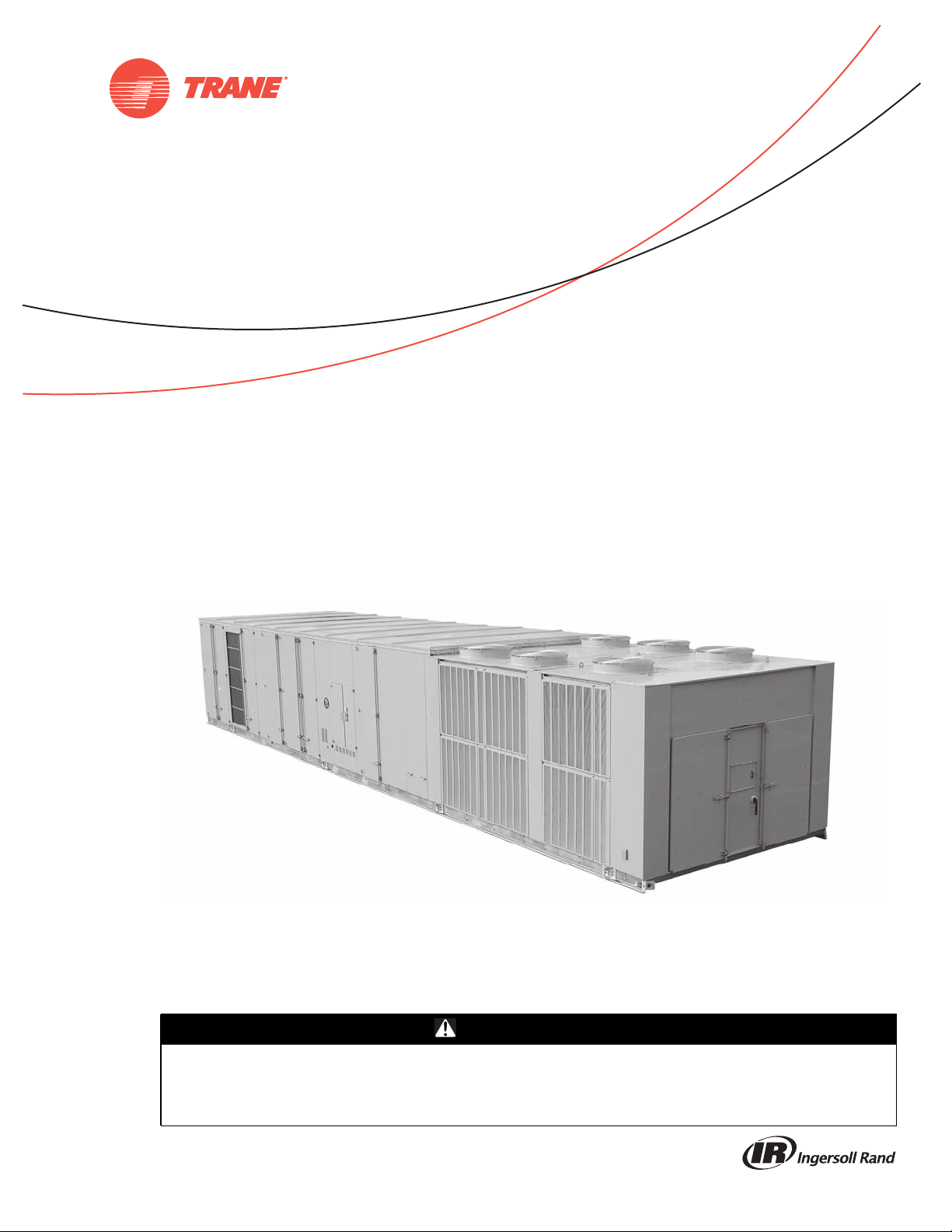

Trane SEHJ090-162, SSHJ090-162, SFHJ090-162, SXHJ090-162, SLHJ090-162 Installation and Maintenance Manual

Installation, Operation,

and Maintenance

IntelliPak™ II

Commercial Single-Zone Rooftop Air Conditioners

with CV, VAV, SZVAV, or RR Controls

“F0” and later design sequence

SEHJ090-162 SSHJ090-162

SFHJ090-162 SXHJ090-162

SLHJ090-162

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury.When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

November 2014

RT-SVX24K-EN

Introduction

Read this manual thoroughly before operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required.Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

About the Manual

Note: This document is customer property and must be

retained by the unit owner for use by maintenance

personnel.

These units are equipped with electronic Unit Control

Modules (UCM). Refer to the “Startup” and “Test Mode”

procedures within this Installation, Operation, and

© 2014Trane All rights reserved RT-SVX24K-EN

Introduction

Maintenance manual and the latest edition of the

appropriate programming manual for Constant Volume

(CV), Rapid Restart (RR), Variable Air Volume (VAV), or

Single Zone Variable Air Volume (SZ VAV) applications

before attempting to operate or service this equipment.

Note: The procedures discussed in this manual should

only be performed by qualified and experienced

HVAC technicians.

Overview of Manual

This booklet describes proper installation, startup,

operation, and maintenance procedures for 90 to 162 ton

rooftop air conditioners designed for CV, RR, VAV, or SZ

VAV applications. By carefully reviewing the information

within this manual and following the instructions, the risk

of improper operation and/or component damage will be

minimized.

Note: One copy of the appropriate service literature ships

inside the control panel of each unit.

It is important that periodic maintenance be performed to

help assure trouble free operation. Should equipment

failure occur, contact a qualified service organization with

qualified, experienced HVAC technicians to properly

diagnose and repair this equipment.

Note: Do Not release refrigerant to the atmosphere!

If adding or removing refrigerant is required, the service

technician must comply with all federal, state, and local

laws.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

RT-SVX24K-EN (November 2014)

Updated the IOM with Ultra-Low Leak, AMCA 1A damper

and FDD.These features are Design Specials only.

RT-SVX24K-EN 3

Table of Contents

Introduction ............................. 2

Warnings, Cautions, and Notices ........ 2

Model Number Descriptions .............. 6

Unit Inspection .......................... 9

As soon as the unit arrives at the job site 9

Storage ............................ 9

Unit Clearances ..................... 9

Unit Dimensions and Weight Information 9

General Information .................... 10

Unit Nameplate ...................... 10

Commonly Used Acronyms ............ 10

Unit Description ...................... 10

Constant Volume (CV) and Variable Air

Volume (VAV) Units

................... 13

Constant Volume (CV) Units ........... 17

Variable Air Volume (VAV) Units ........ 17

Single Zone Variable Air Volume (SZVAV)

