Trane SCWF 35, SCWF 25, SCWF 42, SCWF 38, SCWF 52 Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

IntelliPak™™ Commercial Self-Contained

Signature Series

20 to 110 Tons

SSCCWWFF aanndd SSIIWWFF – 20 to 110 Ton

SSCCRRFF aanndd SSIIRRFF – 25 to 60 Ton

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

June 2018

SSCCXXFF--SSVVXX0011QQ--EENN

Page 2

Introduction

WARNING

CAU

TION

NOTICE

Read this manual thoroughly before operating or

servicing this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper

operation of this machine depend upon the strict

observance of these precautions.

The three types of advisories are defined as follows:

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury. It could also be used to alert

against unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are

refrigerants that contain Chlorine, Fluorine and Carbon

(CFCs) and those containing Hydrogen, Chlorine,

Fluorine and Carbon (HCFCs). Not all refrigerants

containing these compounds have the same potential

impact to the environment. Trane advocates the

responsible handling of all refrigerants-including

industry replacements for CFCs and HCFCs such as

saturated or unsaturated HFCs and HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices

are important to the environment, our customers, and

the air conditioning industry. All technicians who

handle refrigerants must be certified according to local

rules. For the USA, the Federal Clean Air Act (Section

608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management

of refrigerants. Know the applicable laws and follow

them.

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess..

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE))

RReeqquuiirreedd!!

FFaaiilluurree ttoo wweeaarr pprrooppeerr PPPPEE ffoorr tthhee jjoobb bbeeiinngg

uunnddeerrttaakkeenn ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

TTeecchhnniicciiaannss,, iinn oorrddeerr ttoo pprrootteecctt tthheemmsseellvveess ffrroomm

ppootteennttiiaall eelleeccttrriiccaall,, mmeecchhaanniiccaall,, aanndd cchheemmiiccaall

hhaazzaarrddss,, MMUUSSTT ffoollllooww pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall

aanndd oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss,, aass wweellll aass tthhee

iinnssttrruuccttiioonnss bbeellooww::

•• BBeeffoorree iinnssttaalllliinngg//sseerrvviicciinngg tthhiiss uunniitt,,

tteecchhnniicciiaannss MMUUSSTT ppuutt oonn aallll PPPPEE rreeqquuiirreedd ffoorr

tthhee wwoorrkk bbeeiinngg uunnddeerrttaakkeenn ((EExxaammpplleess;; ccuutt

rreessiissttaanntt gglloovveess//sslleeeevveess,, bbuuttyyll gglloovveess,, ssaaffeettyy

ggllaasssseess,, hhaarrdd hhaatt//bbuummpp ccaapp,, ffaallll pprrootteeccttiioonn,,

eelleeccttrriiccaall PPPPEE aanndd aarrcc ffllaasshh ccllootthhiinngg))..

AALLWWAAYYSS rreeffeerr ttoo aapppprroopprriiaattee MMaatteerriiaall SSaaffeettyy

DDaattaa SShheeeettss ((MMSSDDSS))//SSaaffeettyy DDaattaa SShheeeettss

((SSDDSS)) aanndd OOSSHHAA gguuiiddeelliinneess ffoorr pprrooppeerr PPPPEE..

•• WWhheenn wwoorrkkiinngg wwiitthh oorr aarroouunndd hhaazzaarrddoouuss

cchheemmiiccaallss,, AALLWWAAYYSS rreeffeerr ttoo tthhee aapppprroopprriiaattee

MMSSDDSS//SSDDSS aanndd OOSSHHAA//GGHHSS ((GGlloobbaall

HHaarrmmoonniizzeedd SSyysstteemm ooff CCllaassssiiffiiccaattiioonn aanndd

LLaabbeelllliinngg ooff CChheemmiiccaallss)) gguuiiddeelliinneess ffoorr

iinnffoorrmmaattiioonn oonn aalllloowwaabbllee ppeerrssoonnaall eexxppoossuurree

lleevveellss,, pprrooppeerr rreessppiirraattoorryy pprrootteeccttiioonn aanndd

hhaannddlliinngg iinnssttrruuccttiioonnss..

•• IIff tthheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleeccttrriiccaall

ccoonnttaacctt,, aarrcc,, oorr ffllaasshh,, tteecchhnniicciiaannss MMUUSSTT ppuutt

oonn aallll PPPPEE iinn aaccccoorrddaannccee wwiitthh OOSSHHAA,, NNFFPPAA

7700EE,, oorr ootthheerr ccoouunnttrryy--ssppeecciiffiicc rreeqquuiirreemmeennttss

ffoorr aarrcc ffllaasshh pprrootteeccttiioonn,, PPRRIIOORR ttoo sseerrvviicciinngg

tthhee uunniitt.. NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,,

DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE TTEESSTTIINNGG

WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD

AARRCC FFLLAASSHH CCLLOOTTHHIINNGG.. EENNSSUURREE

EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD EEQQUUIIPPMMEENNTT AARREE

PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD

VVOOLLTTAAGGEE..

©2018 Ingersoll Rand

SCXF-SVX01Q-EN

Page 3

IInnttrroodduuccttiioonn

WWAARRNNIINNGG

FFoollllooww EEHHSS PPoolliicciieess!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

•• AAllll IInnggeerrssoollll RRaanndd ppeerrssoonnnneell mmuusstt ffoollllooww

IInnggeerrssoollll RRaanndd EEnnvviirroonnmmeennttaall,, HHeeaalltthh aanndd

SSaaffeettyy ((EEHHSS)) ppoolliicciieess wwhheenn ppeerrffoorrmmiinngg wwoorrkk

ssuucchh aass hhoott wwoorrkk,, eelleeccttrriiccaall,, ffaallll pprrootteeccttiioonn,,

lloocckkoouutt//ttaaggoouutt,, rreeffrriiggeerraanntt hhaannddlliinngg,, eettcc.. AAllll

ppoolliicciieess ccaann bbee ffoouunndd oonn tthhee BBOOSS ssiittee.. WWhheerree

llooccaall rreegguullaattiioonnss aarree mmoorree ssttrriinnggeenntt tthhaann

tthheessee ppoolliicciieess,, tthhoossee rreegguullaattiioonnss ssuuppeerrsseeddee

tthheessee ppoolliicciieess..

•• NNoonn--IInnggeerrssoollll RRaanndd ppeerrssoonnnneell sshhoouulldd aallwwaayyss

ffoollllooww llooccaall rreegguullaattiioonnss..

Copyright

This document and the information in it are the

property of Trane, and may not be used or reproduced

in whole or in part without written permission. Trane

reserves the right to revise this publication at any time,

and to make changes to its content without obligation

to notify any person of such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

• Running edits included.

• Updated motor electrical data.

SCXF-SVX01Q-EN

3

Page 4

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 8

R-410A Compressors . . . . . . . . . . . . . . . . . . . . . 8

Signature Series Self-Contained Unit

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Standard Controls. . . . . . . . . . . . . . . . . . . . . 9

Human Interface Panel . . . . . . . . . . . . . . . . 9

Unit Control Module . . . . . . . . . . . . . . . . . . 9

Optional Controls . . . . . . . . . . . . . . . . . . . . 10

Unit Nameplate . . . . . . . . . . . . . . . . . . . . . . 10

Model Number Description. . . . . . . . . . . . . . . . 11

Commercial Self-Contained Signature

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Commercial Self-Contained Air-Cooled

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Data . . . . . . .. . . . . . . . .. . . . . . . . .. . . . . 14

Pre-Installation . . . . . . . . . .. . . . . . . . . . . . . . . . . . 21

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Receiving Checklist. . . . . . . . . . . . . . . . . . . 21

Contractor Installation

Responsibilities . . . . . . . . . . . . . . . . . . . . . . 21

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . 21

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Protective Covers. . . . . . . . . . . . . . . . 23

Supply Fan Isolators . . . . . . . . . . . . . . . . . 23

Dimensional Data . . . . . . . . . . . . . . . . . .. . . . . . . 24

Steam and Hot Water Coils . . . . . . . . . . . . . . . 28

Steam Coils . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hot Water Coils . . . . . . . . . . . . . . . . . . . . . . 28

Plenum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Airside Economizer . . . . . . . . . . . . . . . . . . . . . . 30

Service Clearances . . . . . . . . . . . . . . . . . . . . . . 31

Weights . . . . . .. . . . . . . .. . . . . . . . . . . . . . . . . . . . . 32

Installation - Mechanical. . . . .. . . . . . . . . . . . . . 34

Unit Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation Preparation . . . . . . . . . . . . . . . . . . 35

Unit Vibration Isolator Option. . . . . . . . . . . . . 35

Unit Isolator Installation

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Duct Connections. . . . . . . . . . . . . . . . . . . . . . . . 36

Installing the Plenum . . . . . . . . . . . . . . . . . . . . 36

Installing the Airside Economizer . . . . . . . . . 37

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Condenser Connections . . . . . . . . . . . . . . 38

Condensate Drain Connections. . . . . . . . 38

General Waterside

Recommendations for Cooling

Towers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Waterside Piping Arrangements. . . . . . . 39

Water Temperature

Requirements . . . . . . . . . . . . . . . . . . . . . . . 39

Water Piping Verification . . . . . . . . . . . . . 39

Installating the Hydronic Coil . . . . . . . . . . . . . 39

Steam and Hot Water Coil . . . . . . . . . . . . 39

Refrigerant System . . . . . . . . . . . . . . . . . . . . . . 40

Interconnecting Piping . . . . . . . . . . . . . . . 40

Preliminary Refrigerant

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installation - Electrical . . . . . . . . . . . . . . . .. . . . . 43

Unit Wiring Diagrams . . . . . . . . . . . . . . . . . . . . 43

Supply Power Wiring . . . . . . . . . . . . . . . . . . . . 43

Voltage Range . . . . . . . . . . . . . . . . . . . . . . . 43

Voltage Imbalance . . . . . . . . . . . . . . . . . . . 43

Phase Monitor . . . . . . . . . . . . . . . . . . . . . . . 43

Control Power . . . . . . . . . . . . . . . . . . . . . . . 43

Selection Procedures . . . . . . . . . . . . . . . . . . . . 44

Static Pressure Transducer Installation

(VAV units only) . . . . . . . . . . . . . . . . . . . . . . . . . 45

Transducer Location . . . . . . . . . . . . . . . . . 45

Installing the Transducer . . . . . . . . . . . . . 46

Zone Sensor Options for Control

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Standard with All Units:

BAYSENS077 . . . . . . . . . . . . . . . . . . . . . . . . 46

CV Unit Zone Sensor Options . . . . . . . . . 47

Integrated Comfort Systems Sensors for

CV and VAV Applications. . . . . . . . . . . . . . . . . 47

CV and VAV Unit Zone Sensor

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Zone Sensor Installation . . . . . . . . . . . . . . . . . 48

Mounting Location . . . . . . . . . . . . . . . . . . . 48

Mounting the Subbase . . . . . . . . . . . . . . . 48

4

SCXF-SVX01Q-EN

Page 5

TTaabbllee ooff CCoonntteennttss

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Standard Remote Sensor

(BAYSENS077) . . . . . . . . . . . . . . . . . . . . . . 49

Programmable Zone Sensors. . . . . . . . . . . . . 49

BAYSENS119 . . . . . . . . . . . . . . . . . . . . . . . . 49

Time Clock Option . . . . . . . . . . . . . . . . . . . . . . . 50

Grasslin Time Clock Option . . . . . . . . . . . 50

Installing the Time Clock. . . . . . . . . . . . . . 50

Surface Mounting Inside Panel . . . . . . . . 50

Wiring the Time Clock . . . . . . . . . . . . . . . . 50

Remote Human Interface Panel

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Human Interface (HI) Panel. . . . . . . . . . . . 50

Remote Human Interface Panel. . . . . . . . 51

Location Recommendations . . . . . . . . . . 51

Ambient Temperature and Humidity

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Mounting the Remote Human Interface

(RHI) Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Wall Mounting the RHI Panel. . . . . . . . . . 52

Wiring the Remote Human Interface. . . . . . . 53

Low Voltage (AC) Field Wiring

Connections . . . . . . . . . . . . . . . . . . . . . . . . . 54

Interprocessor Communication

Bridge Module Wiring . . . . . . . . . . . . . . . . 54

Communication Link (Shielded

Twisted Pair) Wiring. . . . . . . . . . . . . . . . . . 54

At the Self-Contained Unit . . . . . . . . . . . . 54

Connecting to Tracer Summit. . . . . . . . . . . . . 55

Communication Wiring. . . . . . . . . . . . . . . 55

Programming the Time Clock

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Setting the Time Clock. . . . . . . . . . . . . . . . 55

Programming the Time Clock . . . . . . . . . 55

Reviewing and Changing

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Manual Override . . . . . . . . . . . . . . . . . . . . . 56

Operating Principles. . . . . . . . .. . . . . . . . . . . . . . 57

Control Sequences of Operation . . . . . . . . . . 57

Occupied/Unoccupied

Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Field-Supplied Occupied/

Unoccupied Input on the RTM. . . . . . . . . 57

Tracer Summit System . . . . . . . . . . . . . . . 57

Factory-Mounted Time Clock. . . . . . . . . . 57

Unoccupied Sequence of Operation . . . . . . . 57

Morning Warm-up . . . . . . . . . . . . . . . . . . . 57

Full Capacity Morning Warm-up

(MWU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cycling Capacity Morning Warm-up

(MWU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Timed Override Activation—

ICS™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Timed Override Activation—Non-

ICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

VAV Drive Max Output . . . . . . . . . . . . . . . 58

Occupied Sequence. . . . . . . . . . . . . . . . . . . . . . 58

Occupied Zone Temperature—

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Zone Temperature Control (Unit

Model Number Digit 9 = 4 or 5) . . . . . . . . 58

Supply Air Temperature Control

(Unit Model Number Digit 9 = 1, 2, 3,

or 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Units With Economizer . . . . . . . . . . . . . . . 59

Cooling/Waterside Economizer. . . . . . . . 59

Cooling/Airside Economizer. . . . . . . . . . . 59

Mechanical Cooling . . . . . . . . . . . . . . . . . . 59

Air-Cooled Units Only . . . . . . . . . . . . . . . . 59

Water-Cooled Units Only . . . . . . . . . . . . . 59

Auto Changeover (Units with Heat

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Occupied Zone Temperature—

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . 59

Hydronic Heat: Hot Water or

Steam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Supply Air Setpoint Reset (VAV Units

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Reset Based on Outdoor

AirTemperature. . . . . . . . . . . . . . . . . . . . . . 60

Reset Based on zone

temperature . . . . . . . . . . . . . . . . . . . . . . . . . 60

Supply AirTempering (Hot Water

and Steam VAV Units Only) . . . . . . . . . . . 60

Daytime Warm-up (Units with

Supply Air Temperature Control

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Supply AirTempering . . . . . . . . . . . . . . . . 60

SCXF-SVX01Q-EN

5

Page 6

TTaabbllee ooff CCoonntteennttss

Changeover . . . . . . . . . . . . . . . . . . . . . . . . . 60

Thermostatic Expansion Valve. . . . . . . . . . . . 60

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Compressor Cycling. . . . . . . . . . . . . . . . . . 61

Compressor Lead/Lag

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Step Control . . . . . . . . . . . . . . . . . . . . . . . . . 61

Compressor Safety Devices. . . . . . . . . . . 62

Low Ambient Compressor

Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Evaporator Coil Frost Protection

FROSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Service Valve Option . . . . . . . . . . . . . . . . . 63

Waterside Components . . . . . . . . . . . . . . . . . . 63

Water Purge . . . . . . . . . . . . . . . . . . . . . . . . . 63

Water Piping Options. . . . . . . . . . . . . . . . . 63

Basic Water Piping . . . . . . . . . . . . . . . . . . . 63

Intermediate Water Piping . . . . . . . . . . . . 63

Water Flow Switch Option . . . . . . . . . . . . 63

Water-Cooled Condensers . . . . . . . . . . . . 63

Waterside Economizer Option. . . . . . . . . 63

Waterside Economizer Flow

Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Constant Water Flow with

Intermediate Piping . . . . . . . . . . . . . . . . . . 64

Variable Water Flow with

Intermediate Piping . . . . . . . . . . . . . . . . . . 64

Unit Airside Components. . . . . . . . . . . . . . . . . 65

Supply Air Fan. . . . . . . . . . . . . . . . . . . . . . . 65

Low Entering Air Temperature

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

High Duct Temperature

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Dirty Filter Sensor Option . . . . . . . . . . . . . 65

Low Ambient Sensor (Air-Cooled

Units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Supply Air Static Pressure Limit . . . . . . . 65

