User’s Guide

SIBTF10xx-1xx-MR & SIBTF10xx-1xx-MS

Substation-Rated Industrial Ethernet Switch

• 10/100Base-TX to 100Base-FX

• Single or Redundant Wide Input Power

Supply

The SIBTF10xx-1xx-Mx Ethernet industrial switches

allow connecting 10Base-T Ethernet/100Base-TX fast

Ethernet twisted-pair copper network devices to

network devices on a 100Base-FX fast Ethernet fiber

140-MR

and one fiber port. The SIBTF10xx-140-MR model includes redundant power-supply

terminal blocks that can handle 48–170VDC or 90–125VAC, 50/60Hz input power. The

SIBTF10xx-140-MS model, not shown, has a single power-supply terminal block (TB).

The SIBTF10xx-130-MR has three RJ-45 copper ports

and two fiber ports. The SIBTF10xx-130-MR model

includes redundant power-supply terminal blocks that

can handle 48–170VDC or 90–125VAC, 50/60Hz

input power. The SIBTF10xx-130-MS model, not

shown, has a single power-supply terminal block (TB).

network.

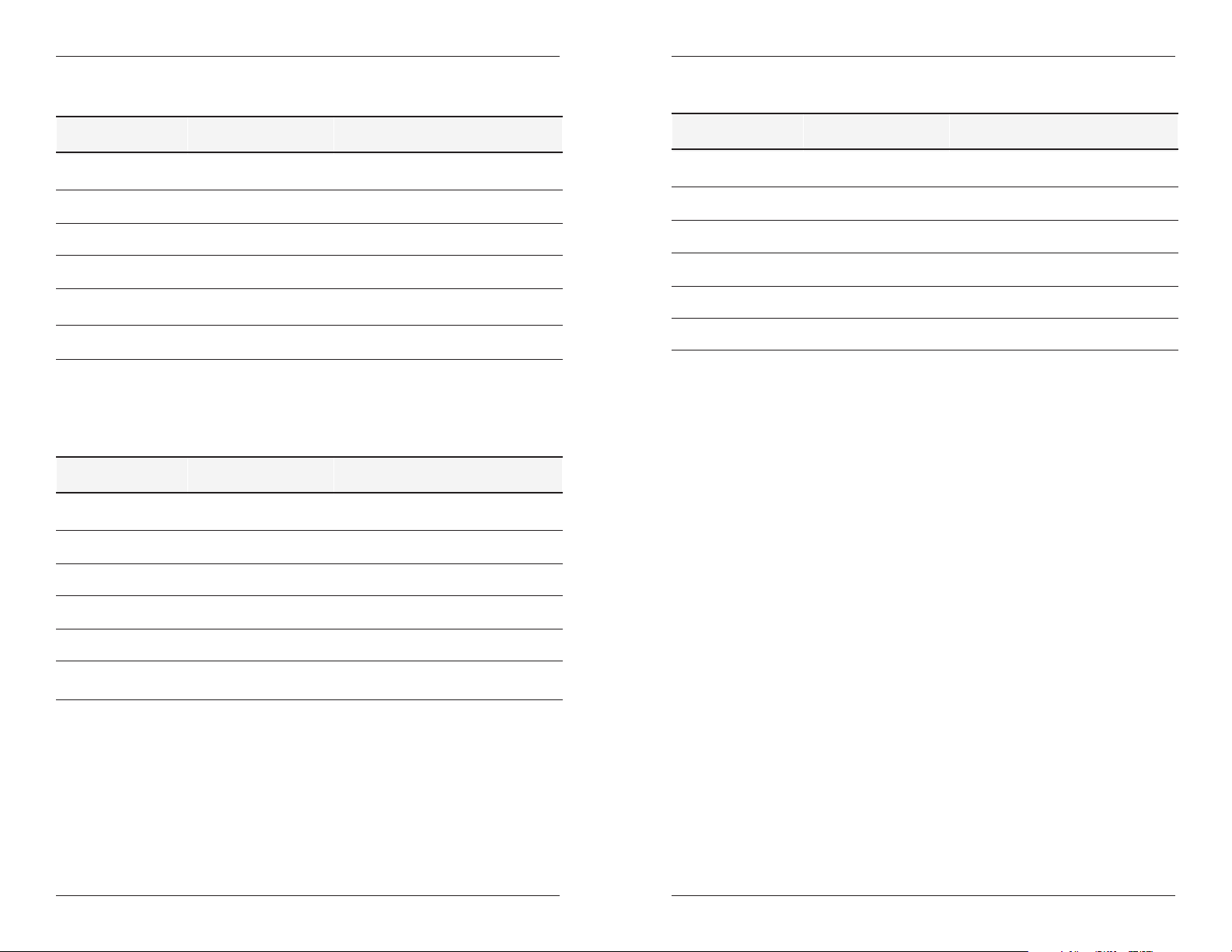

The SIBTF10xx-140-MR has four RJ-45 copper ports

110-MR

130-MR

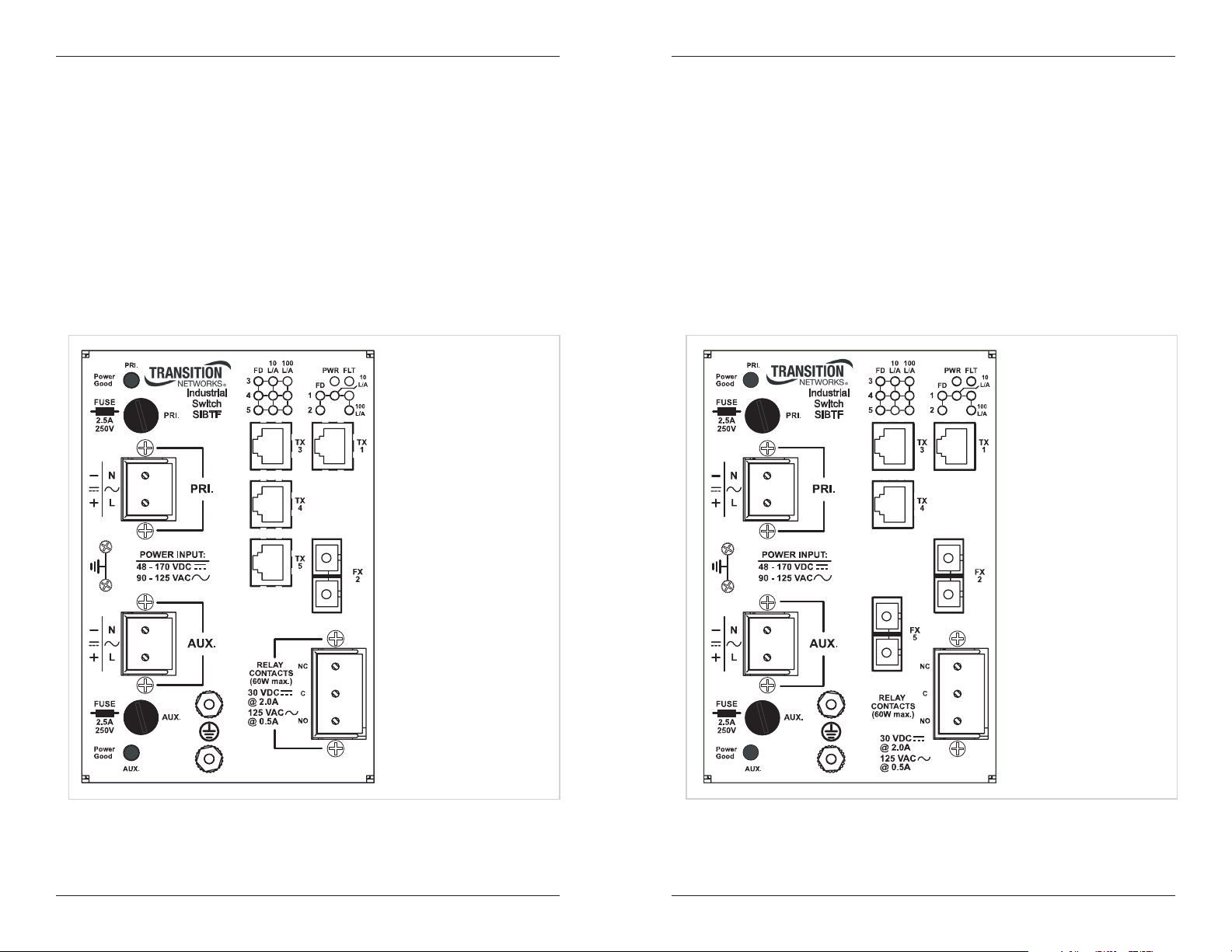

The SIBTF10xx-110-MR has one RJ-45 copper port

and one fiber port. The SIBTF10xx-110-MR model

includes redundant power-supply terminal blocks that

can handle 48–170VDC or 90–125VAC, 50/60Hz

input power. The SIBTF10xx-110-MS model, not

shown, has a single power-supply terminal block (TB).

Available Models . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . .4

Operation . . . . . . . . . . . . . . . . . .15

Cable Specifications . . . . . . . . . .20

Technical Specifications . . . . . . .22

Troubleshooting . . . . . . . . . . . . .24

Contact Us . . . . . . . . . . . . . . . . .26

Compliance Information . . . . . . .27

SIBTF10xx-1xx-Mx

Available Models

Available SIBTF10xx-140-MR and MS models*

Part Number (4) Copper - 10Base-T/

100Base-TX ports

SIBTF1011-140-Mx

SIBTF1013-140-Mx

SIBTF1014-140-Mx

SIBTF1015-140-Mx

SIBTF1016-140-Mx

SIBTF1017-140-Mx

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

*MR = Redundant power-supply terminal blocks, MS = Single power-supply terminal block.

Note: The cable distances listed are maximum distances typically. The actual distance

is dependent upon the physical characteristics of the network.

Available SIBTF10xx-130-MR and MS models*

Part Number (3) Copper - 10Base-T/

SIBTF1011-130-Mx

SIBTF1013-130-Mx

SIBTF1014-130-Mx

SIBTF1015-130-Mx

SIBTF1016-130-Mx

SIBTF1017-130-Mx

100Base-TX Ports

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

(1) Duplex Fiber-Optic - 100Base-FX port

ST, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1310 nm single mode, duplex

20 km (12.4 miles)

