Page 1

Installation, Operation, and

Maintenance

Midrange Self-Contained Units

Models SCWH/SCRH

3, 5, 7.5, 10, 12, & 15-tons

“AO” and later design sequence

October 2008

PKG-SVX14A-EN

Page 2

general information

About This Manual

Literature Change History

Use this manual for commercial selfcontained models SCWH and SCRH.

This is the original issue of this

manual. It provides specific installation,

owner maintenance, and diagnostic

troubleshooting instructions for “AO” and

later design sequences.

Note: The procedures discussed in this

manual should only be performed by

qualified, experienced HVAC technicians.

Note: This document is customer

property and must be retained for use by

maintenance personnel.

It is important to perform periodic

maintenance to help ensure trouble free

operation. Should equipment failure

occur, contact a qualified Trane service

organization for an experienced HVAC

technician to properly diagnose and

repair this equipment.

Warnings and Cautions

Warnings and cautions appear at

appropriate sections throughout this

manual. Read these carefully.

WARNING

Indicates a potentially hazardous

situation, which could result in death

or serious injury if not avoided.

CAUTION

Indicates a potentially hazardous

situation, which may result in minor or

moderate injury if not avoided. Also, it

may alert against unsafe practices.

CAUTION

Indicates a situation that may result in

equipment or property-damage-only

accidents.

Example Warnings and

Cautions

WARNING

Hazardous Voltage!

Disconnect all electric power,

including remote disconnects before

servicing.Follow proper lockout/tagout

procedures to ensure power cannot

be inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious injury.

CAUTION

Use Copper Conductors Only!

Unit terminals are not designed to

accept other type conductors. Failure

to use copper conductors may result

in equipment damage.

Common HVAC Acronyms

For convenience, a number of acronyms

and abbreviations are used throughout

this manual. These acronyms are

alphabetically listed and defined below.

CFM = Cubic-feet-per-minute

CKT. = Circuit

CV = Constant volume

CW = Clockwise

CCW = Counterclockwise

E/A = Exhaust air

F/A = Fresh air

HGBP = Hot gas bypass

HVAC = Heating, ventilation and air

conditioning

IGV = Inlet guide vanes

I/O = Inputs/outputs

IOM= Installation/operation/maintenance

manual

LH = Left-hand

O/A = Outside air

psig = Pounds-per-square-inch, gauge

pressure

R/A = Return air

RH = Right-hand

RPM = Revolutions-per-minute

S/A = Supply air

SZ = Single-zone (unit airflow)

VAV = Variable air volume

w.c. = Water column

Special Note on Refrigeration

Emissions

World environmental scientists have

concluded that ozone in our upper

atmosphere is being reduced due to the

release of CFC fully halogenated

compounds.

Trane urges all HVAC service personnel

to make every effort to prevent any

refrigerant emissions while installing,

operating, or servicing equipment.

Always conserve refrigerants for

continued use.

2 PKG-SVX14A-EN

© 2008 Trane All rights reserved

Page 3

contents

Cross reference to related publications/information:

Midrange Self-Contained catalog, PKG-PRC012-EN

Installation…………………………………………………2

general information ……………………………………………2

pre-installation considerations ………………………………6

dimensions & weights ………………………………………11

mechanical requirements ……………………………………17

electrical requirements ………………………………………19

installation procedure ………………………………………21

pre-startup requirements ……………………………………22

startup …………………………………………………………23

Operation…………………………………………………24

sequence of operation ………………………………………24

Maintenance ……………………………………………25

general information …………………………………………25

maintenance procedures ……………………………………26

periodic checklists ……………………………………………29

troubleshooting ………………………………………………30

typical wiring diagrams ……………………………………32

PKG-SVX14A-EN 3

Page 4

general

Installation

information

Midrange Model Number Description

Following is a complete description of the midrange model number. Each digit in the model number has a corresponding code that

identifies specific unit options.

S C W H 075 4 2 A0 1 0 1 0

1 2 3 4 567 8 9 1011 12 13 14 15

Digit 14 - unit finish

1 = painted

2 = corrosion resistant coating

Digit 15 - coil finish/Cu-Ni Condenser

0 = none

E = evaporator coated (SCRH)

J = Cupronickel condenser &

Evaporator coated (SCWH)

