Page 1

▲

WARNING

!

▲

WARNING

!

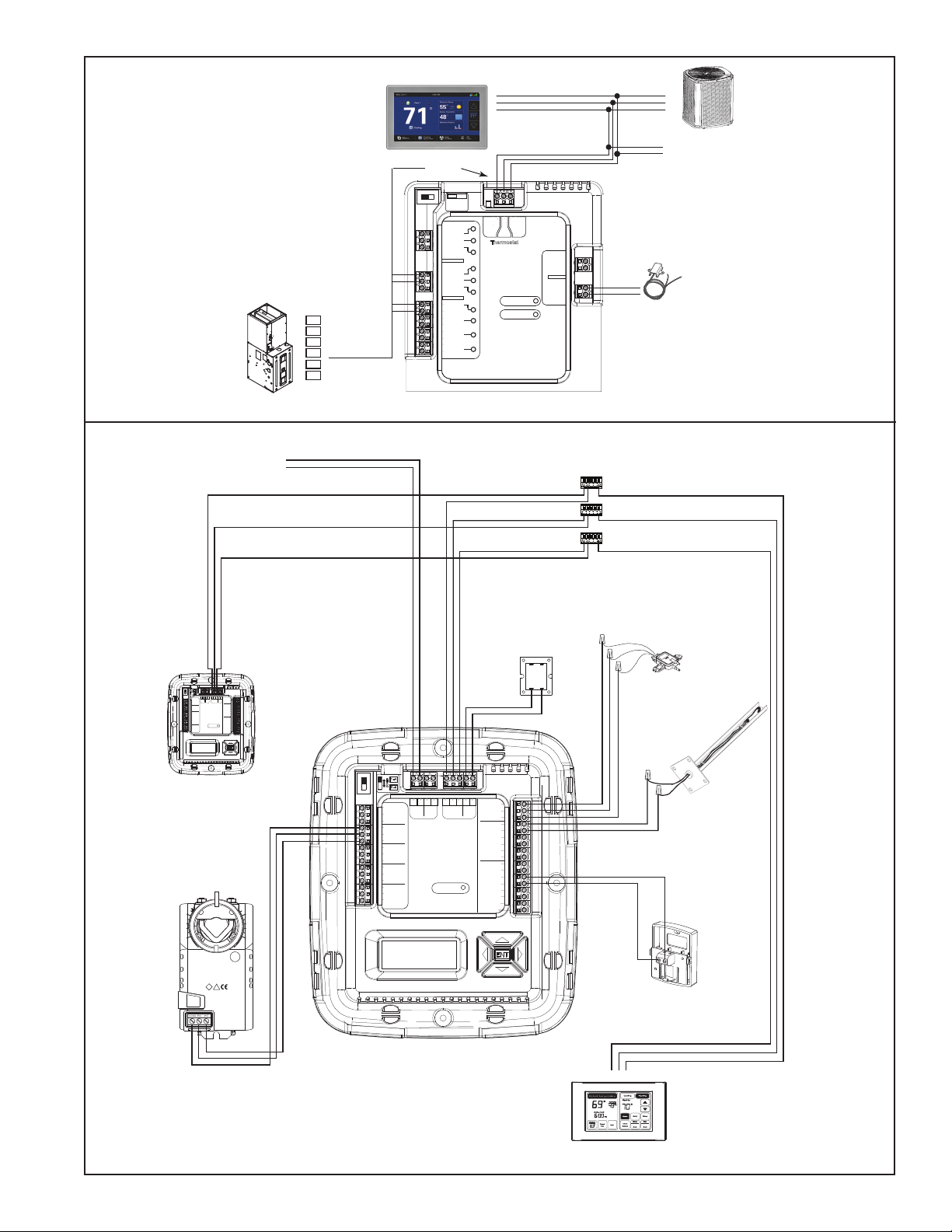

Zone Panel

ZZONEPNLAC52ZB (Kit)

ZZONEEXPAC52ZB (Zone Panel)

18-HD66D1-4

Installation Guide

Other Installation Guides may be necessary, based on system configuration.

A complete list of other optional components is shown below.

Control (required) *ZONE950AC52ZA or

1

*ZON1050AC52ZA

Relay Panel

2

For use with 24V indoor systems (optional)

3 Zone Panel

Zone Sensor with Display (optional)

4

Zone Sensor (optional)

5

Zone Dampers (optional)

6

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — Proper application is critical when installing zoning systems. Not done correctly, the HVAC

and zoning systems will not provide the expected comfort. Reference application bulletins CNT-APG003EN/Trane and CNT-APG004-EN/AS for detailed information on Zoning Application

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service information pack upon completion of work.

These instructions do not cover all variations in systems or provide for every possible contingency to be met in connection with

the installation. Should further information be desired or should particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to your installing dealer or local distributor.

Section 1. Safety

Table of Contents

This information is intended for use by individuals possessing adequate backgrounds of electrical and mechanical

experience. Any attempt to repair a central air conditioning

product may result in personal injury and/or property damage. The manufacture or seller cannot be responsible for

the interpretation of this information, nor can it assume any

liability in connection with its use.

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and troubleshooting of this product, it may be necessary to work with live

electrical components. Failure to follow all electrical safety

precautions when exposed to live electrical components

could result in death or serious injury.

Section 1. Safety ................................................1

Section 2. General Information .......................... 2

Section 3. Installation ......................................... 6

Section 4. Zoning Setup .................................. 16

Section 5. Zone Sensor Setup ......................... 22

Section 6. Damper Test Mode ..........................24

Section 7. User Interface .................................25

Section 8. Control Board Test Points ............... 26

Section 9. Troubleshooting ...............................28

10/17

Page 2

Section 2. General Information

1

2

4

3

5

10

11

6

8

9

7

ZONES

1 - 4

5 - 8

ByPass

Zone Dampers

Sensors

C

ommon

PO/Open

PC/Clos

e

Static Press

Gnd/Grn

S

ignal/Blk

+5

V/Red

Temper

atureRemote Indoor

Disch

ar

ge Air

Dischar

ge Air

Return A

i

r

R

e

tu

rn

Air

Mix

ed

Air

Mixed Air

Zo

ne 1

or 5

Zone

1 or 5

Zone 2

or 6

Zon

e

2

o

r 6

Zone

3 or 7

Z

one

3 or 7

Z

one

4

or 8

Zone 4 or 8

Zone

1 or 5

Ind

oor/

Relay P

anel

Ou

tdoor

Zone Panel

(Zones 5-8)

24V

Tran

s

.

Co

mmon

PO/Open

PC/Clo

s

e

Zone

2 or 6

C

ommon

PO/

Ope

n

PC/Clo

s

e

Zone

3 or 7

Common

PO/Ope

n

PC/Close

Zone

4 or 8

Common

PO/Ope

n

PC/

Close

Comm

R

BD B

B

R

BD

D

Zone Panel

2.1 Overview

The Zone Panel is a wall mounted low voltage panel that enables the control to connect to and manage

zoning components.

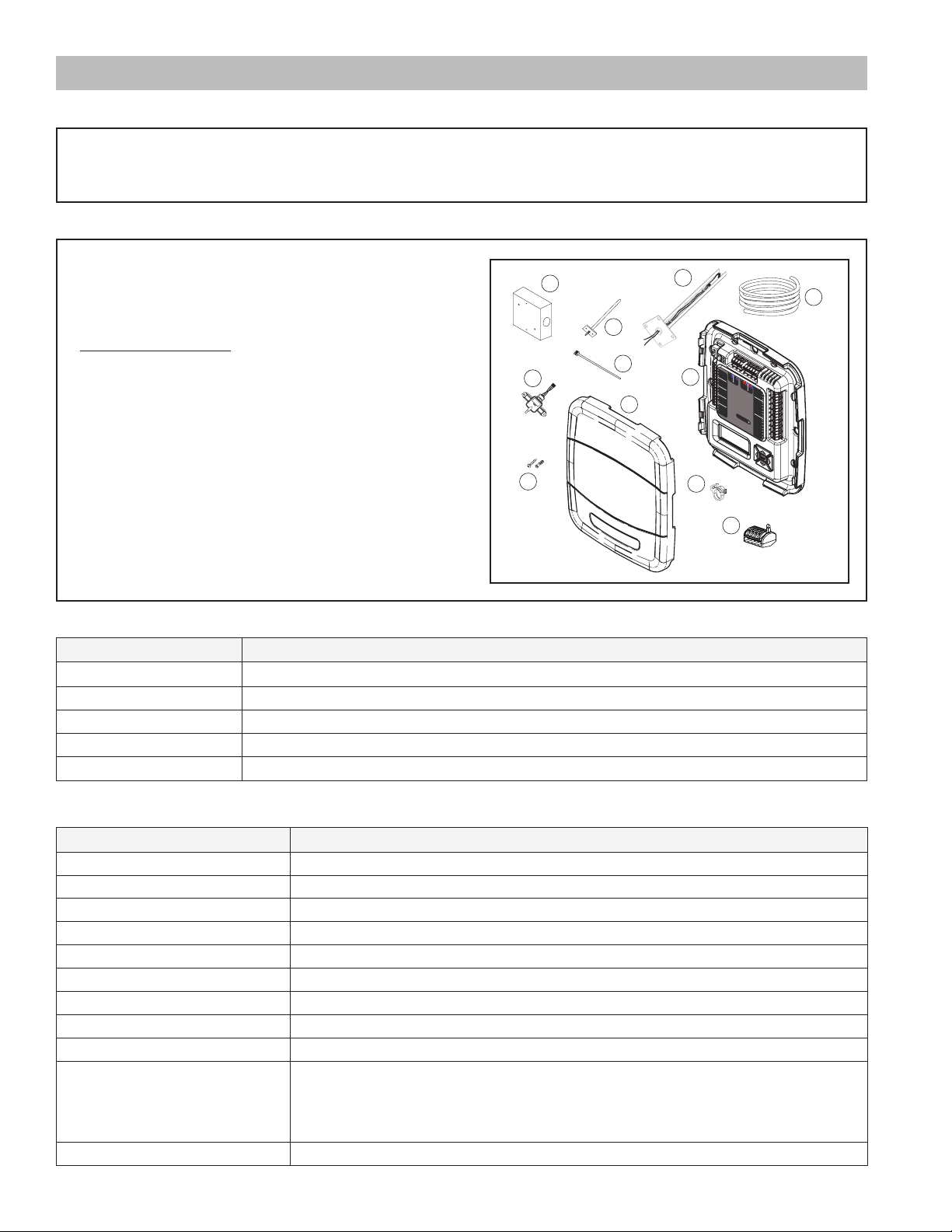

2.2 Contents in Zone Panel Kit (ZZONEPNLAC52ZB)

Open and inspect contents for damaged or missing

items. Each kit will contain:

Item Qty Description

1 1 Zone Panel cover

2 1 Zone Panel base

3 1 Discharge Air Temperature Sensor

4 1 Static Pressure Transducer

5 1 Transducer Enclosure

6 2 Static Pressure Probe

7 1 Clear Flexible Tubing (8 ft.)