SC, 1310 nm single mode, duplex

40 km (24.8 miles)

SC, 1310 nm single mode, duplex

60 km (37.2 miles)

SC, 1550 nm single mode, duplex

80 km (49.7 miles)

(2) Duplex Fiber-Optic - 100Base-FX

Ports

ST, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1310 nm single mode, duplex

20 km (12.4 miles)

SC, 1310 nm single mode, duplex

40 km (24.8 miles)

SC, 1310 nm single mode, duplex

60 km (37.2 miles)

SC, 1550 nm single mode, duplex

80 km (49.7 miles)

Available Models -- continued

Available SIBTF10xx-110-MR and MS models*

Part Number (1) Copper - 10Base-T/

100Base-TX Port

SIBTF1011-110-Mx

SIBTF1013-110-Mx

SIBTF1014-110-Mx

SIBTF1015-110-Mx

SIBTF1016-110-Mx

SIBTF1017-110-Mx

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

RJ-45

100 m (328 ft)

*MR = Redundant power-supply terminal blocks, MS = Single power-supply terminal block..

Note: The cable distances listed are maximum distances typically. The actual distance

is dependent upon the physical characteristics of the network.

(1) Duplex Fiber-Optic - 100Base-FX Port

ST, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1300 nm multimode, duplex

2 km (1.2 miles)

SC, 1310 nm single mode, duplex

20 km (12.4 miles)

SC, 1310 nm single mode, duplex

40 km (24.8 miles)

SC, 1310 nm single mode, duplex

60 km (37.2 miles)

SC, 1550 nm single mode, duplex

80 km (49.7 miles)

*MR = Redundant power-supply terminal blocks, MS = Single power-supply terminal block.

Note: The cable distances listed are maximum distances typically. The actual distance

is dependent upon the physical characteristics of the network.

2

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

3

SIBTF10xx-1xx-Mx

Installation

Features

• The SIBTF10xx-140-MR industrial switch includes four (4) RJ-45, twisted-pair

copper ports and one (1) 100 Mb fiber optic port.

• The Auto-Negotiation feature on port “1” can be turned OFF and forced to a

selected speed (100 Mb/s or 10 Mb/s) also duplex mode (full or half).

• All SIBTF models include a primary input terminal block (TB) for 48–170VDC or

90–125VAC power, a 2.5A, 250V fuse, an LED power indicator, and a red-fault

LED. The red-fault LED “ON state” indicates the microcontroller did not initialize

correctly.

• The “MR” models include an auxiliary power-supply terminal block—not available

on “MS” models.

See Figure 1.

Installation -- continued

Features -- continued

• The SIBTF10xx-130-MS industrial switch includes three (3) RJ-45, twisted-pair

copper ports and one (2) 100 Mb fiber optic port.

• The Auto-Negotiation feature on port “1” can be turned OFF and forced to a

selected speed (100 Mb/s or 10 Mb/s) and duplex mode (full or half).

