Page 1

TCONT802AS32DA Touch Screen and

TCONT803AS32DA Touch Screen with

Dehumidification Control Comfort Controls

18-HD25D19-3

INSTALLATION INSTRUCTIONS

APPLICATION

The TCONT802AS32DA and TCONT803AS32DA Touch Screen Comfort Controls provide electronic control of 24 Vac

heating and cooling systems. See Table 1 for a general description.

Table 1. TCONT802AS32DA and TCONT803AS32DA Comfort Control Description.

Power Method Changeover System Selection Fan Selection Comments

24 Vac common

wire

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash. Dispose of properly.

Contact your local waste management authority

for instructions regarding recycling and the

proper disposal of the old control.

Automatic or

manual selectable

Heat-Off-CoolAuto (Em. Heat

for heat pumps)

On-Auto-Circ System and Fan selection

vary based on system type

System and Fan selection

vary based on System type.

Humidity sensor to control

dehumidification.

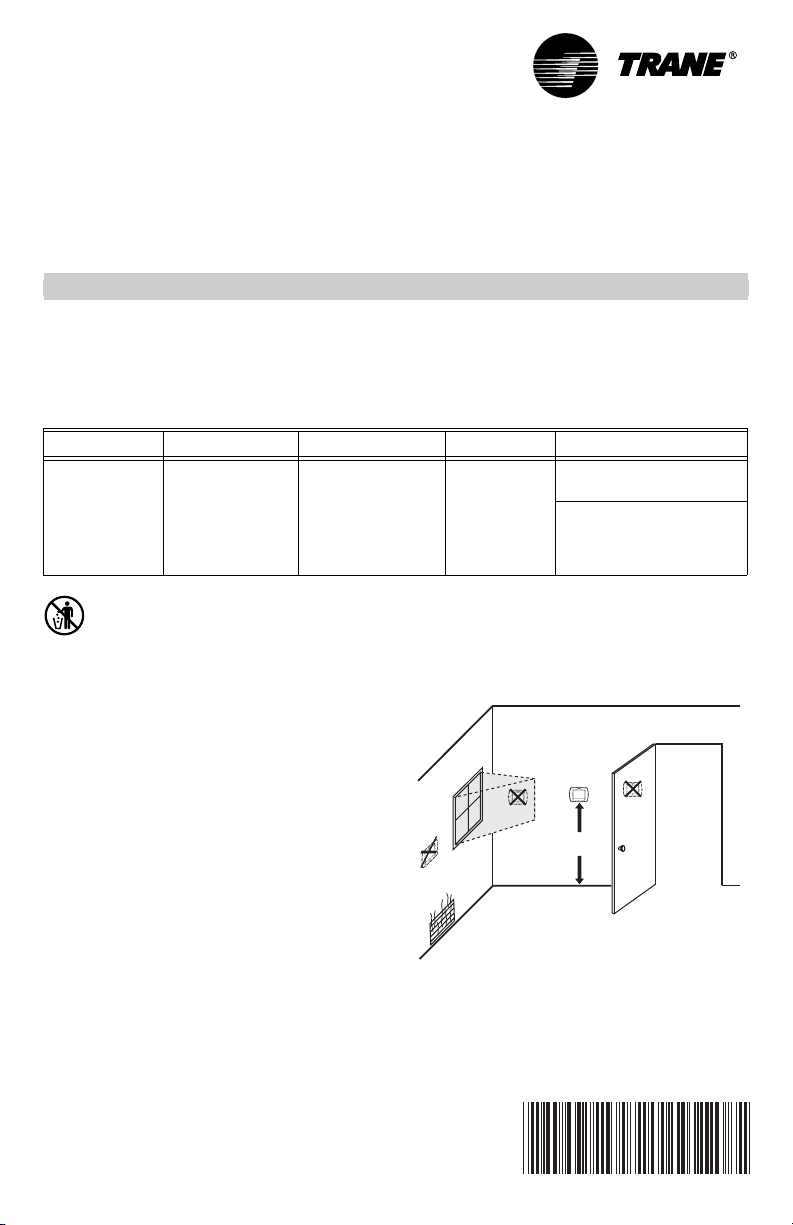

Selecting Location

Install the comfort control about 5 ft. (1.5m) above the

floor in an area with good air circulation at average

temperature. See Fig. 1.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

the instructions can damage the product or cause

a hazardous condition.

2. Installer must be a trained, experienced service

technician.

3. After completing installation, use these instructions

to check out the product operation.

U.S. Pat. No. 6595430, D509151, and Other Patents Pending

NO

YES

NO

NO

Fig. 1. Selecting comfort control location.

5 FEET

[1.5 METERS]

M19925

69-1790-3

Page 2

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

/COOL

SC

S

P

S1

S2

C

G

Do not install the comfort control where it can be affected

by:

— Drafts or dead spots behind doors and in corners.

— Hot or cold air from ducts.

— Radiant heat from sun or appliances.

— Concealed pipes and chimneys.

— Unheated (uncooled) areas such as an outside wall

behind the comfort control.

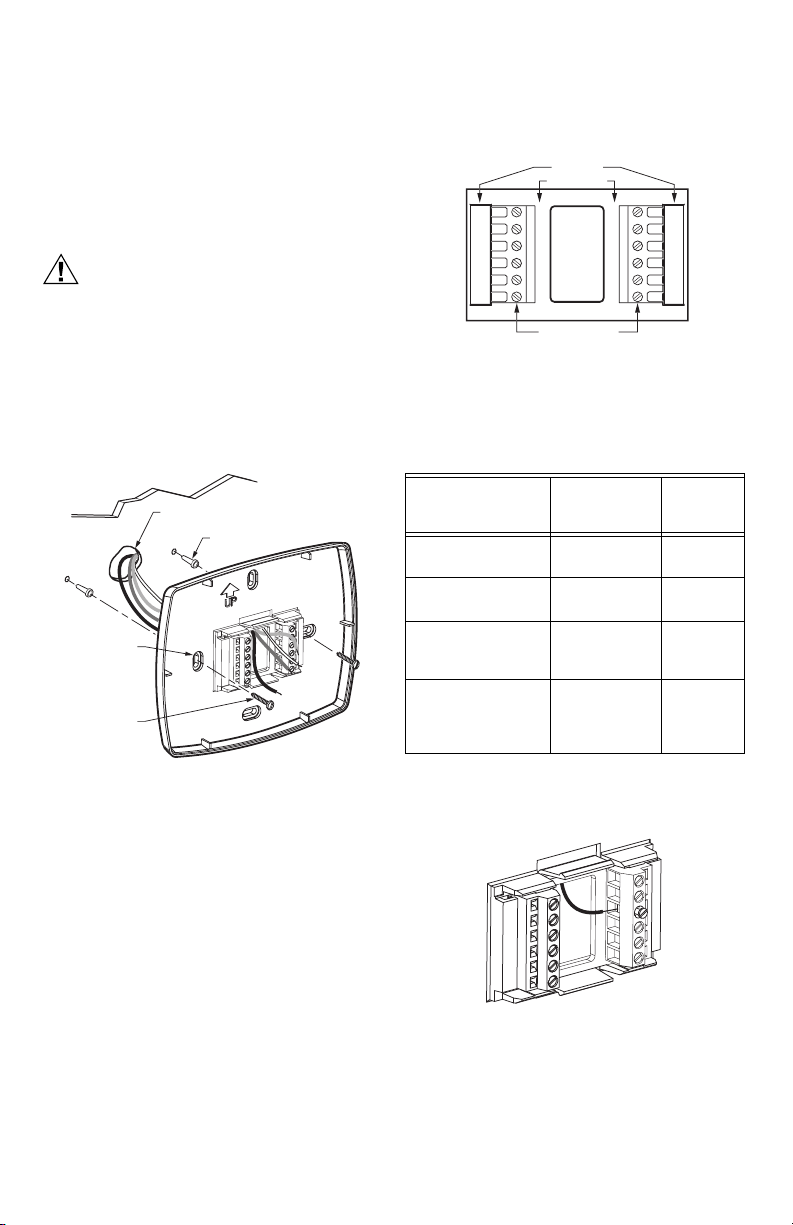

Installing Wallplate

CAUTION

Electrical Hazard.

