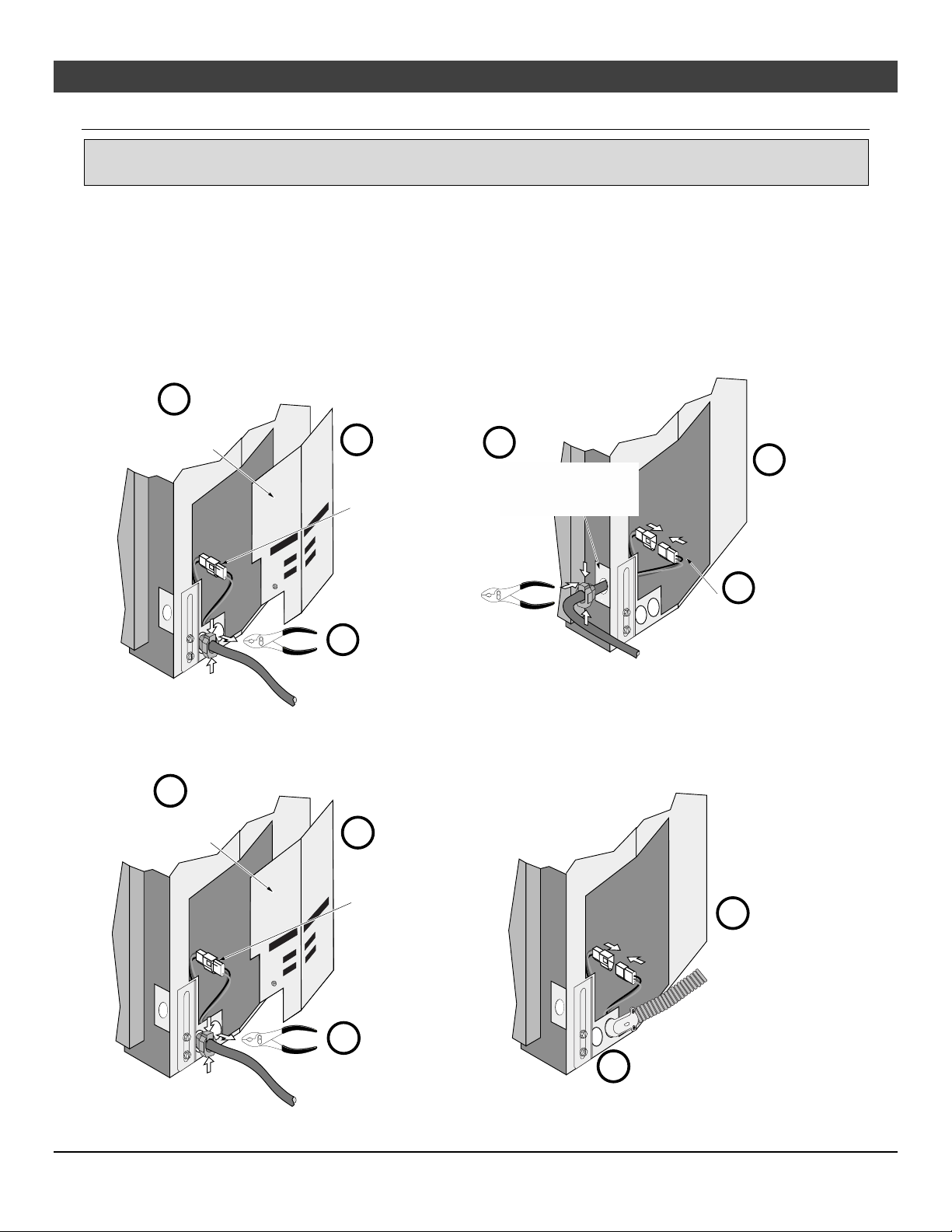

Re-Routing the Power Cord to the Front of the Insert

The power cord is shipped attached to the side of the insert. It may be routed to the front where it exits

behind the face but in front of the surround panel. See the directions below for details.

a

Remove the side

access panel.

c

Disconnect the

molex connection

and remove the

power cord.

d

Route wires through the

front mounting bracket.

Use pliers to reinstall the

strain relief.

d

Reinstall the

access panel

a

b

Use pliers to remove

the strain relief.

Using the Insert Wiring Kit

See the instructions included with the wiring kit for attaching the kit to the side of the insert.

a

Remove the side

access panel.

c

Disconnect the

molex connection

and remove the

power cord.

a

e

Reconnect the

molex connection.

e

Reconnect the Molex connector

and replace the access panel.

b

Use pliers to remove

the strain relief.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

d

Attach the hard wire kit to

insert (see kit instructions for details).

14

Installation (for qualified installers only)

Gas Line Requirements

MASSACHUSETTS INSTALLATIONS - WARNING:

THIS PRODUCT MUST BE INSTALLED BY A LICENSED PLUMBER OR GAS FITTER WHEN INSTALLED WITHIN THE

COMMONWEALTH OF MASSACHUSETTS.

OTHER MASSACHUSETTS CODE REQUIREMENTS:

Flexible connector must not be longer than 36 inches.

Shutoff valve must be a “T” handle gas cock.

Only direct vent sealed combustion products are approved for bedrooms or bathrooms.

Fireplace dampers must be removed or welded in the open position prior to the installation of a fireplace insert or gas log.

A carbon monoxide (CO) detector is required in the same room as the appliance.

The gas line must be installed in accordance with all local codes if any; if not, follow ANSI 223.1 and

the requirements listed below.

A manual shutoff valve is required within 3’ of the heater. It should be placed upstream of the flex line

(if used) and may be installed behind the access door inside the heater.