Only

................................ 20

Unit Clearances ......................... 23

Dimensional Data ....................... 25

Weights ................................ 44

Installation ............................. 47

Roof Curb and Ductwork ............. 47

Field Converting Horizontal Ductwork

(Supply or Return) from Right to

Left Side .......................... 49

Unit Rigging and Placement ........... 51

Air-Cooled and Evaporative Condensers—

Three-Piece Unit Fit Up .............. 54

Air-Cooled and Evaporative Condensers—

Two-Piece Unit Fit Up ............... 58

Complete Tubing and Wiring

Connections as follows: .............. 61

Air-Cooled Tubing Connection ........ 61

Evaporative Condenser Tubing

Connection ........................ 62

Electric Heat Wiring Connection ....... 63

Power and Control Wiring Connections . 63

General Unit Requirements ........... 64

Rigging the Unit .................... 65

Main Electrical Power Requirements ....65

Field Installed Control Wiring ..........65

Requirements for Electric Heat Units ....65

Requirement for Gas Heat .............65

Requirements for Hot Water Heat ......65

Requirements for Steam Heat ..........65

O/A Pressure Sensor and Tubing

Installation .........................65

Condensate Drain Connections ........65

Units with Gas Furnace ...............66

Removing Compressor Assembly

Shipping Hardware ..................66

Removing Supply and Exhaust Fan

Shipping Channels ...................66

Spring Isolators .....................66

Remove Evaporative Condenser Fan

Shipping Brackets ...................66

O/A Sensor and Tubing Installation .....68

Units with Statitrac: ..................68

Evaporative-Cooled Condenser Make-up

Water and Drain Line Installation .......69

Gas Heat Units ......................70

Disconnect Switch w/External Handle . . .78

Electric Heat Units ...................78

Main Unit Power Wiring ..............79

Power Wire Sizing and Protection Devices 81

Field Installed Control Wiring ..........83

Controls using 24 VAC ................83

Controls using DC Analog Input/Outputs .83

Constant Volume System Controls ......84

Variable Air Volume System Controls . . .84

Constant Volume or Variable Air Volume

System Controls .....................84

Single Zone Variable Air Volume & Rapid

Restart System Control ...............85

Emergency Override .................85

Ventilation Override Module (VOM) .....86

Temperature vs. Resistance Coefficient . .87

Installation Checklist .....................95

General Checklist (applies to all units) . . .95

4 RT-SVX24K-EN

Table of Contents

Unit Rigging and Placement (Two-Piece—

addition to General Checklist) ......... 95

Unit Rigging and Placement (Three-piece

unit) (in addition to Two-piece unit rigging

and placement) ..................... 95

Unit Startup ............................ 98

Sequence of Operation ................ 98

Cooling Sequence of Operation ....... 98

Compressor Sequence of Operation . . . 98

Units with Evaporative Condenser

Sequence of Operation .............. 99

Modulating Dehumidification (Hot Gas

Reheat) Sequence of Operation ...... 103

Energy Recovery Sequence of

Operation ........................ 105

Gas Heating Sequence of Operation

Standard ......................... 107

Honeywell Ignition System .......... 107

Modulating Gas Sequence of Operation 108

Electric Heat Sequence of Operation . . 108

Electric Heat—CV, VAV Daytime

Warm-up ......................... 109

VAV Active Occupied Discharge Heating 109

SZVAV Occupied Heating ........... 109

Demand Control Ventilation Sequence

of Operation ...................... 109

Return Fan Sequence of Operation .... 109

Wet Heat Sequence of Operation ..... 110

Unit Startup Check List ............... 110

Voltage Supply and Voltage Imbalance 111

Service Testing—Evaporative Condenser

Components ...................... 115

Verifying Proper Fan Rotation ........ 115

If all of the fans are rotating backwards; 116

If some of the fans are rotating

backwards; ....................... 116

System Airflow Measurements ....... 117

Exhaust Airflow Measurement

(Optional) ........................ 118

TRAQ™ Sensor Airflow Measurement . 119

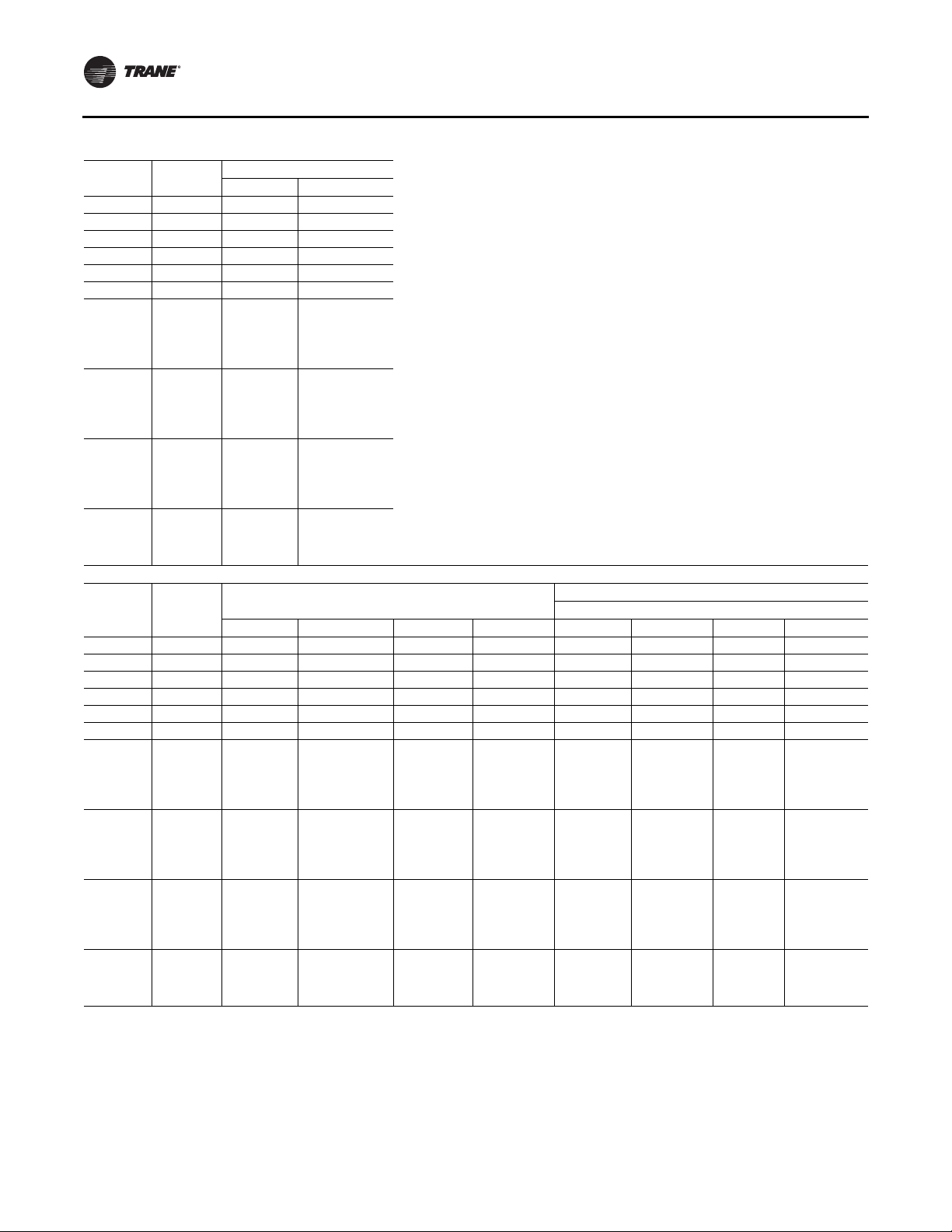

Performance Data ................... 120

Supply Fan with or without Variable

Frequency Drive ................... 120

Airside Pressure Drop Standard

Evaporator Coil .....................122

Exhaust Fan Performance ............124

Return Fan Performance .............125

Component Static Pressure Drops .....127

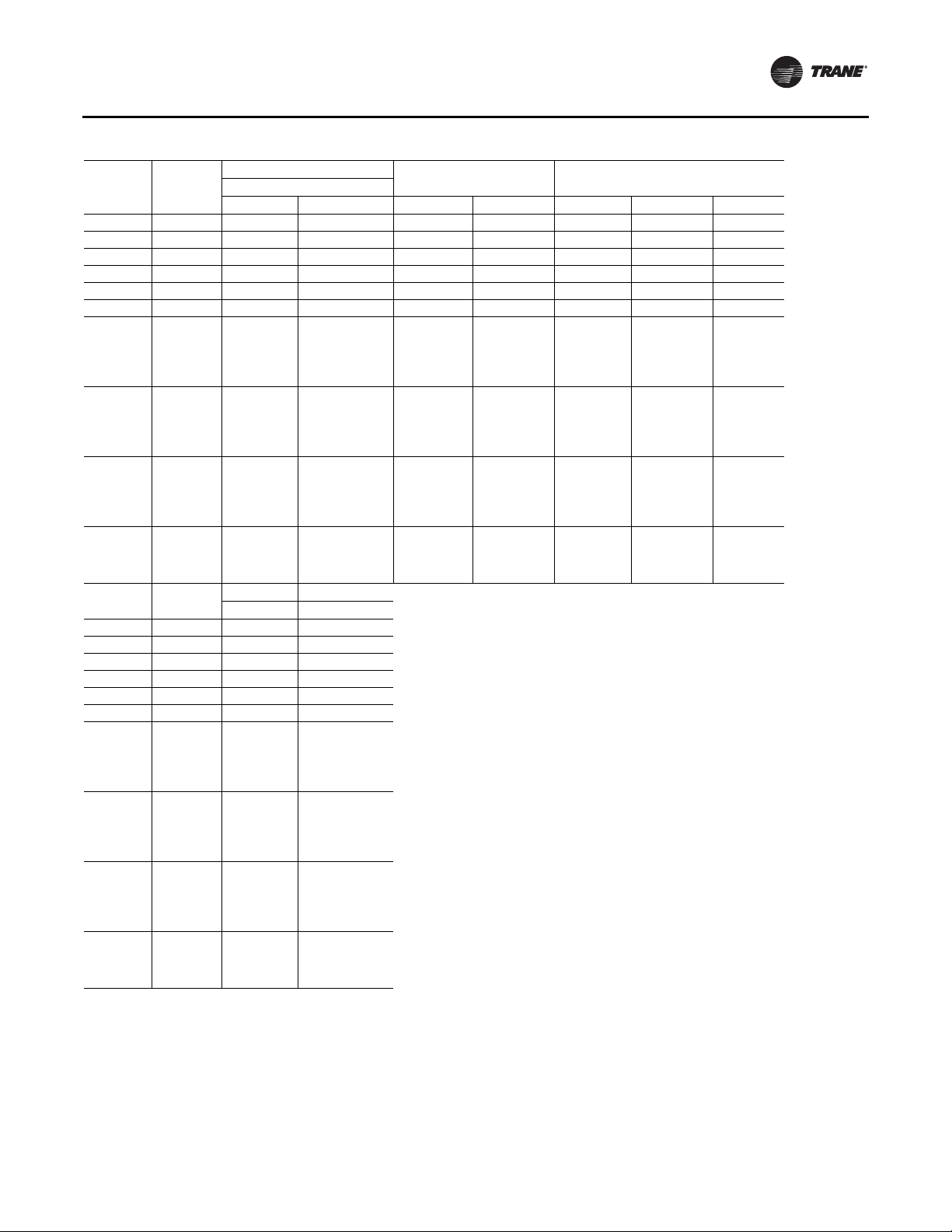

Pressure Curves ......................136

(60 Hz) Air-Cooled Condensers ........136

Components .........................145

Standard Unit without Energy Recovery

Wheel ............................145

Standard Unit with Energy Recovery

Wheel ............................148

Energy Recovery Wheel (ERW) ........153

Service and Repair ..................158

Seal Adjustment ....................160

Compressor Startup .................161

Compressor Operational Sounds ......162

Evaporative Condenser Startup .......163

Thermostatic Expansion Valves .......165

Measuring Superheat ...............165

Charging by Subcooling .............165

Standard Ambient Units .............165

Electric, Steam and Hot Water Startup . .166

Gas Furnace Startup ................166

Two Stage Gas Furnace ..............167

Full Modulating Gas Furnace .........169

Final Unit Checkout .................171

Service and Maintenance ...............175

Scroll Compressor Replacement ......183

VFD Programming Parameters ........184

Monthly Maintenance ...............185

Filters .............................185

Air-Cooled Coil Cleaning .............187

Evaporative Condenser Coil Cleaning . .188

Final Process .......................190

Unit Wiring Diagram Number ............192

Warranty and Liability Clause ............198

Commercial Equipment ...............198

Rated 20 Tons and Larger and Related

Accessories

..........................198

RT-SVX24K-EN 5

Model Number Descriptions

SXHJ10540AA715MFDE81D1100A1BA1000AA1A1

1 2 3 4 567 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38

DIGIT 1 — UNIT TYPE

S Self-Contained (Packaged

Rooftop)

DIGIT 2 — UNIT FUNCTION

E DX Cooling, Electric Heat

F DX Cooling, Natural Gas Heat

L DX Cooling, Hot Water Heat

S DX Cooling, Steam Heat

X DX Cooling, No Heat,

Extended Casing

DIGIT3—SYSTEMTYPE

H Single Zone

DIGIT 4 — DEVELOPMENT

SEQUENCE

J Ninth

DIGIT 5, 6, 7 — NOMINAL

CAPACITY

090 90Ton Air-Cooled

105 105Ton Air-Cooled

120 120Ton Air-Cooled

130 130Ton Air-Cooled

150 150Ton Air-Cooled

100 100Ton Evap Condenser

118 118 Ton Evap Condenser

128 128Ton Evap Condenser

140 140Ton Evap Condenser

162 162Ton Evap Condenser

DIGIT 8 — VOLTAGE SELECTION

4 460/60/3 XL

5 575/60/3 XL

C 380/50/3 XL

DIGIT 9 — HEATING CAPACITY

SELECTION

0 No Heat

1 Electric heat 90/56 kW 60/50 Hz

2 Electric heat 140/88 kW 60/50 Hz

3 Electric heat 265/166 kW 60/50 Hz

4 Electric Heat 300/188 kW 60/50 Hz

A Low Gas Heat — 2-stage

B Medium Gas Heat — 2-stage

C High Gas Heat — 2-stage

D Low Gas Heat — Modulating

E Medium Gas Heat — Modulating

F High Gas Heat — Modulating

Steam or Hot Water Heat:

G Low Heat - 1.0" (25mm) Valve

H Low Heat - 1.25" (32mm) Valve

J Low Heat - 1.5" (38mm) Valve

K Low Heat - 2.0" (50mm) Valve

L Low Heat - 2.50" (64mm) Valve

M Low Heat - 3.0" (76mm) Valve

N High Heat - 1.0" (25mm) Valve

P High Heat - 1.25" (32mm) Valve

Q High Heat - 1.5" (38mm) Valve

R High Heat - 2.0" (50mm) Valve

T High Heat - 2.50" (64mm) Valve

U High Heat - 3.0" (76mm) Valve

DIGIT 10, 11 — DESIGN

SEQUENCE

A-ZZ (Factory Assigned) Sequence may

be any letter A to Z, or any digit 1 to 9.

DIGIT 12 — UNIT

CONFIGURATION SELECTION

1 One-Piece Unit w/o Blank Section

2 One-Piece Unit w/4' Blank Section

3 One-Piece Unit w/8' Blank Section

4 Two-Piece Unit w/o Blank Section

5 Two-Piece Unit w/4' Blank Section

6 Two-Piece Unit w/8' Blank Section

7 Three-Piece unit w/o Blank Section

8 Three-Piece Unit w/4' Blank Section

9 Three-Piece Unit w/8' Blank Section

DIGIT 13 — AIRFLOW DIRECTION

1 Downflow Supply /Upflow Return

2 Downflow Supply / Horiz End Return

3 Downflow Supply / Horiz Right Return

4 Right Side Horiz Supply/Upflow

Return

5 Right Side Horiz Supply / Horizontal

End Return

6 Right Side Horiz Supply / Horizontal

Right Return

DIGIT 14 — SUPPLY FAN

OPTIONS

1 Standard CFM

3 Standard CFM - TEFC Motor(s)

4 Low CFM

6 Low CFM -TEFC Motor(s)

7 = Standard CFM - w/ Motor Shaft

Grounding

9 = Standard CFM -TEFC Motor(s) w/

Shaft Grounding

A = Low CFM - w/ Motor Shaft Grounding

C = Low CFM -TEFC Motor(s) w/ Shaft

Grounding

DIGIT 15 — SUPPLY FAN MOTOR

SELECTION

F15hp

G20Hp

H25Hp

J30Hp

K40Hp

L50Hp

M60Hp

N75Hp

P100Hp

DIGIT 16 — SUPPLY FAN RPM

SELECTION

7700

8800

9900

A 1000

B1100

C 1200

D 1300

E 1400

F 1500

G 1600

H 1700

J 1800

K 1900

L2000

DIGIT 17 — EXHAUST/RETURN

FAN OPTIONS

0 None

1 Std CFM Exhaust Fan

w/o Statitrac CV Only

2 Low CFM Exhaust Fan

w/o Statitrac CV Only

3 Std CFM Exhaust w/o VFD

w/ Statitrac

4 Low CFM Exhaust w/o VFD

w/ Statitrac

5 Std CFM Exhaust w/ VFD w/

Bypass w/ Statitrac

6 Low CFM Exhaust w/ VFD w/

Bypass w/ Statitrac

7 Std CFM Exhaust w/ VFD w/o

Bypass w/ Statitrac

8 Low CFM Exhaust w/ VFD w/o

Bypass w/ Statitrac

A Std CFM Return w/o Statitrac CV

Only

B Low CFM Return w/o Statitrac CV

Only

C Std CFM Return w/ VFD w/

Bypass w/ Statitrac

D Low CFM Return w/ VFD w/

Bypass w/ Statitrac

E Std CFM Return w/ VFD w/o

Bypass w/ Statitrac

F Low CFM Return w/ VFD w/o

Bypass w/ Statitrac

6 RT-SVX24K-EN

Model Number Descriptions

DIGIT 18 — EXHAUST/RETURN

FAN MOTOR SELECTION

0 None

D 7.5 Hp

E10Hp

F15Hp

G20Hp

H25Hp

J30Hp

K40Hp

L50Hp

M60Hp

DIGIT 19 — EXHAUST/RETURN

RPM SELECTION

0 None

3300

4400

5500

6600

7700

8800

9900

A 1000

B1100

C 1200

D 1300

E 1400

DIGIT 20 — SYSTEM CONTROL

SELECTION

1 Constant Volume (CV) (Zone

Temperature Control)

2 CV w/ DischargeTemp Control

4 VAV w/ VFD Supply w/o Bypass

(DischargeTemp Control)

5 VAV w/ VFD Supply w/ Bypass

(DischargeTemp Control)

6 VAV – Single Zone VAV w/VFD w/o

Bypass (Zone Temperature Control)

7 VAV – Single Zone VAV w/VFD w/

Bypass (Zone Temperature Control)

DIGIT 21 — OUTSIDE AIR and

ECONOMIZER OPTION/

CONTROLS

A 0-25% Motorized Damper

B Economizer w/Dry Bulb

C Economizer w/Reference

Enthalpy

D Economizer w/Comparative

Enthalpy

E Econ w/Outside

Air Measure/Dry Bulb

F Econ w/Outside Air Measure/Ref

Enthalpy

G Econ w/Outside Air

Measure/Comp Enthalpy

H Econ w/DCV/Dry Bulb

J Econ w/DCV/Ref Enthalpy

K Econ w/DCV/Comp Enthalpy

1

1

1

DIGIT 22 — DAMPER OPTION

0 Standard

1 Low Leak

2 Ultra Low Leak

U Ultra Low Leak, AMCA 1A, w/ FDD

(Design Special)

DIGIT 23— PRE-EVAPORATOR

COIL FILTER SELECTION

0 Two Inch High Efficiency

Throwaway

1 Two InchThrowaway Rack/Less

Filters

2 90-95% Bag Filters w/Prefilters

3 Bag Filter Rack/Less Filters

4 90-95% Cartridge Filters w/

Prefilters

5 Cartridge Rack/Less Filters

6 90-95% Low Pressure Drop

Cartridge Filters w/ Prefilters

7 Low Pressure Drop Cartridge

Rack/Less Filters

DIGIT 24 — BLANK SECTION

APPLICATION OPTIONS

0 None

A 90-95% Bag w/Prefilters

B 90-95% Low Pressure Drop

Cartridge w/ Prefilters

C 90-95%, Cartridge Filters w/

Prefilters

D 90-95% HighTemp Cartridge

w/ Prefilters

E HEPA w/Prefilters

F HighTemp HEPA w/Prefilters

DIGIT 25 — ENERGY RECOVERY

WHEEL

0 None

1 Low CFM ERW w/ Bypass Defrost

2 Standard CFM ERW w/ Bypass

Defrost

DIGIT 26 — UNIT MOUNTED

POWER CONNECTION

SELECTION

A Terminal Block

B Non-Fused Disconnect

C Non-Fused Disconnect w/

Powered Convenience Outlet

D Circuit Breaker w/ high fault SCCR

E Circuit Breaker w/ high fault SCCR/

Powered Convenience Outlet

DIGIT 27 — CONDENSER COIL

SELECTION

0 Air-Cooled Aluminum

A Evap Condenser

B Evap Condenser w/ Sump Heater

C Evap Condenser w/ Dolphin

WaterCare System

D Evap Condenser w/ Dolphin

WaterCare System & Sump Heater

E Evap Condenser w/ Conductivity

Controller

F Evap Condenser w/ Conductivity

Controller and Sump Heater

J Corrosion Protected Condenser Coil

DIGIT 28 — EVAPORATOR COIL

AND DRAIN PAN

0 Standard Evap Coil w/Galvanized

Drain Pan

A Standard Evap Coil w/ Stainless

Steel Drain Pan

B High Cap Evap Coil w/Galvanized

Drain Pan

C High Cap Evap Coil w/Stainless

Steel Drain Pan

DIGIT 29 — REFRIGERATION

SYSTEM SELECTION A

0 Standard

A Suction Service Valves

B Replaceable Core Liquid Filter

Driers

C Suction Service Valves &

Replaceable Core Liquid Filter

Driers

DIGIT 30 — REFRIGERATION

SYSTEM SELECTION B

0 Standard

1 Hot Gas Reheat

2 Hot Gas By-Pass

3 Hot Gas Reheat2/Hot Gas By-Pass

2

DIGIT 31 — AMBIENT CONTROL

OPTION

0 Standard Ambient

1 Low Ambient

DIGIT 32 — HIGH DUCT TEMP

THERMOSTAT

0 None

1 High Duct TempThermostat

DIGIT 33 — CONTROLS OPTION

0 None

1 Remote Human Interface (RHI) &

Inter-Processor Communication

Bridge (IPCB)

2 IPCB

3 Rapid Restart

1

Requires CO2 Zone Sensor(s)

RT-SVX24K-EN 7

2

Humidity sensor required

Model Number Descriptions

DIGIT 34 — MODULE OPTIONS

0 None

A 0-5 volt Generic Building

Automation System (GBAS)

B 0-10 volt GBAS

C 0-5 volt GBAS and 0-10 volt GBAS

F LonTalk® Communication

Interface (LCI)

D Ventilation Override

G 0-5 volt GBAS volt & Ventilation

Override

H 0-10 volt GBAS & Ventilation

Override

J 0-5 volt GBAS and 0-10 volt GBAS

& Ventilation Override

L LCI & Ventilation Override

M BACnet Communication Interface

(BCI)

N BCI & Ventilation Override

DIGIT 35 — ZONE SENSOR

OPTION

0 None

A Dual Setpoint w/Man/Auto

Changeover — BAYSENS108

B Dual Setpoint w/Man/Auto

Chgovr & Sys Lights —

BAYSENS110

C Room Sensor w/timed Override &

Cancel — BAYSENS073

D Room Sensor w/TO (Timed

Override) & Cancel &

Local Stpt Adj — BAYSENS074

G VAV w/System Lights —

BAYSENS021

L Programmable

Night Setback — BAYSENS119

DIGIT 36 — AGENCY APPROVAL

OPTION

0 None

1 cULus

DIGIT 37 — SERVICE

ENHANCEMENTS

0 Single Side Access Door

A Dual Side Access Door

B Single Side Access Doors/

Marine Lights

C Dual Side Access Doors/

Marine Lights

DIGIT 38 — MISCELLANEOUS

OPTIONS

0 None

1 Belt Guards

2 Burglar Bars

3 Belt Guards/Burglar Bars

Tip: EXAMPLE

Model number

SXHJ10540AA715MFDE81D1100A

1BA1000AA1A1

describes a unit with the following

characteristics:

DX Cooling, No Heat, Extended

Casing, 105Ton nominal capacity,

with 460/3/60 power supply,

3 piece construction with

downflow supply and upflow

return, low CFM fans, a 60 hp

supply fan w/ a 1500 rpm drive, a

10 Hp return fan with VFD, bypass

and statitrac, with CV control, and

economizer w/ comparative

enthalpy, low leak dampers,

2” throwaway rack less filters,

terminal blank connection, Air

Cooled Copper Condenser coil,

high cap evap with galvanized

drain pan, suction service valves,

hot gas reheat, 0-5V GBAS, dual

setpoint with Manual/Auto

Changeover, cULus approval,

Dual side access, and belt guards.