Digit 1 - unit model

S = self contained

Digit 2 - unit type

C = commercial

Digit 3 - condenser medium

R = remote air-cooled

W = water cooled

Digit 4 - development sequence

H = development series

Digit 5, 6, 7- unit nominal capacity

030 = 3 tons

050 = 5 tons

075 = 7.5 tons

100 = 10 tons

120 = 12 tons

150 = 15 tons

Digit 8 - unit voltage

3 = 208 - 230 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

Digit 9 - air flow configuration

2 = vertical discharge / front return

3 = vertical discharge / rear return

Digit 10, 11 - design sequence

A0 = design sequence

Digit 12 - air filter type

1 = one-inch fiberglass throwaway

Digit 13 - control

0 = control interface

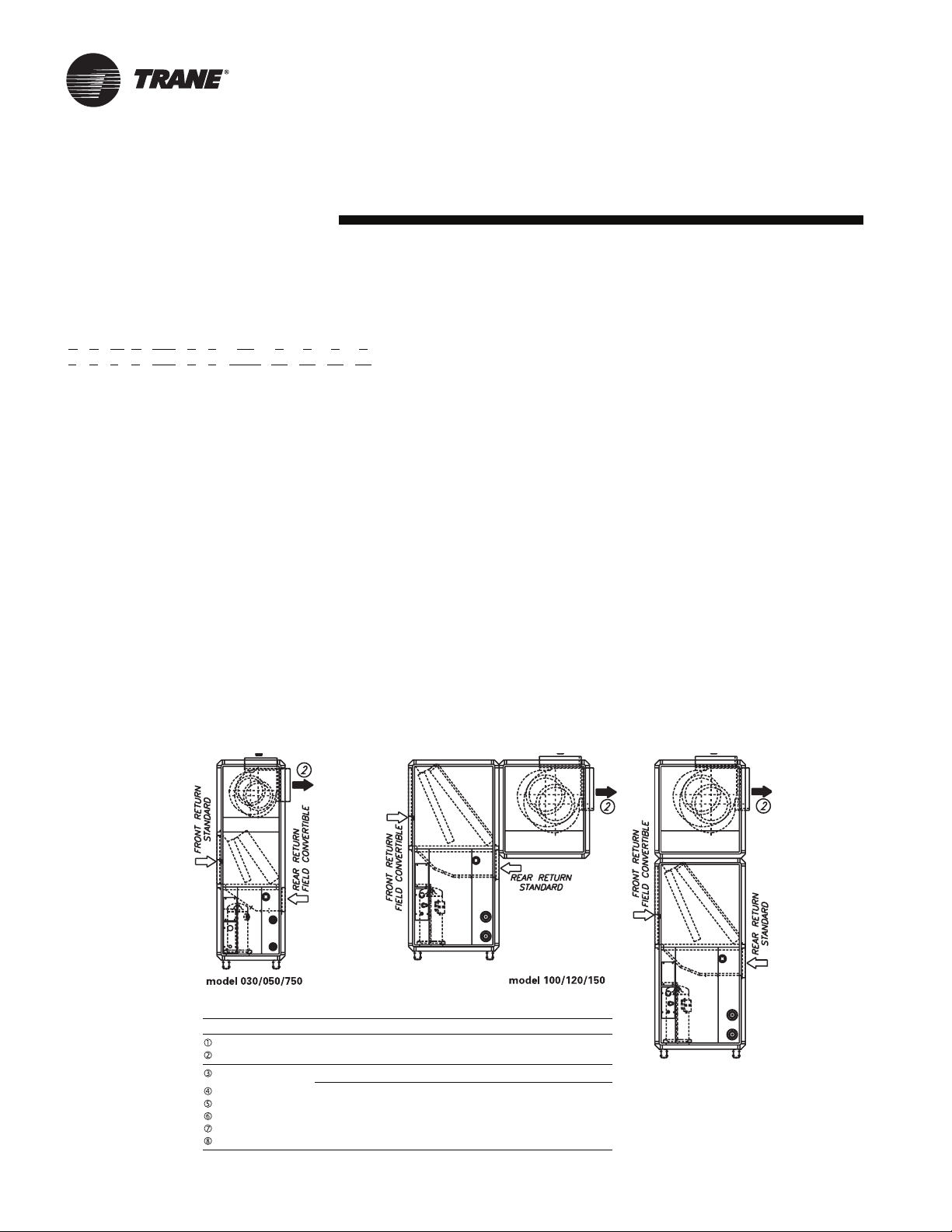

Unit Airflow Configurations

unit size discharge fan location comments

030/050/075 vertical CCW top standard

100/120/150 vertical CCW top standard

horizontal CW top field converted

vertical CW top field converted

horizontal CW top

vertical CW rear

horizontal CW rear

horizontal CCW rear

4 PKG-SVX14A-EN

Page 5

general

General

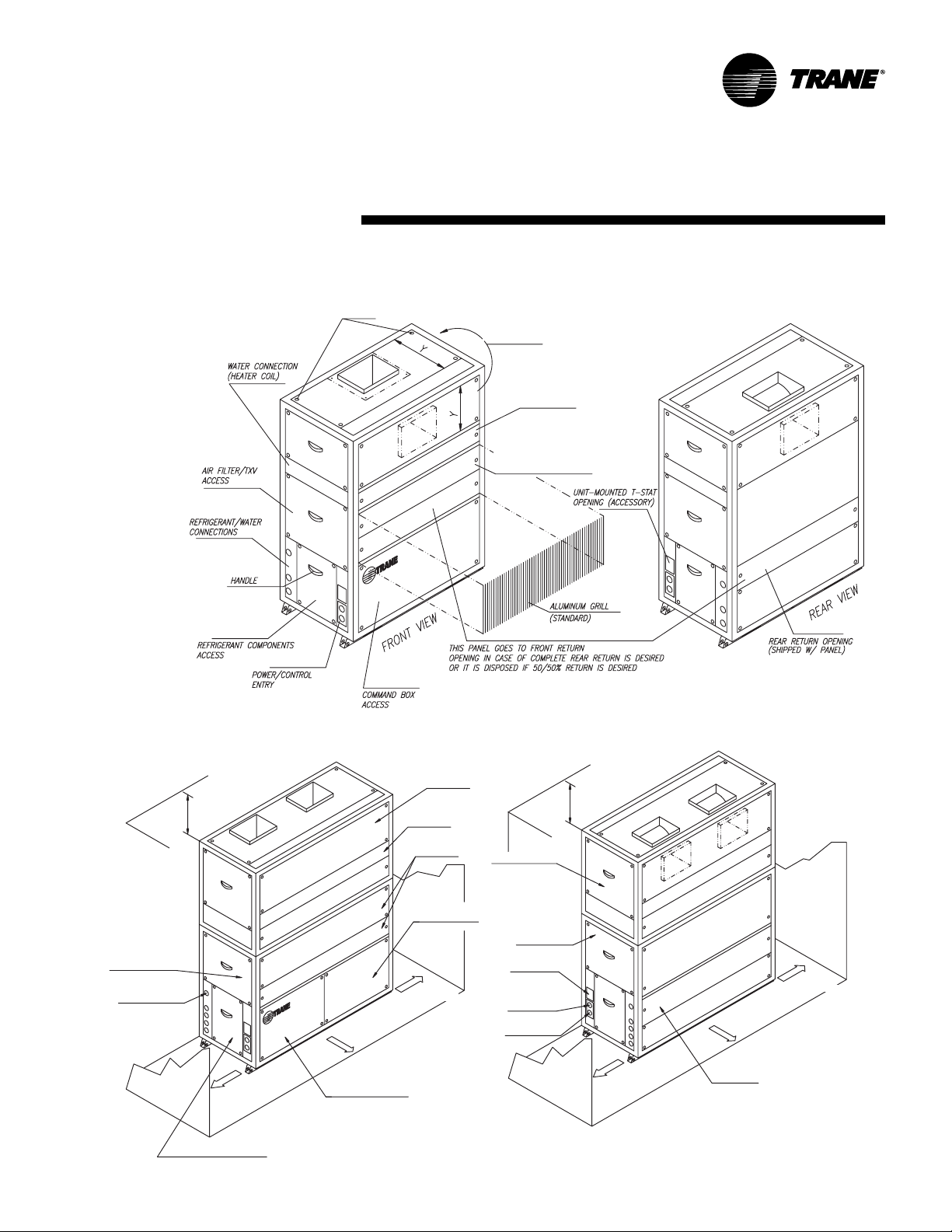

The midrange models SCWH/SCRH

is a high efficiency, vertical air

condioner. units have either front or top

discharge configuration options and easy

service access. Unit construction is heavy

gage steel with a baked enamel finish.

Available unit voltages are 208/3/60, 230/

3/60, 460/3/60, and 575/3/60.

Refrigeration Circuits

Units are configured in single or double

refrigeration circuits. Each circuit consists

of:

• high efficiency scroll compressor

mounted on rubber isolation grommets

• evaporator coils designed for optimum

performance and efficiency with lanced

fins and rifled tubing

• filter-drier

Evaporator Section

The evaporator fan section consists of

one or two forward curved centrifugal

fans powered by a premium efficiency

motor through an adjustable motor

sheave and fixed diameter blower pulley.

Controls

The standard control panel consists of a

high voltage terminal block, overload

relays for each fan motor, transformer, 3pole 24-volt contactors for eachmotor

and compressor, and a 5-second delay

timer. Remote thermostat controls are

field installed.

Field-Installed Accesories

These items ship separately for field

installation:

• steam coil

• hot water coil

• plenum

• oversized motors

• remote thermostat

Note: Application of the above options

and/or accessories may require field

adjustment of fan speeds to ensure

proper airflow and performance.

Unit Nameplate

The unit nameplate identifies the unit

model number, appropriate service

literature, and wiring diagrm numbers. It

is mounted on the control panel door.

Reference this information when making

inquires or ordering parts or literature.

Installation

Refrigerant Handling

Procedures

Environmental Accountability Policy

Trane urges that all HVAC servicers to

make every effort to eliminate, if possible,

or vigorously reduce the emission of CFC,

HCFC, and HFC refrigerants to the

atmosphere. Always act in a responsible

manner to conserve refrigerants for

continued usage even when acceptable

alternatives are available.

Recover and Recycle Refrigerants

Never release refrigerant to the

atmosphere! Always recover and/or

recycle refrigerant for reuse,

reprocessing (reclaimed), or properly

dispose if removing from equipment.

Always determine the recycle or reclaim

requirements of the refrigerant before

beginning the recovery procedure.

Obtain a chemical analysis of the

refrigerant if necessary. Questions about

recovered refrigerant and acceptable

refrigerant quality standards are

addressed in ARI Standard 700.

Refrigerant Handling and Safety

Consult the manufacturer’s material

safety data sheet (MSDS) for information

on refrigerant handling to fully

understand health, safety, storage,

handling, and disposal requirements. Use

the approved containment vessels and

refer to appropriate safety standards.

Comply with all applicable transportation

standards when shipping refrigerant

containers.

Service Equipment and Procedures

To minimize refrigerant emissions while

recovering refrigerant, use the

manufacturer’s recommended recycling

equipment per the MSDS. Use

equipment and methods which will pull

the lowest possible system vacuum while

recovering and condensing refrigerant.

Equipment capable of pulling a vacuum of

less than 1,000 microns of mercury is

recommended.

Do not open the unit to the atmosphere

for service work until refrigerant is fully

removed/recovered. When leak-testing

with trace refrigerant and nitrogen, use

HCFC-22 (R-22) rather than CFC-12 (R-

12) or any other fully-halogenated

refrigerant . Be aware of any new leak

test methods which may eliminate

information

refrigerants as a trace gas. Perform

evacuation prior to charging with a

vacuum pump capable of pulling a

vacuum of 1,000 microns of mercury or

less. Let the unit stand for 12 hours and

with the vacuum not rising above 2,500

microns of mercury.

A rise above 2,500 microns of mercury

indicates a leak test is required to locate

and repair any leaks. A leak test is

required on any repaired area.

Charge refrigerant into the equipment

only after equipment does not leak or

contain moisture. Reference proper

refrigerant charge requirements in the

maintenance section of this manual to

ensure efficient machine operation.

When charging is complete, purge or

drain charging lines into an approved

refrigerant container. Seal all used

refrigerant containers with approved

closure devices to prevent unused

refrigerant from escaping to the atmosphere. Take extra care to properly

maintain all service equipment directly

supporting refrigerant service work such

as gauges, hoses, vacuum pumps, and

recycling equipment .

When cleaning system components or

parts, avoid using CFC-11 (R-11) or CFC113 (R-113). Use only cleaning-solvents

that do not have ozone depletion factors.

Properly dispose of used materials.

Refrigeration system cleanup methods

using filters and driers are preferred.

Check for leaks when excessive purge

operation is observed.

Keep abreast of unit enhancements,

conversion refrigerants, compatible

parts, and manufacturer’s recommendations that will reduce refrigerant emissions and increase equipment operating

efficiencies.

PKG-SVX14A-EN 5

Page 6

pre-installation

Pre-Installation Considerations

Pre-Installation Checklist

Complete the following checklist before

beginning unit installation.

Verify the unit size and tagging with the

unit nameplate.

Make certain the floor or foundation is

level, solid, and sufficient to support the

unit and accessory weights. Level or

repair the floor before positioning the

unit if neccesary.

Allow minimum recommended

clearances for routine maintenance and

service. Refer to unit submittals for

dimensions.

Allow three fan diameters above the

unit for the discharge ductwork. Return

air enters the rear of the unit and

conditioned supply air discharges

through the top.

Electrical connection knockouts are on

the top, left side of the unit.

Allow adequate space for piping

access and panel removal. Condenser

water piping, refrigerant piping, and

condensate drain connections are on

the lower left end panel.

Electrical supply power must meet

specific balance and voltage

requirements as described in the

“Electrical Requirements” section.

Water-cooled units only: The installer

is responsible for providing a condenser

main, standby water pump, cooling

tower, pressure gauges, strainers, and

all components for waterside piping.

See the “Water Piping” section for

general waterside recommendations.

Air-cooled units only: The installer is

responsible for providing and installing

the remote air-cooled condenser and

refrigerant piping, including filter driers.

Receiving and Handling

Shipping Package

Midrange units ship assembled on skids.

Units ship assembled, piped, and charged

with either R410a (model SCWH)

or a dry nitrogen charge (model SCRH).

Installation

Receiving Checklist

Complete the following checklist

immediately after receiving unit

shipment to detect possible shipping

damage.

Inspect individual cartons before

accepting. Check for rattles, bent carton

corners, or other visible indications of

shipping damage.

If a unit appears damaged, inspect it

immediately before accepting the

shipment. Make specific notations

concerning the damage on the freight

bill. Do not refuse delivery.

Inspect the unit for concealed damage

before it is stored and as soon as

possible after delivery. Report

concealed damage to the freight line

within the allotted time after delivery.

Check with the carrier for their allotted

time to submit a claim.

Do not move damaged material from

the receiving location. It is the receiver’s

responsibility to provide reasonable

evidence that concealed damage did

not occur after delivery.

Do not continue unpacking the

shipment if it appears damaged. Retain

all internal packing, cartons, and crate.

Take photos of damaged material if

possible.

Notify the carrier’s terminal of the

damage immediately by phone and

mail. Request an immediate joint

inspection of the damage by the carrier

and consignee.

Notify your Trane representative of

the damage and arrange for repair.

Have the carrier inspect the damage

before making any repairs to the unit.

Unit Storage

Take precautions to prevent condensate

from forming inside the electrical

compartments and motors if the unit is

stored before it is installed.

considerations

Service Access

Maintain adequate clearances around

and above the unit to ensure proper unit

operationa nd allow sufficient service

accesss. Trane recommends 36-inches

service access on all sides fo the unit.

Service access locations are shown in

figures on pages 8 through 9.

WARNING

Hazardous Voltage!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout

procedures to ensure power cannot

be inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious injury.

Installation Preparation

Before installing the unit, perform the

following procedures to ensure proper

unit operation.

1. Verify the floor or foundation is level.

Shim or repair as necessary. To ensure

proper unit operation, install the unit

level in both horizontal axes.

2. Allow adequate service and code

clearances as recommended in

“Service Access” section. Position the

unit and skid assembly in its final

location. Test lift the unit to determine

exact unit balance and stability before

hoisting it to the installation location.

See the “Proper Lifting Procedure”

section for proper rigging procedures

and cautions.

3. Remove the skids from under the unit.

If you find internal damage, file a claim

immediately to the delivering carrier.

4. Remove the protective shipping covers

from the unit.

5. Verify the compressor isolator shipping

brackets are removed and the isolators

are properly tightened for operation.