The heater and gas control valve must be disconnected from the gas supply piping during any

pressure testing of that system at test pressures in excess of 1/2 psig. For pressures under 1/2 psig,

isolate the gas supply piping by closing the manual shutoff valve.

Leak test all gas line joints and the gas control valve prior to and after starting the heater.

This heater is designed either for natural gas or for propane (but not for both). Check the sticker on

the top of the gas control valve to make sure the correct fuel is used (see illustration on page 4).

Installation must be performed by a qualified installer, service agency, or the gas supplier (In

Massachusetts a licensed plumber/gas-fitter).

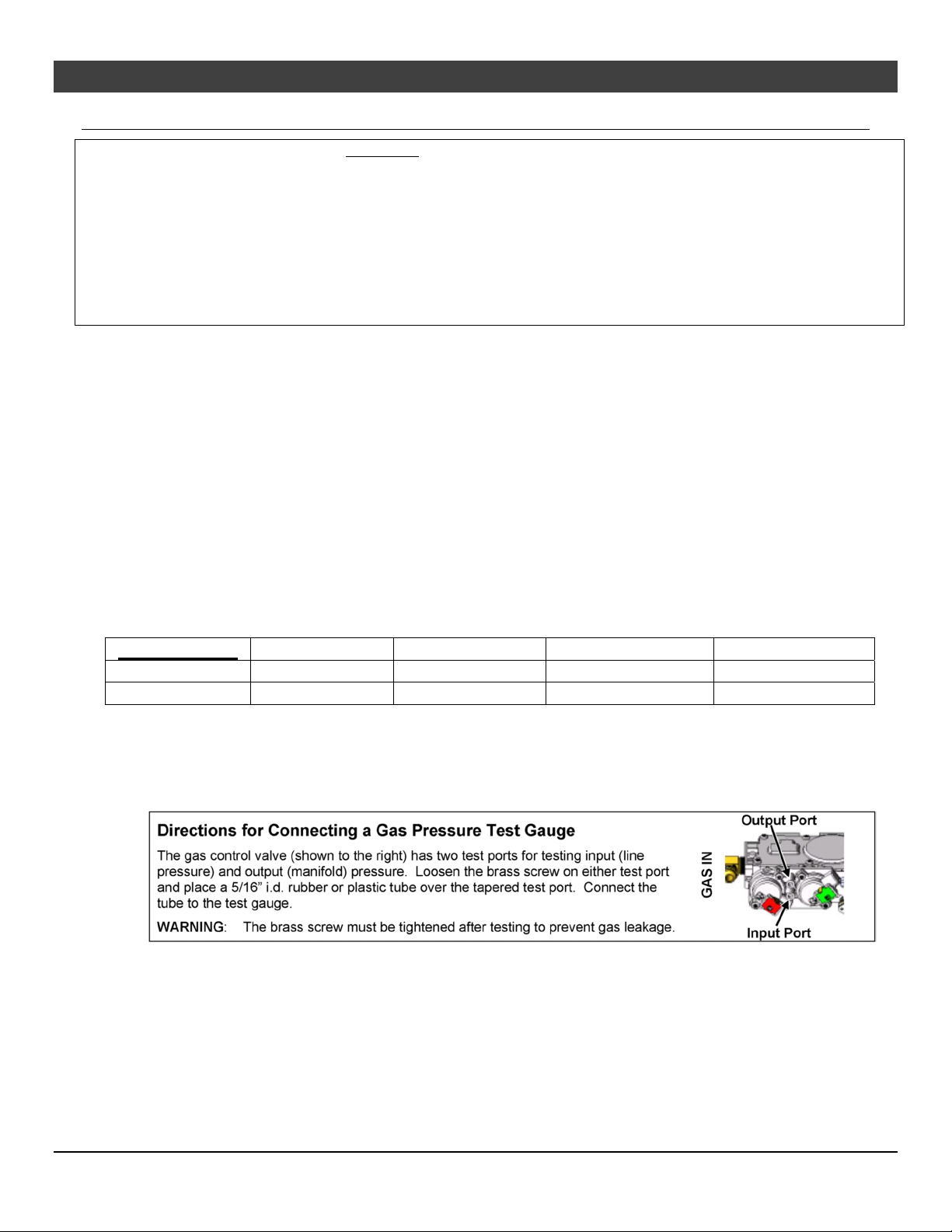

Gas Inlet Pressure

Gas Pressure

Natural Gas

Propane

If the pressure is not sufficient, make sure the piping used is large enough, the supply regulator is

adequately adjusted, and the total gas load for the residence does not exceed the amount supplied.

The supply regulator (the regulator that attaches directly to the residence inlet or to the propane tank)

should supply gas at the suggested input pressure listed above. Contact the local gas supplier if the

regulator is at an improper pressure.

Max. Input Pressure Min. Input Pressure Max. Manifold Pressure Min. Manifold Pressure

7" W.C. (1.74 kPA) 5.5” W.C. (1.37 kPA) 3.5” W.C. (0.87 kPA) 1.6” W.C. (0.40 kPA)

13" W.C. (3.23 kPA) 11” W.C. (2.74 kPA) 11” W.C. (2.74 kPA) 2.9” W.C. (0.72 kPA)

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Installation (for qualified installers only) 15

Gas Line Installation

1. Route the included flex tube through the hole in the left side of the insert and out the front as shown below.

2. Bend the flex tube up.

3. Attach the included gas shutoff valve to the end of the flex tube and gas inlet as shown below.

Position so the valve handle is on the right as shown.

Leak-test all gas line connections.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

16 Installation (for qualified installers only)

Vent Requirements

Travis Industries manufactures a vent kit specifically for this insert (sku

96200339). It includes 30’ (10M) of vent, hose clamps, and a high wind

cap. The flashing on the cap is 18” (458mm) by 18” (458mm).

