Transmille 1000 User Manual

1000 Series

Precision Multi Product Calibrator

Operation Manual

TRANSMILLE LTD. Version 1.30 Page 1

1000 SERIES OPERATION MANUAL

IMPORTANT NOTICE

THIS CALIBRATOR

WILL

REQUIRE AN

UNLOCK CODE

AFTER THE EVALUATION

PERIOD HAS EXPIRED.

(60 Days after invoice date)

AFTER THE EVALUATION PERIOD HAS EXPIRED THE

OPERATION OF THE CALIBRATOR IS LOCKED AND THE DISPLAY

SHOWS A NUMBER WHICH MUST BE QUOTED TO TRANSMILLE

TO RECEIVE THE UNLOCK CODE

THE UNLOCK CODE IS AVAILALBLE

FROM TRANSMILLE

ONLY AFTER PAYMENT

HAS BEEN RECEIVED.

This code only needs to be entered once

in the life of the instrument.

Please contact Transmille or use the form in the

back of the manual to obtain the unlock code.

Transmille Ltd.

Staplehurst, Kent.

Tel: 44 (0)1580 890700 Fax: 44(0)1580 890711

Email: sales@transmille.com

TRANSMILLE LTD. Version 1.30 Page 2

1000 SERIES OPERATION MANUAL

DECLARATION OF CONFORMITY

Manufacturer’s Name: Transmille Ltd.

Manufacturer’s Address: Unit 4, Select Business Centre

Lodge Road

Staplehurst

TN12 0QW

Declares, that the product

Product Name: Multi-product Calibrator

Model Number: 1000A / 1000B

Product Options: This declaration covers all options of the above product(s)

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage

Directive 73/73EEC and the EMC Directive 89/336/EEC (including 93/68/EEC)

and carries the CE Marking accordingly

Conforms with the following product standards:

EMC

EN 61326-1:1997+A1:1998 • EN55011:1991 (Group 1 : Class A)

Standard Limit

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995 4kV CD, 8kV AD

IEC 61000-4-3:1995 / EN 61000-4-3:1995 3 V/m, 80-1000 MHz

IEC 61000-4-4:1995 / EN 61000-4-4:1995 0.5kV signal lines, 1kV power lines

IEC 61000-4-5:1995 / EN 61000-4-5:1995 0.5kV line-line, 1kV line-ground

IEC 61000-4-6:1996 / EN 61000-4-6:1996 3V, 0.15-80 MHz / cycle, 100%

IEC 61000-4-11:1994 / EN 61000-4-11:1994 Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

SAFETY

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

01/07/2013

Revision No: 1.0 Managing Director

Date: 01/07/2013

TRANSMILLE LTD. Version 1.30 Page 3

1000 SERIES OPERATION MANUAL

TABLE OF CONTENTS

1000 SERIES CALIBRATION INTRODUCTION .......................................................................................... 6

MAIN FEATURES ................................................................................................................................................ 6

ACCURACY AND FUNCTIONALITY ..................................................................................................................... 7

TRUE MULTIPRODUCT CALIBRATION ................................................................................................................ 7

USB INTERFACE ................................................................................................................................................ 7

OUTPUT CONNECTION INDICATION ................................................................................................................... 7

PREPARING THE CALIBRATOR FOR USE. ............................................................................................... 8

INITIAL INSPECTION. .......................................................................................................................................... 8

LIFTING AND CARRYING THE CALIBRATOR ....................................................................................................... 8

POSITIONING THE CALIBRATOR ......................................................................................................................... 9

POWER AND INTERFACE CONNECTIONS ........................................................................................................... 10

CHECKING THE LINE VOLTAGE ....................................................................................................................... 11

POWER LINE INLET FUSE AND RATING ............................................................................................................ 11

REPLACING THE POWER LINE FUSE ................................................................................................................. 11

CONNECTING TO A COMPUTER ......................................................................................................................... 13

CONNECTION DETAILS .................................................................................................................................... 13

POWERING UP THE CALIBRATOR ...................................................................................................................... 14

OUTPUT CONNECTIONS ................................................................................................................................... 15

OUTPUT OVERLOADS ...................................................................................................................................... 16

OPERATION ..................................................................................................................................................... 17

SAFETY WARNINGS ......................................................................................................................................... 17

INTRODUCTION TO OPERATION ....................................................................................................................... 17

FRONT PANEL CONTROLS AND INDICATORS .................................................................................................... 18

GRAPHIC LCD DISPLAY .................................................................................................................................. 19

FRONT PANEL KEYBOARD ............................................................................................................................... 20

DIGITAL CONTROL AND CURSOR KEYS ........................................................................................................... 22

TERMINAL STATUS LED’S ............................................................................................................................... 22

9 PIN ADAPTER INTERFACE CONNECTOR. ....................................................................................................... 25

SOFT KEY MENUS .......................................................................................................................................... 26

MENU STRUCTURE .......................................................................................................................................... 26

PROCEDURE MENU .......................................................................................................................................... 27

SETUP MENU ................................................................................................................................................... 28