• All SIBTF models include a primary input terminal block (TB) for 48–170VDC or

90–125VAC input power power, a 2.5A, 250V fuse, an LED power indicator, and a

red-fault LED. The red-fault LED “ON state” indicates the microcontroller did not

initialize correctly.

• The “MR” models include an auxiliary power-supply terminal block—not available

on “MS” models.

See Figure 2.

Figure 1: SIBTF10xx-140-MR Front Panel

4

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Figure 2: SIBTF10xx-130-MR Front Panel

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

5

SIBTF10xx-1xx-Mx

Installation -- continued

Features -- continued

• The SIBTF10xx-110-MS industrial switch includes one (1) RJ-45, twisted-pair

copper port and one (1) 100 Mb fiber optic port.

• The Auto-Negotiation feature on port “1” can be turned OFF and forced to a

selected speed (100 Mb/s or 10 Mb/s) and duplex mode (full or half).

• All SIBTF models include a primary input terminal block (TB) for 48–170VDC or

90–125VAC power, a 2.5A, 250V fuse, an LED power indicator, and a fault LED.

The red-fault LED “ON state” indicates the microcontroller did not initialize

correctly.

• The “MR” models include an auxiliary power-supply terminal block—not available

on “MS” models.

See Figure 3.

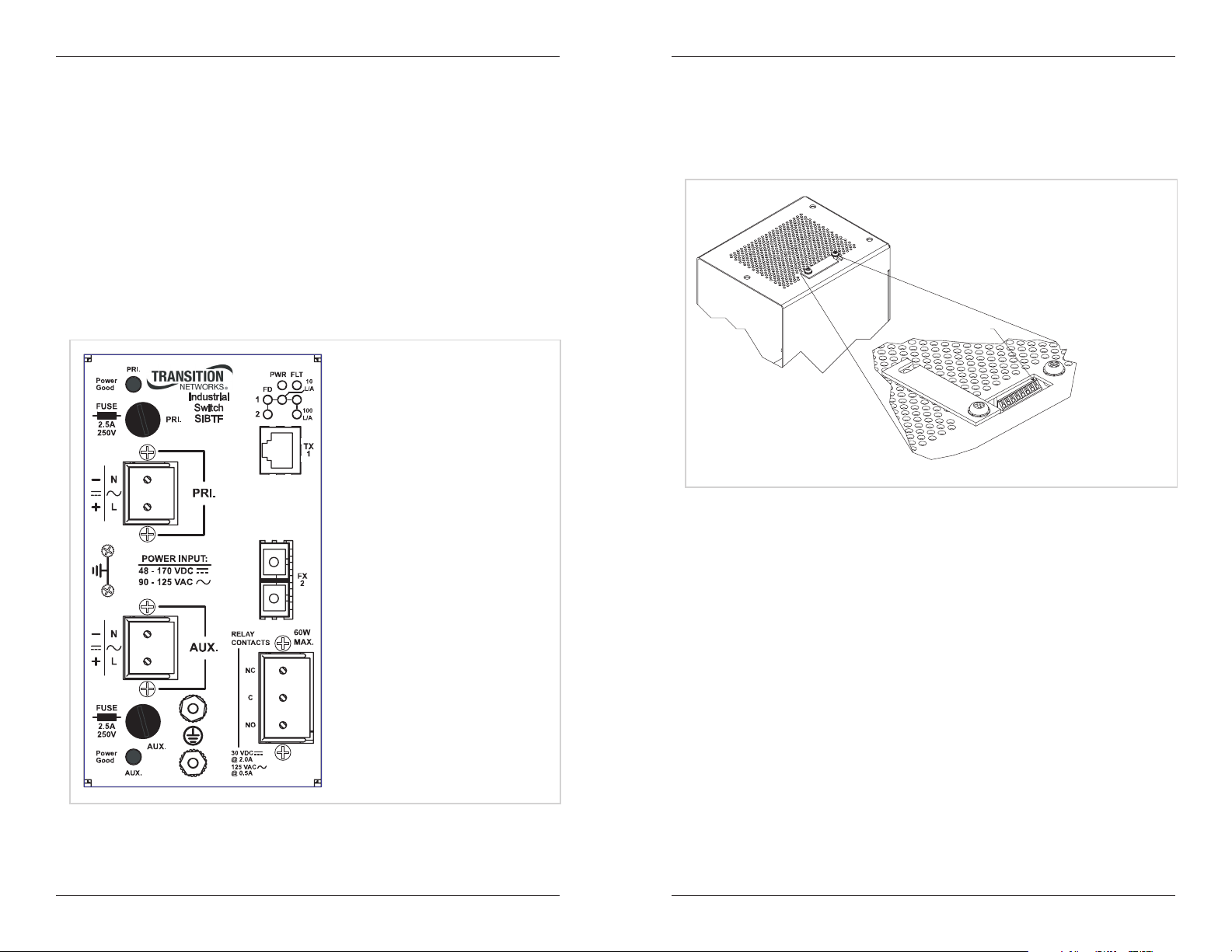

Installation -- continued

Enclosure top view (configuration switches)

The SIBTF10xx-1xx-Mx has eight (8) configuration (DIP) switches located under the

switch cover on top of the enclosure. See Figure 4.

Switch Position 1

1-Config Switches

Figure 4: Enclosure Top View Configuration Switches

Figure 3: SIBTF10xx-110-MR Front Panel

6

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Setting configuration switches

To set the DIP switches:

1. Using a small, phillips-head screwdriver, loosen (do not remove) the two screws

that secure the cover to the switch.

2. Swing the switch cover counter-clockwise to expose the DIP switches.

3. Use a small, flathead screwdriver to set the recessed switches as required by the

network application.*

4. Slide the switch cover back over the DIP switches and then secure it by

tightening both screws.

*Note: Switches 1, 2, and 3 apply only to twisted-pair “copper port #1.”

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

7

SIBTF10xx-1xx-Mx

g

Installation -- continued

DIP switch settings

1. Port 1 copper Auto-Negotiation:

UP (Enabled) - Advertises switch speed and mode

capabilities to the network:

• 100Mb/s full-duplex • 100Mb/s half-duplex,

• 10Mb/s full-duplex • 10Mb/s half-duplex.

DOWN (Disabled) - Does not advertise switch speed

and mode capabilities to the network. With AutoNegotiate disabled switches 2 and 3 are used to set the

twisted-pair speed and mode.

2. Port 1 copper speed:

UP (100Base-TX) - Sets the twisted-pair speed to

100Base-TX.

