Trane YSD 155F, YHD 155F, YSH 155F, YHH 155F, YSD 180F Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Packaged Rooftop Air Conditioners

Voyager™

– Gas/ Electric

12½ – 25 Tons, 60/50Hz

Model Number:

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all pre cautions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

May 2014

YS*150–300

YH*150-300

SAFETY WARNING

RT-SVX26K-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert

installing contractors to potential hazards that could result

in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while not ices indicate a situation that may

result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may af fect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. T rane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servi cin g th is un it, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut r esistant glov es/sleev es,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When workin g with or around hazardous c hemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of ener gized electrical contact, ar c, or

flash, technicians MUS T put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, y ou MUST follo w requir ements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

WARNING

© 2014 Trane All rights reserved RT-SVX26K-EN

Page 3

NOTICE:

Water Damage!

Non-factory penetrations through the base of this unit

are not allowed. Any penetration in the base of the unit

may aff ect the water tight integrity of the unit and lead

to water leaks in to the conditioned space. Failure to

follow instructions could result in equipment and

property damage.

Overview of Manual

Note: One copy of this document ships inside the control

panel of each unit and is customer property . It must

be retained by the unit’s maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for air cooled systems.

By carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component dama ge will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual.

Should equipment failure occur, contact a qualified

service organization with qualified, experienced HVAC

technicians to properly diagnose and repair this

equipment.

Warnings, Cautions and Notices

Revision Summary

RT-SVX26K-EN (27 May 2014)

• New Low Leak Economizer & Fault Detection

Diagnostics (FDD) Options

• Updated Model Number Description Section

• Added back Warranty Section

RT-SVX26K-EN 3

Page 4

Table of Contents

Model Number Description . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . 7

Unit Description . . . . . . . . . . . . . . . . . . . . . . . 7

System Input Devices & Functions . . . . . . . 7

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . 11

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . 11

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 12

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General Unit Requirements . . . . . . . . . . . . 19

Main Unit Power . . . . . . . . . . . . . . . . . . . . . 21

Space Temperature Averaging . . . . . . . . . 25

Factory-Mounted Unit Options . . . . . . . . . . . 30

Circuit Breaker (FIYUCB) & Unit Disconnect

(FIYUDC)

Powered and Unpowered Convenience . . 31

Return Air Smoke Detector . . . . . . . . . . . . . 32

Through the Base Gas Utility Option . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ReliaTel Control . . . . . . . . . . . . . . . . . . . . . . .44

System Status Checkout Procedure . . . . . .44

Resetting Cooling and Heating Lockouts . .45

Zone Temperature Sensor (ZTS) Service Indi-

cator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Zone Temperature Sensor (ZTS) Test . . . .46

Programmable & Digital Zone Sensor Test 47

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .49

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Pre Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Test Modes . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Verifying Proper Air Flow (Units with Belt

Drive Indoor Fan)

. . . . . . . . . . . . . . . . . . . . . 36

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Economizer Start-Up . . . . . . . . . . . . . . . . . . 37

Compressor Start-Up . . . . . . . . . . . . . . . . . 37

Dehumidification Option . . . . . . . . . . . . . . . 38

Heating Start-Up . . . . . . . . . . . . . . . . . . . . . 38

Variable Air Volume Applications (Multi-zone,

Traditional VAV)

Final System Set Up . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . 38

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fan Belt Adjustment—Belt Drive Units . . 41

Monthly Maintenance . . . . . . . . . . . . . . . . . 42

Final Process . . . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 44

4 RT-SVX26K-EN

Page 5

Model Number Descriptions

Model Number Description

YS D 150 F 3 R H A A

12 3 456 7 8 9 10 11 12

All products are identified by a

multiple character model number that

precisely identifies a pa rticular type of

unit. An explanation of the

alphanumeric identification code is

provided. Its use will enable the

owner/operator, installing

contractors, and service engineers to

define the operation, specific

components, and other options for

any specific unit.

When ordering replacement parts or

requesting service, be sure to refer to

the specific model number and serial

number printed on the unit

nameplate.

Digit 1 — Unit Type

Y = Packaged Gas/Electric

Digit 2 — Efficiency

S = Standard Efficiency

H = High Efficiency

Digit 3 — Airflow Configuration

D=Downflow

H=Horizontal

Digit 4, 5, 6 — Nominal Gross

Cooling Capacity (MBh)

150 = 12½ Tons, 60Hz

155 = 15 Tons, 50Hz

180 = 15 Tons, 60Hz

175 = 17½ Tons, 50Hz

210 = 17½ Tons, 60Hz

200= 20 Tons, 50Hz

240 = 20 Tons, 60Hz

250= 25 Tons, 50Hz

300 = 25 Tons, 60Hz

Digit 7 — Major Design

Sequence

F = Microchannel Type Condenser

Coils

Digit 8 — Voltage Selection

3 = 208-230/60/3

4 = 460/60/3

W = 575/60/3

K = 380/60/3

D = 380-415/50/3

Digit 9 — Unit Controls

R = Reliatel

Digit 10 — Heating Capacity

H = Gas Heat - High

L=Gas Heat - Low

V = Gas Heat - SS Ht Ex - Modulating

X = Gas Heat - SS Ht Ex - Low

Z = Gas Heat - SS Ht Ex - High

Digit 11 — Minor Design

Sequence

Digit 12, 13 — Service Sequence

00 = None

01 = 18mm Microchannel Condenser

Note: ‘01’ only available on select

Coil

models.

Digit 14 — Fresh Air Selection

0=No Fresh Air

D = Econ Dry Bulb w/ Barometric

F = Econ Reference Enthaply w/

H = Econ Comparative Enthaply w/

K = Low Leak Econ w/ Barometric

M = Low Leak Econ Reference

P = Low Leak Econ Comparative

1

Relief

Barometric Relief

Barometric Relief

1

Relief

Enthalpy w/ Barometric Relief

Enthalpy w/ Barometric Relief

1

1

1

1

Digit 15 — Supply Fan/Drive

Type/Motor

0=Standard Motor

1 = Oversized Motor

3 = High Efficiency Motor

6 = Single Zone Variable Air Volume

Standard Motor

7 = Multi-Speed Standard Motor

8 = Single Zone Variable Air Volume

Oversized Motor

9 = Multi-Speed Oversized Motor

A = Single Zone Variable Air Volume

Standard Motor w/ Shaft

Grounding Ring

B = Multi-Speed Standard Motor w/

Shaft Grounding Ring

C = Single Zone Variable Air Volume

Oversized Motor w/ Shaft

Grounding Ring

D = Multi-Speed Oversized Motor w/

Shaft Grounding Ring

E = VAV Supply Air Temperature

Control - Standard Motor

F = VAV Supply Air Temperature

Control - Oversized Motor

G = VAV Supply Air Temperature

Control - Standard Motor w/ Shaft

Grounding Ring

H = VAV Supply Air Temperature

Control - Oversized Motor w/

Shaft Grounding Ring

6

6

Digit 16 — Hinged Service

Access / Filters

0 = Standard Panels/Standard

A = Hinged Access/Standard Filters

B = Standard Panels/MERV 8 Filters

C = Hinged Access/MERV 8 Filters

Filters

24

6

D = Standard Panels/MERV 13 Filters

E = Hinged Access/MERV 13 Filters

Digit 17 — Condenser Coil

Protection

0 = Standard Coil

1 = Standard Coil With Hail Guard

4 = CompleteCoat™Condenser Coil

5 = CompleteCoat™Condenser Coil

with Hail Guard

Digit 18 — Through The Base

Provisions

0 = No Through The Base Provisions

A = Through The Base Electric

B = Through The Base Gas

C = Through The Base Electric/Gas

D = Through The Base Access

Digit 19 — Disconnect Switch/

Circuit Breaker

0 = No Disconnect/circuit break

1 = Unit Mounted Non-Fused

Disconnect Switch

2 = Unit Mounted Circuit Breaker

11

Digit 20 — Convenience Outlet

Option

0 = Without Convenience Outlet

A = Unpowered Convenience Outlet

B = Powered Convenience Outlet

Digit 21 — Communications

Options

0 = Without Communications Options

3 = Novar 2024 Controls Interface

4 = Novar 3051 Controls Interface

5 = Novar 3051 Communications

6 = Building Automation Control

Interface with Demand Control

Ventilation

Network Communications

Interface

18

Digit 22 — Refrigeration System

Option

0 = Standard refrigeration system

A = Thermal Expansion Valve (TXV)

B = Dehumidification (Hot Gas

Reheat)

4,14

Digit 23 — Refrigeration Controls

0 = Without Refrigeration Controls

1=Frostat

9, 20

Digit 24 — Smoke Detector

0 = Without Smoke Detector

A = Return Air Smoke Detector

B = Supply Air Smoke Detector

C = Return/Supply Air Smoke

D = Plenum Smoke Detector

24

6

Detector

12

5

2,10

21

6

6

12

5

18

18

14

RT-SVX26K-EN 5

Page 6

Model Number Description

Digit 25 — System Monitoring

Controls

0 = No Monitoring Controls

1 = Clogged Filter Switch

2 = Fan Failure Switch

3 = Discharge Air Sensing

4 = Clogged Filter Switch and Fan

Failure switch

5 = Clogged Filter Switch and

Discharge Air Sensing

6 = Fan Failure Switch and Discharge

Air Sensing

7 = Clogged Filter Switch, Fan Failure

Switch and Discharge Air

Sensing

8 = NOVAR Return Air Sensor (Novar

2024)

9 = NOVAR Zone Temp Sensor

(Novar 3051)

