Trane X1351153001, X1351152701, X1379084501, X1379085101, X1379084801 Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation, and

Maintenance

Wired Temperature Sensors

December 2008

BAS-SVX10C-EN

Page 2

Copyright

© 2008 Trane All rights reserved

This document and the information in it are the property of Trane and may not be used

or reproduced in whole or in part, without the written permission of Trane. Trane reserves

the right to revise this publication at any time and to make changes to its content without

obligation to notify any person of such revision or change.

Trademarks

Trane and its logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

Warnings, Cautions, and Notices

Warnings, cautions, and notices are provided in appropriate places throughout this

document:

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

NOTICE: Indicates a situation that may result in equipment or property-damage-

only accidents.

Page 3

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Height Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation and Configuration: Display Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Configuring the Display Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Optional Configuration Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation: All Models Other Than the Display Sensor . . . . . . . . . . . . . . . . . . . 17

Mounting the Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the COMM Module (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Changing the Setpoint Thumb Wheel (optional) . . . . . . . . . . . . . . . . . . . . . . 21

Wiring the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Changing Temperature Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Changing System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Changing Fan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Selecting Temporary Occupancy (Timed Override) . . . . . . . . . . . . . . . . . . . . 24

Service Pin Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sensors with Occupied/Unoccupied Buttons . . . . . . . . . . . . . . . . . . . . . . 25

Display Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Star(*)/Double Star(**) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Sensors with Thumb Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Display Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Display Sensor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing Temperature Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing Heating and Cooling Temperature Settings (dual setpoint sys-

tems only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Changing Fan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BAS-SVX10C-EN 3

Page 4

Requesting Temporary Occupancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Lock Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Error Codes (Display Sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Display Sensor: Output Values—Failure and Default Modes of Operation 29

Measuring Output Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Display Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

All Models Other Than the Display Sensor . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Replacing the Thumb Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Temperature sensors with fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Temperature sensors with fan and system control . . . . . . . . . . . . . . . . . . . . 37

Optional COMM module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Specifications and Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Declaration of CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4

Page 5

General Information

This section provides a description of the wired temperature sensors, as well as part numbers and

dimensions.

Product Description

Note: The information in this manual applies to both factory and field installed versions of Trane

wired temperature sensors.

®

Tra ne

wired temperature sensors are compatible with any Trane unit controller that uses a

standard 10 kW temperature input. Temperature monitoring is standard on all models. Additional

features are available on some models:

• Fan control

•System control

• Dual or single temperature setpoint control

• Occupancy (timed override) request function

• COMM module—Optional accessory that provides an RJ22 connection for a Trane service tool

for system communication. Must be ordered separately.

• Hot/cold setpoint thumb wheel—Optional accessory allows selecting a temperature setpoint by

color (red/blue for hot/cold) on thumbwheel, rather than by a number. Must be ordered

separately.

The display sensor (p/n X13790886) has an LCD display and includes an RJ11 (RJ22 compatible)

connection for a Trane service tool for system communication. The following features on this

sensor are configurable:

• Temperature units: Fahrenheit (ºF) or Celsius (ºC)

• Temperature resolution: 1.0, 0.5, or 0.1 degrees

• Ability to display setpoint only (zone temperature does not display)

• Single, dual, or no setpoint

• System settings: auto, off, cool, heat, emergency heat

• Deadband (heat/cool setpoint offset for dual setpoint systems)

• Fan settings: high, medium, low, auto, off

• Occupancy (timed override request) function

• Lockable settings to protect against unauthorized use

• Service pin request

BAS-SVX10C-EN 5

Page 6

General Information

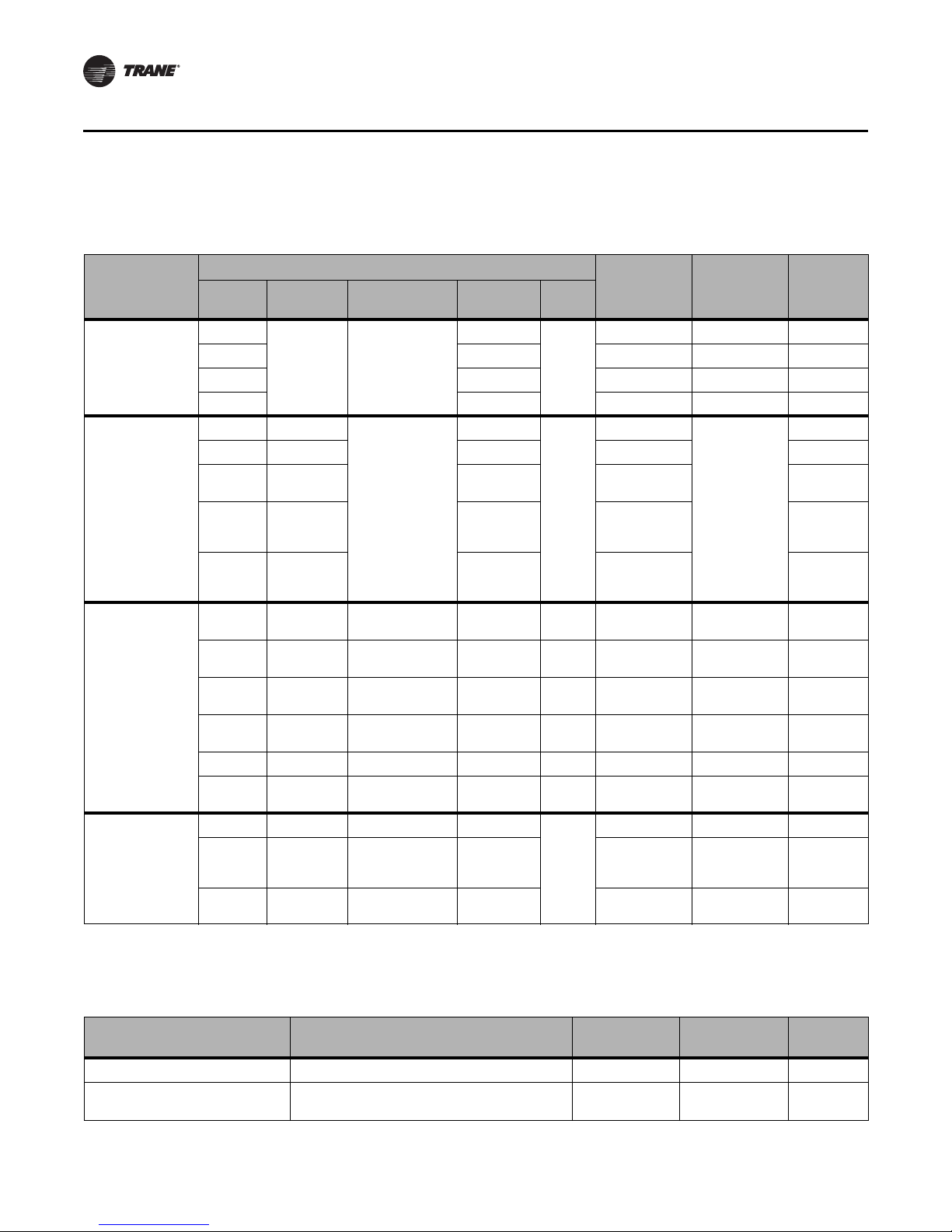

Part Numbers

The following table lists part numbers for each sensor type.

Features

Sensor type

Single

Temperature

sensors

Temperature

sensors with fan

control

Temperature

sensors with fan

and system control

Temperature

sensor with LCD

(1)(2)

display

(1)These sensors can be field configured to match the appli cable unit controller options.

(2)Unit controller inputs for system status, fan status, and service required are not available on this sensor. If replacing a BAYSENS031A or a BA YSENS035A

sensor, and status indicators are required, replace with non-display sensor BAYSENS109A or BAYSENS110A.

No No X1351152801 BAYSENS077A SEN01448

Single No X1351152901 BAYSENS075A SEN01449

No Yes X1351153001 BAYSENS073A SEN01450

Single Off/Auto

Single Off/Run Yes X1379085101 SEN01527

Single

Single

Single

Dual Auto/High

Single Auto/High

Dual Auto/High

Dual Auto/High

Single Auto/High Cool/Off/Heat No No X1379083901 BAYSENS106A SEN01515

Single Low/High

Single No No Yes

Single

Dual

control System Occupancy LEDs

Yes

No No

Yes

Off/Auto/

Low/High

Off/Auto/

Low/Med/

High

Off/Auto/

Low/Med/

High

Off/On/

Auto/Low/

Med/High

Auto/On Cool/Off/Auto/

No

Cool/Off/Auto/

Heat/Em Heat

Cool/Off/Heat/

Em Heat

Cool/Off/Auto/

Heat

Cool/Off/Auto/

Heat

Cool/Off/Heat/

Fan

No

Heat/Em Heat

Yes X1379084801 SEN01524

No X1379084101 SEN01517

Yes X1379084201 SEN01518

No Yes (4) X1379084701 BAYSENS109A SEN01523

No Yes (1) X1379085201 BAYSENS107A SEN01528

No No X1379083701 BAYSENS108A SEN01513

No Yes (4) X1379084601 BAYSENS110A SEN01522

No No X1379085001 NA SEN01526

No X1379088604 NA NA

No X1379088605 BAYSENS135A NA

Part number BAYSENS

X1351152701 BAYSENS074A SEN01447

No

X1379084501

No

X1379088601 NA SEN01599

No

NA

Fan

Global

partsSetpoint

SEN01521

The following table lists part numbers for optional accessories.

