Page 1

Project Quantity Item #

Model Specied: CSI Section 11400

Roll-In/Roll-Thru Refrigerated-Heated

Models/Self-Contained

Includes Traulsen's patented

INTELA-TRAUL® control

Model RIDH232LUT-FHS

(shown with standard left/right hinging)

Standard Product Features

• R-Series: Stainless Steel Exterior & Interior

• A-Series: Stainless Steel Exterior/Anodized Aluminum Interior

• INTELA-TRAUL® Microprocessor Control System

• One-Time Start-Up Temperature Adjustment Feature &

ON/OFF Switch (for heated compartment only)

• Balanced, Self-Contained Refrigeration System Using R-134a

• Scroll Blower Type Evaporator Fan

• Biased Return Air Duct

• Full Length Stainless Steel Doors With Locks

• Self-Closing Doors With Stay Open Feature At 120 Degrees

• Guaranteed For Life Cam-Lift Hinges

• Guaranteed For Life Horizontal Work Flow Door Handle

• Standard Door Hinging: 232L = Left/Right,

F & R: 232LP = Left/Right (other hingings available)

• Automatically Activated Incandescent Lights

• Stainless Steel Breaker Caps

• Accommodates Roll-In Racks Up To 66" High (provided by

others)

• Automatic Non-Electric Condensate Evaporator

• Magnetic Snap-In Door Gaskets

• Gasket Protecting Metal Door Liner

• Controllable Anti-Condensate Door Perimeter Heaters

• Thermostatic Expansion Valve Metering Device

• Stainless Steel One-Piece Louver Assembly & Heater Guards

• 9' Cord & Plug Attached

• Stainless Steel Interior Rack Guides

• Stainless Steel Threshold Ramps

• One Year Parts And Labor Warranty

• Two Year Control Warranty (parts and labor)

• Five Year Compressor Warranty

Two Section Models, 32" Deep

R

SERIES

Stainless Exterior

& Interior

A

SERIES

Stainless Exterior,

Anodized Alumi-

num Interior

The R & A Series represent Traulsen's Top-of-the-Line product offering.

The roll-in and roll-thru refrigerated/heated models are all designed to offer

convenient storage for 66" high racks. Each is supplied standard with such

high quality features as balanced refrigeration systems, microprocessor

controls, communications ability and stainless steel exteriors. Additionally,

they offer the widest range of optional accessories to choose from, and can

be specied for use with many different applications, including: Foodservice,

Correctional, Institutional, Export, etc.

Roll-In Model RIDH232LUT-FHS

Roll-Thru Model RIDH232LPUT-FHS

Roll-In Model AIDH232LUT-FHS

Roll-Thru Model AIDH232LPUT-FHS

Options & Accessories

• Stainless Steel Finished Back With Rear Louvers (reach-in

models only)

• Re-Hinging Feature For Doors

• Wire Shelf Package For Roll-In/Roll-Thru Model (includes

three shelves per section)

• Additional Wire Shelves For Above

• Stainless Steel Shelf Package For Roll-In/Roll-Thru Model

(includes three shelves per section)

• Additional Stainless Steel Shelves For Above

• Locking Hasps (padlocks supplied by others)

• Kool Klad Exterior Laminate Decor

• Prison/Correctional Facilities Options

• Remote Applications (see spec sheet TR35837 for details)

• Two Year Service/Labor Warranty Available

Listed by Underwriters Laboratories Inc.,

and classied by Underwriters Laboratories

Inc., in accordance with ANSI/NSF7.