Can cause electrical shock or equipment

damage.

Disconnect power before wiring.

The comfort control can be mounted horizontally on the

wall or on a 4 in. x 2 in. (101.6 mm x 50.8 mm) wiring box.

1. Position and level the wallplate (for appearance

only).

2. Use a pencil to mark the mounting holes.

WALL

WIRES THROUGH WALL

AND WIRE SLOT

WALL ANCHORS (2)

MOUNTING

HOLES

MOUNTING

SCREWS (2)

Fig. 2. Mounting wallplate.

3. Remove the wallplate from the wall and, if drywall,

drill two 3/16-in. holes in the wall, as marked. For

firmer material such as plaster, drill two 7/32-in.

holes. Gently tap anchors (provided) into the drilled

holes until flush with the wall.

4. Position the wallplate over the holes, pulling wires

through the wiring opening. See Fig. 2.

5. Insert mounting screws into the holes and tighten.

M19916

3. Securely tighten each screw.

4. Push excess wire back into the hole.

5. Plug the hole with nonflammable insulation to pre-

vent drafts from affecting the comfort control.

HEAT PUM

HEAT

Y2

F

X2

W1

S1

S2

Fig. 3. Selecting terminal identifications for

Table 2. Selecting Terminal Identifications for

W2

system type.

System Type.

System Type

R

W1

REW TERMINAL

Wallplate

Ter mi nal

Identifications

Standard Heat/Cool Heat/Cool Fig. 5,

Standard Multistage

up to 2 Heat/2 Cool

Heat Pump with

Electric Auxiliary

(Backup) Heat

Heat Pump with

Fossil Fuel Auxiliary

(Dual Fuel) Heat

NOTE: The factory default setting is configured for a

1 Heat/1 Cool System with a gas furnace.

Heat/Cool Fig. 7,

Heat Pump Fig. 9,

Heat Pump Fig. 12,

RC

R

O

Y

Y

G

B

M22636

Wiring

Diagram

Reference

Fig. 6

Fig. 8

Fig. 10,

Fig. 11

Fig. 13,

Fig. 14,

Fig. 15

WIRING (FIG. 5-15)

All wiring must comply with local electrical codes and

ordinances.

1. Select set of terminal identifications (Table 2) that

corresponds with system type (heat/cool or heat

pump in Fig. 3).

2. Loosen the screws for the appropriate system type

selected; see Table 2. Insert wires in the terminal

block under the loosened screw. See Fig. 4.

Pub. No. 18-HD25D19-3

69-1790—3 2

Fig. 4. Inserting wires in terminal block.

IMPORTANT

Use 18 gauge comfort control wire.

M19917

Page 3

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

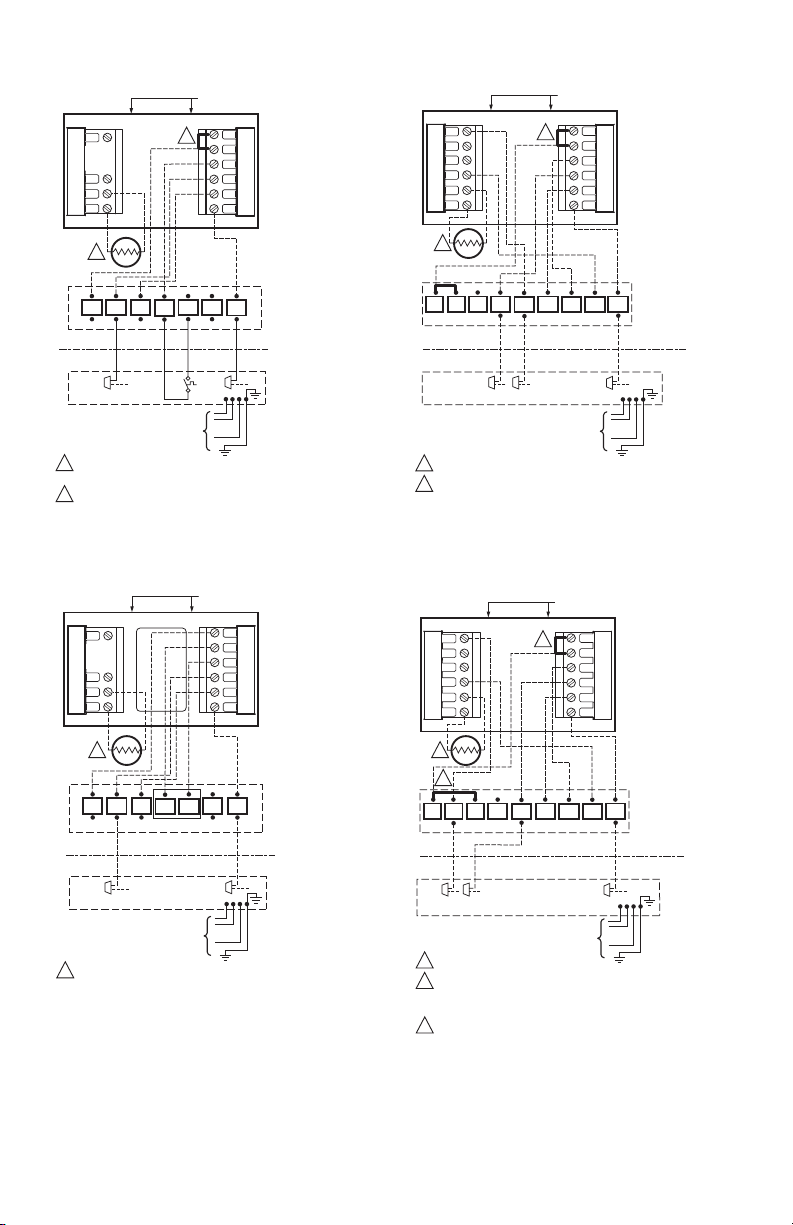

HEAT/COOL

Y2

W2

S1

S2

T

2

GYR

W1

INDOOR

OUTDOOR

ODT

Y

TO POWER SUPPLY

PER LOCAL CODES

FACTORY INSTALLED JUMPER.