A = Condensate Drain Pan Overflow

Switch

B = Clogged Filter Switch and

Condensate Drain Pan Overflow

Switch

C = Fan Failure Switch and

Condensate Drain Pan Overflow

Switch

D = Discharge Air Sensing and

Condensate Drain Pan Overflow

Switch

E = Clogged Filter Switch, Fan Failure

Switch and Condensate Drain Pan

Overflow Switch

F = Clogged Filter Switch, Discharge

Air Sensing Tube and Condensate

Drain Pan Overflow Switch

G = Fan Failure Switch, Discharge Air

Sensing Tube and Condensate

Drain Pan Overflow Switch

H = Clogged Filter Switch, Fan Failure

Switch, Discharge Air Sensing

and Condensate Drain Pan

Overflow Switch

9

9

13,18

18

9

9

9

9

9

9

9

9

9

9

9

9

Digit 26 - System Monitoring

Controls

0 = No Monitoring Controls

A = Demand Control Ventilation

B = FDD (Fault Detection and

C = FDD (Fault Detection Diagnostics)

19

(CO

)

2

Diagnostics)

& Demand Control Ventilation

19

(CO

)

2

Digit 27 - Unit Hardware

Enhancements

0 = No Enhancements

1 = Stainless Steel Drain Pan

Digit 28 - Short Circuit Current

Rating

0 = Standard SCCR

A = 65kA SCCR Option

22, 23

Digit 31 - Advanced Unit

Controls

0 = Standard Unit Controls

1=Human Interface

Note: Most Factory Installed Options

available for Downflow Air

Discharge units only. Please verify

with ordering system for

availability.

25

Model Number Notes

1. Some field set up required.

2. Requires ReliaT el Options Module.

3. Requires Economizer.

nd

4. All 22

reheat coil (B) require additional

factory installed options: Frostat,

and 2” pleated filters.

5. Must be orde red with Through-

the-Base Electrical option or

Horizontal-Side Access and either

Unit Mounted Disconnect or

Circuit Breaker.

6. Available factory installed on

downflow AND horizontal units.

Verify with ordering system.

7. Cannot be fused.

8. Must be factory installed when

using Through-the-Base Options.

9. ReliaTel Options Module is

required when ordering the

following accessories: Clogged

Filter Switch, Fan Fail Switch,

Condensate Overflow Switch,

Discharge Air Se nsing Kit, Frostat,

V enti latio n Override, Smoke

Detector, Dehumidification and

Modulating Gas Heat Furnace.

10. Opti on cannot be ordered in

conjunction with field installed

economizer on downflow units.

Must be factory installed. The

return air smoke detector may not

fit up or work properly on the

Voyager units when used in

conjunction with 3

accessories (such as bolt on heat

wheels, economizers, and power

exhaust). Do not order the return

air smoke detectors when using

this type of accessory.

11. Unit mounted disconnect and

circuit breakers are mutually

exclusive of each other.

digit model numbers for

rd

party

12. Through-the-base electrical

option or Horizontal-Side Access

must be ordered with either unit

mounted disconnect or circuit

breaker. When adding heat, you

must order Electric Heat.

13. This option consists of the Novar

return air sensor (Novar #WTS-10)

that is wired and shipped in the

return air section of the unit. The

sensor ships with approximately

15’ of extra wire for dropping

down the return air duct

(downflow only).

14. Available on high efficiency,

downflow units only.

15. All Factory Installed Options are

Built-to-Order. Check order

services for estimated production

cycle.

16. The Novar control option includes

the following factory installed and

wired devices: Novar ETM-2024 or

Novar 3051 rooftop controller, fan

proving switch, clogged filter or

unit shutdown switch, Cool 1,

Cool 2, Heat switch and disc harge

air sensor (Novar 2024 is

downflow only).

Note: Option cannot be ordered in

conjunction with a factory

installed smoke detector.

17. For use with multi-speed and

SZVAV units only.

18. Novar is not available with SZ VAV

products.

19. Demand Control Ventilation

Option includes wiring only. The

sensor is a field-installed only

C0

2

option.

20. Frostat is standard on VAV units.

21. Supply and/or return smoke

detector may not be used with the

plenum smoke detector.

22. Only available where MOP is

above 60A.

23. 575 VAC option is 25kA.

24. Standard filters are not available

with Low Leak Economizers.

25. Human Interface is standard with

FDD (Fault Detection Diagnostics).

6 RT-SVX26K-EN

Page 7

General Information

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and compressor oil, and run

tested for proper control operation.

For major design sequence F units, the condenser coils are

microchannel type aluminum coils.

Direct-drive, vertical discharge condenser fans are

provided with built-in thermal overload protection.

The ReliaT el™ Control Module is a microelectronic control

system that is referred to as “Refrigeration Module”

(RTRM). The acronym RTRM is used extensively

throughout this document when referring to the control

system network.

This module through Proportional/Integral control

algorithms perform specific unit functions that governs

unit operation in response to; zone temperature, supply air

temperature, and/or humidity conditions depending on

the application.

The stages of capacity control for these units are achieved

by starting and stopping the compressors.

The RTRM is mounted in the control panel and is factory

wired to the respective internal components. The RTRM

receives and interprets information from other unit

modules, sensors, remote panels, and customer binary

contacts to satisfy the applicable request for cooling.

Economizer Control Actuator ReliaTel™

Control

The ECA monitors the mixed air temperature, return air

temperature, minimum position setpoint (local or

remote), power exhaust setpoint, CO

ambient dry bulb/ enthalpy sensor or comparative

humidity (return air humidity against ambient humidity)

sensors, if selected, to control dampers to an accuracy of

±5 percent of stroke. The actuator is spring returned to the

closed position any time that power is lost to the unit. It is

capable of delivering up to 25 in·lb of torque and is

powered by 24 Vac.

RTCI—ReliaTel™ Trane Communication

Interface (Optional)

This module is used when the application calls for an ICS™

building management type control system. It allows the

control and monitoring of the system through an ICS

panel. The module can be ordered from the factory or

ordered as a kit to be field installed. Follow the installation

instruction that ships with each kit when field installation

is necessary.

setpoint, CO2, and

2

RLCI—ReliaTel™ LonTalk Communication

Interface (Optional)

This module is used when the application calls for an ICS™

building management type control system that is LonT alk.

It allows the control and monitoring of the system th rough

an ICS panel. The module can be ordered from the factory

or ordered as a kit to be field installed. Follow the

installation instruction that ships with each kit when field

installation is necessary.

RBCI—ReliaTel BACnet™ Communications

Interface (Optional)

This module is used when the application calls for an open

BACnet protocol. It allows the control and monitoring of

the system through an ICS panel. The module can be

ordered from the factory or as a kit to be field installed.

Follow the installation instructions that ships with each kit

when field installation is necessary.

RTOM—ReliaTel™ Options Module

(Optional)

The RT OM monitors the supply fan proving, clogged filter ,

supply air temperature, exhaust fan setpoint, supply air

tempering, Frostat™ and smoke detector. R efer to system

input devices and functions for operation.

RTAM—ReliaTel™ Air Handler Module

(Standard with Traditional VAV)

RTAM receives information from the supply duct static

pressure transducer. Attached to the module are the

supply air heating potentiometer, supply air cooling

setpoint potentiometer, supply pressure setpoint

potentiometer, static pressure deadband potentiometer,

morning warm-up setpoint potentiometer, reset setpoint

potentiometer , an d 5 DIP switches.

System Input Devices &

Functions

The RTRM must have a zone sensor or thermostat input in

order to operate the unit. The flexibility of having several

mode capabilities depends upon the type of zone sen sor or

thermostat selected to interface with the RTRM.

The descriptions of the following basic Input Devices used

within the RTRM network are to acquaint the operator with

their function as they interface with the various modules.

Refer to the unit’s electrical schematic for the specific

module connections. The following controls are available

from the factory for field installation.

RT-SVX26K-EN 7

Supply Fan Failure Input (Optional)

The Fan Failure Switch (FFS) can be connected to sense

indoor fan operation. If air flow through the unit is not

Page 8

General Information

proven by the differential pressure switch connected to the

RTOM (factory set point 0.07“ w.c.) within 40 seconds

nominally, the RTRM will shut off all mechanical

operations, lock the system out, send a diagnostic to ICS,

and the SERVICE output will flash. The system will remain

locked out until a reset is initiated either manually or

through ICS.

Drain Pan Condensate Overflow Switch

(Optional)

This input incorporates the Condensate Overflow Switch

(COF) mounted on the drain pan and the ReliaT el Options

Module (RTOM). When the condensate level reaches the

trip point for 6 continuous seconds, the RTOM will shut

down all unit function until the overflow condition has

cleared. The unit will return to normal operation after 6

continuous seconds with the COF in a non-tripped

condition. If the condensate level causes the unit to

shutdown more than 2 times in a 3 day period, the unit will

be locked-out of operation. A manual reset of the

diagnostic system through the Zone Sensor or Building

Automation System (BAS) will be required. Cycling unit

power will also clear the fault."

Clogged Filter Switch (Optional)

The unit mounted clogged filter switch monitors the

pressure differential across the return air filters. It is

mounted in the filter section and is connected to the

RTO M. A diagnostic SER V ICE signal is sent to the remote

panel if the pressure differential across the filters is at least

0.5” w.c.

The contacts will automatically open when the pressure

differential across the filters decreases to approximately

0.4” w.c.

The clogged filter output is energized when the supply fan

is operating and the clogged filter switc h has been clo sed

for at least 2 minutes. The system will continue to operate

regardless of the status of the filter switch.