6 PKG-SVX14A-EN

Page 7

pre-installation

Service Access

3 through 7.5-ton SCRH/SCWH

Installation

LATCH

PROVIDED DISASSEMBLED

(FOR FIELD-INSTALLED REAR RETURN)

considerations

THIS PANEL GOES TO TOP ON

HORIZONTAL AIR DISCHARGE

CONFIGURATION

HEATER

ACCESS

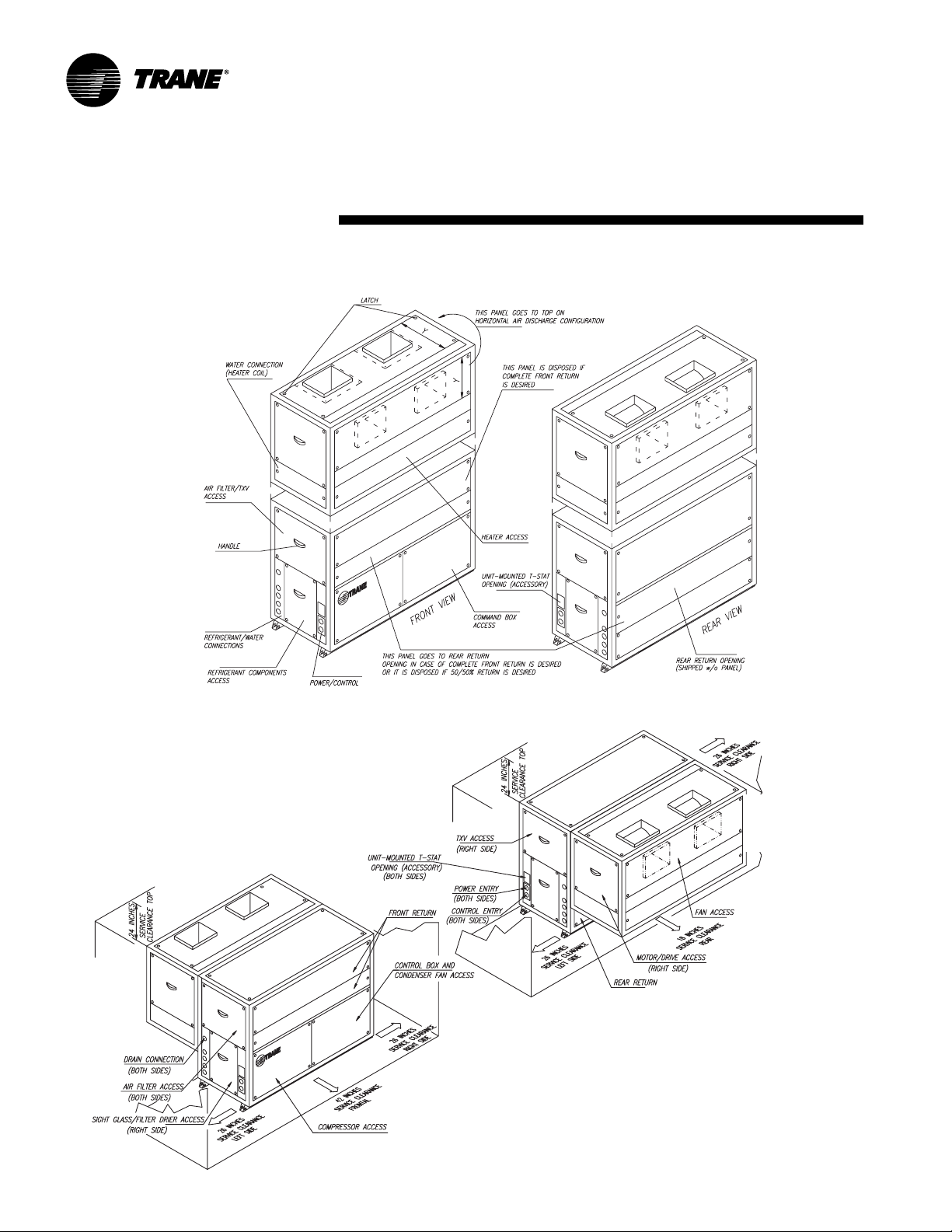

10 through 15-ton SCWH/SRCH with top-mounted fan configuration

FAN ACCESS

AIR FILTER ACCESS

(BOTH SIDES)

DRAIN CONNECTION

(BOTH SIDES)

24"

26" SERVICE CLEARANCE

LEFT SIDE

SIGHT GLASS/FILTER DRIER ACCESS

(RIGHT SIDE)

42" SERVICE CLEARANCE FRONT

COMPRESSOR ACCESS

COIL / ELECTRIC HEATER

ACCESS

FRONT RETURN

CONTROL BOX &

CONDENSER FAN ACCESS

26" SERVICE CLEARANCE

RIGHT SIDE

MOTOR / DRIVE ACCESS

(RIGHT SIDE)

TXV ACCESS

(RIGHT SIDE)

UNIT-MOUNTED T-STAT

OPENING (BOTH SIDES)

POWER ENTRY

(BOTH SIDES)

CONTROL ENTRY

(BOTH SIDES)

PKG-SVX14A-EN 7

24"

26" SERVICE CLEARANCE

LEFT SIDE

18" SERVICE CLEARANCE

REAR

REAR RETURN

26" SERVICE CLEARANCE

RIGHT SIDE

Page 8

pre-installation

Service Access

10 through 15-ton SCRH/SCWH

Installation

considerations

10, 12, & 15-ton SCWH/SRCH

with side-mounted fan configuration, field converted

8 PKG-SVX14A-EN

Page 9

pre-installation

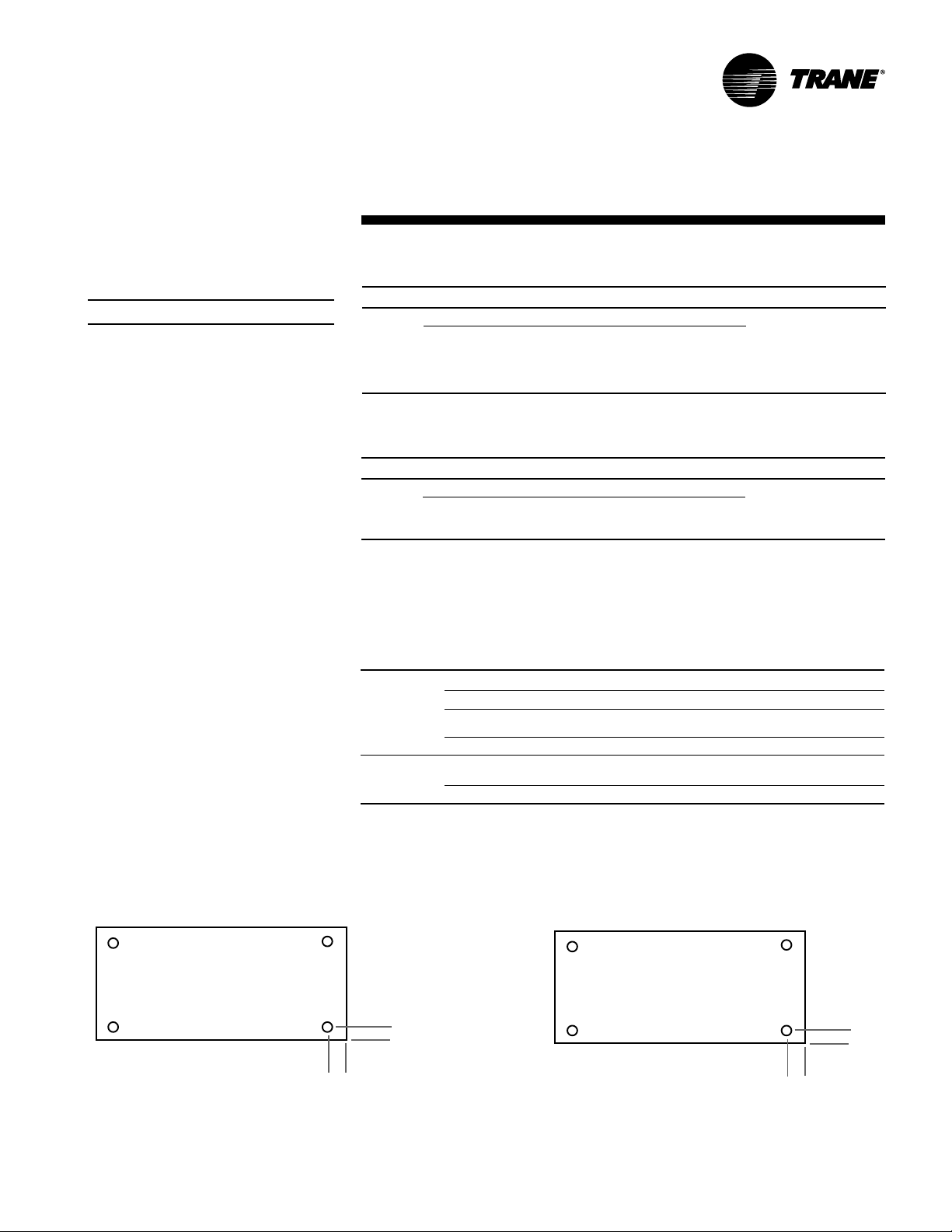

Isolator Placement

Note: Isolators are field-provided.

Installation

considerations

Table I-PC-1. Isolator load points, units with a vertical discharge configuration, lbs.

model L1 L2 L3 L4 L1 L 2 L3 L4

SCRB/SIRB SCWB/SIWB

3-ton 99 105 120 127 105 133 118 124

5-ton 115 122 157 166 129 165 166 165

7.5-ton 154 203 227 221 177 234 230 231

10-ton 208 266 273 253 263 334 293 300

15-ton 243 332 359 356 315 388 382 375

Table I-PC-2. Isolator load points, units with a horizontal discharge configuration, lbs.

model L1 L 2 L3 L4 L1 L 2 L 3 L 4

SCRB/SIRB SCWB/SIWB

7.5-ton 250 108 313 135 285 126 319 140

10-ton 318 150 363 169 383 211 383 211

15-ton 404 166 510 210 514 215 514 215

Table I-PC-3. Isolator load points & types, units with a horizontal discharge, inverted “L”

configuration, lbs.

10-ton unit 318 150 363 169 383 211 383 211

spring red yellow red yellow red yellow red yellow

rubber-in-shear green red green red green red green red

15-ton unit 404 166 510 210 514 215 514 215

spring purple yellow purple yellow purple yellow purple yellow

rubber-in-shear gray red gray red gray red gray red

Note: Units ship with two different color isolators and should be placed as depicted in this chart to properly support the

unit weight. See Figures I-PC-1 & I-PC-2 for correct isolator positions by unit size.

