Page 1

Accessories

Thermostats/Sensors

WSHP-PRC003-EN

R

180

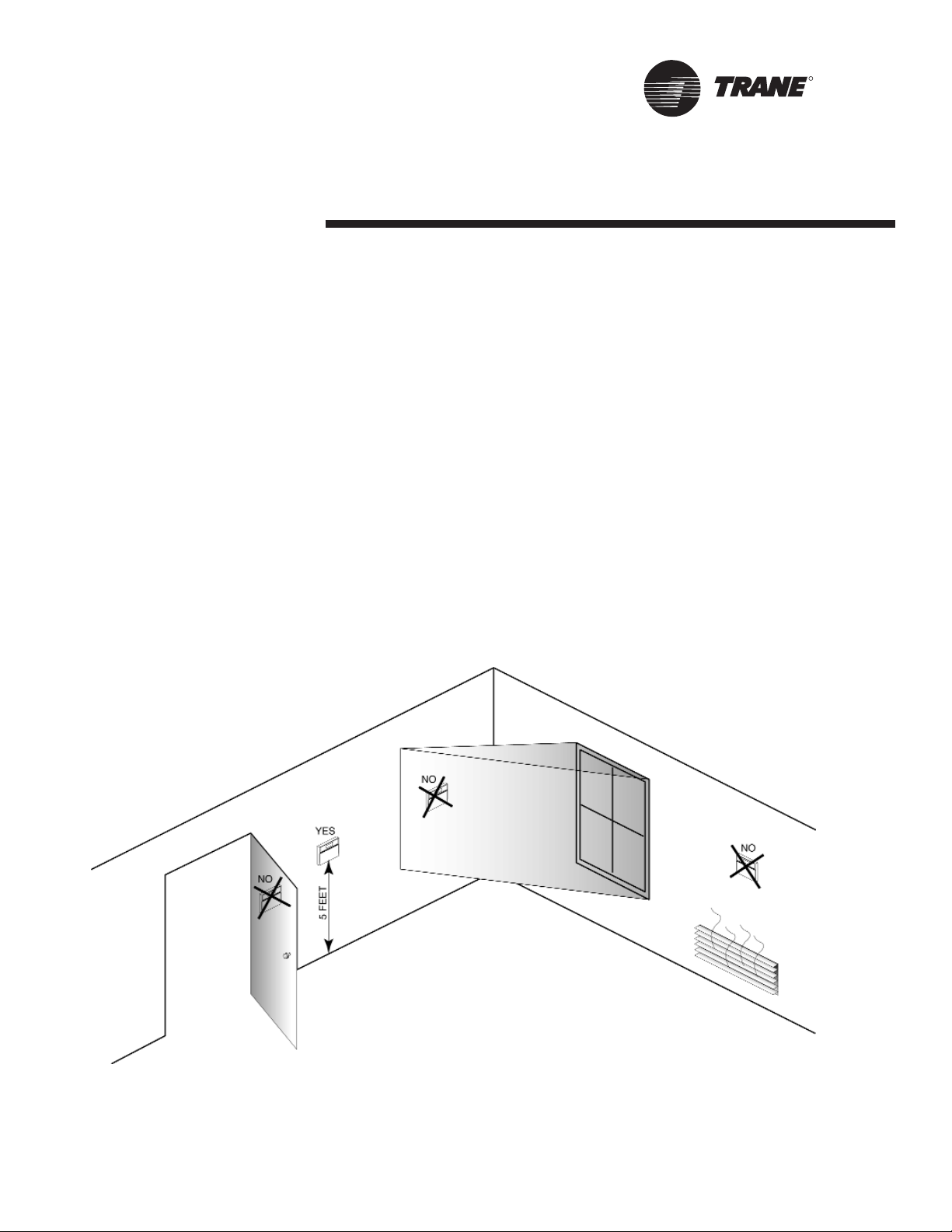

Thermostat/Sensor Location

Location of the thermostat or zone sensor is an important element of effective

room control and comfort.

The best location is typically on a wall,

remote from the HVAC unit. Readings at

this location assure that the desired setpoint is achieved across the space, not

just near the unit itself. It may be necessary to subdivide the zone to ensure

adequate control and comfort.