Please note that on units equipped with factory installed

MERV 13 filters, a clogged filter switch with different

pressure settings will be installed. This switch will close

when the differential pressure is approximately 0.8”w.c.

and open when the differential falls to 0.7” w.c.

Compressor Disable (CPR1/2)

This input incorporates the low pressure control (LPC) of

each refrigeration circuit and can be activated by opening

a field supplied contact installed on the LTB.

If this circuit is open before the compressor is started, the

compressor will not be allowed to operate. Anytime this

circuit is opened for 1 continuous second during

compressor operation, the compressor for that circuit is

immediately turned “Off”. The compressor will not be

allowed to restart for a minimum of 3 minutes should the

contacts close.

If four consecutive open conditions occur during the first

three minutes of operation, the compressor for that circuit

will be locked out, a diagnostic communicated to the

remote panel (if installed), and a manual reset will be

required to restart the compressor .

Phase Monitor

The Phase Monitor is a three-phase line monitor module

that protects against phase loss, phase reversal and phase

unbalance. It is intended to protect compressors from

reverse rotation. It has an operating input voltage range of

190–600 Vac, and LED indicators for ON and FAULT. There

are no field adjustments and the module will automatically

reset from a fault condition.

Low Pressure Control ReliaTel Control

When the LPC is opened for 1 continuous second, the

compressor for that circuit is turned off immediately. The

compressor will not be allowed to restart for a minimum

of 3 minutes.

If four consecutive open conditions occur during the first

three minutes of operation, the compressor will be loc ked

out, a diagnostic communicated to ICS™ if applicable, and

a manual reset will be required to restart the compressor.

Discharge Line Thermostat ReliaTel

Control

The high pressure controls and disc harge line thermostats

are wired in series between the compressor outputs on the

RTRM and the compressor contactor coils. If the high

pressure control switch or discharge line thermostat open,

the RTRM senses a lac k of current while calling for cool ing

and locks the compressor out. This is an auto reset loc kout.

If the circuit is open three consecutive times when the

contactor coil should be on, the RTRM sets a manual

lockout for that compressor.

Power Exhaust Control (Optional)

The power exhaust fan is started whenever the position of

the economizer dampers meets or exceed the power

exhaust setpoint when the indoor fan is on.

The setpoint panel is located in the return air section and

is factory set at 25 percent.

Lead/Lag Control (Dual Circuit Only)

Lead/Lag is a selectable input located on the RTRM. The

RTRM is configured from the factory with the Lead/Lag

control disabled. T o activate the Lead/Lag function, simply

cut the wire connected to J3-8 at the RTRM. When it is

activated, each time the designated lead compressor is

shut off due to the load being satisfied, the lead

compressor or refrigeration circuit switches. When the

RTRM is powered up, i.e. af ter a power failure, the control

will default to the number one circuit compressor.

8 RT-SVX26K-EN

Page 9

General Information

Evaporator Frost Control

This input incorporates the Frostat™ control (FOS)

mounted in the indoor coil and can be activated by closing

a field supplied contact installed in parallel with the FOS.

If this circuit is closed before the compressor is started, the

compressor will not be allowed to operate. Anytime this

circuit is closed for 1 continuous second during

compressor operation, the compressor for that circuit is

immediately turned “Off”. The compressor will not be

allowed to restart for a minimum of 3 minutes should the

FOS open.

Sensors

Note: Zone sensor required for units configured for

Single Zone VAV indoor fan system control to

enable Single Zone VAV functionality.

Zone Sensor Module (ZSM)

(BAYSENS106*)

This electronic sensor features three system switch

settings (Heat, Cool, and Off) and two fan settings (On and

Auto). It is a manual changeover control with single

setpoint. (Cooling Setpoint Only.)

Zone Sensor Module (ZSM)

(BAYSENS108*)

This electronic sensor features four system switch settings

(Heat, Cool, Auto, and Off) and two fan settings (On and

Auto). It is a manual or auto changeover control with dual

setpoint capability. It can be used with a remote zone

temperature sensor BAYSENS075*.

Zone Sensor (BAYSENS110*)

This electronic sensor features four system switch settings

(Heat, Cool, Auto, and Off) and two fan settings (On and

Auto) with four system status LEDs. It is a manual or auto

changeover contro l with dual setpoint capability . It can be

used with a remote zone temperature sensor

BAYSENS075*.

Programmable Zone Sensor

(BAYSENS119*)

Programmable Night Setback: Auto or manual c hangeover

with seven-day programming. Keyboard selection of Heat,

Cool, Fan, Auto, or On. All programmable sensors have

System On, Heat, Cool, Service LED/indi cato rs as

standard. Night Setback Sensors have one (1) Occupied,

one (1) Un-occupied, and one (1) Override program per

day.

Remote Zone Sensor (BAYSENS073*)

This electronic sensor features remote zone sensing and

timed override with over ride cancellation. It is used with a

Trane Integrated Comfort™ building management

system.

Remote Zone Sensor (BAYSENS074*)

This electronic sensor features single setpoint capability

and timed override with override cancellation. It is used

with a Trane Integrated Comfort™ building managemen t

system.

Remote Zone Sensor (BAYSENS016*)

This bullet type temperature sensor can be used for

outside air (ambient) sensing, return air temperature

sensing, supply air temperature sensing, and remote

temperature sensing (uncovered). Wiring procedures vary

according to the particular application and equipment

involved. Refer to the unit’s wiring diagrams for proper

connections.

Remote Zone Sensor (BAYSENS075*)

This electronic sensor can be used with BAYSENS119*

Remote Panels. When this sensor is wired to a

BAYSENS119* Remote Panel, wiring must be 18 AWG

Shielded Twisted P air (Belden 8760 or equivalent). Refer to

the specific Remote Panel for wiring details.

Wireless Zone Sensor (BAYSENS050)

This electronic sensor features five system settings (Auto,

Off, Cool, Heat, and Emerg ency Heat) and with On and

Auto fan settings. It is a manual or auto c hangeover control

with dual setpoint capability. Other features include a

timed override function, lockable system settings, and

Fahrenheit or Celsius temperature display. Included with

the wireless zone sensor will be a receiver that is to be

mounted inside the unit, a mounting bracket, and a wire

harness.

High Temperature Sensor (BAYFRST003*)

This sensor connects to the RTRM Emergency Stop Input

on the L TB and provides high limit “sh utdown” of the unit.

The sensor is used to detect high temperatures due to fire

in the air conditioning or ventilation ducts. The sensor is

designed to mount directly to the sheet metal duct. Each kit

contains two sensors. The return air duct sensor

(X1310004001) is set to open at 135°F.

The supply air duct sensor (X131 0004002) is set to open at

240°F. The control can be reset after the temperature has

been lowered approximately 25°F below the cutout

setpoint.

Thermostat (BAYSTAT150)

This thermostat is a multi-stage 3 heat/2 cool, autochangeover digital display thermostat. It is a

programmable thermostat, and a 7-day programmable

stat with night setback shall be available. In addition, it is

wall mounted.

RT-SVX26K-EN 9

Page 10

General Information

Thermostat (BAYSTAT151)

This thermostat is a single-stage 1 heat/1 cool, autochangeover digital display thermostat. It is a nonprogrammable, wall-mounted thermostat.

Thermostat (BAYSTAT155)

This thermostat is a multi-stage 3 heat/2 cool, auto

changeover digital display thermostat. It is a nonprogrammable, wall-mounted thermostat, and it can be

used for Economizer Operation.

Smoke Detector Sensor (Optional)

This sensor is only applicable on units equipped with a

RTOM. It provides high limit “shutdown” of the unit and

requires a manual reset. The sensor is used to detect

smoke due to fire in the air conditioning or ventilation

ducts.

Notes:

• The supply and return air smoke detectors are

designed to shut off the unit if smoke is sensed in the

supply air stream or return air stream. This function is

performed by sampling the airflow entering the unit at

the return air opening. Follow the instructions

provided below to assure that the airflow through the

unit is sufficient for adequate sampling. Fa il ure to

follow these instructions will prevent the smoke

detectors from performing it's desig n function.

• Airflow through the unit is affected by the amount of

dirt and debris accumulated on the indoor coil and

filters. To insure that airflow through the unit is

adequate for proper sampling by the return air smoke

detector, complete adherence to the maintenance

procedures, including recommended intervals

between filter changes, and coil cleaning is required.

• Periodic chec ks an d maintenance procedures must be

performed on the smoke detector to insure that it will

function properly . For detailed instructions concerning

these checks and procedures, refer to the appropriate

section(s) of the smoke detector Installation and

Maintenance Instructions provided with the literature

package for this unit.

In order for the supply air smoke detector or return air

smoke detector to properly sense smoke in the supply air

stream or return air stream, the air velocity entering the

smoke detector unit must be between 500 and 4000 feet

per minute.

Equipment covered in this manual will develop an airflow

velocity that falls within these limits o ver the entire airflow

range specified in the evaporator fan performance tables.

There are certain models, however, if operated at low

airflow, will not develop an airflow velocity that falls within

the required 500 to 4000 feet per minute range. For these

models, the design airflow shall be greater than or equal

to the minimum cfm specified in the table provided below.

Failure to follow these instructions will prevent the smoke

detector from performing its design function.

Unit Model

Number

YHD180 5300 cfm

Minimum Allowable Airflow with

Return Air Smoke Detector

Wa ll Mounted Relative Humidity Sensor

(BAYSENS036*)

Field installed, wall mounted humi dity sensor is used to

control activation of the hot gas reheat dehumidification

option.

Humidity set points can be selected for relative humidity

levels between 40 percent and 60 percent by adjusting the

DEHUMID setting on the ReliaTel Options Module; see

“RTOM—ReliaTel™ Options Module (Optional),” p. 7.