1

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

2

ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

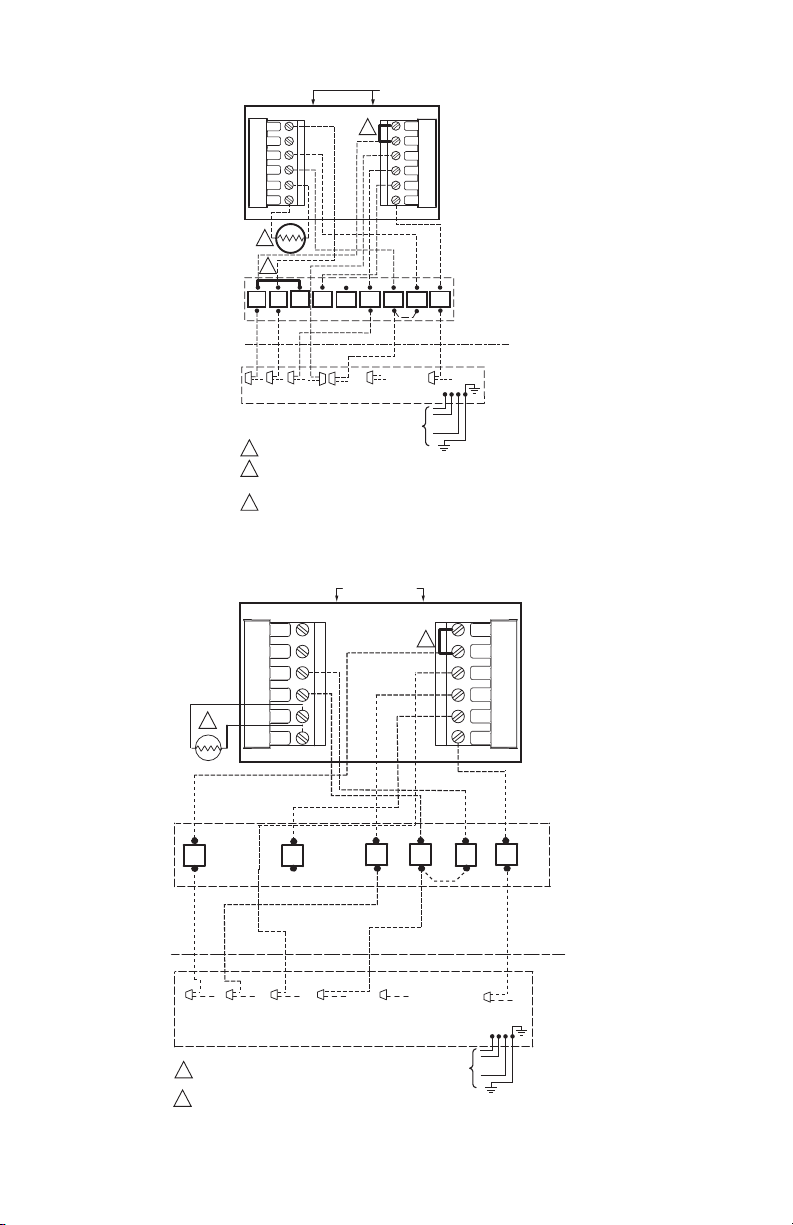

Fig. 5. Typical hookup of single-stage heat and cool

system with single transformer (1H/1C).

Y2

W2

S1

S2

T

1

GYR

T

OIL BURNER PRIMARY

INDOOR

OUTDOOR

Y

TO POWER SUPPLY

PER LOCAL CODES

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

1

ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

Fig. 6. Typical hookup of single-stage heat and cool

system with two transformers (1H/1C).

1

W2

T

W3

B/C

B

(3 PH

ONLY)

HEAT/COOL

W

B/C

B

(3 PH

ONLY)

RC

R

W1

Y

G

B

RC

R

W1

Y

G

B

AIR

HANDLER

COOLING UNIT

O.D. SECTION

(SINGLE STAGE)

OIL

FURNACE

COOLING UNIT

O.D. SECTION

(SINGLE STAGE)

M22637

M22638

HEAT/COOL

Y2

W2

S1

S2

T

2

O

LO

BKR

Y

Y

Y2

Y1

TO POWER SUPPLY

PER LOCAL CODES

FACTORY INSTALLED JUMPER.

1

2

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

Fig. 7. Typical hookup of two-stage indoor and

two-stage cooling unit in a single transformer system

Y2

W2

S1

S2

1

2

3

Fig. 8. Typical hookup of two-stage indoor and

two-step scroll cooling unit in a single transformer

(2H/2C or 2H/1C or 1H/2C).

T

2

3

O

BK R

Y2

FACTORY INSTALLED JUMPER.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

THE INSTALLER MUST JUMPER AT THE LVTB “R” TO “O”.

LO

Y

Y1

Y

TO POWER SUPPLY

PER LOCAL CODES

system (2H/2C or 2H/1C or 1H/2C).

1

G

W1

INDOOR

OUTDOOR

HEAT/COOL

1

W1

G

W2

RC

R

W1

Y

G

B

B/C

W2

B

(3 PH

ONLY)

RC

R

W1

Y

G

B

B/C

B

(3 PH

ONLY)

VARIABLE SPEED

TWO-STAGE

FURNACE/VARIABLE

SPEED AIR HANDLER

COOLING UNIT

O.D. SECTION

(TWO STAGE)

M22640

VARIABLE SPEED

TWO STAGE

FURNACE

INDOOR

OUTDOOR

16 SEER

COOLING UNIT

O.D. SECTION

(TWO STEP)