See Figure 36 for detailed areas where

the thermostat or zone sensor should

and should not be mounted. These

include:

• Near drafts or “dead spots”

(Behind doors or corners)

• Near hot or cold air ducts

• Near radiant heat (appliances,

windows, etc.)

• Near concealed pips or chimneys

• On outside walls or other

non-conditioned surfaces.

• In air flows from adjacent zones or

other units.

Figure 36: Proper thermostat and sensor location.

Page 2

R

Accessories

Thermostats/Sensors

WSHP-PRC003-EN

181

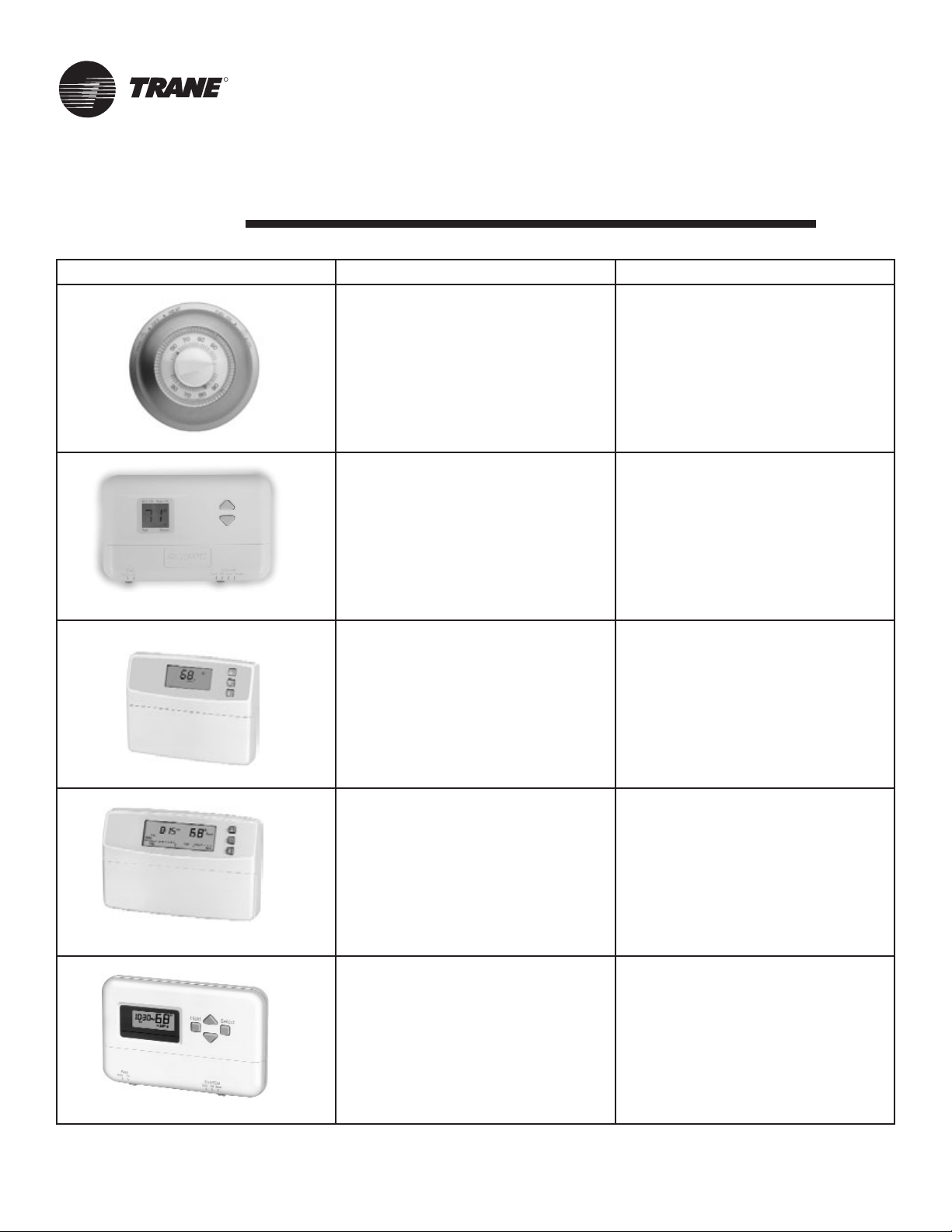

Thermostat/Sensor Part Number Description

X13510309010 - thermostat

X13530069010 - subbase

(006 - 060 models only)