The service digit for each model

number contains 38 digits; all 38

digits must be referenced.

8 RT-SVX24K-EN

Unit Inspection

As soon as the unit arrives at the job site

[ ] Verify that the nameplate data matches the data on

the sales order and bill of lading (including electrical

data).

[ ] Verify that the power supply complies with the unit

nameplate specifications.

[ ] Verify that the power supply complies with the

electric heater specifications on the unit nameplate.

[ ]Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

[ ] Check for material shortages. Refer to the

Component Layout and Ship with Location illustration.

Important: If the job site inspection of the unit reveals

damage or material shortages, file a claim

with the carrier immediately. Specify the

type and extent of the damage on the “bill of

lading” before signing.

[ ] Visually inspect the internal components for

shipping damage as soon as possible after delivery

and before it is stored. Do not walk on the sheet metal

base pans.

WARNING

No Step Surface!

Do not walk on the sheet metal drain pan. Walking on

the drain pan could cause the supporting metal to

collapse, resulting in the operator/technician to fall.

Failure to follow this recommendation could result in

death or serious injury.

[ ] If concealed damage is discovered, notify the

carrier's terminal of damage immediately by phone

and by mail. Concealed damage must be reported

within 15 days.

Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove

damaged material from the receiving location. Take

photos of the damage, if possible.The owner must

provide reasonable evidence that the damage did not

occur after delivery.

[ ] Remove the protective plastic coverings that

shipped over the compressors.

openings) from the ambient air until the unit is

ready for startup.

Note: Do not use the unit heater for temporary heat

without first completing the startup procedure

detailed under “Unit Startup,” p. 98.

Trane will not assume any responsibility for equipment

damage resulting from condensate accumulation on the

unit electrical and/or mechanical components.

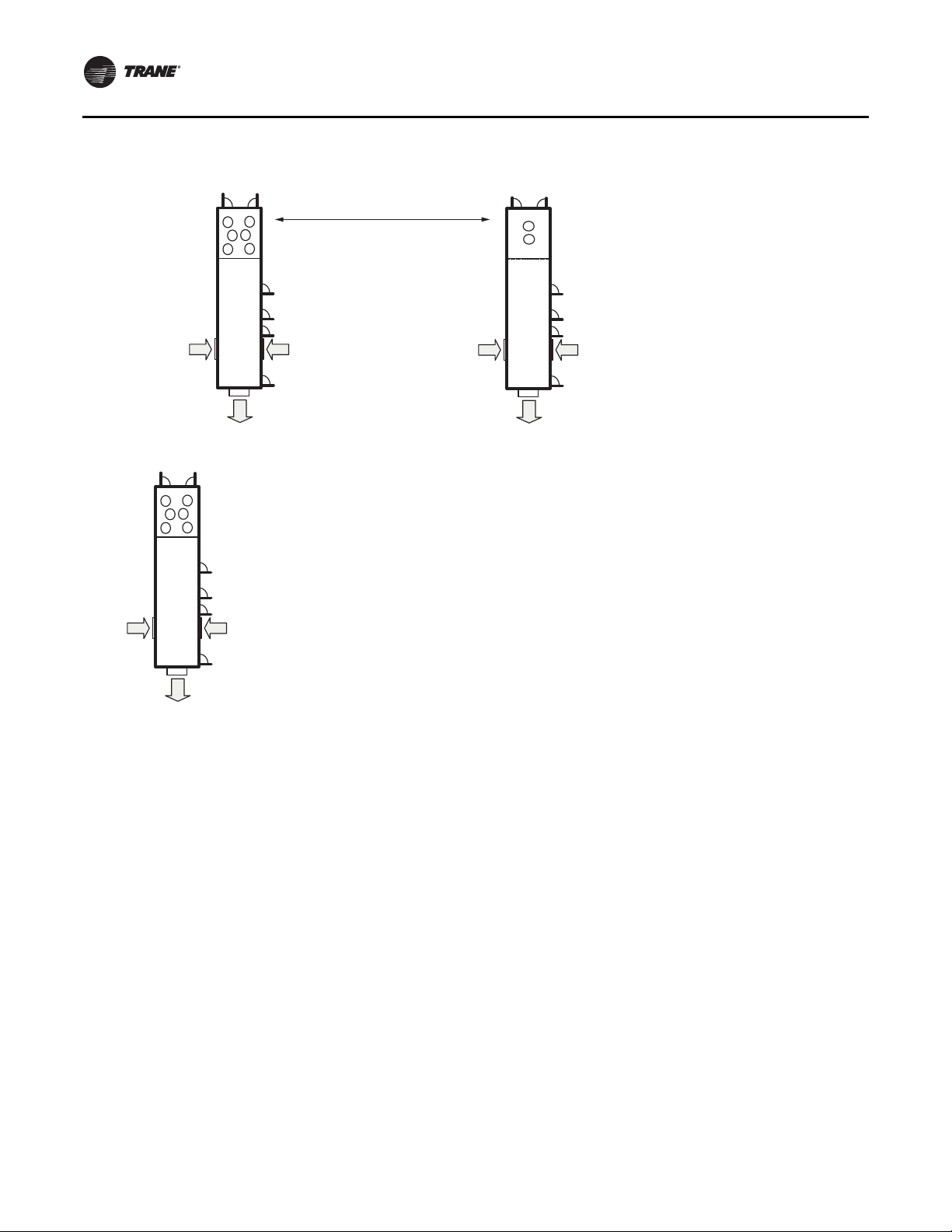

Unit Clearances

Figure 10, p. 23 Table 4, p. 23 illustrates the minimum

operating and service clearances for either a single or

multiple unit installation.These clearances are the

minimum distances necessary for adequate service,

cataloged unit capacity, and peak operating efficiency.

Providing less than the recommended clearances may

result in condenser coil starvation, “short-circulating” of

exhaust and economizer airflows, or recirculation of hot

condenser air.

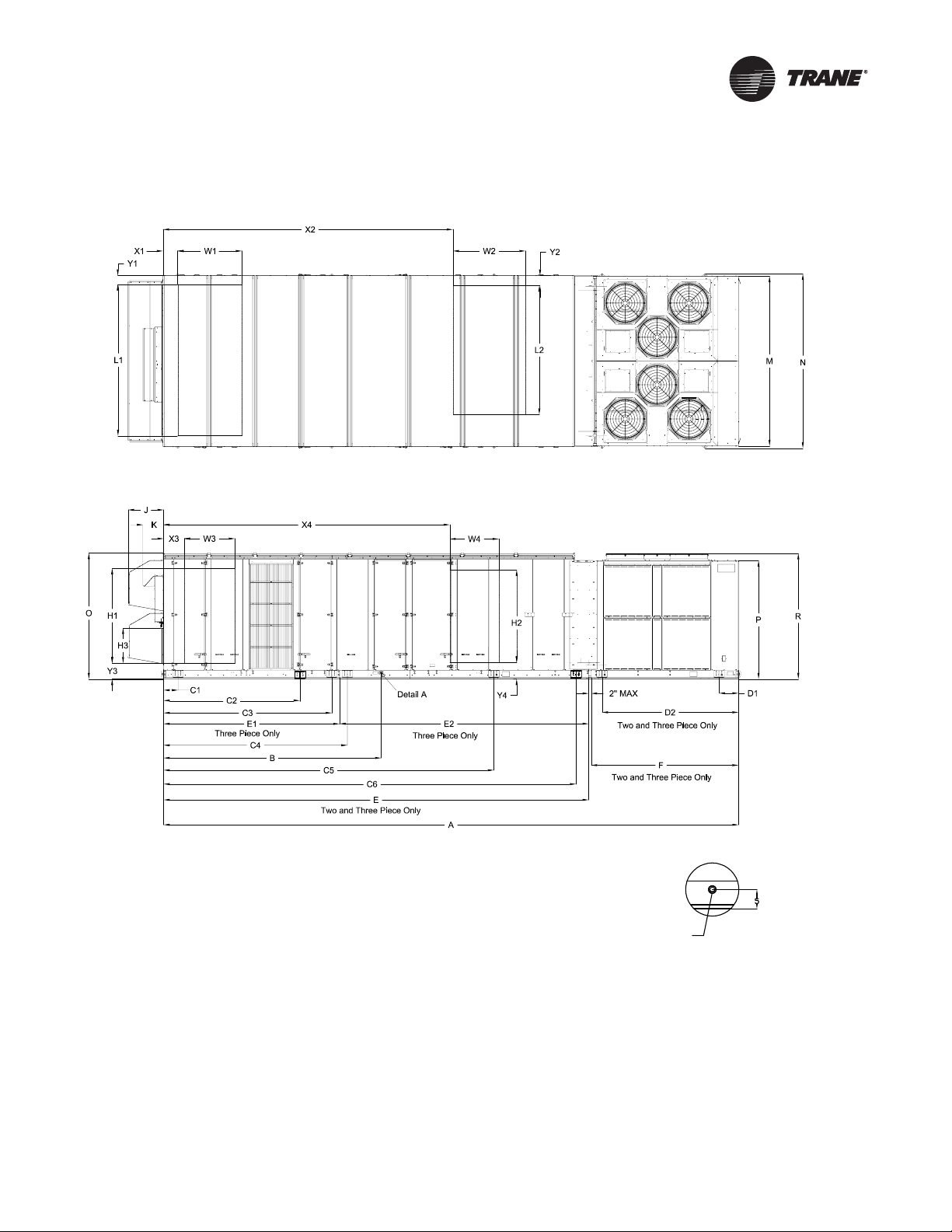

Unit Dimensions and Weight Information

Description Reference

Air-Cooled Condenser

One-piece unit dimensions Figure 12, p. 25, Table 5, p. 26

Two-piece unit dimensions Figure 12, p. 25, Table 6, p. 27

Three-piece unit dimensions Figure 12, p. 25, Table 8, p. 33

T ypical unit and operation weights Table 12, p. 44

Evaporative Condenser

Two-piece unit dimensions Figure 12, p. 25, Table 7, p. 30

Three-piece unit dimensions Figure 12, p. 25, Table 9, p. 36

Typical unit and operation

(a)Weights shown represent approximate operating weights. Actual

weights are stamped on the unit nameplate.

weights

(a)

Table 12, p. 44

Storage

Take precautions to prevent condensate from forming

inside the unit electrical compartments and motors if:

a. The unit is stored before it is installed; or,

b. The unit is set on the roof curb, and temporary heat

is provided in the building. Isolate all side panel

service entrances and base pan openings (e.g.,

conduit holes, S/A and R/A openings, and flue

RT-SVX24K-EN 9

General Information

Unit Nameplate

One Mylar unit nameplate is located on the outside upper

left corner of the control panel door. It includes the unit

model number, serial number, electrical characteristics,

weight, refrigerant charge, as well as other pertinent unit

data. A small metal nameplate with the Model Number,

Serial Number, and Unit Weight is located just above the

Mylar nameplate, and a third nameplate is located on the

inside of the control panel door.

Compressor Nameplate

The Nameplate for the Scroll Compressor is located on the

compressor lower housing. Max amps is listed on the

nameplate and is the absolute highest amp load on the

compressor at any operating condition (does not include

locked rotor amps or inrush).This value should never be

exceeded.

Commonly Used Acronyms

For convenience, a number of acronyms and

abbreviations are used throughout this manual.These

acronyms are alphabetically listed and defined below.

• AC = Air Cooled Condenser

• BAS = Building automation systems

• BCI = BACnet® Communication Interface module

• CFM = Cubic-feet-per-minute

• CKT. = Circuit

• CLV = Cooling valve (reheat only)

• CV = Constant volume

• CW = Clockwise

• CCW = Counterclockwise

• E/A = Exhaust air

• EC = Evaporative Condenser

• ECEM = Exhaust/comparative enthalpy module

• FDD = Fault Detection and Diagnostic

• RT = Rooftop unit

• O/A = Outside air

• GBAS = Generic building automation system

• HGBP = Hot gas bypass

• MCHE = Microchannel Condenser Coil

• HGRH = Hot gas reheat

• HI = Human Interface

• HVAC = Heating, ventilation and air conditioning

• I/O = Inputs/outputs

• IOM = Installation/operation/ maintenance manual

• IPC = Interprocessor communications

• IPCB = Interprocessor communications bridge

• LCI-I = LonTalk® Communication Interface for

IntelliPak

• LH = Left-hand

• MCM = Multiple compressor module

• MDM = Modulating Dehumidification Module

• MPM = Multipurpose module

• MWU = Morning warm-up

• NSB = Night setback

• O/A = Outside air

• psig = Pounds-per-square-inch, gauge pressure

• PTFE = Polytetrafluoroethylene (Teflon®)

• R/A = Return air

• RAH = Return air humidity

• RH = Right-hand

• RHV = Reheat valve

• RPM = Revolutions-per-minute

• RTM = Rooftop module

• S/A = Supply air

• SCCR = Short circuit current rating

• SCM = Single circuit module

• SZ = Single-zone (unit airflow)

• SZVAV = Single zone variable air volume

• TCI = Tracer communications module

• UCM = Unit control modules

• VAV = Variable air volume

• VCM = Ventilation control module

• VOM = Ventilation override module

• w.c. = Water column

• WCI = Wireless Communication Interface

Unit Description

Available tonnages

Air-Cooled Tonnages

90 100

105 118

120 128

130 140

150 162

EachTrane commercial, single-zone rooftop air

conditioner ships fully assembled from the factory. An

optional roof curb, specifically designed for the S_HJ units

is available fromTrane.The roof curb kit must be field

assembled and installed according to the latest edition of

the roof curb installation manual.

