Page 1

Installation Manual

Split Water-Cooled

Condensing Units

7,000 - 60,000 Btu/h

WTK Series 50 Hz

50Hz Models

Cooling Only

WTK507

WTK509

WTK512

WTK518

WTK524

WTK530

WTK536

WTK048

WTK060

April 2004

WTK-SVN001-EN

Page 2

General Information

Introduction

This Installation Manual is given

as a guide to good practice in the

installation by the installer of mini-split

system. Installation procedures should

be performed in the sequence that

they appear in this manual.

For installing the unit to operate

properly and reliably, it must be

installed in accordance with these

instructions. Also, the services of a

qualified service technician should be

employed, through the maintenance

contract with a reputable service

company.

Read these Installation Manual

completely before installing the

condensing unit.

About the Unit

The units are assembled, pressure

tested, dehydrated, charged and run

tested before shipment. The information

contained in this manual applies to

units that are designed to operate in

cooling mode only.

Important

This document is customer property

and is to remain with unit. Please place

in service information pack upon

completion of work. These instructions

do not cover all variations in systems,

nor do they provide for every possible

contingency to be met in connection

with installation. Should further

information be desired or should

particular problems arise which are

not covered sufficiently in this manual,

the matter should be referred to your

Trane sales representative.

Reception

On arrival, inspect the unit before

signing the delivery note. Verify that

the nameplate data matches the date

on the sales order, submittal data and

delivery note (including electrical data)

to insure the proper unit was shipped.

Specify any damage of the unit on the

delivery note, and send a registered

letter of protest to the last carrier of

the goods within 72 hours of delivery.

Notify the dealer at the same time.

The unit should be totally inspected

within 7 days of delivery. If any

concealed damage is discovered,

send a registered letter of protest to

the carrier within 7 days of delivery

and notify the dealer.

Warranty

Warranty is based on the general

terms and conditions by country.

The warranty is void if the equipment

is modified or repaired without the

written approval of The Trane Company,

if the operating limits are exceeded or

if the control system or the electrical

wiring is modified. Damage due to

inappropriate installation, lack of

knowledge or failure to comply with

the manufacturer’s instructions, is not

covered by the warranty obligation.

If the installer does not conform to the

rules described in Installation Manual,

it may entail cancellation of warranty

and liabilities by The Trane Company.

Storage

Take precautions to prevent

condensate from forming inside the

unit’s electrical board and motors

if the unit is stored before it is installed.

The Trane Company will not assume

any responsibility for unit damage

resulting from condensate

accumulation on the unit’s electrical

and/or mechanical components.

About this Manual

Cautions and warnings appear at

appropriate places in this instruction

manual. Your personal safety and the

proper operation of this machine

require that you follow them carefully.

The Trane Company assumes no

liability for installations or servicing

performed by unqualified personnel.

All phases of the installation of this

air conditioning system must conform

to all national, provincial, state and

local codes.

Warning

Warnings are provided at appropriate

places in this manual to indicate to

installers, operators and service

personnel of potentially hazardous

situations which, if not avoided,

COULD result in death or serious

injury.

Caution

Cautions are provided at appropriate

places in this manual to indicate to

installers, operators, and service

personnel of potentially hazardous

situations which, if not avoided,

MAY result in minor or moderate

injury or malfunction of the unit.

2

© American Standard Inc. 2003

WTK-SVN001-EN

Page 3

Contents

General Information 2

Model Nomenclature 4

Location and Preparation of Unit 5

Refrigerant Tube Size Selection 5

Connection of Refrigerant Tubing

(Flaring and Brazing Procedure) 6

Water Pipe Connection 8

Gas Leakage Inspection 9

Air Evacuation and Refrigerant Charge 10

Wiring and System Inspection

before Test Run 11

Condenser Cleaning 11

Wiring Diagram 12

Dimensional Data 14

WTK-SVN001-EN

3

Page 4

Model Nomenclature

W T K 5 0 7 A B 0 0 B A

123456789101112

Digit No. 1 = Product Type

W=Split Water Cooled Condensing Unit

Digit No. 2

T=Cooling Only

W=Heat Pump

Digit No. 3 = Refrigerant Circuit(s)/Compressor(s)

K=Single Refrigerant Circuit/Compressor

D=Dual Refrigerant Circuits/Compressors

T=Tr iple Refrigerant Circuits/Compressors

(Others to be determined as needed.)