3, 5, & 7.5-ton units

bottom view of unit

L1

L2 L4

7

/8” dia. hole under all 4 corners

L3

1 7/

1 7/

8

Figure I-PC-1. Isolator mounting hole locations on 3, 5, &

7.5-ton units

air-cooled models water-cooled models

L1 L2 L3 L4 L1 L2 L3 L4

10 & 15-ton units

bottom view of unit

L1

8

L2 L4

9

/16” dia. hole under all 4 corners

Figure I-PC-2. Isolator mounting hole locations on 10 & 15ton units

L3

1 3/

8

3 3/

4

PKG-SVX14A-EN 9

Page 10

pre-installation

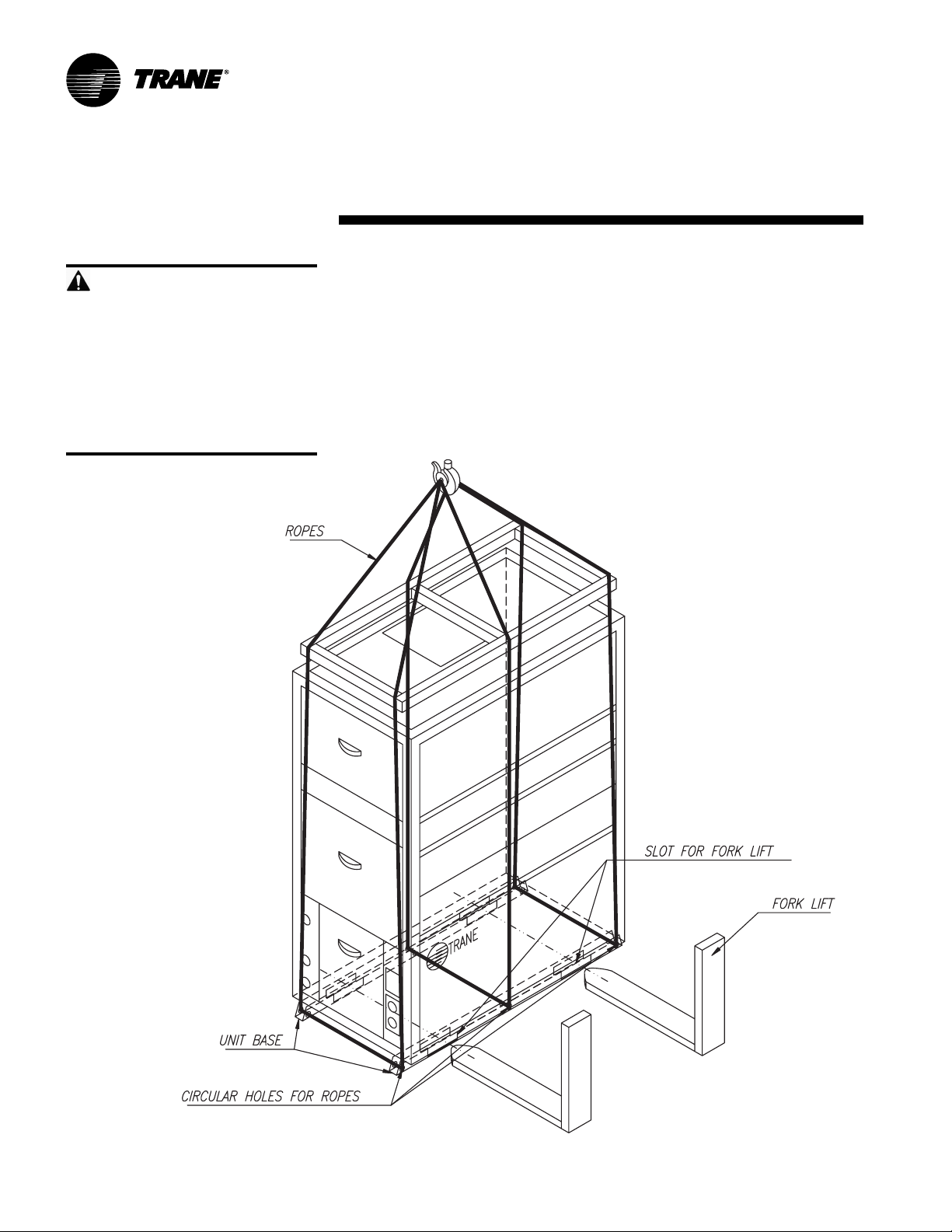

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches

high to verify the proper center-ofgravity lift point. To avoid dropping the

unit, reposition the lifting point if the

unit is not level. Failure to properly lift

the unit could result in death, serious

injury, or possible equipment/

property-only damage.

Installation

Proper Lifting Procedure

Follow these instructions and reference

Figure I-PC-3.

1. Slide a fork lift into the opening

provided on the unit base. Move the

fork lift carefully.

considerations

2. Using slings, attach through the circular

holes provided on the unit base. Protect

the unit from damage by rigging

equipment.

Figure I-PC-3. Proper unit lifting procedure

10 PKG-SVX14A-EN

Page 11

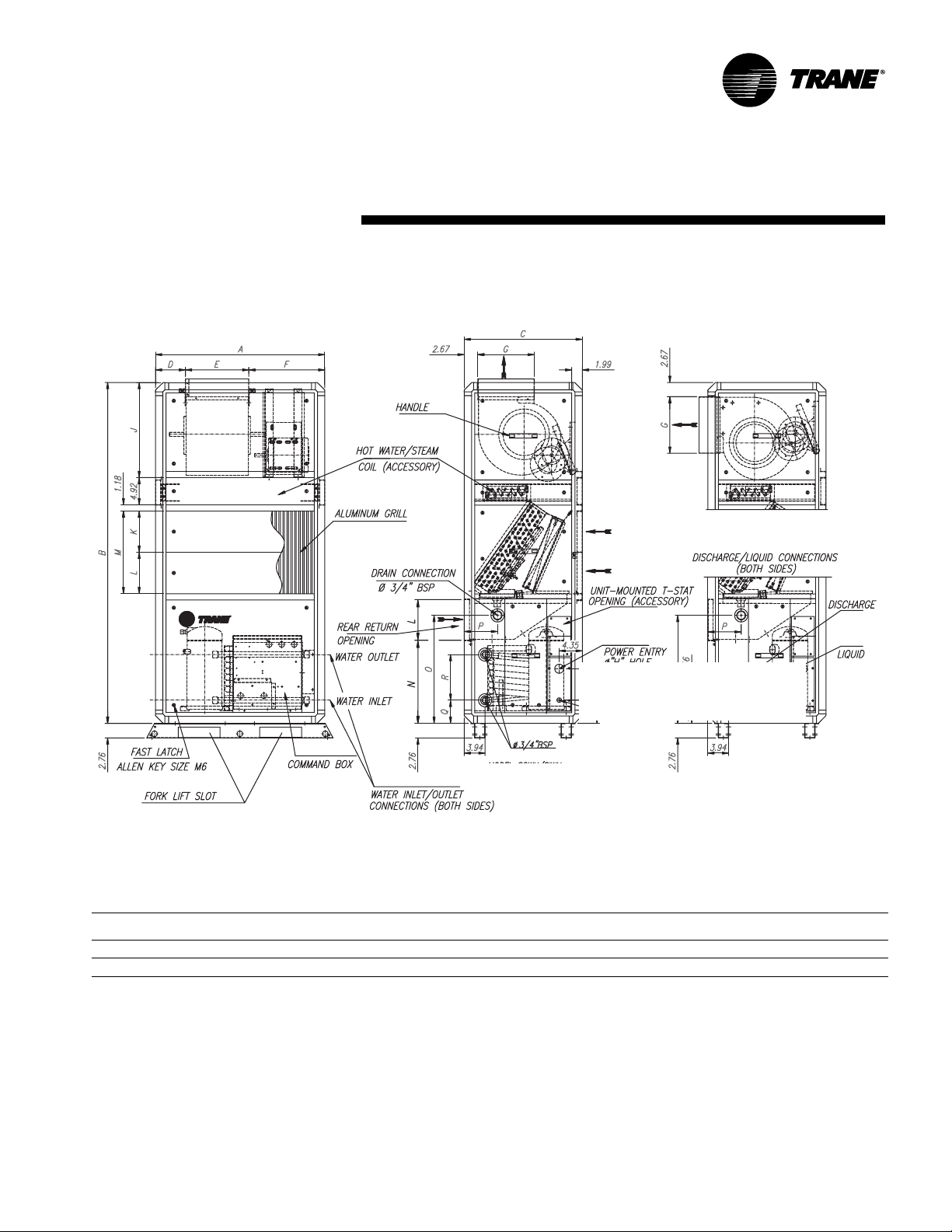

3 & 5-tons

SCWH/SCRH

vertical discharge

dimensions & weightsInstallation

horizontal discharge

(field converted)

SCRH

SCWH

SCWH/SCRH dimensions & weight, in-lbs.

unit shipping operating

size A B C D E F G J K L M N O P Q R S weight weight

3 31.89 64.17 22.24 5.65 11.93 14.31 10.63 18.00 7.80 7.80 15.60 15.63 20.20 6.28 4.33 8.58 4.37 494 459

5 36.41 75.98 24.01 7.73 13.03 15.65 11.61 20.31 12.32 8.66 20.98 18.58 24.20 7.10 5.43 6.38 7.12 592 555

PKG-SVX14A-EN 11

Page 12

dimensions &

7.5-tons

SCWH/SCRH

Installation

vertical discharge

weights

horizontal discharge

(field converted)

SCWH

SCWH/SCRH weight, lbs.

unit shipping operating

size weight weight

7.5 702 657

12 PKG-SVX14A-EN

SCRH

Page 13

10, 12, & 15-tons with top-mounted fan configuration

SCWH/SCRH

dimensions &

weightsInstallation

vertical discharge

horizontal discharge

(field converted)

SCWH

SCWH/SCRH dimensions & weight, in-lbs.

unit shipping operating

tons A B C D E F G J K M N weight weight

10 66.75 88.78 7.04 18.07 57.28 19.01 25.0 5.23 7.485/88.3 0 984 917

12 65.75 92.71 7.04 18.07 61.22 22.95 29.01 5.23 7.485/812.24 977 907

15 80.31 92.71 19.83 19.83 61.22 22.95 29.01 4.76 5.123/412.24 1098 1021

PKG-SVX14A-EN 13

SCRH

Page 14

10, 12, & 15-tons with side-mounted fan configuration, field converted

SCWH/SCRH

dimensions &

weightsInstallation

SCWH/SCRH Dimensions, in.

unit

tons A C D E F G

10 65.75 7.04 18.07 57.28 66.93 25.79

12 65.75 7.04 18.07 61.22 66.93 29.73

15 80.31 19.83 19.83 61.22 81.49 29.73

Notes:

1. Base rail must be attached to the floor before converting

unit to side-mounted fan configuration.

2. Coil or electric heater cannot be assembed inside the

cabinet with the side-mounted fan configuration.