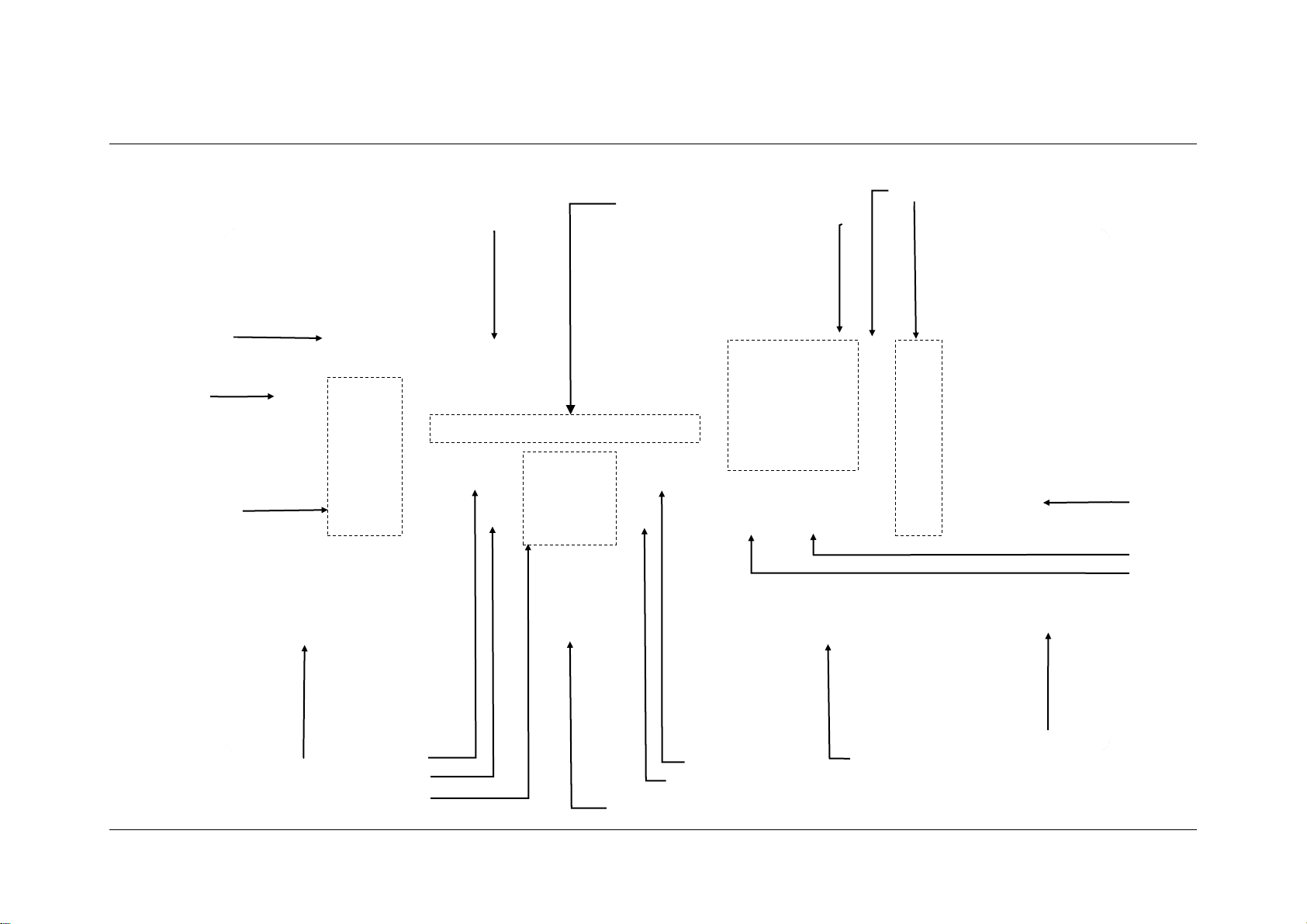

CONNECTION DIAGRAMS .......................................................................................................................... 29

DC / AC VOLTAGE .......................................................................................................................................... 29

DC / AC CURRENT – OUTPUTS BELOW 1A ...................................................................................................... 29

DC/AC CURRENT – OUTPUTS ABOVE 1A ........................................................................................................ 30

RESISTANCE .................................................................................................................................................... 30

CAPACITANCE ................................................................................................................................................. 31

FREQUENCY ..................................................................................................................................................... 31

THERMOCOUPLE .............................................................................................................................................. 32

PRT / RTD ...................................................................................................................................................... 32

INSULATION RESISTANCE / TEST VOLTAGE MEASUREMENT ........................................................................... 33

CONTINUITY RESISTANCE / CURRENT MEASUREMENT .................................................................................... 33

SETTING AN OUTPUT ................................................................................................................................... 34

USING THE KEYBOARD .................................................................................................................................... 34

ADJUSTING THE OUTPUT USING THE DIGITAL CONTROL ................................................................................... 35

DISPLAY OF % OR PPM ERROR ......................................................................................................................... 35

SETTING A DC VOLTAGE OUTPUT ................................................................................................................... 36

SETTING A DC CURRENT OUTPUT ................................................................................................................... 38

SETTING AN AC VOLTAGE OUTPUT. ............................................................................................................... 40

SETTING AN AC CURRENT OUTPUT ................................................................................................................. 43

SETTING THE SIMULATED RESISTANCE OUTPUT ............................................................................................. 46

TRANSMILLE LTD. Version 1.30 Page 4

1000 SERIES OPERATION MANUAL

SETTING PASSIVE RESISTANCE OUTPUT .......................................................................................................... 48

SETTING CAPACITANCE OUTPUT ..................................................................................................................... 50

SETTING FREQUENCY OUTPUT. ....................................................................................................................... 52

THERMOCOUPLE SIMULATION ......................................................................................................................... 54

PRT OUTPUT ................................................................................................................................................... 56

EA002 – 2/10/50 TURN COIL ADAPTER (OPTION) ........................................................................................... 58

INSULATION RESISTANCE CALIBRATION (OPTION) .......................................................................................... 61

INSULATION TEST VOLTAGE MEASUREMENT (OPTION) .................................................................................. 63

CONTINUITY RESISTANCE CALIBRATION (OPTION) ......................................................................................... 65

CONTINUITY CURRENT MEASUREMENT [1 OHM] (OPTION) ............................................................................ 67

OUTPUT PROTECTION AND SAFETY FEATURES ................................................................................ 69

WARNING AND OUTPUT OVERLOAD INDICATIONS .......................................................................................... 69

HIGH VOLTAGE TIMEOUT. ............................................................................................................................... 69

HIGH VOLTAGE OUTPUT RAMP ....................................................................................................................... 69

HIGH VOLTAGE CURRENT LIMIT ..................................................................................................................... 70

10 AMP TEMPERATURE CUT-OUT .................................................................................................................... 70

REMOTE PROGRAMMING .......................................................................................................................... 71

USB INTERFACE .............................................................................................................................................. 71

RETURNING TO LOCAL CONTROL .................................................................................................................... 72

PROGRAMMING COMMANDS OVERVIEW ......................................................................................................... 72

RESPONSE CODES ............................................................................................................................................ 73

DC VOLTAGE COMMANDS .............................................................................................................................. 74

AC VOLTAGE COMMANDS .............................................................................................................................. 76

DC CURRENT COMMANDS .............................................................................................................................. 78

AC CURRENT COMMANDS .............................................................................................................................. 80

PASSIVE RESISTANCE COMMANDS .................................................................................................................. 82

CAPACITANCE COMMANDS ............................................................................................................................. 84

SIMULATED RESISTANCE COMMANDS ............................................................................................................. 85

FREQUENCY COMMANDS ................................................................................................................................. 86

THERMOCOUPLE SIMULATION COMMANDS ..................................................................................................... 88

TECHNICAL DESCRIPTION ........................................................................................................................ 91

GENERAL ......................................................................................................................................................... 91

INTERNAL FUSES ............................................................................................................................................. 92

OPENING THE CASE ......................................................................................................................................... 93

ACCESS TO INTERNAL FUSES ........................................................................................................................... 94

GETTING THE BEST OUT OF THE CALIBRATOR. ................................................................................................. 95

CALIBRATION AND MAINTENANCE ....................................................................................................... 97

GENERAL ......................................................................................................................................................... 97

ELECTRICAL SAFETY TESTS ............................................................................................................................ 97

CLEANING OF THE FAN VENTS ........................................................................................................................ 98

CLEANING THE EXTERNAL CASE ...................................................................................................................... 98

CALIBRATION .................................................................................................................................................. 99

GUARANTEE AND SERVICE ............................................................................................................................ 100

APPENDIX A .................................................................................................................................................. 102

INSTALLING THE USB INTERFACE DRIVER (WINDOWS XP) .......................................................................... 102

INSTALLING THE USB INTERFACE DRIVER (WINDOWS VISTA / 7)................................................................. 103

CHECKING THE COM PORT SETTING FOR THE USB INTERFACE .................................................................... 104

TRANSMILLE LTD. Version 1.30 Page 5

1000 SERIES OPERATION MANUAL

1000 Series Calibration Introduction

The 1000 series of calibrators offer the smallest and by far the most portable multi

product multi-function calibrator in the world.

Main Features

AC/DC Volts to 1025V

AC/DC Current to 10 Amps

AC/DC Current to 500 Amps with 50 Turn Clamp coil Adapter EA002

Simulated 2 wire Resistance 0 ohms to 10 Mohms

Passive 2 wire Resistance 10 ohms to 100 Mohms

Capacitance 10nF to 1uF

Frequency to 100kHz

PT100 resistance Simulation

Thermocouple Simulation (°C / °F)

USB Interface

Expandable via the Adapter Interface for added functionality

TRANSMILLE LTD. Version 1.30 Page 6

1000 SERIES OPERATION MANUAL

Accuracy and Functionality

The 1000 Series calibrators are available in a rugged portable case or a bench

case. A rack mounting option is also available.