Travis Industries manufactures a vent kit specifically for this insert (sku

96200330). It includes 30’ (10M) of vent, hose clamps, and a prairie

cap. The flashing on the cap is 18” (458mm) by 18” (458mm).

The gas appliance and vent system must be vented directly to the outside of the building, and never be attached to

a chimney serving a separate solid fuel or gas-burning appliance. Each direct vent gas appliance must use its own

separate vent system.

Make sure the exhaust pipe on the heater connects to the exhaust portion of the cap. The illustrations below show

how the flex liners should be attached.

The exhaust vent must reline the entire length of the chimney and terminate above the chimney top.

Be careful not to crimp or rupture the liner when bending it into chimney offsets.

When installed, the vent must meet all of the vent manufacturer's requirements.

Use the following vent:

3” UL 441 or 1777 Gas Liner for Exhaust, 3” UL 441 or 1777 Gas Liner for Air Inlet

Duravent 6-5/8” to 3” Co-Linear Adapter and Flashing (46DVA-Gk)

Duravent High-Wind Vertical Termination (46DVA-VCH) for high-wind applications or Prairie Cap

Max. Ht. 40' (12.2M)

Min. Ht. 16' (5M)

Max. 4'

(1.2M)

offset

Drafting Performance

This direct vent appliance requires natural draft to operate (similar to a wood stove or other heating appliance). Draft

can be adjusted using the included restrictor. The restrictor settings detailed in the manual should be followed

(variations may occur depending upon installation parameters).

Many factors may negatively influence the draft of the appliance. Travis Industries will not be responsible for improper

draft due to factors such as trees, hills, buildings, obstructions, excessive wind, extreme hot or cold outdoor

temperatures, restrictive vent terminations, or influence from mechanical systems.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Finalizing the Installation 17

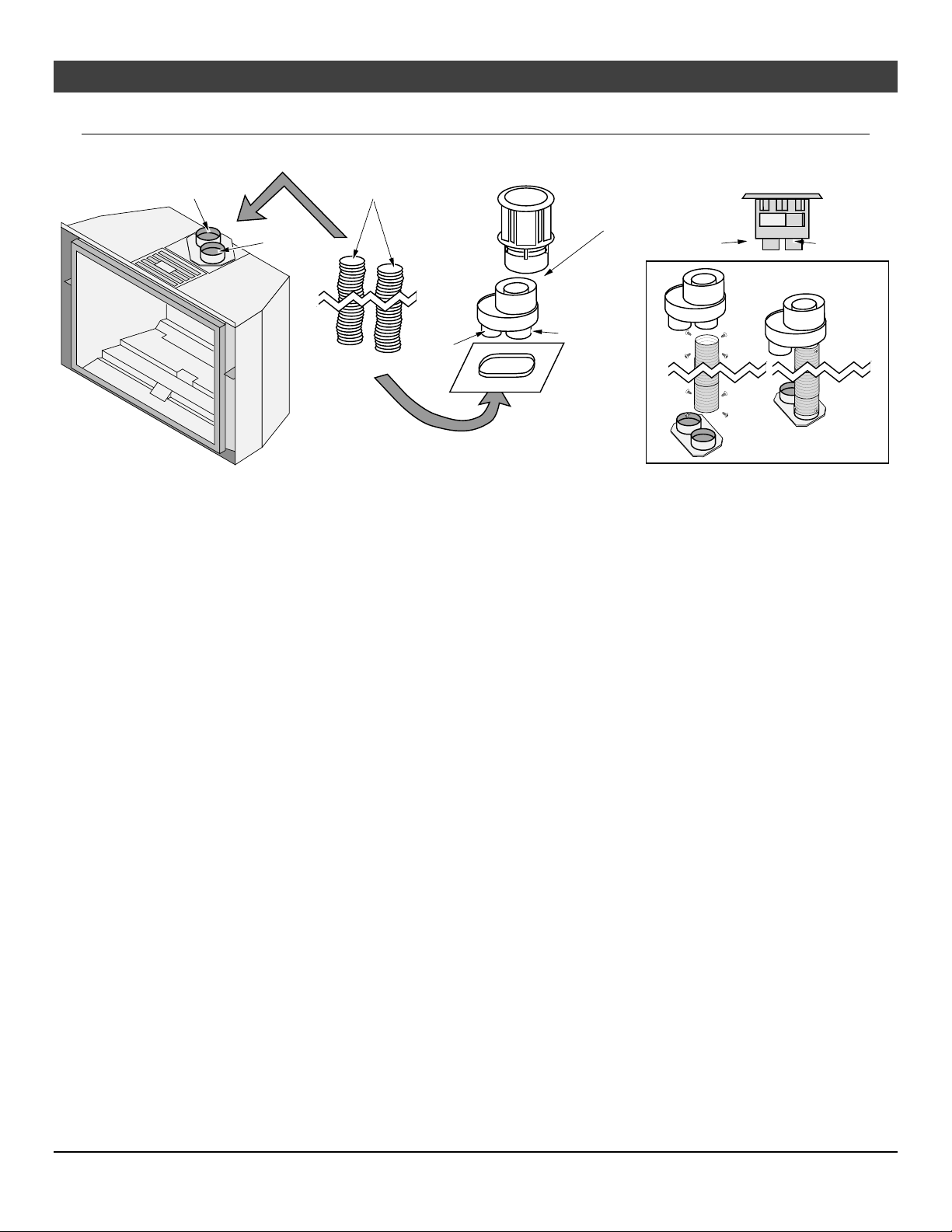

Vent Installation

Secure the vent to the insert and termination kit using screws.