Accessory Available for . . . Part number BAYSENS

COMM module (box of 12) All sensors other than the display sensor X1365146702 BAYCOMM005A CON01313

Setpoint thumb wheel: Hot/cold

(box of 12)

6 BAS-SVX10C-EN

Sensors with thumb wheels X1316105702 NA KNB00182

Global

parts

Page 7

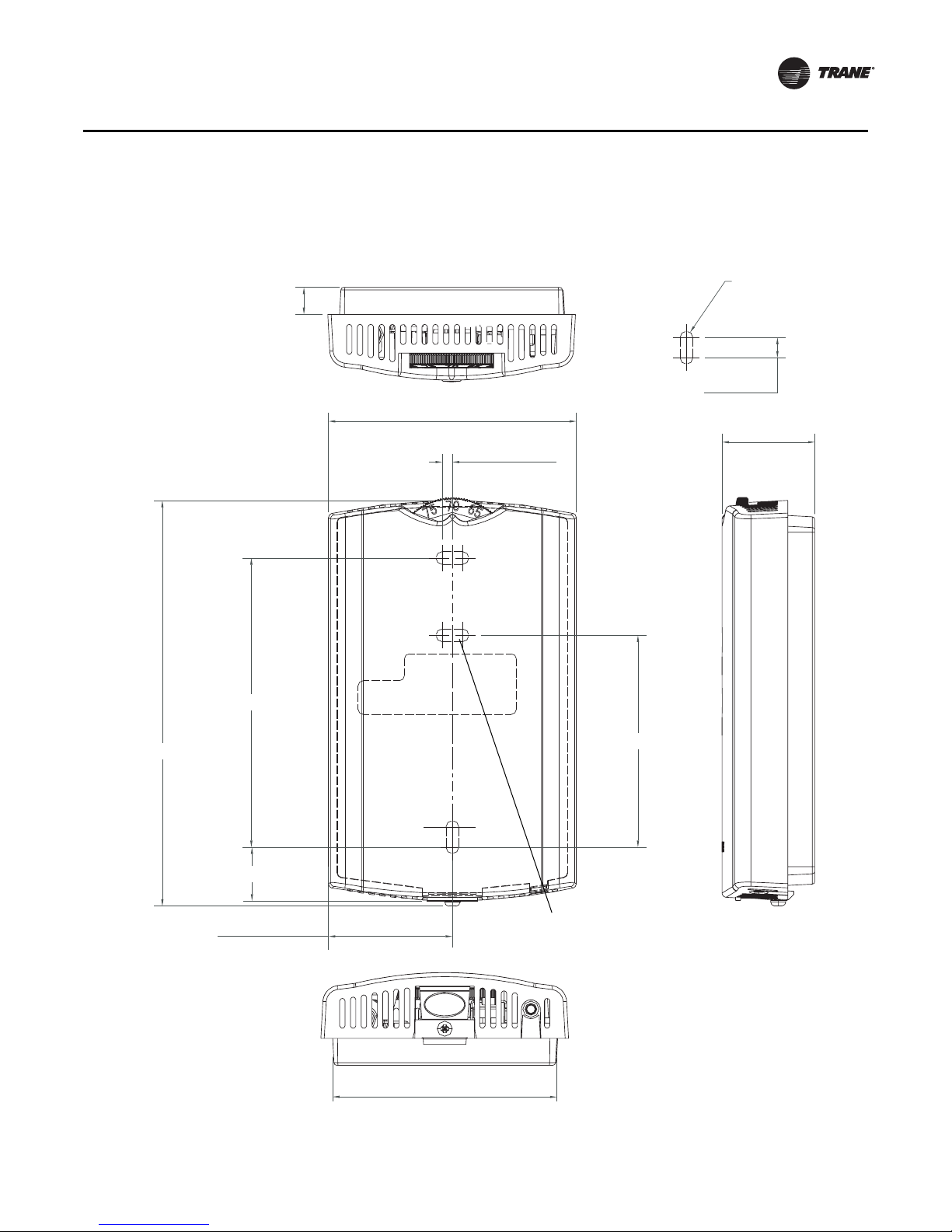

Dimensions

2.9 in (73.5 cm)

1.08 in (27.5 mm)

4.68 in (118.9 mm)

1.45 in (36.8 mm)

0.63 in (15.9 mm)

0.31 in (8 mm)

0.12 in (3 mm)

TYP R.07 in

(R1.9) mm)

3.39 in (86 mm)

2.48 in (63 mm)

2.62 in (66.5 mm)

TYP 0.24 in (6 mm)

Note: There is no center

mounting hole on the

display sensor.

General Information

The following illustration provides specific dimension details. The dimensions are the same for all

models.

BAS-SVX10C-EN 7

Page 8

Pre-Installation

This section provides the following pre-installation information:

• Location considerations

• Height requirements

• Mounting surfaces

Location Considerations

Placement of the sensor is critical to proper operation. When selecting a location, avoid the

following:

• Areas of direct sunlight

• Areas in the direct airstream of air diffusers

• Exterior walls and other walls that have a temperature differential between the two sides

• Areas that are close to heat sources such as sunlight, appliances, concealed pipes, chimneys,

or other heat-generating equipment

• Drafty areas

• Dead spots behind doors, projection screens, or corners

• Walls that are subject to high vibration

• Areas with high humidity

• High traffic areas (to reduce accidental damage or tampering)

Height Requirements

The recommended maximum mounting height is 54 inches from the bottom of the back plate to

the floor. If a parallel approach by a person in a wheelchair is required, reduce the maximum height

to 48 inches.

Note: Consult section 4.27.3 of the 2002 ADA (Americans with Disability Act) guideline, and local

building codes, for further details regarding wheelchair requirements.

Mounting Surfaces

Using the hardware provided, mount the back plate to a flat surface such as sheetrock or plaster,

or an electrical junction box. The sensor must be mounted plumb for accurate temperature control

and to ensure proper air movement through the sensor.

• If mounting onto sheetrock or plaster, use the plastic threaded anchors (pre-drilling holes is not

usually necessary) and the two M3.5 x 20 mm mounting screws.

• For mounting onto an electrical junction box, use the two 6-32 x 3/4 in. screws.

8 BAS-SVX10C-EN

Page 9

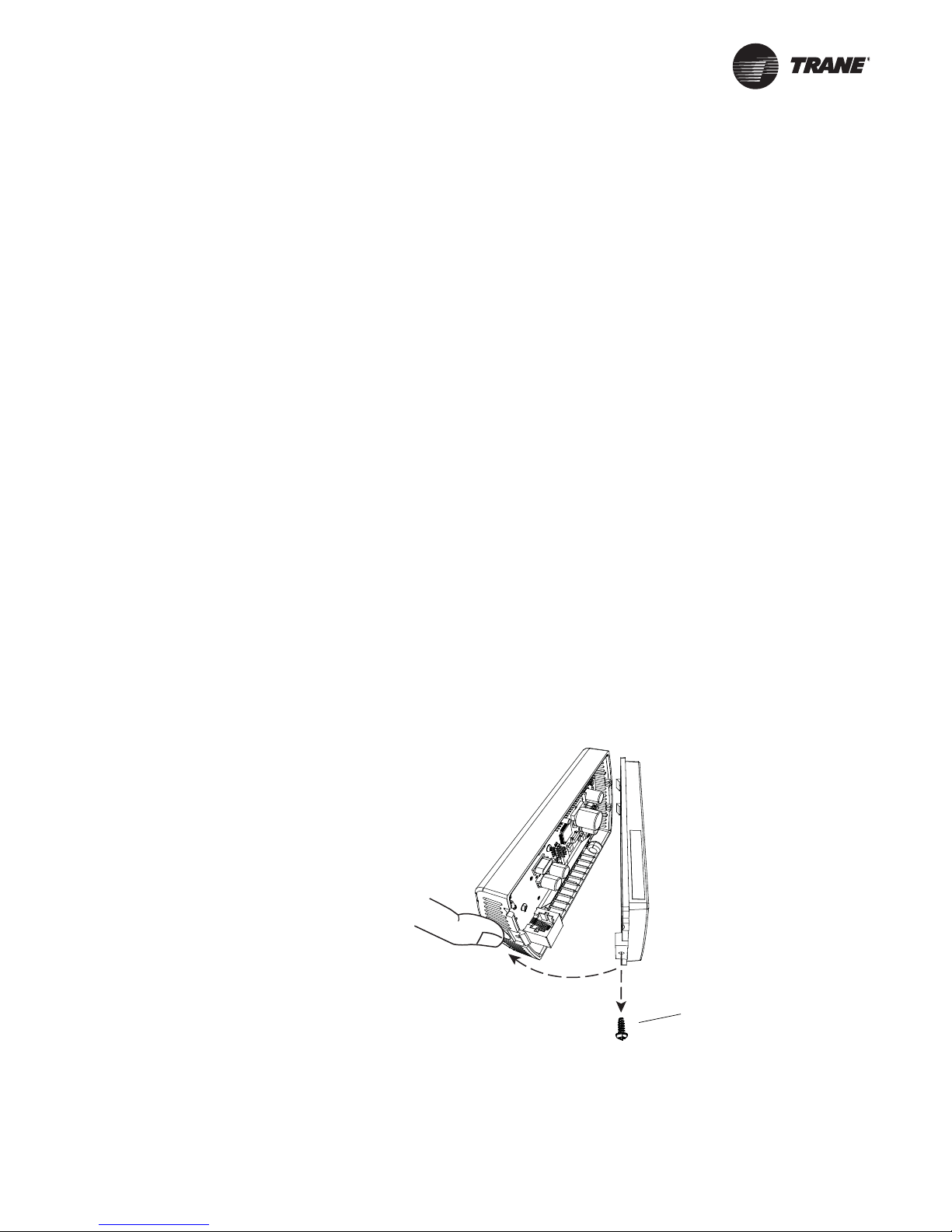

Security screw

Installation and Configuration: Display Sensor

This section provides step-by-step installation instructions for the display sensor (see applicable

part numbers for the temperature sensor with LCD display on p. p. 6). For installation of all other

sensor models, see p. 17.