True Multiproduct Calibration

Designed to provide an accurate cost effective portable instrument for the calibration

of multimeters, clamp meters, frequency meters and temperature meters.

Designed for use in the laboratory or portable onsite calibration. The fast warm up

time combined with the small case and low weight make the 1000 series calibrator

also ideal for onsite calibration. The USB interface allows direct connection to a

computer/laptop.

USB Interface

All functions and outputs of the series 1000 calibrator are fully programmable over

the USB interface. The use of the USB interface saves the cost of fitting GPIB cards

to the computer, and also allows easy connection to laptops, reducing the set up

time for on-site calibration.

Output Connection Indication

The output terminal configuration is designed to match the majority of multimeter

input connections, e.g. volts/ohms, low current and high current eliminating the need

for lead changing during calibration. All outputs are isolated when not in use and an

LED indicator shows the active output(s).

TRANSMILLE LTD. Version 1.30 Page 7

1000 SERIES OPERATION MANUAL

Preparing The Calibrator For Use.

Initial inspection.

After shipment the calibrator should be inspected for any signs of external damage.

Should external damage be found contact the carrier immediately. Do not connect a

damaged instrument to the line power as this may result in internal damage. Please

retain the original packaging; this should be used when returning the calibrator for

service and recalibration.

Before connecting to Line power, ensure that the input voltage of the calibrator

matches your supply voltage. For further information on verifying the input voltage,

please refer to Page 11

Lifting and Carrying the Calibrator

The calibrator weighs 9.5kg so can be carried by one person. (note: observe all

normal practices for health and safety when carrying). The calibrator should always

be placed down on a firm flat surface on its base feet. Avoid knocking or banging the

calibrator and always place down smoothly.

The 1000A, in the ruggedized case should always be transported with the lid closed

to protect the front panel of the instrument from accidental damage.

Warning: DO NOT DROP THE CALIBRATOR

This may cause internal damage which will not be covered under

warranty

TRANSMILLE LTD. Version 1.30 Page 8

1000 SERIES OPERATION MANUAL

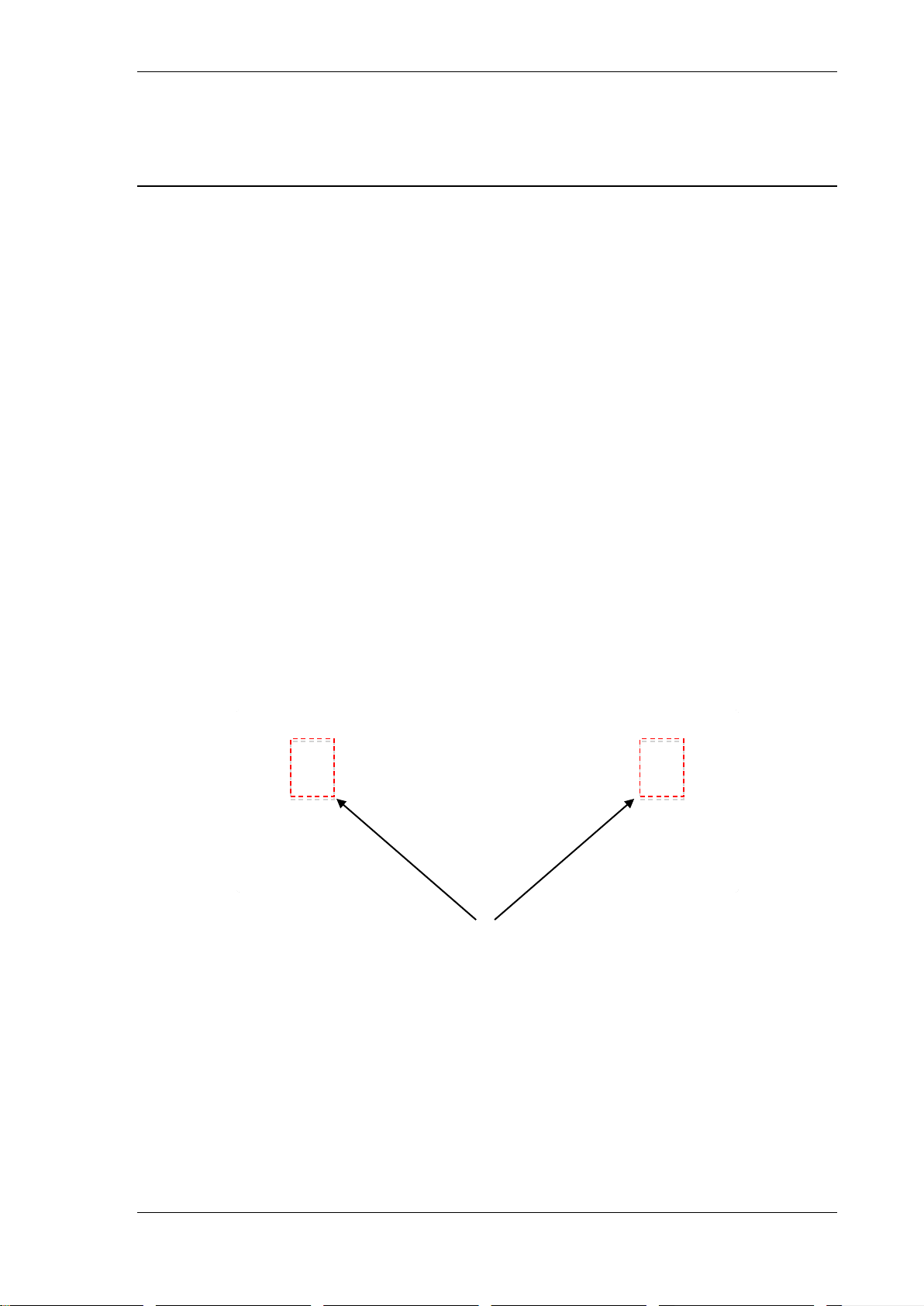

Moveable ‘arms’ attached to

front pair of feet

Positioning the Calibrator

The 1000 series calibrator is available in a variety of different casings for use on

site, on a bench or in a rack.

Care should be taken when positioning the calibrator to ensure that items are not

placed against the cooling vents. Placing items against the cooling vents will affect

the performance of the calibrator and reduce the amount of time that the 10A output

will operate for before reaching thermal cut-out conditions (see Page 70)

When considering placement of the 1000A (in ruggedized casing), ensure that the

calibrator is placed on a flat, stable surface.

For bench-top use, the 1000B (bench top casing) is fitted with 4 non-slip feet. The

front pair of feet are fitted with moveable ‘arms’ that can be positioned to raise the

front of the calibrator to a more ergonomic position.

TRANSMILLE LTD. Version 1.30 Page 9

1000 SERIES OPERATION MANUAL

Adapter Interface

Mains / Line Inlet

(IEC) Connector

Fuse Holder

USB Interface

Connector

Power

Switch

Line Power / Fuse Ratings

Cooling Vents

Power and Interface Connections

Connections on the front panel are for Line Power via a 3 Pin IEC connector

incorporating the Line fuse and on-off switch, and a Female Type B USB connector

for interfacing with a computer.

The 1000 Series is provided with an IEC lead suitable for the country of shipping, if

a different lead is required please inform Transmille prior to shipping.

TRANSMILLE LTD. Version 1.30 Page 10

1000 SERIES OPERATION MANUAL

Checking the Line Voltage

Warning: The line power cord must have an earth

conductor to avoid risk of shock.