Variable Frequency Drive

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

VFD with Bypass . . . . . . . . . . . . . . . . . . . . . 66

Airside Economizer Option . . . . . . . . . . . 66

Comparative Enthalpy Control . . . . . . . . 66

Airside Economizers with Traq

Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Standard Two-Position Damper

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Airside Economizer Interface. . . . . . . . . . 67

Airside Economizer Interface with

Comparative Enthalpy. . . . . . . . . . . . . . . . 67

Air-Cooled Condensers . . . . . . . . . . . . . . . 67

Controls . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 68

Points List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

RTM Module. . . . . . . . . . . . . . . . . . . . . . . . . 68

GBAS Module . . . . . . . . . . . . . . . . . . . . . . . 68

ECEM Module . . . . . . . . . . . . . . . . . . . . . . . 68

BCI-I option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

LCI-I Points List. . . . . . . . . . . . . . . . . . . . . . . . . . 68

Phase Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Unit Control Components . . . . . . . . . . . . . . . . 68

RTM Module Board—Standard on all

Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Compressor Module . . . . . . . . . . . . . . . . . 71

Human Interface Module—Standard

on all Units . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Remote Human Interface Module

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Waterside Module—Standard on All

Water-cooled Units. . . . . . . . . . . . . . . . . . . 71

Heat Module. . . . . . . . . . . . . . . . . . . . . . . . . 71

Ventilation Override Module (VOM)

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Trane Communications

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Exhaust/Comparative Enthalpy

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Ventilation Control Module

(VCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Generic Building Automation

System Module Option . . . . . . . . . . . . . . . 73

Input Devices and System

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Pre-Startup . . . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . 79

Units with VFD . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Pre-Startup Checklist. . . . . . . . . . . . . . . . . . . . . 79

Supply Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Water-Cooled Unit Piping . . . . . . . . . . . . . . . . 79

Air-Cooled Units Only. . . . . . . . . . . . . . . . . . . . 79

6

SCXF-SVX01Q-EN

Page 7

TTaabbllee ooff CCoonntteennttss

Units with Hydronic Heat . . . . . . . . . . . . . . . . . 80

Units with Electric Heat . . . . . . . . . . . . . . . . . . 80

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Startup . . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . .. . . . 81

Air-Cooled Only . . . . . . . . . . . . . . . . . . . . . . . . . 81

Final Refrigerant Charge . . . . . . . . . . . . . . . . . 82

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . 83

Operating & Programming

Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . 83

Startup Log. . . . . . . . . . . . . . . . . . . . . . . . . . 83

Maintenance . . . . . . . . .. . . . . . . . .. . . . . . . .. . . . 85

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Variable Frequency Drive (VFD) . . . . . . . 85

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Inspecting and Cleaning the Drain

Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Inspecting and Cleaning the Fan . . . . . . . . . . 87

Supply Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fan Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fan Bearings . . . . . . . . . . . . . . . . . . . . . . . . 88

Fan Belt Tension . . . . . . . . . . . . . . . . . . . . . 88

Measuring Belt Tension . . . . . . . . . . . . . . 88

Adjusting Belt Tension . . . . . . . . . . . . . . . 89

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Scroll Compressor Failure Diagnosis

and Replacement . . . . . . . . . . . . . . . . . . . . 91

40 Ton Air-Cooled Compressor

Suction Restrictor Replacement . . . . . . . 91

Refrigerant System . . . . . . . . . . . . . . . . . . . . . . 92

Refrigerant Leak Test Procedure. . . . . . . 92

Brazing Procedures . . . . . . . . . . . . . . . . . . 93

System Evacuation Procedures . . . . . . . 93

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Scroll Compressor Failure Diagnosis

and Replacement . . . . . . . . . . . . . . . . . . . . 95

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Cleaning Coil Fin . . . . . . . . . . . . . . . . . . . . . . . . 97

Inspecting and Cleaning Coils . . . . . . . . . 97

Steam and Hot Water Coils . . . . . . . . . . . 97

Refrigerant Coils . . . . . . . . . . . . . . . . . . . . . 98

Draining the Waterside Economizer

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Cleaning the Condenser . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chemical Cleaning of Condenser and

Economizer Coil . . . . . . . . . . . . . . . . . . . . . 99

Piping Components. . . . . . . . . . . . . . . . . . . . . . 99

Water Valves . . . . . . . . . . . . . . . . . . . . . . . . 99

Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . 99

Maintenance Periodic Checklists . . . . . . . . . . 99

Monthly Checklist . . . . . . . . . . . . . . . . . . . . 99

Semi-Annual Maintenance. . . . . . . . . . . 100

Annual Maintenance . . . . . . . . . . . . . . . . 100

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . 101

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . 101

System Checks . . . . . . . . . . . . . . . . . . . . . 101

Additional Diagnostic Resources. . . . . . . . . 102

Wiring Diagrams . . . . . . . . . .. . . . . . . . . . . . . . . 115

SCXF-SVX01Q-EN

7

Page 8

Overview

NNoottee:: One copy of this document ships inside the

control panel of each unit and is customer

property. It must be retained by the unit’s

maintenance personnel.

This manual describes proper installation, operation,

and maintenance procedures for air cooled systems. By

carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be

minimized. It is important that periodic maintenance be

performed to help assure trouble free operation. A

maintenance schedule is provided at the end of this

manual. Should equipment failure occur, contact a

qualified service organization with qualified,

experienced HVAC technicians to properly diagnose

and repair this equipment.

This manual covers installation, operation and

maintenance of 20-110 ton Signature Series

Commercial Self Contained products with R-410A

refrigerant.

R-410A Compressors

• Use crank case heaters which must be energized 24

hours prior to compressor start.

• Contain POE oil which readily absorbs potentially

damaging moisture from air.

• Control box includes a phase monitor to detect

phase loss, line voltage imbalance and reversal.

Refer to previous IOM versions for R-407C and R-22

units, or contact your local Trane representative.

Refer to the appropriate IOM for air-cooled condenser

CXRC-SVX01*-EN and programming IntelliPak™

controls PKG-SVP01*-EN.

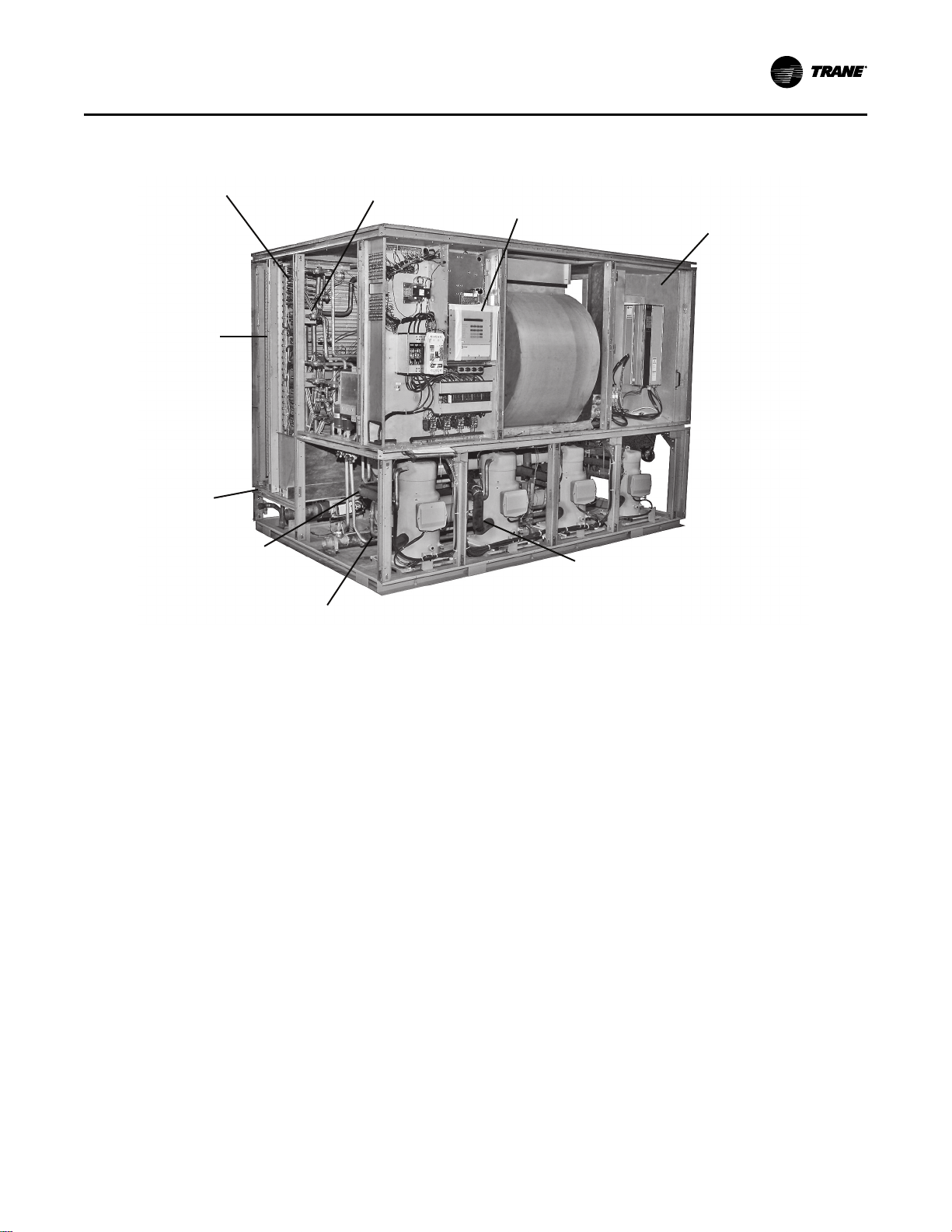

Signature Series Self-Contained Unit Components

Commercial self-contained units are complete HVAC

systems used in floor-by-floor applications. Units are

easy to install because they feature:

• A single point power connection.

• Factory-installed and tested controls.

• A single water point connection.

• Factory-installed options.

• An internally trapped drain connection.

NNoottee:: Refer to the following figure for typical unit

components.

The hermetically sealed scroll compressor motors

utilize internal motor protection and time delays to

prevent excessive cycling.

Water-cooled units have 2-6 refrigerant circuits and

ship with a full refrigerant and oil charge. Each circuit

includes filter drier, pressure relief valve, sight glass/

moisture indicator, thermal expansion valve with

sensing bulb and external equalizing line, discharge

line schrader valve, suction line schrader valve and

high and low pressure cutout switches. The watercooled condensers are shell and tube type with an

internal subcooler. Condensers are available as

mechanically or chemically cleanable.

Air-cooled units have two circuits and ship with oil and

a dry nitrogen holding charge. Therefore, air-cooled

units require field piping refrigerant connections to an

air-cooled condensing unit and charging. Each circuit

includes filter drier (field installed), sight glass/

moisture indicator, thermal expansion valve with

sensing bulb and external equalizing line, discharge

line schrader valve, suction line schrader valve, high

and low pressure cutout switches, discharge line check

valve and liquid line solenoid valve.

All units include liquid line service valves for each

circuit as standard (suction and discharge service

valves are optional).

Evaporator fans are double width, double inlet and

forward curved with fixed pitch belt drive assembly.

Variable frequency drives are optional. EISA efficiency

open drip proof (ODP) and totally enclosed fan cooled

(TEFC) motor options are available.

8

SCXF-SVX01Q-EN

Page 9

Figure 1. Commercial self-contained signature series unit components

Waterside economizer

(cleanable option shown)

Sight glasses with

ports for viewing

while unit is running

Unit mounted microprocessor

control with easy-to-read human

interface panel

Swing out VFO panel with

Tri-VFO for efficient VAV

operation

Trane 3-D® Scroll Compressor

for reliability, efficiency and

quiet operation

Two-bolt connection on

cleanable condenser for

quick, easy maintenance

Waterside valve

package option

to enhance system

efficiency

Internally trapped

drain for low cost

installation

2-inch flat filter

box inside unit

casing

OOvveerrvviieeww

Standard Controls

Standard controls supplied with the unit include the

human interface (HI) panel with unit control module

(UCM). All basic setup parameters are preset from the

factory.

Human Interface Panel

The HI is unit mounted and accessible without opening

the unit’s front panel. It allows easy setpoint

adjustment using the HI keypad. In addition, the HI

displays all unit operating parameters and conditions

in a clear language display, which can be configured

for either English, French, or Spanish.

The optional remote human interface (RHI) will control

up to four self-contained units, each containing an

interprocessor communications bridge (IPCB). It has all

the same features as the unit-mounted HI except for the

service mode.

For more information on setpoint defaults and ranges

and unit programming, see the Self-Contained

Programming Guide, PKG-SVP01*-EN. A copy ships

with each unit.

Unit Control Module

The UCM provides “smart” unit control with safety

features and control relays for pumps, dampers, etc.

SCXF-SVX01Q-EN

The Signature Series self-contained unit is controlled

by a microelectronic control system that consists of a

network of modules. Modular Series self-contained

unit is controlled by microelectronic control system

consisting of a network of modules.These modules are

referred to as unit control modules (UCM). In this

manual, the acronym UCM refers to the entire control

system network.

These modules perform specific unit functions using

proportional/integral control algorithms. They are

mounted in the unit control panel and are factory wired

to their respective internal components. Each module

receives and interprets information from other unit

modules, sensors, remote panels, and customer binary

contacts to satisfy the applicable request; i.e.,

economizing, mechanical cooling, heating, ventilation.

See the Owner’s section of this manual for a detailed

description of each module’s function.

9

Page 10

OOvveerrvviieeww

Figure 2. Right side view of unit Optional Controls

Optional controls include a disconnect switch, dirty

filter switch, water flow switch (water-cooled only),

supply air temperature reset, or external setpoint

inputs. Daytime heating is available on units with

electric, steam, or hot water heat control options.

Morning warm-up operation is available on all units.

The static pressure probe, zone night heat/morning

warm-up, supply air temperature reset sensor options

ship separate inside the unit control panel for field

installation. For more detailed information on the unit

control options, see the Owner’s section of this

manual.

Unit Nameplate

The unit nameplate identifies the unit model number,

appropriate service literature, and wiring diagram

numbers. It is mounted on the left end of the unit

control panel.