DOWN (10Base-T) - Sets the twisted-pair speed to

10Base-T.

3. Port 1 copper duplex:

UP (Full-Duplex) - The twisted-pair cable distances

are constrained by the cable requirements.

DOWN (Half-Duplex): - The twisted-pair cable

distances are constrained by the 512-Bit Rule.

4. Fiber port FX 1 duplex:

UP (Full-Duplex) - The cable distances for the fiber

port are constrained by the cable requirements.

DOWN (Half-Duplex) - The cable distances for the

fiber port are constrained by the 512-Bit Rule.

1

Auto-Negotiation E nabled

Auto-Ne

otiation Dis abled

2

100Bas e-TX

10Bas e-TX

3

Full Duplex

Half Duplex

4

Full Duplex (fiber)

Half Duplex (fiber)

Installation -- continued

6. Link Pass-Through (model 110 only):

UP (Enable) - When Link Pass-Through is enabled, a fault

on one side of the switch stops the signal and data

transmission on the other side. See the detailed explanation

of Link Pass-Through on page 18.

DOWN (Disable) - When Link Pass-Through is disabled, a

fault on one side of the switch does not stop the signal and

data transmission on the other side.

7. Fiber redundancy (model 130 only):

UP (Disable) - When fiber redundancy is disabled, the

two fiber ports (1 and 2) act as normal bridging ports.

DOWN (Enable) - When fiber redundancy is enabled,

the two fiber ports (1 and 2) are configured as

forwarding or disabled. At any given time one port will

be disabled and one port will be forwarding.

8. AutoCross:

UP (Enable) - The switch will connect to a straightthrough or a crossover twisted-pair copper cable

automatically.

DOWN (Disable) - In the down position the straightthrough or crossover twisted-pair copper cable must be

installed according to the site requirements.

6

Link Pa ss- Through E nabled

Link Pa ss- Through Disabled

7

Redund ant Fiber E nabled

Redund ant Fiber Disabled

8

AutoCross E nabled

AutoCross Disab led

5. Fiber port FX 2 duplex (model 130 only):

UP (Full-Duplex) - The cable distances for the fiber

port are constrained by the cable requirements.

DOWN (Half-Duplex) - The cable distances for the

fiber port are constrained by the 512-Bit Rule.

8

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Full Duplex (fiber)

Half Duplex (fiber)

5

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

9

SIBTF10xx-1xx-Mx

Installation -- continued

WARNING: Make sure that the external power source is turned OFF before

attempting to connect power leads to the industrial switch. Failure to observe

this warning could result in an electrical shock.

WARNING: The SIBTF10xx-1xx-Mx is a class I device. It has a provision

for protective earth grounding. Equipment grounding is vital to ensure safe

operation. The SIBTF switch must be earth grounded during and after

installation. Failure to observe this warning could result in an electric shock.

Note: DO NOT use bare (exposed) or un-lugged power-source wires to connect to the

industrial switch.

Connecting primary power

The industrial switch is designed to accommodate 48 – 170VDC or 90 – 125VAC,

50/60 Hz input power via its primary terminal block (TB).

To provide power to the industrial switch via the primary TB, view Figure 5, and then

do the following:

1. Verify that the external power source is turned OFF and disconnect.

2. Loosen the grounding screw and then connect the power source functional-ground

lead to the grown screw, as shown in Figure 5. Tighten the screw to secure.

3. Loosen the TB screw marked “-” and then connect the power source neutral or (-)

negative lead to the TB negative terminal, as shown in Figure 5. Tighten the

screw to secure.

4. Loosen the TB screw marked “+” and then connect the power source line phase or

positive (+) lead to the TB positive terminal, as shown in Figure 5. Tighten the

screw to secure.

5. Re-connect and turn ON the external power source.

6. Verify that the industrial switch has powered up by observing the illuminated

“Power Good” LED on the front panel.

Installation -- continued

WARNING: Make sure that the external power source is turned OFF before

attempting to connect power leads to the industrial switch. Failure to observe

this warning could result in an electrical shock.

WARNING: The SIBTF10xx-1xx-Mx is a class I device. It has a provision

for protective earth grounding. Equipment grounding is vital to ensure safe

operation. The SIBTF switch must be earth grounded during and after

installation. Failure to observe this warning could result in an electric shock.

Note: DO NOT use bare (exposed) or un-lugged power-source wires to connect to the

SIBTF10xx-10x-MR industrial switch.

Connecting auxiliary power

The SIBTF10xx-10x-MR switches support a redundant power supply. If the primary

power source fails, the auxiliary power source supplies power to the industrial switch.

To provide auxiliary power to the industrial switch, view Figure 6 and do the

following:

1. Verify that the external power source is turned OFF and disconnected.

2. Loosen the grounding screw and connect the power source functional-ground lead

to the grown screw, as shown in Figure 6. Tighten the screw to secure.

3. Loosen the TB screw marked “-” and then connect the power source neutral or (-)

negative lead to the TB negative terminal, as shown in Figure 6. Tighten the

screw to secure.

4. Loosen the TB screw marked “+” and then connect the power source line phase or

positive (+) lead to the TB positive terminal, as shown in Figure 6. Tighten the

screw to secure.

5. Re-connect and turn ON the external power source.

6. Verify that the industrial switch is powered UP: auxiliary “Power Good” LED on

the lower front panel will be ON.

N

L

POWER I NPUT

48 - 170 VDC

90 - 125 VAC

PRI.

Figure 5: Primary Power Connection

10

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

AUX.

Figure 6: Auxiliary Power Connection

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

11

SIBTF10xx-1xx-Mx

Installation -- continued

Internal relay connections

The internal relay can activate an external fault indicator. The fault indicator connects

to the relay contacts on the front panel. An example would be a fault circuit connected

to a warning light located in a control room. The light can be connected in a normally

open (NO) or normally closed (NC) configuration with respect to circuit common (C)

to turn the light ON/OFF when a fault occurs.

To connect a fault indicator to the relay, view Figure 7 and then do the following:

1. Verify that the external power source is turned OFF.

2. Loosen the relay’s “NO” screw and then connect the fault indicator’s return lead

to terminal “NO.” Tighten the screw to secure.

3. Loosen the relay’s “C” screw and then connect the fault indicator’s common lead

terminal “C.” Tighten the screw to secure.

Or:

4. Loosen the relay’s “NC” screw and then connect the fault indicator’s return lead

to terminal “NC.” Tighten the screw to secure.

5. Loosen the relay’s “C” screw and then connect the fault indicator’s common lead

terminal “C.” Tighten the screw to secure.

Relay

Contacts

(600W max.)

