Transmille 2100 Operation Manual

21002100

Electrical Test Equipment Calibrator

Operation Manual

Version 4.00

December 2004

All product names are trademarks of their respective companies

2100 Operation Manual

IMPORTANT NOTICE

THIS CALIBRATOR

WILL

REQUIRE AN

UNLOCK CODE

AFTER THE EVALUATION

PERIOD HAS EXPIRED.

( 60 Days after invoice date)

AFTER THE EVALUATION PERIOD HAS EXPIRED THE

OPERATION OF THE CALIBRATOR IS LOCKED AND THE

DISPLAY SHOWS A NUMBER WHICH MUST BE QUOTED TO

TRANSMILLE TO RECEIVE THE UNLOCK CODE

THE UNLOCK CODE IS

AVAILALBLE

FROM TRANSMILLE

ONLYAFTER PAYMENT

HAS BEEN RECEIVED.

(This code is only entered once in the life of the instrument.)

Please contact Transmille or use the form in the back

of the manual to obtain the code.

Transmille Ltd.

Staplehurst , Kent.

Tel: 44 (0)1580 890700 : Fax 44(0)1580 890711

email:- sales@transmille.com

Transmille Ltd. Issue 4.00 Page 2

2100 Operation Manual

DECLARATION OF CONFORMITY

Manufacturer’s Name: Transmille Ltd.

Manufacturer’s Address: Unit 4, Select Business Centre

Lodge Road

Staplehurst

TN12 0QW

Declares, that the product

Product Name: Electrical Test Calibrator

Model Number: 2100

Product Options: This declaration covers all options of the above

product(s)

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive

73/73EEC and the EMC Directive 89/336/EEC (including 93/68/EEC) and carries the

CE Marking accordingly

Conforms with the following product standards:

EMC

Standard Limit

IEC616326-1:1997+A1:1998 / EN 61326-1 :1997+A1:1998

EN55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995 Group 1Class A

IEC 61000-4-3:1995 / EN 61000-4-3:1995 4kV CD, 8kV AD

IEC 61000-4-4:1995 / EN 61000-4-4:1995 3 V/m, 80-1000 MHz

IEC 61000-4-5:1995 / EN 61000-4-5:1995 0.5kV signal lines, 1kV power lines

IEC 61000-4-6:1996 / EN 61000-4-6:1996 0.5kV line-line, 1kV line-ground

IEC 61000-4-11:1994 / EN 61000-4-11:1994 3V, 0.15-80 MHz I cycle, 100%

Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

SAFETY

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

12/12/2001

Revision No: 1.1 Managing Director

Date :12/12/2001

Transmille Ltd. Issue 4.00 Page 3

2100 Operation Manual

Table of Contents

2100 ELECTRICAL TEST EQUIPMENT CALIBRATOR INTRODUCTION..............................6

INSTALLATION & POWER REQUIREMENTS FOR THE 2100 ..................................................7

PREPARING THE CALIBRATOR FOR USE. ..................................................................................9

I

NITIAL INSPECTION. .............................................................................................................................9

S

HIPPING CHECKLIST ............................................................................................................................9

L

IFTING AND CARRYING THE CALIBRATOR ............................................................................................9

P

OSITIONING THE CALIBRATOR...........................................................................................................10

R

EAR PANEL CONNECTIONS AND CONTROLS ......................................................................................10

S

ETTING AND CHECKING THE LINE VOLTAGE......................................................................................11

C

ONNECTING TO A COMPUTER............................................................................................................11

P

OWERING UP THE CALIBRATOR..........................................................................................................12

O

UTPUT CONNECTIONS.......................................................................................................................12

OPERATION........................................................................................................................................13

I

NTRODUCTION TO OPERATION...........................................................................................................13

F

RONT PANEL CONTROLS AND INDICATORS .......................................................................................13

F

RONT PANEL KEYBOARD...................................................................................................................14

G

RAPHIC LCD DISPLAY .....................................................................................................................15

U

SING THE DIGITAL POTENTIOMETER.................................................................................................16

T

ERMINAL STATUS LEDS....................................................................................................................17

CALIBRATING INSTRUMENTS USING THE 2100......................................................................18

C

ALIBRATING INSULATION TESTERS...................................................................................................18

1. High Value Resistance for Insulation Testing...........................................................................18

2. Measuring Insulation Test Voltages & Current........................................................................19

3. Low Value Resistance for Continuity Testing ...........................................................................21

4. A.C. Voltage Output..................................................................................................................21

5. 5kV Insulation Tester Extension Adapter [OPTION] ...............................................................22

I

NTRODUCTION TO RCD TESTERS ......................................................................................................23

C

ALIBRATING RCD TESTERS USING THE 2100....................................................................................24

1. RCD Current Measurements.....................................................................................................25

2. RCD Trip Time Measurements..................................................................................................27

3. RCD Current Duration Measurements .....................................................................................29

C

ALIBRATING PORTABLE APPLIANCE TESTERS (PATS)......................................................................30

1. PAT : Earth Bond Resistance....................................................................................................30

2. PAT : Earth Bond Current........................................................................................................31

3. PAT : Insulation Testing ...........................................................................................................32

4. PAT : Load Testing...................................................................................................................33

5. PAT : Flash Testing [OPTION]................................................................................................34

6. PAT : Leakage [OPTION]........................................................................................................35

I

NTRODUCTION TO LOOP TESTERS....................................................................................................36

C

ALIBRATING LOOP TESTERS USING THE 2100 .................................................................................40

PSC (P

ROSPECTIVE SHORT CIRCUIT) TESTING ...................................................................................42

REMOTE PROGRAMMING.............................................................................................................43

T

HE RS232 INTERFACE.......................................................................................................................43

P

ROGRAMMING COMMANDS...............................................................................................................43

E

XAMPLE COMMAND SEQUENCES.......................................................................................................46

Transmille Ltd. Issue 4.00 Page 4

2100 Operation Manual

TECHNICAL DESCRIPTION............................................................................................................47

G

ENERAL............................................................................................................................................47

C

ONSTRUCTION ..................................................................................................................................47

I

NTERNAL FUSES. ...............................................................................................................................48

O

PENING THE CASE ............................................................................................................................48

A

CCESS TO INTERNAL FUSES ..............................................................................................................48

PCB R

EMOVAL (NOT REQUIRED TO GAIN ACCESS TO INTERNAL FUSES). ............................................48

P

ROCESSOR BOARD............................................................................................................................49

CALIBRATION AND MAINTENANCE...........................................................................................50

G

ENERAL............................................................................................................................................50

E

LECTRICAL SAFETY TESTS................................................................................................................50

C

LEANING THE EXTERNAL CASE..........................................................................................................50

C

ALIBRATION OVERVIEW ...................................................................................................................50

GUARANTEE AND SERVICE...........................................................................................................52

APPENDIX A................................................................................................. 2100 SPECIFICATIONS

APPENDIX B..................................................................................................APPLICATION NOTES