This instrument must be correctly earthed.

The calibrator must be ordered with 100-120 Volt line supply or 220 - 240 Volt line

supply option. Check that the line voltage matches the configured voltage before

connecting the power to the instrument. The input voltage is indicated on the front

panel underneath the power switch.

Warning: Connecting the calibrator to the wrong supply will

cause internal damage to the instrument.

Power Line Inlet Fuse and rating

The power line inlet fuse is located directly below the power inlet within the voltage

selector housing. The correct fuse rating is 2A anti-surge (slow blow) for 230V

operation and 4A anti-surge (slow blow) for 110V operation.

Replacing the Power Line Fuse

In the event of the Power Line fuse being damaged, the fuse will need to be

replaced. This operation can be performed by the user.

TRANSMILLE LTD. Version 1.30 Page 11

1000 SERIES OPERATION MANUAL

Warning: Ensure Line Power has been disconnected from

the instrument before performing this procedure

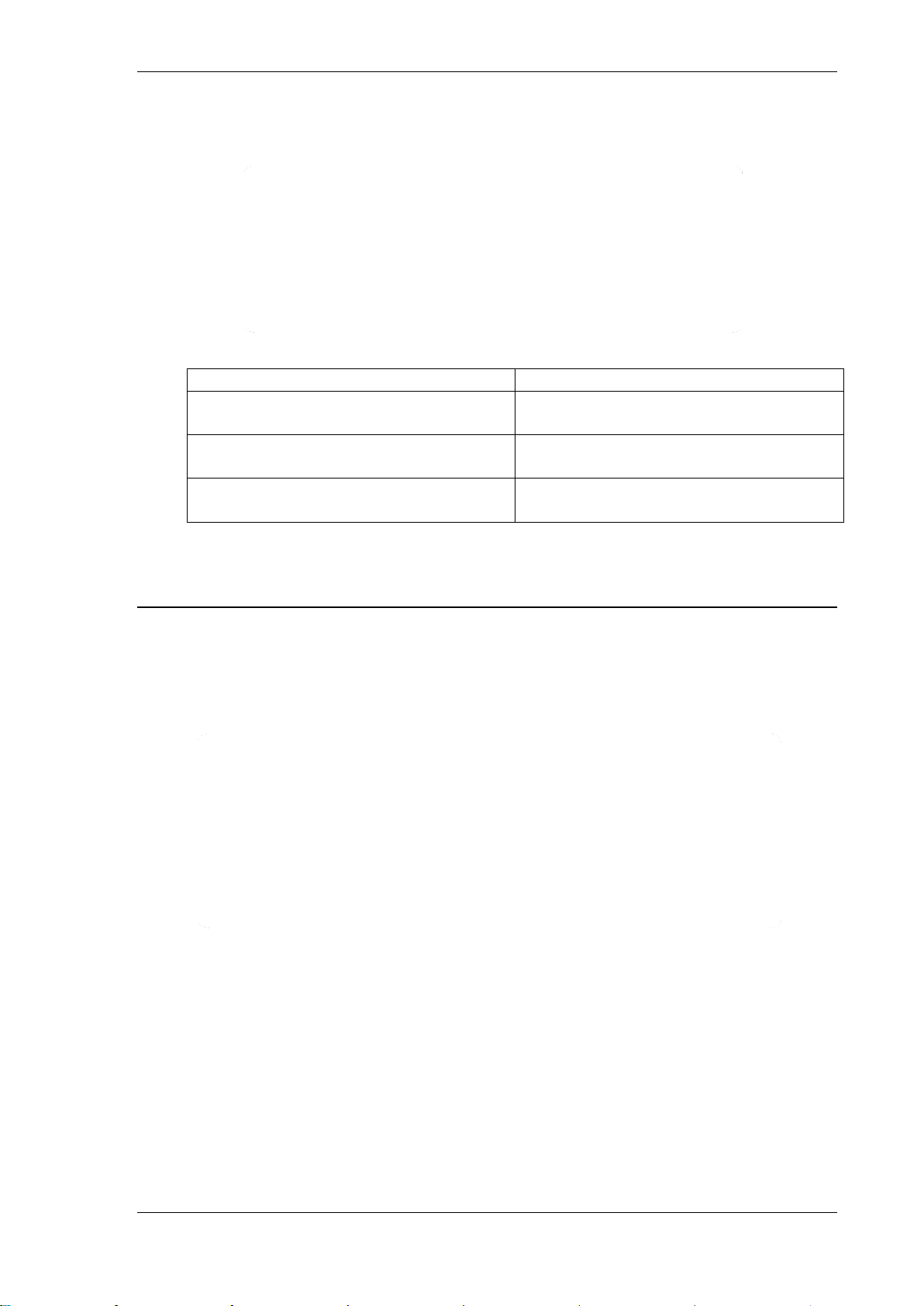

Using a Flat Head screwdriver, insert the end of the screw driver into the recess on

the fuse holder. The screwdriver must be parallel to the front panel of the calibrator

Once the screwdriver is in the recess of the fuse holder, gently hinge the fuse holder

up (away from the front panel). Be careful not to damage the fuse holder by applying

too much force. The fuse holder will lift out, revealing the fuse. Check the fuse using

a continuity tester to ensure that the problem is the fuse. If the fuse is damaged,

replace the fuse with an anti-surge fuse of the recommended rating for the supply

voltage. Re-insert the fuse holder in the same orientation as it was removed.

TRANSMILLE LTD. Version 1.30 Page 12

1000 SERIES OPERATION MANUAL

Connecting to a computer

A USB cable (supplied) should be used to connect the calibrator to a USB port

on a computer.

Connection Details

Connection from calibrator to a computer :

The USB connection on the 1000 series calibrator is a Female type B connection.

Also supplied is a USB driver on CD :

For details on installing USB driver see appendix A.

TRANSMILLE LTD. Version 1.30 Page 13

1000 SERIES OPERATION MANUAL

Powering up the calibrator

After connecting line power, the calibrator can be switched on with the line power

switch above the mains inlet socket on the front panel.

The fan will start and the front panel display will illuminate indicating power. The

display will show a firmware version number and after a short delay, during which

time the processor performs a self-test of the instrument, the display will show an

output of 0.0000mV DC. The default start condition of the calibrator is as follows:

Output Status : Standby

Range : 100mV DC

Negative to Ground Enabled

Allow the calibrator to warm up for 20 minutes to obtain full accuracy; the fast start

feature of the calibrator will give approximately 90% of full specifications within 10

minutes. The calibrator has been designed to be powered up continuously and does

not need to be turned off when not in use.

If required, a control program (i.e. ProCal) can now be started on the computer; the

program will establish communication with the calibrator. If used with ProCal, the

stored value of the passive standards will be downloaded to the computer, and the

calibrator will indicate ‘ProCal Control’ on the screen when ProCal is started.

TRANSMILLE LTD. Version 1.30 Page 14

1000 SERIES OPERATION MANUAL

Output Connections

Warning: Risk of shock.

High voltages may be present on the output sockets.

Output sockets are 4mm safety type, the voltage pair contacts are low thermal gold

plated for minimum thermal EMF.

The 1000 series calibrator’s outputs have been designed to allow most multimeters

to be calibrated without changing connections. There are 4 sets of outputs:

1) Voltage, Resistance, Capacitance, Frequency.

2) Current to 1A.

3) High 10A Current.