Duct Mounted Relative Humidity Sensor

(BAYSENS037*)

Field installed, duct mounted humidity sensor is used to

control activation of the hot gas reheat dehumidification

option.

Humidity set points can be selected for relative humidity

levels between 40 percent and 60 percent by adjusting the

DEHUMID setting on the ReliaTel Options Module; see

“RTOM—ReliaTel™ Options Module (Optional),” p. 7.

Human Interface - 5 Inch Color

Touchscreen (Optional)

The 5 inch Color T ouc hscreen Human Interface provides an

intuitive user interface to the rooftop unit that speeds up

unit commissioning, shortens unit troubleshooting times,

and enhances preventative maintenance measures. The

human interface includes several features including:

• Data trending capabilities by means of time seri es

graphs

• Historical alarm messages

• Real-time sensor measurements

• On board system setpoints

• USB port that enables the downloading of component

runtime information as well as trended historical

sensor data

• Customized reports

10 RT-SVX26K-EN

Page 11

General Information

Unit Inspection

As soon as the unit arrives at the job site:

• V erify that the nameplate data matches the data on the

sales order and bill of lading (includin g electrical data).

• Verify that the power supply complies with the unit

nameplate specifications.

• Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

• Visually inspect the internal components for shipping

damage as soon as possible after delivery and before

it is stored. Do not walk on the sheet metal base pans.

• If concealed damage is discovered, notify th e carrier’s

terminal of damage immediately by phone and by

mail. Concealed damage must be reported within 15

days.

– Request an immediate joint inspection of the

damage by the carrier and the consignee.

– Do not remove damaged material from the

receiving location.

– T ake photos of the damage, if possible. The owner

must provide reasonable evidence that the damage

did not occur after delivery.

• Notify the appropriate sales representative before

installing or repairing a damaged unit.

Precautionary Measur es

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or rep air will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. You MUST wear all necessary Personal

Protective Equipment (PPE) including gloves, eye

protection, a NIOSH approved dust/mist respir ator , long

sleeves and pants when working with products

containing fiberglass wool. Exposition to glass wool

fibers without all necessary PPE equipm ent could r esult

in cancer, respiratory, skin or eye irritation, which could

result in death or serious injury.

First Aid Measures

• Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

• Skin Contact - Wash affected areas gently with soap

and warm water after handling.

Storage

Take precautions to prevent condensate from forming

inside the unit’s electrical compartments and motors if:

• The unit is stored before it is installed; or,

• The unit is set on the roof curb, and temporary heat is

provided in the building. Isolat e al l side p anel servi ce

entrances and base pan openings (e.g., conduit holes,

S/A and R/ A openings, and flue openings) from the

ambient air until the unit is ready for start-up.

Note: Do not use the unit’s heater for temporary heat

without first completing the start-up procedure

detailed under “Start Up,” p. 37.

The manufacturer will not assume any responsibility for

equipment damage resulting from condensate

accumulation on the unit’s electrical and/or mechanical

components.

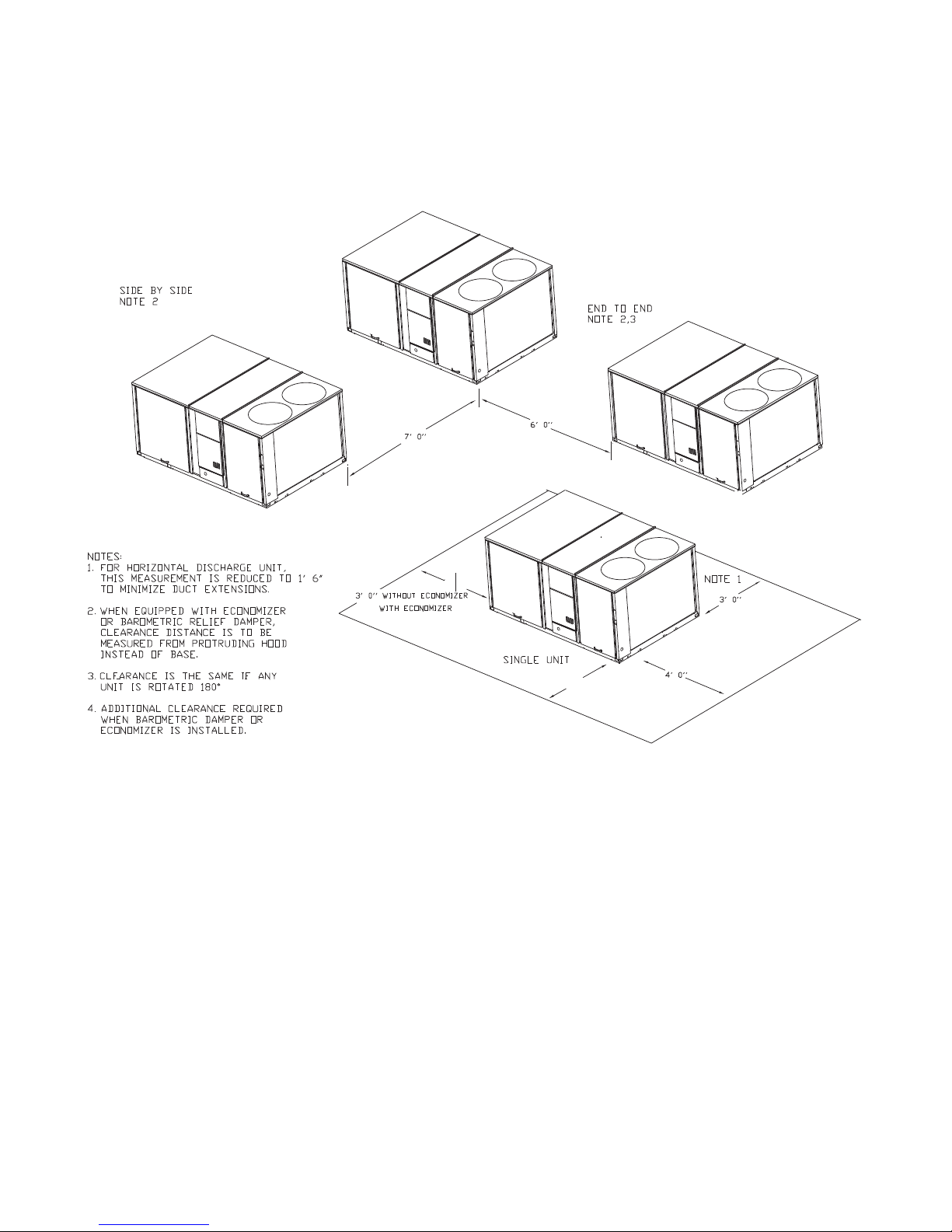

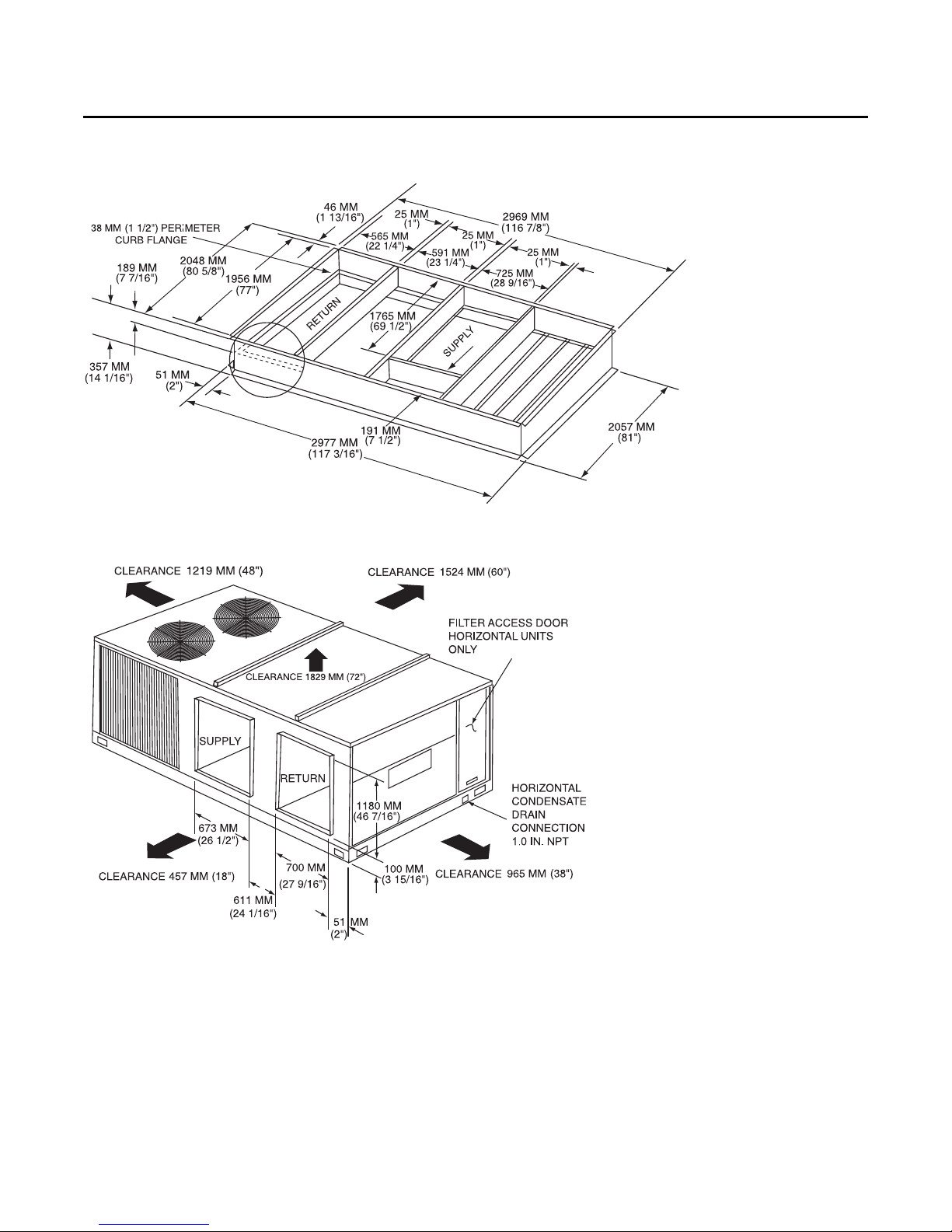

Unit Clearances

Figure 1, p. 12 illustrates the minimum operating and

service clearances for either a single or multiple unit

installation. These clearances are th e minimum distances

necessary to assure adequate serviceability, cataloged

unit capacity, an d peak operating efficiency.