Transmille Ltd. Issue 4.00 Page 5

2100 Operation Manual

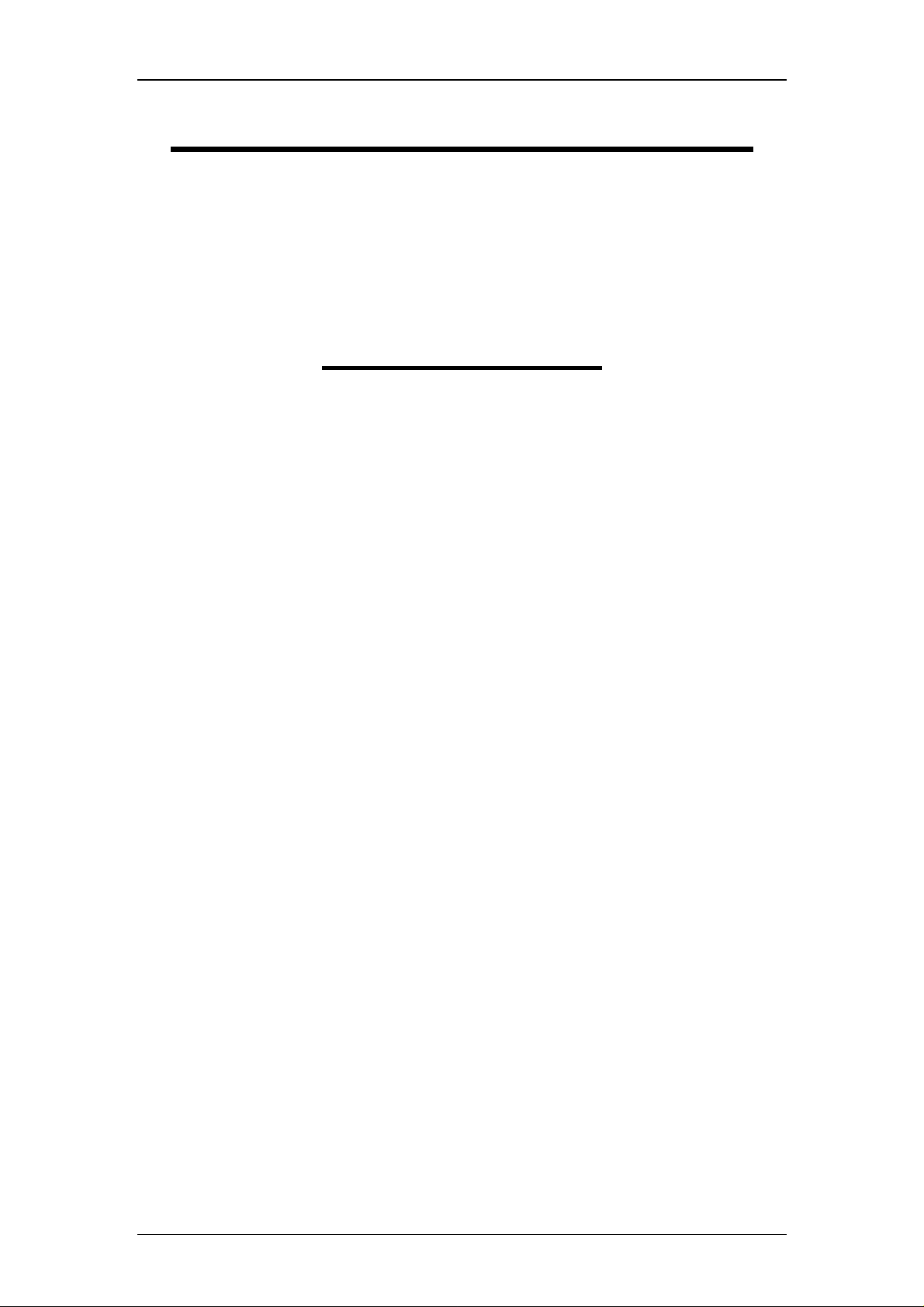

2100 Electrical Test Equipment Calibrator Introduction

The 2100 Electrical Test Equipment Calibrator is a breakthrough in electrical test

equipment calibration providing a complete solution for testing :

§ Insulation Testers

§ RCD Testers

§ LOOP Testers

§ Portable Appliance Testers (PATs)

Extended Functionality

The 2100 Calibrator can be enhanced with options to provide high accuracy

resistance, auto loop measurement and two external resistance inputs to extend the

range of available resistors.

A complete electrical test equipment calibration solution from one instrument.

Designed to provide an accurate cost effective portable instrument for the calibration

of Insulation testers, RCD testers, LOOP testers and PATs the 2100 calibrator can be

combined with the

ProCal Calibration System to allow automated calibration.

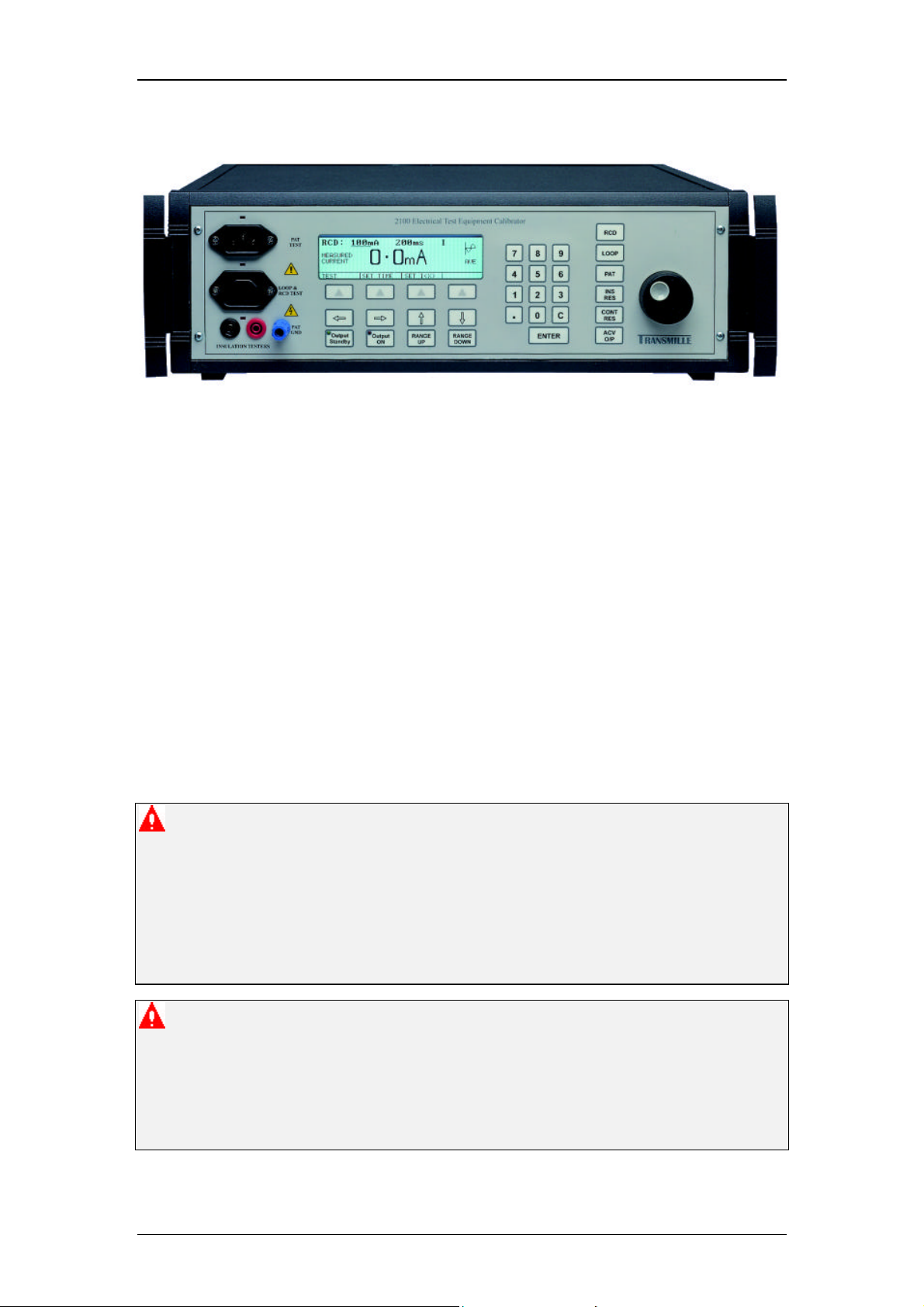

IMPORTANT OPERATIONAL NOTE 1

DUE TO THE OPERATIONAL CHARACTERISTICS OF THE 2100

ELECTRICAL TEST EQUIPMENT CALIBRATOR, AN UNPROTECTED

SUPPLY (WITHOUT RCD TRIP) MUST BE USED *.

* Use of an isolation transformer can be employed in conjunction with a protected supply

(with RCD Trip), however this will degrade performance of the calibrator.

Please contact Transmille for further details.

IMPORTANT OPERATIONAL NOTE 2

It is also necessary that for correct operation the Phase (Live) and

Phase (Neutral) MUST be connected round the correct way (some plugs

used in non-UK countries can be connected either way round, therefore

this check is necessary). There should only be a small voltage between

Phase (Neutral) and Phase (Earth).