4) Thermocouple Output

The Voltage and Current terminals share a single common terminal. This allows the

1000 series to connect directly to all inputs on typical multimeters without the need

for changing leads as below:

When an output terminal pair is not active they are completely open circuit and

isolated from the other outputs.

Note: When outputting resistance, capacitance and frequency the calibrator will use

the voltage output terminals.

TRANSMILLE LTD. Version 1.30 Page 15

1000 SERIES OPERATION MANUAL

It is recommended that the voltage and low current leads be high quality screened

cable with gold plated 4mm plugs fitted. The cable must be able to withstand 1025

volts AC and have an insulation resistance greater than 1T to avoid introducing

any shunting effect on the high resistance ranges.

Poor quality test leads will introduce noise, thermal emf and leakage errors on low

voltage & current ranges and also unstable readings on resistance and capacitance

outputs (see measurement techniques). Special test leads are available from

Transmille for ensuring accurate measurements, see accessories.

Warning: Under no circumstances should any voltage

be connected to the calibrator outputs*. The 1000 Series

calibrator outputs are protected with IGuard however we

advise to be vigilant against accidental connections

* Insulation testers up to 1000V may be connected when using the Insulation test functions

Output Overloads

If the calibrator is unable to drive the load then the output will be turned off and the

calibrator returned to standby mode. The message Standby will be displayed on

the front panel. The output will be automatically reset on setting the output again.

TRANSMILLE LTD. Version 1.30 Page 16

1000 SERIES OPERATION MANUAL

Operation

Safety Warnings

WARNING: The information in this section is intended only

for qualified personnel. The user must at all times be

adequately protected from electric shock. Qualified

personnel must ensure that operators of the equipment are

adequately insulated from connection points.

WARNING: This instrument is capable of generating both

DC and AC high voltages.

Introduction to Operation

All functions of the 1000 Series Calibrator can be controlled from the front panel, or

controlled remotely by a computer over the interface.

The front panel controls are ‘locked out’ when controlled by a computer, but local

control may be resumed by selecting the ‘local’ soft key - it must be remembered

that this action may disrupt the computer program.

TRANSMILLE LTD. Version 1.30 Page 17

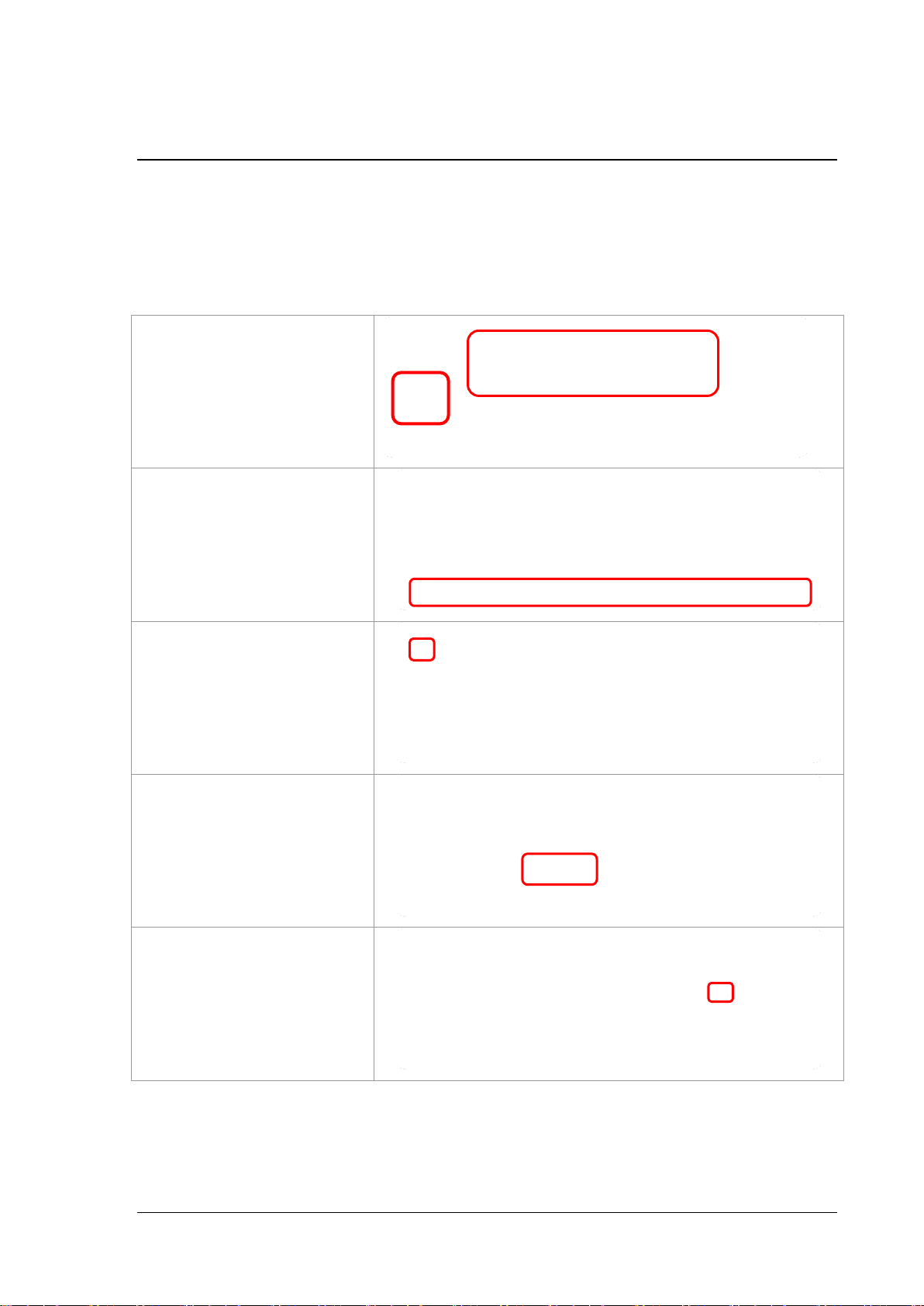

LCD Display with

integral Backlight

Menu buttons

(Soft Keys)