M24231

3 69-1790—3

Pub. No. 18-HD25D19-3

Page 4

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

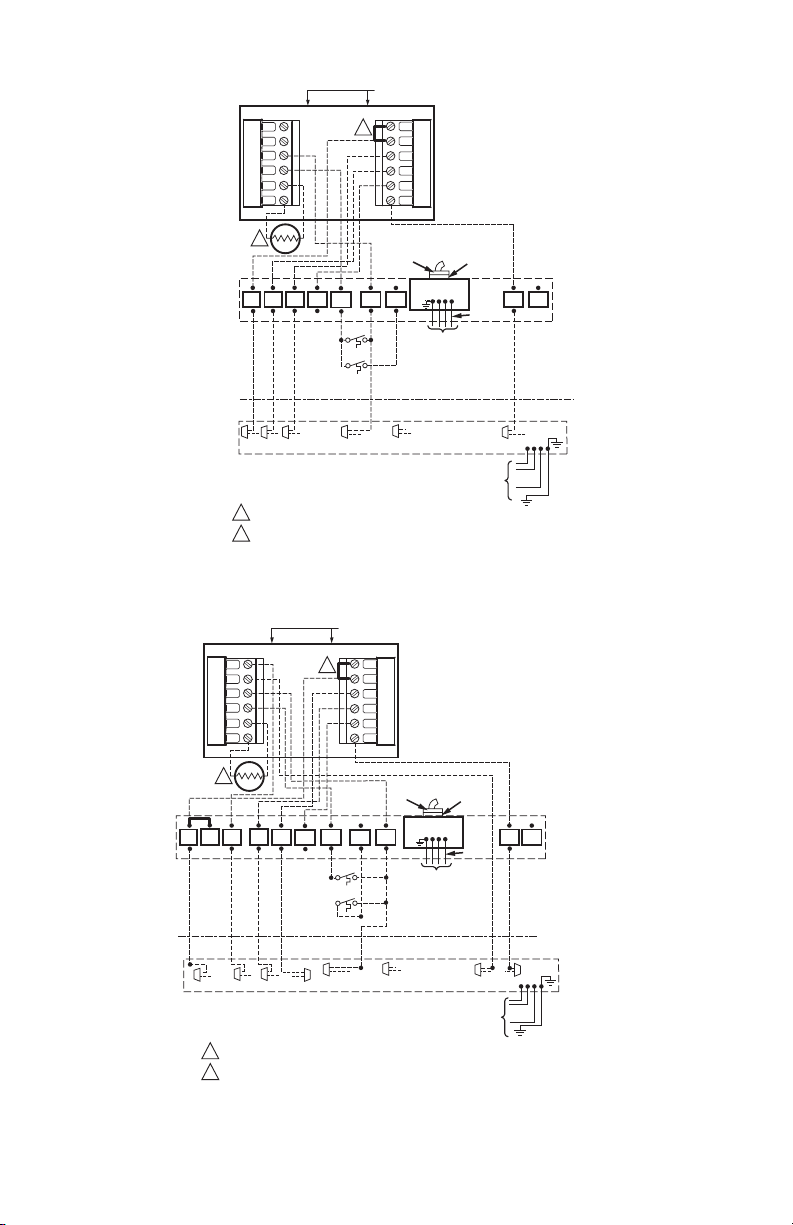

HEAT PUMP

Y2

F

X2

W1

S1

S2

T

2

O

GYR

W1

ODT-1

ODT-2

INDOOR

OUTDOOR

O

Y

R

FACTORY INSTALLED JUMPER.

1

2

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

1

W2

RC

R

O

Y

G

B

I-PF

SUPPL. HTR.

CONTROL BOX

W3

TO POWER

SUPPLY PER

LOCAL

CODES AND

AS DEFINED

IN FIELD

WIRING TABLE

BR(T)X2/BK

TO POWER SUPPLY

PER LOCAL CODES

PM-A

REQ.

FOR

3 PH

AIR

B/C

T

HANDLER

HEAT PUMP

O.D. SECTION

B

(SINGLE STAGE)

(3 PH

ONLY)

M22641

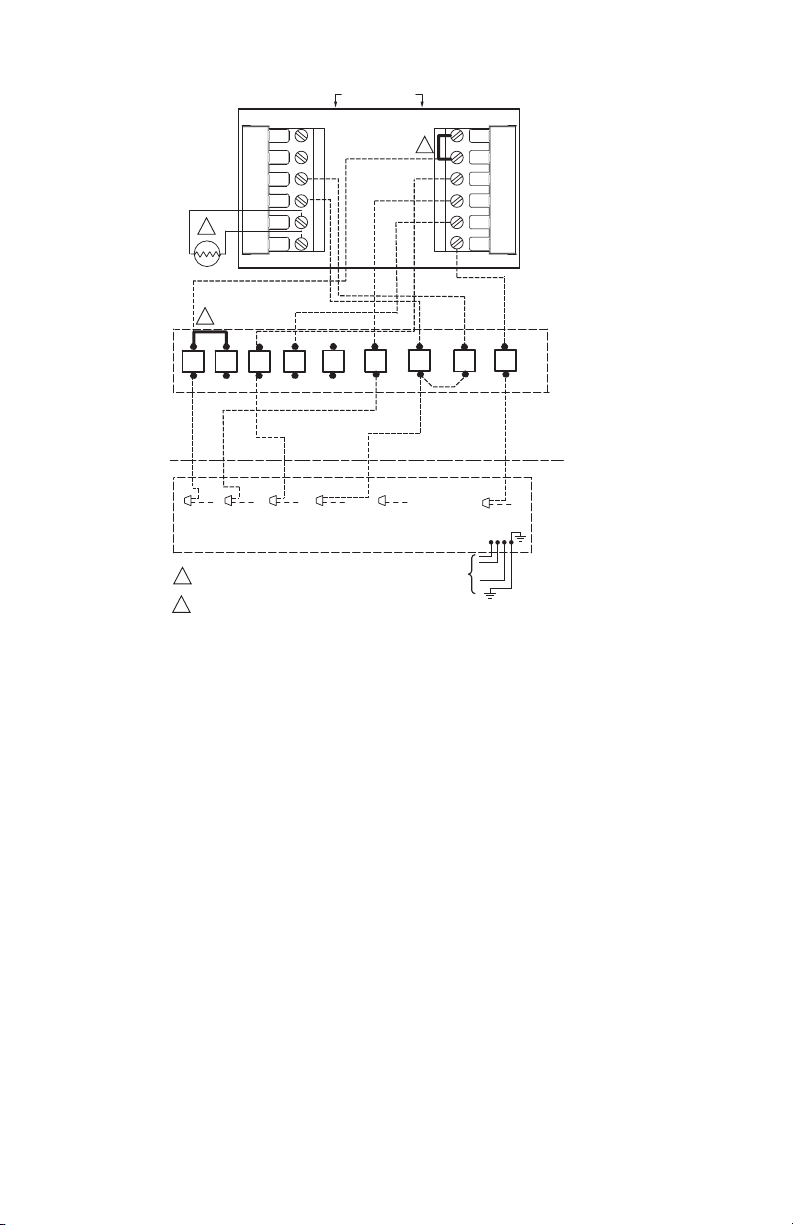

Fig. 9. Typical hookup of single-stage heat pump with auxiliary/backup heat (2H/1C heat pump).

HEAT PUMP

Y2

F

X2

W1

S1

S2

T

2

BK

YLO

OYR

G

INDOOR

OUTDOOR

Y2

O

R

1

2

Y1

FACTORY INSTALLED JUMPER.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS.

WIRES MUST HAVE A CABLE SEPARATE FROM THE THERMOSTAT CABLE.

1

W1

ODT-1

ODT-2

X2/BK

RC

R

O

Y

G

B

I-PF

PM-A

SUPPL. HTR.

CONTROL BOX

W3

W2

WIRING TABLE

BR(T)

REQ.

FOR

3 PH

TO POWER

SUPPLY PER

LOCAL

CODES AND

AS DEFINED

IN FIELD

TO POWER SUPPLY

PER LOCAL CODES

F

VARIABLE

B/C

T

SPEED AIR

HANDLER

HEAT PUMP

O.D. SECTION

B

(TWO STAGE)

(3 PH

ONLY)

M22642

Fig. 10. Typical hookup of multistage heat pump with auxiliary/backup heat (3H/2C heat pump).

Pub. No. 18-HD25D19-3

69-1790—3 4

Page 5

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

Y2

F

X2

W1

S1

S2

T

2

3

O

BK R

G

LO

Y

Y2

Y1

O

R

FACTORY INSTALLED JUMPER.

1

2

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A CABLE

SEPARATE FROM THE THERMOSTAT CABLE.

THE INSTALLER MUST JUMPER AT THE LVTB “R” TO “O”.

3

X2/BK

TO POWER SUPPLY

PER LOCAL CODES

1

Y

BR(T)

W1

W2

RC

R

O

Y

G

B

VARIABLE SPEED

B/C

AIR HANDLER

INDOOR

OUTDOOR

B

(3 PH

ONLY)

16 SEER

HEAT PUMP

O.D. SECTION

(TWO STEP)

M24230

Fig. 11. Typical hookup of multistage two-step scroll heat pump with auxiliary/backup heat (3H/2C heat pump).