Mercury Thermostat

• 0-stage heat/1-stage cool manual

changeover with COOL-OFF

• Non Programmable

• Fan switching includes

• FAN ON-AUTO

X13511039010

(006 - 060 models only)

Manual Changeover Digital Stat

• 2-stage heat/1-stage cool

• System switching includes HEAT-OFFCOOL

• Fan switching includes AUTO-ON

• Non programmable

• Auto compatible with F

O

or C

O

temperature readings

X13511041010

Auto/Manual Changeover Digital Stat

• 1-stage heat/1-stage cool

• System switching includes HEAT-OFFCOOL-AUTO

• Fan switching includes ON-AUTO

• Non programmable

• Auto compatible with F

O

or C

O

temperature readings

X13511042010

Auto/Manual Changeover Digital Stat

• 3-stage heat/2-stage cool

• System switching includes HEAT-OFFCOOL-AUTO

• Fan switching includes ON-AUTO

• 7-day programmable

• Adjustable 1 to 15-degree night setback

• Auto compatible with F

O

or C

O

temperature readings

X13511043010

Manual Changeover Digital Stat

• 2-stage heat/1-stage cool

• System switching includes HEAT-OFFCOOL

• Fan switching includes ON-AUTO

• 5-day programmable

• Adjustable 1 to 15-degree night setback

• Auto compatible with F

O

or C

O

temperature readings

Page 3

Accessories

Thermostats/Sensors

WSHP-PRC003-EN

R

182

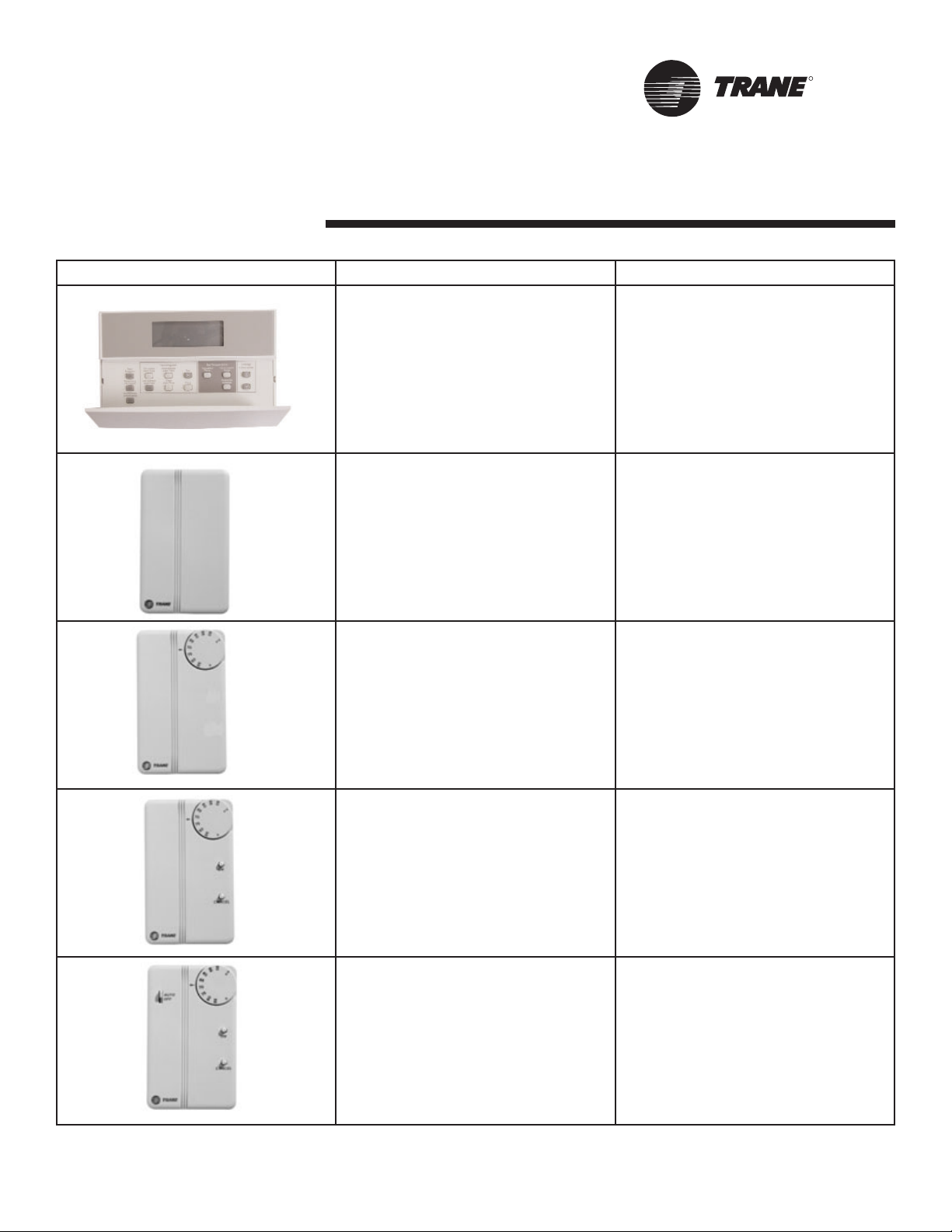

Thermostat/Sensor Part Number Description

X13511091010 - thermostat

X13511092010 - subbase

(072 - 150/240 models only)

Digital Thermsostat

• 3-stage heat/2-stage cool with AUTOEM HEAT-HEAT-OFF-COOL

• Non Programmable

• Fan switching includes FAN ON-AUTO

• 2 LEDs

• Auto compatible with F

O

or C

O

temperature readings

X13510628010

Zone Sensor

• Tracer ZN510 and ZN524 compatible

• Internal setpoint adjustment wheel

• Communication Jack

X13510606010

Zone Sensor

• Tracer ZN510 and ZN524 compatible

• External setpoint adjustment wheel

• Communication Jack

X13510606020

Zone Sensor

• Tracer ZN510 and ZN524 compatible

• External setpoint adjustment wheel