Digit No. 4 = Refrigerant Connection Type

0=Sweat (Brazed)

5=Flared (Tubing)

7=Quick Connect

Digit No. 5 and No. 6 = Nominal Capacity

Btu/h X 1000

(Note: Exact system capacities/performance when matched with selected indoor

unit are specified in Product Catalogs.)

Digit No. 7 = Major Development Sequence

Digit No. 8 = Electric Power Supply Characteristics

A=220V/1ph/50Hz or 200-220V/1ph/50Hz

B=240V/1ph/50Hz or 220-240V/1ph/50Hz

1=220V/1ph/60Hz or 200-240V/1ph/60Hz

3=200-240V/3ph/60Hz

D=380-415V/3ph/50Hz

4=460V/3ph/60Hz

Digit No. 9 and 10 = Factory Installed Options

(Note: The Alphabetic Letter “O” is not used in digit 9 or 10, Only the Number “0”

is used.)

00 = No option

0E = 3 minute time delay (for use w/ MCD)

0F = Hi/Lo Pressure Cut Off

0G = 3 minute time delay + Hi/Lo Pressure Cut Off

0S = Special request to be provided in wording and to be approved by factory

i.e. service valve at the water side, insulation on suction line, emergency stop.

Digit No. 11 = Minor Design Sequence/Series - Design Change

Alphabetic Letter, “A” through “Z”