Providing less than the recommended clearances may

result in condenser coil starvation, “short-circuiting” of

exhaust and economizer airflows, or recirculation of hot

condenser air.

• Avoid breathing fibergl as s dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. W ear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing: rinse

washer thoroughly.

• Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

RT-SVX26K-EN 11

Page 12

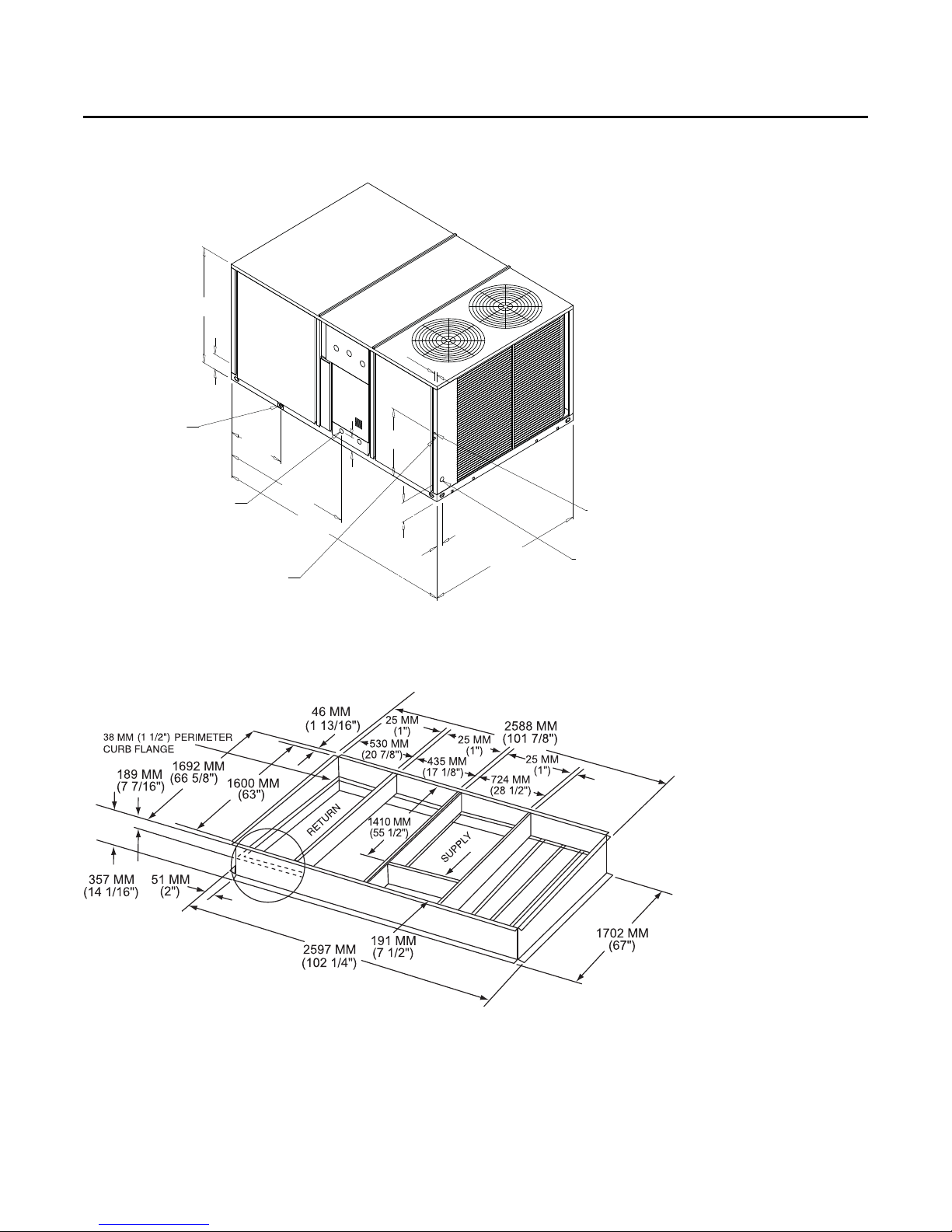

Unit Dimensions

5' 8"

5' 0"

Figure 1. Typical installation clearance for single and multiple unit applications

12 RT-SVX26K-EN

Page 13

Figure 2. Unit dimensional data for 12½ tons standard efficiency units

2710 mm

(106 11/16”)

1273 mm

(50 1/8”)

168 mm

(6 5/8”)

651 mm

(25 5/8”)

1799 mm

(70 13/16”)

213 mm

(8 3/8”)

745 mm

(29 5/16”)

68 mm

(2 11/16”)

25 mm

(1”)

1453 mm

(57 3/16”)

152 mm

(6”)

(SEE NOTE)

22 mm (7/8”) DIA. HOLE

(UNIT CONTROL WIRE)

51 mm (2”) DIA. HOLE

(UNIT POWER WIRE)

DOWNFLOW CONDENSATE

DRAIN CONN 25 mm (1”) NPT

SERVICE GAUGE

PORT ACCESS

Unit Dimensions

Note: ½ NPT Gas Connection

Figure 3. Unit dimensional data for 12½ tons standard efficiency units

RT-SVX26K-EN 13

Page 14

Unit Dimensions

3091 mm

(121 11/16”)

1372 mm

(54”)

173 mm

(6 13/16”)

679 mm

(26 3/4”)

2138 mm

(84 3/16”)

227 mm

(8 15/16”)

25 mm

(1”)

830 mm

(32 11/16”)

1643 mm

(64 11/16”)

151 mm

(5 15/16”)

22 mm (7/8”) DIA. HOLE

(UNIT CONTROL WI RE)

51 mm (2”) DIA. HOLE

(UNIT POWER WIRE)

DOWNFLOW CO NDENSATE

DRAIN CONN 25 mm (1”) NPT

(SEE NOTE)

68 mm

(2 11/16”)