Approval: __________________________________

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Page 2

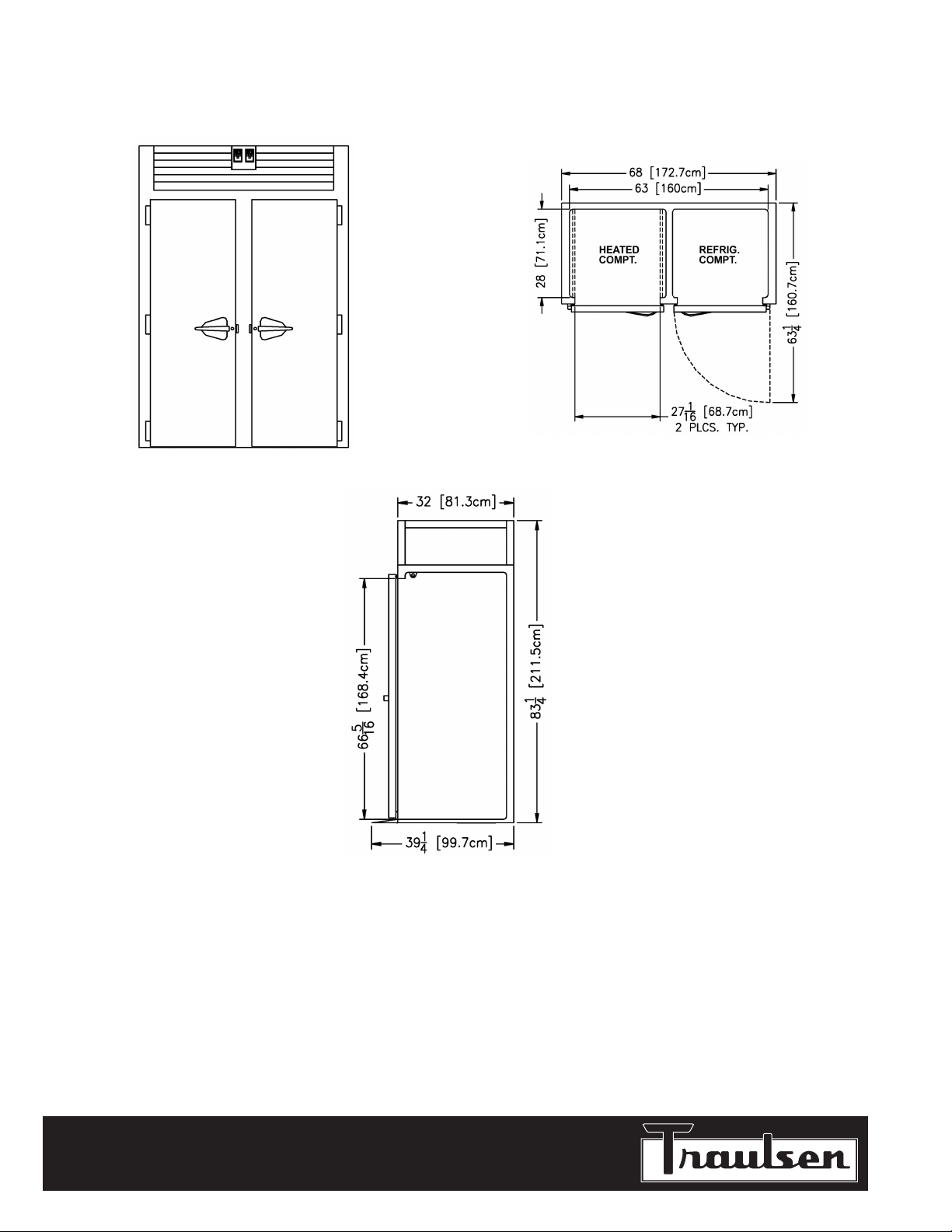

Elevation - R/AIDH232LUT

Plan - R/AIDH232LUT

Section - R/AIDH232LUT

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Page 3

Elevation - R/AIDH232LPUT

Plan - R/AIDT232LPUT

Section - R/AIDH232LPUT

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Page 4

Project Quantity Item #

Model Specied: CSI Section 11400

Specications

Construction, Hardware and Insulation

Cabinet exterior, including front, one piece sides, louver assembly and doors are

constructed of heavy gauge stainless steel. Cabinet interior and door liners are

constructed of stainless steel. Exterior cabinet top and back are constructed of

heavy gauge aluminized steel. The exterior bottom is constructed of heavy gauge

galvanized steel and insulated with 3⁄4" of resilient cork. A readily attachable

stainless steel ramp is provided.

Doors are equipped with heavy-duty, extruded wiper gasket for sealing to bottom ramp, removable plug cylinder locks and guaranteed for life cam-lift, gravity

action, self-closing metal, glide hinges with stay open feature at 120 degrees.

Hinges include a switch to automatically activate the interior incandescent lighting.

Guaranteed for life, work ow door handle is mounted horizontally over recess in door

which limits protrusion from door face into aisleways.

Easily removable for cleaning, vinyl magnetic door gasket assures tight door seal.

Anti condensate heaters are located behind each door opening.

Cabinet and door contains high density, non-CFC, foamed in place polyurethane

insulation.