Read through the pre-installation information(p. 8) before proceeding with the installation.

Note: Before installing a wired sensor, ensure that a wire access hole is available at the sensor

location and the wire is accessible through the hole. The technician should assume that the

wires are attached to the appropriate unit controller, that there is continuity between the

sensor location and the controller, and that the wires are accurately labeled or identified by

color.

Mounting the Back Plate

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

Note: Refer to the illustration below when installing the sensor.

1. Shut off power to the unit controller.

2. Remove the cover by firmly pressing the thumb tab at the bottom of the cover and pulling the

cover away from the back plate.

Note: If present, remove the security screw before removing the cover.

3. Feed the wires through the opening in the back plate.

4. Hold the back plate against the mounting surface and mark the screw locations.

5. Secure the back plate to the mounting surface using the included hardware.

BAS-SVX10C-EN 9

Page 10

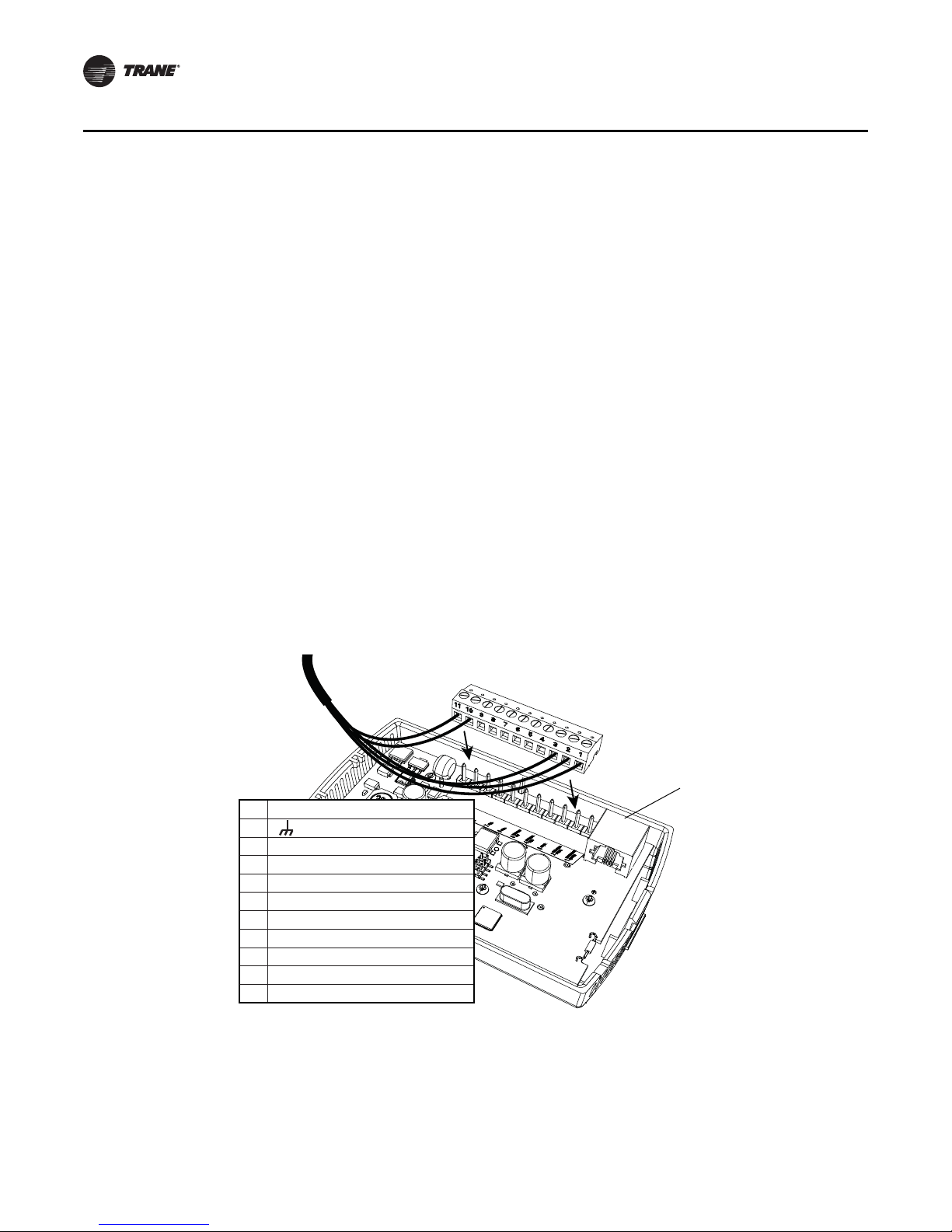

11 24 VAC/VDC

10 (GROUND)

9

8

7COMM–

6COMM+

5 HEAT SETPOINT (HSP)

4 SYS/FAN MODE (MODE)

3 SETPOINT

2 SIGNAL COMMON (COMMON)

1 ZONE TEMPERATURE (ZONE TEMP)

RJ11 (RJ22 compatible)

connection for a Trane

service tool

Installation and Configuration: Display Sensor

Wiring the Sensor

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

To wire the sensor to the unit controller:

1. Ensure that the wires are connected to the appropriate terminals at the unit controller.

2. Insert each wire into the appropriate location in the terminal block (see the table in Figure 1).

Tighten the terminal screw.

Note: The wire connections can be made while the terminal block is either on the circuit board,

or removed from it.

3. Perform a pull test to ensure that the wires are properly connected.

4. If the terminal block was removed from the circuit board, attach it to the pins inside the sensor

cover (Figure 1).

Figure 1. Attaching the terminal block to the pins on the circuit board

10 BAS-SVX10C-EN

5. Push the excess wire into the wall cavity and plug it with nonflammable insulation to prevent

drafts from affecting the sensor.

Important: Do not coil excess wire inside the back plate.

Page 11

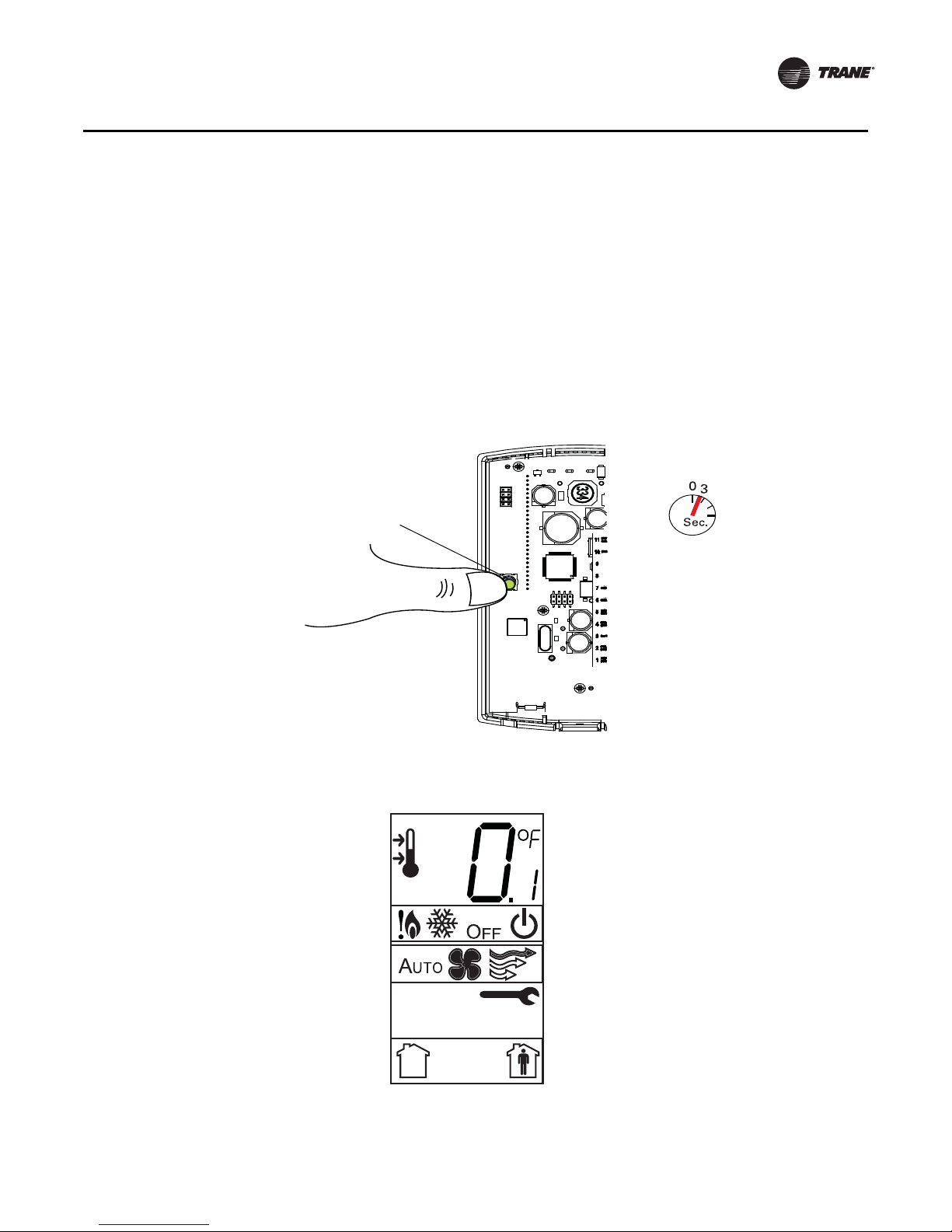

Configuring the Display Sensor

Configuration button

The configuration of the display sensor determines which system features can be accessed and

changes can be made by the tenant (for example, changes to cooling/heating mode, setpoint, or

fan speed. Verify system and associated unit features before configuring the sensor.