Active

Terminal

Indication

LEDs

Safety Output

Terminals

Output On Button

Standby Button

Numeric Keypad

Multiplier Keys

Function Keys

Digital Control

Adapter Interface

Range Up / X 10 Key

Range Up / ÷ 10 Key

Ref Key and

Directional Arrows

Instrument Serial

Number

Calibration Label

Thermocouple

Output

USB Interface

Enter Key

Shift Key

Front Panel Controls and Indicators

TRANSMILLE LTD. Version 1.30 Page 18

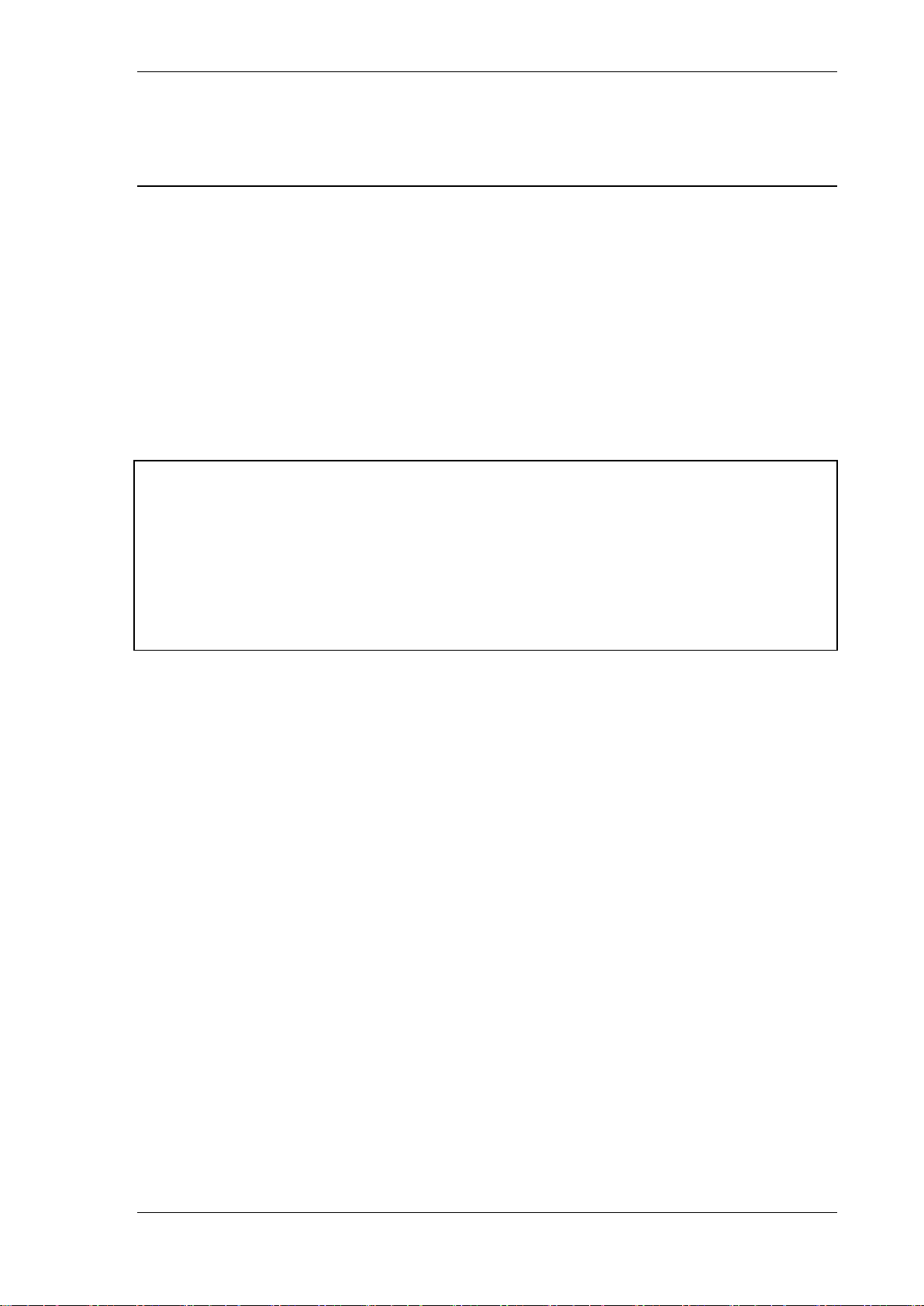

Output Value &

Range

Dynamic

Soft key Menu

Low to Ground

Output On / Standby

Indicators

Deviation (ppm)

Function Specific

Configuration

Display

Graphic LCD Display

The graphic backlit LCD display shows the present output, instrument status, % or

ppm change from the entered value, and also the new value being entered. The

bottom portion of the display is used to assign the function of the four ‘soft keys’.

TRANSMILLE LTD. Version 1.30 Page 19

1000 SERIES OPERATION MANUAL

Front Panel Keyboard

The front panel of the 1000 Series Calibrator utilises a high quality custom rubber

keyboard with tactile feel buttons and integral display window. The front panel is

therefore sealed against the ingress of moisture and dirt enabling the calibrator to be

used in most working environments without risk of early failure of the operating

buttons. The front panel can easily be wiped clean with a soft cloth. Care should be

taken not scratch the display window. All graphics are ‘under printed’ making them

rugged and durable.

IMPORTANT NOTE

The front panel key buttons are for use with fingers only - do not press

the key with hard or sharp objects e.g. Ball-point pens, pencils,

screwdrivers etc. Repeated actions like this will almost certainly cause

the keyboard to fail. (This will not be covered under warranty). Care

should also be taken when transporting the instrument, do not place

test leads or other objects on top of the panel which may come into

contact with the display area and cause damage.

TRANSMILLE LTD. Version 1.30 Page 20

1000 SERIES OPERATION MANUAL

Numeric section

Allows numeric values to be entered, also contains the + / - key

for entering polarity for DC settings, the Back space and Clear

key for information entry, the Shift key for selecting additional

functions and the Enter key for confirming data entry

Multiplier section

Mega (M), kilo (k), milli (m), micro(u) or nano (n)

Function section

Volts (V), Amps(A), Ohms,

Farads(F), Celsius(C), & Frequency(Hz)

Range Up / Range Down

Allow the output to be multiplied / divided by 10.

Left / Right / Up / Down Cursor Keys

To select the digit to be controlled by the rotary control.

Output On / Standby keys

Allow the calibrators output to be disconnected from the

terminals. LED indicators are incorporated in these switches to

clearly show the output status.

The Keyboard is divided into sections to allow easy operation.