8 4 Mounting screws/anchors

9 4 Wire Ties

10 4 Tubing Clamps

11 3 Clamp-style Connectors

12 1 Installer’s Guide (not pictured)

2.3 Optional Accessories

Product Model Description

*ZONE940AC52ZA Communicating Zone Sensor with Display

ZZSENSAL0400AA Non-Communicating Zone Sensor

SEN 00462 Return Air/Mixed Air Sensor

ZZONEEXPAC52ZB Additional Zone Panel for zones 5-8

120/240VAC Transformer

Field-Supplied, sizing dependent on VA requirements of Zone Panel and installed components

2.4 Specifications

Specification Description

Product Model: ZZONEEXPAC52ZB

Product: Zone Panel

Size: 8.0” width x 9.3” height x 1.9” depth

Storage Temperature: -40° to 175°F, 5% to 95% RH non-condensing

Operating Temperature: -40° to 150°F, 5% to 95% RH non-condensing

Input Power: 24 VAC from external transformer (Range: 18-32 VAC)

Power Consumption: 2 VA for each Zone Panel (damper VA not included)

Wire usage: Minimum 18 gauge NEC approved control wiring

HVAC System Type Compatible: Standard (gas/oil/electric/hydronic), Heat Pump, Dual Fuel

Multistage System Compatible: Standard HVAC Systems: Up to 3 stages of heating and 2 stages of cooling (including

Communications: ~12 VDC

2 18-HD66D1-4

modulating heating)

Heat Pump Systems: Up to 5 stages of heating (2 compressor, 3 aux heat—including

modulating heating) and 2 stages of cooling

Page 3

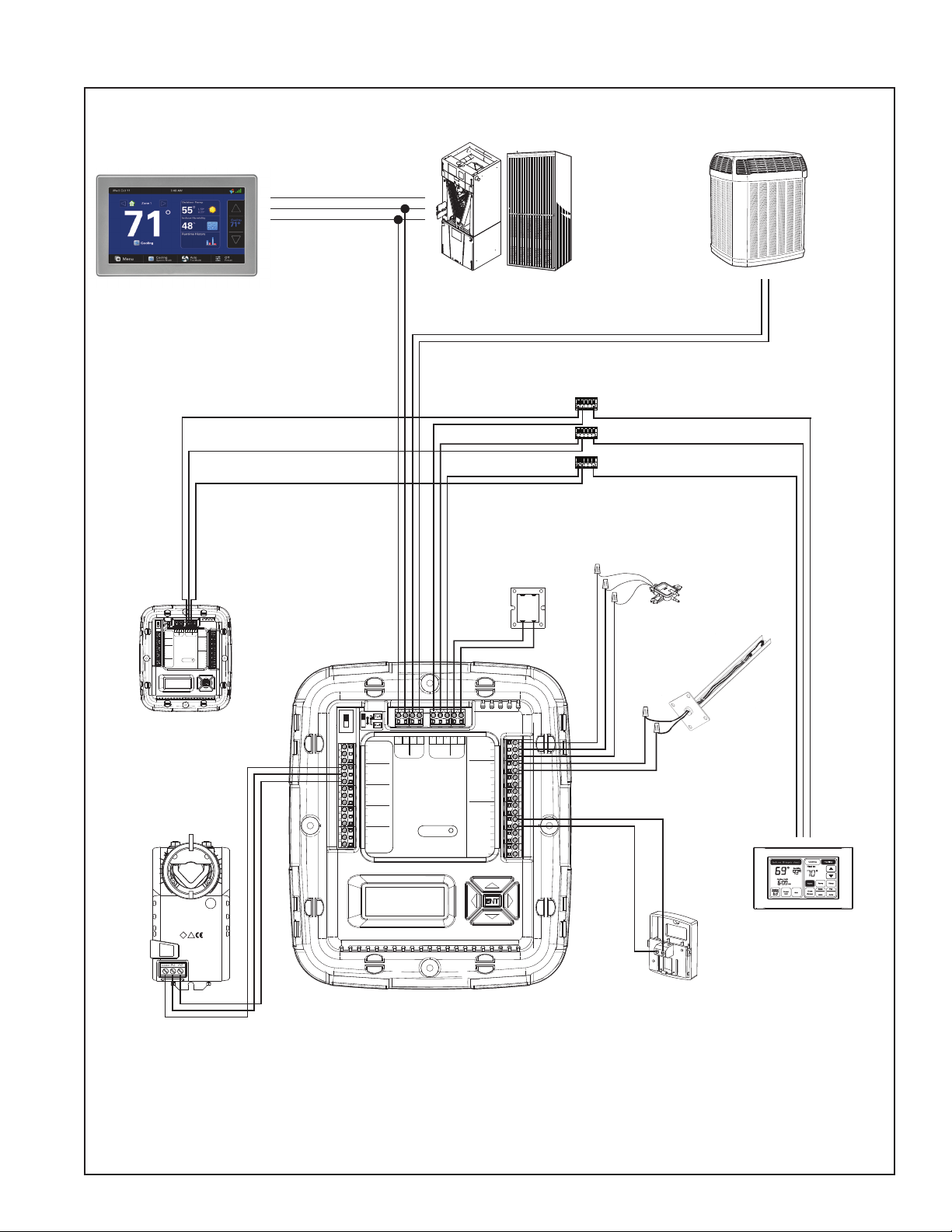

2.4 System Connections

PCPOCOM

Communicating

Communicating Indoor Unit

Communicating Outdoor Unit

Control

R

B

D

R

B

D

Communicating

Indoor Unit

Communicating

Outdoor Unit

BDD

Clamp-style Connectors

R

B

Static Pressure

Field-Supplied 24V

Transformer

TRANS.

1 - 4

1 - 4

ZONES

ZONES

5 - 8

5 - 8

BRBD D

BD B

R

Gnd/Grn

Common

Indoor/

24V

Outdoor

Zone Panel

Signal/Blk

Relay Panel

Trans.

(Only Use For

PO/Open

Zones 5-8)

Static Press

+5V/Red

ByPass

PC/Close

Discharge Air

Common

Discharge Air

PO/Open

Return Air

Zone

1 or 5

PC/Close

Return Air

Common

Mixed Air

PO/Open

Temperature

Mixed Air

Zone

2 or 6

PC/Close

Zone 1 or 5

Common

Sensors

Zone 1 or 5

PO/Open

Zone Dampers

Zone 2 or 6

Zone

3 or 7

PC/Close

Zone 2 or 6

Common

Comm

Zone 3 or 7

PO/Open

Remote Indoor

Zone 3 or 7

Zone

4 or 8

PC/Close

Zone 4 or 8

Zone 4 or 8

Zone Panel

Transducer

(OPTIONAL)

Temperature

Sensor(s)

1 - 4

Reserved

Reserved

Reserved

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

1 - 4

ZONES

ZONES

5 - 8

5 - 8

BRBD D

BD B

R

Comm Zone Sensor

2nd Zone Panel

24V

Trans.

Sensors

Gnd/Grn

Signal/Blk

Static Press

+5V/Red

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

TemperatureNon Comm Zone Sensor

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Comm

Indoor/

Outdoor

Relay Panel

Zone

1 or 5

Zone

2 or 6

Zone Dampers

Zone

3 or 7

Comm

Zone

4 or 8

Zone Panel

(Zones 5-8)

0 1

CNT06430

24VAC 50/60Hz

1.5VA

60s

18in-lb(2Nm)

Made in Switzerland

Trane US, Inc.

MANUAL

GEAR

III

!

RELEASE

Zone Panel

Damper(s)

*Transformer must be sized to handle the VA requirements of all dampers and zone panels installed

(Zones 1-4)

Discharge

(REQUIRED)

Return

(OPTIONAL)

Mixed

(OPTIONAL)

Communicating Zone Sensor(s)

Non-Communicating Zone Sensor(s)

(ZZSENSAL0400A)

RB D

*ZONE940AC52ZA

3

Page 4

Control

24V System

Non-Communicating Indoor Unit

Non-Communicating Outdoor Unit

Non-Communicating

Outdoor Unit

See Relay Panel

Installer’s Guide

for specific

wiring instructions.

NORM

Dual Fuel

Switch

0 SOV

Y1 Stg1

Y2 Stg2

W1 Stg1

W2 Stg2

W3 Stg3

G

PWM

BK

Hum

Hum

Aux1

Aux1

Aux2

Aux2

B

R

D

DUAL

Fan

24 Vac

Only

24 Vac

Only

24 Vac

Only

D R

B

Data

Hot

Com

Thermostat

and Indoor Unit

HVAC System

Comm

Bit Master

Relay Panel

Remote

Sensors

Outdoor

RS

RS

Indoor

ODT

ODT

D

To Zone Panel

B

See Page 5 for

Zone Panel

Connections

Wired Remote

Outdoor Sensor

BAYSEN01ATEMPA

(may be wired to Control)

Non-Communicating

Indoor Unit

Hybrid System

Communicating Indoor Unit

Non-Communicating Outdoor Unit

See Relay Panel

Installer’s Guide

for specific

wiring instructions.