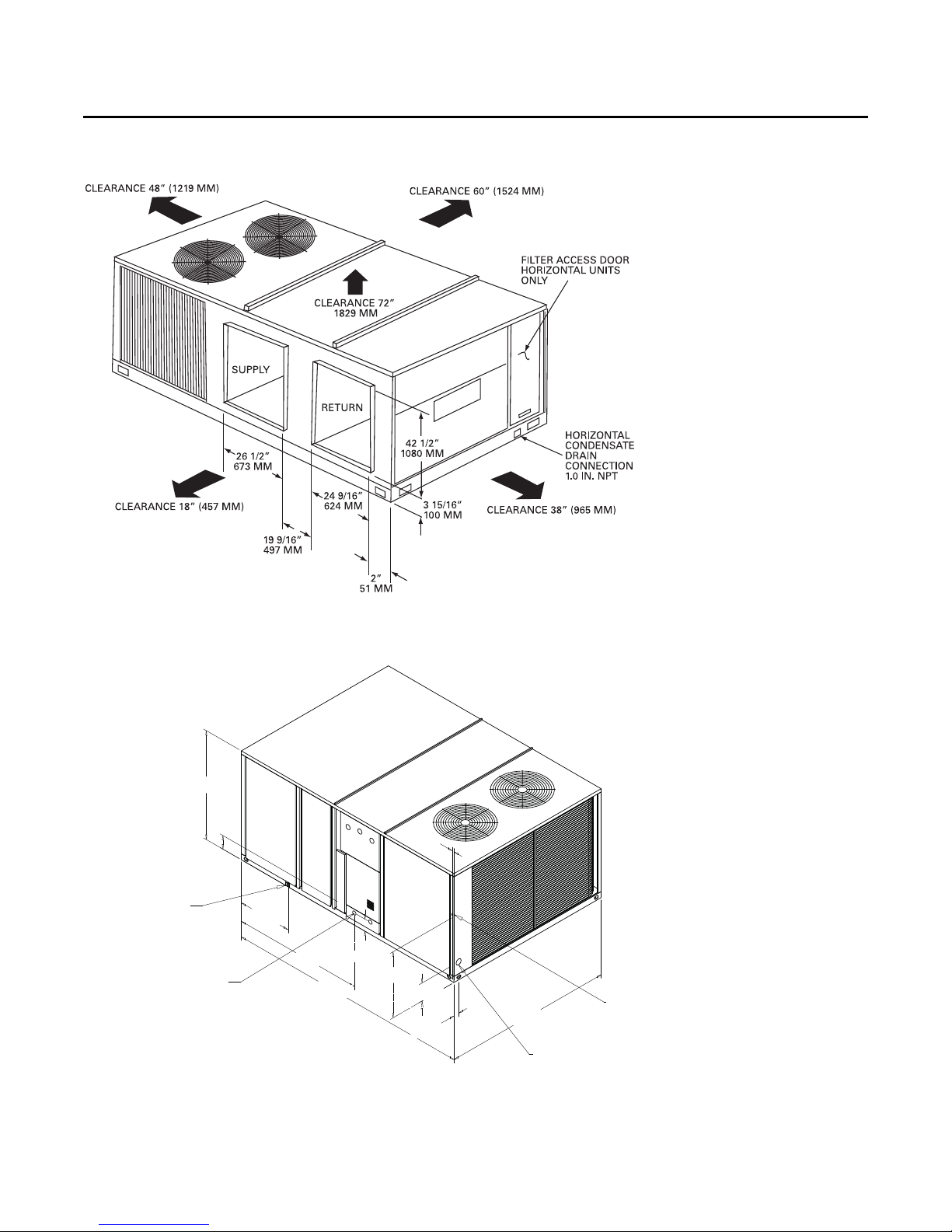

Figure 4. Horizontal duct dimensional data 12½ tons standard efficiency units

Figure 5. Unit dimensional data 15–25 tons standard efficiency units

Note: ½ NPT Gas Connection

14 RT-SVX26K-EN

Page 15

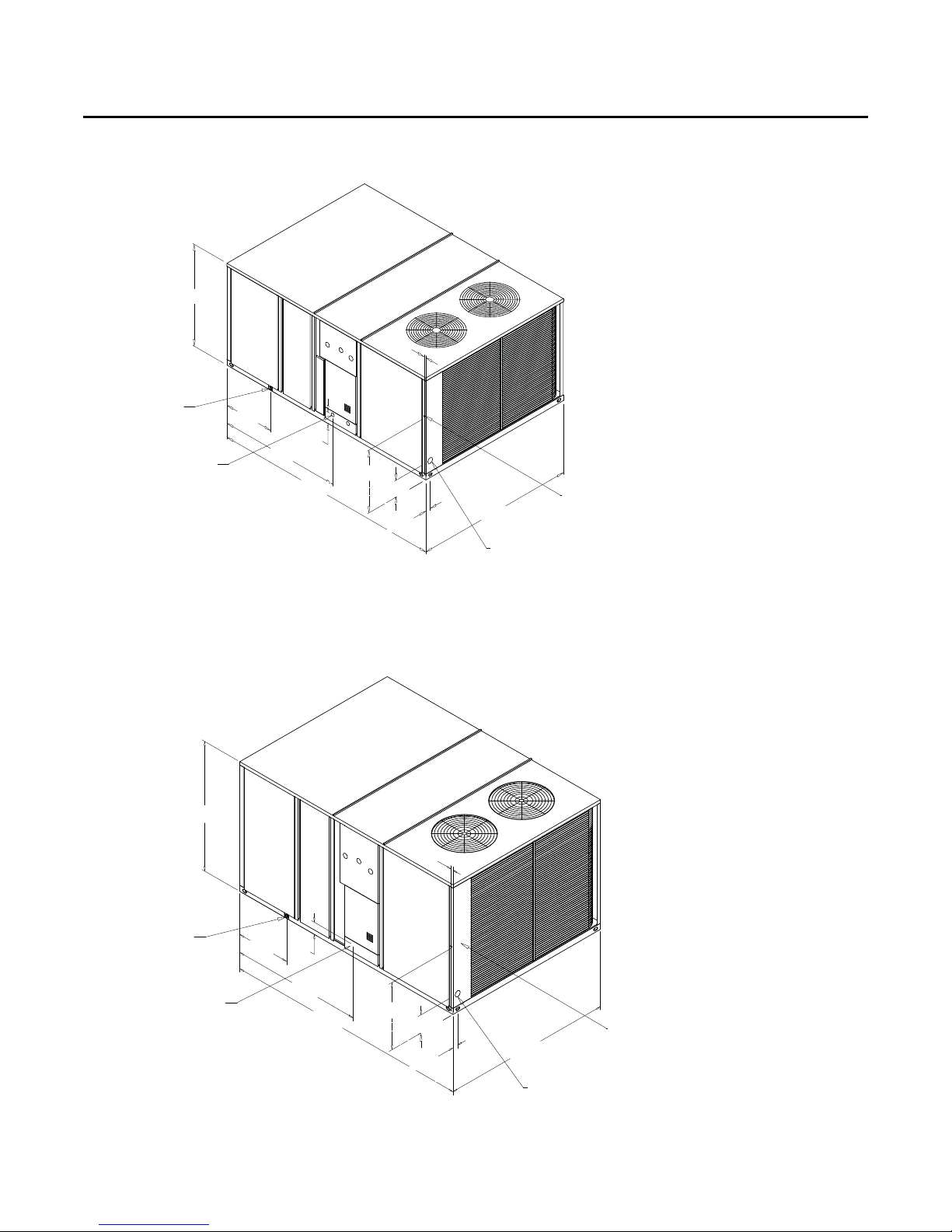

Figure 6. Unit dimensional data 12½ ton high efficiency units

1372 mm

(54”)

25 mm

(1”)

DOWNFLOW CONDENSATE

DRAIN CONN 25 mm (1”) NPT

GAS CONNECTION (SEE NOTE 1)

679 mm

(26 3/4”)

1643 mm

(64 11/16”)

(121 11/16”)

152 mm

(6”)

3091 mm

843 mm

(33 3/16”)

227 mm

(8 15/16”)

68 mm

(2 11/16”)

2138 mm

(84 3/16”)

76 mm (3”) DIA. HOLE

(UNIT POWER W IRE)

22 mm (7/8”) DIA. HOLE

(UNIT CONTROL WIRE)

Unit Dimensions

Note: ½ NPT Gas Connection

Figure 7. Unit dimensional data 15–25 tons high efficiency units

1629 mm

(64 1/8”)

25 mm

(1”)

DOWNFLOW CO NDENSATE

DRAIN CONN 25 mm (1”) NPT

GAS CONNECTION (SEE NOTE 1)

679 mm

(26 3/4”)

152 mm

(6”)

1643 mm

(64 11/16”)

(121 11/16”)

3091 mm

843 mm

(33 3/16”)

227 mm

(8 15/16”)

68 mm

(2 11/16”)

(84 3/16”)

2138 mm

76 mm (3”) DIA. HOLE

(UNIT POWER WIRE)

22 mm (7/8”) DIA. HOLE

(UNIT CONTROL WIRE)

Note: ½ NPT Gas Connection

RT-SVX26K-EN 15

Page 16

Unit Dimensions

Figure 8. Unit dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units

Figure 9. Horizontal duct dimensional data 15–25 tons standard efficiency units, 12½–25 tons high efficiency units

16 RT-SVX26K-EN

Page 17

Unit Weights

Table 1. Typical unit w eights and point loading data (lb)

Net

Weights

(25mm/

Unit Models

YS*150F 1508 506 390 275 337

YH*150F 2126 676 555 406 487

YH*150F Reheat unit 2146 682 560 410 491

YS*155F 1958 628 534 387 406

YS*180F 1925 666 505 343 410

YH*180F 2129 677 556 407 488

YH*180F Reheat unit 2149 683 561 410 491

YS*175F 2007 637 547 400 421

YS*210F 2007 639 547 399 419

YH*210F 2201 700 574 420 504

YH*210F Reheat unit 2221 706 579 424 508

YS*200F 2069 659 551 402 455

YS*240F 2069 659 551 402 455

YH*240F 2203 701 575 421 504

YH*240F Reheat unit 2223 707 580 425 509

YS*250F 2054 655 555 403 442

YS*300F 2054 655 555 403 442

YH*300F 2207 702 579 422 507

18mm)

Corner Weights (lb)

ABCD

Table 2. Typical unit weights and point loading data

(kg)

Net

Weights

(25mm/

Unit Models

YS*150F 684 230 177 125 153

YH*150F 964 307 252 184 221

YH*150F Reheat unit 973 309 254 186 223

YS*155F 877 282 242 175 177

YS*180F 873 302 229 156 186

YH*180F 966 307 252 185 221

YH*180F Reheat unit 975 310 254 186 223

YS*175F 899 286 248 181 184

YS*210F 910 290 248 181 190

YH*210F 998 318 260 190 229

YH*210F Reheat unit 1007 320 263 192 230

YS*200F 924 295 250 182 197

YS*240F 938 299 250 182 206

YH*240F 999 318 261 191 229

YH*240F Reheat unit 1008 321 263 193 231

YS*250F 917 293 251 182 191

YS*300F 932 297 252 183 200

YH*300F 1001 318 263 191 230

18mm)

Corner Weights (kg)

ABCD

Figure 10. Corner weights

RT-SVX26K-EN 17

Page 18

Unit Weights

Rigging

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in unit dropping and

possibly crushing operator/technician which coul d

result in death or serious injury and possible equipment

or property-only damage.

Figure 11. Rigging and center of gravity data

Refer to Figure 11, p. 18 and Table 1, p. 17 and Table 2,

p. 17 for typical unit operating weights rigging before

proceeding.

26. Remove the shipping crate from around the unit. Do

not remove the crating from the top of the unit.

27. Rig the unit as shown in Figure 11, p. 18. Attach

adequate strength lifting slings to all four lifting

brackets in the unit base rail. Do not use cables, chains,

or slings except as shown.

28. Install a lifting bar, as shown in Figure 11, p. 18, to

protect the unit and to facilitate a uniform lift. The

minimum distance between the lifting hook and the

top of the unit should be 7 feet.

29. Test-lift the unit to ensure it is properly rigged and

balanced, make any necessary rigging adjustments.

30. Lift the unit and position it into place.

31 . Downflow units; align the base rail of the unit with the

curb rail while lowering the unit onto the curb. Make

sure that the gasket on the curb is not damaged while

positioning the unit.

