Trane S9V2B040U3PSBA, S9V2B060U3PSBA, S9V2B060U4PSBA, S9V2B080U3PSBA, S9V2B080U4PSBA Specification Sheet

...Page 1

Product Data

Upflow/ Horizontal Left/Right, Downflow

Two Stage Condensing

Gas Fired Furnace

UUppffllooww,, CCoonnvveerrttiibbllee ttoo

HHoorriizzoonnttaall RRiigghhtt oorr

HHoorriizzoonnttaall LLeefftt

S9V2B040U3PSBA

S9V2B060U3PSBA

S9V2B060U4PSBA

S9V2B080U3PSBA

S9V2B080U4PSBA

S9V2C080U5PSBA

S9V2C100U4PSBA

S9V2C100U5PSBA

S9V2D120U5PSBA

DDoowwnnffllooww OOnnllyy

S9V2B040D3PSBA

S9V2B060D3PSBA

S9V2B080D3PSBA

S9V2B080D4PSBA

S9V2C100D4PSBA

S9V2C100D5PSBA

S9V2D120D5PSBA

NNoottee:: Graphics in this document are for representation

only. Actual model may differ in appearance.

March 2017

2222--11992211--11CC--EENN

Page 2

General Features

NNAATTUURRAALL GGAASS MMOODDEELLSS

Central Heating furnace designs are certified by the American Gas Association for both natural

and L.P. gas. Limit setting and rating data were established and approved under standard rating

conditions using American National Standards Institute standards.

SSAAFFEE OOPPEERRAATTIIOONN

The Integrated System Control is a solid state device which continuously monitors for presence

of flame when the system is in the heating mode of operation. Dual solenoid combination gas

valve and regulator provide additional safety.

QQUUIICCKK HHEEAATTIINNGG

Durable, cycle tested, heavy gauge ttuubbuullaarr ssttaaiinnlleessss sstteeeell pprriimmaarryy hheeaatt eexxcchhaannggeerr quickly

transfers heat to provide warm conditioned air to the structure. LLooww eenneerrggyy ppoowweerr vveenntt

bblloowweerr,, to increase efficiency and provide a positive discharge of gas fumes to the outside.

BBUURRNNEERRSS

Multiport Inshot burners will give years of quiet and efficient service. All models can be

converted to LL..PP.. ggaass with LP conversion kit.

IINNTTEEGGRRAATTEEDD SSYYSSTTEEMM CCOONNTTRROOLL

Exclusively designed operational program provides total control of furnace limit sensors,

blowers, gas valve, flame control and includes self diagnostics for ease of service. Also contains

dry contacts for EAC and HUM.

EENNEERRGGYY EEFFFFIICCIIEENNTT OOPPEERRAATTIIOONN

Furnace is certified by the manufacturer to leak 1% or less of nominal air conditioning CFM

delivered when pressurized to .5" water column with all inlets, outlets, and drains sealed.

AAIIRR DDEELLIIVVEERRYY

The variable speed blower motor has sufficient airflow for most heating and cooling

requirements and will switch from heating to cooling speeds on demand from room thermostat.

SSEECCOONNDDAARRYY HHEEAATT EEXXCCHHAANNGGEERR

The S-Series furnace has a special type 29- 4C™ stainless steel secondary heat exchanger to

reclaim heat from flue gases which would normally be lost.

SSTTYYLLIINNGG

HHeeaavvyy ggaauuggee sstteeeell aanndd ""wwrraapp--aarroouunndd"" ccaabbiinneett ccoonnssttrruuccttiioonn is used in the cabinet with bakedon enamel finish for strength and beauty. Every orientation has at least two venting options.

There are no knockouts on cabinet.

FFEEAATTUURREESS AANNDD GGEENNEERRAALL OOPPEERRAATTIIOONN

The S-Series furnace utilizes a Silicon Nitride Hot Surface Ignition system, which eliminates the

waste of a constant burning pilot. The integrated system control lights the main burners upon a

demand for heat from the room thermostat. Complete front service access.

a. Low energy power venter

b. Vent proving pressure switches.