10

SCXF-SVX01Q-EN

Page 11

Model Number Description

Commercial Self-Contained Signature Series

Digit 1 — Unit Model

S = Self-Contained

Digit 2 — Unit Type

C = Commercial

I = Industrial

Digit 3 — Condenser Medium

W = Water-cooled

R = Air-cooled

Digit 4 — Development Sequence

F = Signature Series

Digit 5— Refrigerant Circuit

Configuration

U = Standard Capacity

V = High Capacity

Digit 6, 7 — Unit Nominal Capacity

20 = 20 Tons (water only)

22 = 22 Tons (water only)

25 = 25 Tons (water or air)

29 = 29 Tone (water or air)

30 = 30 Tons (air only)

32 = 32 Tons (water only)

35 = 35 Tons (water or air)

38 = 38 Tons (water only)

40 = 40 Tons (air only)

42 = 42 Tons (water only)

46 = 46 Tons (water only)

50 = 50 Tons (air only)

52 = 52 Tons (water only)

58 = 58 Tons (water only)

60 = 60 Tons (air only)

65 = 65 Tons (water only)

72 = 72 Tons (water only)

80 = 80 Tons (water only)

90 = 90 Tons (water only)

C0 = 100 Tons (water only)

C1 = 110 Tons (water only)

Digit 8 — Unit Voltage

6 = 200 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

Digit 9 — Air Volume/Temp Control

2 = VFD and supply air temp ctrl

3 = VFD w/ bypass and supply air temp ctrl

4 = Constant volume, zone temp cool only

5 = Constant volume, w/ zone temp heat/

cool

6 = Constant volume and supply air temp ctrl

Digit 10, 11 — Design Sequence

** = Factory Assigned

Digit 12 — Unit Construction

A = Vertical discharge

B = Vertical discharge with double wall

Digit 13— Flexible Horizontal

Discharge Plenum Type

B = STD plenum w/ factory-cut holes

C = Low plenum w/ factory-cut holes

E = Std plenum w/ field-cut holes

F = Low plenum w/ field-cut holes

H = STD plenum double wall w/ field-cut

holes

J = Low plenum double wall w/ field-cut holes

K = Extended height plenum w/factory-cut

holes, ship separate

L = STD plenum w/factory-cut holes, ship

separate

M = Low plenum w/factory-cut holes, ship

separate

N = Extended height plenum w/field-cut

holes, ship separate

P = STD plenum w/field-cut holes, ship

separate

R = Low plenum w/field-cut holes, ship

separate

T = Extended height double-wall plenum w/

field-cut holes, ship separate

U = STD double-wall plenum w/field-cut

holes, ship separate

V = Low double-wall plenum w/field-cut

holes, ship separate

W = STD double-wall (perf) plenum w/fieldcut holes (90 to110 ton only)

X = Low double-wall (perf) plenum w/field-

cut holes (90 to 110 ton only)

Y = Extended height double-wall (perf)

plenum w/field-cut holes, ship separate (90

to 110 ton only)

0 = None

Digit 14— Motor Type

2 = ODP motor

4 = TEFC motor

Digit 15, 16 — Motor HP

05 = 5 hp

07 = 7.5 hp

10 = 10 hp

15 = 15 hp

20 = 20 hp

25 = 25 hp

30 = 30 hp

40 = 40 hp

50 = 50 hp (460V, 575V only)

60 = 60 hp (90 to 110 ton only)

Digit 17, 18, 19 – Fan RPM

040 = 400 rpm

045 = 450 rpm

050 = 500 rpm

052 = 525 rpm

055 = 550 rpm

057 = 575 rpm

060 = 600 rpm

065 = 650 rpm

070 = 700 rpm

075 = 750 rpm

080 = 800 rpm

085 = 850 rpm

090 = 900 rpm

095 = 950 rpm

100 = 1000rpm

105 = 1050 rpm

110 = 1100 rpm

115 = 1150 rpm

120 = 1200 rpm

125 = 1250 rpm

130 = 1300 rpm

135 = 1350 rpm

Digit 20 — Unit Isolators

A = Steam coil

B = Hot water coil

C = Electric heat, 1 stage

D = Electric heat, 2 stage

F = Hydronic heat ctrl interface

G = Electric heat ctrl interface

K = Steam coil ship separate, LH

L= Hot water coil ship separate, LH

T = Hot water coil, high capacity, LH

U = Hot water coil, high capacity, LH, ship

separate

0 = None

Digit 21 — Unit Isolators

A = Isopads

B = Spring isolators

0 = None

Digit 22— Unit Finish

1 = Paint - Slate Gray

Digit 23— Supply Fan Options

0 = Standard fan

1 = Low CFM fan

Digit 24— Unit Connection

1 = Disconnect switch

2 = Terminal block

3 = Dual point power (2 blocks)

SCXF-SVX01Q-EN

11

Page 12

MMooddeell NNuummbbeerr DDeessccrriippttiioonn

Digit 25— Industrial Options

A = Protective coating evaporator coil

B = Silver solder

C = Stainless steel screws

D = A and B

E = A and C

F = B and C

G = A, B, and C

0 = none

Digit 26 — Drain PanType

A = Galvanized sloped

B = Stainless steel sloped

Digit 27 — Waterside Economizer

A = Mechanical clean full capacity (4-row)

B = Mechanical clean low capacity (2-row)

C = Chemical clean full capacity (4-row)

D = Chemical clean low capacity (2-row)

0 = None

Digit 28 — Ventilation Control

B = Airside econ w/Traq damper, top O/A

C = Airside econ w/ std damper, top O/A

E = Airside econ w/Traq damper &

comparative enthalpy, top O/A

F = Airside econ w/ std damper &

comparative enthalpy, top O/A

H = 2-position damper ventilation interface

J = Airside economizer interface

K = Airside economizer interface w/

comparative enthalpy

Digit 29 — Water Piping

D = Left hand basic piping

F = Left hand Intermediate piping

K = Left hand basic w/ flow switch

M = Left hand intermediate w/ flow switch

0 = None

Digit 30 — Condenser Tube Type

A = Standard condenser tubes

B = 90/10 CuNi condenser tubes

0 = None (air-cooled only)

Digit 31 — Compressor Service Valves

1 = With service valves

0 = None

Digit 32— Miscellaneous System

Control

1 = Time clock

2 = Interface for remote HI (IPCB)

3 = Dirty filter switch

4 = 1 and 2

5 = 1 and 3

6 = 2 and 3

7 = 1, 2 and 3

0 = None

Digit 33 — Control Interface Options

A = Generic BAS Module; 0-5 VDC (GBAS)

B = Ventilation Override Module (VOM)

D = Remote Human Interface (RHI)

G = GBAS and VOM

H = GBAS and RHI

J = VOM and RHI

M = GBAS, VOM, and RHI

N = BACnet Communications Interface (BCI)

P = BCI and GBAS

Q = BCI and VOM

R = BCI and RHI

T = BCI and GBAS and VOM

U = BCI and GBAS and RHI

V = BCI and VOM and RHI

W = BCI and GBAS and VOM and RHI

0 = None

1 = Lontalk Comm5 Interface (LCI)

2 = LCI and GBAS

3 = LCI and VOM

4 = LCI and RHI

5 = LCI and GBAS and VOM

6 = LCI and GBAS and RHI

7 = LCI and VOM and RHI

8 = LCI and GBAS and VOM and RHI

Digit 34— Agency

U = UL agency listing

0 = None

Digit 35— Filter Type

1 = 2” T/A w/ 2” rack

2 = 2” med. eff. T/A w/ 2” rack

3 = 4” bolt-on rack w/ 2” med eff. filter

4 = 6” rack w/ 2” construction T/A pre-filter &

4” filter space

5 = 6” rack w/ 2” med. eff. T/A pre-filter & 4”

filter space

Digit 36— Miscellaneous Control

Option

A = Low entering air temp. protect device

(LEATPD)

B = High duct temp t-stat, ship separate

C = Plenum high static switch, ship separate

E = A and B

F = A and C

H = B and C

L = A, B, and C

0 = None

12

SCXF-SVX01Q-EN

Page 13

Commercial Self-Contained Air-Cooled Condenser

MMooddeell NNuummbbeerr DDeessccrriippttiioonn

Digit 1 — Unit Model

C = Condenser

Digit 2 — Unit Type

C = Commercial

I = Industrial

Digit 3 — Condenser Medium

R = Remote

Digit 4 — Development Sequence

C = C

Digit 5, 6, 7 — Nominal Capacity

020 = 20 Tons

029 = 29 Tons

035 = 35 Tons

040 = 40 Tons

050 = 50 Tons

060 = 60 Tons

Digit 8 — Unit Voltage

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

6 = 200 Volt/60 Hz/3 ph

Digit 12 — Unit Finish

1 = Paint — Slate Gray

Digit 13— Coil Options

A = Non-Coated Aluminum

C = Protective Coating Aluminum

Digit 14— Unit Isolators

0 = None

A = Spring Isolators

B = Isopads

Digit 15— Panels

1 = Louvered Panels

Digit 16— Agency

0 = None

U = With UL Listing

Digit 9 — Control Option

0 = No Low Ambient, IPak

A = No Low Ambient, T-Stat*

B = Low Ambient, IPak

C = Low Ambient, T-Stat*

Note: *T-Stat only available on SCRG.

Digit 10, 11— Design Sequence

** = Factory Assigned

SCXF-SVX01Q-EN

13

Page 14

General Data

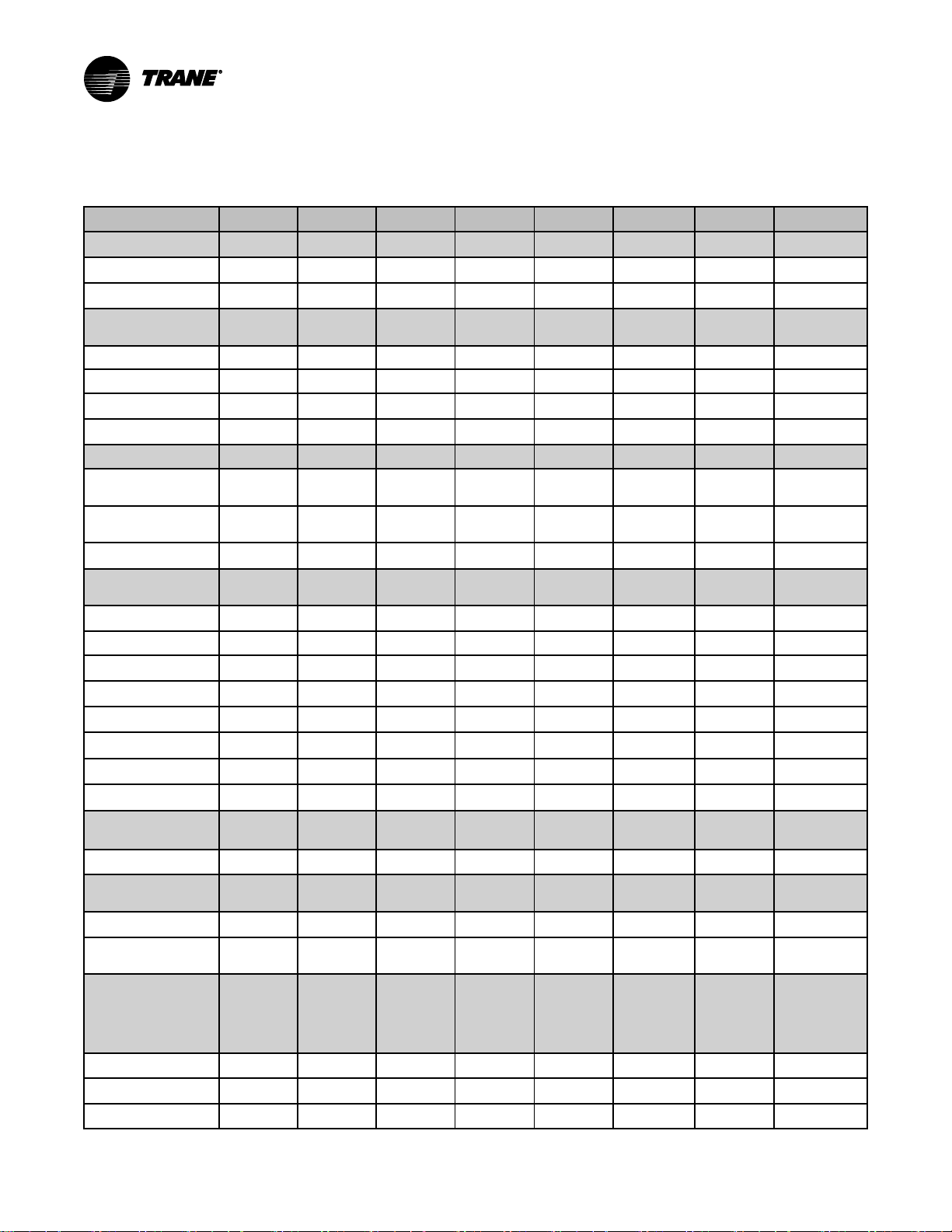

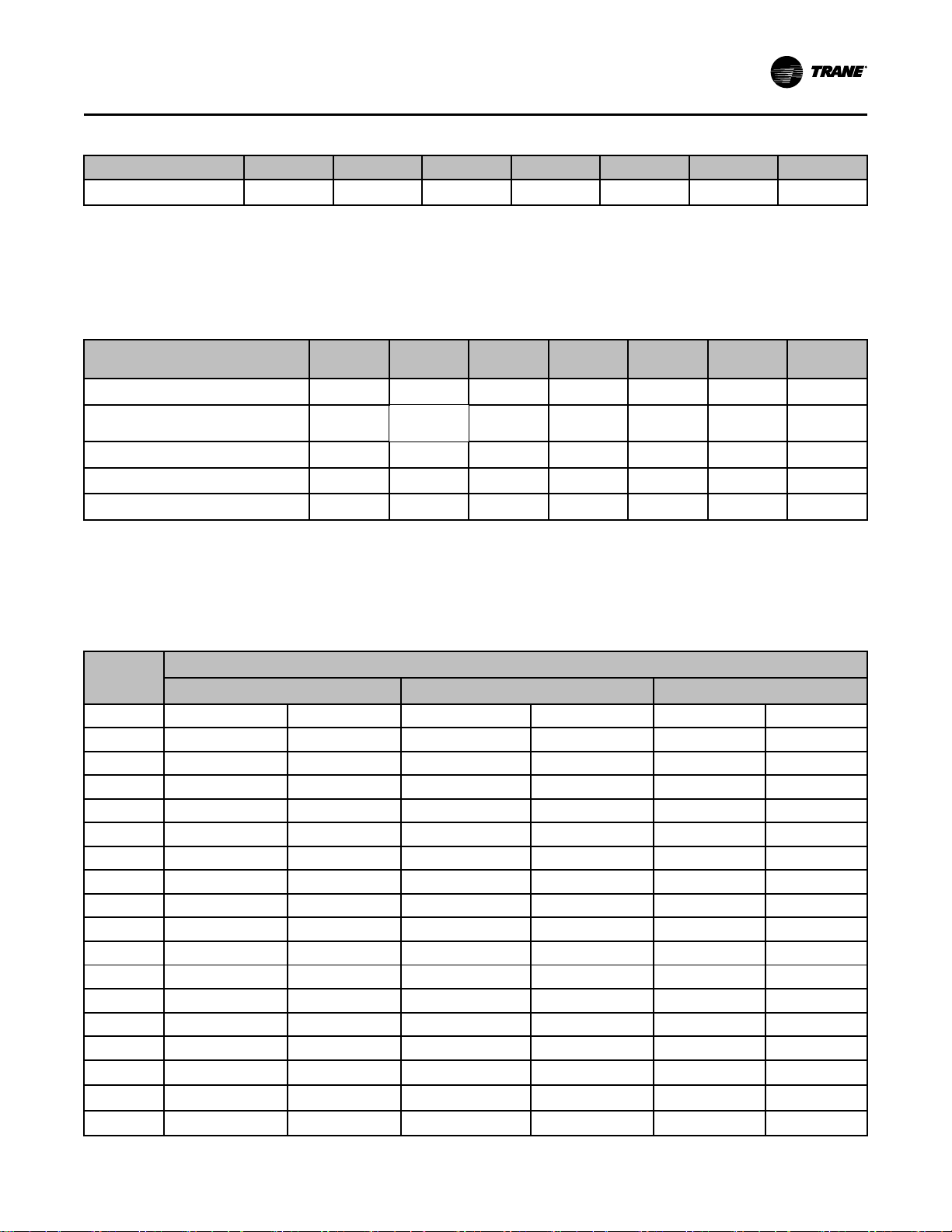

Table 1. SCWF/SIWF Water-cooled self-contained, 20 to 42 tons

Unit Size 20 22 25 29 32 35 38 42

Compressor Data

Quantity

Nominal Ton/comp

Evaporator Coil

Data

Circuits 2 2 2 2 2 3 3 3

Rows 2 2 3 or 6 2 4 or 6 3 4 or 6 3

Sq. Ft.

Fpf

Condenser Data

Minimum Gpm w/o

Econ

Minimum Gpm w/

Econ

Maximum Gpm

Evaporator Fan

Data

Quantity

Diameter 18" 18" 18" 18" 18" 20" 20" 25"

Minimum Hp

Minimum Kw

Maximum Hp

Maximum Kw

Minimum Design Cfm

Maximum Design Cfm

High Capacity

Option

Rows

Optional Low Flow

Fan 6

Diameter

Min/max Design Cfm

Refrigerant Charge,

lbs. R-410A

(Standard

Capacity/High

Capacity)

Circuit A 19.5 19.5 21.5 24.7

Circuit B 19.5 19.5 21.5 20.5

Circuit C

2 2 2

10 10 10

21.81 21.81 21.81 29.98 29.98 31.35 31.35 38.57

144 144 144 144 144 144 144 144

36 36 36 46 46 54 54 64

41 41 41 60 60 65 65 64

80 80 80 102 102 119 119 142

1 1 1 1 1 1 1 1

5 5 5 5 5 5 5 7. 5

(3.73) (3.73) (3.73) (3.73) (3.73) (3.73) (3.73) (5.39)

20 20 20 20 20 25 25 30

(14.91) (14.91) (14.91) (18.64) (18.64) (18.64) (18.64) (22.37)

6325 6325 6500 8700 8700 9100 9880 11200

8500 9350 10625 12325 13600 14875 16150 17850

N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A

6

1/1 1/1

15/10 15/10

N/A

6

28.5/29.3

23.5/23.5

3 3

10 10

N/A

21.5

21.5

21.5

23.5/26.5

23.5/26.5

23.5/26.5

6

18”

6000/

10625

2/1

10/15

N/A

N/A

N/A

22.0

22.0

22.0

14

SCXF-SVX01Q-EN

Page 15

GGeenneerraall DDaattaa

Table 1. SCWF/SIWF Water-cooled self-contained, 20 to 42 tons (continued)

Unit Size 20 22 25 29 32 35 38 42

Capacity Steps - %

Notes:

1. Compressors are Trane 3-D™ scroll.

2. All units operate with R-410A. Units ships with full operating charge.

3. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

4. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

5. Optional low flow fan (unit model number digit 23 = 1) is available ONLY when High Capacity option is selected (unit model number digit 5 = V).