The building owner or operator may choose to limit tenant access to certain features. This can be

done through configuration. Or, if a sensor is configured to match all controllable features of the

associated equipment, the locking feature can be used to restrict the tenant from making changes.

Configuration Procedure

To configure settings on the sensor, follow this procedure in the order presented.

1. Press the configuration button for 3 seconds.

Installation and Configuration: Display Sensor

The display will change to configuration mode. When the sensor is in configuration mode, a wrench

symbol appears on the display and the menus are separated by lines, as illustrated below.

BAS-SVX10C-EN 11

Page 12

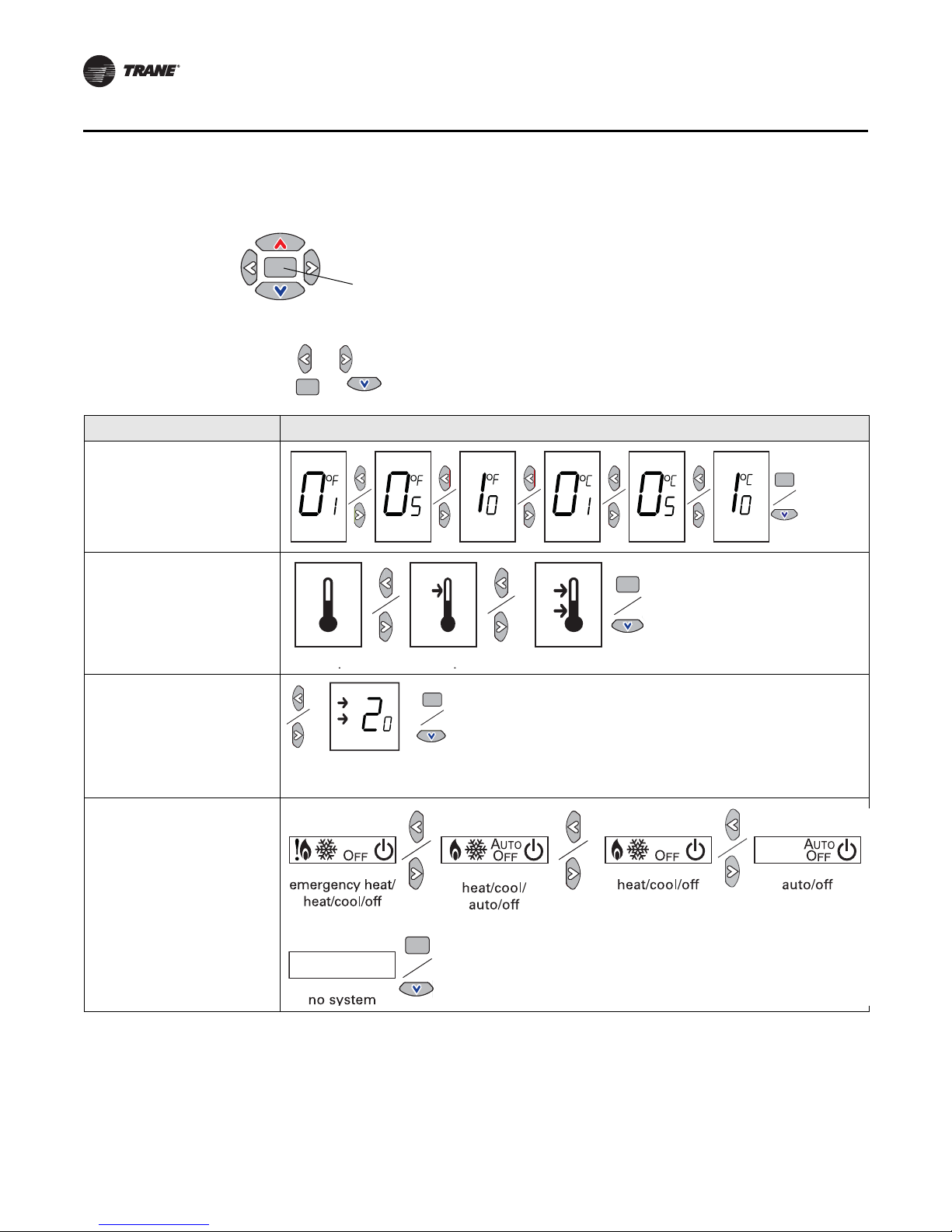

Center button

. .

.

.

.

.

dual setpoint

no

single

heat/cool setpoint offset

2ºF – 10.8ºF, 1.1ºC – 6ºC

Installation and Configuration: Display Sensor

1. Press the center button on the keypad to begin the configuration process.

2. Configure the sensor options in the order shown in the table.

• Press or to scroll to the next selection (as illustrated).

• Press or to move to the next menu (as illustrated).

Setting Configuration options

Temperature

• Choose Fahrenheit or Celsius

• Choose the degree resolution

(whole degrees, half degrees, or

tenths of degrees)

Setpoint

Deadband (available for dual

setpoint system only)

Note: Deadband refers to the

minimum difference between

the heating and cooling

setpoints.

System

a) Single setpoint

.

heat/cool setpoint offset

(1.8˚F – 10.8˚F, 1˚C – 6˚C)

12 BAS-SVX10C-EN

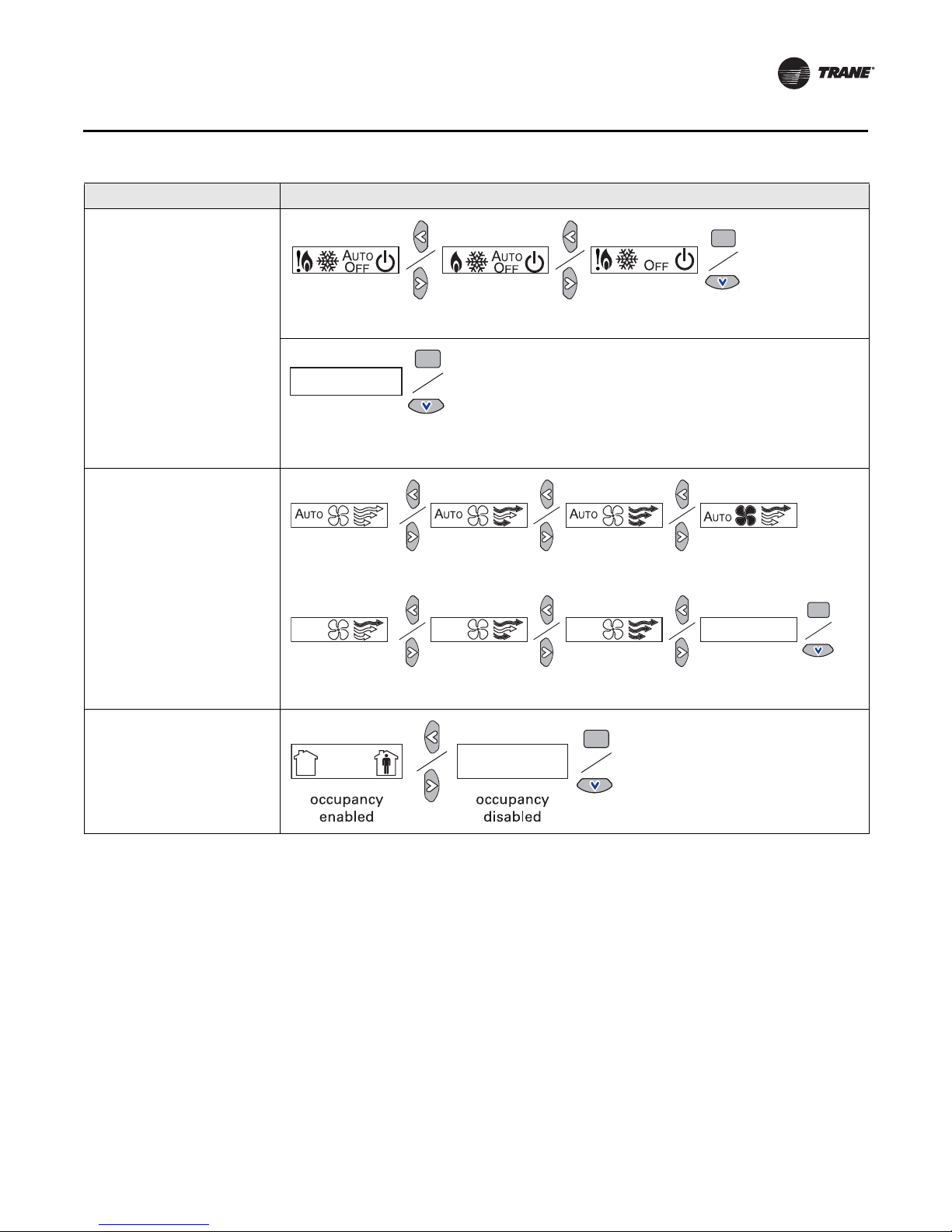

Page 13

Setting Configuration options

emergency heat/

heat/cool/off

heat/cool/

auto/off

emergency heat/

heat/cool/auto/off

no system

options enabled

auto/off/low

med/high

auto/off/

low/high

auto/off

off/high (on)

off/low/high off/low/

med/high

no fan options

enabled

auto/high (on)

System (continued)

b) Dual setpoint

c) No setpoint

Fan

Installation and Configuration: Display Sensor

Note: Not all fan options are

available for all systems.