Digit No. 12 = Service Digit

4

WTK-SVN001-EN

Page 5

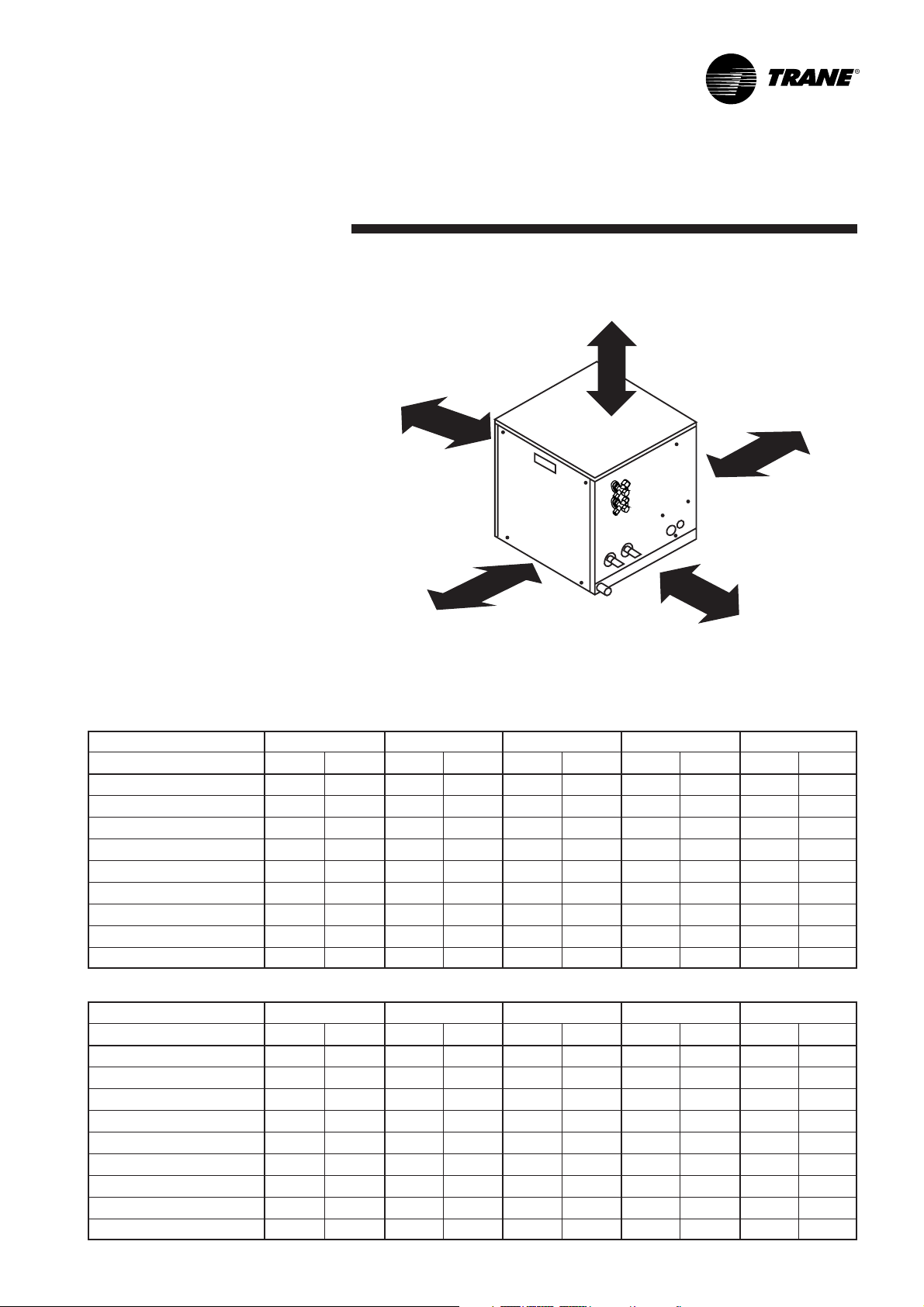

Location and Preparation of Unit

Installation of Condensing Unit at

More than 15 cm

the appropriate places

• The place where is not near the

gas area of potentially hazardous

situations.

More than 10 cm

•Isolated place to avoid noise and

heat disturbing to neighbourhood

• Convenient places for inspection

More than 35 cm

or reparation

Refrigerant Tube Size Selection

To select tube size is necessary to

consider many factors such as:

velocity of refrigerant, number of tube

connector, bended joint and length of

refrigerant tube. Therefore, for quick

selection size of refrigerant tube,

see the detail below:-

Refrigerant tube size for Trane

More than 35 cm

Air-conditioning (size 7,000-60,000 Btu/h)

Figure 1

Domestic

Tubing Length (m) /Tubing size (inch) Minimum 12 m 13 - 18 m 19 - 24 m 25 - 30 m 31 - 36 m

Model Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line

WTK507 1/4 3/8 1/4 3/8 1/4 3/8 1/4 1/2 1/4 1/2

WTK509 1/4 3/8 1/4 3/8 1/4 3/8 1/4 1/2 1/4 1/2

WTK512 3/8 5/8 3/8 5/8 3/8 5/8 3/8 5/8 3/8 5/8

WTK518 3/8 5/8 3/8 5/8 3/8 5/8 3/8 5/8 3/8 5/8

WTK524 3/8 5/8 3/8 5/8 3/8 3/4 3/8 3/4 3/8 3/4

WTK530 3/8 5/8 3/8 5/8 3/8 3/4 3/8 3/4 3/8 3/4

WTK536 3/8 3/4 3/8 3/4 3/8 3/4 3/8 7/8 3/8 7/8

WTK048 1/2 7/8 1/2 7/8 1/2 7/8 1/2 7/8 1/2 1 1/8

WTK060 1/2 7/8 1/2 7/8 1/2 1 1/8 1/2 1 1/8 1/2 1 1/8

More than 35 cm

Export

Tubing Length (m) /Tubing size (inch) Minimum 12 m 13 - 18 m 19 - 24 m 25 - 30 m 31 - 36 m