100/53/0 100/53/0 100/53/0

Table 2. SCWF/SIWF Water-cooled self-contained, 46-110 tons

Unit Size 46 52 58 65 72 80 90 100 110

Compressor

Data

Quantity

Nominal Ton/

Comp

Circuits 3 3 3 4 4 4 5 6 6

Evaporator Coil

Data

Rows 4 or 6 2 4 or 6 3 4 or 6 6 6 or 8 6 or 8 6 or 8

Sq. Ft.

FPF 144 144 144 144 144 144 144 144 144

Condenser Data

Min GPM w/o Econ

Min GPM w/ Econ

Maximum GPM 142 186 186 226 226 248 300 350 350

Evaporator Fan

Data

Quantity

Size (Dia.)

Minimum HP 7.5 7.5 7.5 10 10 10 15 15 15

Minimum kW

Maximum HP 30 40 40 50 50 50 60 60 60

Maximum kW

Min Design CFM

Max Design CFM

High Capacity

Option

Rows 6

Optional Low

Flow Fan

Size (Dia.)

Min./Max Design

CFM

2/1

10/15

38.57 49.09 49.09 49.09 49.09 49.09 56.81 56.81 56.81

64 84 84 102 102 112 140 168 168

64 84 84 102 102 112

1 1 1 1 1 1 1 1 1

25" 25" 25" 27.5" 27.5" 27.5" 27.5" 27.5" 27.5"

(5.59) (5.59) (5.59) (7.46) (7.46) (7.46) (11.19) (11.19) (11.19)

(22.37) (29.84) (29.84) (37.29) (37.29) (37.29) (44.74) (44.74) (44.74)

11960 14250 15080 16900 18700 20800 17500 17500 17500

19550 22100 24650 27625 29800 29800 35000 35000 35000

18"

7700/13600 N/A

3 3

15 15

N/A

N/A

8900/

13600

6

18"

100/62/39/0100/59/39/0100/65/31/0100/65/30/

3/1 3/1

15/10 15/10

N/A

N/A

N/A

6

20"

10700/

16150

4 5

15 15

N/A N/A N/A

N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

8 8 8

0

2/4

10/15

100/71/43/

26/0

6

15

SCXF-SVX01Q-EN

15

Page 16

GGeenneerraall DDaattaa

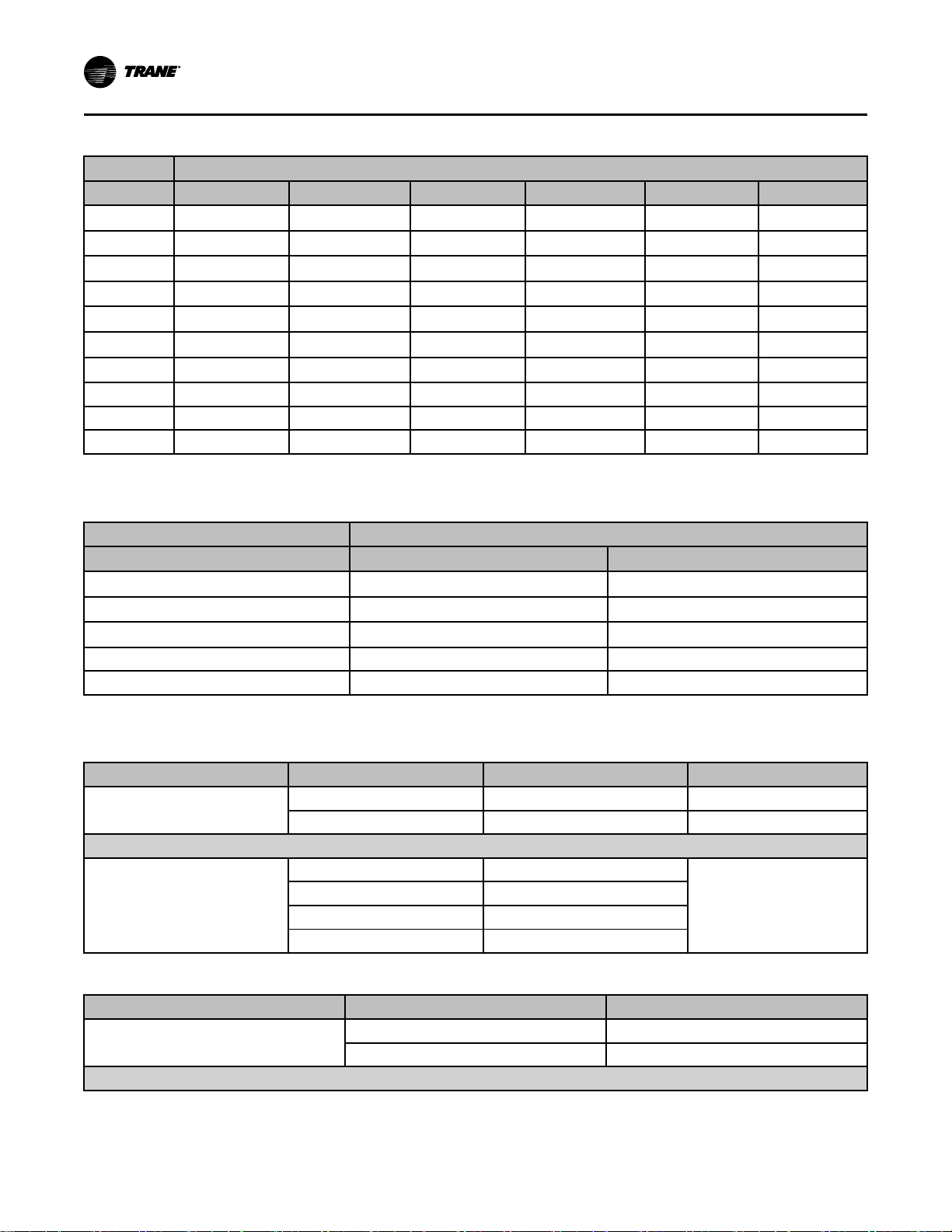

Table 2. SCWF/SIWF Water-cooled self-contained, 46-110 tons (continued)

Unit Size 46 52 58 65 72 80 90 100 110

Refrigerant

Charge — lbs. R410A (Standard

Capacity/High

Capacity)

Circuit A

Circuit B

Circuit C

Circuit D

Circuit E

Circuit F

Capacity Steps - %

Notes:

1. Compressors are Trane 3-D™ scroll.

2. All units operate with R-410A. Units ships with full operating charge.

3. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

4. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

24.5/28.5

24.5/28.5

24.5/28.5

N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A

100/70/41/30/

0

21.0

21.0

21.0

100/65/

32/0

26.5/

31.5

26.5/

31.5

26.5/

31.5

100/65/

30/0

22.0 24.5 28.0 24.5 24.5 24.5

22.0 24.5 28.0 24.5 24.5 24.5

22.0 24.5 28.0 24.5 24.5 24.5

21.0 22.0 28.0 24.5 24.5 24.5

24.5 24.5 24.5

24.5 24.5

100/71/

44/24/0

100/71/

43/23/0

100/73/

46/20/0

100/80/

40/20/0

100/75/

38/19/0

100/66/

33/17/0

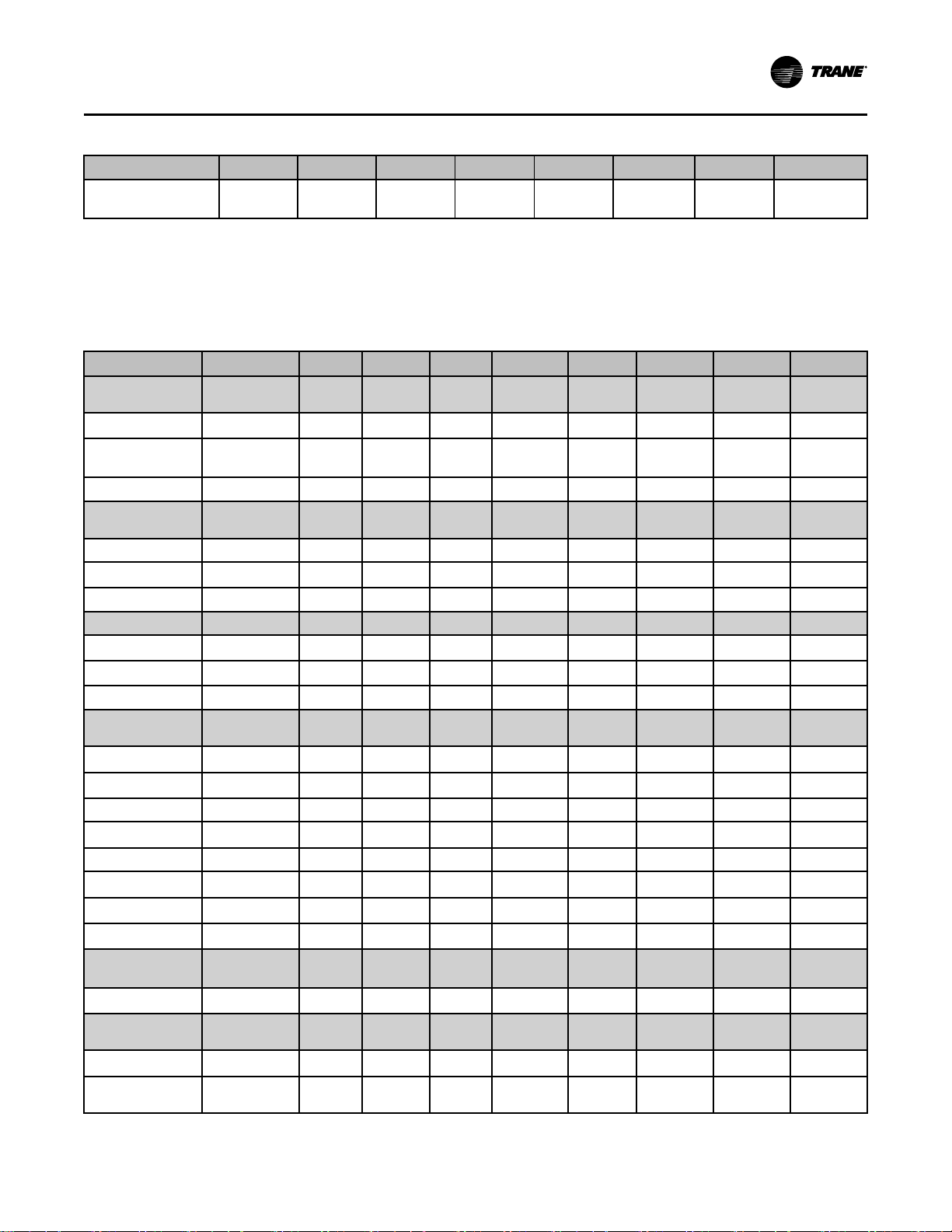

Table 3. SCRF/SIRF Air-cooled self-contained

Unit Size 25 29 30 35 40 50 60

Compressor Data

Quantity

Nominal Ton/Comp

Circuits 2 2 2 2 2 2 2

Evaporator Coil Data

Rows 4 4 3 4 4 4 6

Sq. Ft.

FPF 144 144 120 144 144 144 144

Evaporator Fan Data

Quantity

Size (Dia.)

Minimum HP 5 5 5 5 7.5 7.5 10

Minimum kW

Maximum HP 20 20 25 25 30 40 50

Maximum kW

Minimum Design CFM

Maximum Design CFM

Refrigerant Charge

Capacity Steps - %

1/1 1/1

15/10 15/10

29.98 29.98 31.35 31.35 38.57 49.09 49.09

1 1 1 1 1 1 1

18" 18" 20" 20" 25" 25" 27.5"

(3.73) (3.73) (3.73) (3.73) (5.59) (5.59) (7.46)

(18.64) (18.64) (18.64) (18.64) (22.37) (29.84) (37.29)

8700 8700 9100 9880 11960 15080 20800

12325 13600 14875 16150 19550 24650 29800

100/62/39/0 100/59/39/0 100/65/31/0 100/65/30/0

3 3

10 10

See Note 2 below

2/1

10/15

100/70/41/

30/0

15 15

100/65/30/0

3 4

100/73/46/

20/0

16

SCXF-SVX01Q-EN

Page 17

GGeenneerraall DDaattaa

Table 3. SCRF/SIRF Air-cooled self-contained (continued)

Unit Size 25 29 30 35 40 50 60

CCRC/CIRC Unit Match

Notes:

1. Compressors are Trane 3-D™ scroll.

2. All units operate with R-410A. Units ship with a dry nitrogen holding charge. Field refrigerant system charge required. Refer to Table 4, p. 17 for

amounts required.

3. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

4. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

Table 4. SCRF/SIRF Air–cooled self–contained and CCRC/CIRC remote air-cooled condenser refrigerant data

29 29 35 35 40 50 60

SCRF/SIRF & CCRC/CIRCUnit

Size

No. of Refrigerant Circuits

Operating Charge - lbs. R-410A

Operating Charge - kg R-410A

Cond. Storage Cap. - lbs. R-410A

Cond. Storage Cap. - kg R-410A

Notes:

1. Refrigerant charges are listed as circuit 1 circuit 2 and provide only an estimate. Final charge requires sound field charging practice.

2. Operating charge is for entire system, which includes the air–cooled self–contained, remote air–cooled condenser, and 25 feet of interconnecting

refrigerant piping.

3. At conditions of 95° F (35° C), condenser storage capacity is 95% full.

4. To determine the correct amount of refrigerant needed for a particular application, reference the Trane Reciprocating Refrigeration Manual.