Inlet (3" 76mm)

3" (76mm) dia. Gas Liner

Approved

Cap

Exhaust

(3" 76mm)

Inlet

Additional Coaxial

Sections May Be Added

(support as needed)

Exhaust

For optimum performance, keep the vent as straight as possible (no 90 bends).

Inlet Exhaust

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

18 Finalizing the Installation

Vent Location

An Exhaust Restrictor is built into the appliance to adjust the flow rate of exhaust gases. This

ensures proper combustion for all vent configurations. Depending upon the vent configuration, you

may be required to adjust the restrictor position. See “Exhaust Restrictor Settings” on page 21.

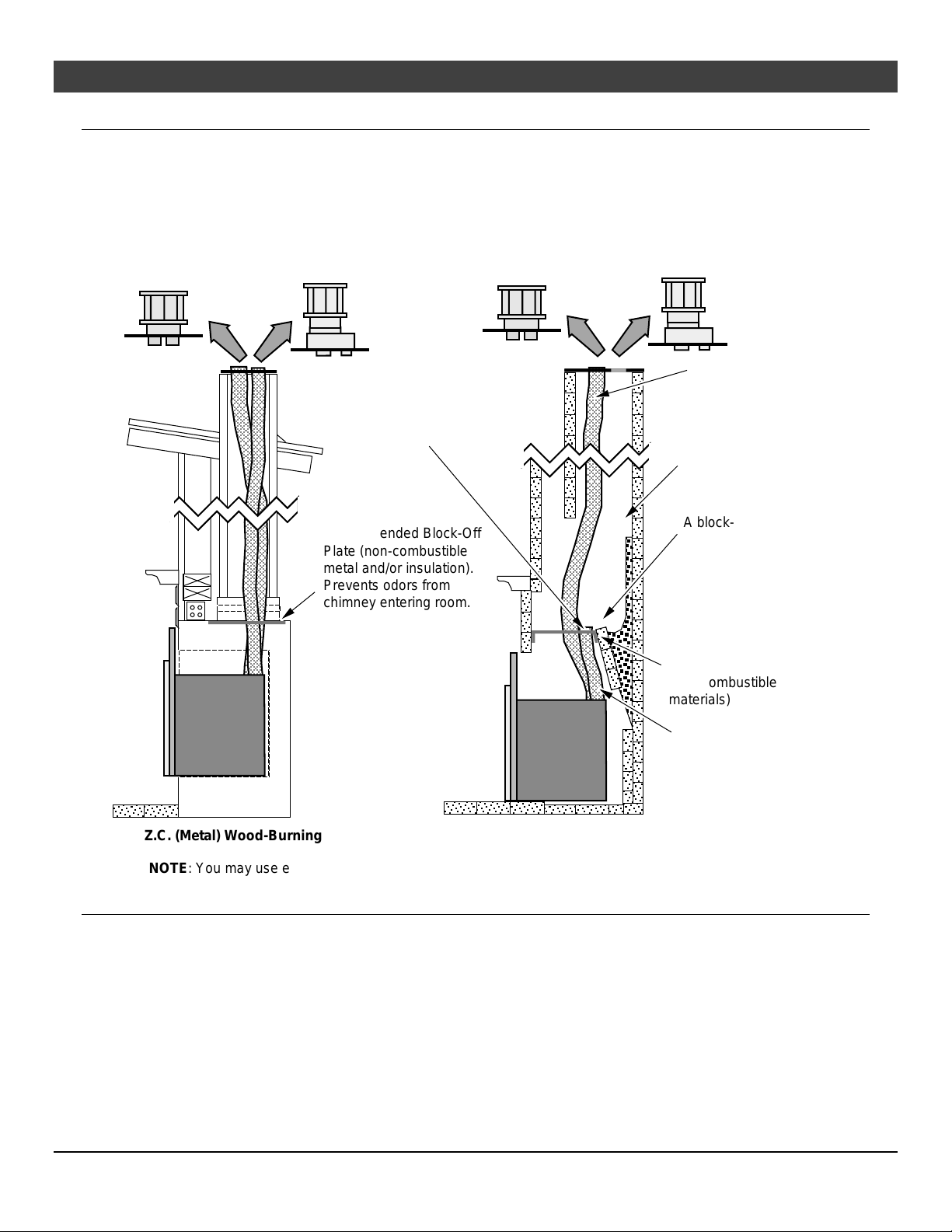

Vent Configurations

Inlet & Exhaust Re-Line

Recommended Block-Off

Plate (non-combustible

metal and/or insulation).

Prevents odors from

chimney entering room.

Inlet

Exhaust Only Re-Line

Exhaust

Any cracks or

damage inside the

chimney must be

repaired.

A block-off plate must

seal the intake to the

chimney space. This

way air is drawn down

the chimney for

combustion air.

Block-Off Plate

(non-combustible

materials)

Inlet

Z.C. (Metal) Wood-Burning Fireplace

NOTE: You may use either re-line configuration with a masonry or zero-clearance fireplace.

Masonry Fireplace

Altitude Considerations

This heater has been tested at altitudes ranging from sea level to 6,000 feet (1,800 M). In this

testing, we have found that the heater, with its standard orifice, burns correctly with just an air shutter

adjustment.