14 PKG-SVX14A-EN

Page 15

Plenum

Hot water coil

3 & 5-ton units

5.91

dimensions &

weightsInstallation

Plenum dimensions & weight, in-lbs.

unit size A B weight

3-ton 31.89 22.24 44

5-ton 36.41 24.01 54

7.5-ton 40.94 28.74 73

10 & 12-ton 65.75 29.52 120

15-ton 80.31 29.52 146

A

B

1.57

0.59

3.15

1.38

D

G

1.38

1.0 NPT

F

0.28

E

0.75

0.39

0.59

1.03

0.39

C

0.75

5.9

2.18

8.39

2.18

1.03

1.08

SCWH/SCRH Hot water coil dimensions & weights, 3 & 5-ton units, in-lbs.

size A B C D E F G weight

3-ton 26.46 18.98 25.67 5.79 5.79 10.00 12.76 13

5-ton 30.98 23.50 30.20 7.040 7.040 12.50 15.26 18

PKG-SVX14A-EN 15

Page 16

dimensions &

weightsInstallation

Hot water coil

7.5-ton units

0.75

17.00

0.75

Hot water coil

10 thru 15-ton units

1.38

1.0 NPT

0.39

1.38

0.43

2.22

16.25

2.22

20.7

0.39

35.51

28.035.91

34.72

0.75

5.9

SCWH/SCRH Hot water coil dimensions & weights, in-lbs.

size A B C D weight

7.5-ton - - - - 24

10-ton 58.72 50.98 6.95 59.51 49

12-ton 58.72 50.98 6.95 59.51 49

15-ton 73.29 63.98 8.52 74.07 55

A

0.75

1.57

0.39

0.39

0.599.54

1.87

0.28

1.87

1.03

1.08

1.03

0.39

8.48

8.48

0.39

1.03

3.15

1.55

14.64

1.55

3.03

1.03

1.08

2.18

20.26

1.38

0.43

1.00 NPT

17.50

8.27

0.28

9.54

0.59

7.48

C

0.75

5.90

B

D

BLOCKOFF (SHIPS DISASSEMBLED)

1.57

0.75

15.89

2.18

9.07

3.19

16 PKG-SVX14A-EN

Page 17

mechanical

Duct Connections

Install all air ducts according to the

National Fire Protection Association

standards for the “Installation of Air

Conditioning and Ventilation Systems

other than Residence Type (NFPA 90A)

and Residence Type Warm Air Heating

and Air Conditioning Systems (NFPA

90B).

Make duct connections to the unit with a

flexible material such as heavy canvas. If

a fire hazard exists, Trane recommends

using Flexweave 1000, type FW30 or

equivalent canvas. Use three inches for

the return duct and three inches for the

discharge duct. Keep the material loose

to absorb fan vibration.

Run the ductwork straight from the

opening for a minimum of three fan

diameters. Do not make abrupt turns or

transitions near the unit due to increased

noise and excessive static losses. Use

elbows with splitters or turning vanes to

minimize static losses.

Poorly constructed turning vanes may

cause airflow generated noise. Check

total external static pressures against fan

characteristics to be sure the required

airflow is available throughout the

ductwork.

WARNING

Hazardous Voltage!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to disconnect power before

servicing could result in death or

serious injury.

Installation

Water Piping

Condenser Connections

Note: To prevent water damage, install

piping drain and vent plugs.

Condenser water piping knockouts are in

the lower left end panel. If necessary,

remove insulation to gain access. All field

installed piping must conform to

applicable local, state, and federal codes.

To complete condenser water

connections follow the procedure below.

1. Remove back panel to access the

water connection fittings.

2. Attach the water supply line to the inlet

connection, and the return line to the

outlet connection. The water connection

fittings are copper, so exercise extreme

care when connecting steel piping to

copper fittings.

3. Ensure that water piping is aligned to

the unit connection fittings. Failure to

align piping could cause stripped

threads, leakage, and possible unit

failure.

4. Connection to the unit water piping

requires a backing wrench to prevent

distortion of connecting tubing. Apply

backing wrench to water connection

points on unit.

Condensate Drain Connections

Install a water regulating valve in the

water supply line to maintainhead

pressure when operating with city water

of varying temperature.

These units require a minimum water

pressure of 15 psig and will operate at a

maximum of 400 psig.

Provide safeguards against cold weather

drain line freeze.

requirements

Cooling Tower Piping

Cooling tower control affects the unit

cycle rates. Condenser water

temperature swings from 10-15°F may

cause excessive compressor, water

valve, and unit cycling. Be sure to set the

tower controls to minimize compressor/

unit cycling.

The cooling tower system requires a

separate drain in the water supply line for

service and repair.

Water Temperature Requirements

Install a water regulating valve in the

water supply line to maintain head

pressure when operating with water of

varying temperature. The valve

modulates condenser water flow to

control condensing pressure. The valve

opens or closes in response to

compressor discharge pressure as

sensed by its capillary line connection iin

the liquid line shrader valve. When the

valve is properly installed, water flow

automatically decreases as discharge

pressure falls and increases as discharge

pressure rises. Field installation of the

water regulating valve assembly

requires one valve for each refrigeration

circuit.

PKG-SVX14A-EN 17

Page 18

mechanical

requirementsInstallation

Refrigerant Piping (Air-Cooled

Units Only)

Reference industry recommendations

for air-cooled unit refrigerant piping. If

suspending piping from the building, use

isolation hangers to prevent vibration

transmission.

Air-cooled units ship with a holding

charge of nitrogen. Before installing unit

piping, momentarily depress either the

suction or discharge line access valve to

verify that the holding charge has not

been lost. If nitrogen does not escape

when depressing the access valve, leaktest the entire refrigerant system to

determine the source of loss.

The charge is contained by a continuous

loop of both hot gas and liquid lines. You

must cut the loop for connection to

discharge and liquid lines. See Figure IMR-1.

WARNING:

Hazard of Explosion and Deadly

Gases!

Never solder, braze or weld on

refrigerant lines or any unit components that are above atmospheric pressure or where

refrigerant may be present.

Always remove refrigerant by following the guidelines established by the EPA Federal Clean

Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry nitrogen to

bring system back to atmospheric

pressure before opening system

for repairs. Mixtures of refrigerants and air under pressure may

become combustible in the presence of an ignition source leading

to an explosion. Excessive heat

from soldering, brazing or welding with refrigerant vapors

present can form highly toxic

gases and extremely corrosive

acids. Failure to follow all proper

safe refrigerant handling practices could result in death or serious injury.

Brazing Procedures

Proper brazing techniques are essential

when installing refrigerant piping. Keep

the following factors in mind when

making sweat connections.

1. When heating copper in the presence

of air, copper oxide forms. To prevent

copper oxide from forming inside the

tubing during brazing, sweep an inert

gas, such as dry nitrogen, through the

tubing. Nitrogen displaces air in the

tubing and prevents oxidation of

interior surfaces. A nitrogen flow of one

to three cubic feet per minute is

sufficient to displace the air. Use a

pressure regulating valve or flow meter

to control the flow.

2. Ensure tubing surfaces that require

brazing are clean and the ends of the

tubes are carefully reamed to remove

any burrs.

3. Make sure the inner and outer tubes of

the joint are symmetrical and have a

close clearance, providing an easy slip

fit. If the joint is too loose, the tensile

strength of the connection will be

significantly reduced. Make the overlap

distance equal to the inner tube

diameter.

4. Wrap the body of each refrigerant line

component with a wet cloth to keep it

cool during brazing. Excessive heat can

damage the components.

5. If using flux, apply it sparingly to the

joint. Excess flux will contaminate the

refrigerant system.

6. Apply heat evenly over the length and

circumference of the joint, making sure

the entire joint becomes hot enough to

melt the brazing material.

Figure I-MR-1. Air-cooled unit refrigerant piping

7. Begin brazing when the joint is hot

enough to melt the brazing rod. The hot

copper tubing, not the flame, should

melt the rod.

8. Continue to apply heat around the joint

circumference until the brazing material

is drawn into the joint by capillary

action, making a mechanically sound

and gas-tight connection.

9. Visually inspect the connection after

brazing to locate any pin holes or

crevices in the joint. Use a mirror to

inspect connections that are difficult to

see.

Electrical Requirements

Follow these guidelines, referring to unit

wiring diagrams and supply power

dimensional information to ensure

correct electrical requirements at the

installation site. Reference supply power

wiring locations on unit submittals orin

the “Dimensions and Weights” section.

Specific unit wiring diagrams are

provided on each unit. Use these

diagrams for connections or trouble

analysis.

Unit Wiring Diagrams

Specific unit wiring diagrams are

provided on the inside of the control

panel door. Use these diagrams for

connections or trouble analysis.

18 PKG-SVX14A-EN

Page 19

electrical requirementsInstallation

Supply Power Wiring

It is the installer’s responsibility to provide

power supply wiring to the unit terminal

block or the non-fused disconnect switch

option. Wiring should conform to NEC and

all applicable code requirements.

1. Verify the power supply available is

compatible with the unit nameplate

ratings. The supply power must be

within 10%of the rated voltage listed on

the unit nameplate.

2. Reference the electrical data in Table IER-1. Protect the electrical service from

over current and short circuit

conditions in accordance with NEC

requirements. Size protection devices

according to the electrical data on the

unit nameplate.

3. If using a field-supplied disconnect,

install it at or near the unit in

accordance with NEC. Do not mount a

field-supplied disconnect on the unit.

Reference the electrical service

entrance location on unit submittals.

4. Complete the unit power wiring

connections onto either the main

terminal block or the field-provided nonfushed disconnect switch.

WARNING

Ground Wire!

All field-installed wiring must be

completed by qualified personnel.

All field-installed wiring must

comply with NEC and applicable

local codes. Failure to follow this

instruction could result in death

or serious injuries.

WARNING

Grounding Required!

Follow proper local and state electrical code on requirements for

grounding. Failure to follow code

could result in death or serious injury.

5. Provide proper unit grounding in

accordance with local and national

codes.

Electrical Data Calculations

RLA = rated load amps

Compressor LRA = locked rotor amps

Fan motor LRA = locked rotor amps,

N.E.C. Table 430 - 151

FLA = Full load amps, N.E.C.

Table 430 - 150

Voltage utilization range is ±10%

Minimum circuit ampacity (MCA)

= 1.25 x largest motor amps (FLA or

RLA) + the sum of the remaining motor

amps.

Maximum fuse size (MFS) and maximum

circuit breaker size (MCB) = 2.25 x largest

motor amps (FLA or RLA) + the sum of

the remaining motor amps.

Note: If the rating value determined does

not equal a standard current rating of

over current protective device, use the

next lower standard rating for the

marked maximum rating.

Voltage Range

Voltages must be within +- 10% the

nameplate voltage. Ensure the unit

voltage is balanced by measuring at the

compressor terminals. Voltage imbalance

on three phase systems can cause motor

overheating and premature failure.

Maximum allowable imbalance is 2.0%.

Voltage Imbalance

Read the voltage at the compressor

terminals to determine if it is balanced.