Occupancy (timed override)

BAS-SVX10C-EN 13

Page 14

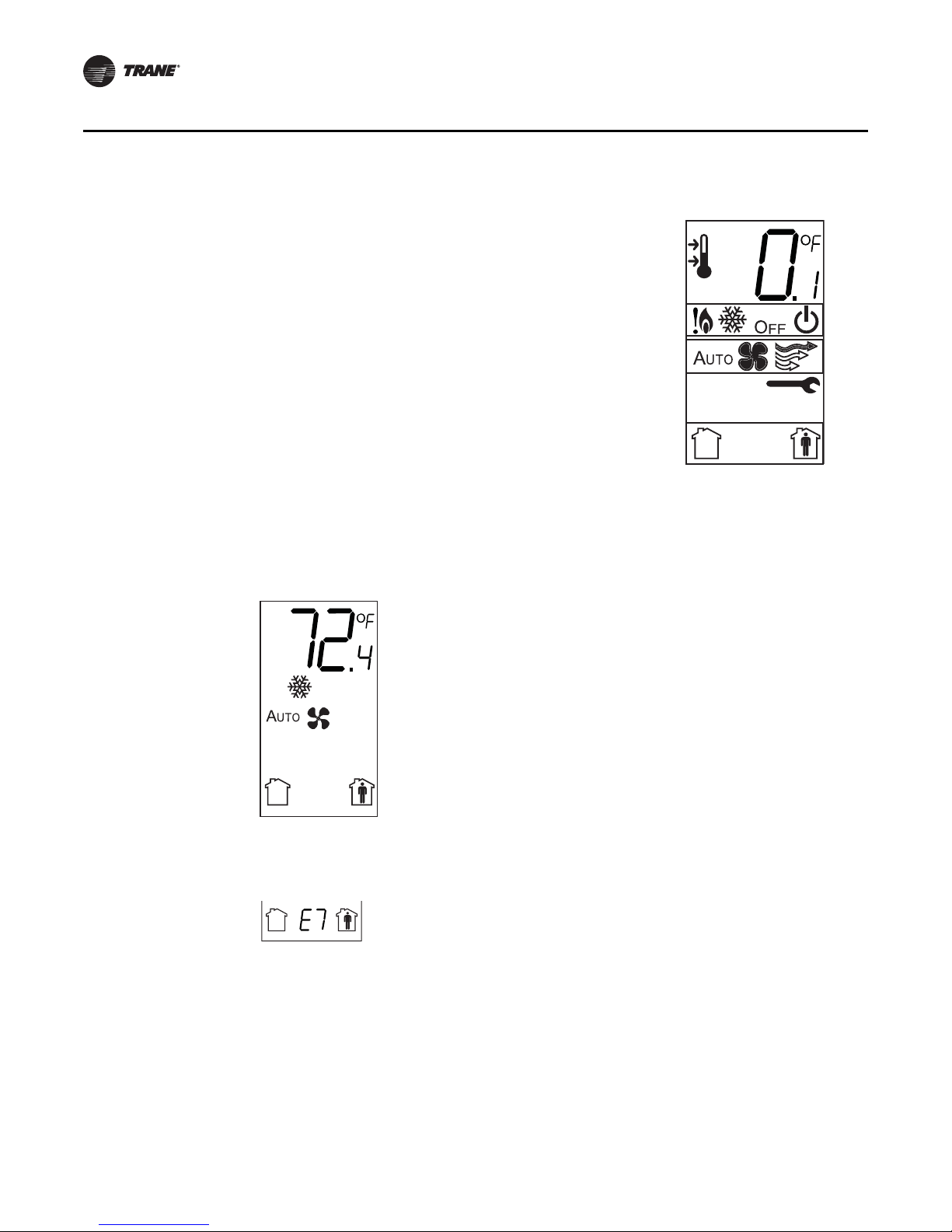

The example shows a display that has been configured for:

• Dual setpoint

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System settings: Emergency Heat, Heat, Cool, Off

• Fan settings: Auto or On

• Occupied/unoccupied option enabled

Display shows the following:

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System setting: Cooling

• Fan setting: Auto

• Occupied/unoccupied option enabled

Installation and Configuration: Display Sensor

1. Review the display to ensure that you have selected the correct configuration options.

2. To return the display to operating mode, press the configuration button (see step 1, p. 11).

Note: The sensor will revert to operating mode if no buttons are pressed for 10 minutes.

The following example shows a configured display in operating mode.

If an error code exists, it appears at the bottom of the display between the occupancy symbols,

as shown below. See “Error codes,” p. 28, for error code definitions.

14 BAS-SVX10C-EN

Page 15

Optional Configuration Features

Arrow

indicates

setpoint is

shown on

display

Setpoint

System menu

Fan menu

Displaying Setpoint or Temperature

You can configure the sensor to display either the temperature (default) or setpoint. To select either

option:

1. Verify that the sensor is in operating mode and at the home screen.

2. Press the up and down arrows for 3 seconds. The arrow indicates setpoint display, as shown

in the illustration.

Installation and Configuration: Display Sensor

Locking or Unlocking Settings

You can lock or unlock the setpoint, system, or fan setting to prevent changes.

To lock or unlock a setting:

1. Verify that the sensor is in operating mode and at the home screen.

2. Choose a setting to lock or unlock:

• Select the setpoint by pressing the up or down arrow.

• Select the system menu by pressing the center button. Use the left or right arrow to choose

the setting.

• From the system menu press the down arrow to select the fan menu. Use the left or right

arrow to choose the setting.

BAS-SVX10C-EN 15

Page 16

Security screw

Installation and Configuration: Display Sensor

3. Press the left and right arrows for 4 seconds. The lock symbol will appear on the display

to indicate that the setting has been locked.

Note: If you try to access a feature that is locked, the locked symbol appears on the display.

If you press a keypad button to try change a locked setting, the locked symbol flashes.

Replacing the Cover

To replace the cover:

1. Hook the cover over the top of the back plate. Apply light pressure to the bottom of the cover

until it snaps in place.

2. Secure the cover by installing the security screw into the bottom of the cover.

16 BAS-SVX10C-EN

Page 17

Installation: All Models Other Than the Display Sensor

This section provides step-by-step installation instructions for all sensor models other than the

display sensor. (For installation of the display sensor, see p. 9.) Read through the pre-installation

information before proceeding with the installation.

Note: Before installing a wired sensor, ensure that a wire access hole is available at the sensor

location and the wire is accessible through the hole. The technician should assume that the

wires are attached to the appropriate unit controller, that there is continuity between the

location and the controller, and that the wires are accurately labeled or identified by color.

Mounting the Back Plate

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

1. Shut off power to the unit controller.

2. Remove the cover by firmly pressing the thumb tab at the bottom of the cover and pulling the

cover away from the back plate.

Note: If present, remove the security screw before removing the cover.

BAS-SVX10C-EN 17

Page 18

Terminal block

Thumb catch

Installation: All Models Other Than the Display Sensor

3. Remove the circuit board by pressing the thumb catch on the left side of the board. Use the

terminal block to lift the circuit board from the back plate.

4. Feed the wires through the opening in the back plate.

5. Hold the back plate against the mounting surface and mark the screw locations.

6. Secure the back plate to the mounting surface using the included hardware.

7. Feed the wires through the opening in the circuit board.

8. Replace the circuit board by sliding the right side of the board under the two catches on the right

side of the back plate, while aligning slot on board with tab on back plate. Press firmly on the

left side of the circuit board to snap it into place.

18 BAS-SVX10C-EN

Page 19

Circuit board fits under catches

Slot on circuit board aligns with tab on back plate

Installation: All Models Other Than the Display Sensor

BAS-SVX10C-EN 19

Page 20

Thumb catch

COMM module

Catches

Installation: All Models Other Than the Display Sensor

Installing the COMM Module (optional)

An optional COMM module is available that provides a local RJ22 connection to a Trane service tool

for maintenance use. It must be ordered separately.

Install the COMM module before wiring the sensor:

1. Slide the two cutouts on the right side of the COMM module into the two keys on the back plate.

2. Press firmly on the left side of the COMM module board until it snaps into place.

20 BAS-SVX10C-EN

Page 21

Installation: All Models Other Than the Display Sensor

Flat portion of potentiometer

Stop

Changing the Setpoint Thumb Wheel (optional)

Sensors with temperature setpoint control have pre-installed Fahrenheit setpoint thumb wheels.

A Celsius setpoint thumb wheel is included with these sensors. An optional hot/cold setpoint

thumbwheel can be ordered separately.

To change the thumb wheel:

1. Remove the cover by firmly pressing the thumb tab at the bottom of the cover and pulling the

cover away from the back plate.

Note: If present, remove the security screw before removing the cover.

2. Remove the existing thumb wheel by pulling it straight out while holding the circuit board

securely onto the back plate.

3. Rotate the replacement thumb wheel until the stop is opposite the flat portion of the

potentiometer. Push down on the thumb wheel until the ribs touch the potentiometer. After it

is inserted, the thumb wheel should turn freely.

Wiring the Sensor

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

To wire the sensor, use the appropriate diagram illustrated in“Wiring Diagrams,” p. 33.