Transmille Ltd. Issue 4.00 Page 6

2100 Operation Manual

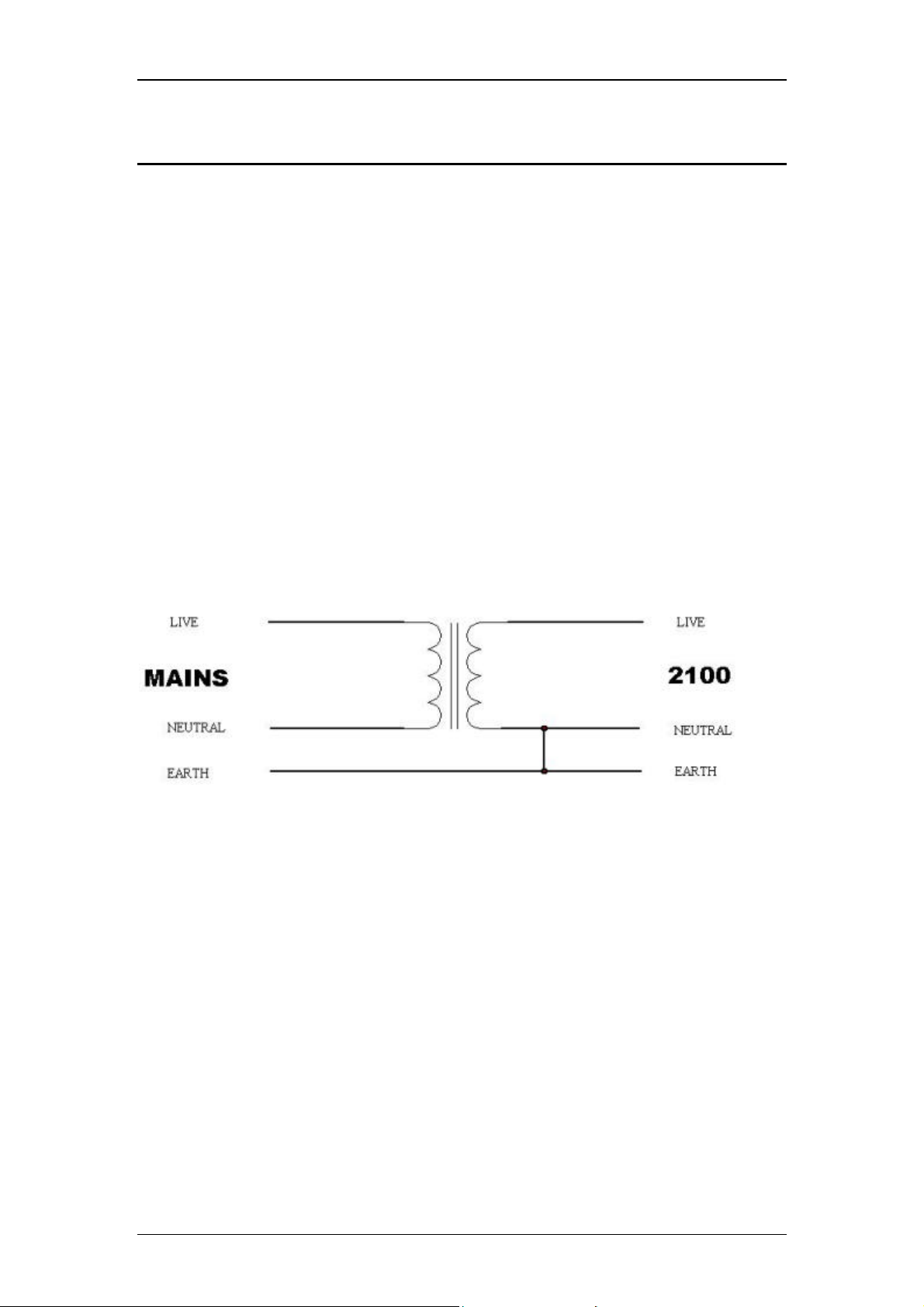

Installation & Power Requirements for the 2100

For correct operation of the 2100 it must be powered from an unprotected (ie. no RCD

trip) supply. This is because the 2100 will pass current down the Earth conductor

when performing tests and therefore trip any protection device present - FOR THIS

REASON IT IS ESSENTIAL THAT THE 2100 IS PROPERLY EARTHED.

It is also necessary that for correct operation the Phase (Live) and Phase (Neutral)

MUST be connected round the correct way (some plugs used in non-UK countries can

be connected either way round, therefore this check is necessary). There should only

be a small voltage between Phase (Neutral) and Phase (Earth).

To keep the LOOP impedance value to a minimum, the mains input to the 2100 is of a

direct cable type. This avoids any introduction of unnecessary impedance.

It is desirable that the 2100 is connected to a supply point with low LOOP impedance

as this will limit the lowest value available LOOP impedance from the 2100 using as

good a quality outlet (contact wise) as possible.

If an unprotected supply is not available, use of an Isolation Transformer can be

employed, however this will increase the lowest LOOP impedance available.

Connection of the isolation transformer should be as detailed below :

Transmille Ltd. Issue 4.00 Page 7

2100 Operation Manual

Designed for on use in the laboratory or portable on site calibration.

The 2100 calibrator is equally suitable for use in the standards laboratory or for on site

calibration work. The Small footprint and low weight makes the 2100 calibrator ideal

for on site calibration. The serial interface allows direct connection to a portable PC.

Retro fit options allows extra functions to be added as required.

Several internal retro fit options including auto loop, high accuracy resistance and

external resistance input allow the user to select the most cost effective solution for

the calibration work required at the time with the ability to add extra functions as

required.

Serial Line RS232 Interface as standard.

All functions and outputs of the 2100 calibrator are fully programmable over the

RS232 interface fitted as standard. The use of the RS232 interface saves the cost of

fitting IEEE cards to the PC, and also allows easy connection to portable PC’s,

reducing the set up time for on site calibration.

Input / Output Connection

The input and output terminal configuration is designed to enable simple connection

to a full range of instrumentation using the supplied adapter lead. Use of a dedicated

input adapter lead allows resistance measurement functions such as LOOP testing to

be calibrated to include residual values right up to the socket into which test

equipment is plugged.

All outputs are isolated when not in use, with an LED indicator showing the active

input / output terminal(s).

Transmille Ltd. Issue 4.00 Page 8

2100 Operation Manual

Preparing the calibrator for use.

Initial Inspection.

After shipment the calibrator should be inspected for any signs of external damage.

Should external damage be found contact the carrier immediately. Do not connect a

damaged instrument to the line power as this may result in internal damage. Please

keep the original box which can be used when returning the calibrator for service and

re-calibration.

Shipping Checklist

1 x Serial Communication lead (9 Way ‘D’ female to 9 Way ‘D’ male connectors)

1 x Operation manual (this document)

1 x Input Adapter lead

Input Adapter Lead

Lifting and carrying the calibrator

The calibrator can be carried easily by one person in any position by either holding the

front handles or by supporting from underneath (note : observe all normal practices for

health and safety when carrying). A custom carry case with shoulder strap is available

if the calibrator is to be regularly transported - see options list. The calibrator should

always be placed down on a firm flat surface on its base feet. Standing the calibrator

down on its back may cause damage. Avoid knocking or banging the calibrator and

always place down smoothly.

Warning

DO NOT DROP THE CALIBRATOR as this may cause internal damage.