Non-Communicating

Outdoor Unit

Control

NORM

Dual Fuel

Switch

0 SOV

Y1 Stg1

Y2 Stg2

W1 Stg1

W2 Stg2

W3 Stg3

G

PWM

BK

Hum

Hum

Aux1

Aux1

Aux2

Aux2

B

R

D

B

R

D

D

B

To Zone Panel

See Page 5 for

Zone Panel

DUAL

D R

B

Data

Hot

Com

Thermostat

and Indoor Unit

RS

RS

Indoor

Remote

Sensors

HVAC System

Fan

24 Vac

Only

24 Vac

Only

24 Vac

Only

Comm

Bit Master

ODT

ODT

Outdoor

BAYSEN01ATEMPA

(may be wired to Control)

Connections

Wired Remote

Outdoor Sensor

Relay Panel

4 18-HD66D1-4

Page 5

PCPOCOM

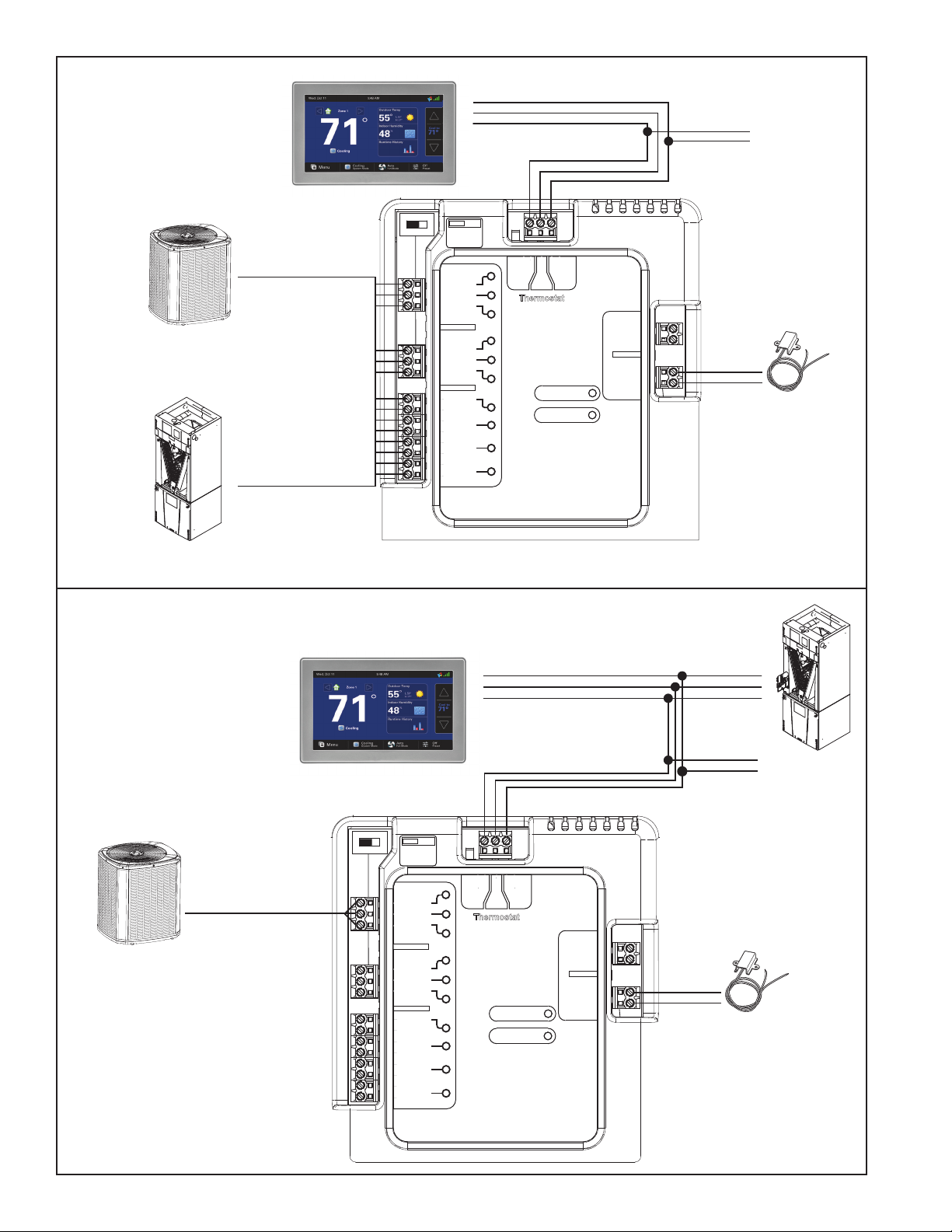

Zone Panel Connections

S-Series Furnace with

S-Series Furnace with Coil

Variable Speed HP/AC

Non-Communicating Furnace with Coil

and Communicating Outdoor Unit

See Relay Panel

Installer’s Guide

for specific

wiring instructions.

R

B/C

W1

W2

G

BK

Non-Communicating

Control

To R & B

NORM

0 SOV

Y1 Stg1

Y2 Stg2

W1 Stg1

W2 Stg2

W3 Stg3

G

BK

Hum

Hum

Aux1

Aux1

Aux2

Aux2

Dual Fuel

Switch

PWM

DUAL

Fan

24 Vac

24 Vac

24 Vac

Only

Only

Only

Relay Panel

B

R

D

D R

Data

Hot

Thermostat

and Indoor Unit

HVAC System

B

Comm

Bit Master

B

R

D

Communicating

Outdoor Unit

D

B

To Zone Panel

See Page 5 for

Zone Panel

Connections

Com

RS

RS

Indoor

Remote

Sensors

ODT

ODT

Outdoor

Wired Remote

Outdoor Sensor

BAYSEN01ATEMPA

(may be wired to Control)

From Communicating

Indoor Unit

or Relay Panel

1 - 4

1 - 4

ZONES

ZONES

5 - 8

5 - 8

BRBD D

BD B

R

Gnd/Grn

Common

Indoor/

24V

Outdoor

Zone Panel

Signal/Blk

Relay Panel

Trans.

(Only Use For

PO/Open

Zones 5-8)

Static Press

+5V/Red

ByPass

PC/Close

Discharge Air

Common

Discharge Air

PO/Open

Return Air

Zone

1 or 5

PC/Close

Return Air

Common

Mixed Air

PO/Open

Temperature

Mixed Air

Zone

2 or 6

PC/Close

Zone 1 or 5

Common

Sensors

Zone 1 or 5

PO/Open

Zone Dampers

Zone 2 or 6

Zone

3 or 7

PC/Close

Zone 2 or 6

Common

Comm

Zone 3 or 7

PO/Open

Remote Indoor

Zone 3 or 7

Zone

4 or 8

PC/Close

Zone 4 or 8

Zone 4 or 8

Zone Panel

Zone Panel

(Zones 5-8)

B

D

Clamp-style Connectors

D

R

B

Static Pressure

Transducer

(OPTIONAL)

Temperature

Sensor(s)

Discharge

(REQUIRED)

Return

(OPTIONAL)

Mixed

(OPTIONAL)

Reserved

Reserved

Reserved

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

Common

PO/Open

PC/Closed

Field-Supplied 24V

Transformer

TRANS.

1 - 4

1 - 4

ZONES

ZONES

5 - 8

5 - 8

Zone

1 or 5

Zone

2 or 6

Zone

3 or 7

Zone

4 or 8

BRBD D

BD B

R

Comm Zone Sensor

2nd Zone Panel

24V

Trans.

Sensors

Gnd/Grn

Signal/Blk

Static Press

+5V/Red

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

TemperatureNon Comm Zone Sensor

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Comm

Indoor/

Outdoor

Relay Panel

Zone Dampers

Comm

0 1

CNT06430

24VAC 50/60Hz

1.5VA

60s

18in-lb(2Nm)

Made in Switzerland

Trane US, Inc.

MANUAL

GEAR

III

!

RELEASE

Non-Communicating Zone Sensor(s)

(ZZSENSAL0400A)

Zone Panel

Damper(s)

(Zones 1-4)

RB D

Communicating Zone Sensor(s)