Model Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line Liquid Line Suction Line

WTK507 1/4 3/8 1/4 3/8 1/4 3/8 1/4 1/2 1/4 1/2

WTK509 1/4 3/8 1/4 3/8 1/4 3/8 1/4 1/2 1/4 1/2

WTK512 1/4 1/2 1/4 1/2 1/4 1/2 1/4 1/2 1/4 1/2

WTK518 1/4 1/2 3/8 5/8 3/8 5/8 3/8 5/8 3/8 5/8

WTK524 3/8 5/8 3/8 5/8 3/8 3/4 3/8 3/4 3/8 3/4

WTK530 3/8 5/8 3/8 5/8 3/8 3/4 3/8 3/4 3/8 3/4

WTK536 3/8 3/4 3/8 3/4 3/8 3/4 3/8 7/8 3/8 7/8

WTK048 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8

WTK060 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8 3/8 1 1/8

WTK-SVN001-EN

5

Page 6

Connection of Refrigerant Tubing

Connection the Unit with Flaring

Procedure

Flaring (If tubing is procured or cut

at the site).

1. Cut the copper tube to the

required length with a tube cutter.

It is recommended to cut approx.

30 cm-50 cm (12” to 20”) longer

than the tubing length you estimate.

2. Hold each tube downward when

cutting, remove burrs at the end of

the copper tube with a tube reamer

or file. This process is important

and should be done carefully to

make a good flare (Figure 2 and

Figure 3).

Copper tubing

Reamer

Figure 2

A good flare should have the

following characteristics:

-Inside surface is glossy and smooth.

- Edge is smooth.

-Tapered sides are of uniform length.

Cautions Before Connecting

Tubes Tightly

1. Be sure to apply a sealing cap or

water-proof tape to prevent dust

or water from getting into the

tubes before they are used.

2. Be sure to apply refrigerant

lubricant to the matching surfaces

of the flare and union before

connecting them together. This is

effective for reducing gas leaks

(Figure 5).

Apply refrigerant lubricant here

4. Tighten the flare nut to the specified

tightening torque with torque

wrench and adjustable wrench

(Figure 7).

5. Repeat the process above for

the remaining line.

Specified tightening torque

Tube diameter Torque

mm inch kg - cm lb - in

6.35 mm (1/4”) dia. 150~200 130~170

9.53 mm (3/8”) dia. 350~400 300~340

12.7 mm (1/2”) dia. 500~550 430~470

15.88 mm (5/8”) dia. 600~650 520~570

19.05 mm (3/4”) dia. 700~750 610~650

22.23 mm (7/8”) dia. 800~850 700~740

28.58 mm (1-1/8”) dia. 900~950 800~825

Before After

Figure 3

When reaming, hold the tube end

downward and be sure that no

copper scraps fall into the tube.

3. Remove the flare nut from the

service valve and be sure to insert

the flare nut onto tube.

4. Make a flare at the end of copper

tube with a flare tool (Figure 4).

Flare nut

Copper

tubing

Flare tool

Figure 5

Connection

3. For proper connection, align the

union tube and flare tube straight

with each other, then screw in the

flare nut lightly at first to obtain a

smooth match (Figure 6).

Union Flare nut

Figure 6

Indoor

unit pipe

To rque wrench

Wrench

(Adjustable)

Tube connection

Flare nut

Figure 7

Figure 4

6

WTK-SVN001-EN

Page 7

Connection Unit

with Brazing Procedure

Connection Unit with Brazing

Procedure

1. Cut the copper tube to the require

length with the tube cutter. It is

recommended to cut approximately

20-30 cm longer than the tube

length you estimate and put in the

straight line while cutting.

2. After cutting, remove burrs at the

end of copper tube with a tube

reamer. Hold the end downward

and be sure that no copper scraps

fall into the tube (Figure 2).