Transmille Ltd. Issue 4.00 Page 9

2100 Operation Manual

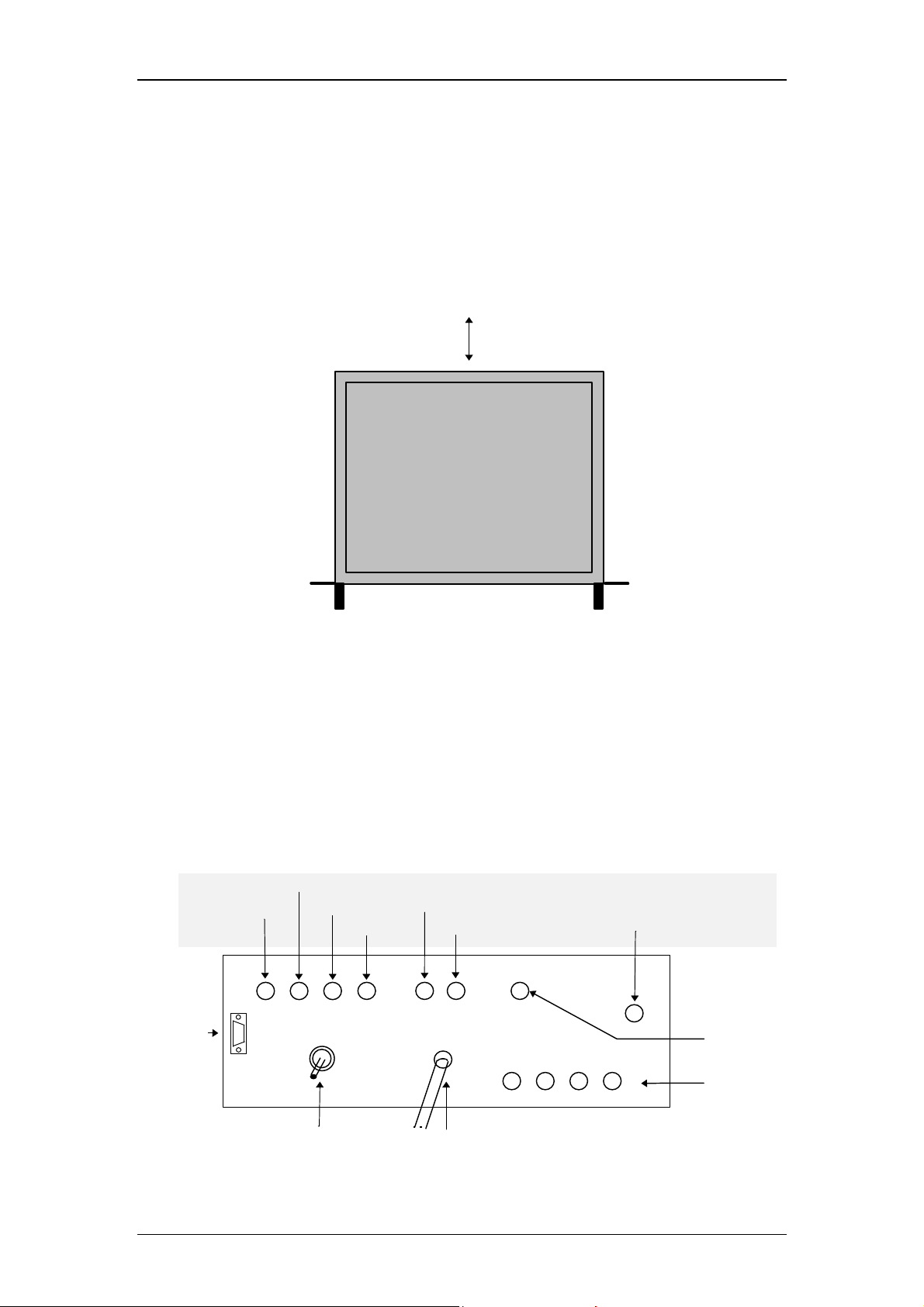

Minimum 2” (5cm) Clearance

LOOP N

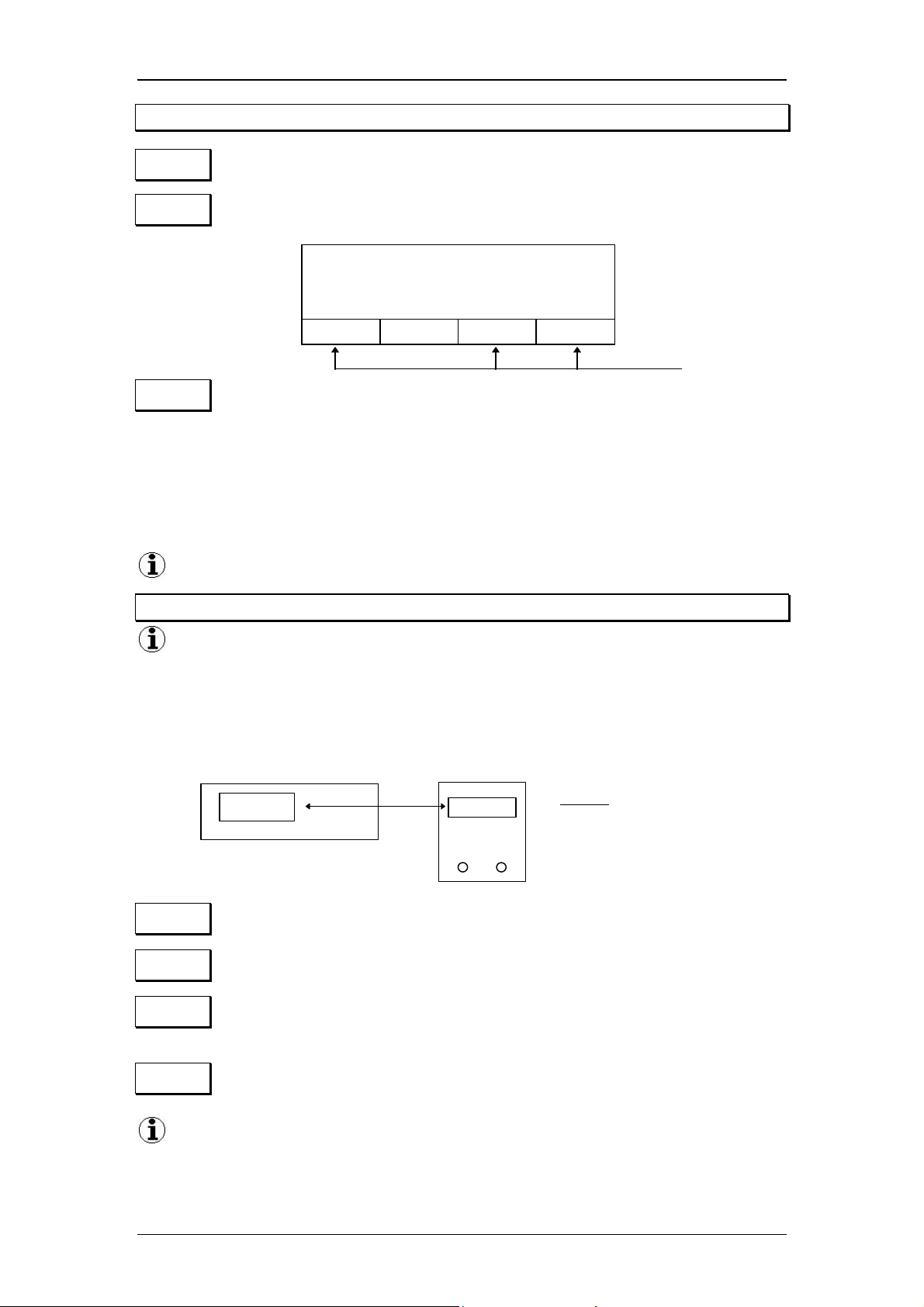

Positioning the Calibrator.

The calibrator can be used free standing on a bench or mounted in a standard 19” rack

enclosure. The calibrator can be operated at any angle, the two front feet have tilt legs

for bench operation. For all installations care must be taken not to cover the

ventilation slots underneath. A 2” (5cm) space behind the instrument is also required

for line and interface connections (See diagram) :

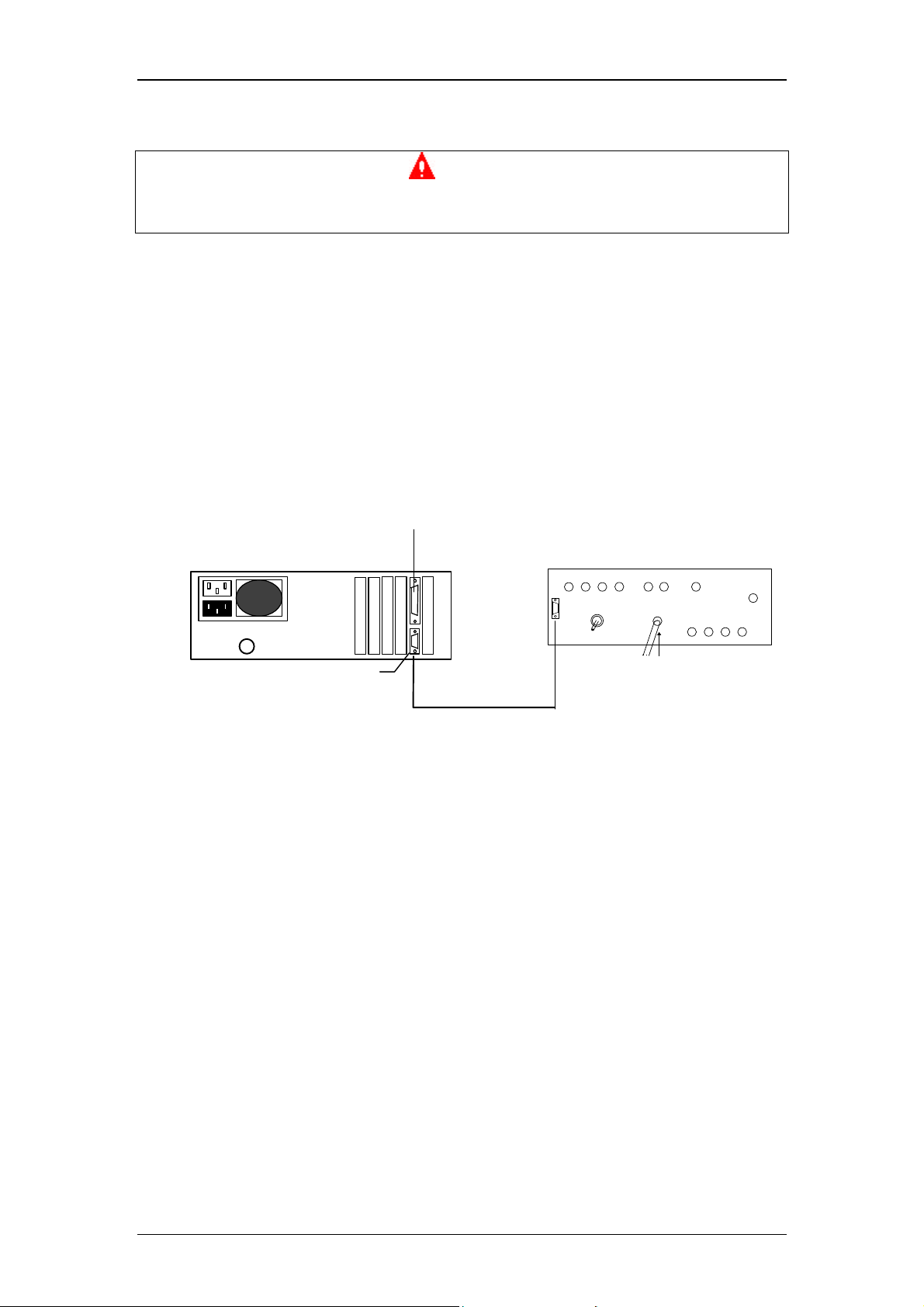

Rear Panel Connections and controls

Connections on the rear panel consist of a 9Pin Serial interface connector for the

computer interface, this is optically isolated from the calibrator outputs.