HEAT PUMP

Y2

F

X2

W1

S1

2

S2

T

1

RC

R

O

Y

G

B

NON-V.S.

ONE OR TWO

R

R O BR(T)X2/BK

1

FACTORY INSTALLED JUMPER.

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

2

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

G

Y

Y

W1

INDOOR

OUTDOOR

TO POWER SUPPLY

PER LOCAL CODES

W2

(3 PH

ONLY)

M24200

B/C

B

STAGE GAS

FURNACE

HEAT PUMP

O.D. SECTION

(SINGLE STAGE)

Fig. 12. Typical hookup of singe-stage heat pump with non-variable speed gas furnace.

5 69-1790—3

Pub. No. 18-HD25D19-3

Page 6

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

(3 PH

ONLY)

M24201

RC

R

O

Y

G

B

B

VARIABLE

SPEED

TWO STAGE

FURNACE

HEAT PUMP

O.D. SECTION

(SINGLE STAGE)

Y2

F

X2

W1

S1

2

S2

T

1

O

R

BK

R O BR(T)BR/X2

1

FACTORY INSTALLED JUMPER.

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

2

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

Fig. 13. Typical hookup of single-stage heat pump with two stage variable speed gas furnace

G

Y

LO

Y

OR BK

(2H/1C heat pump).

1

W1 W2

YB/C

INDOOR

OUTDOOR

TO POWER SUPPLY

PER LOCAL CODES

Pub. No. 18-HD25D19-3

69-1790—3 6

Page 7

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

Y2

F

X2

W1

S1

2

S2

T

1

Y

1/

O

R

BK

Y2

R O BR(T)X2/BK

1

FACTORY INSTALLED JUMPER.

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

2

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

G

Y1

Y/Y2 B/C

Y

LO

1

W1 W2

INDOOR

OUTDOOR

TO POWER SUPPLY

PER LOCAL CODES

RC

R

O

Y

G

B

VARIABLE

SPEED

TWO STAGE

FURNACE

F

(3 PH

ONLY)

M24202

HEAT PUMP

B

O.D. SECTION

(TWO STAGE)

Fig. 14. Typical hookup of multistage heat pump with two stage variable speed gas furnace (3H/2C heat pump).

7 69-1790—3

Pub. No. 18-HD25D19-3

Page 8

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

(3 PH

ONLY)

M24203

RC

R

O

Y

G

B

VARIABLE

SPEED

TWO STAGE

FURNACE

B

16 SEER

HEAT PUMP

O.D. SECTION

(TWO STEP)

Y2

F

X2

W1

S1

2

S2

T

1

O

R

BK

3

Y2

R O BR(T)X2/BK

1

FACTORY INSTALLED JUMPER.

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

2

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

3

REMOVE / CUT JUMPER FROM R TO BK.

Fig. 15. Typical hookup of multistage two-step scroll heat pump with two stage variable speed gas furnace

G

Y

LO

Y1

(3H/2C heat pump).

1

W1 W2

YB/C

INDOOR

OUTDOOR

TO POWER SUPPLY

PER LOCAL CODES

Powering the Comfort Control

The Comfort Control can be powered with 24 Vac.

24 Vac Common Power (Recommended)

Wire the common side of the transformer to the B screw

of the comfort control wallplate. When installing in a single

transformer system, keep the jumper wire between the R

and Rc screws. When installing in a two-transformer

system, use the common from the cooling transformer to

connect to the B screw and remove the jumper wire

between the R and Rc screws.

Battery Power (Optional)

CAUTION

Equipment or Property Damage Hazard.

Using battery power only may not provide

adequate power to comfort control and can

cause damage during freezing conditions.

Connect the 24 Vac Common (B) wire from the

system transformer to the comfort control for

proper operation when the battery power is

drained.

Pub. No. 18-HD25D19-3

69-1790—3 8

Three AAA alkaline batteries can be used to power the

comfort control for armchair programming only. To prevent

the comfort control and heating/cooling system from

shutting down due to lack of battery power, it is not

recommended that the comfort control be solely powered

with the three AAA batteries during normal system

operation. When using batteries, make sure positive and

negative terminals are oriented correctly, as marked on

the device. See Fig. 16.

BATTERIES (3)

M19918

Fig. 16. Installing batteries on comfort control back.

Page 9

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

E

MON

UE

THUSASUN

E

MON

THUSASUN

CHANGE FILTER UV LAMP HUMIDIFIER PAD

OK TO PICK MULTIPLE DAYS SCREEN LOCKED

US

E

R

U

Mounting the Comfort Control

1. Align the terminal screw blocks with the pins on the

back of the comfort control.

2. Push the comfort control straight onto the wallplate.

See Fig. 17.

WALL

INSTALLATION

REMOVE DURING

M22643

Fig. 17. Mounting comfort control on wallplate.

Adjusting Real-Time Clock

Setting Calendar and Time

Locate and remove the tab labeled Remove in the lower

left corner on the comfort control back. The tab must be

removed to activate the real-time clock. See Fig. 18.

REMOVE TAB TO ACTIVATE REAL TIME CLOCK

INSTALLATION

REMOVE DURING

INSTALLATION

REMOVE DURING

M22644

Fig. 18. Removing tab to activate real-time clock.

This comfort control is designed to automatically keep the

current time and day in memory for up to ten years under

normal use once the calendar is set. When the comfort

control is first powered, the display is ready for the

calendar date to be entered. See Fig. 19.

SET CURRENT DAY

SET MONTH

T

DON

E ARROWS TO SET YEAR AND TIM

DON

M22645

Fig. 19. Setting calendar and time after initial

IMPORTANT

The tab on the back of the comfort control in the

lower left corner must be removed for this

feature to be active.

powerup.

Using the Comfort Control

The comfort control has a touch screen interface. Words

or symbols appear, highlighting the keys, as necessary, to

complete tasks. Always press the keys with your

fingertips. Sharp instruments like a pen or pencil point can

damage the comfort control.

1. Use the arrow keys to set the Year, Month and Day,

as shown in Fig. 19.

2. Press the Done key.

3. Use the arrow keys to set the current time. See

Fig. 19.

4. Press the Done key.

9 69-1790—3

Pub. No. 18-HD25D19-3

Page 10

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

OPERATION

78°F

(25.5°C)

85°F

(29.5°C)

78°F

(25.5°C)

82°F

(28°C)

TO C

M22646

SettingHeat Cool

Auto

Auto

Auto

Auto

System and Fan Settings

The System default setting is Heat and the Fan default

setting is Auto.

SYSTEM SETTINGS

Heat: controls heating system.

Off: heating and cooling are off.

Cool: controls cooling system.

Auto: automatically changes between heating and cooling

systems, depending on indoor temperature. (See Installer

Setup section.)

Em Heat: emergency heat cycles to maintain

temperature. Compressor is locked out. (Used only for

heat pump systems with backup heat.)

FAN SETTINGS

The Fan setting can be programmed into the comfort

control schedule for each period (Wake, Leave, Return,

Sleep). See the Owners’ Guide for additional information.

LED Indication (Requires 24 Vac Common

Connection)

An LED indicator is located in the upper right corner of the

comfort control. It is only visible when lighted:

• It indicates when the comfort control is in the

Emergency Heat mode. When in Em. Ht. mode, the F

terminal is continuously energized and the LED is on.