3. There are 2 methods to connect

copper tube

- Use tube connector between

copper tube from fan-coil unit and

copper tube from condensing unit

(Figure 8).

Tube connector

(straight)

- Expand copper tube with the tube

enlarging tool (Figure 9).

Tube enlarging

tool

Tube fixing

Copper

tube

Figure 9

tool

4. Clean copper tube surfaces

both inside and outside before

connection, expansion, or brazing.

5. Insulate the entire gas line.

6. Do not allow uninsulated liquid line

to come in direct contact with bare

gas line.

7. Precautions should be taken to

avoid heat damage to the pressure

tap valve core during brazing. It is

recommended that a wet rag be

wrapped around the valve body.

8. It is recommended to use braze

shield, soak pad in water and place

over suction and liquid lines to

protect unit finish.

9. To braze the copper tube, before

brazing a copper tube to a solder

coupling or a copper tube to an

expanded tube, do not forget to

keep them tight as shown in

figure 10.

Figure 8

Copper tube from

fan coil unit

Copper tube from

condensing unit

Brazing head

COMMET 3

Brazing

wire

Copper tube from

(torch)

connector

(straight)

condensing unit

Figure 10

10. Use a dry nitrogen purge and

brazing alloy without flux when

brazing the field line to the copper

factory connection. Flow dry

nitrogen into either valve pressure

tap port, through the tubing and

out the other port while brazing.

11. Braze using accepted good

brazing techniques.

Tube

WTK-SVN001-EN

7

Page 8

Water Pipe Connection

Installers should prepare the

following equipment:

Should have connected water pipe for

heat exchange. Should have water

pump, cooling tower, pressure gauge,

and other equipments related to the

water pipe connection. Please make

sure that all equipments are according

to the standard (see figure 11).

Water Return Pipe

Connect water return pipe with 3/4

inch pipe connector. Keep them far

away from water tray and add trap

(see figure 12).

Pressure-Reducing/

Water

Return

Water

Supply

Shutoff

Valve

Shutoff

Valve

Balancing Valve

Pressure

Gauge

Plugged

Cleanout

Tee

Water Strainer

Thermometer

Plugged

Cleanout

Tee

Pressure

Gauge

Thermometer

Figure 11

1 inch (25.4 mm) steel pipe and pipe connector

101 mm min

Flow Switch

Union

Union

Flexiible

Connection

To Unit

Flexiible

Connection

Equipment used

1Tee

From Unit

2Plug

70 mm min

3 Steel Elbow

4 140 mm Nipple

1 inch (25.4 mm) PVC pipe or copper pipe and pipe connector

Equipment used

101 mm min

1Tee

1Plug

390o Elbow

70 mm min

1 152 mm Nipple

2 50 mm Nipple

11 NPT to PVC

or copper adapter

Figure 12

8

WTK-SVN001-EN

Page 9

Gas Leakage Inspection

Gas Leakage Inspection

After charging with refrigerant,

it is necessary to check gas leakage.

Inspecting gas leakage should be

done with special precaution. If there

is any leakage that we are unable to

find, afterwards the system would be

damage. For example, if R22

refrigerant loses, cooling coil will be

frozen. There are so many methods to

inspect leakage, but the easiest and

the most economical way is to use

nitrogen gas detector and bubble of

powder detergent per the following

steps:-

•Prepare nitrogen tube with pressure

regulator and pressure gauge or

manifold gauge.

• Open service valve cover (at the

suction side).

• Connect gauge line to the nitrogen

tank, but do not open nitrogen

valve at the nitrogen tank.

• Check out brazing track and all

valves such as flare union.

• Connect the other tails of gauge

line to the service valve (at the

suction side).

•Slowly open nitrogen valve,

let pressure gradually increase until

250 pound/square inches, then put

bubble of powder detergent around

all connected joints, notice any

leakage. Fix the leakage, if any.

If there is no leakage, leave 1-2 hours

to check whether the pressure stays

the same. If the pressure is still

reducing, we need to check leakage

again. Finally, release nitrogen gas

in order to make refrigerant system

to be under vacuum.