18 RT-SVX26K-EN

Page 19

Installation

Foundation

WARNING

Risk of Roof Collapsing!

Confirm with a structural engineer that the roof

structure is strong enough to support the combined

weight of the roofcurb and the unit. Refer to “Unit

Weights, ” p. 17 for typical unit and curb weights. Failure

to ensure proper str uctur al ro of support could cause the

roof to collapse, which could result in death or serious

injury and property damage.

NOTICE:

Water Damage!

Non-factory penetrations through the base of this unit

are not allowed. Any penetration in the base of the unit

may aff ect the water tight integrity of the unit and lead

to water leaks in to the conditioned space. Failure to

follow instructions could result in equipment and

property damage.

Horizontal Units

Notes:

• For units with optional Condensate Overflow Switch

(COF), the switch will not work properly if unit is not

level or slightly sloped toward switch.

• T o assure proper condensate flow during operation the

unit and the curb must be level.

If the unit is installed at ground level, elevate it above the

snow line. Provide concrete footings at each support

location with a “full perimeter” support structure or a slab

foundation for support. Refer to T a ble 1, p. 17 and Table 2,

p. 17 for the unit’s operating and point loading weights

when constructing a footing foundation.

If anchoring is required, anchor the unit to the slab using

hold down bolts or isolators. Isolators should be installed

to minimize the transmission of vibrations into the

building.

For rooftop applications, if anchoring is required, anchor

the unit to the roof with hold-down bolts or isolators.

Check with a roofing contract or for proper w aterp roofing

procedures.

Ductwork

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce static

pressure.

When attac hing the ductwork to the unit, provide a w atertight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Note: For sound consideration, cut only the holes in the

roof deck for the ductwork penetrations. Do not cut

out the entire roof deck within the curb perimeter.

If a Curb Accessory Kit is not used:

a. The ductwork can be attached directly to the

factory-provided flanges around the unit’s supply

and return air openings. Be sure to use flexible duct

connections at the unit.

b. For “built-up” curbs supplied by others, gaskets

must be installed around the curb perimeter flange

and the supply and return air opening flanges.

General Unit Requirements

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, y ou MUS T follo w r equir ements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

The checklist listed below is a summary of the steps

required to successfully install a commercial unit. This

checklist is intended to acquaint the installing personnel

with what is required in the installation process. It does not

replace the detailed instructions called out in the

applicable sections of this manual.

• Check the unit for shipping damage and material

shortage; file a freight claim and notify appropriate

sales representative.

• Verify correct model, options and voltage from

nameplate.

• Verify that the installation location of the unit will

provide the required clearance for proper operation.

• Assemble and install the roof curb (if applicable). Refer

to the latest edition of the curb installers guide that

ships with each curb kit.

• Fabricate and install ductwork; secure ductwork to

curb.

• Rigging the unit.

• Set the unit onto the curb; check for levelness.

• Ensure unit-to-curb seal is tight and without buckles or

cracks.

• Install and connect a condensate drain line to the

evaporator drain connection.

RT-SVX26K-EN 19

Page 20

Installation

Factory Installed Economizer

• Ensure the standard economizer has been pulled out

into the operating position. Refer to the economizer

Installation Instructions for proper setup.

Note: Low Leak Economizers do not pull out. Refer to L ow

Leak Economizers Installation Instructions for

proper setup.

• Install all access panels.

Main Electrical Power Requirements

• Verify that the power supply complies with the unit

nameplate specifications.

• Inspect all control panel components; tighten any

loose connections.

• Connect properly sized and protected power supply

wiring to a field-supplied/ installed disconnect switch

and to the main power terminal bloc k (HTB1) in the unit

control panel.

• Install proper grounding wires to an earth ground.

Note: All field-installed wiring must comply with NEC

and applicable local codes.

Electric Heat Requirements

• V erify that the power supply complies with the electric

heater specifications on the unit and heater nameplate.

• Inspect the heater junction box and control panel;

tighten any loose connections.

• Check electric heat circuits for continuity.

• Low Voltage Wiring (AC and DC) Requirements

• Install the zone thermostat, with or without switching

subbase.

• Connect properly sized control wiring to the proper

termination points between the zone thermostat and

the unit control panel.

Condensate Drain Configuration

An evaporator condensate drain connection is provided

on each unit. Refer to “Unit Dimensions,” p. 12 for the

appropriate drain location.

A condensate trap must be installed at the unit due to the

drain connection being on the “negative pressure” side of

the fan. Install the P -T rap using the guid elines in Figure 12.

A condensate drain line must be connected to the P-Trap.

Pitch the drain lines at least ½-inch for every 10 feet of

horizontal run to assure proper condensate flow. Do not

allow the horizontal run to sag causing a possible doubletrap condition which cou ld result in cond en sate backup

due to “air lock”.

Figure 12. Condensate trap installation

Filter Installation

Each unit ships w ith 2-inch filters installed. The quantity of

filters is determined by unit size. Access to the filters is

obtained by removing the indoor fan access panel. If

included, pull on filter removal tool to remove filters.

Refer to the unit Service Facts (shipped with each unit) for

filter requirements.

Note: Do not operate the unit without filters.

Field Installed Power Wiring

An overall dimensional layout for the standard field

installed wiring entrance into the unit i s illustrated in “Unit

Dimensions,” p. 12. T o insure that the unit’s supply power

wiring is properly sized and installed, follow the guidelines

outlined below.

Note: All field installed wiring must conform to NEC

guidelines as well as state and Local codes.

Ve rify that the power supply available is compatible with

the unit’s nameplate ratings. The available supply power

must be within 10 percent of the rated voltage stamped on

the nameplate. Use only copper conductors to connect the

power supply to the unit.

NOTICE:

Use Copper Conductors Only!

Unit terminals ar e not designed t o accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

Note: If the unit is not equipped with an optional factory

installed nonfused disconnect switch or circuit

breaker, a field supplied disconnect switch must be

installed at or near the unit in accordance with the

National Electrical Code (NEC latest edition).

20 RT-SVX26K-EN

Page 21

Installation

Main Unit Power

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Standard Wiring

The electrical service must be protected from over current

and short circuit conditions in accordance with NEC

requirements.

Protection devices must be sized according to the

electrical data on the nameplate.

• If the unit is not equipped with an optional factory

installed nonfused disconnect switch or circuit breaker,

a field supplied disconnect switc h must be installed at

or near the unit in accordance with the National

Electrical Code (NEC latest edition).

• Location of the applicable electrical service entrance is

illustrated in “Unit Dimensions,” p. 12. Complete the

unit’ s power wiring connections onto either; the main

terminal block HT B1 i nsi de t he u ni t co nt ro l panel, the

factory mounted nonfused disconnect switc h (UCD) or

circuit breaker (UCB), or the electric heat terminal

block. Refer to the customer connection d iagram that

shipped with the unit for specific termination points.

• Provide proper grounding for the un it in ac cordan ce

with local and national codes.

Optional TBUE Wiring (Through the Base

Electrical Option)

• Location of the applicable electrical service is

illustrated below. Refer to the customer connection

diagram that is shipped with the unit for specific

termination points. The termination points, dependin g

on the customer option selected would be a factory

mounted nonfused disconnect switc h (UDC) or circuit

breaker (UCB).

• Provide proper grounding for the un it in ac cordan ce

with local and national codes.

Figure 13. Through the base electrical option

Field Installed Control Wiring

An overall layout of the various control options available

with the required number of conductors for each control

device is illustrated in Figure 18, p. 24.

Note: All field wiring must conform to NEC guidelines as

well as state and local codes.

Control Power Transformer

The 24-volt control power transformers are to be used only

with the accessories called out in this manual.

T ransformers rated greater than 50 Vac are equipped with

internal circuit breakers. If a circuit breaker trips, turn “Off ”

all power to the unit before attempting to reset it.

The transformer is located in the control panel. The circuit

breaker is located on the left side of the transformer and

can be reset by pressing in on the black reset button.

RT-SVX26K-EN 21

Page 22

Installation

Controls using 24 Vac

Before installing any connecting wiring, refer to “Unit

Dimensions,” p. 12 for the electrical access locations

provided on the unit and Table 3, p. 22 for AC conductor

sizing guidelines.

NOTICE:

Use Copper Conductors Only!

Unit terminal s are not designed t o accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

1. Use copper conductors unless otherwise specified.

2. Ensure that the AC control wiring between the controls

and the unit’ s termination point does not exceed three

(3) ohms/conductor for the length of the run.

Note: Resistance in excess of 3 ohms per conductor

could cause component failure due to insufficient

AC voltage supply.

3. Be sure to check all loads and conductors for grounds,

shorts, and mis-wiring.

4. Do not run the AC low voltage wiring in the same

conduit with the high voltage power wiring.

5. Route low voltage wiring per illustrations on the next

page.

Table 3. Electromechanical thermostat 24 Vac

conductors with ReliaTel™

Distance from Unit to

Control Recommended Wire Size

000–460 feet 18 gauge

000–140 m 0.75 mm

461–732 feet 16 gauge

2

Table 4. Zone sensor module wiring

Distance from Unit to

Control Recommended Wire Size

0–150 feet (0–45.7 m) 22 gauge (0.33 mm2)

2

151–240 feet (46–73.1 m) 20 gauge (0.50 mm

241–385 feet (73.5–117.3 m) 18 gauge (0.75 mm

386–610 feet (117.7–185.9 m) 16 gauge (1.3 mm

611–970 feet (186.2–295.7 m) 14 gauge ( 2.0 mm

)

2

)

2

)

2

)

Figure 14. ReliaTel™ options module

Figure 15. ReliaTel conventional ther mostat field wir ing

diagram

RTRM

Controls using DC Analog Input/Outputs

(Standard Low Voltage Multiconductor

Wire)

Before installing any connecting wiring between the unit

and components utilizing a DC an alog input\output signal,

refer to “Unit Dimensions,” p. 12 for the electrical access

locations provided on the unit.