Note: Strip 1/4 inch of insulation from wires before connecting them to the terminal block.

BAS-SVX10C-EN 21

Page 22

Security screw

Installation: All Models Other Than the Display Sensor

Replacing the Cover

To replace the cover:

1. Hook the cover over the top of the back plate. Apply light pressure to the bottom of the cover

until it snaps in place.

2. Secure the cover by installing the security screw into the bottom of the cover.

22 BAS-SVX10C-EN

Page 23

Operation

This section describes sensor operations.

Changing Temperature Settings

To change temperature settings:

• For sensors with temperature setpoint thumb wheels (located on top of the sensor), rotate the

thumb wheel to the desired temperature setting.

Note: If you need to change or replace a thumb wheel, see “Changing the Setpoint Thumb

Wheel (optional),” p. 21.

• For sensors with dual temperature sliders (located on the right front of the sensor): Slide the

blue (cool) slider to the desired maximum temperature setting. Slide the red (heat) slider to the

desired minimum temperature setting.

• For the display sensor, see “Changing Temperature Settings,” p. 27 and “Changing Heating and

Cooling Temperature Settings (dual setpoint systems only),” p. 27.

Changing System Settings

To change system settings:

• For sensors with system thumb wheels (located on the upper left side), rotate the thumb wheel

to the desired setting.

• For the display sensor, see “Changing System Settings,” p. 28.

Notes:

• Not all sensor models have all system setting options.

• The effect of setting changes are dependent on the unit controller. See specific unit controller

manual for details.

Changing Fan Settings

To change fan settings:

• For sensors with fan thumb wheels (located on the lower left side), rotate the thumb wheel to

the desired setting.

• For the display sensor, see “Changing Fan Settings,” p. 28.

Notes:

• Not all sensor models have all fan setting options.

• The effect of setting changes are dependent on the unit controller. See specific unit controller

manual for details.

BAS-SVX10C-EN 23

Page 24

Occupied button

Unoccupied button

Operation

Selecting Temporary Occupancy (Timed Override)

Temporary occupancy (timed override) is available on some sensors. Temporary occupancy can be

selected to adjust temperature, fan, or heat/cool settings after the system has changed to

unoccupied mode. System control will revert to unoccupied after a pre-determined time period.

Note: Not all systems support the occupancy function.

Sensors with Occupied/Unoccupied buttons

To select temporary occupancy, press the Occupied button (Figure 2) for 0.2–6 seconds. The

following occurs:

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 4 seconds.

To cancel temporary occupancy, press the Unoccupied button (Figure 2) for 0.2–6 seconds. The

following occurs:

• Space temperature output is driven to 1330 Ω (nominal).

• The output generates for 4 seconds.

Figure 2. Locations of Occupied button and Unoccupied buttons

Display Sensors

To select and cancel temporary occupancy, see “Requesting Temporary Occupancy,” p. 28.

24 BAS-SVX10C-EN

Page 25

Service Pin Request

Center button

Right arrow key

Some sensor models can communicate a service pin request to their connected unit controller.

Sensors with Occupied/Unoccupied Buttons

To initiate a service pin request, press the Occupied button (Figure 2, p. 24) for 10–25 seconds. The

following occurs:

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 15 seconds.

Display Sensor

To initiate a service pin request, the sensor must be configured to support occupancy and must be

in operating mode (see “Configuring the Display Sensor,” p. 11).

To initiate a service pin request:

1. With the sensor in operating mode, navigate to the occupancy menu.

2. Press the right arrow on the keypad (Figure 3). The occupied symbol remains on the screen; the

unoccupied symbol leaves the screen.

3. Press and hold the center button for 10 seconds. The following occurs:

• The wrench symbol appears.

• A service pin request is initiated.

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 15 seconds.

• After 15 seconds, the wrench symbol disappears.

Operation

Figure 3. Location of keys for service pin request

BAS-SVX10C-EN 25

Page 26

“**” on setpoint thumb wheel

(“*” is hidden from view)

Operation

Star(*)/Double Star(**) Function

The star/double star function is available on sensor models with thumb wheels and on the display

sensor.

Note: Consult the appropriate unit controller documentation for information about this function.

Sensors with Thumb Wheels

Turning the thumb wheel clockwise makes the star(*) visible; turning it counter-clockwise makes

the double star(**) visible (see Figure 4).

• Star(*): A value of 95ºF (35ºC) is communicated.

• Double star(**): A value of 44.6ºF (7ºC) is communicated.

Figure 4. Star/Double star on thumb wheel

Display Sensor

The display sensor supports the star(*) and double star(**) functions if the sensor is configured for

single setpoint operation. Press the up or down arrow on the keypad to display the star(*) or double

star(**), respectively, on the sensor display.

• If the setpoint is increased one increment above 89.6ºF (32ºC), the star (*) appears. A value of

95ºF (35ºC) is communicated.

• If the setpoint is decreased one increment below 50ºF (10ºC), the double star(**) appears. A

value of 44.6ºF (7ºC) is communicated.

26 BAS-SVX10C-EN

Page 27

Display Sensor Operation

.

Keypad

Occupancy indicator/Error code

Temperature

System settings

Fan settings

This section describes display sensor operation. Figure 5 shows an example of a display sensor

that has been configured and is in operating mode.

Figure 5. Display sensor in operating mode

Operation

Changing Temperature Settings

This symbol shows the current room

temperature, or your temperature setting,

.

while you are making an adjustment.

When you select a setpoint, this symbol

appears.

1. To increase the room temperature, press .

To decrease the room temperature, press .

2. To confirm, press or wait 5 seconds. The display will return

to the home screen.

Changing Heating and Cooling Temperature Settings (dual setpoint systems only)

Some systems allow you to select both heating and

cooling room temperature settings. If your system

has this option, this symbol appears when you

adjust the temperature setting.

When you adjust the cooling setting, the top arrow

and snowflake flash.

When you adjust the heating setting, the bottom

arrow and flame flash.

1. Press or to select the heating/cooling setting.

2. If in cooling mode, press to change to heating mode. If in

heating mode, press to change to cooling mode.

3. Press or to select the heating/cooling setting.

4. To confirm, press or wait 5 seconds. The home screen

will appear.

Note: The heat/cool setpoint offset (deadband) chosen during

configuration will apply.

BAS-SVX10C-EN 27

Page 28

Operation

Changing System Settings

Indicates that the system is in cooling mode.

Indicates that the system is in heating mode.

Indicates emergency heat. It is used by facility

operators or service technicians only.

Indicates that the system automatically switches

between heating and cooling as needed.

Indicates that the system is Off.

Changing Fan Settings

Indicates that the fan will operate as needed

to reach the selected temperature.

Indicates that the fan setting is On. The

number of arrows indicates fan speed

(3: high, 2: medium, 1: low).

The example shown indicates a fan on high

speed. Not all systems offer all three speeds.

Indicates fan is Off.

Requesting Temporary Occupancy

1. From the home screen, press . The system setting menu

appears.

2. Press or to choose the desired system setting.

3. When the symbol for the desired setting appears, confirm

your choice by

• Pressing (the home screen will appear), or

• Pressing or (the next menu will appear), or

• Waiting 5 seconds.

1. From the home screen, activate the fan setting menu by

pressing and then .

2. Press or to choose the desired fan setting.

3. When the symbol for the desired setting appears, confirm your

choice by

• Pressing (the home screen will appear), or

• Pressing or (the next menu will appear), or

• Waiting 5 seconds.

Select to request

occupancy

Select to cancel

occupancy

Error codes

Main processor error

Software version conflict

Communication error

T emperature input outside valid operating r ange

(32ºF–122ºF [0ºC–50ºC])

Lock Symbol

Indicates that the keypad is locked

• If you need heating or cooling after normal business hours, you can “request”

temporary occupancy by pressing and holding it for 2 seconds. The occupied

symbol remains on the screen and the unoccupied symbol disappears. After 30

seconds, the unoccupied symbol will re-appear. The system will remain in occupied

mode for a pre-determined period.

• To cancel temporary occupancy, press and hold for 2 seconds. The unoccupied

symbol will remain on the screen and the occupied symbol will disappear. After 30

seconds the occupied symbol will re-appear. (Cancellation can be made at any time

during the temporary occupancy period.)

Replace sensor.

Replace sensor.

Replace sensor.

Replace sensor if space temperature is within valid range.

The lock symbol appears if you try to adjust a setting that cannot be changed.

28 BAS-SVX10C-EN

Page 29

Maintenance and Troubleshooting

This section describes sensor features that can be used for maintenance and troubleshooting.

LEDs

Some sensor models have LEDs. They are located on the front cover and convey the following

information:

Service LED (red)

Cool LED (green)

Heat LED (green)

System LED (green)

The red service LED indicates that service is needed.

• The LED may blink or stay on solid, depending on the unit controller

The green cool LED indicates that the system is in cooling mode.

• Stays on solid during normal cooling operation

• Blinks to indicate a cooling system failure

The green heat LED indicates that the system is in heating mode.

• Stays on solid during normal heating operation

• Blinks to indicate a heating system failure

The green system LED indicates the state of the system.

• Stays on solid to during normal operation

• Blinks to indicate that the system is in Test mode

Error Codes (Display Sensor)

For an explanation of error codes that can appear on the display, see “Error codes,” p. 28.

Display Sensor: Output Values—Failure and Default Modes of

Operation

The following table provides output values for failure and default modes of operation, which can

be used for troubleshooting.

Zone

temperature

Situation

Sensor has no power. Open Open Open Open

Thermistor in sensor has failed to either open or

close.