Failure to adjust the air shutter properly may lead to improper combustion which can create a safety

hazard. Consult your dealer or installer if you suspect an improperly adjusted air shutter.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Finalizing the Installation 19

R

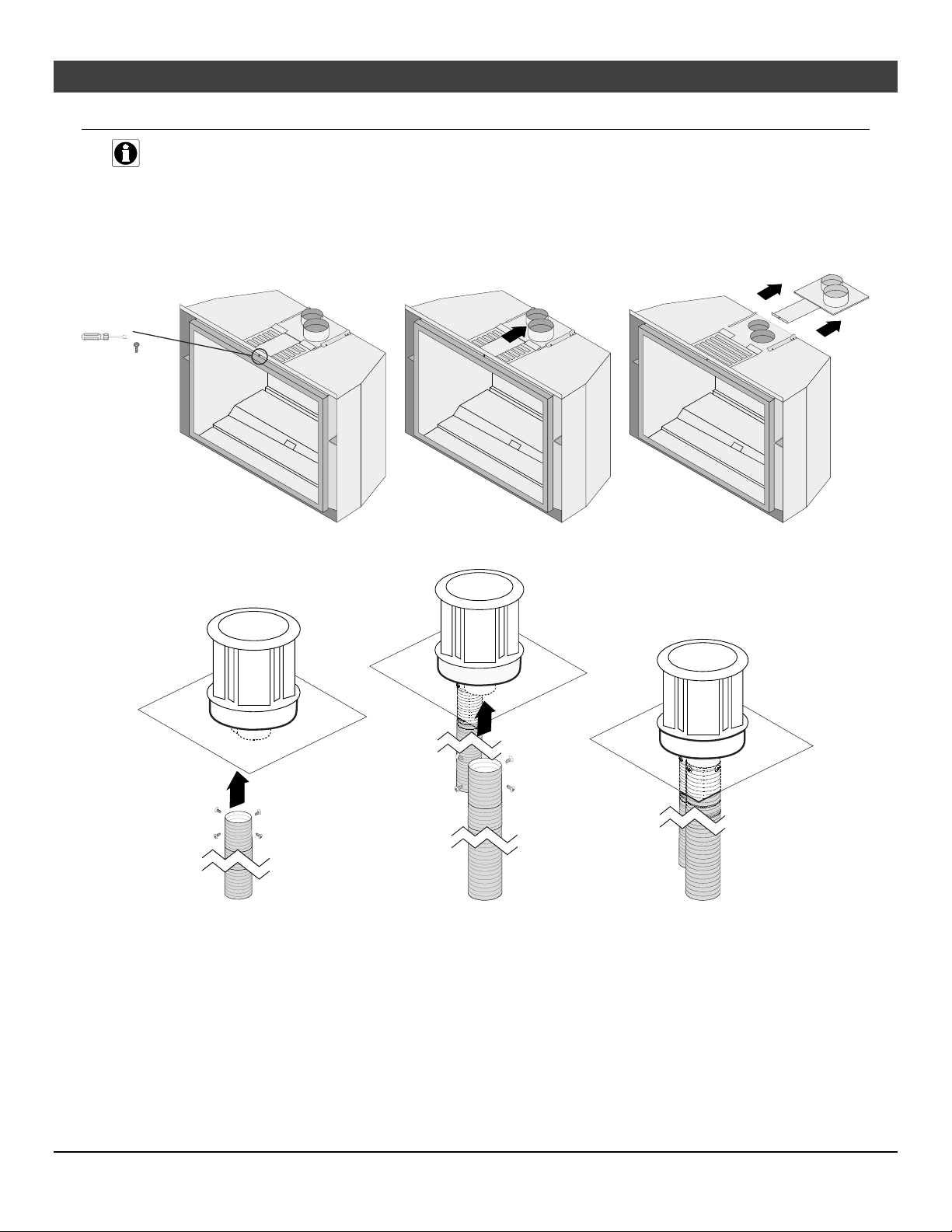

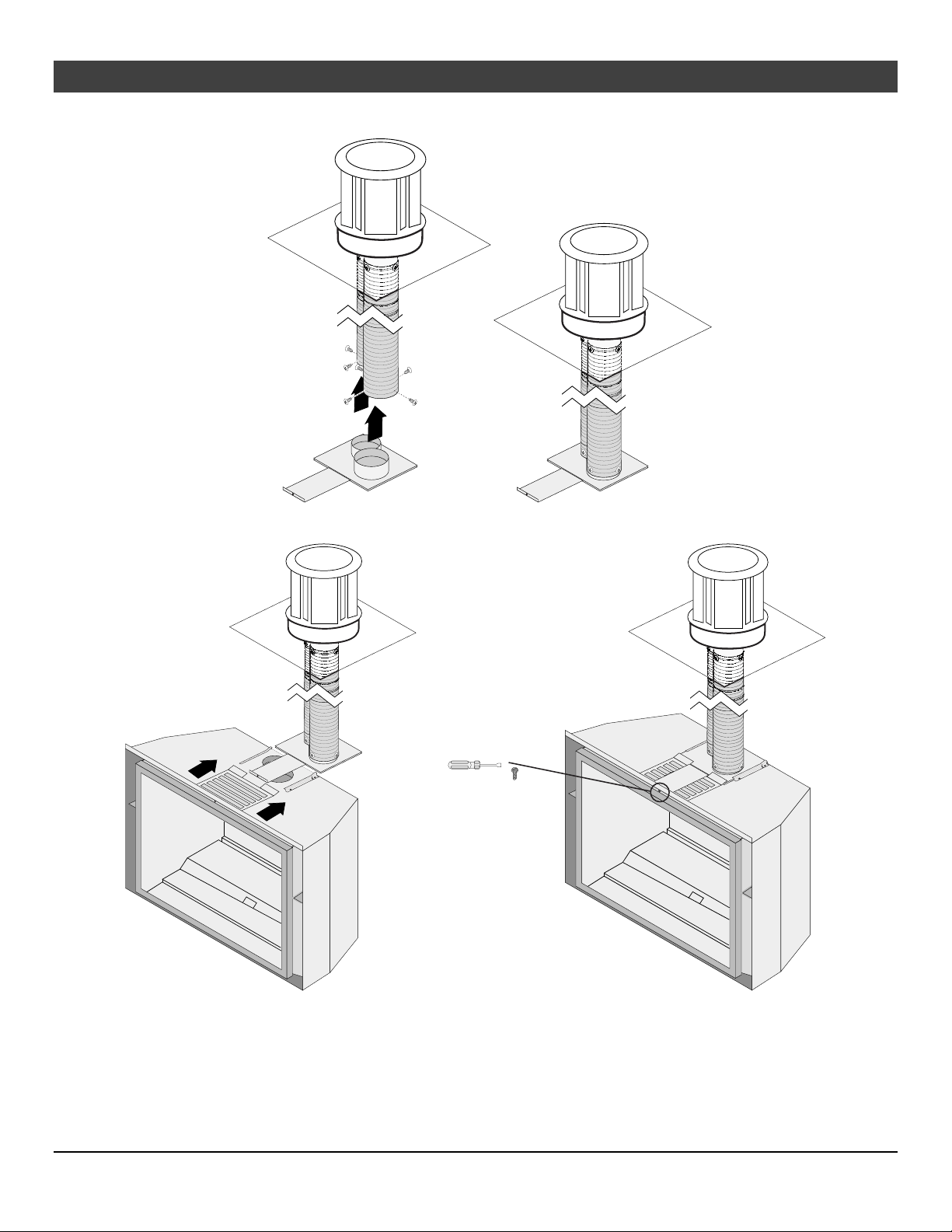

Vent Attachment – Tight Installations

The vent connector is shipped attached to the insert but must be removed to facilitate tight

installations. See the directions below for installation.

1. Locate the screw in the top-center of the front of the insert. Use a ¼” nut driver to remove the screw

and slide the connector toward the back of the insert to disengage the connector from the top of the

insert.

emove Screw