Caution

• Do not fully open nitrogen valve to

250 psig because valve may be

damage.

• Do not forget to check the leakage

at the access valve both at the

liquid line and at the suction line.

WTK-SVN001-EN

9

Page 10

Air Evacuation

and Refrigerant Charge

Evacuation

Air and humidity are the enemy of

the air-conditioning system because

humidity will react with R22 refrigerant

and turns into acid, which will corrode

the wire coil and reduce the

compressor oil’s efficiency. Evacuation

is a must to prevent refrigerant system

from air and humidity.

Evacuation Procedure

Connect the middle hose of service

gauge to the vacuum pump, then

connect the hose at the low side to

“service valve” of air-conditioning

at suction line. Connect the hose at

the high side to “service valve” at

liquid line (figure 13).

Fill up R22 refrigerant into the

system

To fill up R22 refrigerant is the final

step of installation. After leakage

check and power wiring, fill up R22

refrigerant to the system.

How to fill up R22 refrigerant

Normally, this needs to be done

immediately after air evacuation per

the following steps (figure 13)

•Fill up the refrigerant via valve at

liquid line until pressure of the

liquid line is around 120-150 psig

(Don’t forget to evacuate air from

liquid line before)

•Turn on evaporator and condensing

unit.

•Fill up the refrigerant into suction

line at the proper quantity while the

unit is working.

• Let machine run for at least 20

minutes. Read pressure from

pressure gauge “at both high and

low side”, and read current

from amp-meter. Usually, suction

line pressure should be around

65-70 psig , and liquid line pressure

should be around 250-275 psig.

If the pressure readings of both liquid

line and suction line are in the range

stated above and electric current

reading is at full load ampere of

condensing unit, it indicates that

refrigerant’s volume is sufficient.

• But if suction pressure is lower than

normal and electric current is far

below full load ampere, it indicates

that refrigerant is inadequate.

You need to add more refrigerant.

• If suction pressure is higher than

normal and electric current is over

the full load ampere, and you notice

some water spray holds on the

compressor, it indicates over cooling

system. You need to release some

refrigerant.

Remark: When the interconnecting

line is longer than 7.5 m, additional

charging is necessary. For the additional

amount, follow the table belows.

10

Service

hoses

Liquid

line

Suction

line

Electrical

connection

Figure 13

Liquid

pressure

Suction

pressure

Vacuum pump

R22

Piping Per each additional

size meter of

interconnecting line

Liquid-Suction grams/meter

1/4é-3/8

1/4é-1/2

3/8é-5/8

3/8é-3/4

3/8é-11/

1/2é-7/8

é

é

é

é

é

8

é

23 grams/meter

26 grams/meter

59 grams/meter

60 grams/meter

68 grams/meter

117 grams/meter

WTK-SVN001-EN

Page 11

Wiring and System Inspection before

Test Run and Condenser Cleaning

Electric wire and ground wire must

comply with each country’s or regional’s

regulation.

1. Wiring

Importance

- Check the unit nameplate for

electrical rating. Make sure that

the wiring is according to local

codes and wiring system diagram.

-A separate power supply

disconnect and a circuit breaker

for overcurrent protection should

be provided in the external power

supply line.

-Always connect ground wire to

condensing unit every time to

prevent an electric shock in case

of an electric leakage.

-Electric wires shall not contact

to refrigerant pipes, compressor,

motor and the other moving parts.

- Manufacturer assumes no liability

for the problems caused by

unauthorized change in the

internal wiring.

- Should tighten up wire connection.

-Electric conductor parts must be

copper only.

To inspect system before test run.

After finished installing

air-conditioning, all system shall be

inspected before starting.

• Check that all brazings are correctly

made.

• Check that units are correctly

installed and there are no other

tools near or on top of the unit.

• Check the tubing and connections

for leak.

• Check that unit has a proper

ground wiring.