• Communication Jack

• ON and CANCEL buttons

X13510635010

Zone Sensor

• Tracer ZN510 and ZN524 compatible

• External setpoint adjustment wheel

• Communication Jack

• ON and CANCEL buttons

• Fan switch AUTO-OFF

Page 4

R

Accessories

WSHP-PRC003-EN

183

Pump Module

The pump module and hose kit make a

complete self-contained pumping package for distributed pumping systems.

These kits contain all the necessary

components for the installation, operation and maintenance of the water circuit of a closed loop geothermal application. Standard pump module features

include insulated Grundfos pumps,

insulated cabinet, bronze or cast iron

pump, and 3-way brass valves. The

module is factory piped, wired and

mounted. See Figure 40 for pump module assembly. Literature number

WSHPC-IN-5 (72-9006-03) will provide

electrical and dimensional requirements for the PMCA and PMBA products.

Figure 37: Pump module

Pump Module Hose Kit

The pump module hose kit consists of

two brass, 3/4 or 1-inch male pipe

thread (MPT) -by-barb fittings; two

brass 90 degree 1-inch, MPT-by-barb

elbows with pressure/temperature

ports; and 10 feet of rubber hose with 4

hose clamps. The pump module hose

kit is available separately from the

pump module.

Figure 38: Pump module hose kit

Water Regulating Valve

Assembly

The water regulating valve assembly

consists of a direct acting valve and a

reverse acting valve installed on the

water-out side of the unit. The valve

connection sizes shall range from 1/2"

to 1 1/2" FPT. The direct acting valve

opens in response to an increase in discharge pressure during the cooling

cycle. The reverse acting valve opens in

response to a decrease in suction pressure during the heating cycle. Water

regulating valves should be used where

low flow and low or high fluid temperature conditions could occur. See page

29 of this manual for application information.This option is beneficial with

open loop systems, but not necessary.