*ZONE940AC52ZA

5

Page 6

Section 3. Installation

Zone Panel

ZONES

1 - 4

5 - 8

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Temperature

Non Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

I

n

door/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BD B

B

R

BD

D

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Temperature

Non Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

Indoor/

Relay Panel

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BD B

B

R

BD

D

ZONES

1 - 4

5 - 8

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Temperature

Non Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BD B

B

R

BD

D

ZONES

1 - 4

5 - 8

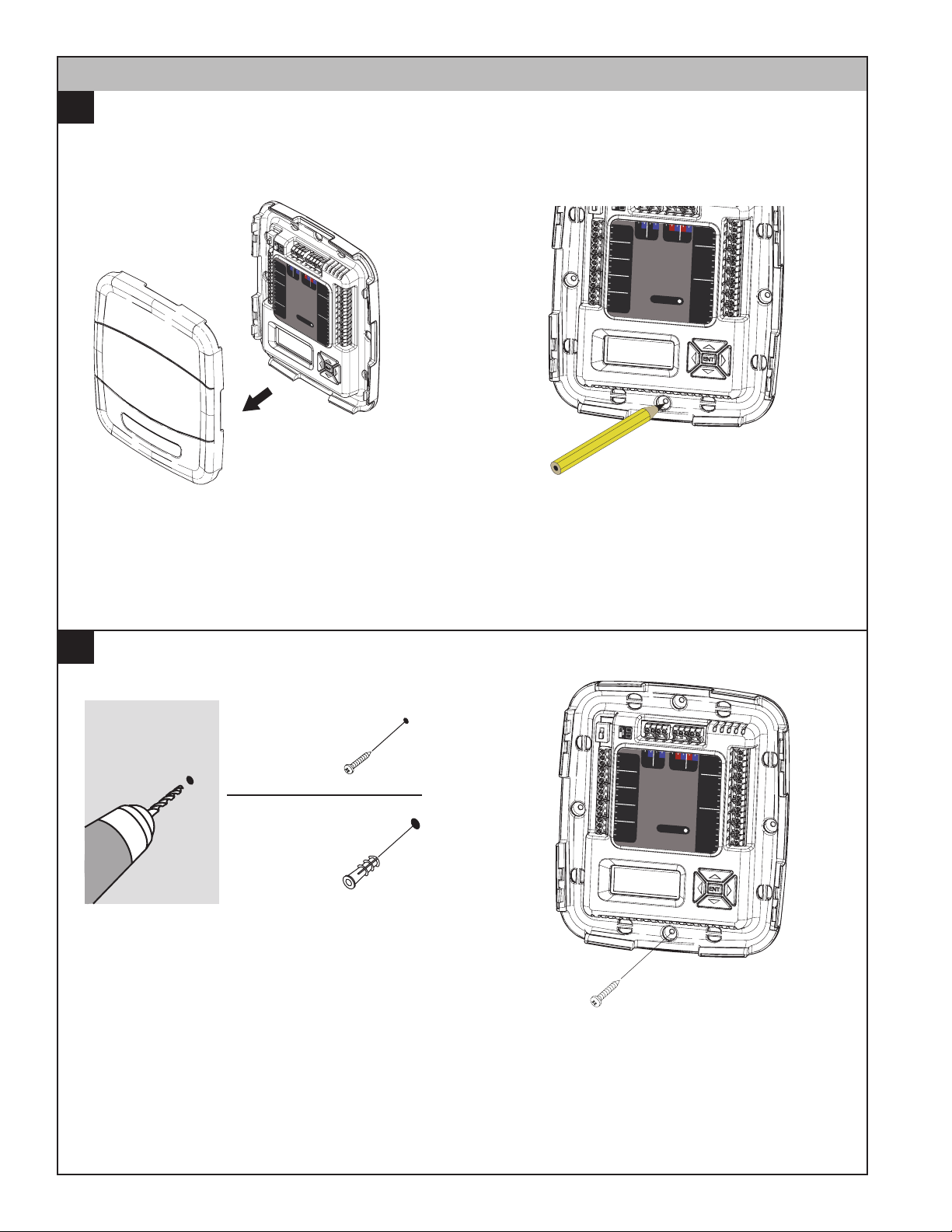

1A

Preparation

The unit’s rugged design allows installation in closet, attic or other non-condensing locations free from

obstructions or other hazards.

Remove cover by grasping at edges and gently

pulling the cover straight towards you. It should

release without much effort.

Mount Panel

1B

DRILL HOLES

1/8” for screws

into studs

3/16” for drywall

anchors

Mounting to studs: Drill 1/8” pilot holes in the four

locations marked above.

Mark four holes on the wall using the base as a

template. A level may be used to ensure accuracy.

Mounting to drywall:

If mounting to drywall with no studs behind it,

enlarge pilot holes to 3/16” for anchors (included

with the control).

Gently tap anchors into the holes.

6 18-HD66D1-4

Attach base to wall using four screws provided.

Do not overtighten.

Page 7

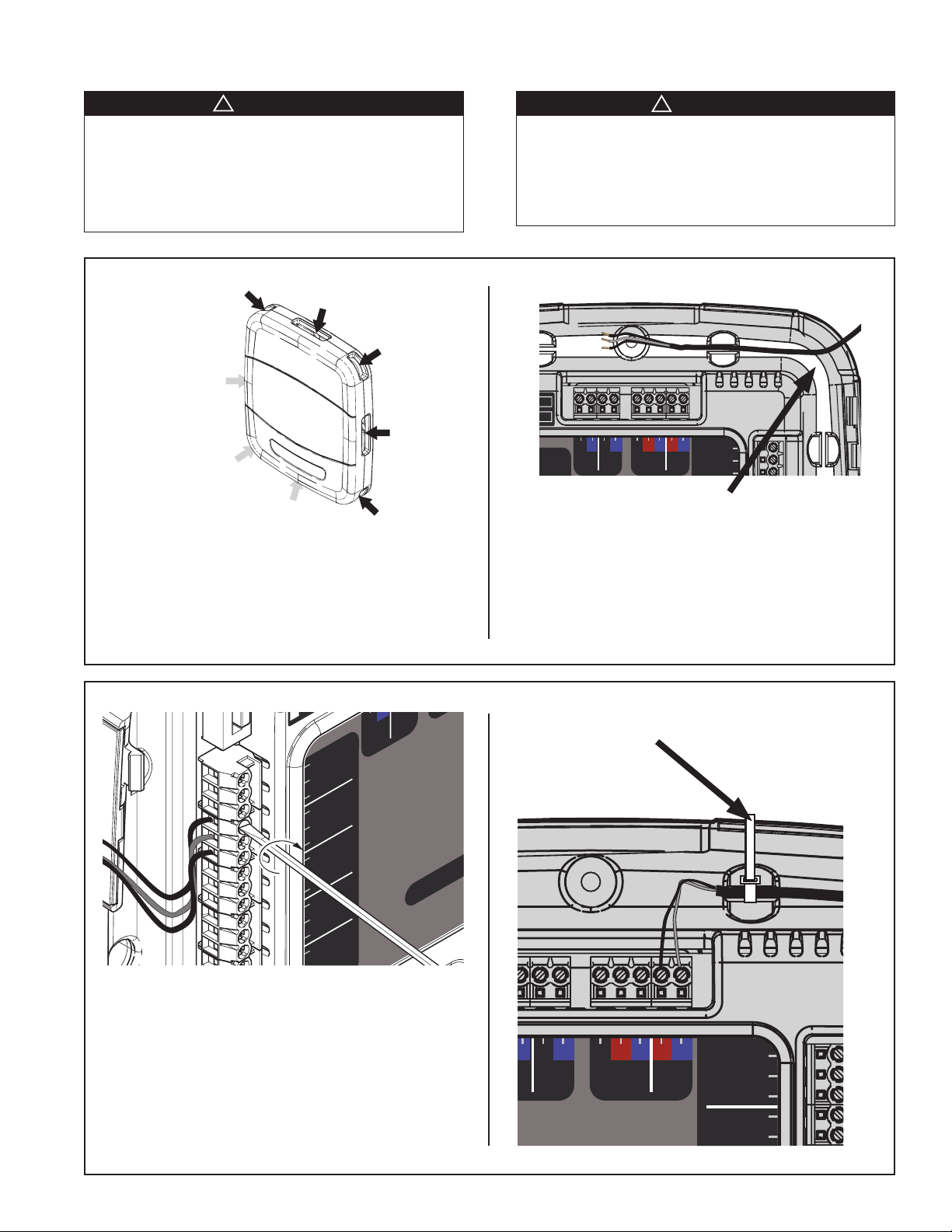

3.1 General Wiring Considerations

▲

CAUTION

!

▲

WARNING

!

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

1 - 4

5 - 8

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

R

BDB

BRBD D

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Discharge Air

Discharge Air

Comm

Outdoor

24V

Trans.

R

BDB

B

R

BD D

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

Comm

R

BD B

B

R

BD

D

ZONES

1 - 4

5 - 8

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and troubleshooting of this product, it may be necessary to work with live

electrical components. Failure to follow all electrical safety

precautions when exposed to live electrical components

could result in death or serious injury.

Wires may

enter at

any of 8

locations

Zone Panel

Wires may enter the Zone Panel through openings

on each corner and at the center of each side.

Necessary wire lengths should be considered when

determining entry points.

CAUTION: EQUIPMENT DAMAGE HAZARD - Improper

wiring can lead to equipment damage. Follow the Terminal

Connection information carefully to ensure the control is

wired properly. After wires are secure, bare wires

MUST NOT touch each other. See the Field Wiring Diagrams for specific system applications.

Route wires into “Raceways”

Run wires within the recessed wire “raceway”. Be

sure there is ample length to reach the connectors.

7

Using 1/8” blade screwdriver, attach all wires

securely to the proper terminals on the Zone

Panel. (See the Field Wiring Diagrams in the

following section.)

NOTE: The wire terminal blocks may be removed

for convenience in wiring. Ensure the terminal

block properly aligns with the pins when resetting.

Secure all wires with the supplied wire ties.