25/29 29/29 30/35 35/35 40/40 50/50 60/60

2 2 2 2 2 2 2

56.2/38.0 56.2/38.0 71/35.5 75/37.5 86.5/39.5 100/52

23.1/17 23.1/17 32.2/16.1 34/17 39.2/17.9 44.5/22.7 46/46

51/37 51/37 74/37 74/37 74/51 102/51 102/102

23.1/16.8 23.1/16.8 33.6/16.8 33.6/16.8 33.6/23.1 46.3/23.1 46.3/46.3

Table 5. SCWF/SIWF water volumes

Water Volume in U.S. Gallons / Liters

Unit Size

20 9.0 34.1 17.4 65.9 16.9 64.0

22 9.0 34.1 17.4 65.9 16.9 64.0

25 9.0 34.1 17.4 65.9 16.9 64.0

29 9.0 34.1 20.5 77.6 18.8 71.2

32 9.0 34.1 20.5 77.6 18.8 71.2

35 10.0 37.9 21.9 82.9 20.2 76.5

38 10.0 37.9 21.9 82.9 20.2 76.5

42 15.0 56.8 32.2 121.9 31.4 118.9

46 15.0 56.8 32.2 121.9 31.4 118.9

52 15.0 56.8 36.9 139.7 35.9 135.9

58 15.0 56.8 36.9 139.7 35.9 135.9

65 16.0 60.6 37.9 143.5 36.9 139.7

72 16.0 60.6 37.9 143.5 36.9 139.7

80 16.0 60.6 37.9 143.5 36.9 139.7

90 22.5 85.2 50.1 189.6

100 23.0 87.1 50.6 191.5

110 24.0 90.8 51.6 195.3

W/o Economizer

Gallons Liters Gallons Liters Gallons Liters

With Mech. Cleanable Econ With Chem. Cleanable Econ

N/A N/A

N/A N/A

N/A N/A

101.5/

101.5

SCXF-SVX01Q-EN

17

Page 18

GGeenneerraall DDaattaa

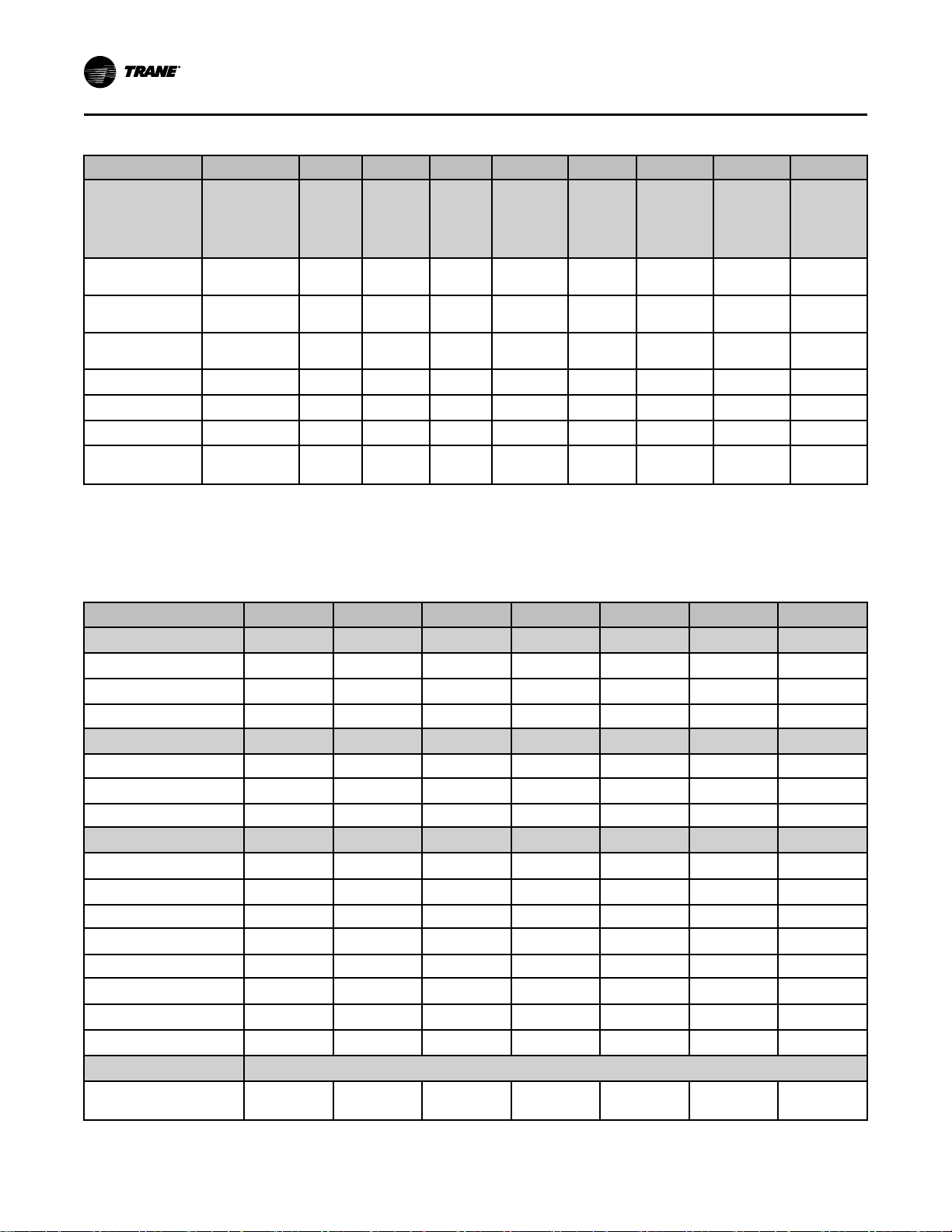

Table 6. SCWF/SIWF Refrigerant circuits, number of compressors by circuit

Circuit

Unit Size 1 2 3 4 5 6

20/22/25 Ton

29/32 Ton

35/38 Ton

42/46 Ton

52/58 Ton

60/72 Ton

80 Ton 1- 15T 1- 15T 1- 15T 1- 15T

90 Ton 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T

100 Ton 1-15T 1-15T 1-15T 1-15T 1-10T 1-10T

110 Ton 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T 1- 15T

Note: This table depicts compressor location in unit, plan view from left corner.

1- 10T 1- 10T

1- 15T 1- 10T

1- 10T 1- 10T 1- 10T

1- 15T 1- 10T 1- 10T

1- 15T 1- 15T 1- 15T

1- 15T 1- 15T 1- 15T 1- 10T

Table 7. SCRF/SIRF Refrigerant circuits, number of compressors by circuit

Unit Size 1 2

25/29 Ton

30/35 Ton

40 Ton

50 Ton 2-15T 1-15T

60 Ton 2-15T 2-15T

Note: This table depicts compressor location in unit, plan view from left corner.

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A

N/A N/A

Circuit

1-15T 1-10T

2-10T 1-10T

1-10T, 1-15T

1-10T

Table 8. Filter data, water-cooled units models SCWF & SIWF

Unit Size 20- 38 tons 40-85 tons 90-110 tons

Number - Size (In.)

Number - Size (In.)

8 - 20 x 18 12 - 25 x 20 15 - 24 x 24

4 - 20 x 20 6 - 20 x 20 3 - 24 x 12

Units With Hot Water Or Steam

4 - 16 x 20 4 - 25 x 20

4 - 20 x 20 2 - 20 x 20

4 - 18 x 20 8 - 25 x 16

Table 9. Filter data, air-cooled units models SCRF & SIRF

Unit size 20- 35 tons 40-60 tons

Number - Size (in.)

Units With Hot Water Or Steam

18

8 - 20 x 18 12 - 25 x 20

4 - 20 x 20 6 - 20 x 20

n/a

4 - 20 x 16

SCXF-SVX01Q-EN

Page 19

Table 9. Filter data, air-cooled units models SCRF & SIRF (continued)

Unit size 20- 35 tons 40-60 tons

4 - 16 x 20 4 - 25 x 20

Number - Size (in.)

4 - 20 x 20 2 - 20 x 20

4 - 18 x 20 8 - 25 x 16

N/A

4 - 20 x 16

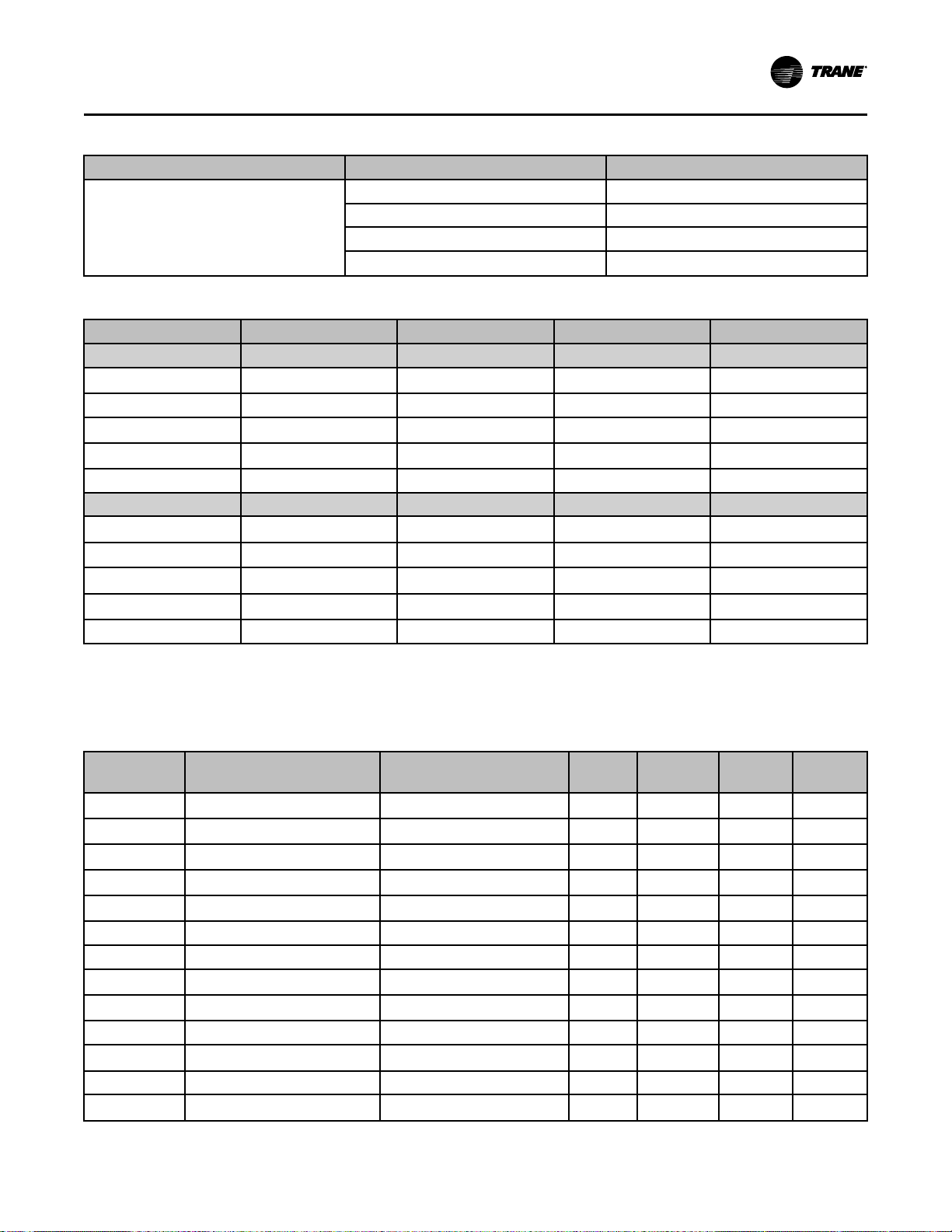

Table 10. Self-contained heating coil

Unit Size SCWF 20 - 38 SCWF 42 - 80 SCRF 20 - 35 SCRF 40 - 60

Steam Coil

Coil Type

Rows 1 1 1 1

No./Size (inches) (2) 24 x 58 (2) 30 x 81 (2) 24 x 58) (2) 30 x 81

No./Size (mm) (2) 609.6 x 1473.2 (2) 762 x 2057.4 (2) 609.6 x 1473.2 (2) 762 x 2057.4

FPF 42 42 42 42

Hot Water Coil

Coil Type

Rows 1 or 2

No./Size (inches) (2) 24 x 58 (2) 30 x 81 (2) 24 x 58 (2) 30 x8 1

No./Size (mm) (2) 609.6 x 1473.2 (2) 762 x 2057.4 (2) 609.6 x 1473.2 (2) 762 x 2057.4

FPF 80 or 108 80 or 108 80 or 108 80 or 108

Notes:

1. Hot water and steam heating coils have Prima-Flo® fins without turbulators.

2. For coil capacities, use TOPSS™ (Trane Official Product Selection Program).

3. Full capacity coils consist of two coils stacked and piped in parallel.

NS NS NS NS

5W 5W 5W 5W

N/A N/A N/A

GGeenneerraall DDaattaa

Table 11. Waterside economizer coil physical data

Model Unit Size

SCXF

SCXF

SCXF

SCXF

SCXF 29 & 32

SCXF 29 & 32 Mechanical Cleanable 2 108 55 78.5

SCXF 29 & 32 Mechanical Cleanable 4 108 55 78.5

SCXF 29 & 32

SCXF 35 & 38

SCXF 35 & 38 Mechanical Cleanable 2 108 57.5 78.5

SCXF 35 & 38

SCXF 35 & 38 Mechanical Cleanable 4 108 57.5 78.5

SCXF 42 & 46

20, 22 & 25 Chemically Cleanable

20, 22 & 25

20, 22 & 25 Chemically Cleanable

20, 22 & 25

Type

Mechanical Cleanable 2 108 40 78.5

Mechanical Cleanable 4 108 40 78.5

Chemically Cleanable

Chemically Cleanable

Chemically Cleanable

Chemically Cleanable

Chemically Cleanable

Rows FPF

2 108 40 78.5

4 108 40 78.5

2 108 55 78.5

4 108 55 78.5

2 108 57.5 78.5

4 108 57.5 78.5

2 144 55 101

SCXF-SVX01Q-EN

Height

(in)

Length

(in)

19

Page 20

GGeenneerraall DDaattaa

Table 11. Waterside economizer coil physical data (continued)

Model Unit Size

SCXF 42 & 46 Mechanical Cleanable 2 144 70 101

SCXF 42 & 46

SCXF 42 & 46 Mechanical Cleanable 4 144 70 101

SCXF

SCXF

SCXF

SCXF

SCXF

52, 58, 65, 72, 80, 85 Chemically Cleanable

52, 58, 65, 72, 80, 85

52, 58, 65, 72, 80, 85 Chemically Cleanable

52, 58, 65, 72, 80, 85

90, 100 & 110

Type

Chemically Cleanable

Mechanical Cleanable 2 144 70 101

Mechanical Cleanable 4 144 70 101

Mechanical Cleanable 4 144 70 119.3

Rows FPF

4 144 55 101

2 144 70 101

4 144 70 101

(in)

Height

Length

(in)

20

SCXF-SVX01Q-EN

Page 21

Pre-Installation

Receiving

Receiving Checklist

Complete the following checklist immediately after

receiving unit shipment to detect possible shipping

damage:

• Inspect individual cartons before accepting. Check

for rattles, bent carton corners, or other visible

indications of shipping damage.

• If a unit appears damaged, inspect it immediately

before accepting the shipment. Make specific

notations concerning the damage on the freight bill.

Do not refuse delivery.

• Inspect the unit for concealed damage before it is

stored and as soon as possible after delivery.

Report concealed damage to the freight line within

the allotted time after delivery. Check with the

carrier for their allotted time to submit a claim.

• Do not move damaged material from the receiving

location. It is the receiver’s responsibility to provide

reasonable evidence that concealed damage did

not occur after delivery.

• Do not continue unpacking the shipment if it

appears damaged. Retain all internal packing,

cartons, and crate. Take photos of damaged

material if possible.

• Notify the carrier of the damage immediately by

phone and mail. Request an immediate joint

inspection of the damage by the carrier and

consignee.

NNoottee:: Notify your Trane representative of the damage

and arrange for repair. Have the carrier inspect

the damage before making any repairs to the

unit.

Ship-Separate Accessories

Field-installed sensors ship separately inside main

control panel of the unit. Extra filters, sheaves, and

belts ship in the fan motor section of the unit.

Condenser plugs, spring isolators, and Iso-pads ship

stored in the bottom left side of the unit.

Contractor Installation Responsibilities

Complete the following checklist before beginning final

unit installation:

• Verify the unit size and tagging with the unit

nameplate.

• Make certain the floor or foundation is level, solid,

and sufficient to support the unit and accessory

weights. Level or repair the floor before positioning

the unit if necessary.

• Allow minimum recommended clearances for

routine maintenance and service. Allow space at

end of the unit for shaft removal and servicing.

Refer to the unit submittals for dimensions. See

also the “Service Clearances” section in the

Dimensional Data chapter.

• Allow three fan diameters above the unit for the

discharge ductwork. Return air enters the rear of

the unit and conditioned supply air discharges

through the top.

• Electrical connection knockouts are on the top, left

side of the unit.

• Allow adequate space for piping access and panel

removal. Condenser water piping, refrigerant

piping, and condensate drain connections are on

the lower left end panel.

NNoottee:: Unit height and connection locations will

change if using vibration isolators. The unit

height may increase up to 5-7/8” with spring

type isolators.

• Electrical supply power must meet specific balance

and voltage requirements as described in chapter

“Electrical Installation”.

• Water-cooled units only: The installer is responsible

for providing a condenser main, standby water

pump, cooling tower, pressure gauges, strainers,

and all components for waterside piping. See

“Water Piping,” p. 38 for general waterside

recommendations.

• Air-cooled units only: The installer is responsible

for providing and installing the remote air-cooled

condenser and refrigerant piping.

Unit Inspection

To protect against loss due to damage incurred in

transit, perform inspection immediately upon receipt of

the unit.

Exterior Inspection

If the job site inspection reveals damage or material

shortages, file a claim with the carrier immediately.

Specify the type and extent of the damage on the bill of

lading before signing. Notify the appropriate sales

representative.

IImmppoorrttaanntt:: Do not proceed with installation of a

damaged unit without sales

representative’s approval.

• Visually inspect the complete exterior for signs of

shipping damages to unit or packing material.

• Verify that the nameplate data matches the sales

order and bill of lading.

• Verify that the unit is properly equipped and there

are no material shortages.

• Verify that the power supply complies with the unit

nameplate specifications.

SCXF-SVX01Q-EN

21

Page 22

Shipping Cover

PPrree--IInnssttaallllaattiioonn

Inspection for Concealed Damage

Visually inspect the components for concealed damage

as soon as possible after delivery and before it is

stored.

If concealed damage is discovered:

• Notify the carrier’s terminal of the damage

immediately by phone and by mail.

• Concealed damage must be reported within 15

days.

• Request an immediate, joint inspection of the

damage with the carrier and consignee.

• Stop unpacking the unit.

• Do not remove damaged material from receiving

location.

• Take photos of the damage, if possible.