30 VDC

@2.0A

125 VAC

@0.5A

NC

C

NO

NC

C

NO

Installation -- continued

DIN-Rail

The industrial switch includes an aluminum DIN-Rail mounting bracket attached to the

back panel of the enclosure. See Figure 8.

Back View

DIN Rail

Mounting Bracket

Figure 8: DIN-Rail Bracket

Mounting the enclosure to a DIN-Rail

CAUTION: The SIBTF10xx-1xx switch is convection cooled, requiring

unrestricted bottom-to-top airflow. Mounting the device in other

orientations could result in unreliable operation or device failure.

CAUTION: To prevent debris from falling through the ventilation holes,

local and national electrical and fire codes might require orienting the device

with its small-diameter vent holes downward.

Figure 7: Internal Relay Connections

Two wiring scenarios:

• Wiring the relay in the normally closed (NC) configuration can be used to

monitor alarm indicators connected in series, where any single event will cause all

alarm indicators to trigger.

• Wiring the relay in the normally open (NO) configuration can be used to monitor

alarm indicators connected in parallel, where any single event will cause that

events alarm indicator to trigger: i.e., a light turning ON or OFF.

CAUTION: Calculate the maximum possible current in each power wire

and relay-contact wire. Observe all electrical codes for maximum current

allowed. If the current goes above the maximum ratings, the wiring could

overheat and cause serious damage to the network wiring or equipment.

12

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

To mount the enclosure onto a DIN-Rail:

1. Insert the top of the DIN-Rail into the upper slot of the mounting plate.

2. Push down and then rotate the industrial switch inward to snap it into place onto

the DIN-Rail.

An illustration of the procedure is shown in Figure 9.

Step 1 Step 2

Mounting Plate

DIN-Rail

Figure 9: Enclosure Mounted to DIN-Rail

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

13

SIBTF10xx-1xx-Mx

Installation -- continued

Installing fiber cable

To install a fiber cable, view Figure 10, and then do the following:

1. Locate or build 100Base-FX fiber cable with male, two-stranded TX to RX

connectors installed at both ends.

2. Connect the fiber cables to the industrial switch as follows:

• Connect the male TX cable connector to the female TX port.

• Connect the male RX cable connector to the female RX port.

3. Connect the fiber cables to the other device (another media converter, hub, etc.)

as follows:

• Connect the male TX cable connector to the female RX port.

• Connect the male RX cable connector to the female TX port.

Connect fiber cable

to media converter

as shown.

RX

TX

Figure 10: Fiber Cable Installation

Installing copper cable

The AutoCross feature allows connecting straight-through (MDI) or crossover (MDIX) copper cable to the RJ-45 port of a second device.

To install an Ethernet cable, view Figure 11, and then do the following:

1. Locate or build 10Base-T or 100Base-TX copper cables with male, RJ-45

connectors installed on both ends.

2. Connect the RJ-45 connector at one end of the cable to the RJ-45 port on the

industrial switch.

3. Connect the RJ-45 connector at the other end of the cable to the RJ-45 port on the

second device (PLC, workstation, etc.).

Connect fiber cable

to other device

(media converter,

hub, etc.) as shown

RX

TX

Installation -- continued

Installing copper cable

R J-45 Po rts

industria l bridge

Figure 11: Copper Cable Installation

RJ-45 Port

P LC, wo rks tat ion, e tc.

Operation

Copper/fiber status LEDs

Copper LEDs

The SIBTF10xx-1xx-Mx comes equipped with status LEDs to monitor the network

connections for the copper and fiber ports.

The numbered LEDs refer to the numbered copper and fiber ports. For example, LED

#1 refers to the twisted-pair copper port #1; LED #2 refers to fiber port #2. See

Figure 12.

Each port has three associated LEDs: Full duplex (FD), 10MB, and 100MB.

Copper Port

Fiber Port

14

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Figure 12: Copper and Fiber Port Status LEDs

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

15

SIBTF10xx-1xx-Mx

Operation -- continued

Copper/fiber status LEDs -- continued

Copper LEDs

The function of the copper port LEDs (1, 2, 3, and 4) are as follows:

100MB ON The copper port has established a link at 100 MB/s.

100MB Flashing The copper port is transmitting signals at 100 Mb/s.

10MB ON The copper port has established a link at 10 MB/s.

10MB Flashing The copper port is transmitting signals at 10 Mb/s.

FD ON The copper port is in full-duplex mode.

FD OFF The copper port is in half-duplex mode.

Fiber LEDs

The functions of the fiber port LEDs (2 and 5) are as follows:

100MB ON The fiber port has established a link.

100MB Flashing The fiber port is transmitting signals.

10MB -- N/A

10MB -- N/A.

FD ON The fiber port is in full-duplex mode.

FD OFF The fiber port is in half-duplex mode.

Fault (red) LED

Fault LED ON (red) indicates that the microcontroller did not initialize correctly; as a

result, the switch will not power up.

Fault LED

Operation -- continued

Product Features

Immunity standards

The industrial switch is designed to meet EN61000-6-2, IEEE1613.

Congestion reduction

The SIBTF10xx-1xx industrial switch does not forward collision signals or error

packets from one collision domain to another, which improves baseline-network

performance. In addition, the industrial switch filters packets destined for local

devices, which reduces network congestion.

Rate conversion

The SIBTF10xx-1xx industrial switch allows connecting 10Mb/s terminal devices on a

10Base-T legacy Ethernet copper network and/or 100Mb/s terminal devices on a

100Base-TX fast Ethernet copper network to 100Mb/s terminal devices on a 100Base

FX fast Ethernet fiber network.

Full-Duplex network

In a full-duplex network, maximum cable lengths are determined by the type of cables

used. See cable specifications section for the different SIBTF10xx-1xx models. The

512-Bit Rule does not apply in a full-duplex network.

Half-Duplex network (512-Bit Rule)

In a half-duplex network, the maximum cable lengths are determined by the round trip

delay limitations of each fast Ethernet collision domain. (A collision domain is the

longest path between any two terminal devices: e.g., a terminal, switch, or router.)

The 512-Bit Rule determines the maximum length of cable permitted by calculating

the round-trip delay in bit-times (BT) of a particular collision domain. If the result is

less than or equal to 512 BT, the path is good.

For more information on the 512-Bit Rule, see the white paper titled “Collision

Domains” on the Transition Networks website at: www.transition.com.