Comm Zone Sensor/

2nd Zone Panel

Page 8

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

ZONES

1 - 4

5 - 8

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BDB

BRBD D

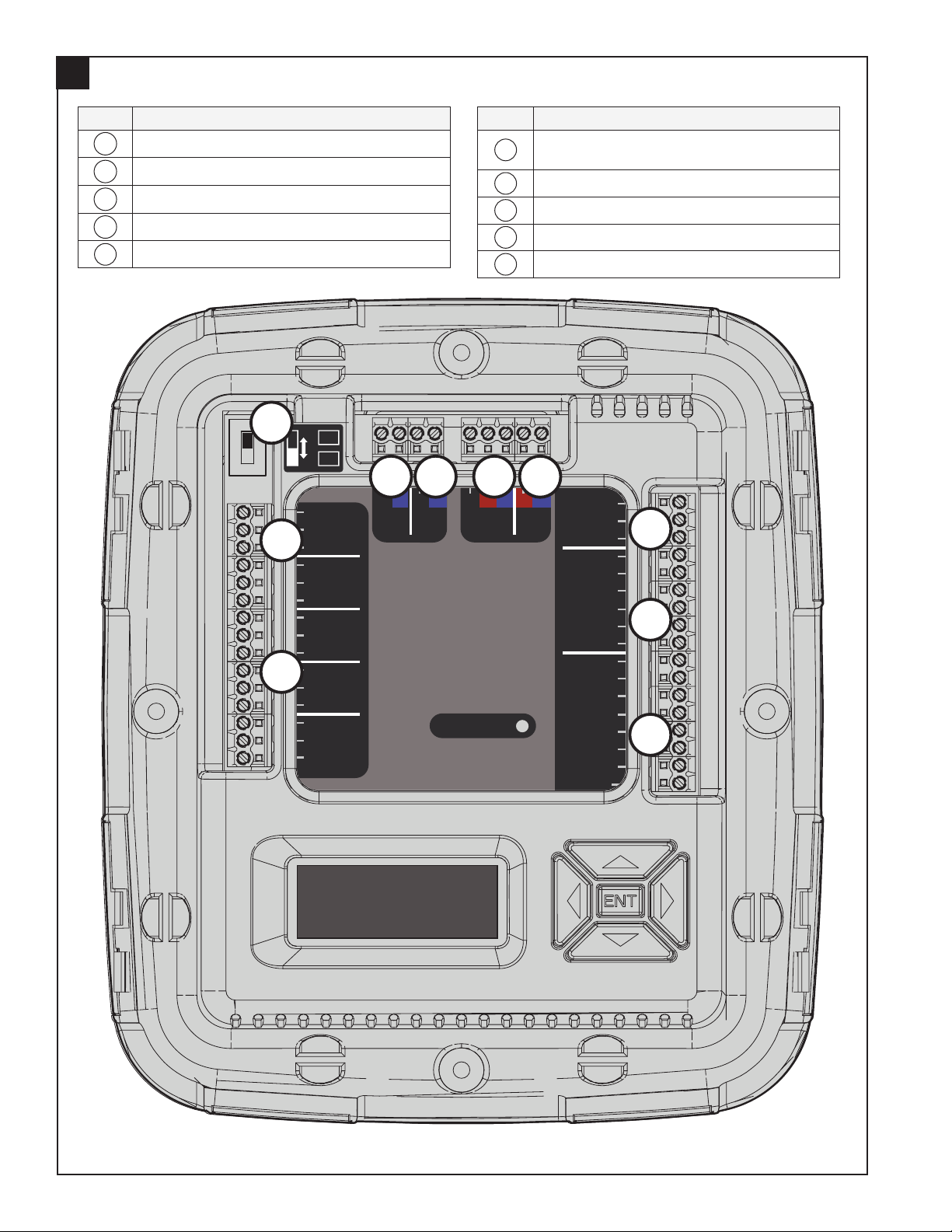

Observe Terminal Locations

2

KEY Identification

A

B

C

D

E

Primary Panel or Secondary Panel

From Indoor Unit or Relay Panel

To Communicating Outdoor Unit

Zone Dampers

Reserved

C

B

KEY Identification

F

G

H

I

J

D E F G

Communicating Zone Sensors / 2nd Zone

Panel

Dedicated 24V Transformer

Static Pressure Sensors

Temperature Sensors

Non-Communicating Zone Sensors

H

I

A

J

8 18-HD66D1-4

Page 9

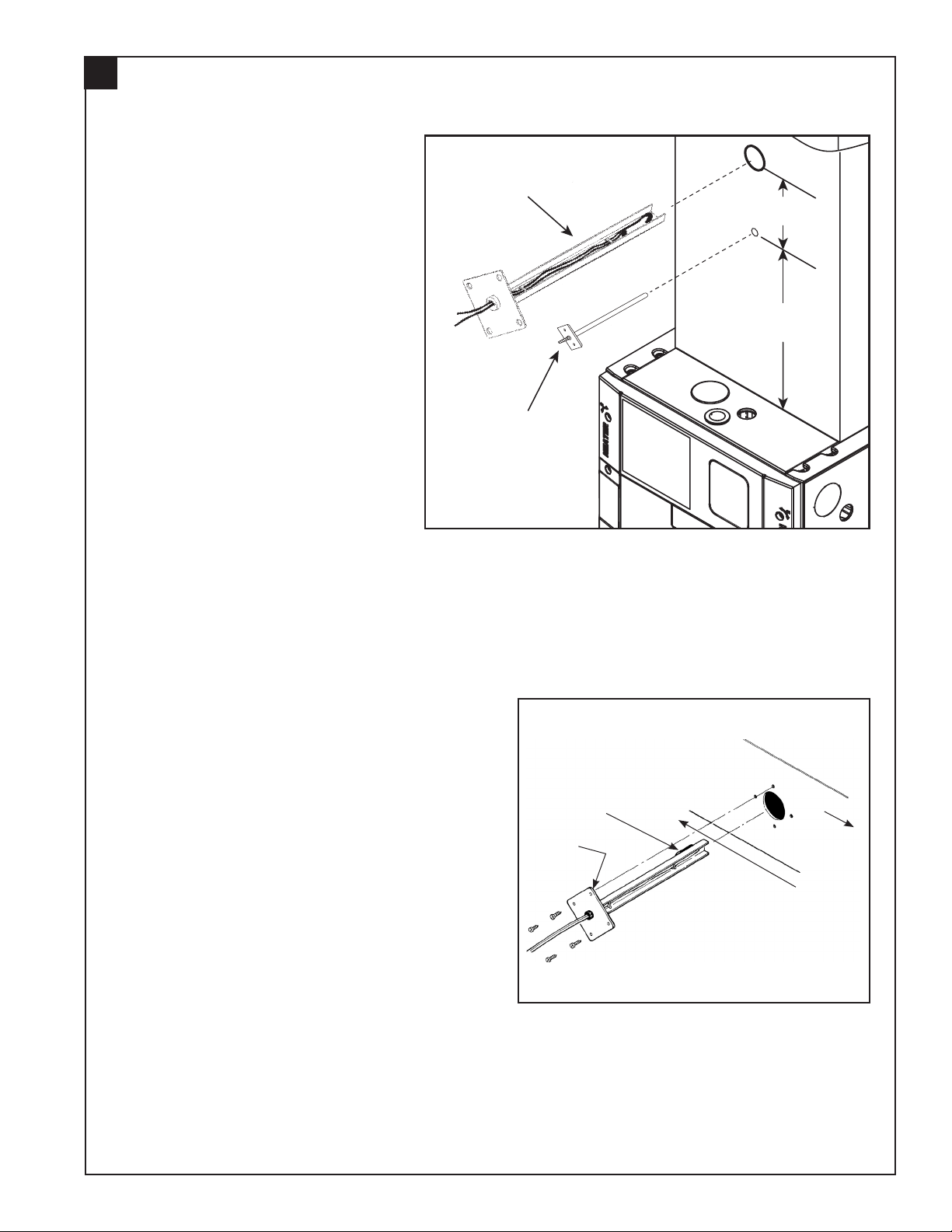

Mount Discharge Temperature Sensor

Discharge

Temp

Sensor

6” Min.

2” Min.

Static

Pressure

Probe

(Supply)

3

REQUIRED: A Discharge

Temperature Sensor is required.

The Discharge Temperature

Sensor (DTS) must be mounted

a minimum of 8” above the edge

of the supply duct (additional

distance is preferred when

possible). In addition, the

DTS must be 2” above the

Static Pressure Probe if used.

Locate the DTS in an area of

the discharge air duct where

less air turbulence is expected.

Avoid dead air areas where

representative discharge air

temperatures may not exist.

OPTIONAL: A return air sensor

(SEN 00462) may be installed to

monitor the return air temperature

at the indoor unit. The mixed

air sensor (SEN 00462) is used

to monitor mix air when using

bypass (future use).

Determine the proper positioning of the DTS as

follows:

• If a radiant heat source such as an electric

Drill a hole for mounting the DTS. A minimum hole

size of 7/8” will be required.

The mounting plate can be used as a template to

locate the four screw holes.

9

heater is in line of sight from the thermistor,

position the sensor so that the black thermistor

faces away from the radiant heat source. (This

will prevent a false reading due to the radiant

effect on the thermistor.)

Thermistor

Apply

Sealant

Airflow

Radiant

Heat

Source

Page 10

Discharge

Temp

Sensor

6” Min.

2” Min.

6” Min.

Static

Pressure

Probe

(Supply)

Static

Pressure

Probe

(Return)

Mount Supply Air and Return Air Static Pressure Probes

4

OPTIONAL: Static Pressure probes

are only required when using Auto Zone

Sizing.

The supply static pressure sensor must

be mounted a minimum of 6” above the

unit cabinet and the return probe must

be mounted a minimum of 6” below the

unit cabinet. Additional distance from

the cabinet is preferred when possible.

Mount the probes in a central area

of duct away from turns, transitions,

take offs or other areas of potential

turbulence.

Drill a hole of 1/4” minimum to accept

the Static Pressure probes.

Insert and mount the sensor as

shown. Insulate the sensor to prevent

condensation.

NOTE: The static probes are used for

Automatic Zone Sizing and are placed

outside the Coil and Electronic Air

Cleaner (if used). The static pressure

reading references external duct static;

not the overall system static imposed

upon the blower motor.

10 18-HD66D1-4

Page 11

Mount Static Pressure Transducer Enclosure

5

Mount the Static Pressure Transducer Enclosure

in an area between the two static probes. The

location should be easily accessible, and in a

position where the tubing can reach both static

pressure probes.

Connect Static Pressure Tubing

6

NOTE: Cut tubing to the proper length for the

supply and return static pressure probes.

Attach the tubing to each of the static pressure

probes and route the tubing back to the enclosure.

Support the tubing to eliminate any kinks. Slide

the return & supply tubing through the hole in the

enclosure.

Attach the tubing to the Pressure Transducer.

The tube from the supply duct will go on the bottom

barb of the transducer.

The tube from the return duct will go on the top

barb of the transducer (the top barb is marked with

a “–” sign).

Install a tubing clamp on each of the Static

Pressure Transducer tubing connectors.

Mount the Pressure Transducer inside the

enclosure using the two screws as shown.

Ensure the tubing is properly supported and not

kinked in any location.

Note: Tubing must be connected as

shown for proper operation

return

tubing

supply

tubing

tubing

clamp

Route wiring through hole in enclosure.

Attach the tubing to the static pressure probes

using the remaining tube clamps.

11

Page 12

7

Sensors

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

24V

Trans.

R

BD D

Sensors

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

24V

Trans.

R

BD D

Connect Temperature Sensor Wires

Connect the required Discharge Air Temperature

Sensor wires to the terminals marked “Discharge

Air” as shown at right. Use a dedicated wire

bundle.

REQUIRED

Terminal

Name

Temperature Sensors

Description Color Used:

OPTIONAL

Discharge Air Discharge Air Sensor

Discharge Air Discharge Air Sensor

Return Air

Return Air

Mixed Air

Mixed Air

Optional Return Air Sensor

Optional Return Air Sensor

Optional Mixed Air Sensor

Optional Mixed Air Sensor

OPTIONAL: If using Return Air or Mixed Air temperature sensors, connect their wires to “Return Air” or

“Mixed Air” respectively.

NOTE: Wiring for all temperature sensors must be run in bundles separate from other 24 VAC circuits.

Connect Static Pressure Transducer Wires

8

Connect the Green wire from the Static Pressure

transducer to the terminal labeled “Gnd/Grn.”

Connect the Black wire from the Static Pressure

transducer to the terminal labeled “Signal/Blk.”

Connect the Red wire from the Static Pressure

transducer to the terminal labeled “+5V/Red.”