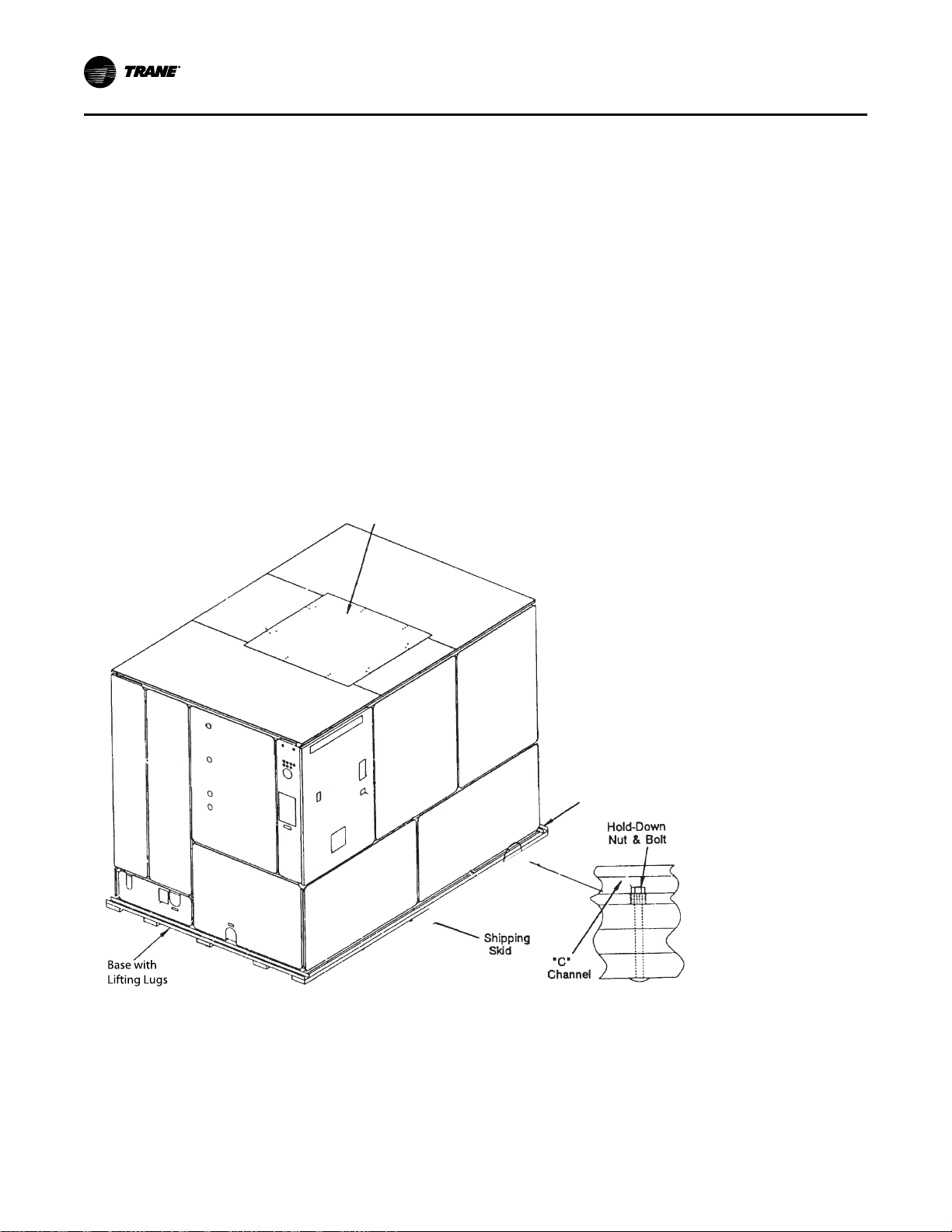

Figure 3. Typical unit shipping package

• The owner must provide reasonable evidence that

the damage did not occur after delivery.

Repair

Notify the appropriate sales representative before

arranging unit installation or repair.

IImmppoorrttaanntt:: Do not repair unit until the damage has

been inspected by the carrier’s

representative.

Unpacking

Commercial self-contained units ship assembled with

protective coverings over the coil and discharge

openings.Figure 3, p. 22 illustrates a typical shipping

package.

22

SCXF-SVX01Q-EN

Page 23

PPrree--IInnssttaallllaattiioonn

Unit Protective Covers

Remove shipping protection coverings from human

interface panel (HI) at control panel, filter box (or air

inlet opening), discharge air opening, and optional

variable frequency drive (VFD).

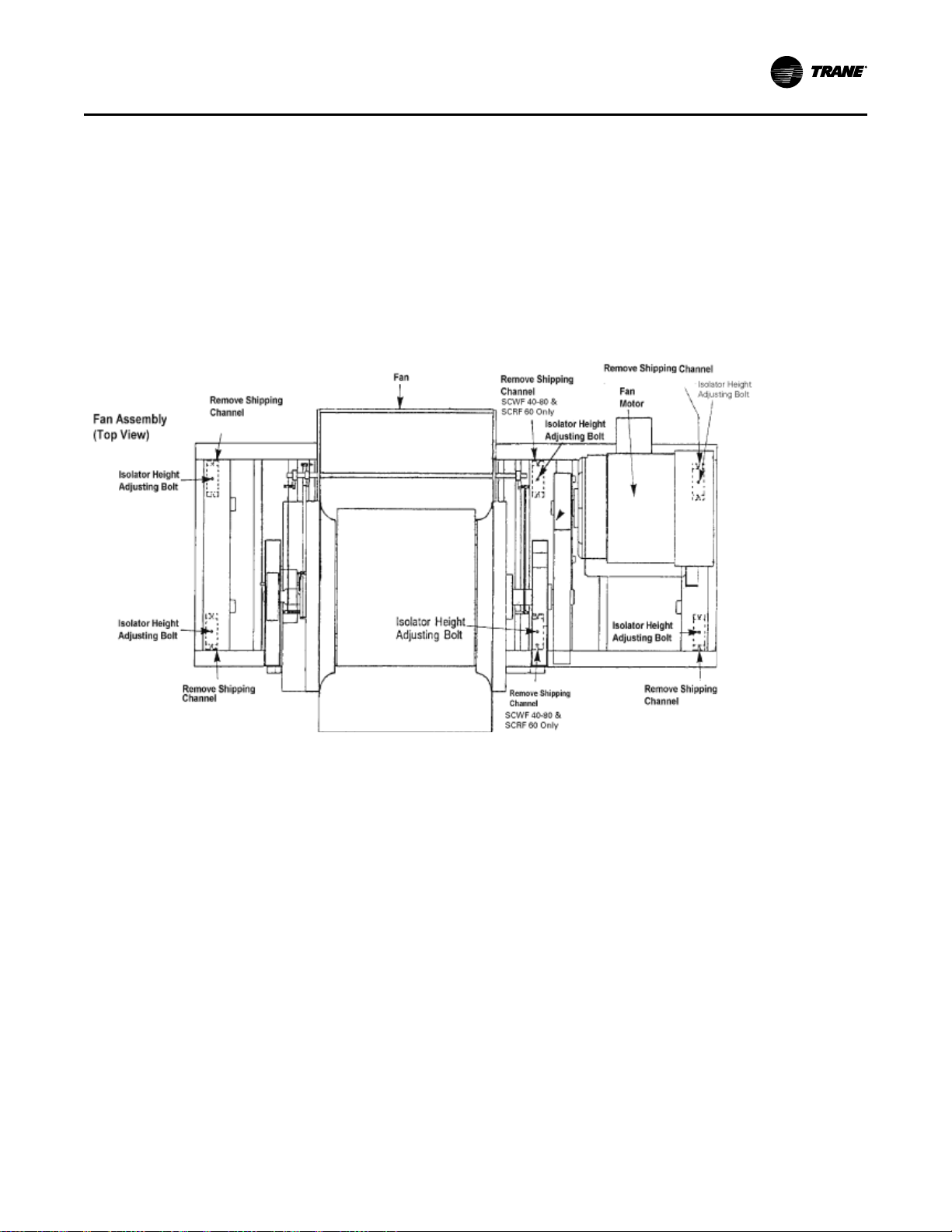

Supply Fan Isolators

Remove the shipping channels and four fan mounting

bolts from beneath the fan. Open both fan

compartment doors to access the channels.

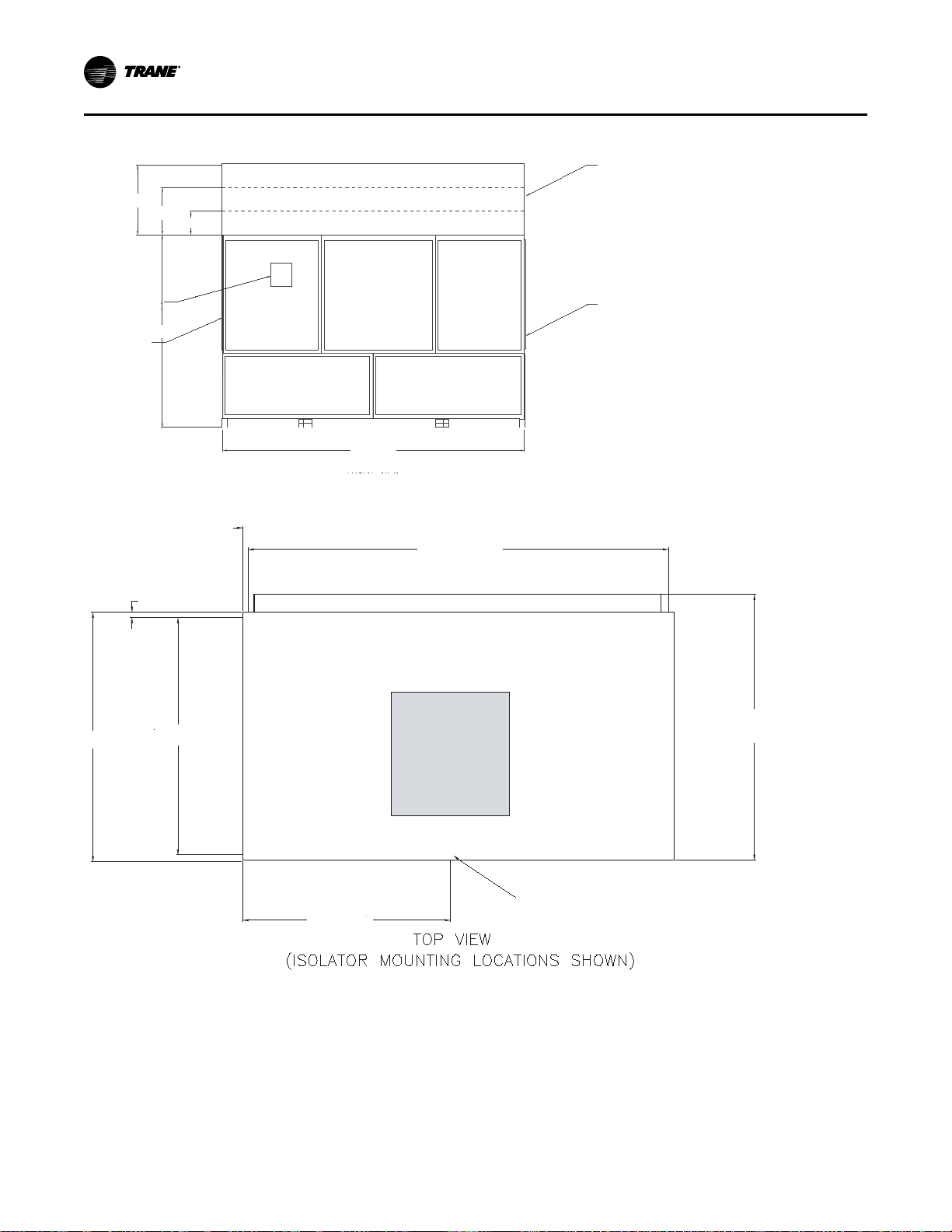

Figure 4. Fan Assembly Shipping Spacer Locations

NNootteess::

• There are six fan mounting points for 40-110

ton units.

• The 20 to 38 ton units use neoprene

isolators, and 40 to 110 ton units use spring

isolators.

SCXF-SVX01Q-EN

23

Page 24

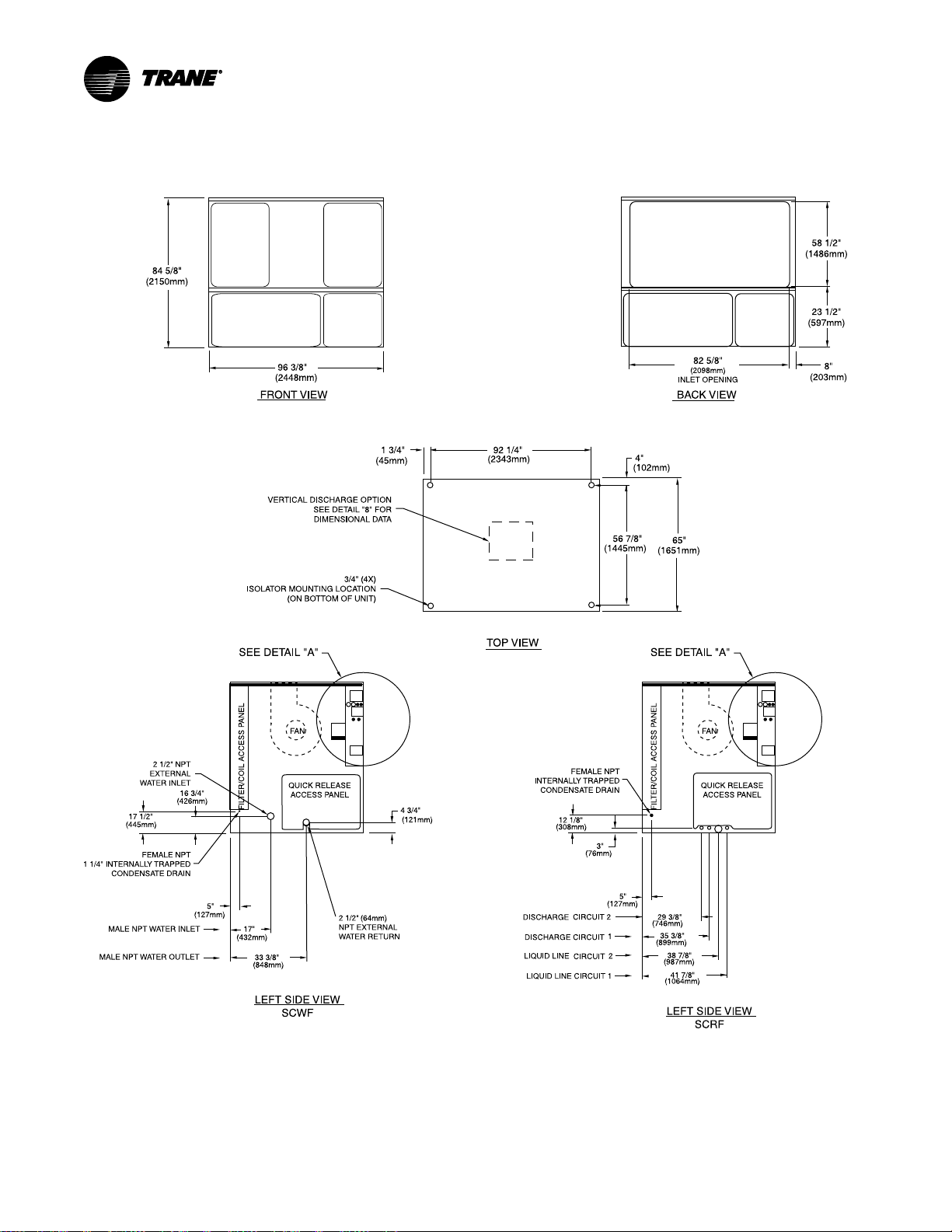

Dimensional Data

Figure 5. 20 to 38 ton self-contained

NNootteess::