Trane Commercial Rooftop Units are controlled by a

microelectronic control system that consists of a network

of modules and are referred to as Unit Control Modules

(UCM).The acronym UCM is used extensively throughout

this document when referring to the control system

network.These modules through Proportional/Integral

control algorithms perform specific unit functions which

provide the best possible comfort level for the customer.

They are mounted in the control panel and are factory

wired to their respective internal components. They

receive and interpret information from other unit

Evaporative Condenser

Tonnages

10 RT-SVX24K-EN

General Information

modules, sensors, remote panels, and customer binary

contacts to satisfy the applicable request for economizing,

mechanical cooling, heating, and ventilation. Refer to the

following discussion for an explanation of each module

function.

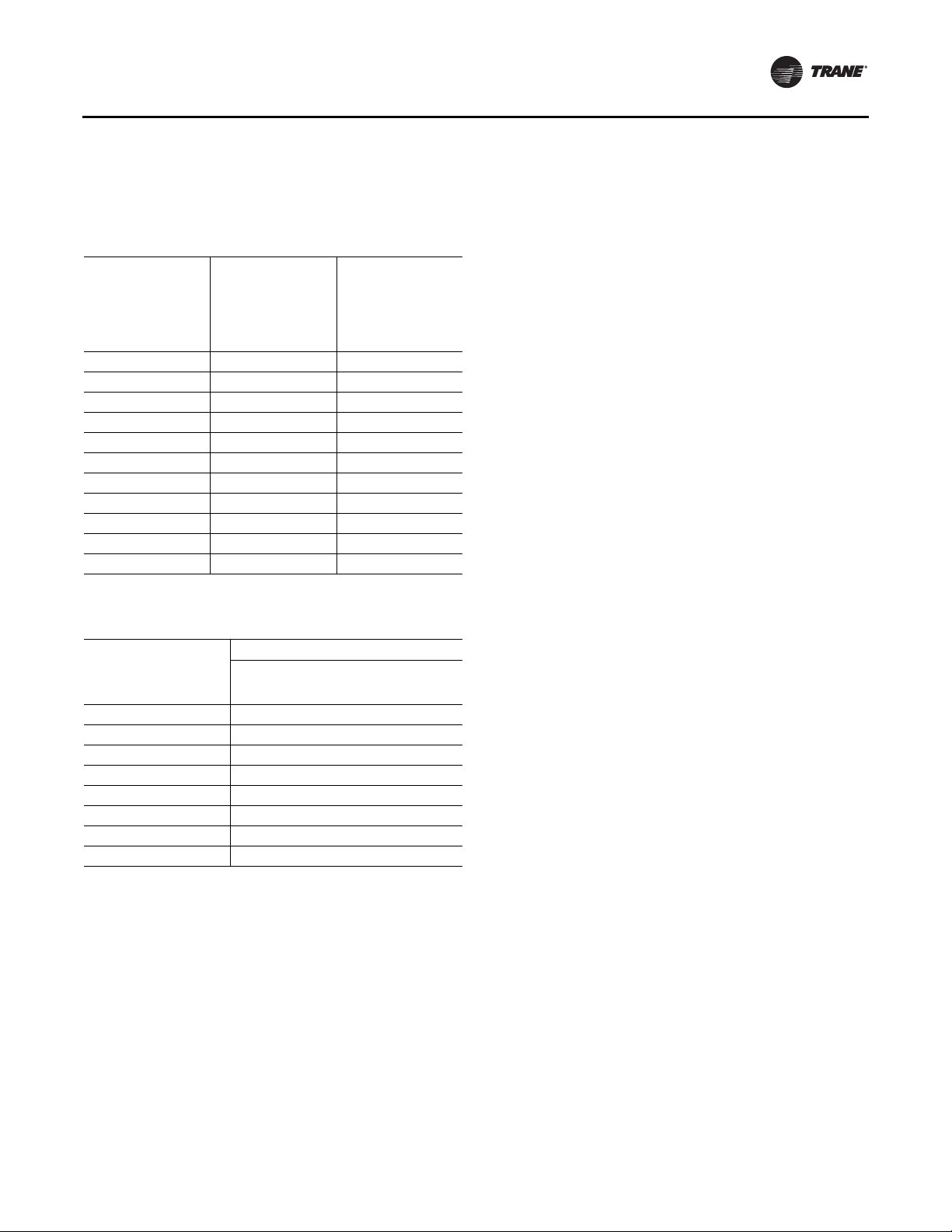

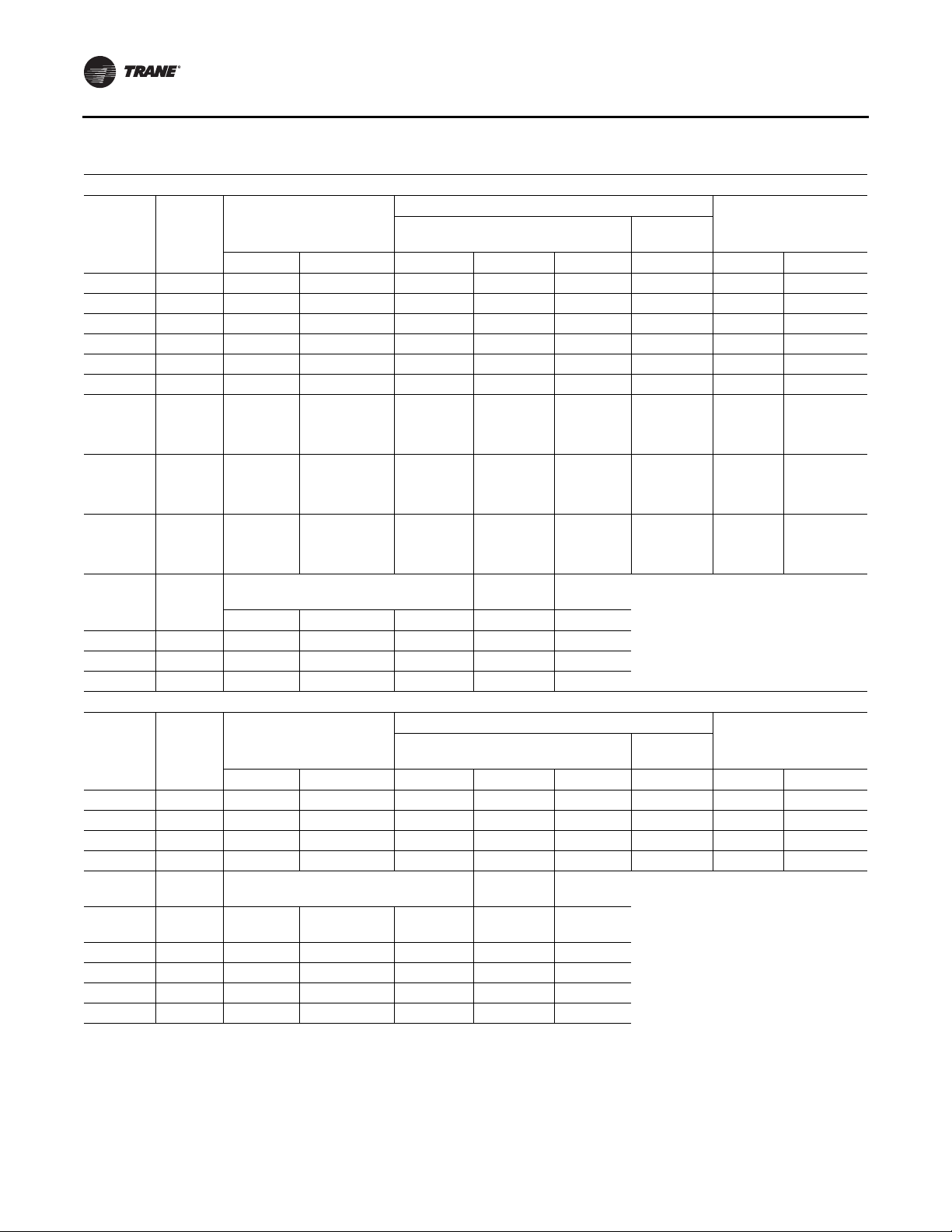

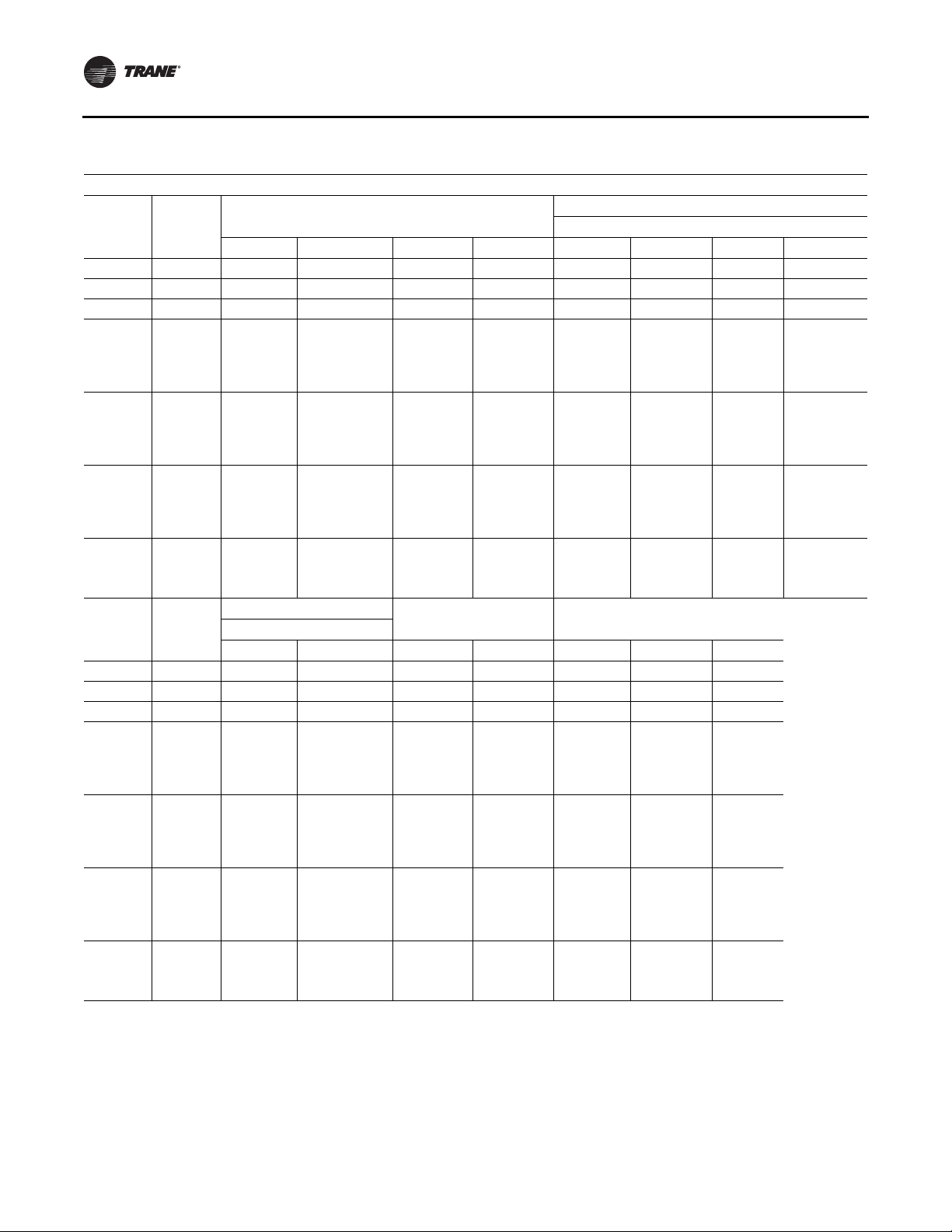

Table 1. Resistance input vs. setpoint temperature

RTM cooling or

heating setpoint

input used as the

source for a ZONE

temp setpoint (°F)

40 40 1084

45 45 992

50 50 899

55 55 796

60 60 695

65 65 597

70 70 500

75 75 403

80 80 305

n/a 85 208

n/a 90 111

RTM cooling

setpoint input

used as the source

for SUPPLY AIR

temp setpoint

cooling (°F)

Resistance (Ohms)

Max.

Tolerance 5%

Table 2. RTM resistance value vs. system operating

mode

Resistance applied to

RTM MODE input

Terminals (Ohms)

Max. Tolerance 5%

2320 Auto Off

4870 Auto Cool

7680 Auto Auto

10770 On Off

13320 On Cool

16130 On Auto

19480 Auto Heat

27930 On Heat

Constant Volume Units

Fan Mode System Mode

Rooftop Module (RTM - Standard on all units)

The rooftop Module (RTM) responds to cooling, heating,

and ventilation requests by energizing the proper unit

components based on information received from other

unit modules, sensors,

remote panels, and customer supplied binary inputs. It

initiates supply fan, exhaust fan, exhaust damper

positioning or variable frequency drive output, and

economizer operation based on

that information.

Compressor Module (MCM - standard on all

units)

The Compressor module, upon receiving a request for

mechanical cooling, energizes the appropriate

compressors and condenser fans. It monitors the

compressor operation through feedback information it

receives from various protection devices.

Human Interface Module (HI - standard on all

units)

The Human Interface module enables the operator to

adjust the operating parameters for the unit using a 16 key

keypad.The 2 line, 40 character LCD screen provides

status information for the various unit functions as well as

menus for the operator to set or modify the operating

parameters.

Heat Module (used on heating units)

The Heat module, upon receiving a request for Heating,

energizes the appropriate heating stages or strokes the

Modulating Heating valve as required.

Ventilation Override Module (VOM - Optional)

The Ventilation Override module initiates specified

functions such as; space pressurization, exhaust, purge,

purge with duct pressure control, and unit off when any

one of the five (5) binary inputs to the module are

activated.The compressors and condenser fans are

disabled during the ventilation operation. If more than one

ventilation sequence is activated, the one with the highest

priority is initiated.

Interprocessor Communications Board (IPCB Optional used with the Optional Remote

Human Interface)

The Interprocessor Communication Board expands

communications from the rooftop unit UCM network to a

Remote Human Interface Panel. DIP switch settings on the

IPCB module for this application should be; Switches 1 and

2“Off”, Switch 3 “On”.

Lontalk®/BACnet® Communication Interface

Module (LCI/BCI - Optional - used on units

with Trane ICS™ or 3rd party Building

Automation Systems)

The LonTalk/BACnet Communication Interface modules

expand communications from the unit UCM network to a

TraneTracer Summit™ or a 3rd party building automation

system and allow external setpoint and configuration

adjustment and monitoring of status and diagnostics.