• When the F terminal is wired to an equipment monitor,

the LED signals when a check or fail signal is sent to

the comfort control from the system. See Fig. 20. (This

can occur only when the comfort control is not in Em.

Ht. mode.)

C

EQUIPMENT

MONITOR

FTO R

Fig. 20. F terminal switch to R (power) side of system

Preprogrammed Settings

Table 3 shows the default program settings. See Owners’

Guide for complete instructions on changing the program.

transformer.

Table 3. Default Program Settings.

Schedule

Period Time

Wake 6:00AM 70°F

Leave 8:00AM 62°F

Return 6:00PM 70°F

Sleep 10:00PM 62°F

Setpoints

(21°C)

(16.5°C)

(21°C)

(16.5°C)

Fan

Pub. No. 18-HD25D19-3

69-1790—3 10

Page 11

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

E

MO

USASU

SYSTE

M

OFF

g

Schedule

de

Se

o

E

DONE

MON

THUSASUN

A

INSTALLER SETUP

The comfort control works with many different system

types. To operate correctly, the comfort control must be

set up to operate the installed heating and/or cooling

system.

Follow these steps to enter the Installer Setup:

1. Be sure the comfort control is powered.

2. Press and release the System Key.

FAN

ON

AUTO

SYSTEM

EM HEAT

OFF

COOL

3. Press and hold the two blank keys on either side of

the center blank key for approximately five seconds

until screen changes.

THU

Inside

SCHED HOLD CLOCK SCREE

Insi

Set To

A

M

T

t T

Following

Schedule

Followin

M22647

4. Release the two blank keys when the screen on the

comfort control matches the screen below.

DON

M22649

5. See screen below to review how the comfort control

keys are used during Installer Setup. See Table 4

for the Installer Setup Numbers and Settings.

ADVANCE TO NEXT

INSTALLER

SETUP

NUMBER

INSTALLER SETUP

CURRENT

SETTING

DON

CANC

M22648

PRESS TO EXIT

INSTALLER SETUP

6. Press the Done key to exit the Installer Setup

screen.

11 69-1790—3

CHANGE THE

CURRENT

SETTING

M22650

Pub. No. 18-HD25D19-3

Page 12

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

IMPORTANT

The Installer Setup Menu (Table 4) shows all the available options. These options customize themselves as

you make selections to the Installer Setup. Therefore, not all Installer Setup Selections are shown or are available to change.

Table 4. Installer Setup Menu.

Factory Setting Other Choices

Installer

Select

Not used. 1 thru

Date (Year

Upper)

Date (Year

Lower)

Date (Month) 0140 6 Digit(s) represents

Date

(Day)

Schedule

Options

System Type

Selection

Fan Operation 0180 0 Heat/Cool

Backup Heat

Source

(Auxiliary

Heat)

External

Fossil Fuel Kit

Cycles per

hour (cph) for

1st Stage

Compressor

Cycles per

hour (cph) for

2nd Stage

Compressor

Setup

Number

0099

0120 20 Set first two digits of

0130 05 Represents last two

0150 15 Digit(s) represents

—— — — —

current calendar year

(20 for year 2005, etc)

digits of current

calendar year (2005).

current calendar

month.

current calendar date.

21 21 —first two digits of current

calendar year (21xx)

00 -99 Select last two digits of current

calendar year.

1-12 Select number that represents

current calendar month.

1-31 Select number that represents

current calendar date.

CommentsOption Description Options Description

2000 - 2178 available

2000 - 2178 available

—

0160 4 7-day programming 0 0—nonprogrammable —

0170 1 1 Heat/1Cool 1-12 1—1heat/1cool

applications where

equipment controls

fan operation in heat

0200 0 Heat pump backup

0210 1 External fossil fuel kit

0220 3 Compressor Stage 1

0230 3 Compressor Stage 2

mode.

heat source is electric.

is controlling heat

pump backup heat

(recommended)

cycles per hour (cph)

cycles per hour (cph)

2—single-stage heat pump (no

aux. heat)

3—heat only (no fan)

4—heat only (with fan)

5—hot water Series 20 (3-wire

or normally open zone valves)

6—cool only

7—2 heat/1cool heat pump

8—2 heat/2 cool

9—2 heat/1cool

10—1 heat/2 cool oil furnace

or 0H/2C

11—2 heat/2 cool heat pump

(with no auxiliary heat)

12—3 heat/2 cool heat pump

(with auxiliary heat)

1 Heat pump or electric heat

applications where comfort

control controls fan operation

in heat mode.

1 Heat pump backup heat

source is fossil fuel.

0 No external fossil fuel kit is

controlling heat pump backup

heat. This comfort control

controls the backup fossil fuel

heat with outdoor sensor.

1-6 1-6 available;

3 is recommended.

1-6 1-6 available;

3 is recommended.

Available options and

defaults vary by

comfort control.

System selection

automatically

modifies some

default settings and/

or hides other

Installer Setup

options.

Only shown if heat/

cool system is

selected. If heat

pump is chosen, fan

defaults to electric.

Only shown if 2 heat/

1 cool or 3 heat/2

cool heat pump is

chosen.

Only shown if fossil

fuel is chosen as

backup heat source.

Only shown if two

stages of cool are

selected.

—

—

Pub. No. 18-HD25D19-3

69-1790—3 12

Page 13

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

Table 4. Installer Setup Menu. (Continued)

Factory Setting Other Choices

Installer

Select

Cycles per

hour (cph) for

1st Stage

Heat

Cycles per

hour (cph) for

2nd Stage

Heat

Cycles per

hour (cph) for

3rd Stage

Heat

Cycles per

hour (cph) for

Em Heat

Continuous

Backlight

Setup

Number

0240 5 Heat Stage 1 cycles

0250 5 Cycles per hour (cph)

0260 9 Cycles per hour (cph)

0270 9 Cycles per hour (cph)

0280 0 Backlight not on

per hour (cph)

for 2nd Stage Heat or

Auxiliary Heat for

2 H/1C Heat Pump

Systems

for Auxiliary Heat in

3H/2C Heat Pump

Systems

for Emergency Heat

continuously. Comfort

control backlight

comes on with each

key press.

1-12 1-12 available; typical settings:

1—1 cph used for steam or

gravity system.

3—3 cph used for 2-stage

fossil fuel forced air systems or

hot water systems.

5—5 cph used for single-stage

fossil fuel forced air systems.

9—9 cph used for electric

forced air heat systems

(electric auxiliary heat for heat

pump systems).

1-12 1-12 available; typical settings:

1—1 cph used for steam or

gravity system.

3—3 cph used for 2-stage

fossil fuel forced air systems or

hot water systems.

5—5 cph used for single-stage

fossil fuel forced air systems.

9—9 cph used for electric

forced air heat systems

(electric auxiliary heat for heat

pump systems).

1-12 1-12 available; typical settings:

1—1cph used for steam or

gravity system.

3—3 cph used for 2-stage

fossil fuel forced air systems or

hot water systems.

5—5 cph used for single-stage

fossil fuel forced air systems.

9—9 cph used for electric

forced air heat systems

(electric auxiliary heat for heat

pump systems).

1-12 1-12 is available; typical

settings:

3—3 cph used for 2-stage

fossil fuel forced air systems or

hot water systems.

5—5 cph used for single-stage

fossil fuel forced air systems.