24

1. All unit weights include refrigerant, water, controllers, electric heat and valves.

2. Add 150 lbs. to total weight to obtain approximate shipping weight.

SCXF-SVX01Q-EN

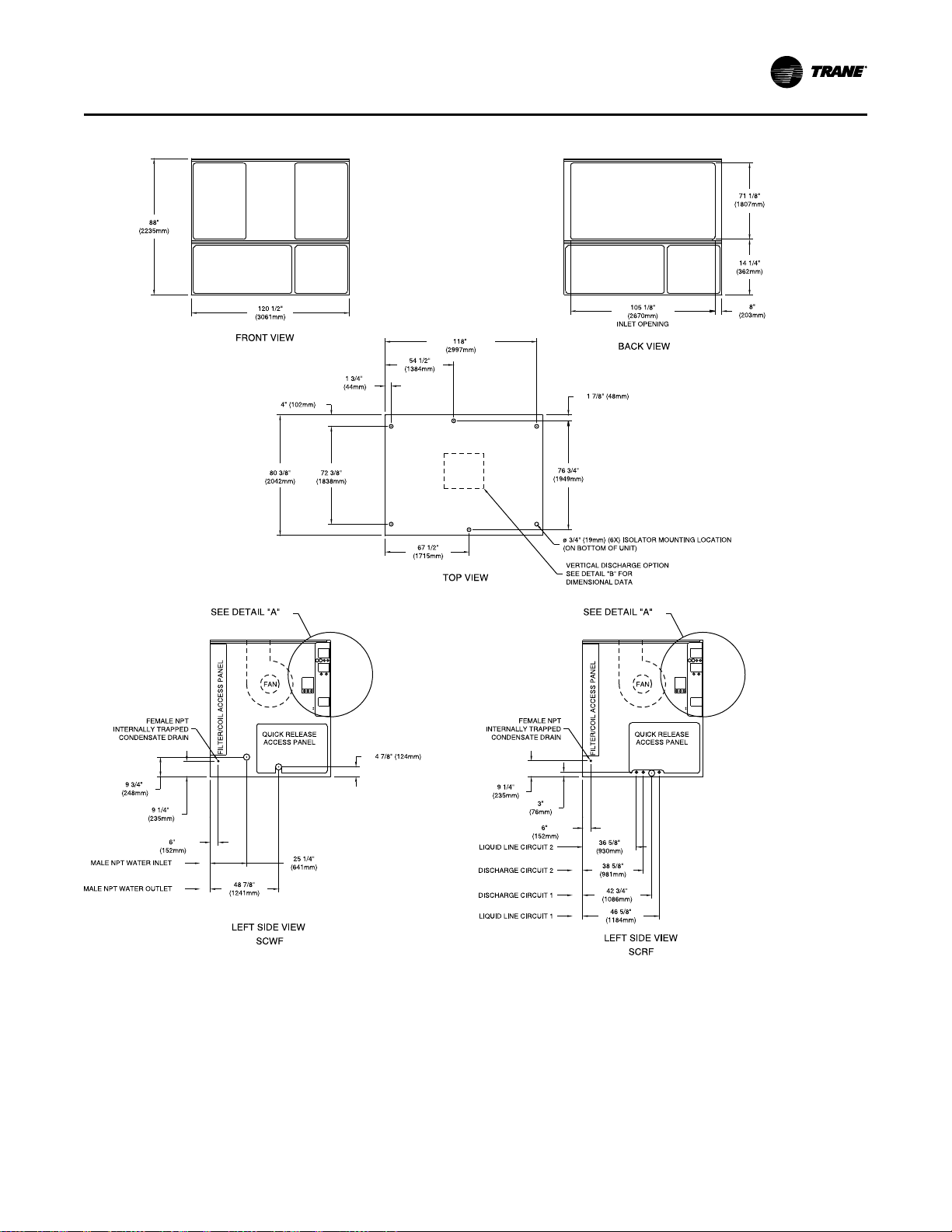

Page 25

Figure 6. 42 to 80 ton self-contained

DDiimmeennssiioonnaall DDaattaa

NNootteess::

1. All unit weights include refrigerant, water, controllers, electric heat and valves.

2. Add 150 lbs. to total weight to obtain approximate shipping weight.

SCXF-SVX01Q-EN

25

Page 26

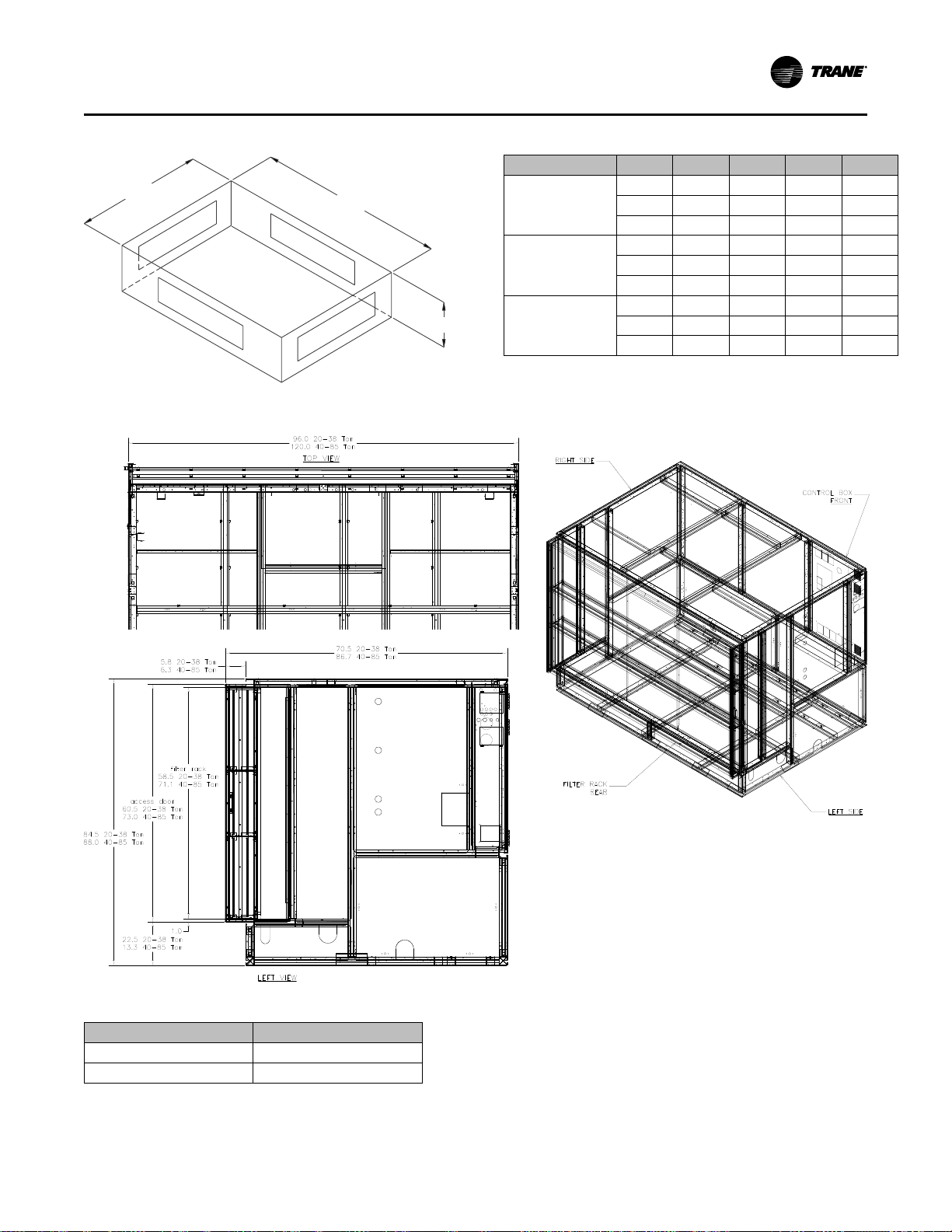

Ext. Height

Std. Height

Low Height

43.50"

27.75"

19.625"

Human

Interface

89.50"

Unit Control

Box

140.00"

VFD/

Interface

Plenum (low, standard,

and extended height shown)

72.00"

3.50"

133.00"

69.75"

3.50"

Filter Rack

*

*

*

*

*

*

Isolator Mounting Location (x6)

on bottom of unit

80.50”

86.25”

DDiimmeennssiioonnaall DDaattaa

Figure 7. 90 to 110 ton self-contained: front view

Figure 8. 90 to 110 ton self-contained: top view (isolator mounting locations shown)

26

SCXF-SVX01Q-EN

Page 27

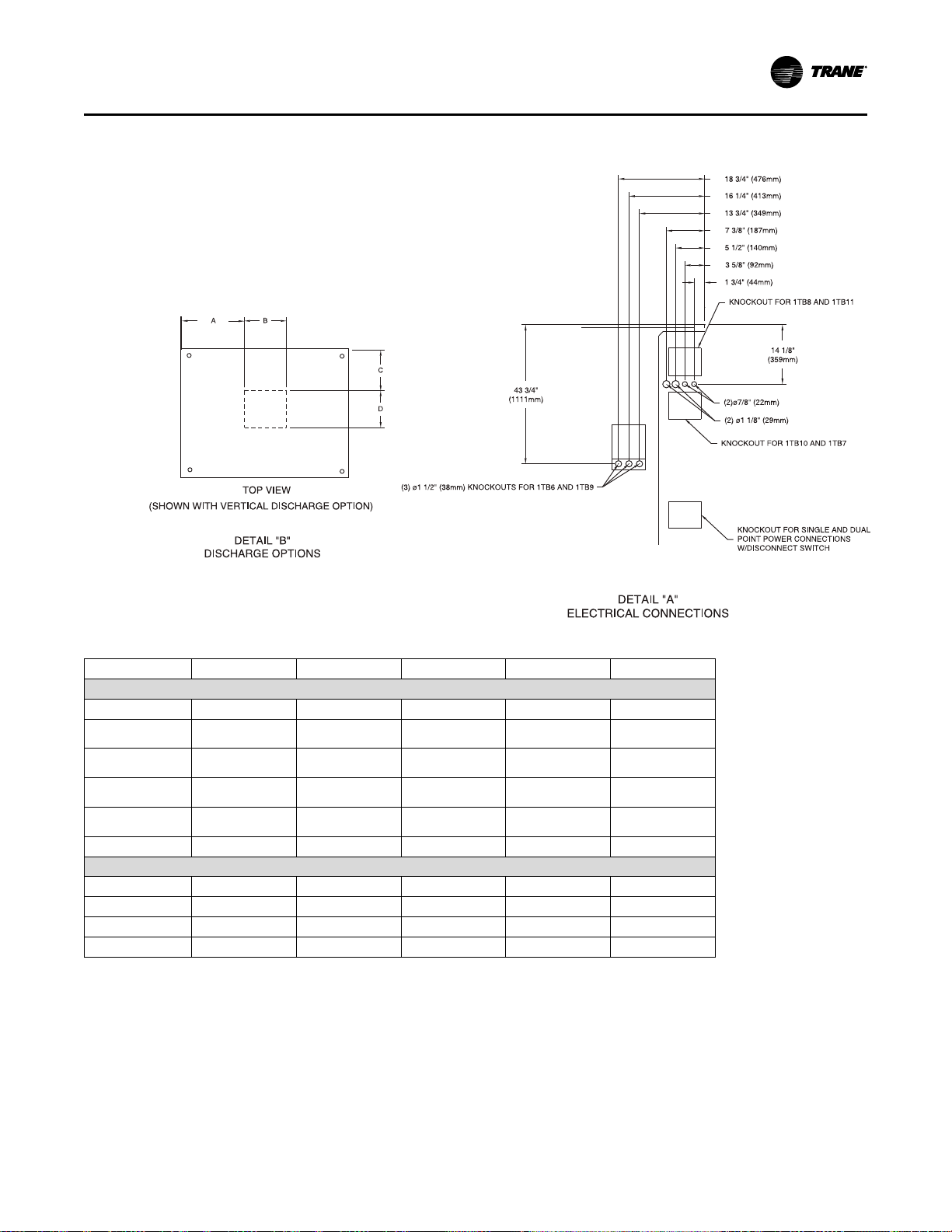

Figure 9. Detail A: electrical connections 20 to 110 tons

40 3/8” (20-38 Ton)

PLUGS

PLUGS

DDiimmeennssiioonnaall DDaattaa

Table 12. Discharge dimensions (in.)

Unit Model Fan Size A B C D

Standard Fan

SCWF 20-25 18” 31.85 23.5 23.11 20.4

SCWF 29-32

SCRF 25-29

SCWF 35-38

SCRF 30-35

SCWF 42-58

SCRF 40-50

SCWF 65-80

SCRF 60

SCWF 90-110 27.5” 50.7 33.5 28.8 34.5

SCWF 38 18” 44.8 23.25 36.78 19

SCWF 46 18” 44.8 23.25 36.78 19

SCWF 58 18” 44.8 23.25 36.78 20.4

SCWF 72 20” 43.4 26.2 34.77 24.6

18” 31.85 23.5 23.11 20.4

20” 30.5 26.2 21.25 25.75

25” 43.75 33 31.5 31.5

27.5” 43.5 33.5 28.63 34.5

Low Flow Fan Option

SCXF-SVX01Q-EN

27

Page 28

Main Control Panel

Vacuum Trap Connection

Condensate Return

Vacuum Trap Connection

Steam Inlet Connection

Condensate Return

Air Inlet

L

K

F

N

M

H

J

A

C

B

Notes:

1. All coils are factory mounted, piped, and wired.

2. All piping connections are 1-1/2” (38.1mm) female NPT fittings.

Main Control Panel

Air Inlet

Hot Water Outlet Connection

Hot Water Inlet Connection

H

F

G

A

B

E

D

C

DDiimmeennssiioonnaall DDaattaa

Steam and Hot Water Coils

Steam Coils

Figure 10. Steam Coil

Table 13. Piping locations for steam coils (in)(lbs)

Unit Size A B C D E F G H J K L M N

20-38 Ton

42-80 Ton

Note: Weight includes complete heating coil box.

60-3/8 82-7/8

72-7/8 105-1/4

18 — —

18 — —

22-3/8

13-1/4

— —

— —

18-1/2 3-7/8

22-1/8 6-3/8

5

5-375

4-3/8 1-1/4

4-3/8 1-1/4

Weight

460

600

Hot Water Coils

Figure 11. Hot Water Coil

Table 14. Hot water coil piping locations & weight (in)(lbs)

Unit Size A B C D E F G H

20-38 Ton

42-80 Ton

Note: Weight includes complete heating coil box.

28

60 3/8 82 7/8

72 7/8 105 1/4

18

18

20 5/8 8 1/8 22 3/8 3 5/8 8 1/4

24 1/2 10 3/4 13 1/4 3 5/8 8 1/4

Weight

460

600

SCXF-SVX01Q-EN

Page 29

B

C

A

DDiimmeennssiioonnaall DDaattaa

Plenum

Figure 12. Six-inch filter rack

Table 15. Plenum dimensions (in)(lbs)

Unit Model A B C

64-7/8 24-5/8 95-7/8

64-7/8 32-3/8 95-7/8

64-7/8

80-3/8 21-1/8 119-7/8

80-3/8 28-5/8 119-7/8

80-3/8

80-1/2 19-5/8

80-1/2 27-3/4

80-1/2 43-1/2

45

45

20-38 Ton

42-80 Ton

90-110 Ton

low

std.

ext.

low

std.

ext.

low

std.

ext.

Filters

95-7/8

119-7/8

140 430

140 595

140 795

Weight

325

430

705

390

540

705

Table 16. Six-inch filter rack weight, lbs.