1/4" Nutdriver

2. Stretch the liners to their full length. Attach the flex liners to the cap (secure with screws). Route the

flex vent through the chimney from above.

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

20 Finalizing the Installation

w

3. Pull the liners straight and cut to length (height of the insert). Attach the bottom of the flex liners to the

connector, removed in step 1.

4. Slide the insert into place while guiding the vent connector into the guides on top of the insert. Secure

the vent connector to the appliance using the screw removed in step 1.

e-install Scre

1/4" Nutdriver

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Finalizing the Installation 21

40 Feet

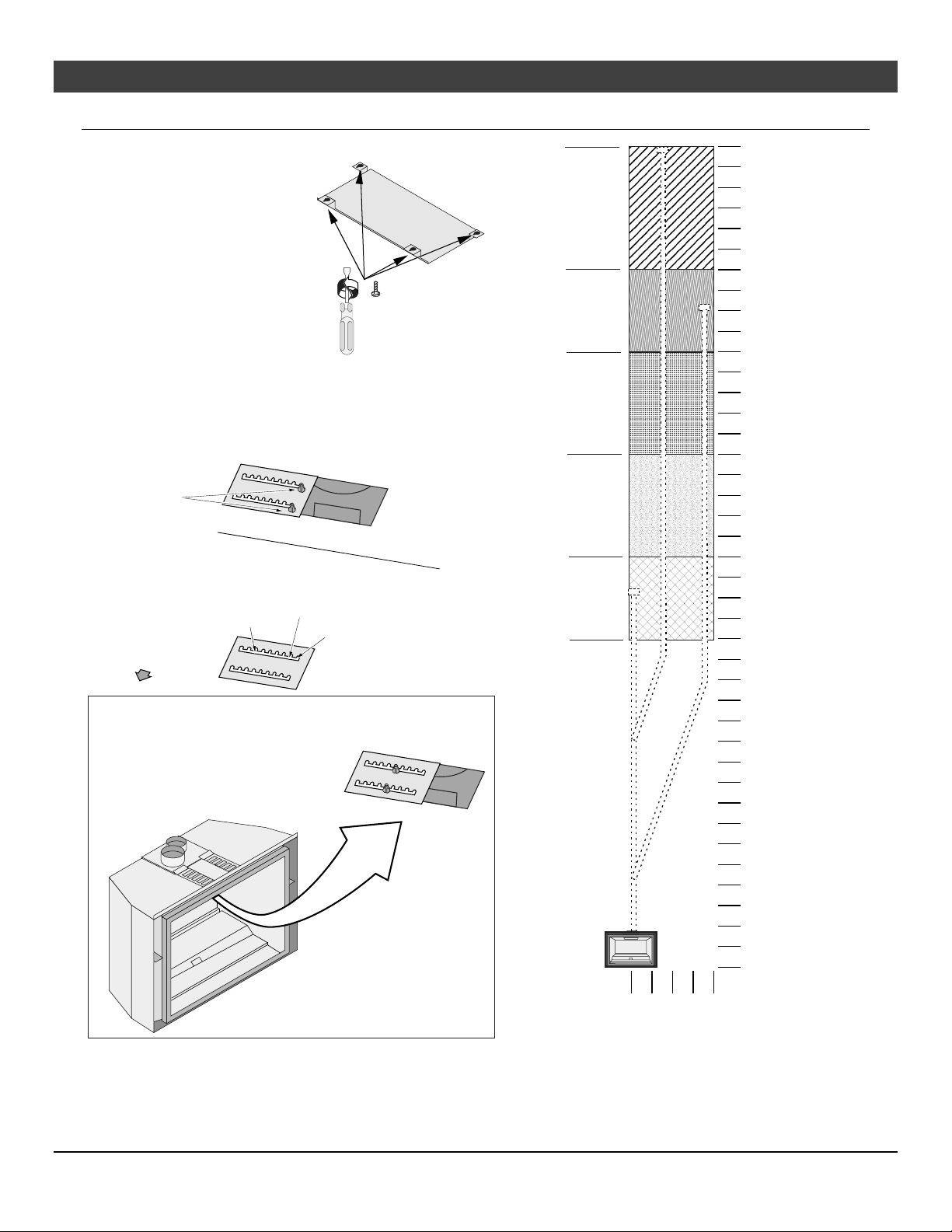

Exhaust Restrictor Settings

(max.)