DIMENSIONAL DATA R/AIDH232LUT R/AIDH232LPUT

Cabinet Type Roll-In Roll-Thru

Net capacity total cu. ft. 74.3 (2105 cu l) 80.2 (2272 cu l)

Length - overall in. 68 (172.7 cm) 68 (172.7 cm)

Depth - overall in. 359⁄16 (90.3 cm) 391⁄8 (99.4 cm)

Depth - over body in. 32 (81.3 cm) 32 (81.3 cm)

Depth - door(s) open 90° in. 631⁄4 (160.7 cm) 941⁄2 (240.0 cm)

Clear door width in. 271⁄16 (68.7 cm) 271⁄16 (68.7 cm)

Clear door height in. 665⁄16 (168.4 cm) 665⁄16 (168.4 cm)

Height - overall 831⁄4 (211.5 cm) 831⁄4 (211.5 cm)

Rack Capacity (66" high by others) 2 2

RIDH Net Wt. lbs. 700 (318kg) 775 (352 kg)

AIDH Net Wt. lbs. 600 (272 kg) 670 (304 kg)

ELECTRICAL DATA

Voltage 208/115/60/1 208/115/60/1

Feed wires with Ground 4 4

Heater Wattage @ 208V 1500 1500

Full load amperes 13.5 13.5

REFRIGERATION DATA

Refrigerant R-134a R-134a

BTU/HR H.P.1 2220 (1⁄3 HP) 2220 (1⁄3 HP)

NOTE: Figures in parentheses reect metric equivalents.

1= Based on a 90 degree F ambient and 20 degree F evaporator.

2= For approximate remote weights deduct 40 lbs. from respective net or gross weight. For other

information on remote models, please refer to spec sheet TR35837.

NOTES

Refrigeration System

A top moun ted, self- contained, balanced refrigeration syst em using R-134a

refrigerant is conveniently located behind the one piece louver assembly. These

models feature an easy to clean front facing condenser, thermostatic expansion

valve, air-cooled hermetic compressor, plenum effect blower coil, large, high

humidity evaporator coil located outside the food zone and a top mounted nonelectric condensate evaporator.

Biased return air duct protects against introduction of warm kitchen air, promoting

even temperature maintenance and efcient operation.

A 9' cord and plug is provided standard. Standard operating temperatures are 34 to

38°F for the refrigerator compartment and 135 to 180°F for the heated compartment.

Heating System

A low watt density, serpentine style, heater is employed for the generation of electric

heat. Low velocity air is forced across its large surface area to efciently move heat

radiating away from these through a down-air distribution duct, where it is then evenly

distributed throughout the cabinet, assuring the proper holding environment for hot

food product, without drying. A vent, located at the top of the cabinet, is included

for positive humidity control.

Controller

The easy to use water resistant INTELA-TRAUL® microprocessor control system

is supplied standard. Unit is NAFEM Data Protocol communication (NDP) ready.

Optional hardware required to be NDP compliant. Third party software required

for network connection. It includes a 3-Digit LED Display, Fahrenheit or Celsius

Temperature Scale Display Capability, and an RS485 data port. In addition it

includes audio/visual alarms for: Hi/Lo Cabinet Temperature, Door Open, Clean

Condenser, Evaporator Coil and Discharge Line Sensor Failures, and Power Supply Interruption. A separate control is provided for both the refrigerated and heated

compartments.

Interior

Readily removable, interior-mounted, stainless steel guides for rack are provided for

protection. Maximum rack size with wheels inboard of frame is 27" wide by 29" deep

by 66" high. Racks supplied by others.

Warranties

Both a one year parts and labor warranty and a ve year compressor warranty (self-

contained models only) are provided standard. An optional 2nd year extended parts

and labor warranty is also available. In addition the INTELA-TRAUL® controls are

warranted by a two year parts and labor warranty.

Equipped With One NEMA L14-20P Plug

NOTE: Full load amps and plug style may vary depending on

electrical options chosen and condensing unit employed.

In order to assure optimum performance, the condensing unit MUST have an adequate supply

of air for cooling purposes. Therefore, the operating location must either have a minimum of 12”

clearance overhead of the condensing unit or allow for unrestricted air ow at the back of the unit.

Clearance of at least 12” above is required in order to perform certain maintenance tasks.

REQUIRED CLEARANCES

NOTE: When ordering please specify: Voltage, Hinging, Door Size, Options and any additional warranties.

Continued product development may necessitate specication changes without notice.

Part No. TR35786 (revised 4/10)

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Loading...

Loading...