2

22-1921-1C-EN

Page 3

Features and Benefits

9966..00%% AAFFUUEE AACCRROOSSSS AALLLL MMOODDEELLSS

Meets utility rebates

Lowers utility bills

EELLEECCTTRRIICCAALLLLYY EEFFFFIICCIIEENNTT

Efficient airflow design reduces electrical energy use

3344 IINNCCHH TTAALLLL

Lighter, easier to move and fit into tight spaces like short basements or tight closets

Works great with larger, high-efficiency coils

No knockouts

33––WWAAYY MMUULLTTII--PPOOIISSEE // DDEEDDIICCAATTEEDD DDOOWWNNFFLLOOWW

9 SKU’s — Upflow / Horizontal Left / Horizontal Right

7 SKU’s — Downflow

Added application flexibility and reduction in specification errors

AAIIRRFFLLOOWW

At least 400 CFM/ton at 0.5 in. H

CFM/ton

RREEGGUULLAATTOORRYY

All models are air tight; 1% or less air leakage as per ASHRAE 193

Open vestibule design provides a full 34” high open vestibule

DDIIMMEENNSSIIOONNSS

Widths are industry standard: 17.5”, 21”, and 24.5”

Depth remains approximately 28”

Cabinet will be compatible with industry standard coils, as well as, other accessories

IINNTTEEGGRRAATTEEDD FFUURRNNAACCEE CCOONNTTRROOLL

Setup / Status / Diagnostics / Digital Display

No dip switches

Last six errors stored

Dry contact EAC and HUM connections

All Molex connections; no spade terminals

Low voltage labeled above and below

Rain shield over IFC keeps condensate off the control

TTUUBBUULLAARR SSTTAAIINNLLEESSSS SSTTEEEELL PPRRIIMMAARRYY HHEEAATT EEXXCCHHAANNGGEERR

2299––44CC SSTTAAIINNLLEESSSS SSTTEEEELL SSEECCOONNDDAARRYY HHEEAATT EEXXCCHHAANNGGEERR

Stainless steel is a more durable, corrosive-resistant material than aluminumized steel

Integrated rail system for easy access if required

Reduces or eliminates need for baffles

VVOORRTTIICCAA IIII BBLLOOWWEERR,, DDEESSIIGGNNEEDD EEXXCCLLUUSSIIVVEELLYY FFOORR TTHHEE SS--SSEERRIIEESS FFUURRNNAACCEE

Improved airflow efficiency

Durable, easy to clean, two piece housing

Single piece belly band/ motor arm assembly

Blower deck has full-length rails for easy removal and replacement, regardless of poise

0 external static pressure; setup airflow options down to 290

2

22-1921-1C-EN

3

Page 4

FFeeaattuurreess aanndd BBeenneeffiittss

TTHHRREEEE––WWAAYY MMUULLTTII--PPOOIISSEE ((UUPPFFLLOOWW,, HHOORRIIZZOONNTTAALL LLEEFFTT AANNDD RRIIGGHHTT)) PPLLUUSS DDEEDDIICCAATTEEDD

DDOOWWNNFFLLOOWW

Easier to specify

Shipped ready to install (no kits required)

Every model has at least two venting options

When in horizontal, trap extends only about 2”

Barbed fitting on trap at hose connection and on cabinet transition for hose has barbed fitting

and clamps at both ends for leak resistance.

Vent table improvements including longer vent lengths; 2” pipe can be used up to 100K