Use a 1/4” nut driver to loosen

the screws that secure the baffle

to the top of the firebox. Slide

the baffle slightly forward until

the screw heads are in line with

the keyhole slots . Lower the

baffle and remove from the

firebox. (Re-install baffle after

the restrictor has been

adjusted).

1/4" Nutdriver

Slide the restrictor to the correct position (consult the vent

chart to the right to determine the proper setting for your

installation). The screw location indicates the restrictor

position.

Loosen these

2 screws on the

exhaust restrictor.

Back of Firebox

# 7...

B

a

c

k

W

a

# 2...

#1 (open - stock position)

F

i

r

e

b

o

x

R

o

l

l

o

f

F

i

r

e

b

o

x

o

f

Position #7

Position #6

Position #5

Position #3

Position #1

(Stock)

35 Feet

30 Feet

25 Feet

20 Feet

16 Feet (Min.)

15 Feet

In this example, the restrictor is set in the #5 position.

Tighten the screws to secure the restrictor.

10 Feet

5 Feet

0 Feet

0 Feet

2 Feet

4 Feet

(max.)

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

22 Finalizing the Installation

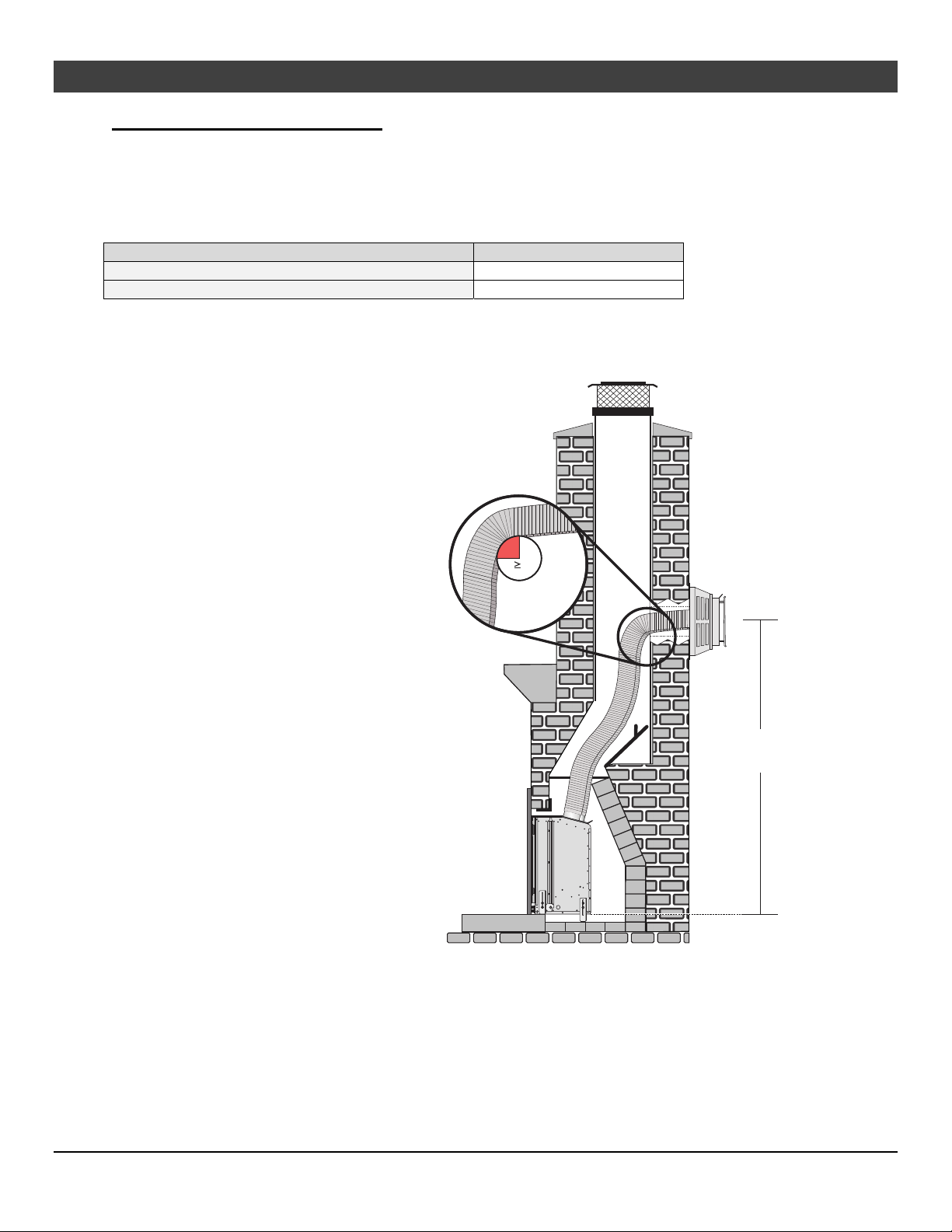

Horizontal Termination

DuraVent manufactures a vent kit for horizontal that allows for terminating horizontally when installed in a

masonry fireplace (not for use with ZC fireplaces). The DuraVent kit (46DVA-HCL33 and 46DVA HCL34)

is approved for use with Travis Industries gas inserts.

These kits can be purchased from your Travis Industries dealer.