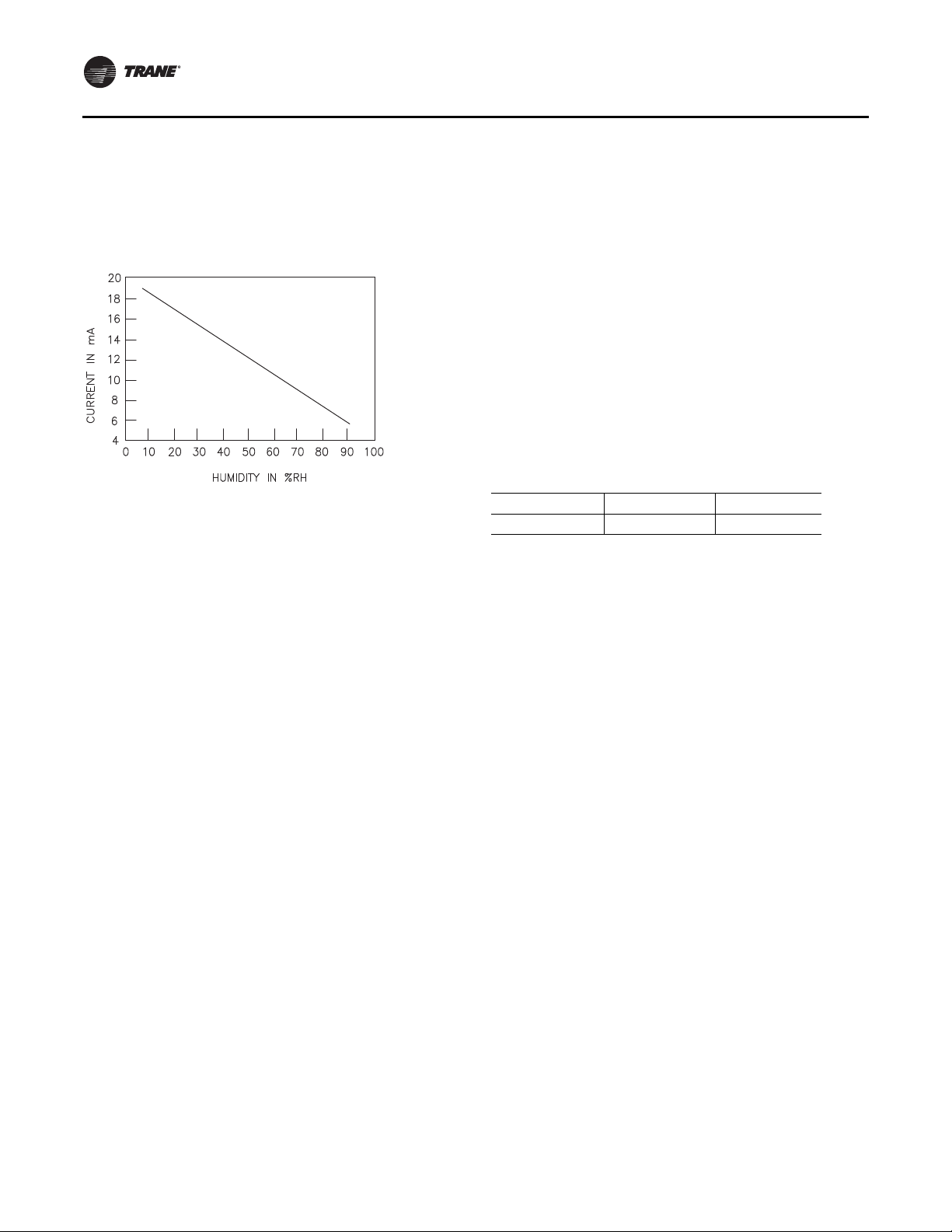

Exhaust/Comparative Enthalpy Module

(ECEM - Optional used on units with Statitrac

and/or comparative enthalpy options)

The Exhaust/Comparative Enthalpy module receives

information from the return air humidity sensor, the

RT-SVX24K-EN 11

General Information

outside air humidity sensor,and the return air temperature

sensor to utilize the lowest possible humidity level when

considering economizer operation. In addition, it receives

space pressure information which is used to maintain the

space pressure to within the setpoint control band. Refer

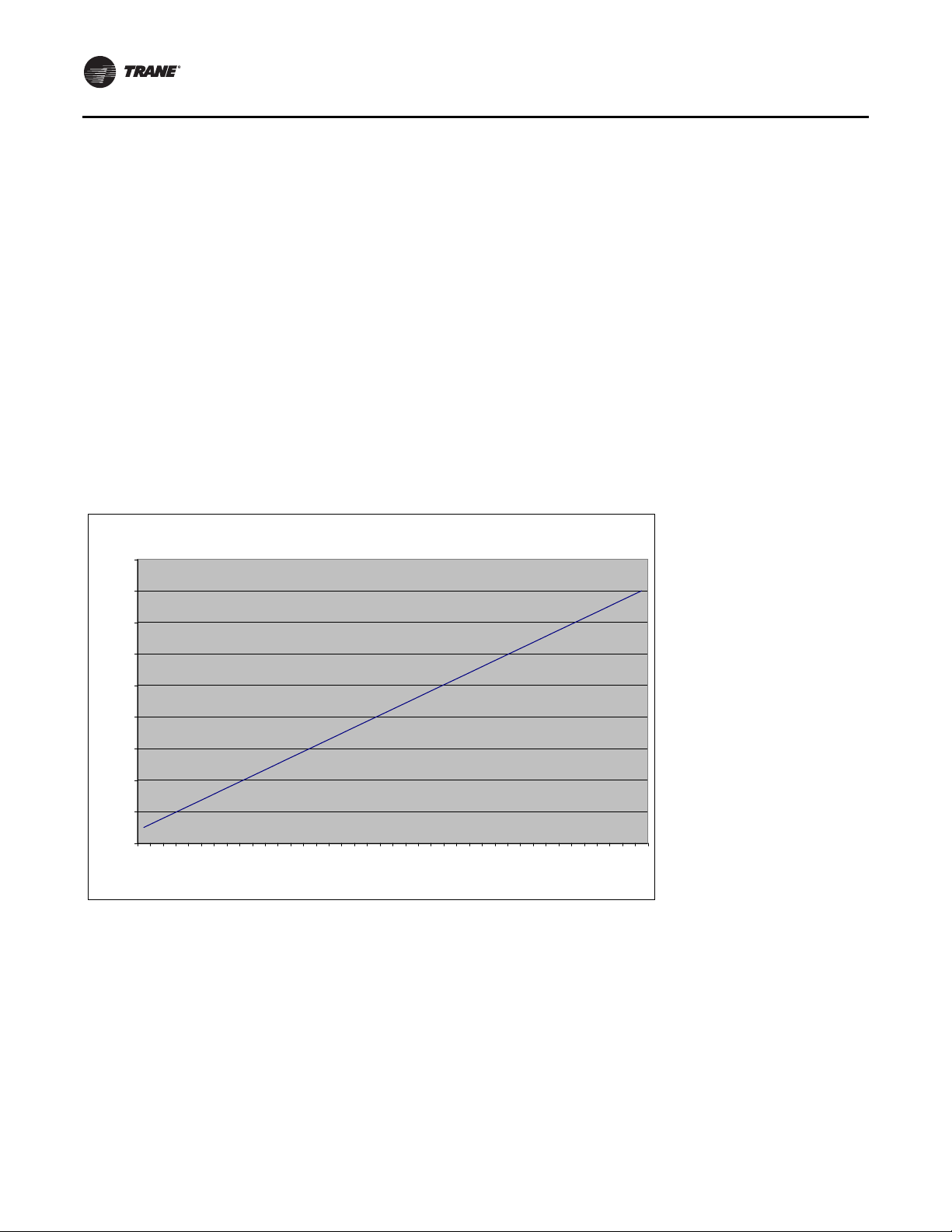

to Figure 1 for the Humidity vs. Voltage input values.

Figure 1. Humidity vs. current

Multi Purpose Module MPM (Optional - used

with Return Fan Control, Energy Recovery, and

Evaporative Condensers)

The MPM supports three optional features.The first of

which is return plenum pressure control by receiving

analog voltage information for measuring return plenum

pressure, calibrating that reading, and providing an output

to control the return fan speed (if variable speed

configured) in response to control algorithm requests.

This module also provides inputs and outputs for control

of all Energy Recovery feature devices including the

energy wheel, exhaust and outdoor air bypass dampers,

and recovery preheat.The liquid line pressure sensor

inputs for both refrigeration circuits are received through

the MPM in support of head pressure control on watercooled condenser units.

Ventilation Control Module (VCM)

The Ventilation Control Module (VCM) is located in the

filter section of the unit and is linked to the unit UCM

network. Using a “velocity pressure” sensing ring located

in the outside air section allows the VCM to monitor and

control the quantity of outside air entering the unit to a

minimum airflow setpoint.

An optional temperature sensor can be connected to the

VCM whichenables it to control a field installed outside air

preheater.An optional CO

VCM to control CO

minimum CFM upward as the CO

increase.

The maximum effective (reset) setpoint value for outside

air entering the unit is limited to the systems operating

CFM.The following table lists the velocity pressure vs.

Input Voltage (see also Figure 6, p. 18.).

Table 3. Minimum outside air setpoint w/VCM and

TRAQ™ sensing

Unit Input Volts CFM

90-162 Tons 0.5 - 4.5 VDC 0 - 46000

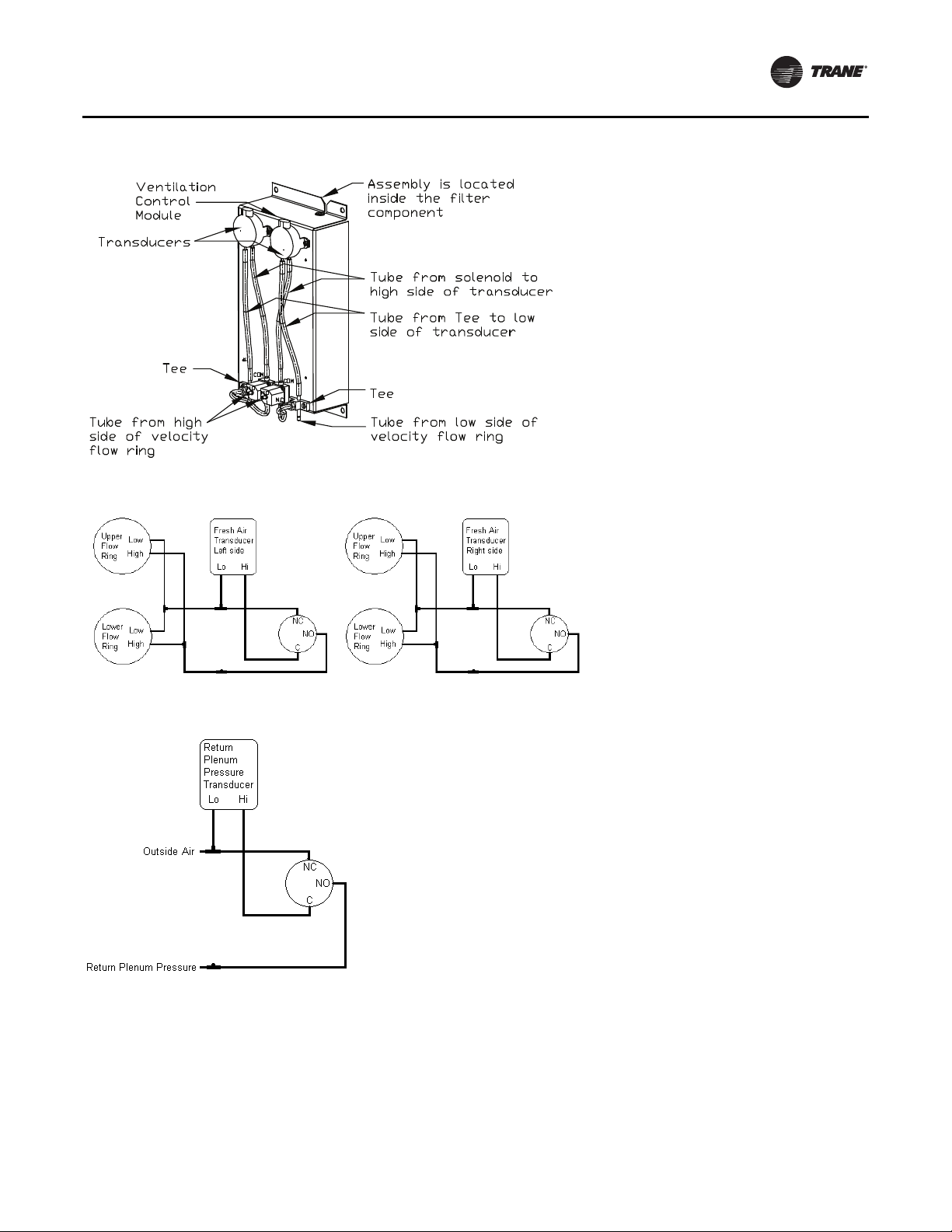

The velocity pressure transducer/solenoid assembly is

illustrated below. Refer to the “Units withTRAQ™ Sensor,”

p. 103 for VCM operation.

2

sensor can be connected to the

2

reset.The reset function adjusts the

concentrations

2

Variable Speed Module (VSM - Optional -

Used with Fault Detection and Diagnostics

FDD)

The VSM is used with FDD.The VSM will accept a 0-10Vdc

actuator feedback position signal which will then be used

to determine the state of OutsideAir Damper system.

Modulating Dehumidification Module MDM

(Optional - used with Dehumidification

Control)

The MDM supports specific control inputs and outputs for

Modulating Dehumidification control including

modulating Reheat and Cooling valve control as well as

the Reheat Pumpout Coil Relay output. The Modulating

Dehumidification control algorithm provides control

requests to the MDM to accomplish proper

Dehumidification control.

12 RT-SVX24K-EN

Figure 2. Velocity pressure transducer/solenoid assembly

Figure 3. Outside air tubing schematic

General Information

Figure 4. Return air pressure tubing schematic

Generic Building Automation System Module

(GBAS - Optional used with

non-Trane building control systems)

The Generic Building Automation System (GBAS) module

allows a non-Trane building control system to

communicate with the rooftop unit and accepts external

setpoints in the form of analog inputs for cooling, heating,

supply air pressure, and a binary Input for demand limit.

Refer to the “Field Installed Control Wiring” section for the

input wiring to the GBAS module and the various desired

setpoints with the corresponding DC voltage inputs for

both VAV, SZVAV, RR and CV applications.

Input Devices and System Functions

The descriptions of the following basic Input Devices used

within the UCM network are to acquaint the operator with

their function as they interface with the various modules.

Refer to the unit electrical schematic for the specific

module connections.

Constant Volume (CV) and

Variable Air Volume (VAV) Units

Supply Air Temperature Sensor

An analog input device used with CV and VAV applications

that monitors the supply air temperature for: supply air

temperature control (VAV), supply air temperature reset

(VAV), supply air temperature low limiting (CV), supply air

tempering (CV/VAV). It is mounted in the supply air

discharge section of the unit and is connected to the RTM.