1. Table 4 lists the conductor sizing guidelines that must

be followed when interconnecting the DC binary

output devices and the system components utilizing a

DC analog input\output signal to the unit.

Note: Resistance in excess of 2.5 ohms per conductor can

cause deviations in the accuracy of the controls.

2. Ensure that the wiring between controls and the unit’ s

termination point does not exceed two and a half (2.5)

ohms/conductor for the length of the run.

3. Do not run the electrical wires transporting DC signals

in or around conduit housing high voltage wires

22 RT-SVX26K-EN

Page 23

Figure 16. ReliaTel relative humidity sensor

(dehumidification option)

Figure 17. ReliaTel humidistat (dehumidification

option)

Installation

RT-SVX26K-EN 23

Page 24

Installation

BAYSENS075*

BAYSENS075*

BAYSENS119*

BAYSENS110*

BAYSENS108*

BAYSENS106*

BAYSENS073* BAYSENS074*

BAYSENS075*

ASYSTAT669A

OPTIONAL REMOTE SENSOR

Figure 18. Typical field wiring diagrams for optional controls (ReliaTel only)

24 RT-SVX26K-EN

Page 25

Space Temperature Averaging

Space temperature averaging is accomplished by wiring a

number of remote sensors in a series/parallel circuit.

Using the BAYSENS016* or BAYSENS077*, at least four

sensors are required to accomplish space temperature

averaging.

Example #1 illustrates two series circuits with two sensors

in each circuit wired in parallel. Th e square of any number

of remote sensors required. Example #2 illustrates three

sensors squared in a series/parallel circuit. Example #3

illustrates the circuit required for this senor. Table 5 lists

the temperature versus resistance coefficient for all

sensing.

Table 5. Temperature vs. resistance

Degrees

-20 -28.9 170.1

-15 -26.1 143.5

-10 -23.3 121.4

-5 -20.6 103.0

0 -17.8 87.56

5 -15.0 74.65

10 -12.2 63.80

15 -9.4 54.66

20 -6.7 46.94

25 -3.8 40.40

30 -1.1 34.85

35 1.7 30.18

40 4.4 26.22

45 7.2 22.85

50 10.0 19.96

55 12.8 17.47

60 15.6 15.33

65 18.3 13.49

70 21.1 11.89

75 23.9 10.50

80 26.7 9.297

85 29.4 8.247

90 32.2 7.330

95 35.0 6.528

100 37.8 5.824

Nominal Resistance

(K-Ohms) °F °C

Installation

RT-SVX26K-EN 25

Page 26

Installation

Table 6. Space temperature averaging examples

26 RT-SVX26K-EN

Page 27

Installation

Table 7. Gas heater operating data

Heating Input Rate—Btu/h

Minimum Supply Gas Pressure Natural/

Manifold Gas Pressure

Combustion Blower Suction Pressure (1

(With Gas Valve Closed) (2

Minimum Flame Sensing Current

Normal Sensing Current Range 8.0 to 16.0 Microamps D.C.

Flue Gas Temperature Rise Above

Flue Gas Content - %CO

Minimum Supply Air Temperat ure Across

(a) For 50 Hertz applications, multiply rated Btu/h by 83 percent.

(b)Staged gas heat units have a negative pressure gas valve. Never adjust

the staged gas pressure valve to a positive pressure.

(c) A voltage reading across pens (V+) & (V-) is eq uatable to the flame sens-

ing current. One volt equals one micro amp.

LP

Stage)

Ambient

Natural LP 9.5 to 10.5

Heat Exchanger

(a)

135,000 205,000

3.5” w.c./ 8.0” w.c.

(b)

st

-2.1 to -3.1”

nd

Stage) N/A -2.1 to -3.1” w.c.

(c)

2

-0.2” w.c

w.c.

5.0 Microamps D.C.

400°F to

500°F

8.3 to 9.5 8.0 to 9.0

-0.8 to -1.2”

w.c.

350°F to

475°F

40°F

Table 8. Piping

Length of

Pipe (ft)

Note: Capacity of Pipe of Different Diameters and Lengths in Cu. Ft. Per

½” Pipe ¾” Pipe 1” Pipe 1¼” Pipe 1½” Pipe

15 76 176 345 750 1220

30 52 120 241 535 850

45 43 99 199 435 700

60 38 86 173 380 610

75 - 77 155 345 545

Hr. with Pressure Drop of 0.3" and Specific Gravity of 0.60

Iron Pipe Size (IPS) Inches

Table 9. Specific gravity multipliers

Specific Gravity Multipliers

0.50 1.10

0.55 1.04

0.60 1.00

0.65 0.96

Figure 19. Schematic diagram for field gas piping to

units

Figure 20. Typical unit gas train configuration

Use the following checklist in conjunction with the general

checklist (“General Unit Requirements,” p. 19) to ensure

that the unit is properly installed and ready for operation.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the pow er can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

• Check all electrical connections for tightness and

“point of termination” accuracy.

• Verify that the condenser airflow will be unobstructed.

• Verify that the condenser fan and indoor blower turn

freely without rubbing and are properly tightened on

the shafts.

• Check the supply fan belts for proper tension an d the

fan bearings for sufficient lubrication. If the belts

require adjustment, or if the bearings need lubricating,

refer to the maintenance section of this manual for

instructions.

• Verify that a condensate trap is installed and the piping

is properly sized and pitched.

• Verify that the cor rect siz e and number of filters are in

place.

• Inspect the interior of the unit for tools and debris and

install all panels in preparation for starting the unit.

RT-SVX26K-EN 27

Voltage Imbalance

Three phase electrical power to the unit must meet

stringent requirements for the unit to operate properly.

Measure each leg (phase-to-phase) of the power supply.

Page 28

Installation

Each reading must fall within the utilization range stamped

on the unit nameplate. If any of the readings do not fall

within the proper tolerances, notify the power company to

correct this situation before operating the unit.

Excessive three phase voltage imbalance between phases

will cause motors to overheat and eventually fail.

The maximum allowable voltage imbalance is 2 percent.

Measure and record the volta ge between phases 1, 2, and

3 and calculate the amount of imbalance as follows:

% Voltage Imbalance =

100 X AV - VD

AV

AV (Average Voltag e) =

Volt 1 + Volt 2 + Volt 3

• V1, V2, V3 = Line Voltage Readings

• VD = Line Voltage reading that deviates the farthest

from the average voltage.

Example: If the voltage readings of the supply power

measured 221, 230, and 227, the average volts would be:

where;

3

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the pow er can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

• T urn the field supplied disconnect switch that provides

power to the main power terminal block or to the

“Line” side of the optional factory mounted disconnect

switch to the “Off” position.

• Connect the phase sequence indicator leads to the

terminal block or to the “Line” side of the optional

factory mounted disconnect switch as follows;

Black (phase A) to L1

Red (phase B) to L2

Yellow (phase C) to L3

• Close the field supplied main power disconnect switch

or circuit protector switch that provides the supply

power to the unit.

221 + 230 + 227

3

• VD (reading farthest from average) = 221

• The percentage of Imbalance equals:

100 X 226 - 221

226

The 2.2 percent imbalance in this example exceeds the

maximum allowable imbalance of 2.0percent. This much

imbalance between phases can equal as much as a

20 percent current imbalance with a resulting increase in

motor winding temperatures that will decrease motor life.

If the voltage imbalance is over 2 percent, notify the proper

agencies to correct the voltage problem before operating

this equipment.

= 226 Avg.

= 2.2%

Electrical Phasing (Three Phase Motors)

The compressor motor(s) and the supply fan motor are

internally connected for the proper rotation when the

incoming power supply is phased as A, B, C.

Proper electrical supply phasing can be quic kl y

determined and corrected before starting the unit by using

an instrument such as an Associated Research Model 45

Phase Sequence Indicator and following the steps below:

WARNING

Live Electrical Components!

During installation, testing, servicing and

troubleshooting of this product, it may be necessary to

work with live electrical components. Have a qualified

licensed electrician or other individual who has been

properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical

safety precautions when exposed to live electrical

components could result in death or serious injury.

• Observe the ABC and CBA phase indicator lights on the

face of the sequencer. The ABC indicator light will glow

if the phase is ABC. If the CBA indicator light glows,

open the disconnect switc h or circuit protection switc h

and reverse any two power wires.

• Restore the main electrical power and recheck the

phasing. If the phasing is correct, open the disconnect

switch or circuit protection switch and remove the

phase sequence indicator.

Compressor Crankcase Heaters

NOTICE:

Compressors Failure!

Unit must be powered and cr ankcase heaters energiz ed

at least 8 hours BEFORE compressors are started. This

will protect the compressors from premature failure.

28 RT-SVX26K-EN

Each compressor can be equipped with a crankcase

heater. The proper operation of the crankcase heater is

important to maintain an elevated compressor oil

Page 29

Installation

temperature during the “Off” cycle to reduce oil foaming

during compressor starts. Oil foaming occurs when

refrigerant condenses in the compressor and mixes with

the oil. In lower ambient conditions, refrigerant migration

to the compressor could increase.

When the compressor starts, the sudden reduction in

crankcase pressure causes the liquid refrigerant to boil

rapidly causing the oil to foam. This condition could