Fuse holders for individual instrument types are accessible from the back of the

calibrator. These are bayonet type fuse holders which allow a screwdriver to be used

to turn the fuse carrier until it ‘pops’ out of the fuse holder body .The fuse carrier can

then be withdrawn from the fuse holder body for inspection / replacement.

FUSES

LOOP L

RS232 9 Way

‘D’ Type

Connector

(Serial Port)

On / Off Switch

MAINS

RCD

ACV

PAT

Mains Lead

Insulation Resistance

FLASH

CONNECTOR

EXTERNAL

RESISTOR

INPUT

Transmille Ltd. Issue 4.00 Page 10

2100 Operation Manual

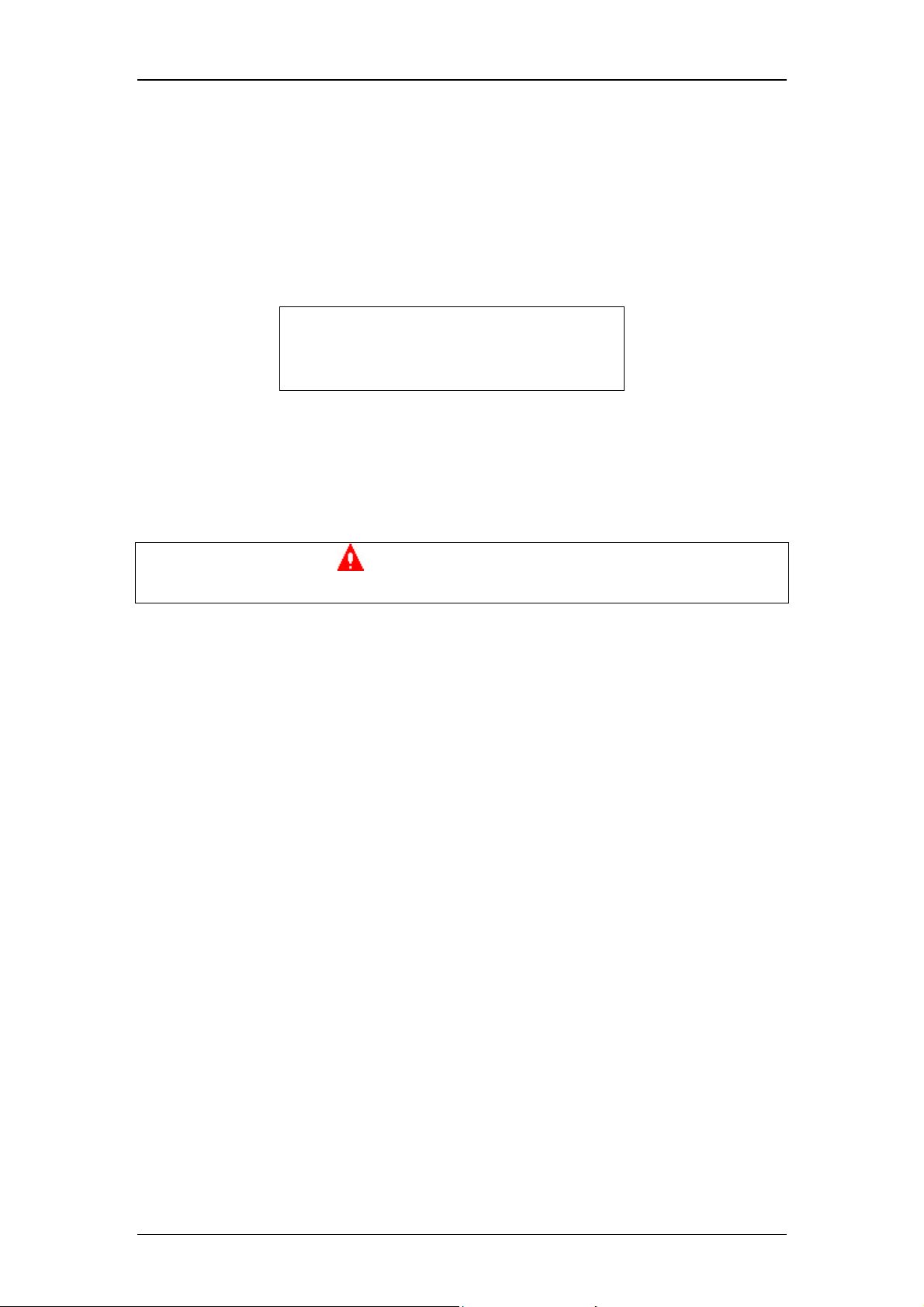

P.C. Rear Panel

2100 Rear Panel

Setting and checking the Line Voltage.

Warning

The line power cord must have an earth conductor to avoid

risk of shock. This instrument must be correctly earthed.

The calibrator has been designed to work from either 100-120 Volt line supply or 200

- 240 Volt line supply. Check Supply voltage as marked on the rear panel before

connecting to power line. Connecting the calibrator to the wrong supply will cause

internal damage to the instrument. To Change the line voltage it is necessary to

remove the rear panel and rewire the transformer. The calibrator will have been

shipped wired for 110V operation for USA, 240V for Europe.

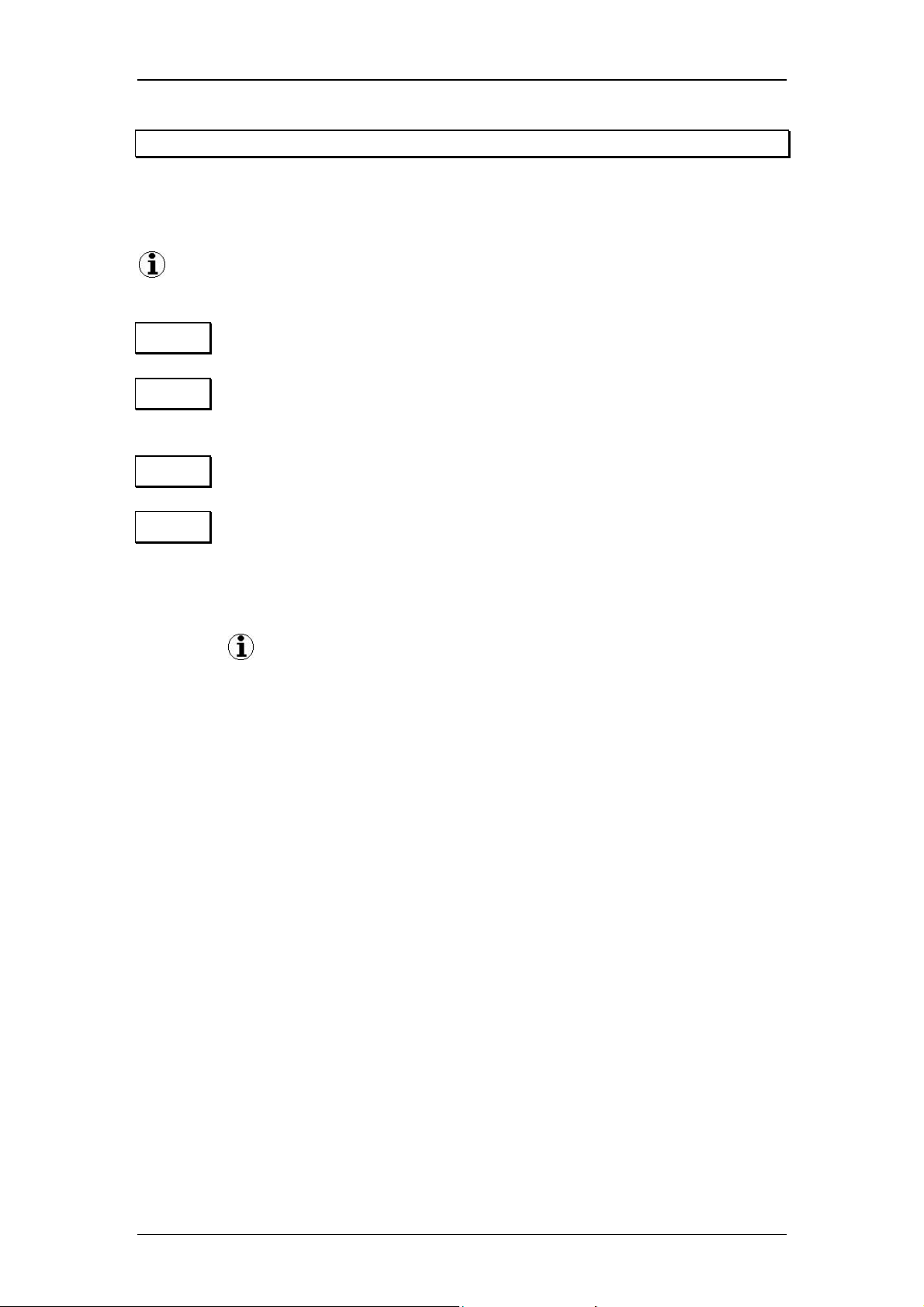

Connecting to a computer

If required a standard serial 9 pin cable may be used to connect the calibrator to a

Comm port on a PC. A Null modem cable is not needed.