RT-SVX24K-EN 13

General Information

Return Air Temperature Sensor

An analog input device used with a return humidity sensor

on CV and VAV applications when the comparative

enthalpy option is ordered. It monitors the return air

temperature and compares it to the outdoor temperature

to establish which temperature is best suited to maintain

the cooling requirements. It is mounted in the return air

section and is connected to the ECEM.

Leaving EvaporatorTemperature Sensor

An analog input device used with CV and VAV applications

that monitors the refrigerant temperature inside the

evaporator coil to prevent coil freezing. It is attached to the

suction line near the evaporator coil and is connected to

the MCM. It is factory set for 30°F and has an adjustable

range of 25°F to 35°F.The compressors are staged “Off” as

necessary to prevent icing. After the last compressor stage

has been turned “Off”, the compressors will be allowed to

restart once the evaporator temperature rises 10°F above

the“coil frost cutout temperature” and the minimum three

minute “Off” time has elapsed.

Entering Evaporator Temperature Sensors

Analog input devices used with CV and VAV applications.

This device is used in conjunction with the Leaving

EvaporatorTemperature Sensor to prevent the unit from

running compressors with insufficient charge.

Filter Switch

A binary input device used on CV and VAV applications

that measures the pressure differential across the unit

filters. It is mounted in the filter section and is connected

to the RTM. A diagnostic SERVICE signal is sent to the

remote panel if the pressure differential across the filters

is at least 0.5" w.c.The contacts will automatically open

when the pressure differential across the filters decrease

to 0.4" w.c.The switch differential can be field adjusted

between 0.17" w.c. to 5.0" w.c. ± 0.05" w.c.

Leaving Recovery Exhaust Temp Sensor

Analog input device used on CV andVAV applications with

Energy Recovery option installed. It is used to monitor the

temperature of the leaving air on the Exhaust Fan side of

the energy recovery wheel.This temperature is used to

determine if the temperature of the wheel is too cold as

compared to the Recovery Frost Avoidance Setpoint.The

result is used to determine when to enable energy wheel

frost avoidance functions.

Supply, Exhaust and Return Fan Airflow

Proving Switches

Supply Airflow Proving Switch is a binary input device

used on CV and VAV applications to signal the RTM when

the supply fan is operating. It is located in the supply fan

section of the unit and is connected to the RTM. During a

request for fan operation, if the differential switch is

detected to be open for 40 consecutive seconds;

compressor operation is turned “Off”, heat operation is

turned “Off”, the request for supply fan operation is turned

“Off” and locked out, exhaust dampers (if equipped) are

“closed”, economizer dampers (if equipped) are “closed”,

and a manual reset diagnostic is initiated.

Exhaust/return Airflow Proving Switch is a binary input

device used on all rooftop units equipped with an exhaust

fan. It is located in the exhaust/return fan section of the unit

and is connected to the RTM. During a request for fan

operation, if the differential switch is detected to be open

for 40 consecutive seconds, the economizer is closed to

the minimum position setpoint, the request for exhaust

fan operation is turned “Off” and locked out, and a manual

reset diagnostic is initiated.The fan failure lockout can be

reset at the Human Interface located in the unit control

panel, byTracer, or by cycling the control power to the

RTM Off/On.

Lead-Lag

A selectable mode of operation through the Human

Interface. It alternates the starting between the first

compressor of each refrigeration circuit. Only the

compressor banks will switch, not the order of the

compressors within a bank, providing the fir st compressor

in each circuit had been activated during the same request

for cooling.

Charge Isolation

During the OFF cycle, most of the charge is isolated

between the compressor (internal) discharge check valves

and liquid line solenoid valve.This reduces the OFF cycle

charge migration, and liquid feedback during subsequent

startup.The liquid line solenoid is energized (opened) with

the start of the circuit compressor.

Supply, Exhaust and Return Fan Circuit

Breakers

The supply fan and exhaust fan motors are protected by

circuit breakers or fuses. They will trip and interrupt the

power supply to the motors if the current exceeds the

breaker's “must trip” value.The rooftop module (RTM)

will shut all system functions “Off” when an open fan

proving switch is detected.

Low Pressure Control

Low Pressure Control is accomplished using a binary input

device on CV andVAV applications. LP cutouts are located

on the suction lines near the scroll compressors.The LPC

contacts are designed to close when the suction pressure

exceeds 41 ± 4 psig. If the LP control is open when a

compressor is requested to start, none of the compressors

on that circuit will be allowed to operate.They are locked

out and a manual reset diagnostic is initiated.

The LP cutouts are designed to open if the suction

pressure approaches 22 ± 4 psig. If the LP cutout opens

after a compressor has started, all compressors operating

on that circuit will be turned off immediately and will

14 RT-SVX24K-EN

General Information

remain off for a minimum of three minutes. If the LP cutout

trips four consecutive times during the first three minutes

of operation, the compressors on that circuit will be locked

out and a manual reset diagnostic is initiated.

Saturated Condenser Temperature Sensors

Analog input devices used on CV and VAV applications

mounted inside a temperature well located on a

condenser tube bend.They monitor the saturated

refrigerant temperature inside the condenser coil and are

connected to the MCM. As the saturated refrigerant

temperature varies due to operating conditions, the

condenser fans are cycled “On” or “Off” as required to

maintain acceptable operating pressures.

Head Pressure Control

Accomplished using two saturated refrigerant

temperature sensors on CV and VAV applications. During

a request for compressor operation, when the condensing

temperature rises above the “lower limit” of the

controlband, the Compressor Module (MCM) starts

sequencing condenser fans “On”. If the operating fans can

not bring the condensing temperature to within the

controlband, more fans are turned on. As the saturated

condensing temperature approaches the lower limit of the

controlband, fans are sequenced “Off”.

The minimum “On/Off” time for condenser fan staging is

5.2 seconds. If the system is operating at a given fan stage

below 100% for 30 minutes and the saturated condensing

temperature is above the “efficiency check point” setting,

a fan stage will be added. If the saturated condensing

temperature falls below the “efficiency check point”

setting, the fan control will remain at the present operating

stage. If a fan stage cycles four times within a 10 minute

period, the control switches from controlling to the “lower

limit” to a temperature equal to the “lower limit” minus

the “temporary low limit suppression” setting. It will

utilize this new “low limit” temperature for one hour to

reduce condenser fan short cycling.

For evaporative condensing units, head pressure is

monitored with pressure transducers attached to the

saturated condensing line and converted to a temperature

by the MPM.This temperature is used to control the

variable speed fan and sump pump. When the

temperature rises above the upper limit (120°F) the sump

pump is energized. If the condensing temperature drops

below the lower limit (70°F) the sump pump is deenergized.

High Pressure Limit Controls

High Pressure controls are located on the discharge lines

near the scroll compressors. They are designed to open

when the discharge pressure approaches 650 ± 10 psig.

The controls reset automatically when the discharge

pressure decreases to approximately 550 ± 10 psig.

However, the compressors on that circuit are locked out

and a manual reset diagnostic is initiated after the fourth

occurrence of a high pressure condition.

Outdoor Air Humidity Sensor

An analog input device used on CV and VAV applications

with 100% economizer. It monitors the outdoor humidity

levels for economizer operation. It is mounted in the

outside air intake section and is connected to the RTM.

Return Air Humidity Sensor

An analog input device used on CV and VAV applications

with the comparative enthalpy option. It monitors the

return air humidity level and compares it to the outdoor

humidity level to establish which conditions are best

suited to maintain the cooling requirements. It is mounted

in the return air section and is connected to the ECEM.

Space Humidity Sensor

Analog input device used on CV andVAV applications with

modulating dehumidification option and/or

humidification field installed option. It is used to monitor

the humidity level in the space and compared to

dehumidification and humidification setpoints to maintain

space humidity requirements. It is field mounted in the

space and connected to the RTM.

Status/Annunciator Output

An internal function within the RTM module on CV and

VAV applications that provides:

c. diagnostic and mode status signals to the remote

panel (LEDs) and to the Human Interface

d. control of the binary Alarm output on the RTM

e. control of the binary outputs on the GBAS module

to inform the customer of the operational status

and/or diagnostic conditions

Low Ambient Compressor Lockout

Utilizes an analog input device for CV and VAV

applications. When the system is configured for low

ambient compressor lockout, the compressors are not

allowed to operate if the temperature of the outside air

falls below the lockout setpoint. When the temperature

rises 5°F above the lockout setpoint, the compressors are

allowed to operate.The factory preset is 50°F.

These compressors come equipped with a protection

module that monitors phase loss, phase sequencing and

motor temperature.

Space PressureTransducer

An analog input device used on CV and VAV applications

with the Statitrac option. It modulates the exhaust

dampers to keep the space pressure within the building to

a customer designated controlband. It is mounted on the

bottom support below the return damper blade assembly

and is connected to the ECEM. Field supplied pneumatic

tubing must be connected between the space being

controlled and the transducer assembly.

RT-SVX24K-EN 15

General Information

MorningWarm-Up—Zone Heat

When a system changes from an unoccupied to an

occupied mode, or switches from STOPPED to AUTO, or

power is applied to a unit with the MWU option, the heater

in the unit or external heat will be brought on if the space

temperature is below the MWU setpoint.The heat will

remain on until the temperature reaches the MWU

setpoint.

If the unit is VAV, then the VAV box/unocc relay will

continue to stay in the unoccupied position and the VFD

output will stay at 100% during the MWU mode.When the

MWU setpoint is reached and the heat mode is terminated,

then the VAV box/unocc relay will switch to the occupied

mode and the VFD output will be controlled by the duct

static pressure. During Full Capacity MWU the economizer

damper is held closed for as long as it takes to reach

setpoint. During Cycling Capacity MWU the economizer

damper is allowed to go to minimum position after one

Compressor Motor Winding Thermostats

A thermostat is embedded in the motor windings of each

Scroll compressor. Each thermostat is designed to open if

the motor windings exceed approximately 221°F. The

thermostat will reset automatically when the winding

temperature decreases to approximately 181°F.

Rapid cycling, loss of charge, abnormally high suction

temperatures, or the compressor running backwards

could cause the thermostat to open. During a request for

compressor operation, if the Compressor Module detects

a problem outside of normal parameters, it turns any

operating compressor(s) on that circuit “Off”, locks out all

compressor operation for that circuit, and initiates a

manual reset diagnostic (compressor trip).

These compressors come equipped with a protection

module that monitors phase loss, phase sequencing and

motor temperature.

hour of operation if setpoint has not been reached.

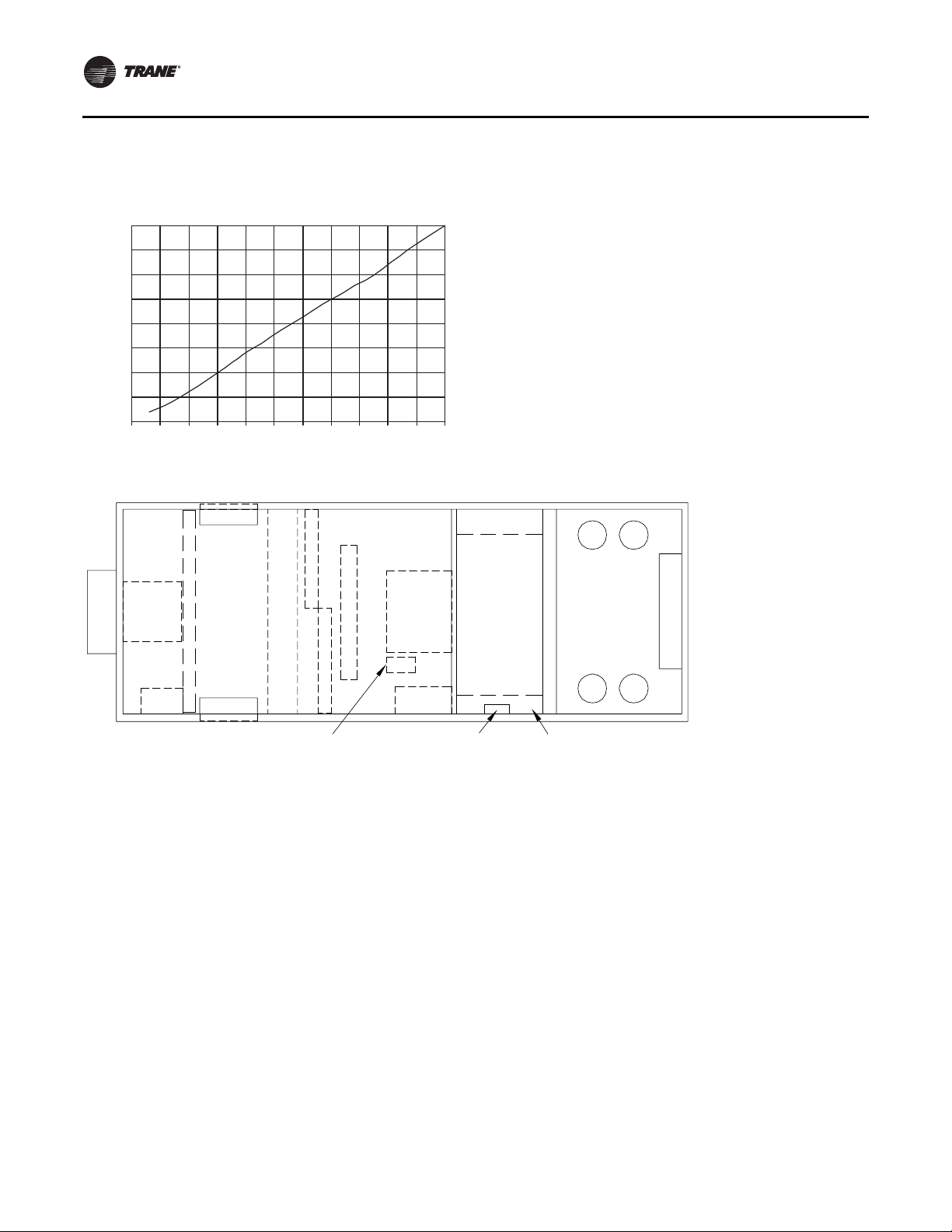

Figure 5. Transducer voltage output vs. pressure input for supply, return and building pressure

-0.75 to 9.0 Iwc Pressure Transducer Voltage Output vs. Pressure Input

4.50

4.00

3.50

3.00

2.50

Volts

2.00

1.50

1.00

0.50

0.00

5

5

5

5

5

5

5

5

5

250.2

75

-0.

-0.

7

2

7

2

7

2

0.

1.

1.

2.

2.

7

3.

3.

Pressure (inches w.c.)

5

2

7

4.

4.

5.

Supply Air Temperature Low Limit

Uses the supply air temperature sensor input to modulate

the economizer damper to minimum position in the event

the supply air temperature falls below the occupied

heating setpoint temperature.