Copper Port

Figure 13: Fault LED

16

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Fiber Port

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

17

SIBTF10xx-1xx-Mx

pp

pp

k

Operation -- continued

Product features -- continued

Auto-Negotiation

The Auto-Negotiation feature allows the SIBTF10xx-1xx industrial switch to

configure itself to achieve the best possible mode of operation over a link

automatically. The industrial switch broadcasts its speed (10 Mb/s or 100 Mb/s) and

duplex capabilities (full or half) to the other devices and negotiates the best mode of

operation. Auto-Negotiation allows quick and easy installation because the optimal

link is established automatically.

In a scenario where the industrial switch is linked to a non-negotiating device, the

admin person may want to disable Auto-Negotiation. In this instance, the mode of

operation will drop to the lowest common denominator between the two devices: 10

Mb/s, half-duplex. Disabling this feature provides the ability to force the connection

to the best mode of operation.

Link Pass-Through

The SIBTF10xx-110 industrial switch provides a Link Pass-Through feature, which

allows monitoring its fiber (FX) and copper (RX) (receive) ports for signal loss. Refer

to Figure 14, in the event of an RX signal loss (1), the industrial switch will

automatically disable the TX (transmit) signal (2) thus “passing through” the link loss

(3). The far-end device is automatically notified of the link loss (4), which prevents

date losses by transmitting data over an invalid link unknowingly.

media converter A

disables the fiber TX link

media converter B

loses the fiber RX link

Operation -- continued

AutoCross™

When the AutoCross feature is activated, it allows the use of straight-through MDI or

crossover MDI-X cables for connecting to 10Base-T or 100Base-TX devices.

AutoCross determines the characteristics of the connection and automatically

configures the unit to link up, regardless of the cable configuration, either MDI or

MDI-X.

Replacing the fuse

Note: The fuse may be “hot swapped” (i.e., replaced while the industrial switch is in

operation) provided the power source associated with the burned-out fuse has

been disconnected. For example, the primary fuse may be replaced provided

that power to the primary power contacts has been turned OFF.

To replace the fuse, view Figure 15, and then do the following:

1. Turn OFF and disconnect the power source associated with the blown fuse.

2. Using a flat-head screwdriver, unscrew (counter-clockwise) and remove the fuse

holder. See Figure 15.

3. Carefully remove the fuse from the fuse holder.

4. Install a same size and rated (2.5 A, 250 V) replacement fuse in the fuse holder.

5. Insert the fuse holder with the fuse into the switch and rotate clockwise to secure.

6. Re-connect and turn ON the power source.

7. Verify that the industrial switch is powered UP: “Power Good” LED on the upper

front panel will be ON.

Near-End

Device

original fault

on the co

1

er link

Media

Converter A

2

3

Converter B

Media

4

media converter B

disables the co

Far-End

Device

er lin

Figure 14: Link Pass-Through

Fiber Redundancy

The SIBTF10xx-130 industrial switch provides stable, fiber redundancy in highly

critical Ethernet and Fast Ethernet segments.

When the fiber redundancy feature is enabled, only one fiber connection (primary) is

active at a time. This primary connection is in the forwarding stage while the other

fiber connection (secondary) is put in the standby state.

When failure on the primary fiber connection occurs, it is detected by the switch. The

secondary connection is activated and becomes the primary link. The original fiber

link is disabled until the failure on the primary fiber connection is corrected. Once

corrected, the original order is restored.

Note: The fiber redundancy feature is for point-to-point applications, and not for

redundant ring applications.

18

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Front Panel

PR I.

Po wer

Good

FUSE

2.5A

250V

N

L

Indust rial

PR I.

PR I.

Switch

SIBFT

Fuse

Fuse Holder

Figure 15: Fuse Replacement

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

19

SIBTF10xx-1xx-Mx

Cable Specifications

The physical characteristics must meet or exceed IEEE 802.3™ specifications.

Copper Cable

Category 3: (Minimum requirement for 10 Mb/s operation)

Gauge 24 to 22 AWG

Attenuation 11.5 dB/100m @ 5-10 MHz

Maximum Cable Distance 100 meters

Category 5: (Minimum requirement for 100 Mb/s operation)

Gauge 24 to 22 AWG

Attenuation 22.0 dB/100m @ 100 MHz

Maximum Cable Distance 100 meters

• Straight-through or crossover twisted-pair cable may be used.

• Shielded (STP) or unshielded (UTP) twisted-pair cable may be used.

• Pins 1&2 and 3&6 are the two active pairs in an Ethernet network .

• Use only dedicated wire pairs for the active pins:

(e.g., blue/white & white/blue, orange/white & white/orange, etc.)

Straight-Through Cable

Twisted Pair #1

Twisted Pair #2

1

2

3

6

1

2

3

6

Figure 16: Copper Cable Configurations

• Do not use flat or silver satin wire.

WARNING: Visible and invisible laser radiation when open. Do not stare

into the beam or view the beam directly or with optical instruments. Failure

to observe this warning could result in an eye injury or blindness.

Twisted Pair #1

Twisted Pair #2

Crossover Cable

1

2

3

6

Cable Specifications -- continued

SIBTF1013-1xx-Mx 1300 nm multimode

Fiber Optic Transmitter Power: min: -19.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -30.0 dBm max: -14.0 dBm

Link Budget: 11.0 dB

SIBTF1014-1xx-Mx 1310 nm single mode

Fiber-optic Transmitter Power: min: -15.0 dBm max: -8.0 dBm

Fiber-optic Receiver Sensitivity: min: -31.0 dBm max: -8.0 dBm

Link Budget: 16.0 dB

SIBTF1015-1xx-Mx 1310 nm single mode

Fiber-optic Transmitter Power: min: -8.0 dBm max: -2.0 dBm

Fiber-optic Receiver Sensitivity: min: -34.0 dBm max: -7.0 dBm

Link Budget: 26.0 dB

SIBTF1016-1xx-Mx 1310 nm single mode

Fiber-optic Transmitter Power: min: -5.0 dBm max: 0.0 dBm

Fiber-optic Receiver Sensitivity: min: -34.0 dBm max: -7.0 dBm

Link Budget: 29.0 dB

SIBTF1017-1xx-Mx 1550 nm single mode

Fiber-optic Transmitter Power: min: -5.0 dBm max: 0.0 dBm

1

2

3

6

Fiber-optic Receiver Sensitivity: min: -34.0 dBm max: -7.0 dBm

Link Budget: 29.0 dB

This device is certified by the manufacturer to comply with DHHS Rule

21/CFR, Subchapter J applicable at the date of manufacture.

CAUTION:

Visible and invisible laser radiation when open. Do not stare

into beam or view directly with optical instruments.

CAUTION:

Use of controls, adjustments or the performance of procedures

other than those specified herein may result in hazardous radiation exposure.