TRANSMILLE LTD. Version 1.30 Page 21

1000 SERIES OPERATION MANUAL

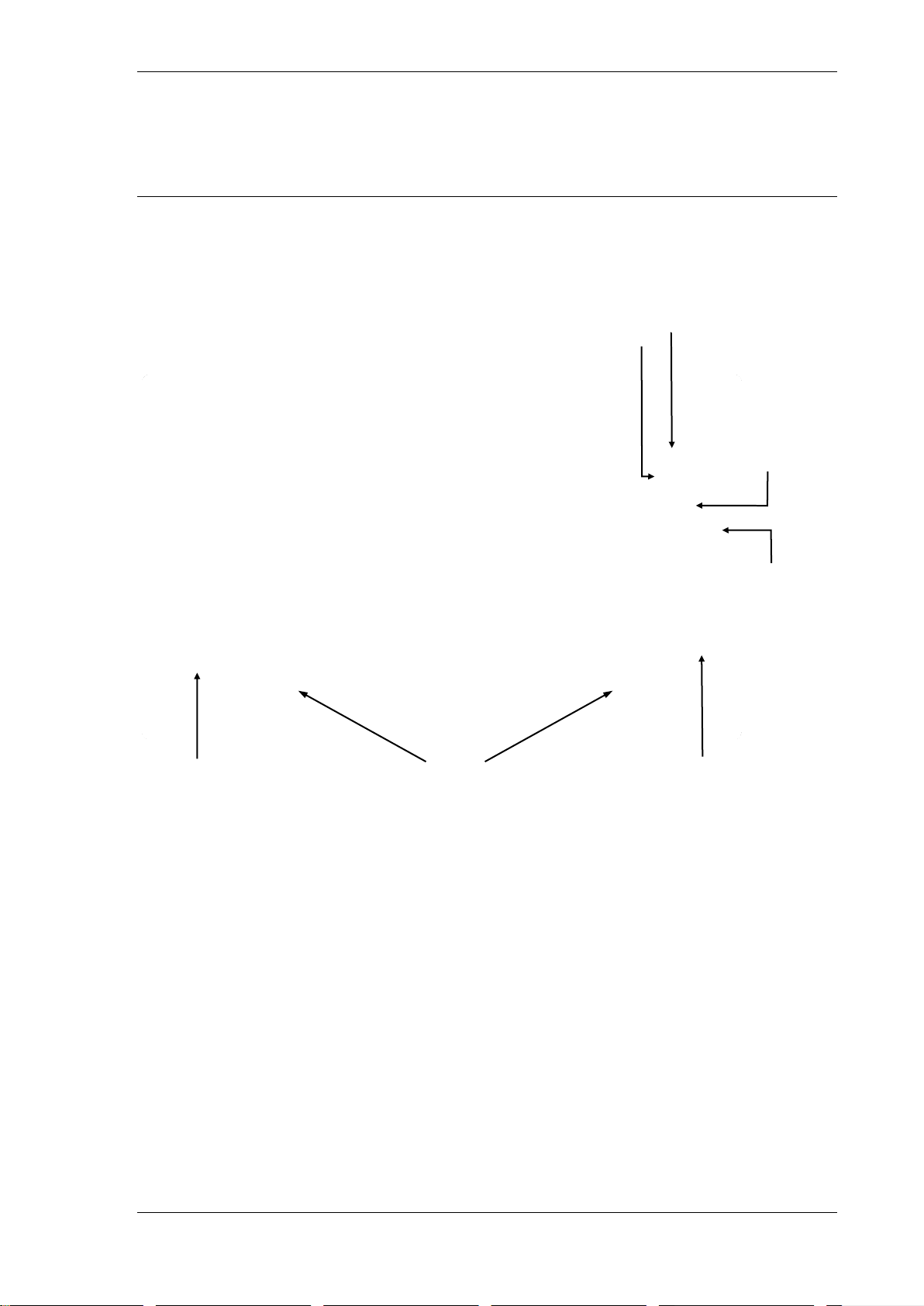

Clockwise Rotation

(Increment Digit)

Anti-Clockwise Rotation

(Decrement Digit)

Cursor indicates the

highlighted digit

Cursor Keys can be

used to move the

position of the digit

marker, and increment /

decrement the digit.

Digital Control and Cursor Keys

A digital potentiometer allows the ‘highlighted digit’ on the display to be incremented

(turning clockwise) or decrement (turning anti-clockwise). As an output is changed,

the deviation from the original value entered on the keyboard is shown in either % or

ppm depending upon the magnitude of the change.

To ‘Reset’ the deviation calculation, press the REF key in the middle of the cursor

keys, this resets the reference value from which the deviation is calculated

TRANSMILLE LTD. Version 1.30 Page 22

1000 SERIES OPERATION MANUAL

Active terminals

indicated by

illuminated LED

Terminal status LED’s

LED’s above the terminals indicate which pair is active. When terminals are not

active they are electrically isolated from each other

All 4mm safety sockets share a single common terminal.

Voltage Output Terminal Pair (Black & White)

Low thermal 4mm safety terminals

Used for all voltage outputs up to 1025V, for resistance,

capacitance and frequency.

Also used for Insulation resistance, test voltage measurement

and continuity current measurement

WARNING: Dangerous voltage may be present on these terminals.

TRANSMILLE LTD. Version 1.30 Page 23

1000 SERIES OPERATION MANUAL

Low Current Output Terminal Pair (Black & Blue)

4mm safety terminals

Used for current outputs up to 1 Amp

High Curent Output Terminals (Black and Yellow)

4mm Safety terminals

Used for all currents above 1 Amp.

Thermocouple Output Terminals (White)

Mini thermocouple socket used for generation of

thermocouple output. Ensure the correct thermocouple

wiring is used to match the type (i.e. Type K, Type J)

TRANSMILLE LTD. Version 1.30 Page 24

1000 SERIES OPERATION MANUAL

9 Pin Adapter Interface Connector.

To expand the 1000 Series calibrators, an adapter interface is provided on the front

panel. This allows for connection to external adapters used for extending calibration

capability, e.g. Pressure measurement etc.

Incorporates a yellow LED to indicate when the adapter interface is active.

The pins connections are as follows:

Pin 1 – +15V

Pin 2 – Digital ground

Pin 3 – Strobe

Pin 4 – Data

Pin 5 – Select

Pin 6 – -15V

Pin 7 – Analogue ground

Pin 8 – Output

Pin 9 – Input

TRANSMILLE LTD. Version 1.30 Page 25

1000 SERIES OPERATION MANUAL

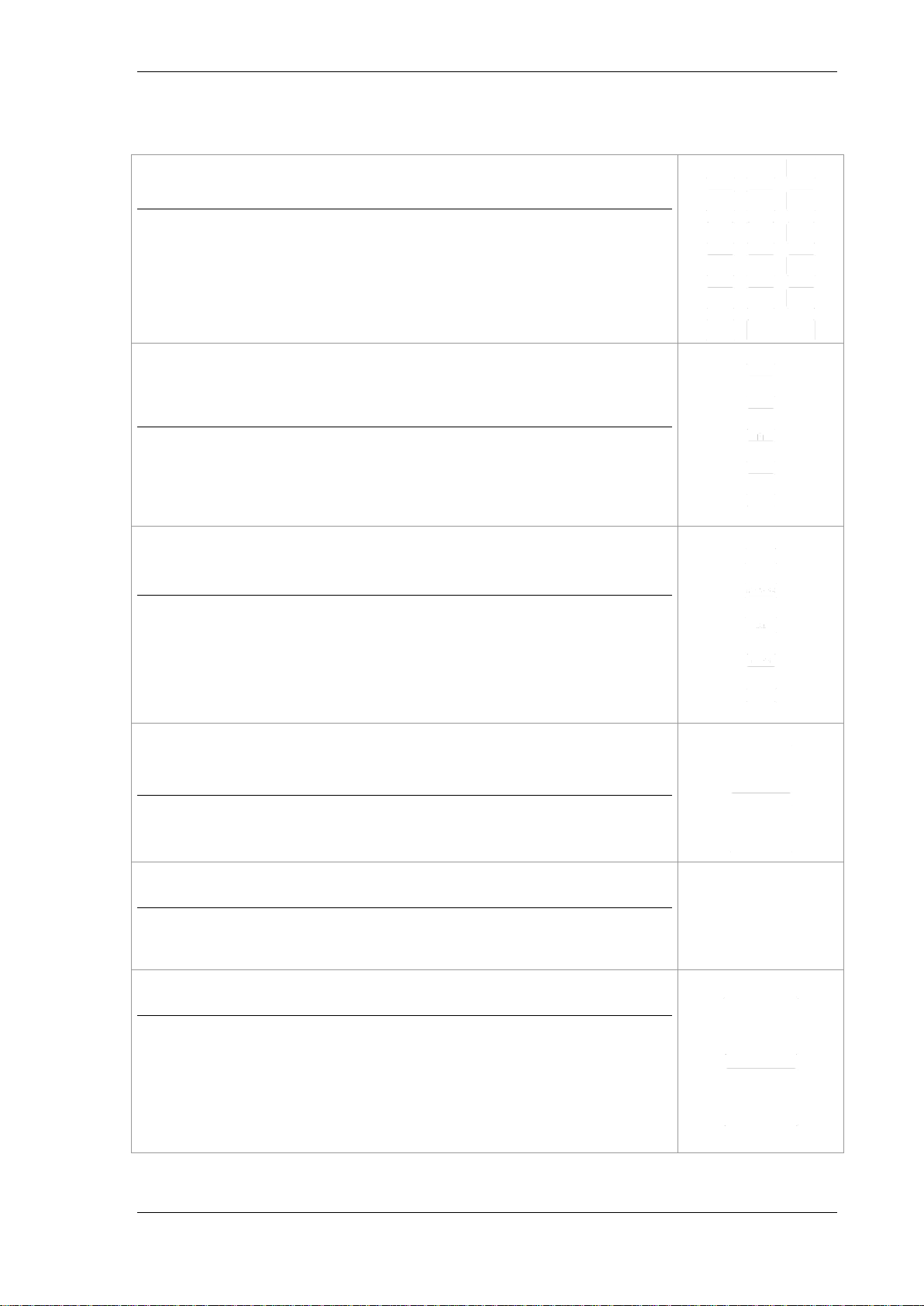

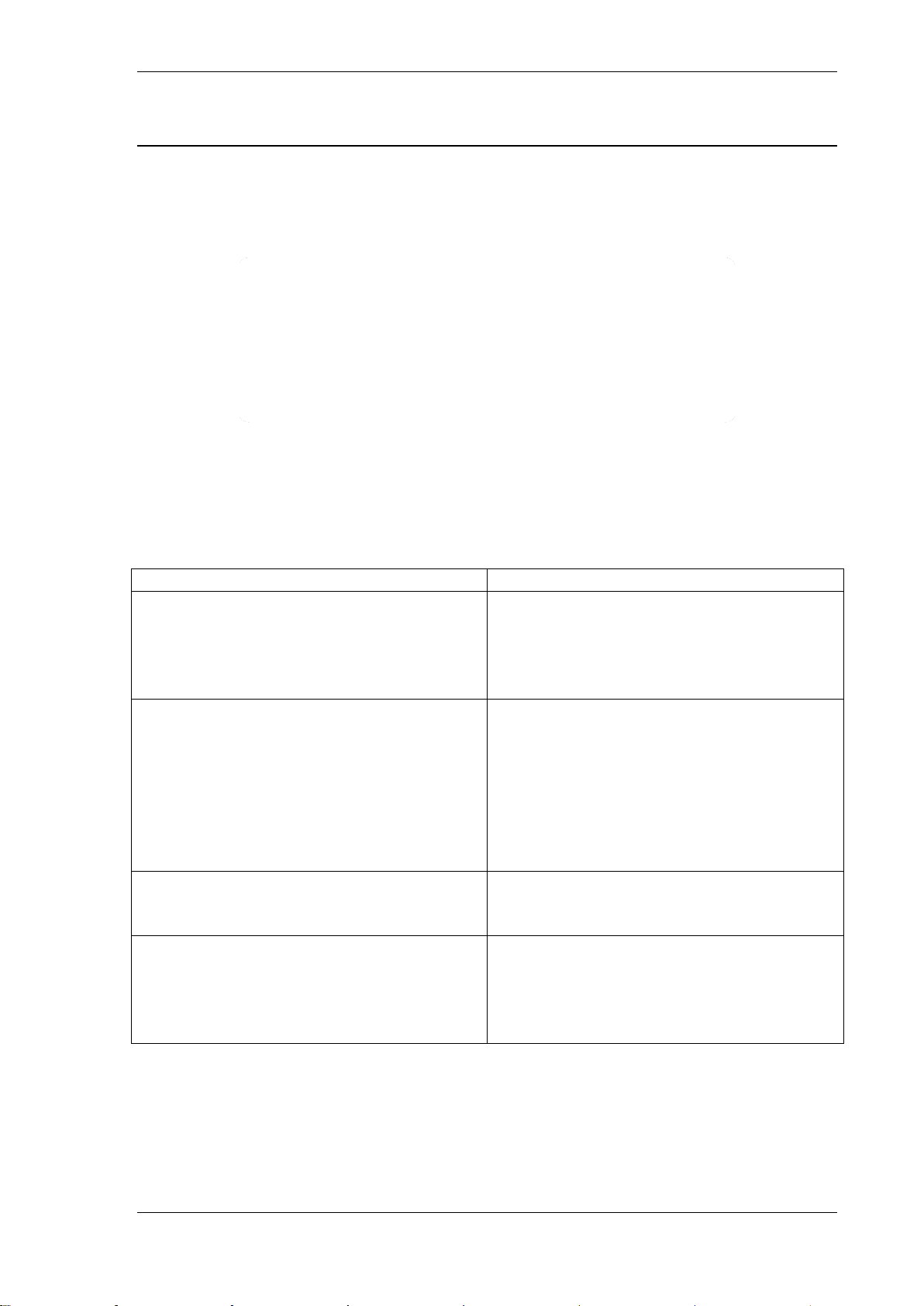

Key Name

Function

+ / -

In DC functions, pressing this key will

invert the polarity, e.g. an existing

setting of +1 V, pressing this key will

change the output to -1V

FREQ

Pressing this key will enter the

frequency output function, further

described

THERMO

Pressing this key will enter the

Thermocouple source function,

operation described

Key Name

Function

PRT

Pressing this key will enter the

simulated PRT output function,

operation described

PROCEDURE

Pressing this key will enter the

procedure select screen, further

described

INS TEST

Pressing this key will enter the

Insulation resistance function,

operation described

Soft Key Menus

Menu Structure

To access advanced functions of the calibrator, the 4 soft keys below the screen can

be used to select the menu functions that appear at the bottom of the screen.

There are 3 pages of menus, each featuring 3 separate functions and a next key.

TRANSMILLE LTD. Version 1.30 Page 26

1000 SERIES OPERATION MANUAL

Key Name

Function

CALIBRATE

Pressing this key will enter the

Calibration function, further described

SETUP

Pressing this key will enter the setup

menu, further described

INFO

Pressing this key will display the info

screen, further described

Procedure Menu

The 1000 series calibrators has the ability to store procedures in memory for on site

use. After pressing the ‘PROCEDURE’ key the calibrator will display a list of

procedures that have been loaded.

Using the arrows keys (as described on page 22), move the cursor to the desired

model number and press the ‘SELECT’ soft key

TRANSMILLE LTD. Version 1.30 Page 27

1000 SERIES OPERATION MANUAL

Function Name

Description

Beeper

This menu item allows the beeper to be

turned on or off. With the beeper off the

unit will not emit any noises for key

presses, however beeps will STILL be

emitted for HV ramps and errors.

Password

This function prompts the user to enter

the calibration password. After entering

the correct password the calibrator will

be in calibration mode.

Another function of this key, once

already in calibration mode, is to edit the

system password to a new password.

Adapters

This menu item allows the user to edit

the displayed unit for pressure adapters

that have been stored in the calibrator

Range Hold

This function enables a ‘Range Hold’

function on the calibrator, enabling

outputs that would not normally be

available from the range to be output, i.e.

50mV from the 1V range

Setup Menu

To configure the 1000 series calibrator, a setup menu is provided. This allows users

to configure options, i.e. the Calibration Password.

Using the arrows keys (as described on page 22), move the cursor to the desired

function and press the ‘Select’ soft key or press the enter button.

TRANSMILLE LTD. Version 1.30 Page 28

1000 SERIES OPERATION MANUAL

Connection Diagrams

Provided in this section are example connection diagrams for typical pieces of test

equipment, indicating the terminals to use

DC / AC Voltage

DC / AC Current – Outputs below 1A

TRANSMILLE LTD. Version 1.30 Page 29

1000 SERIES OPERATION MANUAL

DC/AC Current – Outputs above 1A

Resistance

TRANSMILLE LTD. Version 1.30 Page 30

Loading...

Loading...