Voltage imbalance on three phase

systems can cause motor overheating

and premature failure. The maximum

allowable imbalance is 2.0%. Voltage

imbalance is defined as 100 times the

sum of the deviation of the three voltages

from the average (without regard to sign)

divided by the average voltage. For

example, if the three measured voltages

are 221, 230, and 227, the average

voltage would be:

(221 + 230 + 227) = 226 volts

The percentage of voltage imbalance is

then:

3

(226-221) = 2.2%

100 *

226

In this example, 2.2% imbalance is not

acceptable. Whenever a voltage

imbalance of more than 2.0% exists,

check the voltage at the unit disconnect

switch. If the imbalance at the unit

disconnect switch does not exceed 2.0%,

faulty unit wiring is causing the

imbalance. Conduct a thorough

inspection of the unit electrical wiring

connections to locate the fault, and make

any repairs necessary.

WARNING

Live Electrical Components!

During installation, testing, servicing,

and troubleshooting this equipment, it

may be necessary to work with live

electrical components. Have a

qualified licensed electrician or other

individual who is properly trained in

handling live electrical components

perform these tasks. Failure to follow

all electrical safety precautions when

exposed to live electrical components

could result in death or serious injury.

WARNING

Hazardous Voltage!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to disconnect power before

servicing could result in death or

serious injury.

CAUTION

Use Copper Conductors Only!

Unit terminals are not designed to

accept other type conductors. Failure

to use copper conductors may result

in equipment damage.

PKG-SVX14A-EN 19

Page 20

electrical

p

y

p

y

Installation

requirements

Table I-ER-1. Model SCWH/SCRH electrical data

evaporator standard motor evaporator oversized motor

tons MFS / MCBmodel voltage

SC*H0303.... 208-230V/60Hz/3Ph 12.9 77.0

SC*H0304.... 460V/60Hz/3Ph 5.7 35.0 1.00 8.1 15 1.42 8.5 15

SC*H0305.... 575V/60Hz/3Ph 4.8 31.0 0.80 6.8 15 1.14 7.1 15

SC*H0503.... 208-230V/60Hz/3Ph 22.9 155.0 5.00 33.6 50 5.81 34.4 50

SC*H0504.... 460V/60Hz/3Ph 10.7 75.0 2.50 15.9 25 2.63 16.0 25

SC*H0505.... 575V/60Hz/3Ph 8.5 54.0 1.50 12.1 20 2.10 12.7 20

SC*H0753.... 208-230V/60Hz/3Ph 27.9 164.0 6.30 41.2 60 5.81 40.7 60

SC*H0754.... 460V/60Hz/3Ph 13.6 100.0 3.10 20.1 30 2.63 19.6 30

SC*H0755.... 575V/60Hz/3Ph 10.2 78.0 2.40 15.2 25 2.10 14.9 25

SC*H1003.... 208-230V/60Hz/3Ph 22.9 155.0 6.30 57.8 80 13.70 65.2 80

SC*H1004.... 460V/60Hz/3Ph 10.7 75.0 3.10 27.2 35 6.18 30.3 40

SC*H1005.... 575V/60Hz/3Ph 8.5 54.0 2.40 21.5 30 4.94 24.1 30

SC*H1203.... 208-230V/60Hz/3Ph 25.4 147.7 9.40 66.5 90 13.70 70.8 90

SC*H1204.... 460V/60Hz/3Ph 11.8 75.0 4.60 31.2 40 6.18 32.7 45

SC*H1205.... 575V/60Hz/3Ph 9.3 59.6 3.40 24.4 30 4.94 25.9 35

SC*H1503.... 208-230V/60Hz/3Ph 27.9 164.0 9.40 72.2 100 13.70 76.5 100

SC*H1504.... 460V/60Hz/3Ph 13.6 100.0 4.60 35.2 45 6.18 36.8 50

SC*H1505.... 575V/60Hz/3Ph 10.9 78.0 3.40 27.9 35 4.94 29.5 35

Notes:

1. Voltage range:

Nominal voltage 208 - 230V - acceptable range: 187 - 253V

Nominal voltage 460V - acceptable range: 414 - 506V

Nominal voltage 575V - acceptable range: 518 - 633V

2. Ampacity is calculated per UL formula, ampacity = (1.25 x compressor RLA + sum of the second compressor RLA (if

used) + evaporator motor FLA

3. Maximum fuse size is calculated per UL formula, MFS = (2.25 x compressor RLA) + sum of second compressor RLA (if

used) + evaporator motor FLA

31 11

5111

7.5 1 2 1

10 2 2 1

12 2

15 2 3 1

compressor evap. fan motor

RLA LRA qty. hp FLA qty. hp FLA qty

0.5

2.21

31 51

min. circuit

am

acit

1

18.3 30 3.15 19.3 30

Hazardous Voltage!

Disconnect all electric power,

evap. fan motor

21

21

51

51

min. circuit

am

WARNING

MFS /

acit

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to disconnect power before

servicing could result in death or

serious injury.

MCB

CAUTION

Use Copper Conductors Only!

Unit terminals are not designed to

accept other type conductors. Failure

to use copper conductors may result

in equipment damage.

20 PKG-SVX14A-EN

Page 21

installation

Installation Checklist

Reference the checklist below to verify all

steps required to successfully install a

deluxe self-contained unit are complete.

This checklist is intended to acquaint the

installing personnel with what is required

in the installation process. It does not

replace the detailed instructions detailed

in the applicable sections of this manual.

WARNING

Hazardous voltage!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout procedures

to ensure the power can not be

inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious

injury.

General Unit Requirements

Install and secure the ductwork to the

unit.

Check unit for shipping damage and

material shortage. Refer to the

Receiving Checklist.

Electrical Requirements

Verify that the electrical power supply

characteristics comply with the unit

nameplate specifications.

Inspect all control components; tighten

any loose connections.

Connect properly sized and protected

power supply wiring to a field supplied/

installed disconnect and unit power

terminal block, or to the optional unit

mounted disconnect switch.

Properly ground the unit.

Installation

Field Installed Control Wiring (Optional)

Complete the field wiring connections.

Note: All field installed wiring must

comply with NEC and applicable local

codes.

Fan Discharge Conversion

Complete the steps below to convert the

fan discharge from vertical to horizontal.

1. Remove all mid and top fan section

panels.

2. Loosen the brackets inside the unit that

clamp the mid and fan sections

together.

3. Remove the control box cover and

disconnect the motor power wires.

Feed wires up through the unit and

secure out of the way until rotation is

complete.

4. Rotate the fan section to desired

position.

5. Re-route the motor power wires back

to the control box. Ensure all wiring is

free and not routed over any sharp

edges.

procedure

6. Reconnect the motor power wires per

the unit wiring diagram.

7. Bolt and/or clamp all brackets back into

place.

8. Replace control box cover and all

exterior panels.

9. Verify the fan rotation and motor amp

draw.

Plenum Installation

1. Uncrate the plenum and accessory

bag.

2. Rotate the evaporator blower to the

vertical discharge configuration.

3. Apply the soft gasket provided around

the aluminum frame on top of the unit

as shown in Figure I-IP-1.

4. Using a screwdriver, tighten the selfdrilling screws as shown in Figure I-IP-

1. Be sure to tighten all screws on the

rear, right, and left sides through the

pilot holes on the plenum panels.

5. When installation is complete, adjust

the motor pulley and the discharge

grille for proper airflow.

Figure I-IP-1. Plenum installation

PKG-SVX14A-EN 21

Page 22

pre-startup

Installation

Pre-Startup Checklist

Complete this checklist after installing the

unit to verify all recommended

installation procedures are complete

before unit startup. This does not replace

the detailed instructions in the

appropriate sections of this manual.

Always read the entire section carefully

to become familiar with the procedures.

WARNING

Hazardous Voltage!

Disconnect all electrical power,

including remote disconnects before

servicing. Follow proper lockout/tagout

procedures to ensure power cannot be

inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious injury.

Receiving

Inspect unit and components for

shipping damage. File damage claims

immediately with the delivering carrier.

Check nameplate unit data so that it

matches the sales order requirements.

Check unit for missing material. Look

for ship-with accessories that are

packaged separately and placed inside

the access panel, fan section, or

compressor section. See the

“Receiving and Handling” section.

requirements

Unit Location

Ensure the unit location is adequate for

unit dimensions, ductwork, piping, and

electrical connections.

Ensure access and maintenance

clearances around the unit are

adequate. See the “Service Access”

section.

Unit Mounting

Remove shipping brackets on the

compressor assembly and supply fan.

Component Overview

Verify the fan and motor sheaves are

aligned.

Check the belt tension for proper

adjustment.

Ensure the fan rotates freely.

Tighten locking screws, bearing set

screws and sheaves.

Ensure bearing locking collars do not

wobble when rotated.

Ensure all air filters are properly

installed with consideration of size and

air flow.

Manually rotate the evaporator fan to

ensure free movement. Verify that all of

the fan mounting hardware is tight.

Ductwork

Verify that all ductwork conforms to

NFPA 90A or 90B and all applicable

local codes.

22 PKG-SVX14A-EN

Page 23

Installation

startup

Unit Startup Procedures

1. Check all electrical connections for

tightness.

2. Be sure all unit accessories are

properly set and installed.

3. Model SCWH: Verify condenser

water piping is properly connected,

supply, and return.

4. Model SCRH: Verify refrigerant

piping is properly connected, hot gas,

and liquid.

5. Inspect all ductwork and duct

connections.

6. Check for proper belt tension.

7. Check fan drive sheaves, pulleys, and

bearings.

Unit Startup Checklist

1. Turn the thermostat to the OFF

position.

2. Engage power supply by closing

power disconnect.

3. Switch thermostat to fan position and

adjust temperature setting below room

temperature. Evaporator fan should

start.

4. Check evaporator section for proper

operation.

5. Switch thermostat to cool position and

adjust temperature setting to below

room temperature. The evaporator fan

and compressor(s) should start.

7. Allow unit to run until all system

temperatures and pressures stabilize.

WARNING

Hazardous Service Procedures !

The maintenance and troubleshooting procedures recommended in this section of the

manual could result in exposure to

electrical, mechanical or other potential safety hazards. Always refer

to the safety warnings provided

throughout this manual concerning

these procedures. When possible,

disconnect all electrical power including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure the

power can not be inadvertently energized. When necessary to work

with live electrical components,

have a qualified licensed electrician or other individual who has

been trained in handling live electrical components perform these

tasks. Failure to follow all of the

recommended safety warnings

provided, could result in death or

serious injury.

Note: These units are equipped with high

efficiency scroll compressors. Check for

proper scroll rotation prior to operating

unit.

WARNING

Hazardous voltage!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout procedures

to ensure the power can not be

inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious

injury.