Figure 39: Water regulating valve

Motorized Water Valve

The motorized water valve is installed

on the return line of the water loop system between the loop and the loop’s

pump module. This isolation device is

less expensive and a very effective

alternative to the water regulating

valve.

When the compressor begins running,

the valve will open, allowing water to

flow through the unit. As the compressor shuts down, the valve slowly closes

off. The main purpose of the motorized

valve is to shut-off the flow of water

through the unit when the unit is off,

thus reducing water consumption. The

motorized valve is fast opening to prevent compressor trip-out, and slow

closing to prevent water hammer.

Figure 40: Motorized water valve

Page 5

Accessories

WSHP-PRC003-EN

R

184

Ducted Panel

The return-air arrangement may be

easily converted from a free return-air

system, to a ducted return-air system

with the addition of a return-air side

panel. By replacing the filter racks with

the return-air panel, a complete seal

from the duct to the unit is possible.

The 1-1/2"(38mm) duct flange facilitates ease of field connection to the

mechanical system. This accessory is

typically used when the return-air filter

is placed in a built-in ceiling grille, or

placed within a field provided filter rack

assembly.

Figure 41: Return-air duct panel

Hose Kits

Trane provides three hose kit selections for equipment balancing.

• Ball valve flow control (manual)

• Circuit setter flow control (manual)

• Automatic flow control (automatic)

Each selection provides some accuracy in equipment balancing. Range of accuracy

consist of ±25% for the ball valve method, ±20% for the circuit setter method, and

±10% for the automatic flow control method.

Utilizing the ball valve method, the pressure/temperature measurement on the

leaving and entering side of the heat pump is measured within the water piping.

The ball valve is then throttled to change the amount of flow to the unit to reach

the desired temperature or pressure differential.

The circuit setter method combines both the readout and the adjustment feature in

one device. In order to determine flow rate, the user must record both handle position, and differential pressure drop. Then, the user must consult a chart containing

both pieces of information to make the necessary adjustments to the circuit setter.

For automatic system balancing of a water-source heat pump, the Mesurflo® self

balancing kit provides a constant flow rate over the pressure differential rage of 2

to 80 psid. As system pressure changes (through further addition of heat pumps,

for example) each individual flow control valve will automatically adjust to the new

system conditions. In variable water volume applications, a self balancing hose kit

can provide continuous balancing because of its ability to automatically adjust to

the varying system conditions. For more information pertaining to the automatic

balancing hose kits, see literature

documentation WSHP-SLB005-EN.

Figure 42: System balancing hose kits.

Unit

SizeA(in/mm)B(in/mm)

Model

Number

006-

015

17-1/2

(445)

13

(330)

4474 1133 0100

018-

030

20-1/2

(521)

15

(381)

4474 1134 0100

036-

042

22-1/2

(572)

17

(432)

4474 1135 0100

048-

060

26-1/2

(673)

19

(483)

4474 1136 0100

150,

180

* * 4475 2119 0100

240 * * 4475 2121 0100

Page 6

R

Mechanical Specifications

WSHP-PRC003-EN

185

General

Equipment shall be completely assembled, piped, internally wired, fully

charged with HCFC-22 and test operated at the factory. Filters, thermostat

field interface terminal strip, and all

safety controls are furnished and factory installed.

The system water inlet and outlet connections shall be female NPT composed of either a copper or a bronze

option.

The 5-ton and below equipment shall

contain ETL, CETL and ISO-ARI 13256-1

listings and labels prior to leaving the

factory. Larger units shall be rated in

accordance with ISO-ARI 13256-1.

Service and caution area labels shall

also be placed on the unit in their

appropriate locations.

The 6 through 10-ton equipment shall

contain ETL, CETL and ISO-ARI 13256-1

listings and labels prior to leaving the

factory. Larger units shall be rated in

accordance with ISO-ARI 13256-1.

Service and caution area labels shall

also be placed on the unit in their

appropriate locations.

Cabinet

Unit casing shall be constructed of zinc

coated, heavy gauge, galvanized steel.

Service to the refrigerant and controls

shall be provided through a single

access panel at the front of the equipment. Access to the refrigerant and

controls for the larger units shall be

provided through the front and side

access panels.