Keyboard Socket

Serial (RS232) Port

Parallel

(Printer)

Port

Mains Lead

Serial (RS232)

Cable

Transmille Ltd. Issue 4.00 Page 11

2100 Operation Manual

Powering up the calibrator

After connecting line power the calibrator can be switched on with the line power

switch above the mains inlet socket on the rear panel.

The front panel display will illuminate indicating power. The display will show

program version number and after a short delay, during which time the processor

performs a self test of the instrument, the display will show the default start-up display

:

2100 CALIBRATOR Ver x.x

TRANSMILLE LTD.

The calibrator has been designed to be powered up continuously, automatically

switching the display to power save mode after a pre-set period of time from the last

command. In power save mode the display back light will turn off.

Output Connections

Warning - Risk of shock.

High voltages may be present on the output sockets.

Output sockets comprise of the following types :

IEC 3-Pin Socket : For use directly with the lead of a PAT tester or in

conjunction with the supplied adapter lead.

IEC 3-Pin Plug : For use directly with the lead of a LOOP or RCD tester

or in conjunction with the supplied adapter lead.

4mm Safety Sockets: For connection to Insulation Testers

Transmille Ltd. Issue 4.00 Page 12

2100 Operation Manual

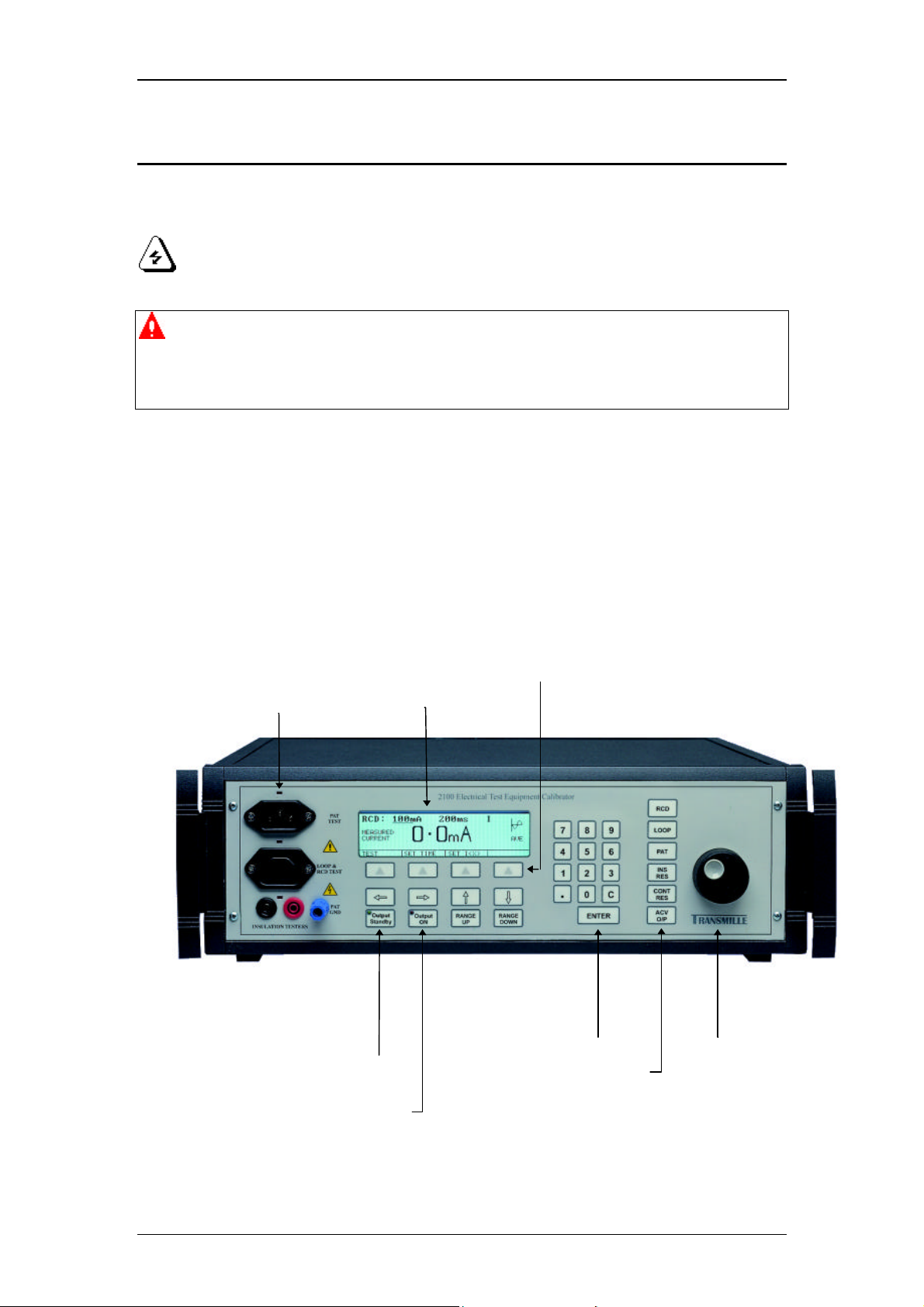

Button

Function Keys

Operation

SAFETY WARNINGS

This instrument is capable of generating high voltages.

WARNING : The information in this section is intended only for qualified

personnel. The user must at all times be adequately protected from electric shock.

Qualified personnel must ensure that operators of the equipment are adequately

insulated from connection points.

A carry-case is available for regular transportation of the calibrator.

Introduction to Operation

All functions of the 2100 Calibrator can be controlled from the front panel or

controlled remotely by a computer over the RS232 interface.

Front Panel Controls and Indicators

LCD

Active

Terminal /

Socket LED

Display with

integral

Backlight

Menu buttons

(SoftKeys)

Numeric

Stand-By

Output On

Button

Transmille Ltd. Issue 4.00 Page 13

Keypad

Digital

Potentiometer

2100 Operation Manual

Front panel Keyboard

The front panel of the 2100 Calibrator utilises a high quality membrane switch panel

with tactile feel buttons and integral display window. The front panel is therefore

sealed against the ingress of moisture and dirt enabling the calibrator to be used in

working environments without risk of dirt causing early failure of the operating

buttons. The front panel can easily be wiped clean with a soft cloth. Care should be

taken not scratch the display window. All graphics are ‘under printed’ so that they will

not wear off with use.

IMPORTANT NOTE

The front panel key buttons are for use with fingers only - do not press the key with

hard or sharp objects e.g. Ball-point pens, pencils, screwdrivers etc. Repeated actions

like this will almost certainly cause the keyboard to fail. (This will not be covered

under warranty). Care should also be taken when transporting the instrument - do not

leave test leads plugged in which may get squashed into the display area or keys

which can also cause damage.

Transmille Ltd. Issue 4.00 Page 14

2100 Operation Manual

SoftKey Menu items

The Keyboard is divided into sections to allow rapid operation.

The Numeric section allowing values to be entered,

Functions keys for RCD, LOOP, PAT, Insulation Resistance, Continuity Resistance

and ACV Output

Range up and range down keys allows range changing for the currently selected

function

Left/right arrow keys select the digit to be controlled by the rotary control knob.

Output on / Standby keys allow the calibrator output to be disconnected from the

terminals. Led indicators are incorporated in these switches to clearly show the output

status.

Graphic LCD Display

A back lit graphic LCD display shows the present setting and instrument status. The

bottom line of the display is used to assign the function of the four ‘ soft (menu) keys’

immediately under the display. The display utilises a back light which automatically

turns off if no activity takes place. The back light turns on as soon as a key is pressed

or a command is received.