4

22-1921-1C-EN

Page 5

Accessories

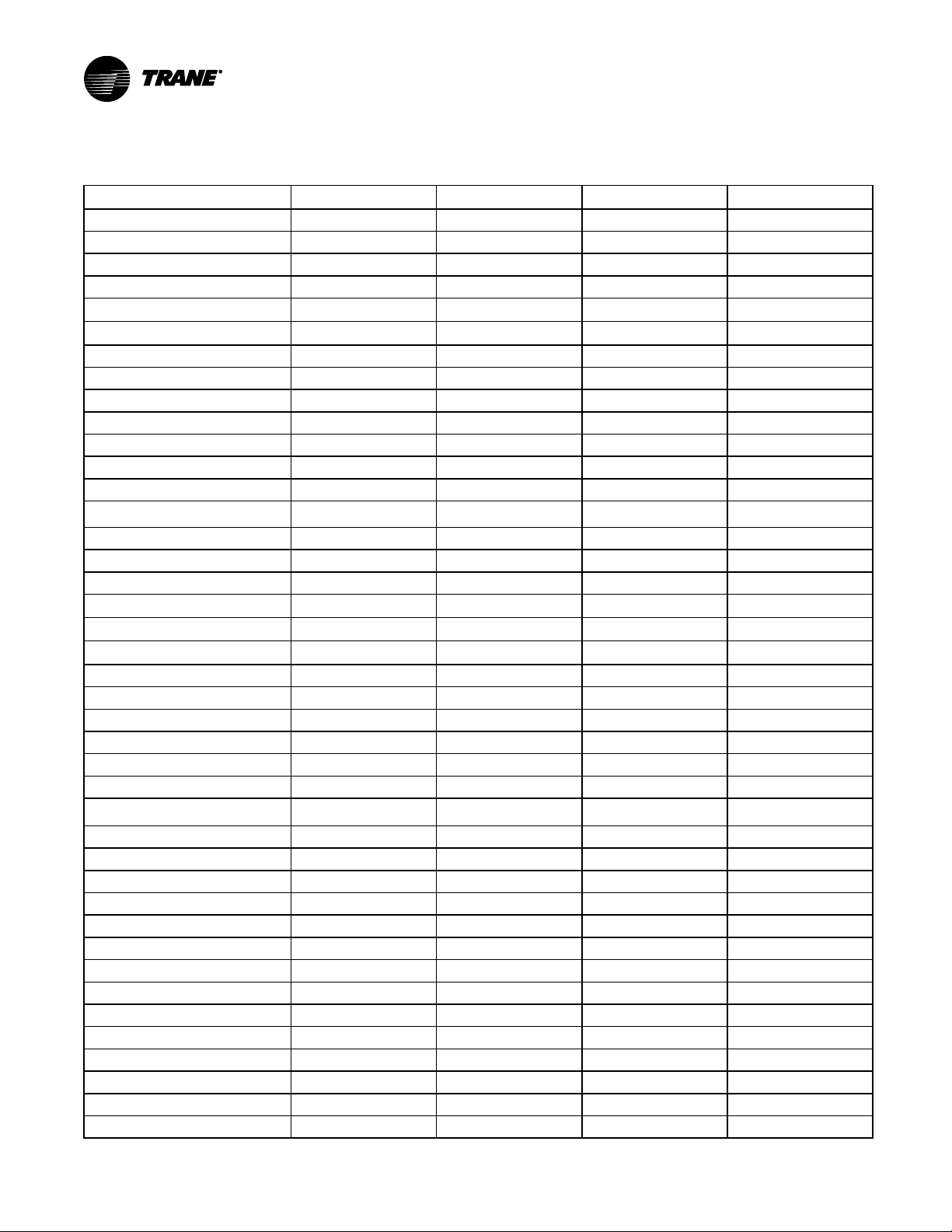

Table 1. Accessories

Model Number Description Use with

BAYHANG Horizontal Hanging Kit All Upflow Furnaces

BAYVENT200B Sidewall Vent Termination Kit All Furnaces

BAYVENTCN200B Sidewall Vent Termination Kit (Canada —

BAYAIR30AVENTA Concentric Vent Kit All Furnaces

BAYAIR30CNVENT Concentric Vent Kit (Canada — CPVC) All Furnaces

BAYREDUCE Reducing Coupling (CPVC) All Furnaces

BAYLIFTB Dual Return Kit (B size extension) B Cabinet Upflow Furnaces

BAYLIFTC Dual Return Kit (C size extension) C Cabinet Upflow Furnaces

BAYLIFTD Dual Return Kit (D size extension) D Cabinet Upflow Furnaces

BAYBASE205

BAYFLTR206

BAYSLF1165AA

BAYFLTR203 Horizontal Filter Kit B Cabinet Furnaces in Downflow/Horizontal

BAYFLTR204 Horizontal Filter Kit C Cabinet Furnaces in Downflow/Horizontal

BAYFLTR205 Horizontal Filter Kit D Cabinet Furnaces in Downflow/Horizontal

BAYLPSS400A LP Conversion Kit with Stainless Steel Burners All Furnaces

BAYMFGH200A Manufactured/Mobile Housing Kit All Furnaces

(a)