All panels shall be insulated with

1/2-inch (13mm) thick dual density

bonded glass fiber. The exposed side is

a high density erosion proof material

suitable for use in air streams up to

3600 feet per minute (FPM). The insulation meets the erosion requirements of

UL 181. It has a flame spread of less

than 25 and a smoke developed classification of less than 50 per ASTM E-84

and UL 723.

Access for inspection and cleaning of

the unit drain pan, coils and fan section

shall be provided. The unit shall be

installed for proper access.

Filters

One inch or two inch, throwaway

filters shall be standard and factory

installed. The filters shall have an average resistance of 76-percent and dust

holding capacity of 26-grams per

square foot.

Sound Attenuation

Sound attenuation shall be applied as a

standard feature in the product design.

The sound reduction package shall

include a compressor discharge muffler,

vibration isolation to the compressor

and water-to-refrigerant coil, unit base

stiffeners, insulated metal compressor

enclosure, and a second stage of vibration isolation to the compressor and

water-to-refrigerant base pan.

All units shall be tested and rated in

accordance with ARI 260.

Compressors

The unit shall contain a high efficiency

rotary, reciprocating, or scroll compressor. External vibration isolation shall be

provided by rubber mounting devices

located underneath the mounting base

of the compressor. A second isolation

of the refrigeration assembly shall be

supported under the compressor

mounting base.

Internal thermal overload protection

shall be provided. Protection against

excessive discharge pressure shall be

provided by means of a high pressure

switch. A loss of charge shall be provided by a low pressure safety.

Refrigerant Tubing

The refrigerant tubing shall be of 99%

pure copper. This system shall be free

from contaminants and conditions such

as drilling fragments, dirt and oil. All

refrigerant and water lines shall be

insulated with an elastomeric insulation

that has a 3/8-inch thick wall in the airside section of the unit.

Refrigerant Circuits

The refrigerant circuit shall contained a

thermal expansion device. Service pressure ports shall be factory supplied on

the high and low pressure sides for

easy refrigerant pressure or temperature testing.

Air-to-Refrigerant Coil

Internally finned, 3/8-inch copper tubes

mechanically bonded to a configured

aluminum plate fin shall be standard.

Coils shall be leak tested at the factory

to ensure the pressure integrity. The

coil shall be leak tested to 200 psig and

pressure tested to 450 psig.

The tubes are to be completely evacuated of air and correctly charged with

proper volume of refrigerant prior to

shipment.The refrigerant coil distributor

assembly shall be of orifice style with

round copper distributor tubes. The

tubes shall be sized consistently with

the capacity of the coil. Suction header

shall be fabricated from rounded copper pipe.

A thermostatic expansion valve shall be

factory selected and installed for a wide

range of control.

Drain Pan

The condensate pan shall be constructed of corrosion resistant material and

insulated to prevent sweating. The bottom of the drain pan shall be sloped on

two planes which pitches the condensate to the drain connection. The drain

pan shall be flame rated per UL945V-B.

Page 7

Mechanical

Specifications

WSHP-PRC003-EN

R

186

When the unit is installed and trapped

per the manufacturers installation manual, and local city specifications, the

drain pan shall be designed to leave

puddles no more than 2-inch in diameter, no more than 1/8-inch deep, no

longer than 3-minutes following Step 3

of the following test:

1. Temporarily plug the drain pan.

2. Fill the drain pan with 1/2-inch of

water or the maximum allowed by

the drain pan depth, whichever is

smaller.

3. Remove the temporary plug.

Water-to-Refrigerant Heat

Exchanger

The water-to-refrigerant heat exchanger

shall be of a high quality co-axial coil

for maximum heat transfer. The copper

or optional cupro-nickel coil shall be

deeply fluted to enhance heat transfer

and minimize fouling and scaling. The

coil shall have a working pressure of

400 psig on both the refrigerant and

water sides. The factory shall provide

rubber isolation to the heat exchanging

device to enhance sound attenuation.

Indoor Fan

The blower shall be a forward-curved

style wheel with four speed combinations, or nine blower motor/sheave

combinations available.

All direct drive motors shall have

sealed bearings that do not require

field lubrication.