The fiber optic transmitters on this device meet Class I Laser safety

requirements per IEC-825/CDRH standards and comply with 21

CFR1040.10 and 21CFR1040.11.

Fiber cable

Bit Error Rate: <10-9

single mode fiber (recommended): 9 μm

Multimode fiber (recommended): 62.5/125 μm

Multimode fiber (optional): 100/140, 85/140, 50/125 μm

SIBTF1011-1xx-Mx 1300 nm multimode

Fiber Optic Transmitter Power: min: -19.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -30.0 dBm max: -14.0 dBm

Link Budget: 11.0 dB

20

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

WARNING:

Use of controls, adjustments, or the performance of

procedures other than those specified herein may result in hazardous

radiation exposure.

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

21

SIBTF10xx-1xx-Mx

Technical Specifications

For use with Transition Networks Model SIBTF10xx-1xx-Mx or equivalent.

Standards: IEEE 802.3™ 2000, IEEE 802.3x™

Data Rate: 10 Mb/s, 100 Mb/s (copper), 100 Mb/s (fiber)

Dimensions: Models 130- & 140-Mx

(W x H x D) 4.125" x 6" x 5" (104.77 x 152.4 x 127 mm)

Dimensions: Model 110-Mx

(W x H x D) 3.375" x 6" x 5" (85.73x 152.4 x 127 mm)

Weight: 3.2 lb. (1.5 kg) approximately

Input Voltage: 48–170VDC +/-15%

90–125VAC +/-15%, 50/60 Hz

Power: 15 W (maximum)

Aux input standby power, 200 mW typically

Fuse: 2.5 A/250 VDC

Alarm Relay: Three-position screw terminal block for the dry contact relay

0.5 A @ 125 VAC / 2.0 A @ 30 VDC (maximum)

switching capacity: 60 W (maximum)

Packet Size: Memory: 64K Bytes

Unicast MAC addresses: 1000

Maximum packet size: 1536 Bytes

MTBF*: 51,115 MIL-HDBK-217F Hours

153,038 Bellcore Hours

Environment

Operating Temp: -40 to 75°C (-40 to 167°F)

Storage Temp: -40 to 85°C (-40 to 185°F)

Humidity: 5 to 95%, non-condensing

Altitude: 3000 m (10,000 ft.)

Warranty: Lifetime

The industrial switch is designed for installation in restricted access locations.

Installing the industrial switch into other equipment or facility control rooms must

comply with the fire-enclosure requirements of IEC60950/EN60950/UL60950, along

with other local, national fire and safety codes.

IMPORTANT:

RS232, RS422, RS485, DS1, DS3, Video Coax, etc. are intended for connecting to

intra-building (inside plant) link segments, not subject to lightening transients or

power faults. Copper based media ports: e.g., Twisted Pair (TP) Ethernet, USB,

RS232, RS422, RS485, DS1, DS3, Video Coax, etc. are NOT for connecting to interbuilding (outside plant) link segments subject to lightening transients or power faults.

*MTBF is estimated using the predictability method. This method is based on MIL217F at 25°C ambient temperature, typical enclosure heat rise of 10°C, and nominal

operating conditions and parameters. Installation and configuration specific MTBF

estimates are available upon request. Contact Technical Support.

Copper based media ports: e.g., Twisted Pair (TP) Ethernet, USB,

Technical Specification -- continued

220–240VAC, 50/60Hz installation

CAUTION: If the main power source is 220-240VAC @50/60Hz, use a 2:1, 50VA or

greater step-down transformer between the main power source and the industrial

switch. Failure to observe this caution could result in a damaged switch.

EMC Type Tests (all test were performed using unshielded cables)

Standard Description Compliance Level Remarks

EN55022/FCC Part15 ITE Emissions Class A Conducted and radiated

EN55024/EN61000-6-2: ITE Emissions

IEC61000-4-2 Level 2 ESD contact discharge

IEC61000-4-3 Level 4 Radiated fields

IEC61000-4-4 Level 3 Fast transients - power port

Level 2 Fast transient – Ethernet port

IEC6100-4-5 Level 3 CM

Level 2 DM

Level 1 DC

Level 2 Surge – relay port

Level 2 Surge – Ethernet port

IEC61000-4-5 EN61000-6-2 Level 3

EN55024 Level 2

EN61000-6-2 Level 3

EN55024 Level 2

EN61000-6-2 Level 3

EN55024 Level 2

EN61000-6-2 Level 3

EN55024 Level 2

IEC61000-4-8 Level 1 Power freq. mag. field

IEC61000-4-11 N/A VoltageDIPs and variations

IEEE1613, Power Substation Testing

IEEE1613, Clause 6.2 Not rated Dielectric power freq.

IEEE1613, Clause 6.3 Compliant Impulse voltage all ports

IEEE1613, Clause 7.3.1 Class 2 transverse and

common Mode

Class 2 transverse and

common Mode

Class 2 common mode Surge oscillatory waveform

Class 2 common mode Surge oscillatory waveform

Class 1 common mode Surge oscillatory waveform

2 meter cable AC

1 meter cable DC

3 meter cable length

Surge – power port

2 meter cable AC

1 meter cable DC

1 meter cable length

3 meter cable length

Conducted – power port

2 meter cable AC,

1 meter cable DC

Conducted – relay port

1 meter cable length

Conducted – PE Studs

2 meter cable length

Conducted – Ethernet port

10 meter cable length

Surge oscillatory waveform

–power AC

Surge oscillatory waveform

–power DC

–relay port

–Ethernet 10 Mbps

– Ethernet 100 Mbps

22

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

23

SIBTF10xx-1xx-Mx

Technical Specification -- continued

EMC Type Tests -- Continued

Standard Description Compliance Level Remarks

IEEE1613, Power Substation Testing -- Continued

IEEE1613, Clause 7.3.2 Class 2 transverse mode

Class 1 common mode

Class 2 transverse mode

Class 1 common mode

Class 1 common mode Surge fast transient

Class 1 common mode Surge fast transient

Class 1 common mode Surge fast transient

IEEE1613, Clause 8 Class 2 Radio frequency

IEEE1613, Clause 9 Class 1 ESD contact discharge 8kV

Surge fast transient

waveform – power AC

Surge fast transient

waveform – power DC

waveform – relay port

waveform – Ethernet 10

Mbps

waveform – Ethernet 100

Mbps

susceptibility

Troubleshooting

If the industrial switch fails, isolate and correct the failure by determining the answers

to the following questions and then taking the indicated action:

1. Is the “PRI” (primary power) LED illuminated?

NO

• Ensure the power source is the proper voltage (48–170 VDC or 90–125

VAC, 50/60Hz).