• Check for proper voltage and fuse

size.

• Check electrical wire size used is

as specified.

• Check all field wiring for tight

connection.

• Make sure that electrical wires

inside the unit do not contact to

refrigerant pipes.

•Turn on the unit, check the system

carefully.

Condenser Cleaning

After air-conditioning works for

a while, it may cause scales at the

surface of pipe in the condensing unit,

which may cause by cooling water

or rust inside cooling tower. Installer

can notice from the reduction of water

velocity, or the reduction of difference

of water temperature in and out,

or condensing temperature is higher

than normal.

Therefore, to maintain efficiency of

condenser, installer must clean up the

pipe’s inside surface of condenser to

prevent scales.

To clean up condenser with chemical

To clean up condenser with chemical

is one of the methods to wipe out

scales. To select proper chemical,

installer need to consult the water

treatment expert.

2. Electric Wire Connection

- See wiring diagram on page 12

-Slipover electric wire at the end

-After connect electric wire,

check whether all screws are

firmly tightened

The electric wire connection between

outdoor and indoor unit should be

according to the wiring diagram.

WTK-SVN001-EN

11

Page 12

Wiring Diagram

POWER SUPPLY 220-240V/1ph/50Hz, 200-240V/1ph/60Hz

POWER CIRCUIT

MS-1

RD

BL

L

CR

R

CPR

S

N

MS-2

BLK

C

CONTROL CIRCUIT FOR MODEL WITHOUT HPCO AND LPCO

*2TC

C1

FROM INDOOR UNIT

200-240VAC/1ph/50,60Hz

MS

CONTROL CIRCUIT FOR MODEL WITH HPCO AND LPCO

BYPASS LPCO WHEN UNIT START, BYPASS TIME PERIOD CAN BE SETTING 0-4.5 MINS

1TC

(FOR BY PART LPCO WHEN UNIT START)

BLK

1R-7

1R

1R-8

1R

LPCO

C1

HPCO

1R-1

1R-5

1R-6

G

C2

2R-7

*2TC

2R

2R-8

MS

C2

12

2R

2R-1

2R-2

2R-5

2R-6

FROM INDOOR UNIT

220-240V/1ph/50,60Hz

COLOR CODE

BL BLUE

BLK BLACK

RD RED

* 2TC AVAILABLE IN OPTIONAL MODEL

** APPLY FOR DOUBLE POLE CONTACTOR ONLY

(FOR SINGLE POLE CONTACTOR,CONNECT ELECTRIC

LINE FROM COMPR-C DIRECT TO TERMINAL-N)

NOTES:

1. LOW VOLTAGE WIRING TO BE

18 AWG MINIMUM CONDUCTOR.

2. POWER WIRING AND GROUNDING OF

EQUIPMENT MUST COMPLY WITH

LOCAL CODES.