9—9 cph used for electric

forced air heat systems

(electric auxiliary heat for heat

pump systems).

1 Backlight is on continuously

(comfort control must have a

common wire attached for this

function).

CommentsOption Description Options Description

Not shown if system

selection is heat

pump. Selection in

this stage changes

default cph for 2nd

stage heat.

Only shown if two

stages of heat are

selected.

Only shown if 3H/2C

heat pump system is

selected.

Only shown if 2 heat/

1 cool or 3 heat/2

cool heat pump is

selected.

Option is always

shown; however,

continuously on

backlight works only if

comfort control is

wired with 24 Vac

Common.

Changeover 0300 0 Manual changeover 1 1—auto changeover —

13 69-1790—3

Pub. No. 18-HD25D19-3

Page 14

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

Table 4. Installer Setup Menu. (Continued)

Factory Setting Other Choices

Installer

Select

Deadband 0310 2 thru 9 Heating and cooling

Temperature

Indication

Scale

Daylight

Savings

Remote

Temperature

Sensor

(Outdoor or

Indoor)

Heat Pump

Compressor

Lockout

Setup

Number

setpoints can be set

no closer than chosen

value:

2—2°F (1°C)

3—3°F (2°C)

4—4°F (2.5°C)

5—5°F (3°C)

6—6°F (3.5°C)

7—7°F (4°C)

8—8°F (4.5°C)

9—9°F (5°C)

0320 0 Temperature is

0330 1 Daylight savings

0340 0 No remote

0350 0 No compressor

displayed in °F.

enabled (use through

2006 and for areas

that do not

new 2007 DST

calendar).

use the

temperature sensor

lockout.

3 Heating and cooling setpoints

can be set no closer than 3°F

(1.5°C).

Shown only if

automatic

changeover is

selected.

The deadband is

restricted to the range

of 5 to 9 if ISU 0380 is

set to

dehumidification

droop control.

1 Temperature is displayed in °C. —

CommentsOption Description Options Description

0, 2 0—daylight savings is

disabled.

2—daylight savings is enabled

(start using in 2007, for areas

that use the new 2007 DST

calendar).

1-3 1—outdoor temperature

sensor for display only.

2—outdoor temperature

sensor for system control,

used for select heat pump

systems. (See Special Heat

Pump Features section for

more details.)

3—indoor temperature sensor

15, 20,

15°F (-9.5°C)

25, 30,

20°F (-6.5°C)

35, 40,

25°F (-4°C)

45

30°F (-1°C)

35°F (1.5°C)

40°F (4.5°C)

45°F (7°C)

Set to 0 in areas that

do not follow daylight

savings.

Defaults and Options

depend on System

Type selection.

Indoor Temperature

Sensor uses an

averaging network

and does not include

on-board sensor.

Default depends on

other selections.

Shown if Outdoor

Temperature for

control is selected.

Heat Pump

Auxiliary

Lockout

Indoor

Dehumidification Control

Furnace Filter

Change

Reminder

Humidifier

Pad

Replacement

Reminder

Pub. No. 18-HD25D19-3

69-1790—3 14

0360 0 No heat pump

0380 0 No indoor

0500 0 Furnace filter change

0510 0 Humidifier pad

auxiliary lockout.

dehumidification

control.

reminder off.

replacement reminder

off.

40, 45,

50, 55,

60

1 1—dehumidification droop

1-6 1—10 run time days

1-3 1—90 calendar days

40°F (4.5°C)

45°F (7°C)

50°F (10°C)

55°F (13°C)

60°F (15.5°C

control.

2—30 run time days

3—60 run time days

4—90 run time days

5—120 run time days

6—365 run time days

2—180 calendar days

3—365 calendar days

Shown if electric is

chosen for backup

heat source and

outdoor temperature

sensor for control is

selected.

Available on models

with humidity sensor.

Run time based on

call for fan.

—

Page 15

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

Table 4. Installer Setup Menu. (Continued)

Factory Setting Other Choices

Installer

Select

Adaptive

Intelligent

Recovery™

Number of

Periods

Minimum

Compressor

Off Time

Heat

Temperature

Range Stop

Cool

Temperature

Range Stop

Setup

Number

0530 1 Adaptive Intelligent

0540 4 Four periods available

0580 5 Five minute minimum

0600 90 Highest heating

0610 50 Lowest cooling

Recovery™ control is

activated (system

starts early so setpoint

is reached by start of

program period).

(Wake, Leave, Return,

Sleep)

off time for

compressor.

setpoint.

setpoint.

0 0—conventional recovery

(system starts recovery at

programmed time)

2 Two periods available (Wake

and Sleep)

0, 2, 3, 4Minimum number of minutes

compressor is off between

calls for compressor.

40 to 89 Temperature range (1°F

increments) of heating

setpoint.

51 to 99 Temperature range (1°F

increments) of cooling

setpoint.

CommentsOption Description Options Description

Not shown if

non-programmable is

selected. 2 or 4

applies to all days of

the week.

Five minutes

recommended

Shown in 1/2 °C.

Shown in 1/2 °C.

Clock Format 0640 12 12-hour clock format 24 24-hour clock format —

Extended Fan

on time Heat

Extended Fan

on time Cool

Keypad

Lockout

0650 0 No extended fan

0660 0 No extended fan

operation after call for

heat ends.

operation after call for

cool ends.

0670 0 Unlocked keypad 1, 2 1—partially locked keypad

90 Fan operation is extended 90

seconds after call for heat

ends.

90 Fan operation is extended 90

seconds after call for cool

ends.

2—fully locked keypad

Not shown if fan

operation is set to

fossil fuel or in Cool

Only Systems

Not shown in Heat

Only Systems.

Unlocked—all

functions are

available.

Partially locked—only

temperature up and

down keys and ability

to enter and modify

Installer Setup mode

are available. Fully

locked—only ability to

enter and modify

Installer Setup mode

are available.

—

15 69-1790—3

Pub. No. 18-HD25D19-3

Page 16

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

Table 4. Installer Setup Menu. (Continued)

Factory Setting Other Choices

Installer

Select

Temperature

Control in

Heat

Temperature

Control in

Cool

Temperature

Display Offset

Reset Comfort

Control

Setup

Number

0680 2 Standard temperature

0690 2 Standard temperature

0700 0 No difference in

0710 0 No comfort control

control in heating.

control in cooling.

displayed temperature

and actual room

temperature.

reset.

1, 3 1—less aggressive

temperature control (could

cause temperature

undershoot)

3—more aggressive

temperature control (could

cause temperature overshoot)

1, 3 1—less aggressive

temperature control (could

cause temperature

undershoot)

3—more aggressive

temperature control (could

cause temperature overshoot)

-3, -2,

-3°F (-1.5°C)

-1, 0, 1,

-2°F (-1°C)

2, 3

-1°F (-0.5°C)

0°F (0°C)

1°F (0.5°C)

2°F (1°C)

3°F (1.5°C)

1 Resets all Installer Setup

Options to default values and

resets schedule to default

setting.

CommentsOption Description Options Description

Applies to recovery

ramp and use of

auxiliary heat during

recovery.

Choose 1 if getting

temperature

overshoot.

Choose 3 if getting

temperature

undershoot.

Applies to recovery

ramp.

Choose 1 if getting

temperature

overshoot.

Choose 3 if getting

temperature

undershoot.