6. Check the evaporator fan for proper

rotation. If fan rotation is incorrect,

switch thermostat to Off position and

disconnect power. Reverse two phase

leads at disconnect and return back to

Step 1 of startup.

PKG-SVX14A-EN 23

WARNING

Rotating Components!

During installation, testing, servicing

and troubleshooting of this product it

may be necessary to measure the

speed of rotating components. Have a

qualified or licensed service individual

who has been properly trained in

handling exposed rotating

components, perform these tasks.

Failure to follow all safety precautions

when exposed to rotating

components could result in death or

serious injury.

8. Check systems for proper operation

and performance. Observe unit in

operation and check for unusual noise,

vibration, belt, and fan clearances.

Page 24

sequence of

Operation

Sequence of Operation

The thermostat controls the unit

operation. It has both manual and

automatic switches so the thermostat

maintains desired comfort levels.

The fan switch allows manual selection of

the fan speed using the On or Auto

setting. With the switch set in the On

position, the evaporator fan runs

continously, independent from the

thermostat temperature setting. The

Auto position cycles the evaporator fan

on and off with the demand for heating or

cooling.

The system switch may have two or

more positions. For example, using a

cooling only thermostat, the system

switch can be set in the Off or the Cool

position. The Off position disconnects

power from the thermostat contacts that

control the condensing unit. This prevents

operation

the condensing unit from running,

regardless of the thermostat temperature setting. The evaporator fan may

circulate air if the fan switch is in the On

position. With the switch in the Cool

position, the condensing unit and evaporator will operate on a signal from the

thermostat calling for cooling.

With the fan switch set to Auto and the

system switch set to Cool, the following

sequence takes place. On a rise in room

temperature,t he thermostat contacts

close to provide power to the evaporator

fan contactor,t he condensing unit fan

contactor,a nd the condensingunit

compressor contactors. As the room

temperature reaches setpoing, the

thermostat contacts open to de-energize

all contactors,a nd the system cycles off.

This system will remain off until additional

cooling is required and the cycle repeats.

24 PKG-SVX14A-EN

Page 25

general

Maintenance

Table M-GI-1. Midrange maintenance general data

SCWH030 SCWH050 SCWH075 SCWH100 SCWH120 SCWH150

dimensions, in-lbs.

height 66.93 78.74 78.94 91.54 95.47 95.47

length 31.89 36.41 40.94 65.75 65.75 80.31

depth 22.24 24.01 28.74 29.52 29.52 29.52

weight (shipping / net) 494 / 459 592 / 555 702 / 657 1094 / 1027 1133 / 1063 1249 / 1172

cooling performance

net cooling capacity, btu/h 36000 65290 87570 116986 138204 167303

EER 12.13 12.28 11.6 11.5 11.1 11.3

nominal air flow, cfm 1200 2000 3000 4000 4800 6000

system power, kW 3.0 5.3 7.6 10.2 12.5 14.8

Copeland scroll compressor

quantity 1 1 1 2 2 2

model ZP32 ZP57 ZP83 ZP57 ZP67 ZP83

indoor coil, 3/8" tube size

face area, sq. ft. 3.19 4.98 7.13 12.12 12.12 14.56

rows / fpf 4 / 144 4 / 144 3 / 168 2 / 168 2 / 168 3 / 168

water condenser, tube & tube

water connection, in. 3/4 NPT 3/4 NPT 3/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT

indoor fan, belt-driven

quantity 1 1 2 2 2 2

diameter x width 9 x 9 10 x 10 9 x 9 12 x 12 12 x 12 12 x 12

motor 1 / 0.5 1 / 1.0 1 / 2.0 1 / 2.0 1 / 3.0 1 / 3.0

motor frame size 56 56 56 56 56 56

air filter, 1" throwaway

size / (quantity), in. 14 x 25 (1)

refrigerant, R-410A, TXV control

refrigerant charge (Ckt 1 / 2), lbs. 3.8 5.4 7.8 5.1 / 5.2 6.5/6.3 7.2/7.2

hot water coil, 2-row, 108 fpf, 1/2" tubes

face area, sq. ft. 1.42 2.08 3.27 6.2 6.2 7.78

14 x 20 (1) +

20 x 20 (1)

18 x 24 (2)

information

12 x 24 (1) + 24 x 24 (2)

18 x 24 (3) +

24 x 24 (1)

Notes:

1. Net cooling capacity is rated at 95°F ambient, 80°F entering dry bulb and 67°F entering wet bulb @ SCFM air condition.

2. EER is rated at ARI condition.

PKG-SVX14A-EN 25

Page 26

maintenance

Maintenance Procedures

This section describes specific

maintenance procedures that must be

preformed as a part of the normal

maintenance program. Always

disconnect electrical power to the unit

before performing these procedures and

heed all warnings and cautions.

WARNING

Live Electrical Components!

During installation, testing, servicing,

and troubleshooting this equipment, it

may be necessary to work with live

electrical components. Have a

qualified licensed electrician or other

individual who is properly trained in

handling live electrical components

perform these tasks. Failure to follow

all electrical components could result

in death or serious injury.

WARNING

Hazardous Voltage!

Disconnect all electrical power including

remote disconnects before servicing

unit. Follow proper lockout/tagout

procedures to ensure power cannot be

inadvertently energized. Failure to

disconnect power before servicing can

result in death or serious injury.

Periodic Maintenance Checklist

Inspect coil surface for cleanliness.

Clean as required, referring to the “Coil

Cleaning” section.

Annual Maintenance Checklist

Perform all monthly maintenance

inspections.

Perform seasonal startup checks.

Leak test refrigerant circuits. Inspect

contacts of fan motor contactors and

relays. Replace all worn contacts.

Clean and repaint any corroded

surface.

Maintenance

Note: the following coil cleaning procedures apply only to the outdoor condensers. Do not use these procedures for the

reheat or evaporator coils.

Cleaning the Condenser Coils

Clean the coil at least once each year or

more frequently if located in a dirty

environment, to help maintain proper unit

operating efficiency. High discharge

pressures are a good indication that the

coil needs cleaning. Follow the detergent

manufacturer instructions as closely as

possible to avoid potential coil damage.

WARNING

Hazardous Chemicals!

Coil cleaning agents can be either acidic

or highly alkaline.Handle chemical

carefully. Proper handling should

include goggles or face shield, chemical

resistant gloves, boots, apron, or

protective suit as required. For personal

safety, refer to the cleaning agent

manufacturer’s materials safety data

sheet and follow all recommended safe

handling practices. Failure to follow all

safety instructions could result in death

or serious injury.

To clean the refrigerant coil, use a soft

brush and sprayer, such as a garden

pump up or high pressure type . In

addition, use a quality detergent; like

“SPREX AC’, “ OAKITE 161” or “OAKITE

166” and “COILOX.”

Note: If detergent is strongly alkaline (i.e.

has a pH value greater that 8.5 ) after

mixing, you must add an aluminum

corrosion inhibitor.

WARNING

Hazardous Voltage!

Disconnect all electrical power including

remote disconnects before servicing

unit. Follow proper lockout/tagout

procedures to ensure power cannot be

inadvertently energized. Failure to

disconnect power before servicing can

result in death or serious injury.

procedures

Coil Cleaning Procedure

1. Disconnect power to the unit.

2. Remove panels from the unit to gain

access to the coil.

3. Use a soft brush to remove loose dirt

and debris form both sides of the coil.

4. Straighten coil fins with fin comb as

required.

5. Mix the detergent with water

according to the manufacturers

instructions.

Observe all recommendations of the

cleanser manufacturer. The coil cleanser

manufacturer’s recommendations,

warnings and cautions will at all times

take precedence to these instructions.

1. Place solution in the sprayer. Be sure to

follow these guidelines if using a highpressure sprayer:

a) Keep minimum nozzle spray angle 15°.

b) Spray solution at a 90° angle to the coil

face.

c) Keep sprayer nozzle at least six inches

from the coil.

d) Sprayer pressure must not exceed

600 psi.

2. Spray leaving air side of the coil first

then spray the entering air side of the

coil. Allow the detergent and water

solution to stand on the coil for five

minutes.

3. Rinse both sides of the coil with cool,

clean water.

4. Inspect the coil. If it still appears dirty,

repeat the cleaning procedure.

5. Reinstall all unit components and

panels, and restore electrical power

and gas supply to the unit.

CAUTION

Freezing Temperatures!

Do not allow liquid refrigerant to come

into contact with the skin. If it does,

treat the injury similar to frostbite.

Slowly warm the ffected area with

lukewarm water and seek immediate

medical attention. Direct contact with

liquid refrigerant may cause minor or

moderate injury.

26 PKG-SVX14A-EN

Page 27

maintenance

Refrigerant System

Special Note on Refrigerant Emissions

Follow the Trane recommended

procedures on operation, maintenance,

and service to ensure refrigerant

conservation and emission reduction.

Also, pay specific attention to the

following:

• Whenever removing refrigerant from

equipment, recover for reuse, recycle,

reprocess (reclaim), or properly destroy

it.

• Always determine possible refrigerant

recycling or reclaiming requirements

before beginning recovery. Questions

about recovered refrigerants and

acceptable refrigerant quality

standards are addressed in ARI

Standard 700.

• Use approved containment vessels and

safety standards. Comply with all

applicable transportation standards

when shipping refrigerant containers.

• To minimize emissions while recovering

refrigerant, use recycling equipment.

Always attempt to use methods that

pull the lowest possible system vacuum

while recovering and condensing

refrigerant into containment.

• When leak checking with trace

refrigerant and nitrogen, use HCFC22

(R22) rather than CFC12 (R12) or any

other fully halogenated refrigerants. Be

aware of any new leak test methods

that eliminate refrigerant as a trace gas.

• When cleaning system components or

parts, do not use CFC11 (R11) or

CFC113 (R113). Refrigeration system

clean up methods using filters and

dryers are recommended. Do not use

solvents that have ozone depletion

factors. Properly dispose of used

materials.

• Take extra care to properly maintain all

service equipment directly supporting

refrigerant service work such as

gauges, hoses, vacuum pumps, and

recycling equipment.

• Stay aware of unit enhancements,

conversion refrigerants, compatible

parts, and manufacturer’s

recommendations that reduce

refrigerant emissions and increase

equipment operating efficiencies.

Follow specific manufacturer’s

guidelines for conversion of existing

systems.

Maintenance

• To assist in reducing power generation

emissions, always attempt to improve

equipment performance with improved

maintenance and operations that will

help conserve energy resources.

WARNING

Confined Space Hazards!

Do not work in confined spaces where

sufficient quantities of refrigerant or

other hazardous, toxic, or flammable

gas may be leaking. Refrigerant or

other gases could displace available

oxygen to breathe, causing possible

asphyxiation or other serious health

risks. Some gases may be flammable

and or explosive. Evacuate the area

immediately and contact the proper

rescue or response authority. Failure

to take appropriate precautions or to

react properly to a potential hazard

could result in death or serious injury.