Discharge Line Thermostat for Evaporative

Condensers

The first compressor on each circuit is equipped with a

Discharge Line Thermostat. If the temperature of the line

exceeds 210°F the thermostat interrupts the 115V circuit for

the compressors and both of the compressors on that

5

5

5

5

5

5

5

2

7

2

7

2

5.

6.

6.

7

7.

7.

5

2

7

8.

8.

circuit will be de-energized. Once the temperature drops

below 170°F the thermostat will close and allow the

compressor to be energized.

Freezestat

A binary input device used on CV and VAV units with

Hydronic Heat. It is mounted in the heat section and

connected to the Heat Module. If the temperature of the air

leaving the heating coil falls to 40°F, the normally open

contacts on the freezestat closes signalling the Heat

Module and the Rooftop Module (RTM) to:

f. drive the Hydronic Heat Actuator to the full open

position

16 RT-SVX24K-EN

General Information

g. turn the supply fan “Off”

h. closes the outside air damper

i. turns “On” the SERVICE light at the Remote Panel

j. initiates a “Low Temp Limit” diagnostic to the

Human Interface

Compressor Circuit Breakers

The Scroll Compressors are protected by circuit breakers

whichinterrupt the power supply to the compressors if the

current exceeds the breakers “must trip” value. During a

request for compressor operation, if the Compressor

Module detects a problem outside normal parameters, it

turns any operating compressor(s) on that circuit “Off”,

locks out all compressor operation for that circuit, and

initiates a manual reset diagnostic (compressor trip).

Constant Volume (CV) Units

Zone Temperature—Cooling

Relies on input from a sensor located directly in the space,

while a system is in the occupied “Cooling” mode. It

modulates the economizer (if equipped) and/or stages the

mechanical cooling “On and Off” as required to maintain

the zone temperature to within the cooling setpoint

deadband.

Zone Temperature—Heating

Relies on input from a sensor located directly in the space,

while a system is in the occupied “Heating” mode or an

unoccupied period, to stage the heat “on and off” or to

modulate the heating valve (hydronic heat only) as

required to maintain the zone temperature to within the

heating setpoint deadband.The supply fan will be

requested to operate any time there is a request for heat.

On gas heat units, the fan will continue to run for 60

seconds after the furnace is turned off.

Supply Air Tempering

On CV units equipped with staged gas heat, if the supply

air temperature falls 10°F below the occupied heating

setpoint temperature while the heater is “Off”, the first

stage of heat will be turned “On”.The heater is turned “Off”

when the supply air temperature reaches 10°F above the

occupied heating setpoint temperature.

Variable Air Volume (VAV) Units

Occupied Cooling—Supply Air Temperature

When a VAV unit is in the occupied mode, the supply air

temperature will be controlled to the customer specified

supply air cooling setpoint by modulating the economizer

and/or staging the mechanical cooling “On and Off” as

required.The changeover relay contacts must be open, or

BAS command set to auto or cool, for the cooling to

operate.

DaytimeWarm-up

On VAV units equipped with heat, if the zone temperature

falls below the daytime warm-up initiate temperature

during the occupied mode, the system will switch to full

airflow. During this mode, theVAV box/unocc relay will be

energized (this is to signal the VAV boxes to go to 100%).

After theVAV box max stroke time has elapsed (factory set

at 6 minutes), the VFD output will be set to 100%.The

airflow will be at 100% and the heat will be turned on to

control to the occupied heating setpoint.

When the zone temperature reaches the daytime warm-up

termination setpoint, the heat will be turned off, the relay

will be de-energized, releasing the VAV boxes, the VFD

output will go back to duct static pressure control and the

unit will return to discharge air control. If the occ zone

heating setpoint is less than the DWU terminate setpoint,

the heat will turn off when the occ zone heat setpoint is

reached, but it will stay in DWU mode and cycle the heat

to maintain setpoint.

Unoccupied Heating—Zone Temperature

When aVAV unit is equipped with gas, electric, or hydronic

heat and is in the unoccupied mode, the zone temperature

will be controlled to within the customer specified setpoint

deadband. During an unoccupied mode for aVAV unit, the

VAV box/unocc relay will be in the unoccupied position

and theVFD output will be at 100%.This means that if there

is a call for heat (or cool) and the supply fan comes on, it

will be at full airflow and the VAV boxes in the space will

need to be 100% open as signaled by the VAV box/unocc

relay.

Supply Air Tempering

On VAV units equipped with “Modulating Heat”,ifthe

supply air temperature falls 10°F below the supply air

temperature setpoint, the heat will modulate to maintain

the supply air temperature to within the low end of the

setpoint deadband.

Occupied Heating—Supply Air Temperature

When a VAV unit is equipped with “Modulating Heat”, and

the system is in an occupied mode, and the field supplied

changeover relay contacts have closed or per a BAS

command, the supply air temperature will be controlled to

the customer specified supply air heating setpoint. It will

remain in the heating status until the changeover relay

contacts are opened or BAS has released the heat

command.

RT-SVX24K-EN 17

Supply Duct Static Pressure Control

(Occupied)

The RTM relies on input from the duct pressure transducer

when a unit is equipped with aVariable Frequency Drive to

set the supply fan speed to maintain the supply duct static

pressure to within the static pressure setpoint deadband.

The transducer compares supply duct pressure to ambient

pressure. Refer to Figure 43, p. 67.

General Information

Figure 6. Transducer voltage output vs. pressure input

with VCM and TRAQ™ sensing

4.0

3.5

3.0

2.5

2.0

Volts

1.5

1.0

0.5

0.0

Transducer Voltage Output vs. Pressure I nput

-0.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Pre ssu re (inche s w.c.)

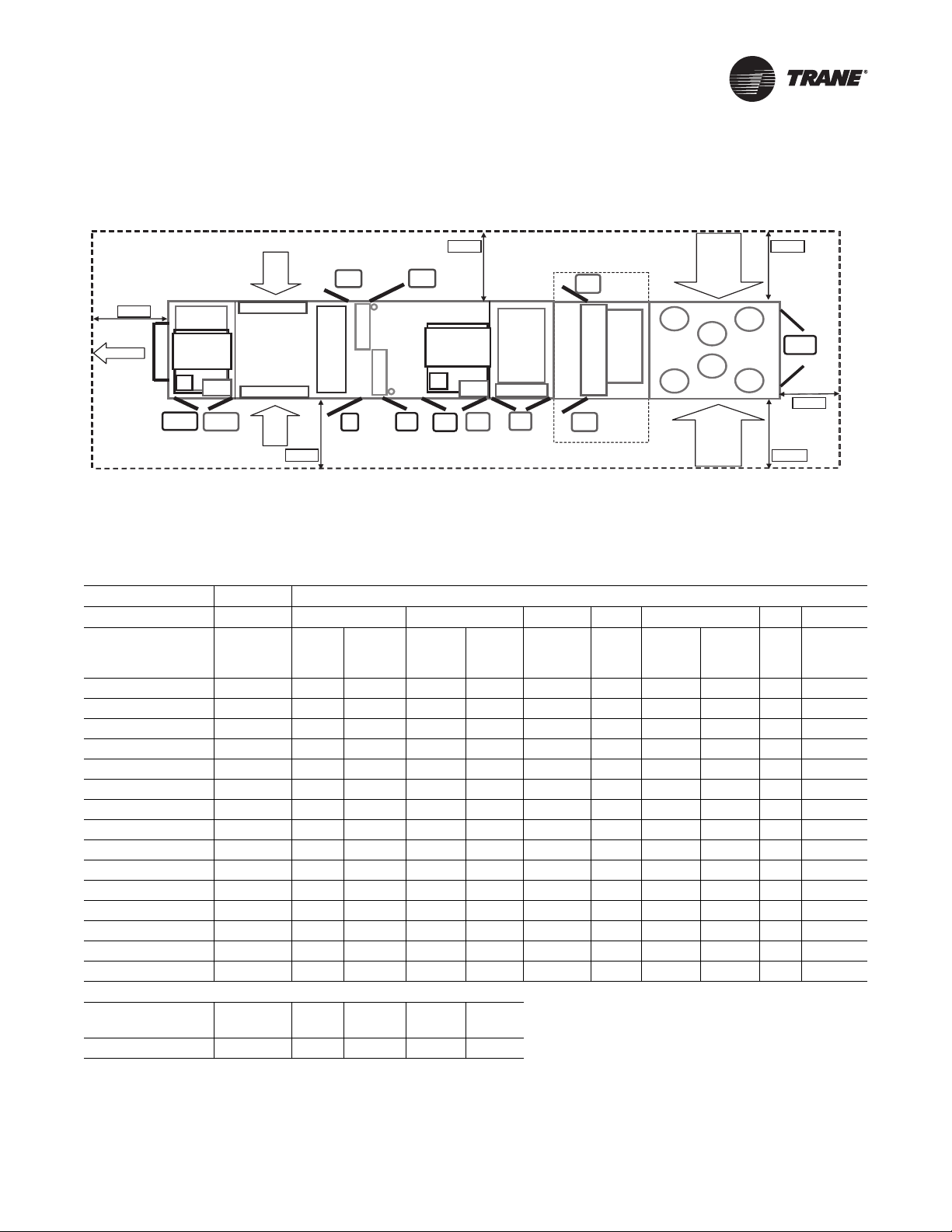

Figure 7. Unit component layout and “ship with” locations

Outside Air

Dampers

Evap Coil

Return/

Exhaust

Hood

Exhaust Damper

Fan

Return Air Dampers

Filter Section

Reheat Coil Option

Evap Coil

Supply Fan

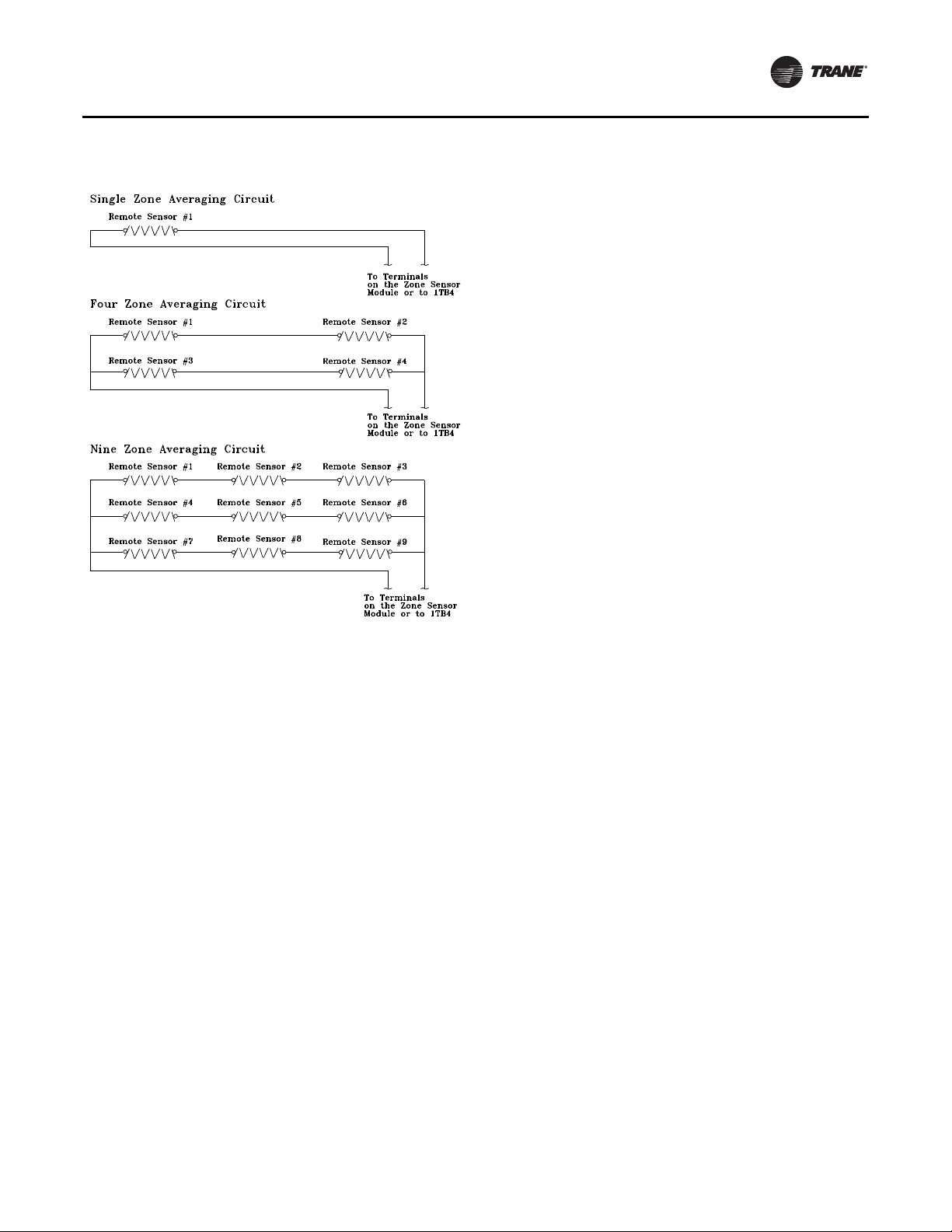

Space Temperature Averaging

Space temperature averaging for Constant Volume

applications is accomplished by wiring a number of

remote sensors in a series/parallel circuit.

The fewest number of sensors required to accomplish

space temperature averaging is four.The Space

Temperature Averaging with Multiple Sensors figure

illustrates a single sensor circuit (Single Zone), four

sensors wired in a series/parallel circuit (Four Zone), nine

sensors wired in a series/parallel circuit (Nine Zone). Any

number squared, is the number of remote sensors

required.

Wiring termination will depend on the type of remote

panel or control configuration for the system. Refer to the

wiring diagrams that shipped with the unit.