—

Only calendar

settings and time are

retained.

Pub. No. 18-HD25D19-3

69-1790—3 16

Page 17

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

SYSTEM CHECKOUT

Installer System Test

The Installer System Test mode is used to test the HVAC

system(s). See Table 5. While in System Test mode,

minimum off-time for compressors is bypassed.

The Installer Test is part of the Installer Setup options.

Enter Installer Setup screen and press the Down arrow

key to bring up test selection(s) quickly.

Table 5. System Test(s).

Select

Installer

Tes t C o o l

Installer

Tes t F a n

Installer

Tes t H e a t

Installer

Tes t E m

Ht

Installer

Setup

Number

Test 1 0 Cool is off 1,2 0—cool off

Test 2 0 Fan is off 1 0—fan off

Test 3 0 Heat is off 1-3 0—heat off

Test 4 0 Emergency

Factory Setting Other Choices

heat is off

CAUTION

Equipment Damage Hazard.

Minimum compressor off-time is bypassed

during Installer System Test.

Avoid cycling compressor quickly.

1—cool stage 1 turns on

2—cool stages 1 and 2 on

1—fan turns on

1—stage 1 heat on

2—stages 1 and 2 heat on

3—stages 1, 2 and 3 (Aux

Ht) on

1 0—emergency heat off

1—emergency heat on

2—emergency heat and

auxiliary heat turn on

CommentsOptions Description Options Description

System selection

determines which

tests are available

and the number of

stages shown.

—

—

Available only if

heat pump with

auxiliary heat is

selected.

17 69-1790—3

Pub. No. 18-HD25D19-3

Page 18

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

ADVANCED FEATURES

Outdoor or Indoor Temperature Sensor

For accuracy, the initial reading of the indoor and outdoor

temperature sensors require five minutes to stabilize. See

the Sensor instructions for installation information.

Special Heat Pump Features

Heat Pump with Fossil Fuel Auxiliary Heat (Dual

Fuel) and Outdoor Temperature Sensor

In this operation there is no external fossil fuel kit (dual

fuel kit) installed; the comfort control controls this function.

1. Choose correct heat pump application in Installer

Setup Number 0170.

2. Choose Fossil Fuel Option as the backup heat

source in Installer Setup Number 0200.

3. Choose No External Fossil Fuel Kit Option as

controlling backup heat in installer Setup Number

0210.

4. Outdoor Temperature Sensor for Control Option

is automatically chosen in Installer Setup Number

0340.

5. Choose appropriate Balance Point Temperature

in Installer Setup Number 0350.

OPERATION IN HEAT MODE ABOVE BALANCE POINT

(OUTDOOR TEMPERATURE)

When the outdoor temperature is above the selected

Balance Point Temperature (ISU 0350), only the

compressor operates and the fan (G terminal) energizes

when the comfort control calls for heat.

OPERATION IN HEAT MODE BELOW BALANCE POINT

(OUTDOOR TEMPERATURE)

When the outdoor temperature is below the selected

Balance Point Temperature (ISU 0350), only the Fossil

Fuel (auxiliary heat) operates and the fan (G terminal)

does not energize when the comfort control calls for heat.

OPERATION IN EMERGENCY HEAT MODE

The balance point (outside) temperature is not used in the

Emergency heat mode. When the comfort control is

moved to the Emergency Heat position, the compressor is

locked out. The first stage of heat is whatever is

connected to the X2 terminal. The second stage of heat is

what is connected to the W1 terminal. Often there is only

one source of non-compressor heat and the X2 terminal is

jumpered to the W1 terminal.

Heat Pump with Electric Auxiliary (Backup) Heat

and Outdoor Temperature Sensor

1. Choose correct heat pump application in Installer

Setup Number 0170.

2. Choose Electric as Auxiliary (Backup) Heat

Source in Installer Setup Number 0200.

3. Choose Outdoor Temperature Sensor for

Control Option in Installer Setup Number 0340.

4. Choose Compressor Lockout Temperature in

Installer Setup Number 0350.

5. Choose Auxiliary Lockout Temperature in

Installer Setup Number 0360.

NOTE: There is a 5°F deadband between the Compres-

sor and Auxiliary Heat Lockout Temperatures

OPERATION IN HEAT MODE

When the outdoor temperature is below the Compressor

Lockout Temperature, only the Auxiliary Heat operates.

When the outdoor temperature is above the Auxiliary

Lockout Temperature, only the Compressor operates.

See Fig. 21.

COMPRESSOR ONLY

50

BOTH COMPRESSOR AND

AUXILIARY HEAT

35

OUTDOOR TEMPERATURE

When the outdoor temperature is between the two

temperatures, both the Compressor and Auxiliary Heat

operate.

AUXILIARY ONLY

Fig. 21. Heat Pump Operation with Lockout

Temperatures Set.

AUXILIARY

LOCKOUT

TEMPERATURE

COMPRESSOR

LOCKOUT

TEMPERATURE

M19950

OPERATION IN THE EMERGENCY HEAT MODE

Once the comfort control is placed into the Emergency

Heat mode, the compressor and auxiliary lockout features

are turned off. In the Emergency heat mode, the

compressor is locked out. The first stage of heat is

whatever is connected to the X2 terminal. The second

stage of heat is connected to the W1 terminal. Usually the

emergency and auxiliary heat sources are electric strip

heat in these cases.

Dehumidification Droop Control

The dehumidification control attempts to control to the

user's humidity setpoint by turning on the air conditioner.

In extremely high humidity conditions, the comfort control

keeps the air conditioner running for up to 3

temperature setpoint. It does this while trying to achieve

the desired humidity setpoint and balancing that with the

temperature setpoint.

°

F below the

Pub. No. 18-HD25D19-3

69-1790—3 18

Page 19

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

TROUBLESHOOTING (SEE TABLE 6)

Table 6. Troubleshooting.

Symptom Possible Cause Action

Display does not come on. Comfort control is not being

Temperature settings do not

change.

Heating or cooling does not come

on.

Comfort control is calling for Heat

(Heat on) or Cool (Cool on) but no

heating or cooling is running.

Comfort control does not respond

when touch areas are pressed.

powered.

The upper or lower temperature

limits were reached.

The keypad is fully locked. Check Installer Setup Number 0670 to

Comfort control minimum offtime is activated.

System selection is not set to

Heat or Cool.

System type Selection is

incorrect.

Heating or cooling equipment is

not operating.

The keypad is locked. Check Installer Setup Number 0670 to

Check for 24 Vac between B and Rc.

Check temperature setpoints.

Check Installer Setup Numbers 0600 and

0610; modify as needed.

change keypad locked options.

Wait up to five minutes for the system to

respond.

Set system Selection to correct position.

Check Installer Setup Number 0170 and

make sure correct System type is

chosen.

Check wiring.

Check Installer Setup Number 0170 and

make sure correct system type is chosen.

Verify operation of equipment in System

Test mode.

change keypad locked options.

19 69-1790—3

Pub. No. 18-HD25D19-3

Page 20

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

® U.S. Registered Trademark

© 2006 American Standard Inc.

All Rights Reserved

Pub. No. 18-HD25D19-3

69-1790—3 M.S. Rev. 01-06

American Standard Inc.

Troup Highway

Tyler, TX 75711-9010

Loading...

Loading...