• Ensure that the positive, negative, and ground wires from the power

source are properly connected to the primary inputs.

• Contact Technical Support: US/Canada: 1-800-260-1312,

International: 00-1-952-941-7600.

YES

• Proceed to step 2.

2. (SIBTF10xx10x-MR models only) is the “AUX” (auxiliary power) LED

illuminated?

NO

• If the device does not have an auxiliary power source, proceed to step 3.

• Ensure the power source is the proper voltage (48–170 VDC or 90–125

VAC, 50/60Hz).

• Ensure that the positive, negative, and ground wires from the power

source are properly connected to the auxiliary inputs.

• Contact Technical Support: US/Canada: 1-800-260-1312, International:

00-1-952-941-7600.

YES

• Proceed to step 3.

Troubleshooting -- continued

3. Is the “FAULT” LED illuminated?

NO

• Proceed to step 4.

YES

• Contact Technical Support: US/Canada: 1-800-260-1312, International:

00-1-952-941-7600.

4. For each port with a cable installed is either the “10MB” or the “100MB” LED

illuminated?

YES

• Proceed to step 5.

NO

• For each port with a cable installed and its LED is OFF, check the cable

for proper connection.

• For the fiber ports, verify that the TX and RX cables on the SIBTF10xx-

10x are connected to the RX and TX ports, respectively, on the device at

the other end of the fiber cables.

• Contact Technical Support: US/Canada: 1-800-260-1312, International:

00-1-952-941-7600

5. For each RJ-45 port with a cable installed (ports 1, 2, 3, and 4), check to see if

the 10MB or 100MB LED is illuminated.

• 10MB is ON = The industrial switch has selected 10Mb/s operation.

• 100MB is ON = The industrial switch has selected 100Mb/s operation.

• If the speed is not correct, disconnect and reconnect the cable to restart the

initialization process.

• Proceed to step 6.

6. For each fiber port with a cable installed, is the “FD” (full-duplex) LED

illuminated?

NO

• The industrial switch has selected half-duplex mode.

• If the mode is not correct, disconnect and reconnect cable to restart the

initialization process.

• Check the cable for proper connection.

• Contact Tech Support: 1-800-260-1312, Int’l: 00-1-952-941-7600.

YES

• The industrial switch has selected full-duplex mode.

• If the mode is not correct, disconnect and reconnect cable to restart the

initialization process.

• Check the cable for proper connection.

• Contact Tech Support: 1-800-260-1312, Int’l: 00-1-952-941-7600.

24

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

25

SIBTF10xx-1xx-Mx

Contact Us

Technical support

Technical support is available 24 hours a day.

US and Canada: 1-800-260-1312

International: 00-1-952-941-7600

Transition now

Chat live via the Web with Transition Networks Technical Support.

Log onto www.transition.com and click the Transition Now link.

Web-Based seminars

Transition Networks provides seminars via live web-based training.

Log onto www.transition.com and click the Learning Center link.

E-Mail

Ask a question anytime by sending an e-mail to our technical support staff.

techsupport@transition.com

Address

Transition Networks

6475 City West Parkway

Minneapolis, MN 55344, U.S.A.

telephone: 952-941-7600

toll free: 800-526-9267

fax: 952-941-2322

Declaration of Conformity

Name of Mfg: Transition Networks

6475 City West Pkwy, Minneapolis MN 55344 U.S.A.

Model: SIBTF10xx-1xx Industrial switches

Part Number(s): SIBTF1011-1xx-MR, SIBTF1013-1xx-MR, SIBTF1014-1xx-MR,

SIBTF1015-1xx-MR, SIBTF1016-1xx-MR, SIBTF1017-1xx-MR,

SIBTF1011-1xx-MS, SIBTF1013-1xx-MS, SIBTF1014-1xx-MS,

SIBTF1015-1xx-MS, SIBTF1016-1xx-MS, SIBTF1017-1xx-MS,

Regulation: EMC Directive 89/336/EEC

Purpose: To declare that the SIBTF10xx-1xx-Mx to which this declaration

refers is in conformity with the following standards:

CISPR 22:1993; EN 55022:1994+A1:1995+A2:1997 Class A; EN 55024:1998; EN 61000-6-2:2001;

EN61000-4-2:1995; -4-3:2002; -4-4:1995; -4-5:1995; -4-6:1995

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive(s)

and Standard(s).

Compliance Information

EN55022, EN55024, EN61000-6-2:2001 & IEEE1613

FCC Regulations This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at the user's own

expense.

Canadian Regulations This digital apparatus does not exceed the Class A limits for radio noise

for digital apparatus set out on the radio interference regulations of the Canadian Department of

Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la Class A prescrites dans le Règlement sur le brouillage

radioélectrique édicté par le ministère des Communications du Canada.

European Regulations

Warning:

interference in which case the user may be required to take adequate measures.

Achtung ! Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei

Betrieb dieses Gerätes Rundfunkstörungen auftreten. In diesem Fäll ist der Benutzer für

Gegenmaßnahmen verantwortlich.

Attention ! Ceci est un produit de Classe A. Dans un environment domestique, ce produit risque

de créer des interférences radioélectriques, il appartiendra alors à l'utilsateur de prende les measures

spécifiques appropriées.

jeweligen einzelstaatlichen Gesetze zur Anwendung der Richtlinie 91/263/EWG zur

Angleichung der Rechtsvorschriften der Mitgliedstaaten über Telekommunikationsendeinrichtungen einschliesslich der gegenseitigen Anerkennung ihrer Konformität.

This is a Class A product. In a domestic environment this product may cause radio

CAUTION: RJ connectors are NOT INTENDED FOR CONNECTION TO THE

PUBLIC TELEPHONE NETWORK. Failure to observe this caution could result in

damage to the public telephone network. Der Anschluss dieses Gerätes an ein

öffentlickes Telekommunikationsnetz in den EG-Mitgliedstaaten verstösst gegen die

In accordance with European Union Directive 2002/96/EC of the European Parliament

and of the Council of 27 January 2003, Transition Networks will accept post usage

returns of this product for proper disposal. The contact information for this activity can

be found in the 'Contact Us' portion of this document.

Stephen Anderson, Vice-President of Engineering Date

26

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

June 30, 2006

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

27

SIBTF10xx-1xx-Mx

Trademark Notice

All trademarks and registered trademarks are the property of their respective owners.

Copyright Restrictions © 2005 Transition Networks. All rights reserved. No part of this work

may be reproduced or used in any form or means (graphic, electronic, mechanical) without written

permission from Transition Networks.

28

Printed in the U.S.A. 33323.A

Loading...

Loading...