Options of the blower motor/fan packages shall be selected and wired from

the factory to match performance criteria suggested in the performance section. The motor shall contain a quick

disconnect plug for service, convertibility and safety precautions.

The fan(s) shall be placed in a draw-

through configuration. They shall be

constructed of corrosion resistant galvanized material.

Electrical

The unit control box shall contain all

necessary devices to allow heating and

cooling operation to occur from a

remote wall thermostat. These devices

shall be as follows:

• 24 VAC energy limiting class II

50 VA (minimum) transformer

• 24 VAC blower motor relay

24 VAC compressor contactor for

compressor control

• Field thermostat connections shall

be provided for ease of hook-up to

a terminal strip located in the unit’s

control box

• Lockout relay which controls

cycling of the compressor shall be

provided to protect the compressor

during adverse operating conditions. The device may be reset by

interrupting power to the 24 VAC

control circuit. Reset may be done

either at a remote thermostat or

through a momentary main power

interruption

• A high pressure switch shall protect

the compressor against operation

at refrigerant system pressures

exceeding 395 psig.

• The low-water temperature switch

or sensor shall prevent the

compressor operation with leaving

water temperatures below

20 F/-6 C.

• Factory installed wire harness shall

be available for the Basic, Deluxe,

ZN510 and ZN524 control packages.

Nameplate information shall be provided for the application of either time-

delay fuses or HACR circuit breakers for

branch circuit protection from the primary source of power.

Basic Controls (option)

The basic control package shall contain

a low and high pressure switch along

with a compressor lockout relay for

control assistance. High voltage power

connections shall be made at the equipments contactor. An optional condensate overflow detection device shall be

made available with this control package. Each device shall be factory

mounted, wired, and tested in the

equipment.

Deluxe Controls (option)

The deluxe control package shall provide a 75 VA transformer with circuit

breaker. The controller shall include a

lockout relay, anti-short cycle compressor protection, random start delay,

brown-out protection, low pressure

time delay, compressor delay on start

and an open relay for night setback or

pump request.

Optional wiring from the factory for

night setback, condensate overflow, hot

gas reheat, electric heat, and compressor enable shall also be provided. Three

LEDs (light emitting diodes) shall also

be included for diagnostics of the

equipment.

Tracer ZN510 or ZN524

Controller (option)

This system shall utilize factory furnished and mounted DDC controls for

operation of up to 120 units on a Comm

5 (LonMark) link. The Tracer ZN510 control package shall include a 75 VA transformer. The controller shall provide random start delay, heating/cooling status,

occupied/unoccupied mode, fan status

and filter maintenance options.

Optional wiring from the factory for

condensate overflow shall be available.

Page 8

R

Mechanical

Specifications

WSHP-PRC003-EN

187

Three LEDs (light emitting diodes) shall

be included for diagnostics of the

equipment.

The ZN510 shall be capable of a standalone application, or as applied to a full

building automation installation.

Tracer ZN524 Controller (option)

The ZN524 controller shall utilize factory furnished and mounted DDC controls

for operation of up to 120 units on a

Comm 5 (LonMark) link. The Tracer

ZN524 control package shall include a

75 VA (minimum) transformer. The controller shall provide random start delay,

heating/cooling status, occupied/unoccupied mode, fan status and filter maintenance options. Optional wiring from

the factory for condensate overflow

shall be available. Three LEDs (light

emitting diodes) shall be included for

diagnostics of the equipment.

The ZN524 shall be capable of a standalone application, or as applied to a full

building automation installation.

With this controller, the unit shall be

capable of a hot gas reheat (for dehumidification), boilerless control for electric heat, waterside economizing, and

support of variable speed pump control

applications.

Orifice Ring

Removal of the motor and fan wheel

for the 1/2 through 5-ton units shall be

made with the assistance of a factory

provided orifice ring device. This device

shall attach the wheel and motor to the

fan housing in one assembly providing

single side service access.

Water Regulating Valve

Assembly

(option)

The water regulating valve assembly

shall consist of a direct acting valve and

a reverse acting valve. The direct acting

valve shall open in response to an

increase in discharge pressure during

the cooling cycle. The reverse acting

valve shall open in response to a

decrease in suction pressure during the

heating cycle. Water regulating valves

shall be used where low flow, or low or

high fluid temperature conditions exist.