SCXF-SVX01Q-EN

Unit Size

20-38 212

42-80 257

Weight

29

Page 30

DDiimmeennssiioonnaall DDaattaa

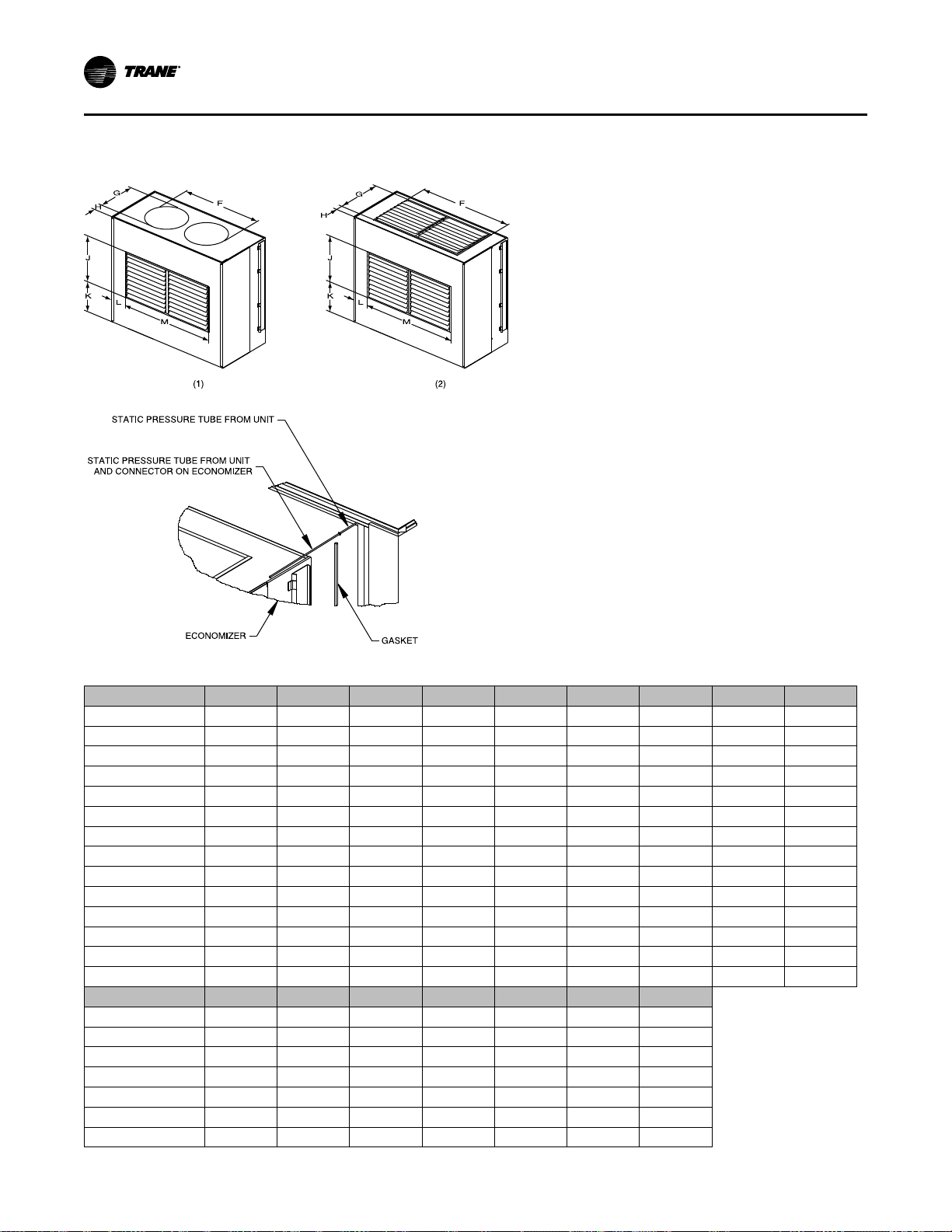

Airside Economizer

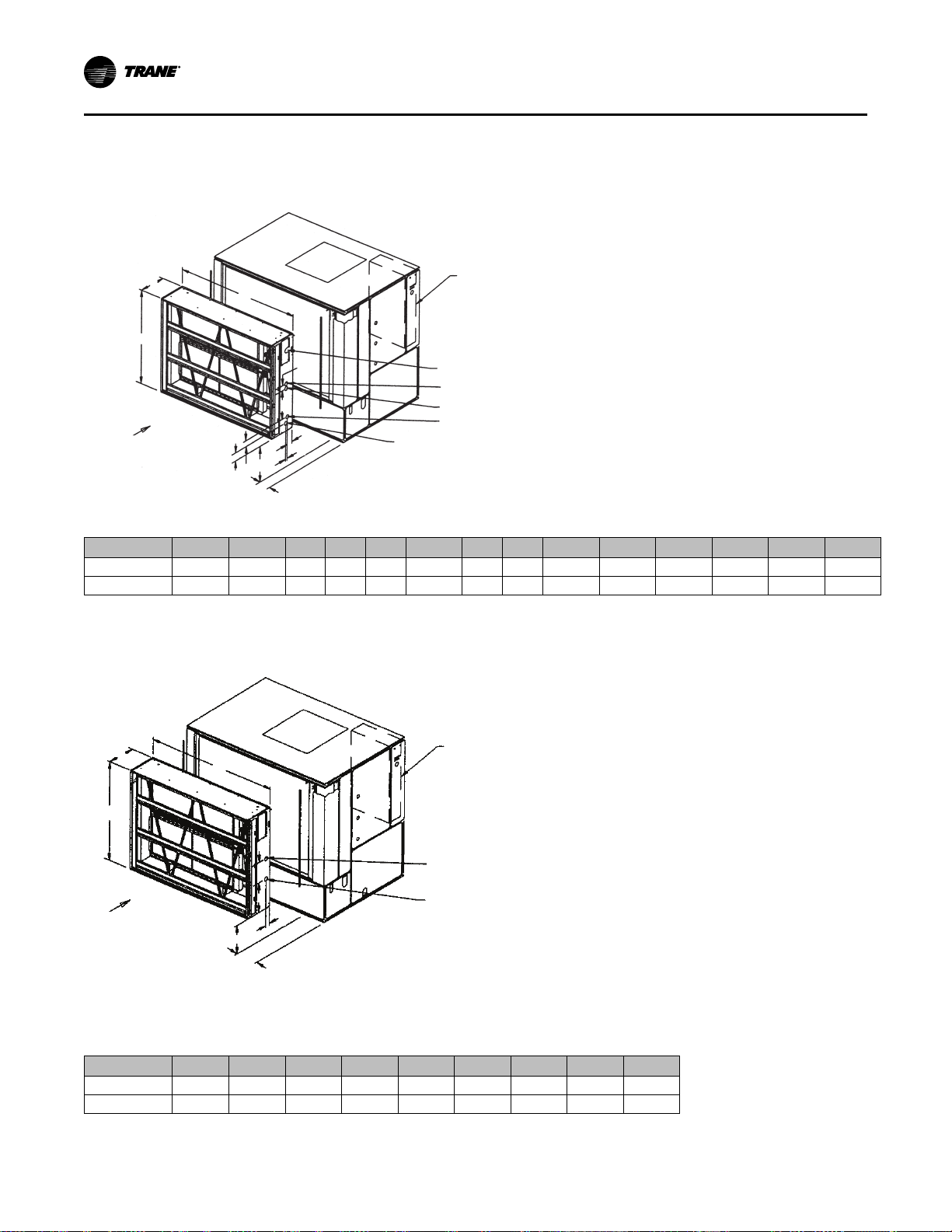

Figure 13. Airside economizer

Table 17. Airside economizer sizes and dimensions (in.)

Size A B C D E

SXWF 20 44 74

SXRF 25 44 74

SXWF 22 44 74

SXRF 29 44 74

SXWF 32 44 74

SXRF 30-35 44 74

SXWF 35-38 44 74

SXWF 42

SXRF 40

SXWF 46

SXRF 50

SXRF 60

SXRF 52-58

SXWF 65-80

Size

SXWF 20

SXRF 25

SXWF 22

SXRF 29

SXWF 32

SXRF 30-35

SXWF 35-38

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 83-5/8 63-1/2

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 94-1/8 63-1/2 28-1/8

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 94-1/8 63-1/2 28-1/8

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 96-5/8 63-1/2

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 96-5/8 63-1/2

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 96-5/8 63-1/2

57-3/8 86-1/2 13-1/4 104-3/8 8-7/8 96-5/8 63-1/2

H (1) H (2)

9-3/4 11-1/8 20-1/2 22-1/4

7-1/4 11-1/8 20-1/2 22-1/4

7-1/4 11-1/8 20-1/2 22-1/4

9-3/4 11-1/8 20-1/2 22-1/4 9-1/2 62-3/4

9-3/4 11-1/8 20-1/2 22-1/4 9-1/2 62-3/4

4-7/8 11-1/8 20-1/2 22-1/4 9-1/2 62-3/4

4-7/8 11-1/8 20-1/2 22-1/4 9-1/2 62-3/4

22-3/8 81-3/4 8-3/4 66-3/4 49-3/4 23-1/4 20-1/2

22-3/8 81-3/4 8-3/4 68-5/8 49-3/4 28-1/8 20-1/2

22-3/8 81-3/4 8-3/4 68-5/8 49-3/4 28-1/8 20-1/2

22-3/8 81-3/4 8-3/4 74-1/4 62-3/4 23-1/4 20-1/2

22-3/8 81-3/4 8-3/4 74-1/4 62-3/4 23-1/4 20-1/2

22-3/8 81-3/4 8-3/4 73-1/2 62-3/4

22-3/8 81-3/4 8-3/4 73-1/2 62-3/4

J K L M

16

16

16

F (1) F (2) G (1) G (2)

33

33

33 26

52

52

52

52

20-1/2

20-1/2

26

26

37-1/2

37-1/2

37-1/2

37-1/2

Weight

49-3/4

49-3/4

49-3/4

430

500

500

500

500

500

500

30

SCXF-SVX01Q-EN

Page 31

Table 17. Airside economizer sizes and dimensions (in.) (continued)

Air Inlet

See Table

42” (1066.8mm) (20-38 Ton)

Minimum

48” (1219mm) (42-110 Ton)

Control

Panel

36” (914.4mm)

Minimum

Left side

Front

Right side

Size

SXWF 42

SXRF 40

SXWF 46

SXRF 50

SXRF 60

SXRF 52-58

SXWF 65-80

H (1) H (2)

2-1/2

6-7/8

6-7/8

1-7/8 9-1/4 37-1/2

1-7/8 9-1/4 37-1/2

1-7/8 9-1/4 37-1/2

1-7/8 9-1/4 37-1/2

15 26

15 26

15 26

J K L M

24-3/4 20-3/8 63-1/2

24-3/4 20-3/8 63-1/2

24-3/4 20-3/8 63-1/2

19

19

19

19

20-3/8 63-1/2

20-3/8 63-1/2

20-3/8 63-1/2

20-3/8 63-1/2

DDiimmeennssiioonnaall DDaattaa

Weight

640

640

640

700

700

700

800

Service Clearances

See figure and table below for recommended service

and code clearances.

Table 18. Service and code clearance requirements

Side

Front

Left

Right

Inlet

Distance—inches (mm) Purpose

42 (1066) (20 to 38 tons) NEC code requirements

48 (1219) (42 to 110 tons)

36 (914) Filter, refrigeration, and waterside components

9 (229) Non VFD w/open return

18 (457)

9 (229) 20 to 80 tons, w/VFD 7.5 to 50 hp

36 (914) 90 to 110 tons (motor, condensers, and refrigeration)

18 (457) (20 to 80 tons)

36 (914) (90 to 110 tons)

Figure 14. Top view of self-contained unit showing

recommended service and code clearances(a)

NNoottee:: (a) See for right side clearance values for various

unit configurations.

Fan service/removal

Non VFD w/ducted return

Provides uniform airflow

Provides uniform airflow

SCXF-SVX01Q-EN

31

Page 32

Weights

Table 19. Unit weights — SCWF/SCRF/SIWF/SIRF

Airside

Economizer

lbs. (kg)

N/A N/A

N/A N/A

N/A N/A

20

22

25

29

32

35

38

42

46

52

58

65

72

80

90

100

110

25

29

30

35

40

50

60

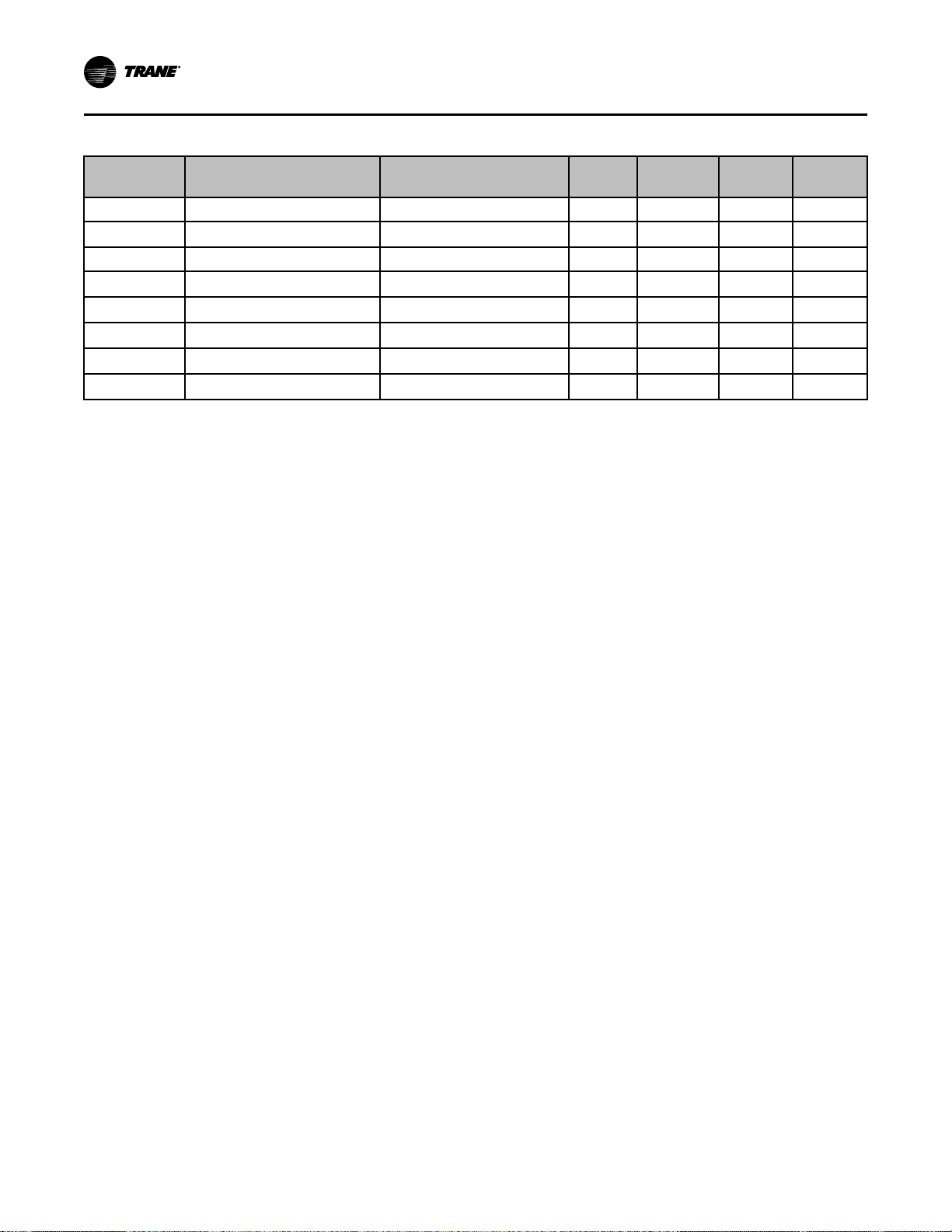

Base Weight

lbs. (kg)

3102 (1407) 430 (195) 140 (64) 340 (154) 460 (209)

3102 (1407) 430 (195) 140 (64) 340 (154) 460 (209)

3170 (1438) 430 (195) 140 (64) 340 (154) 460 (209) 144 (65) 212 (96)

3326 (1508) 500 (227) 190 (86) 390 (177) 460 (209)

3514 (1594) 500 (227) 190 (86) 390 (177) 460 (209) 132 (60) 212 (96)

3721 (1688) 500 (227) 280 (127) 505 (229) 460 (209)

3819 (1732) 500 (227) 280 (127) 505 (229) 460 (209) 138 (63) 212 (96)

4615 (2093) 640 (290) 255 (116) 505 (229) 600 (272)

4705 (2134) 640 (290) 255 (116) 505 (229) 600 (272) 170 (77) 257 (117)

4892 (2219) 700 (318) 335 (152) 665 (302) 600 (272)

5142 (2332) 700 (318) 335 (152) 665 (302) 600 (272) 216 (98) 257 (117)

5371 (2436) 800 (363) 335 (152) 665 (302) 600 (272)

5491 (2490) 800 (363) 335 (152) 665 (302) 600 (272) 216 (98) 257 (117)

5814 (2637) 800 (363) 335 (152) 665 (302) 600 (272)

6330 (2871)

6840 (3103)

6852 (3108)

3231 (1465) 500 (227)

3231 (1465) 500 (227)

3321 (1506) 500 (227)

3421 (1552) 500 (227)

4294 (1948) 640 (290)

4731 (2146) 700 (318)

5288 (2399) 800 (363)

Unit

SCWF/

SIWF

SCRF/

SIRF

Notes:

1. All unit weights include refrigerant, water, and controllers, electric heat and valves.

2. Add 150 lbs. to total weight to obtain approximate shipping weight.

3. Flexible horizontal discharge plenum option weights: 45-inch plenum = 705 lbs., Standard height plenum = 430 lbs., Low height plenum = 325 lbs.

Unit

Size

2-Row

Waterside

Economizer

lbs. (kg)

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

4-Row

Waterside

Economizer

lbs. (kg)

1015 (460)

1015 (460)

1015 (460)

Heating

Coil Box

lbs. (kg)

N/A

N/A

N/A

460 (209)

460 (209)

460 (209)

460 (209)

600 (272)

600 (272)

600 (272)

6-Row

Evap. Coil

lbs. (kg)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

255 (116)

255 (116)

255 (116)

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

6-inch filter

rack lbs.

(kg)

212 (96)

212 (96)

212 (96)

212 (96)

257 (117)

257 (117)

257 (117)

257 (117)

N/A

N/A

N/A