WARNING

Hazard of Explosion!

Use only dry nitrogen with a pressure

regulator to pressurize the unit. Do not

use acetylene, oxygen, compressed

air, or mixtures containing them.

Do not use mixtures of a hydrogen

containing refrigerant and air above

atmospheric pressure for pressure

testing as they may become

flammable and could result in an

explosion. Refrigerant, when used as

a trace gas should only be mixed with

dry nitrogen for pressurizing units.

Failure to follow these

recommendations could result in

death, serious injury, equipment, or

property-only damage.

WARNING

Leak Testing!

Do not exceed 200 psig when leak

testing system. Failure to follow these

instructions could result in an

explosion causing death or serious

injury.

procedures

In the event of required system repair,

leak test the liquid line, evaporator coil,

and suction line at pressures dictated by

local codes, and using the following

guidelines.

1. Charge enough refrigerant and dry

nitrogen into the system to raise the

pressure to 100 psig.

2. Use a halogen leak detector, halide

torch, or soap bubbles to check for

leaks. Check interconnecting piping

joints, the evaporator coil connections,

and all accessory connections.

3. If a leak is detected, release the test

pressure, break the connections and

reassemble it as a new joint, using

proper brazing techniques.

4. If no leak is detected, use nitrogen to

increase the test pressure to 150 psig

and repeat the leak test. Also, use soap

bubbles to check for leaks when

nitrogen is added.

5. Retest the system to make sure new

connections are solid.

6. If a leak is suspected after the system

has been fully charged with refrigerant,

use a halogen leak detector, halide

torch, or soap bubbles to check for

leaks.

Refrigerant Evacuation

For field evacuation, use a rotary style

vacuum pump capable of pulling a

vacuum of 100 microns or less.

When connecting the vacuum pump to a

refrigeration system, it is important to

manifold the pump to both the high and

low side of the system. Follow the pump

manufacturer’s directions.

WARNING

Use of Pressure Regulator –

Valves – Gauges!

Always use pressure regulators,

valves, and gauges to control drum

and line pressures when pressure

testing equipment. Failure to follow

these instructions could result in an

explosion causing death, serious

injury, or equipment damage.

PKG-SVX14A-EN 27

Page 28

maintenance

Maintenance

CAUTION

Motor Winding Damage!

Do not use a megohm meter or apply

greater than 50 VDC to a compressor

motor winding while it is under a

deep vacuum. Voltage sparkover may

cause damage to the motor windings.

WARNING

Hazardous Pressures!

If a heat source is required to raise

the tank pressure during removal of

refrigerant from cylinders, use only

warm water or heat blankets to raise

the tank temperature. Do not exceed

a temperature of 150°F. Do not, under

any circumstances, apply direct flame

to any portion of the cylinder. Failure

to follow these safety precautions

could result in a violent explosion,

which could result in death or serious

injury.

procedures

Charging the Refrigerant System

To completely charge the system, charge

gaseous refrigerant into the suction line

shrader valve with the unit running.

However, make sure that some

refrigerant is present in each circuit

before starting the compressors.

CAUTION

Compressor Damage!

Do not allow liquid refrigerant to enter

the suction line. Excessive liquid

accumulation in the liquid lines may

result in compressor damage.

CAUTION

Compressor Damage!

Never manually or automatically

pump down below 7 psig. This may

cause the compressor to operate in a

vacuum and result in compresor

damage.

Table M-MP-1. Normal operation condition

water-cooled air-cooled

high pressure 280 to 430 psig 320 to 570 psig

low pressure

superheat

subcooling

Table M-MP-2. Controls adjustment

control disarming rearming

high pressure control (air-cooled & 12-ton water cooled) 624±17.5 psig 464±29 psig

high pressure control (water-cooled except 12-ton)

low pressure contol 51±7 psig 94±7 psig

motor windings thermostat, standard motor only

28 PKG-SVX14A-EN

450±10 psig 348±14.5 psig

266±5F 194±5 3 / 204-230 & 575

275±5F 198 5 / 208-230

266±5F 198 5 / 575

194±5 F 135 7.5 - 10 / 208-230

248±5F 156 7.5 - 10 / 575

194±5F 135 12 - 15 / 208-230

221±5F 142 12 - 15 / 575

100 to 160 psig

4 to 9°F

5 to 10°F

unit (ton / voltage)

Page 29

periodic

Periodic Checklists

Monthly Checklist

The following checklist provides the

recommended maintenance schedule to

keep the unit running efficiently.

WARNING

Hazardous Voltage!

Disconnect all electrical power including

remote disconnects before servicing

unit. Follow proper lockout/tagout

procedures to ensure power cannot be

inadvertently energized. Failure to

disconnect power before servicing could

result in death or serious injury.

1. Inspect unit air filters. Clean or replace

if airflow is blocked or if filters are dirty.

2. Inspect coils for icing. Icing on the coils

may indicate low airflow supply,

restricted airflow from dirty fins.

3. Check the fan belt condition and

tension. Adjust tension if belt is floppy or

squeals continually.

4. Check and record operating pressures.

Semi-Annual Maintenance

1. Verify the fan motor is properly aligned

and bolted tight to the motor frame.

2. Lubricate fan bearings.

3. With power disconnected, manually

rotate the fan wheel to check for

obstructions in the housing or

Maintenance

interference with fan blades. Remove

obstructions and debris. Center the fan

wheel if necessary.

4. Check the fan assembly sheave

alignment. Tighten set screws to their

proper torques.

Note: Perform this procedure monthly if

the unit is in a coastal or corrosive

environment.

Annual Maintenance

Check and tighten all set screws, bolts,

locking collars and sheaves.

1. Inspect, clean, and tighten all electrical

connections.

2. Visually inspect the entire unit casing

for chips or corrosion. Remove rust or

corrosion and repaint surfaces.

3. Visually check for leaks in refrigerant

piping.

4. Inspect fan, motor, and control

contacts. Replace badly worn or eroded

contacts.

checklists

5. Inspect the thermal expansion valve

sensing bulbs for cleanliness, good

contact with the suction line, and

adequate insulation from ambient air.

WARNING

Live Electrical Components!

During installation, testing, servicing,

and troubleshooting this equipment, it

may be necessary to work with live

electrical components. Have a

qualified licensed electrician or other

individual who is properly trained in

handling live electrical components

perform these tasks. Failure to follow

all electrical components could result

in death or serious injury.

WARNING

Rotating Components!

During installation, testing, servicing

and troubleshooting of this product it

may be necessary to measure the

speed of rotating components. Have a

qualified or licensed service individual

who has been properly trained in

handling exposed rotating

components, perform these tasks.

Failure to follow all safety precautions

when exposed to rotating

components could result in death or

serious injury.

PKG-SVX14A-EN 29

Page 30

Maintenance

WARNING

Hazardous voltage!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout procedures

to ensure the power can not be

inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious

Troubleshooting

Use the following steps and procedures to help correct these common problems.

injury.

troubleshooting

Problem

The entire unit does not operate.

Possible cause

1. Power interruption

2. Thermostat not operating

3. Electrical panel: a) 24-volt transformer

defective; b) loose wire

Problem

Fan runs but compressor does not start.

Possible cause

1. Low voltage

2. Remote thermostat

3. Compressor contactor open or burned

4 .High pressure control cutting out unit

5. Refrigerant leak - no gas

6. Loose or defective wires.

7. Compressor shorted, open or burned

8. Defective compressor

Problem

Unit held off by safety.

Possible cause

1. Unit cutout on high pressure control, set at

385 psig

2. Refrigerant leak

3. Air restriction, dirty coils

4. Partial restriction in refrigerant system

5. High pressure control

6. TXV power element charge loss

7. Loose connection in electrical unit

Remedy

1. Check for blown fuses or tripped circuit breakers. Replace or reset if necessary.

2. Setting may be too high; check unit and reset. Thermostat may be out of calibration

or otherwise defective; replace.

3. Correct as required.

Remedy

1. Check power supply for voltage outside the acceptable voltage range.

2. Check the control unit for loose wires. Firm any loose connections.

3. Replace.

4. Check for loose wire connection, broken or burned contacts. If defective, replace.

5. Locate leak and repair. Recharge unit.

6. Tug on wires to see if they will separate from connections. Replace terminals if

necessary.

7. Check for shorts, opens, and grounded. Remove and replace compressor.

8. Remove and replace.

Remedy

1. Adjust tubes by bending slightly to firm position without touching other unit parts.

2. Level unit base. Fully support base.

3. Check and tighten loose screws.

4. Tighten screws on fan wheel shaft.

5. Adjust wheel position on motor shaft

6. Replace fan motor.

7. Replace fan bearing.

Problem

Noisy operation.

Possible cause

1. Copper tubing vibrating

2. Machine vibrating out of level

30 PKG-SVX14A-EN

Remedy

2. See if unit is low on refrigerant charge. Repair leak and recharge unit.

3. Verify if the air filter is dirty or has an airflow restriction, and correct problem.

4. Locate restriction by inspecting refrigerant lines for temperature changes. Remove

restriction, evacuate, and recharge.

5. Replace, if defective.

6. Evacuate, replace element, recharge.

7. Trace and firm up connection.

Page 31

Maintenance

troubleshooting

Problem

Insufficient cooling

Possible cause

1. Insufficient air flow due to: a) dirty

evaporator; b) ice on evaporator coils

(indicates airflow restriction through

evaporator); c) dirty filter; d)

obstructed discharge air intake; e)

fan motor not running; f) evaporator

fan or fan wheel slipping on motor

shaft

2. Heat gain or loss in room exceeds

unit capacity

3. Defective compressor

4. Insufficient refrigerant charge

indicated

by: a) low wattage; b) condenser air

outlet cold

5. Overcharge of refrigerant indicated

by high wattage and sweating of the

compressor return line

6. Thermostat not set for full cooling

7. Insufficient airflow through

condenser

due to: a) dirty condenser; b) loose belt;

c) fan loose on shaft

8. Cutout on high pressure

9. Only one refrigerant circuit

operational

in 2-circuit units

WARNING

Hazardous voltage!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout procedures

to ensure the power can not be

inadvertently energized. Failure to

disconnect power before servicing

could result in death or serious

injury.

Remedy

1. Correct as follows: a) clean; b) defrost (using fan operation only); c) clean or

replace filter; d) remove obstruction; e) check electrical system; f) adjust fan

position. Tighten set screw on fan wheel.

2. Refer to original load calculations. Recalculate heat gain or loss.

3. Replace, if necessary.

4. Check refrigerant charge pressure with gauges. If refrigerant is low, recharge