Application DuraVent Part #

For inserts that use 3” exhaust and 3” intake 46DVA-HCL33

For inserts that use 4” exhaust and 3” intake 46DVA-HCL34

Refer to the kit manufacturer’s instructions for details and requirements for installation. In addition to the

manufacturer’s requirements, the following requirements must be met:

The termination center MUST be

a minimum of 5’ from the base of

insert.

The termination center MUST

NOT be more than 8’ from the

base of the insert.

The radius of any bends in the

flexible venting MUST NOT be

less than a 4” radius

All portions of the venting MUST

have at least a 1/4” rise per 12” of

horizontal run

r 4”

Radius

4” Min

Min. 5’

Max. 8’

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Finalizing the Installation 23

’

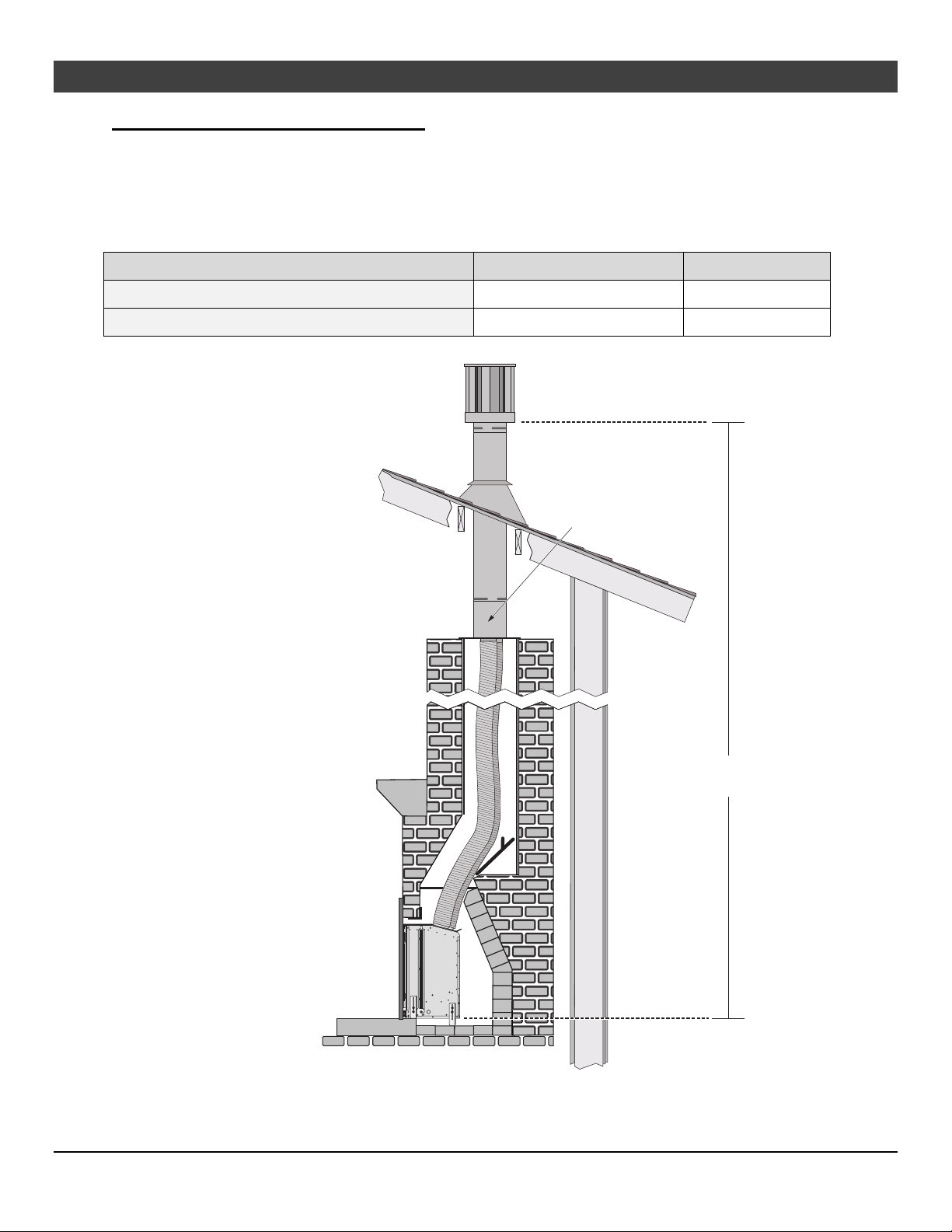

Co-Linear to Co-Axial Pipe

DuraVent manufactures a vent kit that adapts flexible co-linear venting to co-axial pipe. This can be

helpful for situations such as when a damaged masonry chimney top is removed to below the roofline or

when an additional story is added to a home and the added height covers the existing masonry chimney

height. The DuraVent kits (46DVA-CLTA and 46DVA-34CLTA) are approved for use with Travis

Industries gas inserts.

These kits can be purchased from your DuraVent dealer.

Application DuraVent Part # DuraVent Stock #

For inserts that use 3” exhaust and 3” intake 46DVA-CLTA 810014742

For inserts that use 4” exhaust and 3” intake 46DVA-34CLTA 810014340

- Check with the local

Authority Having

Jurisdiction before

installing in this manner.

- The fireplace must be

permanently marked to

indicate that it has been

altered and no longer

suitable for burning solid

fuel (wood).

- All additional

requirements in the

manual for the installation

must be met.

- Refer to the vent

manufacturer’s

instructions for further

details.

DuraVent Co-Linear

to Co-Axial Adapter

Max. 40

(12.2M)

© Travis Industries 1/11/2021 - 1521 430 EG GSR2

Loading...

Loading...