3. USE COPPER CONDUCTOR ONLY.

LEGEND

CPR COMPRESSOR

MS COMPRESSOR MOTOR CONTACTOR

HPCO HIGH PRESSURE CUT-OUT

LPCO LOW PRESSURE CUT-OUT

TC TIME-DELAYED CONTACT 3 MINUTES

1R LOCK OUT CIRCUIT RELAY

2R LOW PRESSURE SENSOR BYPASS RELAY

TERMINAL

COIL

TERMINAL BOARD BY OTHER

TERMINAL BOARD BY FACTORY

FIELD WIRING

FACTORY WIRING

RELAY CONTACT NORMALLY OPEN

CAPACITOR

LOW PRESSURE SENSING SWITCH

HIGH PRESSURE SENSING SWITCH

WTK-SVN001-EN

Page 13

Wiring Diagram

WTK048-060

POWER SUPPLY 380-415V/3ph/50Hz ,460V/3ph/60Hz

G L1

BLK

MS-1

BLK

LPCO HPCO

C1

LEGEND

CPR COMPRESSOR

MS COMPRESSOR MOTOR CONTACTOR

HPCO HIGH PRESSURE CUT-OUT

LPCO LOW PRESSURE CUT-OUT

TC TIME-DELAYED CONTACT 3 MINUTES

TERMINAL

COIL

TERMINAL BOARD BY OTHER

TERMINAL BOARD BY FACTORY

FIELD WIRING

FACTORY WIRING

RELAY CONTACT NORMALLY OPEN

CAPACITOR

LOW PRESSURE SENSING SWITCH

HIGH PRESSURE SENSING SWITCH

1R

FROM INDOOR UNIT 220V/1ph/50Hz

L2 L3

MS-2

RD

2

CPR

1

87

1R

MS-3

3

*TC

651

*AVAILABLE IN OPTIONAL MODEL

NOTES:

1. LOW VOLTAGE WIRING TO BE

18 AWG MINIMUM CONDUCTOR.

2. POWER WIRING AND GROUNDING OF

EQUIPMENT MUST COMPLY WITH

LOCAL CODES.

3. USE COPPER CONDUCTOR ONLY.

YL

MS

COLOR CODE

YL YELLOW

BLK BLACK

RD RED

C2

WTK-SVN001-EN

13

Page 14

Dimensional Data

WTK507-518

400

400

WATER OUTLET

50.8

50.8

302.2

232.2

Ø3/4 FTP DRAIN PIPE

WATER INLET

LIQUID LINE

SUCTION LINE

358.2

293.2

POWER SUPPLY

Ø3/4 In.

53.543

69

DOMESTIC

MODEL

REFRIGERANT CONNECTION SIZE (In.) WATER

LIQUID SUCTION CONNECTION SIZE (In.)

WTK507-509 1/4 3/8 3/4

WTK512-518 3/8 5/8 3/4

400

14

EXPORT

MODEL

REFRIGERANT CONNECTION SIZE (In.) WATER

LIQUID SUCTION CONNECTION SIZE (In.)

WTK507-509 1/4 3/8 3/4

WTK512-518 1/4 1/2 3/4

WTK-SVN001-EN

Page 15

109

22

179

49

Dimensional Data

WTK524-060

500

400

WATER INLET

LIQUID LINE

SUCTION LINE

477.6

179

WATER OUTLET

432.6

Ø3/4 FTP DRAIN PIPE

DOMESTIC

EXPORT

POWER SUPPLY

Ø5/8 In.

477.6

412.6

43

51.1

200.4

MODEL REFRIGERANT CONNECTION SIZE (In.) WATER

LIQUID SUCTION CONNECTION SIZE (In.)

WTK524-530 3/8 5/8 3/4

WTK536 3/8 3/4 3/4

WTK048-060 1/2 7/8 7/8

MODEL REFRIGERANT CONNECTION SIZE (In.) WATER

LIQUID SUCTION CONNECTION SIZE (In.)

WTK524-530 3/8 5/8 3/4

WTK536 3/8 3/4 3/4

WTK048-060 3/8 1-1/8 7/8

520

WTK-SVN001-EN

15

Page 16

Trane Thailand

7th Floor, Ploenchit Center Building

2 Sukhumvit Road, Klongtoey

Bangkok 10110

Amair Limited

35 Mu 8, Poochaosamingprai Road

Samrong Tai, Samutprakarn 10130

http://www.trane.com

An American Standard Company

Literature Order Number

Supersedes

Stocking Location Bangkok, Thailand

WTK-SVN001-EN0404

WTK-SVN001-EN0303

∫√‘…—∑ ·Õ¡·Õ√å ®”°—¥ 35 À¡Ÿà 8 ∂.ªŸÉ‡®â“¡‘ßæ√“¬ µ.”‚√ß„µâ Õ.æ√–ª√–·¥ß ®.¡ÿ∑√ª√“°“√ 10130

Since The Trane Company has a policy of continuous product and product data improvement,

it reserves the right to change design and specifications without notice.

Loading...

Loading...