Setpoint potentiometer has failed to either ope n or

close.

output

Open Normal value

Normal value

(See Table 1)

Zone setpoint

output

(See Table 1)

Open Open N/A

Heating

setpoint

output

Normal value

(See Table 1)

Fan/System

output

N/A

BAS-SVX10C-EN 29

Page 30

Maintenance and Troubleshooting

Measuring Output Resistance

Measure output resistance as follows, according to sensor type.

Display Sensors

For display sensors, measure the outputs for zone temperature, setpoints, heat setpoint, and

system/fan mode as described:

1. Ensure that the GROUND (terminal 10) and the SIGNAL COMMON (terminal 2) wires are

grounded to the transformer.

2. To measure zone temperature resistance, disconnect the ZONE TEMP (terminal 1) wire from the

sensor. Measure between the ZONE TEMP (terminal 1) and SIGNAL COMMON (terminal 2).

Compare resistance measurements to those in Ta b le 1 .

3. To measure setpoint resistance:

• For single setpoint systems, disconnect the SETPOINT (terminal 3) wire from the sensor.

Measure between the SETPOINT (terminal 3) and the SIGNAL COMMON (terminal 2).

Compare resistance measurements to those in Ta bl e 1 .

• For dual setpoints systems, disconnect the HEAT SETPOINT (terminal 5) wire from the

sensor. Measure between the HEAT SETPOINT (terminal 5) and the SIGNAL COMMON

(terminal 2). Compare resistance measurements to those in Ta bl e 1.

4. To measure the system/fan mode resistance, disconnect the SYS/FAN MODE (terminal 4) wire

from the sensor. Measure between the SYS/FAN MODE (terminal 4) and the SIGNAL COMMON

(terminal 2). Compare resistance measurements to those in Ta b le 2 .

Notice:

Potential Equipment Damage!

Because the output circuits are not electrically powered, resistance can be measured without

risk of damage to the volt-ohm meter. However, damage to the volt-ohm meter could potentially

result if terminal 11 (24 VAC/VDC) is inadvertently contacted.

All Models Other Than the Display Sensor

For all other wired sensors, measure the outputs for temperature and setpoints and, if applicable,

the system/fan mode and heat setpoint:

1. To measure zone temperature resistance, measure between SIGNAL COMMON (terminal 2)

and ZONE TEMP (terminal 1). Compare resistance measurements to those in Ta b le 1 .

2. To measure setpoint resistance:

• For single setpoint systems, measure between SIGNAL COMMON (terminal 2) and

SETPOINT (terminal 3).

• For dual setpoint system, measure between SIGNAL COMMON (terminal 2) and CSP

(terminal 3), and between SIGNAL COMMON (terminal 2) and HSP (terminal 5).

Compare resistance measurements to those in Ta b le 1 .

3. To measure the system/fan mode resistance, measure between SIGNAL COMMON (terminal 2)

and MODE (SYS/FAN SWITCH) (terminal 4). Compare resistance measurements to those in

Ta bl e 2 .

Note: The output circuits are not electrically powered; consequently, resistance can be

measured without risk of damage to the volt-ohm meter.

30 BAS-SVX10C-EN

Page 31

Maintenance and Troubleshooting

Table 1. Resistance measurements for zone temperature and setpoints

Zone or setpoint temperature

** NA 938 Ω

55°F (12.8°C) 17.47 kΩ 792 Ω

60°F (15.6°C) 15.3 kΩ 695 Ω

65°F (18.3°C) 13.5 kΩ 597 Ω

70°F (21.1°C) 11.9 kΩ 500 Ω

75°F (23.9°C) 10.5 kΩ 403 Ω

80°F (26.7°C 9.3 kΩ 305 Ω

85°F (29.4°C) 8.25 kΩ 208 Ω

* NA 49 Ω

Notes:

1. Sensors are calibrated at 70°F (21.1ºC).

2. Single setpoint systems: Varies ±28

(29.4ºC). Dual setpoint systems: Cooling setpoint varies ±10

scale. Heating setpoint varies ±20

output resistance

Ω at 70°F (21.1ºC); varies ±128 Ω at endpoints of scale 55ºF (12.8ºC) and 85ºF

Ω at 70ºF (21.1ºC); varies at ±120 Ω at endpoints of scale.

Ω at 70ºF (21.1ºC); varies at ±110 Ω at endpoints of

Nominal zone temperature

Nominal setpoint and heating

setpoint output resistance

Table 2. Resistance measurements for fan and system modes

Fan mode System mode Nominal output resistance

Auto or invalid Emergency heat 35,000 Ω

Auto or invalid Heat 19,480 Ω

Auto or invalid Auto 7680 Ω

Auto or invalid Off 2320 Ω

Auto or invalid Cool 4870 Ω

On Emergency heat 43,450 Ω

On Heat 27,930 Ω

On Auto 16,130 Ω

On Off 10,770 Ω

On Cool 13,320 Ω

High Invalid (fan control only) 16,130 Ω

Med Invalid (fan control only) 13,320 Ω

Low Invalid (fan control only) 10,770 Ω

Auto Invalid (fan control only) 2320 Ω

Off Invalid (fan control only) 4870 Ω

BAS-SVX10C-EN 31

Page 32

Maintenance and Troubleshooting

Cleaning the Sensor

NOTICE

Equipment damage!

Spraying glass cleaner or any other solution directly on the sensor may damage it.

You can clean the sensor by applying glass cleaner to a soft, non-abrasive cloth, and gently wiping

the face, including the buttons and LCD display. Use of a pre-moistened towelette designed for lens

or screen cleaning is also acceptable.

Avoid inadvertent pressing buttons on sensors that have them or the keypad on the display sensor,

as this may result in an unwanted timed override or settings change.

Replacing the Thumb Wheel

If you need to replace a setpoint thumb wheel, see “Changing the Setpoint Thumb Wheel

(optional),” p. 21.

32 BAS-SVX10C-EN

Page 33

Wiring Diagrams

X1351152701

X1351152801

X1351152901

Each wiring diagram is identified by sensor part number (see “Part Numbers,” p. 6 for reference.)

For wiring information for the display sensor, see Figure 1, p. 10.

R1, 1.5 kΩ

Timed

override

Unoccupied

(Cancel) SW2

Setpoint

potentiometer

Pot 1, 1 k

Dwg. source: 3270 3435 B

RT1 thermistor,

10 k at 25°CΩ

Dwg source: 3270 3436

Timed

override

Occupied

(On) SW1

Ω

RT1

thermistor,

10 k at 25°CΩ

Calibration potentiometer

Pot 2 (see )Note

NOTE: POT 1 and POT2 are factory calibrated.

Field adjustment voids warranty.

Zone temperature

1

Signal common

2

Setpoint

3

Zone temperature

1

Signal common

2

BAS-SVX10C-EN 33

Setpoint

Pot 1, 1 k

Dwg source: 3270 3437

potentiometer

Ω

RT1 thermistor,

10 k at 25°CΩ

Calibration potentiometer

Pot 2 (see )Note

Note: Pot 1 and Pot 2 are factory

calibrated. Field adjustment voids

warranty.

Zone temperature

1

Signal common

2

Setpoint

3

Page 34

Timed

override

Cancel SW4

R9, 1.5 kW

Timed

override

On SW3

Thermistor,

10 k at 25°CW

1

2

4

Calibration

Pot 1 (see )Note 1

RT1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R1, 4.87 kW

R2, 2.32 kW

Auto

Off

R11, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

Mode

(Fan switch)

TB1

R10, zero W

Te mperature

setpoint

Pot 5,

1 kW

Fan

SW1

Dwg source: X39641092-01

X1379084501

Temperature sensors with fan control

X1351153001

Wiring Diagrams

R1, 1.5 kΩ

Timed

override

Cancel SW2

Dwg source: 3270 3438

Timed override

On SW1

RT1 thermistor,

10 k at 25°CΩ

Zone

temperature

1

Signal common

2

34 BAS-SVX10C-EN

Page 35

Timed

override

Cancel SW4

R9, 1.5 kW

Timed

override

On SW3

Thermistor,

10 k at 25°CW

1

2

4

Calibration

Pot 1 (see )Note 1

RT1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R1, 4.87 kW

Off

R2, 16.2 kW

Te mperature

Setpoint

Pot 5,

1 kW

Run

R11, zero W

R10, zero W

System

SW1

Signal common

Cool setpoint (CSP)

Zone

temperature

Mode

(System switch)

TB1

Dwg source: X39641098-01

X1379085101

Timed

override

Cancel SW4

R9, 1.5 kW

Timed

override

On SW3

Thermistor,

10 k at 25°CW

1

2

4

Calibration

Pot 1 (see )Note 1

RT1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R1, 4.87 kW

R2, 2.32 kW

R3, 10.7 kW

Low

Auto

Off

R5, 16.2 kW

High

R11, zero W

R10, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

Mode

(Fan switch)

TB1

Te mperature

setpoint

Pot 5,

1 kW

Fan

SW1

Dwg source: X39641095-01

X1379084801

Wiring Diagrams

BAS-SVX10C-EN 35

Page 36

2

4

Calibration

Pot 1 (see )Note 1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R1, 4.87 kW

R2, 2.32 kW

R3, 10.7 kW

R4, 13.3 kW

Med

Low

Auto

Off

R5, 16.2 kW

High

RT1 thermistor,

10 k at 25°CW

1

R11, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

Mode

(Fan switch)

TB1

R10, zero W

Te mperature

setpoint

Pot 5,

1 kW

Fan

SW1

Dwg source: X39641088-01

X1379084101

Timed

override

Cancel SW4

R9, 1.5 kW

Timed

override

On SW3

Thermistor,

10 k at 25°CW

1

2

4

Calibration

Pot 1 (see )Note 1

RT1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R1, 4.87 kW

R2, 2.32 kW

R3, 10.7 kW

R4, 13.3 kW

Med

Low

Auto

Off

R5, 16.2 kW

High

R11, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

Mode

(Fan switch)

TB1

R10, zero W

Te mperature

setpoint

Pot 5,

1 kW

Fan

SW1

Dwg source: X39641089-01

X1379084201

Wiring Diagrams

36 BAS-SVX10C-EN

Page 37

RT1 thermistor,

10 k at 25°CΩ

1

2

4

Calibration

Pot 1 (see )Note 1

R7, 3.92 kΩ

Note 1:

Pot 1 and

Pot 2 are

factor y

calibrated.