Place the cover on the Pressure Transducer

Enclosure once the tubing is attached and wiring is

complete.

Terminal

Name

Gnd/Grn Ground

Signal/Blk Output Signal (5VDC)

+5V/Red Power (5VDC)

NOTE: Wiring for the pressure sensor must be run in bundles separate from other 24 VAC circuits.

12 18-HD66D1-4

Static Pressure Sensor

Description Color Used:

Page 13

Connect Communicating Indoor Unit/Relay Panel

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

R

BDB

B

R

BD D

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

R

BDB

B

R

BD D

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

R

BDB

B

R

BD D

9

Connect the Indoor Unit or Relay Panel B and D

low voltage wiring to the Zone Panel’s “Indoor/

Relay Panel” B and D terminals.

Indoor Unit or Relay Panel Connections

Terminal

Name

Description Color Used:

D Data

B Common

NOTE: R from the Indoor Unit/Relay Panel is not

connected because power is provided from a field

supplied 24VAC transformer.

Connect Wiring to Communicating Outdoor Unit

10

The Zone Panel provides an optional low voltage

connection point for a communicating outdoor unit.

The communicating outdoor requires B and D from

one location; this can either be from the indoor unit

or the Zone Panel.

NOTE: If a non-communicating outdoor unit is

installed, these connections will not be used.

Outdoor Unit Connections

Terminal

Name

Description Color Used:

D Data

B Common

Connect Wiring to Communicating Zone Sensors and 2nd Zone Panel (if used)

11

Connect wiring (D, R, B) between each Communicating Zone

Sensor using the provided clamp-style wire connectors. If

required, a 2nd Zone Panel can also be connected.

13

Power Supply Connections

Terminal

Name

Description Color Used:

D Data

R 24V Hot

B Common

See Communicating Zone Sensor Installer’s Guide for setup information

Page 14

Mount the Zone Panel 24V Power Supply

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

R

BDB

B

R

BD D

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone

1 or 5

ZONES

1 - 4

5 - 8

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BDB

B

R

BD D

12

A separate, field-supplied 24 volt transformer is required

to power the Zone Panel, communicating sensors

and dampers. VA sizing of the transformer will be

dependant on the total VA of all installed zone panels,

communicating sensors and zone dampers. Connect this

dedicated 24 volt source to the R and B terminals.

NOTE: To prevent possible communication errors,

connect the B/common of the field-supplied Zone Panel

transformer to the indoor unit B/common or equipment

ground.

EXAMPLE:

Transformer Sizing Example (8 Zone System, 1 Damper per Zone)

Component Qty VA (ea) Total VA

Zone Panel 2 2 4

Zone Dampers* 8 1.5 12

Communicating

Sensor

4 2 8

Minimum Transformer VA Required 24

*Add the VA of each communicating sensor

Power Supply Connections

Terminal

Name

Description Color Used:

R 24V Hot

B Common

Connect the Dampers

13

The dampers will have the same terminal

designation as the Zone Panel.

Zone Dampers

For each damper:

• Connect Common from the damper to

Common on the Zone Panel.

• Connect PO/Open from the damper to

PO/Open on the Zone Panel.

• Connect PC/Close from the damper to

PC/Close on the Zone panel.

Repeat this for each damper installed (see

the damper installer’s guide).

14 18-HD66D1-4

Terminal Name Description Color Used:

Reserved Common

Reserved Power Open

Reserved Power Close

Common Common

PO/Open Power Open

or 5*

Zone 1

PC/Close Power Close

Common Common

PO/Open Power Open

or 6*

Zone 2

PC/Close Power Close

Common Common

PO/Open Power Open

or 7*

Zone 3

PC/Close Power Close

Common Common

PO/Open Power Open

of 8*

Zone 4

PC/Close Power Close

* Zones 5–8 are only when a second zone panel is used.

NOTES:

• 60 second drive dampers are the default. 15-60 second dampers

can be used, timing must be set at the 950/1050 Control.

• Up to 4 dampers may be used per zone (6 VA Max.).

• Mixing dampers from multiple manufacturers in the same zone is

not permitted.

Page 15

Connect Non-Communicating Zone Temperature Sensors

Sensors

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

24V

Trans.

R

BD D

Reserved

Gnd/Grn

Signal/Blk

ZONES

1 - 4

5 - 8

Indoor/

Relay Panel

Comm

Comm Zone Sensor/

2nd Zone Panel

24V

R

BDB

B

R

BD D

14

If using non-communicating zone temperature sensors, connect them to the non-communicating

zone terminal block. These are two wire sensors and are not polarity sensitive. Attach each

sensor to its respective zone.

NOTE: When using communicating zone sensors, the non-communicating indoor terminal block

will not be used.

IMPORTANT: If using the 950/1050 Control as Zone 1, do not connect a non-communicating

zone sensor to Zone 1 slot.

NOTE: The 1050 will always be addressed as Zone 1. If using a remote sensor it will need

configured and wired directly to the 950/1050

subbase. The 940 can also be used as a remote

sensor for Zone 1 if it is tied into R, D, B and

addressed as Zone 1.

Non-Communicating Indoor Temperature Sensors

Terminal

Name

Zone 1

Zone 1

Zone 2

Zone 2

Zone 3

Zone 3

Zone 4

Zone 4

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Non-Communicating Zone Temp Sensor

Description

Color

Used:

15

Zone Switch Position

Set the Zone Switch to the up position if only one zone

panel is used (4 zones or less).

If two panels are used (5 or more zones), the zone

switch must be moved down on the second zone panel

(the panel that is controlling zones 5 through 8).

NOTE: If the Zone Switch position is changed after

power has been applied, an additional Zone Panel will

be created. Use the Summary Screen in the 950/1050

Control to remove the offline device.

15

Page 16

Section 4. Zoning Setup

Required Steps before enabling zoning:

1) Zone Panel must be powered (24VAC transformer)

2) Zone Panel must be connected to communicating bus (D, B)

3) All non-communicating zone temperature sensors must be connected to corresponding zone slots

4) All communicating zone temperature sensors must be addressed to corresponding zone number

5) All dampers should be installed and connected to corresponding zone slot

6) Discharge Temperature Sensor must be connected

7) Install and wire Differential Static Pressure Sensor and probes (only required for Auto Zone Sizing)

STEP 1 - Enable Zoning

Enter the Installer Setup section on the 950/1050

Control:

Home screen --> Menu --> Service --> Technician

Access* --> Proceed --> Installer Setup

Move through the Standard Installation Set Up

options and Enable Zoning on the first screen of

Group 2.

Important: Must use a Trane/American

Standard manufactured indoor unit with a

variable speed blower. If a TAM9, TEM8, or TAM8

air handler is being used, verify the Airflow

Mode selected on the air handler CDA or 7

segment display is set to Constant CFM.

STEP 2 - Damper Travel Time

Select the travel time that matches the dampers.

NOTE: Trane and American Standard dampers

use a 60 second travel time.

NOTE: The zone control can handle many types of

dampers, but all dampers in the system must have

the same drive time (15 to 60 seconds) and must

be power open/power close. Spring controlled

dampers are not allowed. See the damper

installation guide for additional information.

STEP 3 - Auto Detect Dampers

The zone control will send out a signal to open and

close the dampers when “Yes” is selected. The

control will see the load on each damper slot and

automatically configure the number of zones with

dampers detected.

STEP 4 - Manually Detect Dampers

The dampers will be automatically checked if auto

damper detection was selected.

The technician will need to manually select the

appropriate dampers if auto damper detection is

not used.

16 18-HD66D1-4

Page 17

STEP 5 - Auto Zone Sizing

The zone control has the ability to energize the

blower and modulate dampers to determine how

much air each zone can handle. The Static

Pressure kit is required to use Auto Zone Sizing.

NOTE: All zones less than 25% cannot be a

voting zone (See STEP 7). Press “Yes” to accept

or press “No” to change the size of the zone.

STEP 6 - Zone Size Adjustment

Auto zone sizing will calculate the amount of air that the

ductwork for each zone can handle. There are three

available options:

• The Normal mode calculates zone sizes based on an

average external duct static

• The Less Aggressive option calculates on a lower

external duct static and will deliver a reduced amount

of air into each calling zone. This strategy provides a

quieter air flow system, but increases the amount of

excess air that must be managed. This may increase

the amount of excess air that is relieved into other zones.

• The More Aggressive option calculates on a higher external duct static and will deliver an increased

amount of air into each calling zone. This strategy may produce a noisier air flow system, but reduces the

amount of excess air that must be managed. This may reduce the amount of excess air that is relieved

into other zones.

It is recommended to begin with the Normal mode. You can re-run auto zone sizing with Less Aggressive if

a customer is concerned about air noise, or at More Aggressive if a customer is concerned about relief air or

simply desires higher velocity air flow rates.

NOTE: Auto Zone Sizing typically takes 10 to

15 minutes for 2 – 4 zone systems and up to 30

minutes for 5 – 8 zone systems.

If Auto Zone Sizing returns an error, follow the onscreen prompts for diagnosing the failure.

The auto zone sizing process calculates and

displays the size of each zone. The technician can

select and modify any zone setting to satisfy the

homeowners air flow desires.