Transmille Ltd. Issue 4.00 Page 15

2100 Operation Manual

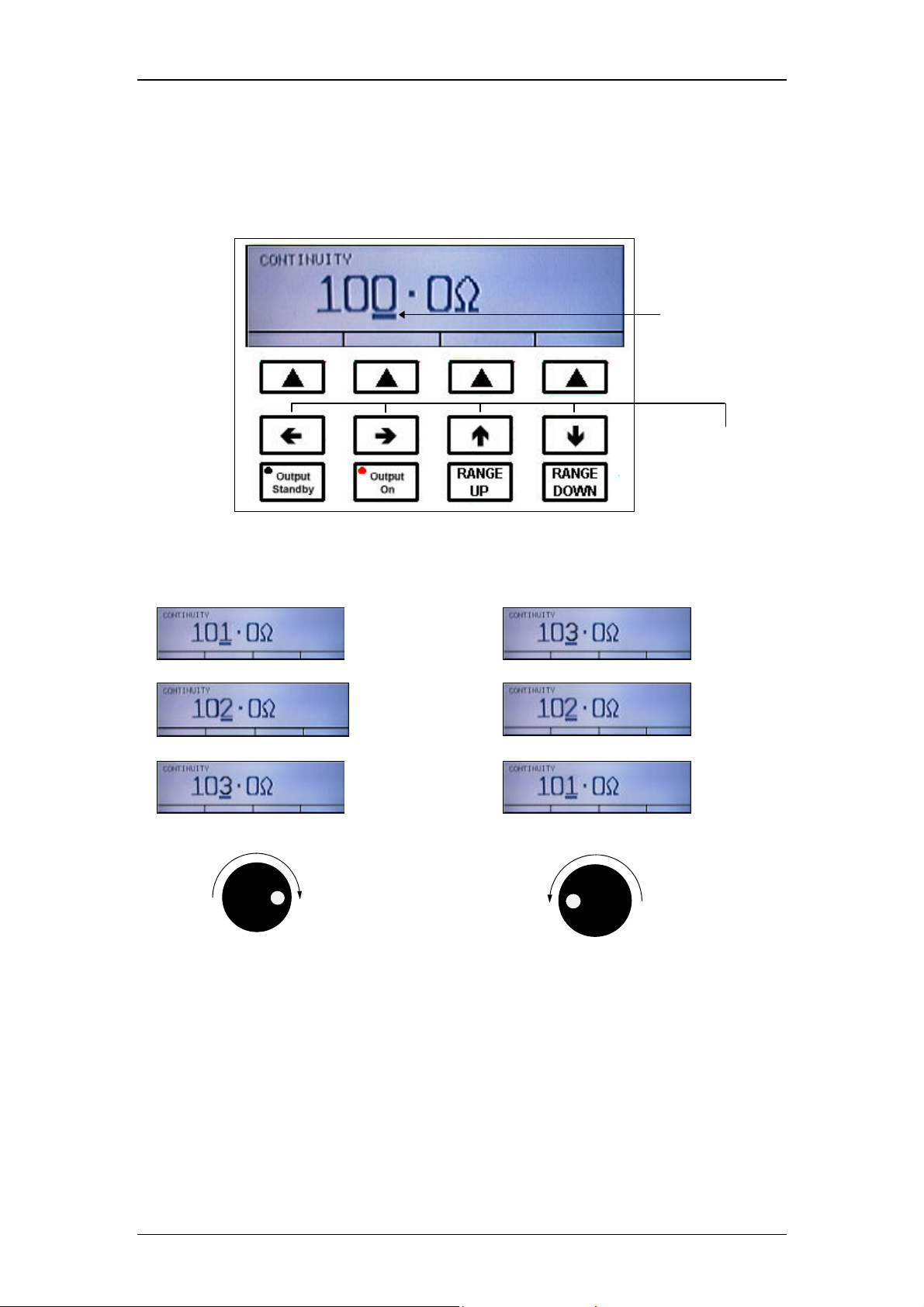

Using the Digital Potentiometer

A digital potentiometer allows selected digits on the display to be incremented

(turning clockwise) or decrement (turning anti-clockwise).

Selected digit

marker.

Cursor Keys can be used

to move the position of the

digit marker, and increment

/ decrement the digit.

Clockwise Rotation Anti-Clockwise Rotation

(Increment Digit) (Decrement Digit)

Transmille Ltd. Issue 4.00 Page 16

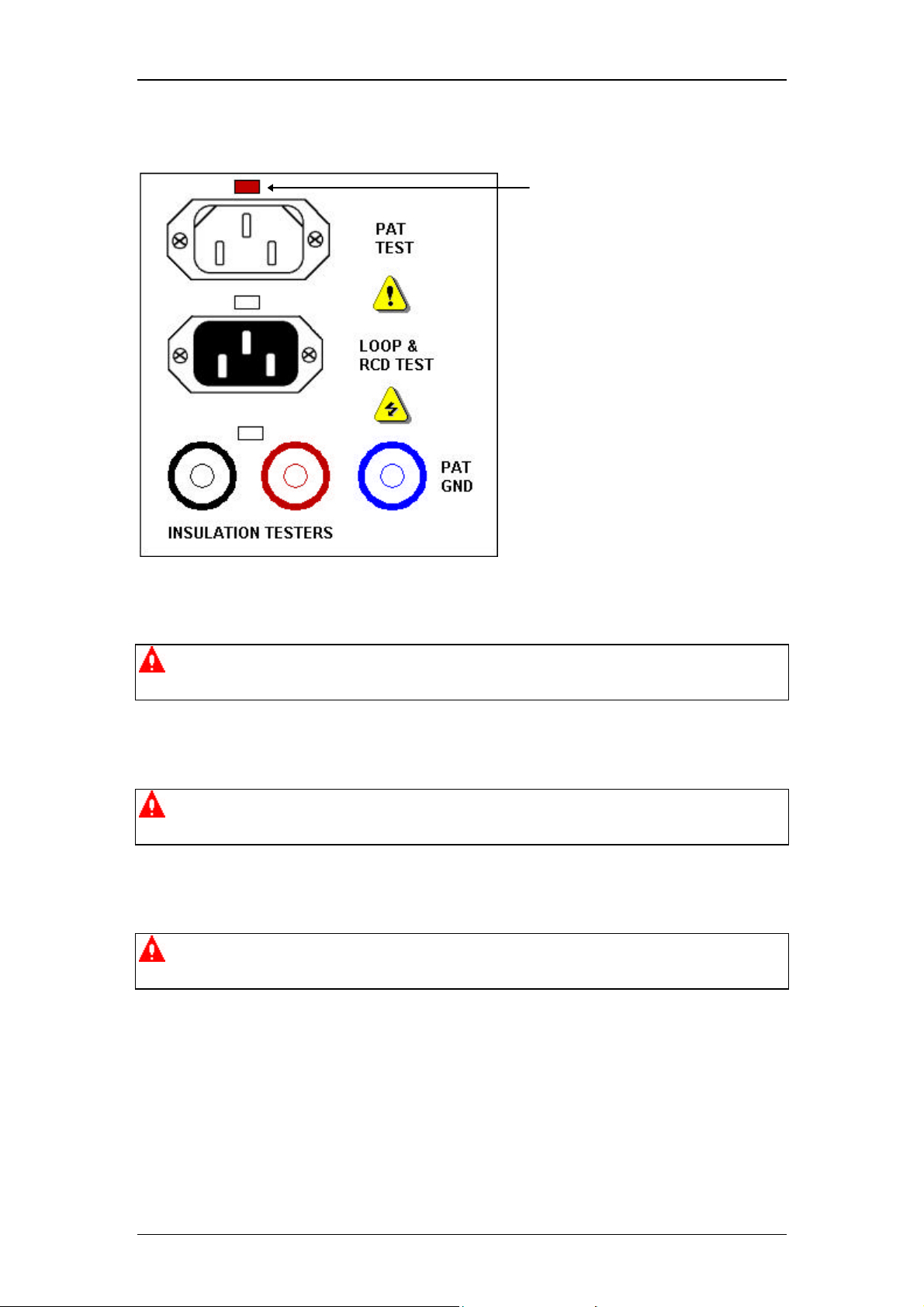

Terminal status LEDs

LED’s above the terminals indicate the active terminal.

2100 Operation Manual

Active terminals

indicated by

illuminated LED

PAT Test IEC Socket

WARNING

Dangerous voltage may be present on these terminals.

LOOP & RCD TEST IEC Plug

WARNING

Dangerous voltage may be present on these terminals.

INSULATION TEST 4mm terminals

WARNING

Dangerous voltage may be present on these terminals.