Condenser

Heating

Section

Fans

Compressor

Section

Controls

Variable

Frquency

Drive (VFD)

Outside Air

Dampers

Outside Air

Static Kit and

sensors

Variable

Frquency

Drive (VFD)

Flue Vent

Access

Hot Water/Steam

Hydronic Connection

18 RT-SVX24K-EN

Figure 8. Space temperature averaging with multiple

sensors

General Information

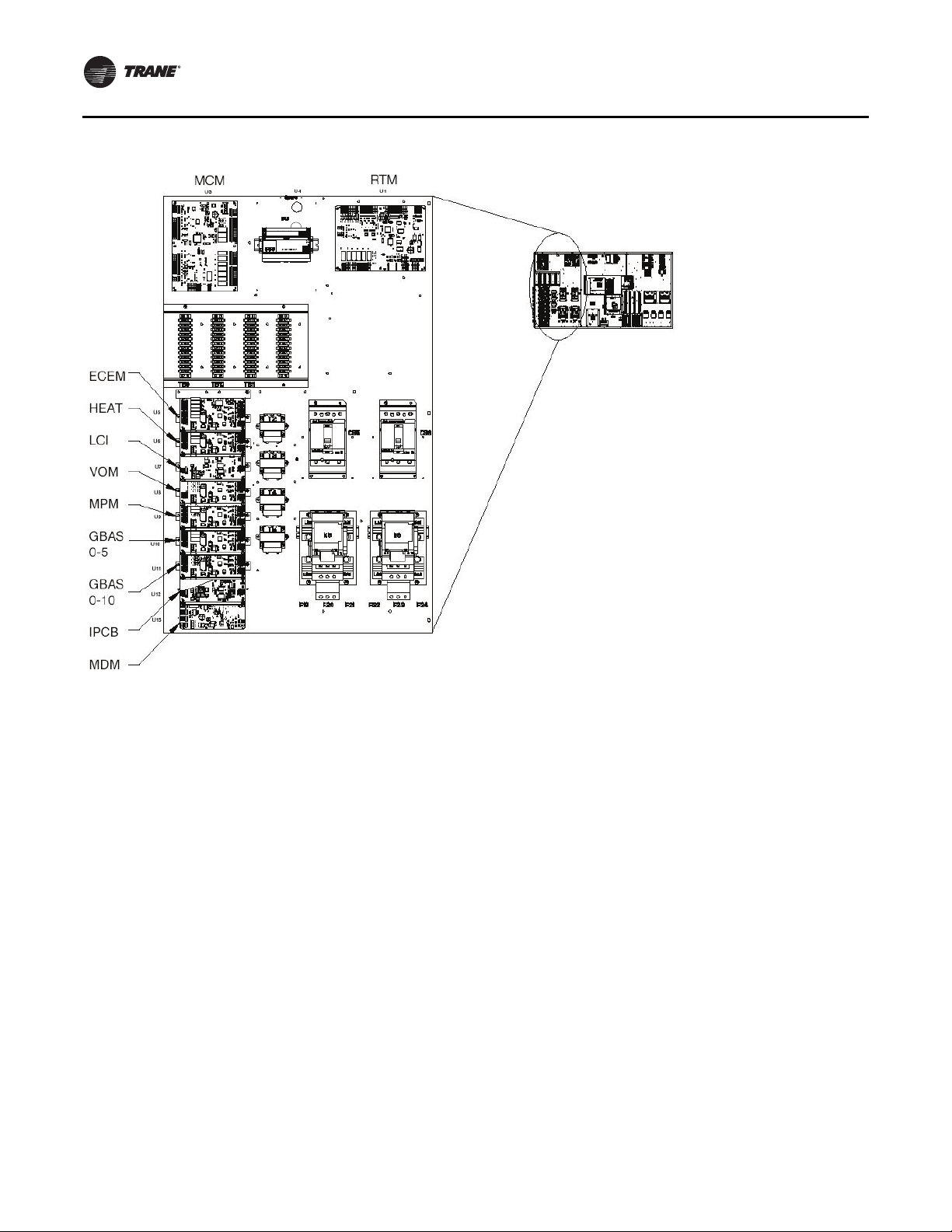

Unit Control Modules

Unit control modules are microelectronic circuit boards

designed to perform specific unit functions.The control

modules, through proportional/integral control

algorithms, provide the best possible comfort level for the

customer.They are mounted in the control panel and are

factory wired to their respective internal components.

The control modules receive and interpret information

from other unit modules, sensors, remote panels, and

customer binary contacts to satisfy the applicable request

for economizing, mechanical cooling, heating, and

ventilation. Figure 9 illustrates the typical location of each

designated module.

RT-SVX24K-EN 19

General Information

Figure 9. Control module locations

BCI

Single Zone Variable Air Volume (SZVAV) Only

The IntelliPak controls platform will support Single Zone

VAV as an optional unit control type in order to meet

ASHRAE 90.1. The basic control will be a hybrid VAV/CV

configured unit that provides discharge temperature

control to a varying discharge air temperature target

setpoint based on the space temperature and/or humidity

conditions. Concurrently, the unit will control and optimize

the supply fan speed to maintain the zone temperature to

a zone temperature setpoint.

Supply Fan Output Control

Units configured for Single Zone VAV control will utilize

the same supply fan output control scheme as on

traditional VAV units except the VFD signal will be based

on zone heating and cooling demand instead of the supply

air pressure.

VFD Control

Single Zone VAV units will be equipped with a VFDcontrolled supply fan which will be controlled via a 010VDC signal from the Rooftop Module (RTM). With the

RTM supply fan output energized and the RTM VFD output

at 0VDC, the fan speed output is 37% (22Hz) from the VFD

by default; and at 10VDC the fan speed output is 100%

(60Hz).The control scales the 0-10VDC VFD output from

the RTM linearly to control between the 37-100% range.

The VFD will modulate the supply fan motor speed,

accelerating or decelerating as required to maintain the

zone temperature to the zone temperature setpoint.When

subjected to high ambient return conditions the VFD will

reduce its output frequency to maintain operation. Bypass

control is offered to provide full nominal airflow in the

event of drive failure.

Ventilation Control

Units configured for Single Zone VAV control will require

special handling of the OA Damper Minimum Position

control in order to compensate for the non-linearity of

airflow associated with the variable supply fan speed and

damper combinations. Units configured for TRAQ with or

without DCV will operate identically to traditional units

with no control changes.

Space Pressure Control

For units configured with Space Pressure Control with or

without Statitrac, the new schemes implemented for

economizer minimum position handling require changes

to the existing Space Pressure Control scheme in order to

20 RT-SVX24K-EN

General Information

prevent over/under pressurization.The overall scheme

will remain very similar to VAV units with Space Pressure

Control with the exception of the dynamic Exhaust Enable

Setpoint.

For SZVAV an Exhaust Enable Setpoint must be selected

during the 100% Fan Speed Command. Once selected, the

difference between the Exhaust Enable Setpoint and

Design OA Damper Minimum Position at 100% Fan Speed

Command will be calculated.The difference calculated will

be used as an offset and added to the Active Building

Design OA Minimum PositionTarget in order to calculate

the dynamic Exhaust EnableTarget, which will be used

throughout the Supply Fan Speed/OA Damper Position

range.

The Exhaust EnableTarget could be above or below the

Active Building Design OA Minimum PositionTarget

Setpoint, based on the Active Exhaust Enable Setpoint

being set above or below the Building Design Minimum

Position at 100% Fan Speed Command. Note that an

Exhaust Enable Setpoint of 0% will result in the same effect

on Exhaust Fan control as on VAV applications with and

without Statitrac.

Occupied Cooling Operation

For normal cooling operation, cooling capacity will be

staged or modulated in order to meet the calculated

discharge air target setpoint. If the current active cooling

capacity is controlling the discharge air within the

deadband, no additional cooling capacity change will be

requested. As the Discharge Air Temperature rises above

the deadband, the algorithm will request additional

capacity as required (additional compressors or

economizer).As the Discharge AirTemperature falls below

the deadband, the algorithm will request a reduction in

active capacity.

Default Economizer Operation

By default, the unit will be setup to optimize the minimum

supply fan speed capability during Economizer Only

operation. If the economizer is able to meet the demand

alone, due to desirable ambient conditions, the supply fan

speed will be allowed to increase above the minimum

prior to utilizing mechanical cooling if discharge air

setpoint falls below the discharge air Lower Limit

(Cooling) setpoint.

Unoccupied Mode

In Unoccupied mode the unit will utilize setback setpoints,

0% Minimum OA Damper position, and Auto Fan Mode

operation as on normal CV units.The Supply Fan speed,

and cooling and modulating types of heat, will be

controlled to the discharge air target setpoint as is done

during occupied periods.The Supply fan speed during

staged heat control will be forced to 100% as on normal CV

units.

Occupied Heating Operation

Occupied heating operation has two separate control

sequences; staged and modulated. All staged heating

types will drive the supply fan to maximum flow and stage

heating to control to the Zone Heating Setpoint. For units

with Hydronic and Gas heat, modulated SZVAV Heating.

On an initial call for heating, the supply fan will drive to the

minimum heating airflow.

On an additional call for heating, the heat will control in

order to meet the calculated discharge air target setpoint.

As the load in the zone continues to request heat

operation, the supply fan will ramp-up while the control

maintains the heating discharge air temperature. Heating

can be configured for either the energy saving SZVAV

Heating solution as described above, or the traditional,

less efficient CV Heating solution.

Compressor (DX) Cooling

Compressor control and protection schemes will function

identical to that of a traditional unit. Normal compressor

proving and disable input monitoring will remain in effect

as well as normal 3-minute minimum on, off, and interstage timers. Also, all existing head pressure control

schemes will be in effect.

Cooling Sequence

If the control determines that there is a need for active

cooling capacity in order to meet the calculated discharge

air target setpoint, once supply fan proving has been

made, the unit will begin to stage compressors

accordingly. Note that the compressor staging order will

be based on unit configuration and compressor lead/lag

status.

Once the discharge air target setpoint calculation has

reached the Minimum Setpoint and compressors are

being utilized to meet the demand, as the discharge air

target setpoint value continues to calculate lower the

algorithm will begin to ramp the supply fan speed up

toward 100%. Note that the supply fan speed will remain

at the compressor stage’s associated minimum value (as

described below) until the discharge air target setpoint

value is calculated below the discharge air temperature

Minimum Setpoint (limited discharge air target setpoint).

As the cooling load in the zone decreases the zone cooling

algorithm will reduce the speed of the fan down to

minimum per compressor stage and control the

compressors accordingly. As the compressors begin to

de-energize, the supply fan speed will fall back to the

Cooling Stage’s associated minimum fan speed, but not

below. As the load in the zone continues to drop, cooling

capacity will be reduced in order to maintain the discharge

air within the ± ½ discharge air target deadband.

Fault Detection and Diagnostics

Fault Detection of the Outdoor Air Damper will be

evaluated based on the commanded position of the

damper compared to the feedback position of the damper.

RT-SVX24K-EN 21

General Information

The damper is commanded to a position based on a 2-10

VDC signal. If the Damper position is outside of ±10% of the

commanded position, a diagnostic is generated.

Unit Not Economizing when it should be:

The Unit is operating in Cooling Mode, Economizing is

enabled and/or Mechanical Cooling is enabled. If the

Commanded Economizer Position is greater than Current

Economizer Feedback Position + 10% for 5 continuous

minutes, Unit Not Economizing when it should be

diagnostic is generated.

Unit Economizing when it should not be:

The unit is operating in Cooling Mode, Economizing is

enabled and or Mechanical Cooling is enabled. If the

commanded Economizer Position is less than the current

Economizer Feedback Position - 10% for 5 continuous

minutes, Unit Economizing When it should not be

diagnostic is generated.

Outdoor Air Damper Not Modulating

The unit is operating in Ventilation Only Mode - not

attempting to Economize and the Commanded Damper

Position is greater than the Current Damper Feedback

Position + 10% for 5 continuous minutes, Outdoor Air

Damper Not Modulating diagnostic is generated.

Excessive Outdoor Air

The unit is operating in Ventilation Only Mode - not

attempting to Economize and the Commanded Damper

Position is less than the Current Damper Feedback Position

- 10% for 5 continuous minutes. Excessive Outdoor Air

diagnostic is generated.

To changethe Economizer Control Function to dry bulb, go

to the Configuration Menu on the Human Interface Module

and set Comparative Enthalpy to "Not Installed".This

allows the user to select dry bulb under the Economizer

Control Function which is a Submenu of the Setup Menu.

For additional instructions please see the Programming

andTroubleshooting Guide.

22 RT-SVX24K-EN

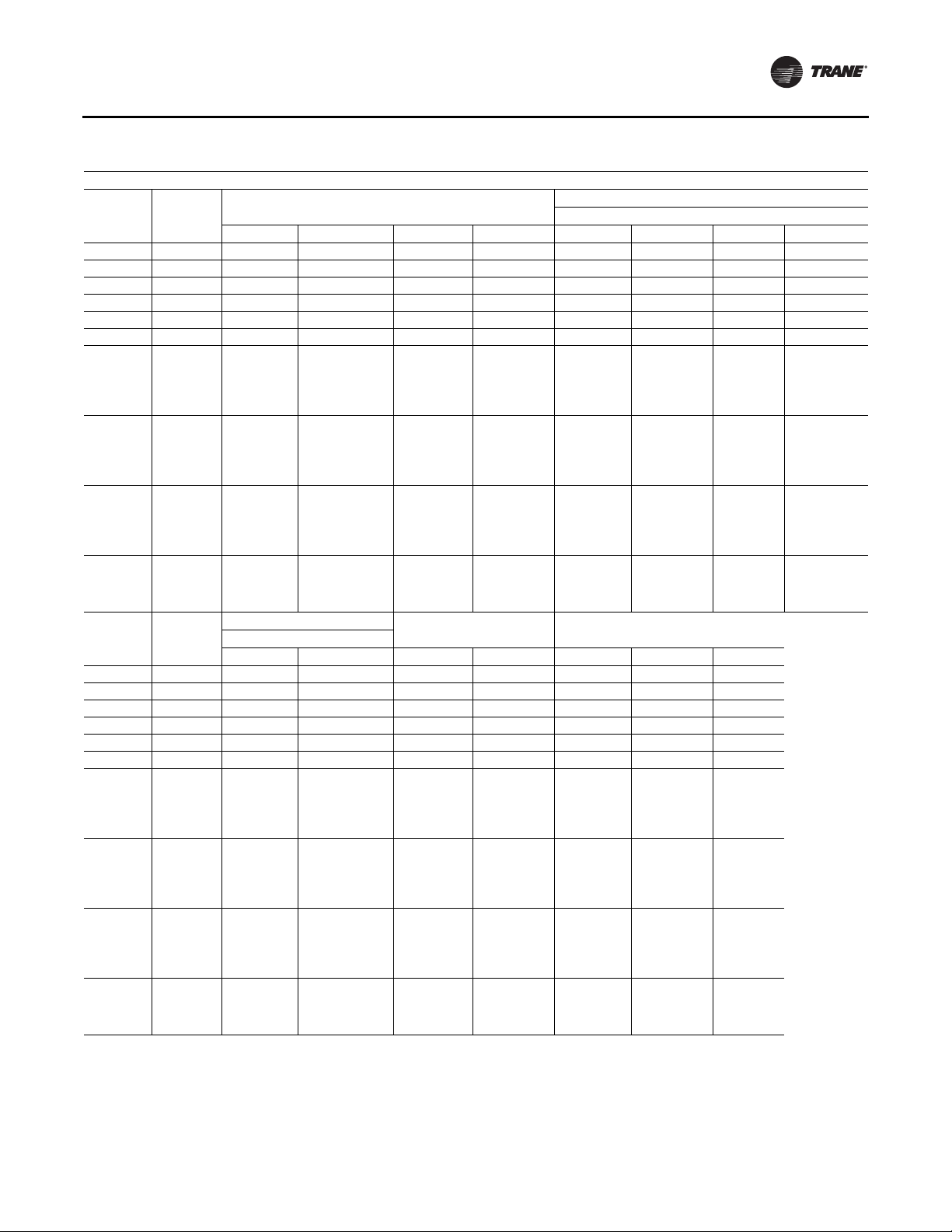

Unit Clearances

(F)

(R)

(

(

)

e

Filters

(a)

AH R

Fltr

Fltr

Std StdStd

Evp

OptionOption

VFD

Evp

Sup

Sup

VFD

Mtr

Std