17

Page 18

Damper

Diameter

Damper

Diameter

Damper

Diameter

Damper

Diameter

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Damper

Diameter

Damper

Diameter

CFM CFM

Damper

Diameter

Damper

Diameter

CFM CFM

500 600 700 800

4" 9% 12% 16% 4" 7% 10% 13% 4" 6% 9% 11% 4" 6% 8% 10%

6" 19% 27% 35% 6" 16% 23% 29% 6" 14% 19% 25% 6" 12% 17% 22%

7" 26% 36% 46% 7" 22% 30% 38% 7" 19% 26% 33% 7" 16% 23% 29%

8" 34% 48% 62% 8" 29% 40% 52% 8" 25% 34% 44% 8" 22% 30% 39%

9" 44% 61% 79% 9" 36% 51% 66% 9" 31% 44% 56% 9" 27% 38% 49%

10" 54% 78% 98% 10" 45% 65% 82% 10" 39% 56% 70% 10" 34% 49% 61%

12" 79% 100% 100% 12" 66% 87% 117% 12" 56% 74% 100% 12" 49% 65% 88%

14" 100% 100% 100% 14" 87% 100% 100% 14" 74% 100% 100% 14" 65% 94% 100%

16" 100%

100% 100% 16" 100% 100% 100% 16" 99% 100% 100% 16" 86% 100% 100%

18" 100% 100% 100% 18" 100% 100% 100% 18" 100% 100% 100% 18" 100% 100% 100%

Damper

Diameter

Damper

Diameter

Damper

Diameter

Damper

Diameter

Damper

Diameter

CF

M CFM

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM CFM

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM CFM

Damper

Diameter

CFM

900 1000 1100

1200

4" 5% 7% 9% 4" 4% 6% 8% 4" 4% 5% 7% 4" 4% 5% 7%

6" 11% 15% 19% 6" 10% 14% 18% 6" 9% 12% 16% 6" 8% 11% 15%

7" 14% 20% 26% 7" 13% 18% 23% 7" 12% 16% 21% 7" 11% 15% 19%

8" 19% 27% 34% 8" 17% 24% 31% 8" 16% 22% 28% 8" 14% 20% 26%

9" 24% 34% 44% 9" 22% 31% 40% 9" 20% 28% 36% 9" 18% 25% 33%

10" 30% 43% 54% 10" 27% 39% 49% 10" 25% 35% 45% 10" 23% 33% 41%

12" 44% 58% 78% 12" 40% 52% 70% 12" 36% 47% 64%

12"

33%

43%

58%

14" 58% 84% 100% 14" 52% 76% 96% 14" 47% 69% 87% 14" 43% 63% 80%

16" 77% 100% 100% 16" 69% 98% 100% 16" 63% 89% 100%

16"

58%

81%

100%

18" 100% 100% 100% 18" 90% 100% 100% 18" 82% 100% 100% 18" 75% 100% 100%

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM CFM

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM

Damper

Diameter

Damper

Diameter

CFM

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

CFM

Damper

Diameter

Damper

Diameter

CFM CFM

Damper

Diameter

Damper

Diameter

1300 1400 1500

CFM

1600

4" 3% 5% 6% 4" 3% 4% 6% 4" 3% 4% 5% 4" 3% 4% 5%

6" 7% 10% 13% 6" 7% 10% 13% 6" 6% 9% 12% 6" 6% 8% 11%

7" 10% 14% 18% 7" 9% 13% 16% 7" 9% 12% 15% 7" 8% 11% 14%

8" 13% 18% 24% 8" 12% 17% 22% 8" 11% 16% 21% 8" 11% 15% 19%

9" 17% 23% 30% 9" 16% 22% 28% 9" 15% 20% 26% 9" 14% 19% 25%

10" 21% 30% 38% 10" 19% 28% 35% 10" 18% 26% 33% 10" 17% 24% 31%

12" 30% 40% 54% 12" 28% 37% 50% 12" 26% 35% 47% 12" 25% 33% 44%

14" 40% 58% 73% 14" 37% 54% 68% 14" 35% 50% 64% 14" 33% 47% 60%

16"

53% 75% 96% 16" 49% 70% 89% 16" 46% 65% 83% 16" 43% 61% 78%

18" 69% 96% 100% 18" 64% 89% 100% 18" 60% 83% 100% 18" 56% 78% 100%

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM

Damper

Diameter

Damper

Diameter

CFM CFM

Damper

Diameter

Damper

Diameter

Damper

Diameter

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Less Aggressive

Normal

More Aggressive

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM CFM cfm

Damper

Diameter

CFM

1800 1900 2000 2200

4" 2% 3% 4% 4" 2% 3% 4% 4" 2% 3% 4% 4" 2% 3% 4%

6" 5% 8% 10% 6" 5% 7% 9% 6" 5% 7% 9% 6" 4% 6% 8%

7" 7% 10% 13% 7" 7% 9% 12% 7" 7% 9% 12% 7" 6% 8% 10%

8" 10% 13% 17% 8" 9% 13% 16% 8" 9% 12% 16% 8" 8% 11% 14%

9" 12% 17% 22% 9" 11% 16% 21% 9" 11% 15% 20% 9" 10% 14% 18%

10" 15% 22% 27% 10" 14% 21% 26% 10" 14% 20% 25% 10" 12% 18% 22%

12" 22% 29% 39% 12" 21% 27% 37% 12" 20% 26% 35% 12" 18% 24% 32%

14" 29% 42% 53% 14" 27% 40% 50% 14" 26% 38% 48% 14" 24% 34% 43%

16" 38%

54% 69% 16" 36% 51% 66% 16" 35% 49% 63% 16" 31% 44% 57%

18" 50% 69% 89% 18" 47% 66% 84% 18" 45% 63% 80% 18" 41% 57% 73%

Damper

Diameter

Damper

Diameter

Damper

Diameter

CFM CFM cfm

Damper

Diameter

CFM

MANUAL ZONE SIZING

Auto Zone Sizing is the optimal way to determine the amount of air flow into each zone, but this process is not

mandatory. Zone sizes can be set manually using the following guidelines.

EXAMPLE (highlighted below): A 2-zone, 3-ton AC system is configured to move 1200 CFM. Zone 1 has a

12” zone damper and Zone 2 has a 16” zone damper.

The Normal sizing strategy would set Zone 1 at 43% and Zone 2 at 81%. If Zone 1 had two dampers (6” and

10”) the zone size % should be added together (11% & 33%) and set to 44%.

18 18-HD66D1-4

Page 19

ZONE SIZING EXAMPLE:

The zone size has a direct impact on system operation and homeowner comfort. The system uses zone sizes

to determine the air handling capability of each zone and determines the amount of excess air that has to be

managed. Incorrect zone sizes will undermine the performance and comfort levels within the space.

NOTE:

For zoning, the duct system should be sized to handle the peak load of each zone. Therefore, the duct system

is typically sized larger than a conventional non-zoned application.

EXAMPLE:

A 4-zone system is installed on a two compressor system. Each zone can handle 40% of the system air flow.

All zones are set to off at the . The homeowner now turns one zone to cool and lowers the setting to 5 degrees

below the current temperature. Since this zone can handle a maximum of 40% of the system capacity, the zone

control will lock the system in first stage operation. There is no reason to move to second stage operation

since all the additional air flow and capacity would be forced into non-calling zones.

The system would be allowed to energize second stage if another zone is calling. The total zone size would

now be 80% and first stage operation may not be enough to satisfy this demand.

• On a two compressor system, the sum of the calling zone sizes must be at least 51% to enable second

stage operation.

• On a single compressor, two stage system, the sum of the calling zone sizes must be at least 68% to

enable second stage operation.

• On a two stage furnace, the sum of the calling zone sizes must be at least 66% to enable second stage

operation.

• On a three stage furnace, the sum of the calling zone sizes must be at least 41% to enable second stage

operation. Third stage is not inhibited.

STEP 7 - Voting Zones

A voting zone has the ability to turn on the HVAC

system.

A non-voting zone has the ability to control the

damper, but does not have the ability to turn on

the system. A non-voting zone cannot keep the

system running if all voting zones are satisfied.

19

Page 20

EXAMPLE:

A home has a 5-ton single stage AC system with

3 zones. Zone #1 is a 6 inch duct that feeds

the laundry room. Since this zone is sized less

than 25%, the zone is forced to non-voting and

should not be allowed to energize the equipment.

However, it should be allowed to control the

temperature in the zone when another voting zone

brings on the equipment.

All zones less than 25% cannot be a voting zone.

Press “Yes” to accept or press “No” to change the

size of the zone.

Zone 1 has been removed as a voting zone since

it was sized less than 25%.

20 18-HD66D1-4

Page 21

STEP 8 - Indoor Heating Airflow Offset%

The air flow offset is the difference between

cooling and indoor heating (fossil/electric) air

flow. The control uses this offset to calculate and

manage excess air.

EXAMPLE:

The system is a 3-ton AC configured at 1200 CFM.

The furnace is configured to move 960 CFM.

The heating air flow offset is 960 / 1200 or a

reduction of 20%. Configure the control at -20%.

STEP 9 - Discharge Temperature Limit

If the discharge temperature exceeds the max/min

limits the following occurs:

• Heating/cooling operation is defeated

• Indoor blower is cycled ON (VS blower runs at

continuous fan speed)

• All supply dampers are driven full open

NOTE: Discharge Temperature Limit trips will

create an alert (SOP.004.56) and heating/cooling

operation is temporarily defeated. Once the

discharge temperature is within max/min limits

and the minimum off times has elapsed, zoning

operation will resume and the alert will clear.

Discharge Temperature Limit Table

Mode Normal Extended

Cooling 38 34 5

Compressor Heating

Only

Compressor Heating w/

Electric Heat or Electric

Heat Only

Compressor Heating w/

Hydronic Heat

Gas Furnace Heating 135 145 3

Oil Furnace Heating 160 170 3

116 128 5

160 170 5

135 145 5

Min OFF

Time

STEP 10 - Exiting Zoning Setup

After saving the zoning settings a pop-up

message will appear prompting the technician to

associate temperature sensors to all zones before

proceeding. If “Yes” is selected, the Zone Sensors

screen will appear. If “No” is selected, the pop-up

message will disappear and the technician can

continue configuring the settings.

NOTE: All zones must have a temperature sensor

assigned before exiting the Service Menu.

21

Page 22

Section 5. Zone Sensor Setup

The Zone Sensors Screen is used to associate

temperature sensors with zones. The Zone Sensor

Setup Screen is compromised of two sections:

Select Zone/Damper and Available Sensors.

STEP 1 - Select Zone/Damper

All enabled zones will be displayed in the left

column of the Zone Sensor Setup. Select the zone

to which a sensor will be assigned by touching it on

the display screen.

Note: The onboard sensor of the 950/1050 control

is automatically assigned to Zone 1. All other zones

sensors must be manually assigned.

STEP 2: Select an Available Sensor

Available zone sensors are displayed in the right

column. Select a sensor by touching the sensor

listed. A green mark will indicate the sensor has

been selected.

Note:

Communicating Sensors are displayed only if

they are addressed the same as the selected

zone.

Non-Communicating Sensors are displayed only

if they are wired to the corresponding zone slot.