This accessory shall be used with openloop systems.

Economizing Coil (GEH option)

The waterside economizing package

shall be an external unit accessory prepiped and pre-wired ready for turn-key

installation to the unit. The economizing

coil shall be designed to perform with

the WSHP at unit measured flow rate of

80.6 F DB/66.2 F WB with 45 F EWT.

All hydronic coils shall be of 5/8" copper and aluminum plate fin combination. All coils shall be proof and leak

tested from the manufacturer. The proof

test shall be performed at 1.5 times the

maximum operating pressure and the

leak test at the maximum operating

pressure.

A dual sloped non corrosive drain pan

shall be easily accessible and cleanable

for the hydronic economizing coil.

An electronic two-position, 3-way valve

shall meter water flow to the economizing coil during the economizing mode.

It shall be factory set to energize the

economizing mode at 55 F, while simultaneously halting mechanical operation

of the compressor.

Hanging brackets with rubber isolation

shall be provided for the horizontal version of the economizing coil option. The

bracket design shall be the same

throughout the equipment.

Electric Heat (option)

Boilerless control electric heat shall be

factory wired and tested. It shall be

composed of a nichrome open wire coil

designed for 2-kW per unit ton. The

design consist of a single stage of electric heat used as a primary heating

source when compressor lockout has

occurred due to the entering water temperature falling below 55 F with an

adjustable range between 25 F to 60 F.

All power connections to the electric

heat shall be made in the equipment’s

control box.

Hot Gas Reheat (option)

Dehumidification shall be provided

through a hot gas reheat option. The

coil shall consist of 3/8"/1/2" copper

tubes mechanically expanded into

evenly spaced aluminum fins. All coils

shall be proof and leak tested. The

proof test must be performed at 1.5

time the maximum operating pressure

and the leak test performed at the maximum operating pressure.

Ball Valves (option)

Ball valves shall be field installed

between the unit and the supply and

return lines of the loop to stop water

flow to the unit in a maintenance or

service situation.

Motorized Water Valve (option)

When extreme fluid temperature conditions do not exist with an open loop

system, a motorized water valve shall

be applied to each water-source heat

pump. The motorized valve shall stop

flow to the unit, causing pressures to

rise. This rise in pressure will halt pump

operation to provide greater energy

savings of the entire system.

Pump Module (option)

The pump module shall be a complete

self contained pumping package for an

earth-coupled heat pump system.

The module shall consist of a single,

1/6-HP bronze pump, and a brass 3-way

shut-off valve. These kits shall contain

the necessary components for the

installation, operation, and maintenance of the water circuit of a closedloop distributed pumping application.

Page 9

Mechanical

Specifications

WSHP-PRC003-EN

R

188

Hoses (option)

Hoses shall consist of a stainless steel

outer braid with an inner core of tube

made of a nontoxic synthetic polymer

material. The hoses shall be suitable for

water temperatures ranging between 33

F and 211 F without the use of glycol.

Automatic Flow Devices (option)

The automatic flow kit shall contain a

Hays Mesurflo® automatic flow control

valve, two ball valves, two flexible

hoses, a high flow Y-strainer, and may

include a strainer blow-down and various other accessories.

The automatic flow control valve shall

be factory set to a rated flow, and shall

automatically control the flow to within

10% of the rated value over a 40 to 1

differential pressure, operating range (2

to 80 PSID). Operational temperature

shall be rated from fluid freezing, to

225-degrees F. The valve body shall be

constructed from hot forged brass UNS

C37700 per ASTM B-283 latest revision.

For more information pertaining to the

automatic balancing hose kits, see literature documentation

WSHP-SLB005-EN.

Page 10

Literature Order Number WSHP-PRC003-EN

Date PL-RF-WSHP-PRC003-05-04

Supercedes Update

Stocking Location Electronic Only

Since the Trane Company has a policy of continuous product and product data

improvement, it reserves the right to change design and specifications without

notice.

The Trane Company

An American Standard Company

www.trane.com

For more information, contact

your local district office or

e-mail us at comfort@trane.com

Loading...

Loading...