Field

adjustment

voids

warranty.

3

5

R6, 8.45 kΩ

Auto

On

R8, 3.92 kΩ

Heat Setpoint

Pot 3,

1 kΩ

Calibration Pot 2 (see )Note 1

R1, 4.87 kΩ

R2, 2.32 kΩ

R3, 7.68 kΩ

R4, 19.6 kΩ

Heat

Auto

Off

Cool

CR2

Green

CR4

Green

CR3

Green

CR1

Red

6

7

9

8

10

LED Service

LED Heat

LED Common

LED Sys_On

LED Cool

R5, 34.8 kΩ

EM Heat

R9, zero Ω

Signal common

Cool setpoint (CSP)

Heat

Setpoint (HSP)

Zone

temperature

TB1

Mode

(Sys/Fan switch)

System

SW1

Fan

SW2

Cool setpoint

Pot 4,

1 kΩ

Dwg source: X39641094-01

RT1 thermistor,

10 k at 25°CW

Te mperature

setpoint

Pot 5,

1 kW

1

2

4

Calibration

Pot 1 (see )Note 1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R6, 8.45 kW

Auto

On

R1, 4.87 kW

R2, 2.32 kW

R3, 19.6 kW

Heat

Off

Cool

Fan

SW2

R4, 34.8 kW

EM Heat

CR3

Green

6

7

LED Heat

LED Common

TB2

R9, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

TB1

Mode

(Sys/Fan switch)

System

SW1

Dwg Source: X39641099-01

X1379084701

X1379085201

Temperature sensors with fan and

system control

Wiring Diagrams

BAS-SVX10C-EN 37

Page 38

2

4

3

5

Signal common

Cool setpoint (CSP)

Calibration

Pot 1 (see )Note 1

R7, 3.92 kW

Note 1:

Pot 1 and

Pot 2 are

factory

calibrated.

Field

adjustment

voids

warranty.

Heat

Setpoint (HSP)

R6, 8.45 kW

Auto

On

R8, 3.92 kW

Calibration Pot 2 (see )Note 1

R1, 4.87 kW

R2, 2.32 kW

R3, 7.68 kW

R4, 19.6 kW

Heat

Auto

Off

Cool

RT1 thermistor,

10 k at 25°CW

Zone

temperature

1

R11, zero W

TB1

Mode

(Sys/Fan switch)

Cool setpoint

Pot 4,

1 kW

Heat setpoint

Pot 3,

1 kW

System

SW1

Fan

SW2

Dwg source: X39641084-01

RT1 thermistor,

10 k at 25°CW

1

2

4

Calibration

Pot 1 (see )Note 1

R7, 3.92 kW

Note 1:

Pot 1 and

Pot 2 are

factory

calibrated.

Field

adjustment

voids

warranty.

3

5

R6, 8.45 kW

Auto

On

R8, 3.92 kW

Calibration Pot 2 (see )Note 1

R1, 4.87 kW

R2, 2.32 kW

R3, 7.68 kW

R4, 19.6 kW

Heat

Auto

Off

Cool

CR2

Green

CR4

Green

CR3

Green

CR1

Red

6

7

9

8

10

LED Service

LED Heat

LED Common

LED Sys_On

LED Cool

R9, zero W

Signal common

Cool setpoint (CSP)

Heat

Setpoint (HSP)

Zone

temperature

TB1

Mode

(Sys/Fan switch)

System

SW1

Fan

SW2

Cool setpoint

Pot 4,

1 kW

Heat setpoint

Pot 3,

1 kW

Dwg source: X39641093-01

X1379083701

X1379084601

Wiring Diagrams

38 BAS-SVX10C-EN

Page 39

2

4

Calibration

Pot 1 (see )Note 1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R6, 8.45 kW

R1, 4.87 kW

R2, 2.32 kW

R3, 19.6 kW

Heat

Off

Cool

RT1 thermistor,

10 k at 25°CW

1

R11, zero W

Signal common

Cool setpoint (CSP)

Mode

(Sys/Fan switch)

Zone

temperature

TB1

Auto

On

Te mperature

setpoint

Pot 5,

1 kW

System

SW1

Fan

SW2

Dwg source: X39641086-01

2

4

Calibration

Pot 1 (see )Note 1

Note 1:

Pot 1 is

factory

calibrated.

Field

adjustment

voids

warranty.

3

R6, 8.45 kW

Auto

On

R1, 4.87 kW

R2, 2.32 kW

R3, 7.68 kW

Heat

Off

Cool

R4, 19.6 kW

Fan

RT1 thermistor,

10 k at 25°CW

1

R11, zero W

Signal common

Cool setpoint (CSP)

Zone

temperature

TB1

Mode

(Sys/Fan switch)

Te mperature

setpoint

Pot 5,

1 kW

System

SW1

Fan

SW2

Dwg source: X39641097-01

X1379083901

X1379085001

Wiring Diagrams

BAS-SVX10C-EN 39

Page 40

2 (+)

1 (–)

COMM Module

J1

2

3

Optional COMM module

X1365146702

Wiring Diagrams

40 BAS-SVX10C-EN

Page 41

Specifications and Agency Compliance

Specifications

Sensor operating temperature From 32°F to 122°F (0°C to 50°C)

Storage temperature From -40°F to 185°F (-40°C to 85°C)

Storage/operating humidity range 5% to 95% relative humidity (RH), noncondensing

Thermistor accuracy 0.2°C at 25°C, 1%

Setpoint functional range

Setpoint markings

Housing material

Mounting

Resolution (display sensor) 0.125ºF over a range of 60 to 80ºF (15.6 to 26.7°C); 0.25ºF when outside this range

Accuracy (display sensor) 0.5°F over a range of 55 to 85°F (12.8 to 29.4ºC)

Power consumption (display sensor) <1 VA

Display sensor: 50°F to 89.6°F (10°C to 32°C)

All other sensors: 45°F to 95°F (7.2°C to 35°C)

Setpoint thumb wheel:

• 50°F to 85°F (in 5°F increments) and *, **

• 10°C to 29°C (in 3°C increments) and *, **

Dual setpoint slider:

• 50 to 85ºF (stamped every 5ºF)

• 10 to 29ºC (stamped every 3ºC)

Polycarbonate/ABS blend, UV protected, UL 94-5VA flammability rating, suitable for

application in a plenum

Fits a standard 2 in. by 4 in. junction box (vertical mo unt only). Mounting holes are spaced

3.2 in. (83 mm) apart on vertical center line. Includes mounting screws for junction box and

wall anchors for sheetrock walls. Overall dimensions: 2.9 in (74 mm) by 4.7 in. (119 mm)

Agency Compliance

• United States:

– UL listed: 94, 5 VA Flammability rating; 916, Energy management equipment

– FCC Part 15, Subpart B

• Canada:

– CUL listed: 916, Energy management equipment

• Europe:

–CE marked

BAS-SVX10C-EN 41

Page 42

Specifications and Agency Compliance

CE Declaration of Conformity

Manufacturer: Trane, 4833 White Bear Parkway, Saint Paul, MN 55103, USA

Product: Wired display sensor

Model number: X1379088601, X1379088604, X1379088605

The manufacturer hereby declares that the product conforms to the following:

Electromagnetic Emission: Council Directive 89/336/EEC)

Electromagnetic Immunity for

Industrial

Date of issue: October 14, 2008

European Contact: Societé Trane (Epinal, France)

Design/Compliance Engineer:

EN61326-1:2006, Class B limit

Radiated EN55011:2006, Class B limit

Conducted EN55011:2006, Class B limit

Harmonic EN61000-3-2, Class A limit

Flicker EN61000-3-3:1995+A1:2001+A2:2006

by Council Directive 89/336/EEC

EN61326-1:2006

EN61000-2:2006, ±4.0 kV by contact, ±8.0 kV by air

EN61000-4-3:2006, 10.0 V/m

EN61000-4-4:2006, ±1.0 kV signal lines, ±2.0 kV ac power lines

EN61000-4-5:2006, ±1.0 kV signal lines, ±2.0 kV ac power lines

EN61000-4-6:2006, 3 V

EN61000-4-11:2006

1, rue des Ameriques, B.P. 6

F-88191 Golbey Cedex, France

Phone: (33) 329.31.73.00

Fax: (33) 329.81.24.98

Robert Jacobs

42 BAS-SVX10C-EN

Page 43

Specifications and Agency Compliance

BAS-SVX10C-EN 43

Page 44

www.trane.com

For more information, contact your local Trane

office or e-mail us at comfort@trane.com

Literature Order Number BAS-SVX10C-EN

Date December 2008

Supersedes BAS-SVX10B-EN (March 2008)

Trane has a policy of continuous product and product data improvement and reserves the right to

change design and specifications without notice.

Loading...

Loading...