STEP 3 - Confirm the Assignment

Confirm the assignment of the selected sensor to

the selected zone by pressing the “Assign” button.

22 18-HD66D1-4

Page 23

STEP 4 - Assign Remaining Sensors

Repeat Steps 1-3 until all zones have been

assigned a sensor.

STEP 5 - Exit Sensor Setup

When all zones have been assigned a sensor,

press “Done.”

Note: All zones must be assigned a temperature

sensor before exiting the Service Menu.

23

Page 24

Section 6. Damper Test Mode

Damper Test Mode gives the user the ability to open specific dampers to verify the dampers are performing

properly. Each damper can be driven independently or in any combination. The blower will operate during an

active damper test. The blower speed is determined by the sum of the Zone Size’s of each damper selected to

be tested. Damper Test Mode will automatically time out after 30 minutes or immediately if you press and hold

the screen.

Upon entering Damper Test Mode, all system operation will stop and each damper will be driven full open.

Once a damper(s) is selected for test, the non-selected dampers will be driven fully closed.

Example (testing Zones 1 and 4):

• 4 Zone System

• Zone 1 = 25%, Zone 2 = 40%, Zone 3 = 25%,

Zone 4 = 50%

Select Zone 1 and Zone 4. Press “Test” and

confirm you want to run the test by pressing “Yes”.

The dampers for Zone 1 and Zone 4 will remain

full open and dampers for Zone 2 and Zone 3 will

drive closed. The indoor blower speed will be

75%.

Zone 1 (25%) + Zone 4 (50%) = 75%

Press and hold to stop system test.

Wait while the dampers are being reset. A 60

second timer will run before any additional testing

can be completed.

24 18-HD66D1-4

Page 25

Section 7. User Interface

Standard Menu Tree

(Zoning Enabled)

SYSTEM STATUS

HEATING STG=NONE

CFM=000%

DSP=0.30

SYSTEM STATUS

CFM=000%

DSP=0.30

SUPPLY AIR=063*

SYSTEM STATUS

DSP=0.30

SUPPLY AIR=063*

RETURN AIR=OPN

SYSTEM STATUS

SUPPLY AIR=063*

RETURN AIR=OPN

DELTA(SA-RA)OPN

SYSTEM STATUS

RETURN AIR=OPN

DELTA(SA-RA)OPN

MIXED AIR=OPN

Initial Power Up

****************

ACQUIRING

DATA

****************

Before Zoning Enabled

ZONING DISABLED

---------------SEE MAIN CONTROL

FOR DETAILS

SYSTEM STATUS

DELTA(SA-RA)OPN

MIXED AIR=OPN

BYPASS=000%

ZONES

[ more menus ]

INFORMATION

[ more menus ]

ZONE STATUS

ZONE=1 SIZE=051%

MODE=OFF

ACTIVE CALL=NO

ZONE STATUS

MODE=OFF

ACTIVE CALL=NO

DAMPER=100%

ZONE STATUS

ACTIVE CALL=NO

DAMPER=100%

RELIEVING=NO

MODEL NUMBER

ZZONEPNLAC52ZAA

SERIAL NUMBER

1000WE0001

ZONE STATUS

ZONE=8 SIZE=051%

MODE=OFF

ACTIVE CALL=NO

ZONE STATUS

MODE=OFF

ACTIVE CALL=NO

8 ZONES

SOFTWARE INFO

VERSION=001

BUILD=1234567890

DAMPER=100%

ZONE STATUS

ACTIVE CALL=NO

DAMPER=100%

RELIEVING=NO

25

Page 26

Section 8. Control Board Test Points

ZONES

1 - 4

5 - 8

Zone Dampers

Sensors

Reserved

Reserved

Reserved

Static Press

Gnd/Grn

Signal/Blk

+5V/Red

TemperatureNon Comm Zone Sensor

Discharge Air

Discharge Air

Return Air

Return Air

Mixed Air

Mixed Air

Zone 1 or 5

Zone 1 or 5

Zone 2 or 6

Zone 2 or 6

Zone 3 or 7

Zone 3 or 7

Zone 4 or 8

Zone 4 or 8

Zone

1 or 5

ZONES

1 - 4

5 - 8

Indoor/

Relay Panel

Comm

Outdoor

Comm Zone Sensor/

2nd Zone Panel

24V

Trans.

Common

PO/Open

PC/Closed

Zone

2 or 6

Common

PO/Open

PC/Closed

Zone

3 or 7

Common

PO/Open

PC/Closed

Zone

4 or 8

Common

PO/Open

PC/Closed

Comm

R

BDB

BRBD D

SEE

TABLE 1

SEE

TABLE 2

SEE

TABLE 3

SEE

TABLE 4

SEE

TABLE 6

SEE TABLE 5

* See Note

TABLE 1

Zone Dampers

Terminals Volts (AC) Status

26 18-HD66D1-4

Common & PO/Open 24 Damper drive open

Common & PO/Open 0 Damper not being driven

Common & PC/Close 24 Damper drive closed

Common & PC/Close 0 Damper not being driven

System Connections

Terminals Volts (DC)

D & B 12 Good Communication

D & B 16 No Communication

D & B 0 Grounded or no power

* Status LED (non-functional) may be present on early production models.

TABLE 2

Communication

Status

TABLE 3

Power from Transformer

Terminals Volts (AC) Status

R & B 18 – 30 Good

R & B < 18 Low voltage

R & B 0 No voltage

Page 27

TABLE 4

Static Pressure Sensors

Pressure (In WC)

0.08 0.4

0.11 0.45

0.16 0.55

0.21 0.65

0.27 0.75

0.32 0.85

0.37 0.95

0.43 1.05

0.48 1.15

0.53 1.25

0.59 1.35

0.64 1.45

0.69 1.55

0.75 1.65

0.80 1.75

0.85 1.85

0.91 1.95

0.96 2.05

1.01 2.15

1.07 2.25

1.12 2.35

1.17 2.45

1.25 2.6

Volts (DC)

Measured G to Blk

TABLE 6

Non-Communicating & Return Air Sensors

TEMP

(deg. F)

100 37.8 5815 2.07

95 35.0 6527 2.21

90 32.2 7331 2.35

85 29.5 8248 2.50

80 26.7 9279 2.65

75 23.9 10497 2.80

70 21.1 11868 2.95

65 18.4 13455 3.10

60 15.6 15276 3.25

55 12.8 17430 3.39

50 10.1 19851 3.53

45 7.3 22710 3.67

40 4.5 26051 3.80

35 1.7 29994 3.92

30 -1.0 34446 4.03

25 -3.9 39909 4.14

20 -6.6 46134 4.24

TEMP

(deg. C)

Sensor Resistance

(Ohms)

Volts

(DC)

TABLE 5

Discharge/Mixed Air Temperature Sensors

TEMP

(deg. F)

200 93.4 829 0.41

195 90.8 895 0.44

190 87.8 982 0.48

185 85.1 1070 0.52

180 82.2 1170 0.56

175 79.7 1272 0.60

170 76.8 1397 0.65

165 73.9 1536 0.71

160 71.3 1678 0.76

155 68.5 1847 0.83

150 65.7 2033 0.90

145 62.8 2250 0.97

140 60.0 2489 1.05

135 57.3 2750 1.14

130 54.5 3037 1.23

125 51.8 3368 1.33

120 49.0 3749 1.44

115 46.2 4169 1.55

110 43.4 4654 1.67

105 40.6 5193 1.79

100 37.8 5819 1.92

95 35.0 6523 2.06

90 32.3 7322 2.20

85 29.5 8233 2.35

80 26.7 9282 2.50

75 23.9 10501 2.65

70 21.2 11849 2.80

65 18.4 13442 2.95

60 15.6 15294 3.11

55 12.8 17408 3.26

50 10.1 19842 3.40

45 7.2 22764 3.55

40 4.4 26104 3.69

35 1.7 29936 3.81

30 -1.1 34520 3.94

25 -3.9 39869 4.05

20 -6.6 46134 4.16

TEMP

(deg. C)

Sensor Resistance

(Ohms)

Volts

(DC)

27

Page 28

Section 9. Troubleshooting

Troubleshooting

Symptom Possible Cause Action

Check for proper incoming 24VAC power at

Zone Panel 24v Trans terminals

Access the Summary Table on the 950/1050

Control to view the communication status of all

discovered communicating devices.

Troubleshoot the offline device utilizing the units

service facts

Fix/replace the communicating device which is

causing the excessive communication traffic

Check for open or grounded field wiring

An Err 126 may be displayed on comfort control

On the control, enable zoning in the Installer

Setup > Standard settings

On the control, check for critical/major alerts in

Diagnostic > Current Alerts

Set dip switch of primary Zone Panel to Zones

1-4

COMM LED is not

flashing the appropriate number

of devices

COMM LED is

flashing rapidly

COMM LED is

steady “ON”

Zoning Disabled

is displayed on the

Zone Panel user

interface

Loss of 24VAC between power (R) and common (B)

One or more communicating devices is not communicating

• ~12VDC between D & B = Proper communication

• ~16VDC between D & B = Loss of communication

• Less than ~12VDC between D & B = grounded or no power

Note: Voltage may fluctuate while devices are transmitting on the

communication bus

One or more communicating devices has corrupted

the communication traffic

• ~12VDC between D & B = Proper communication

• ~16VDC between D & B = Loss of communication

Zone Panel is not communicating

• ~16VDC between D & B = Loss of communication

Zoning has not been enabled on the Comfort

Control

Zoning has been disabled due to a system fault

Primary Zone Panel dip switch is set to Zones 5-8

Damper is open

when damper

should be closed

Damper is closed

when damper

should be open

Damper not wired correctly

Verify damper wiring is connected and has not

been reversed

Damper actuator has failed Replace damper actuator

Damper blade is stuck/broke Replace the damper assembly

Damper not wired correctly

Verify damper wiring is connected and has not

been reversed

Damper actuator has failed Replace damper actuator

Damper blade is stuck/broke Replace the damper assembly

6200 Troup Highway

Tyler, TX 75707

© Trane U.S. Inc. 2017

The manufacturer has a policy of continuous product and product data improvement

and reserves the right to change design and specifications without notice.

Representative-only illustrations included in this document.

28 18-HD66D1-4

Loading...

Loading...