PAT GND 4mm Terminal (Blue)

Transmille Ltd. Issue 4.00 Page 17

2100 Operation Manual

Calibrating Instruments Using the 2100

Calibrating Insulation Testers

The 2100 has five functions for calibrating insulation testers :

1. High value resistance output for insulation testing (0MΩ to 2,000MΩ)

2. Measurement of the insulation test voltage

3. Low value resistance for continuity testing

(0.1Ω to 20.0Ω Variable, 100R & 1kΩ Fixed Ranges)

4. Insulation test current measurement

5. A.C. voltage output at 100V, 200V, 240V, 300V and 400V

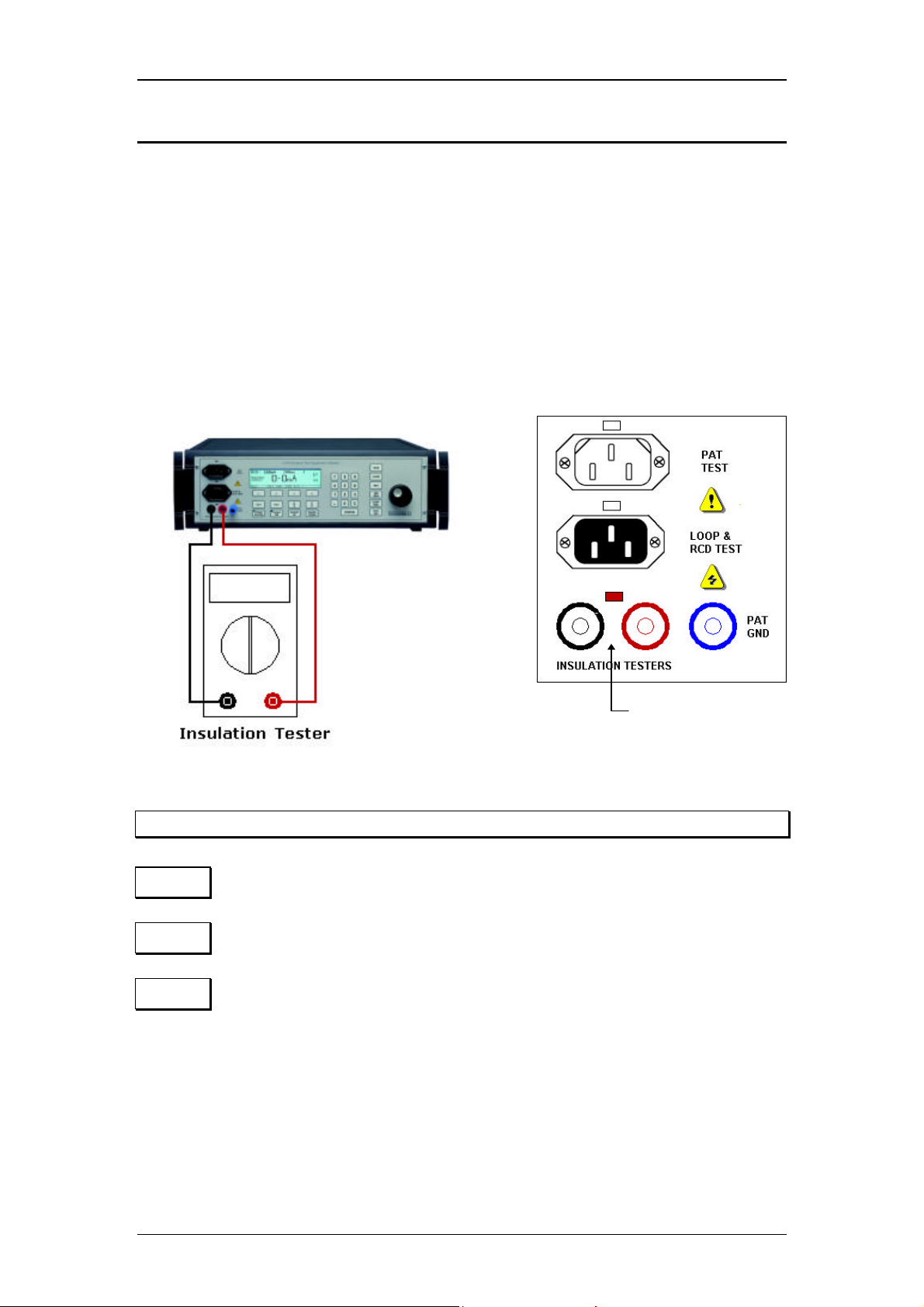

Use the 4mm sockets

labelled INSULATION

TESTERS for all

insulation meter tests.

1. High Value Resistance for Insulation Testing

Step 1 Select ‘INS RES’ from the function key section of the 2100 front panel

Step 2 Connect the insulation tester to the Black & Red 4mm terminals.

Step 3 Enter the required resistance in MΩ from 10kΩ to 10,000MΩ

on the keyboard followed by Enter. An alternative way to select the

required resistance is to use the digital potentiometer to increment /

decrement the digit indicated by the cursor. The Left and Right

arrow keys allow the selected digit to be changed

Transmille Ltd. Issue 4.00 Page 18

2100 Operation Manual

100.00 MΩ

2. Measuring Insulation Test Voltages & Current

Step 1 From the Insulation Resistance menu displayed on the 2100, select the

Voltage function using the ‘SoftKey’.

INSULATION RESISTANCE

VOLTAGE

Step 2 Select the required voltage range using either the digital potentiometer or the

up / down arrow keys. Ranges include 50V, 100V, 250V, 500V and 1000V.

The impedance of each range is automatically set to give the correct

load 1mA / 0.5mA (see test current below) at the applied nominal

voltage range.

RANGE INPUT IMPEDANCE

1mA 0.5mA

50V 50kOhm 100kOhm

100V 100kOhm 200kOhm

250V 250kOhm 500kOhm

500V 500kOhm 1Mohm

1000V 1Mohm 2MOhm

Step 3 Select the required measurement current using the SoftKeys.

The default setting for current load is 1mA nominal which is the correctly

load/test current for the 16th Edition equipment - e.g. must be able to supply

1mA at the test voltage. Older insulation testers (15th Edition Reg.) only had

to produce 0.5mA current at the test voltage. The 2100 should be set to

0.5mA current for these instruments. Very old tester’s may only produce a

very small current and the voltage will collapse under any load - these cannot

be tested with the 2100.

Transmille Ltd. Issue 4.00 Page 19

2100 Operation Manual

The correct polarity must be applied to obtain a reading

TEST VOLTAGE - 1000V / 1mA

UNDER-RANGE/POLARITY

TEST CURRENT : 1.00mA

CURRENT BACK

Step 4 Press the test button on the insulation tester to apply the insulation test voltage

and read the voltage and current on the 2100 display.

To return from the Voltage measurement screen to the insulation

resistance select the Back menu item using the Softkey.

If the voltage applied by the tester is less than 30% of the range or

the polarity is incorrect, the display will show

UNDER-RANGE / POLARITY (note some tester’s ‘positive’ red

terminals are supplying negative voltage and need to have test leads

reversed.

NOTE:- NEGATIVE INPUT OF 2100 (BLACK) IS CONNECTED

TO SUPPLY EARTH.

Warning : The maximum input voltage is 1100 volts

Transmille Ltd. Issue 4.00 Page 20

2100 Operation Manual

1.00 Ω

3. Low Value Resistance for Continuity Testing

Step 1 Connect the insulation tester to the Black & Red 4mm sockets.

Step 2 Select ‘CONT RES’ from the function key section of the 2100 front panel

CONTINUITY RESISTANCE

CURRENT

0.0mA

20mOHMS 0.1-20R 100 OHMS 1kOHMS

Fixed values

Step 3 Select the required resistance in Ω from 20mΩ to 1kΩ

on the 2100 keyboard followed by Enter, or by using the softkeys.

An alternative way to select the required resistance is to use the digital

potentiometer to increment / decrement the digit indicated by the cursor.

The Left and Right arrow keys allow the selected digit to be changed.

NOTE : 20mΩ, 100Ω and 1kΩ are fixed values. 0.1Ω to 20Ω is a variable range

The measured current is also displayed when a resistance of 1Ω is set..

4. A.C. Voltage Output

Notes on ACV Output

To provide the power necessary for some insulation testers, the AC output

from the 2100 is derived from transformer tappings. The output is

unregulated and will vary with line voltage and loading. The actual output

voltage at any time is measured and displayed by the 2100 which can be

compared to the displayed value on the UUT.

234.1V

234.1V

2100

UUT

Example

2100 set to 230V range, measures mains

and displays a measured value of 234.1V.

The UUT is compared to check its accuracy

at this value.

Step 1 Connect the insulation tester to the Black & Red 4mm sockets.

Step 2 Select ‘ACV O/P’ from the function key section of the 2100 front panel

Step 3 Select the required voltage using either the range up / range down buttons

Step 4 Read the voltage displayed on the insulation tester meter.

Transmille Ltd. Issue 4.00 Page 21

or by incrementing / decrementing the range using the digital potentiometer.

and compare it with the value displayed on the 2100

Use the Output Standby and Output On buttons to control the output.

2100 Operation Manual

5. 5kV Insulation Tester Extension Adapter [OPTION]

This option allows the testing of Insulation Testers with test voltages up to 5kV and

Insulation range up to 200GΩ.

The insulation tester must have a guard terminal for this adapter to function

correctly

Step 1 Select ‘INS RES’ from the function key section of the 2100 front panel

Step 2 Connect the 5kV Adapter flying leads to the 2100 Insulation tester terminals

(observing correct polarity)

Step 3 Connect the Insulation tester to the adapter box

Step 4 Calculate the value needed to be entered in order to give the required resistance

(this will be 100th of the actual required resistance less the input

impedance of the tester - typically 10MΩ, example to simulate

100GΩ select 990MΩ on the 2100)

In most cases it is not necessary to allow for the input impedance of the tester.

This value can be entered on the keyboard followed by Enter. An

alternative way to select the required resistance is to use the digital

potentiometer to increment / decrement the digit indicated by the

cursor. The Left and Right arrow keys allow the selected digit to be

changed

Transmille Ltd. Issue 4.00 Page 22

Loading...

Loading...