Airflow greater than 1600 CFM requires dual returns

(a)

CPVC)

Downflow Subbase All Downflow Furnaces

Filter Access Door Kit (Downflow only) All Upflow Furnaces

1” SlimFit Box with MERV 4 Filter All Upflow Furnaces

All Furnaces

22-1921-1C-EN

5

Page 6

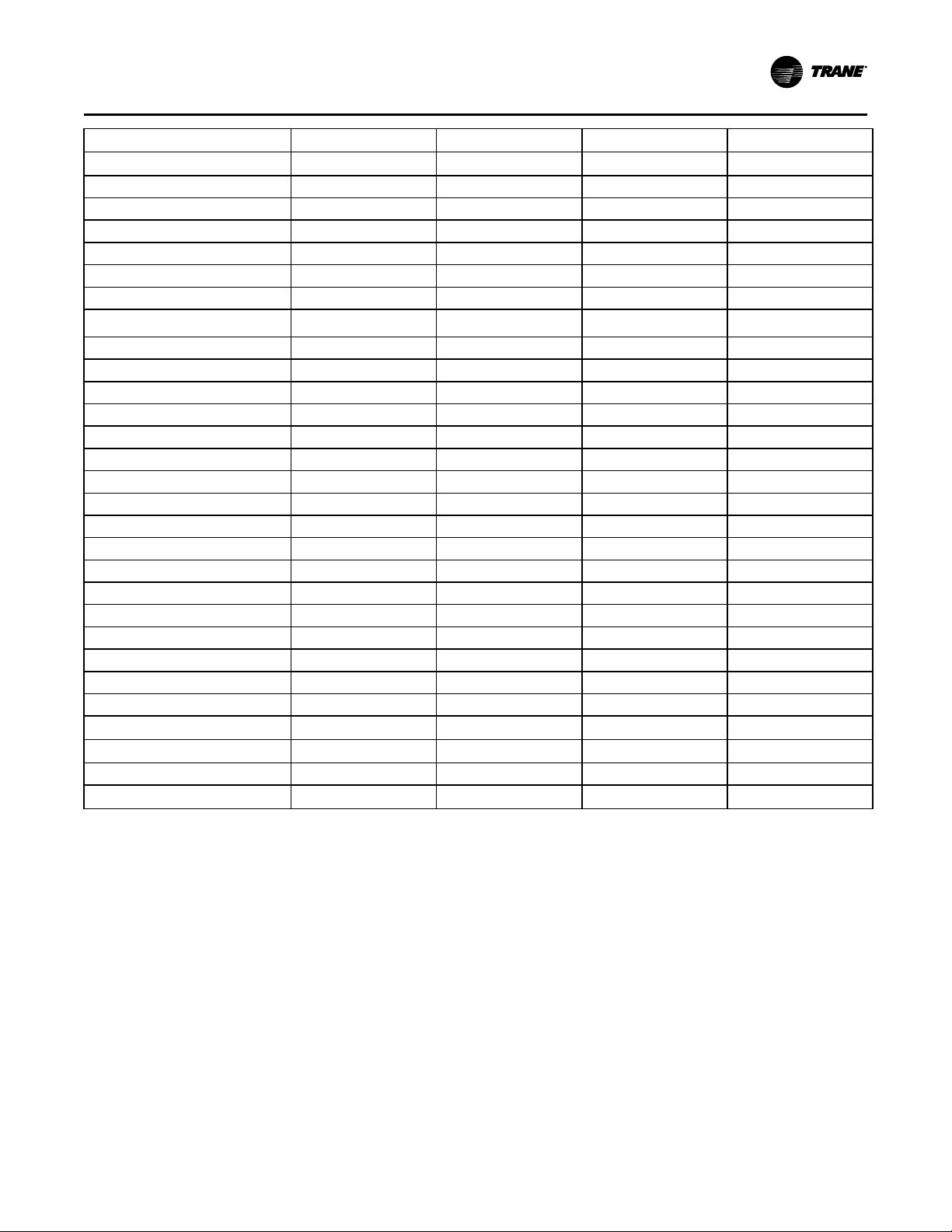

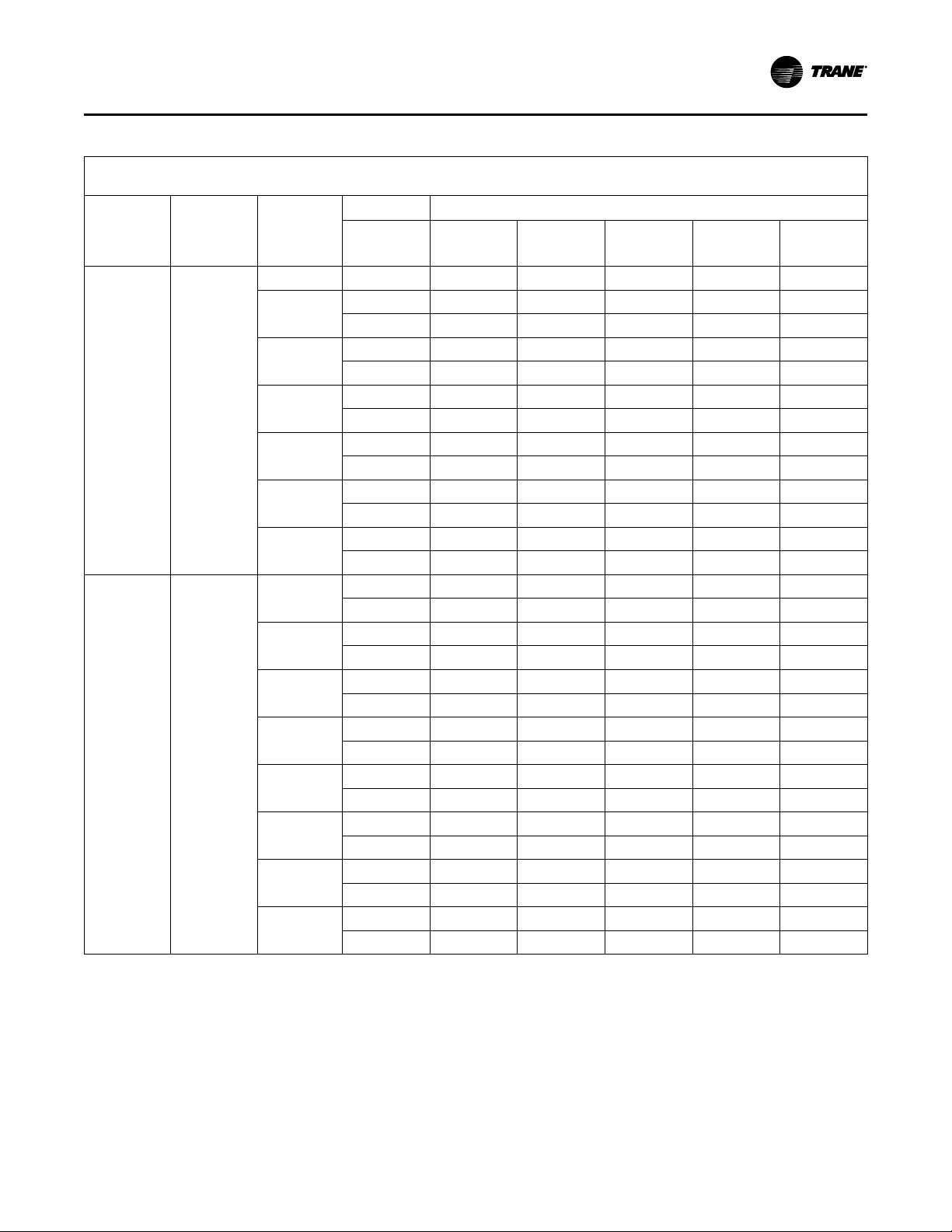

Product Specification

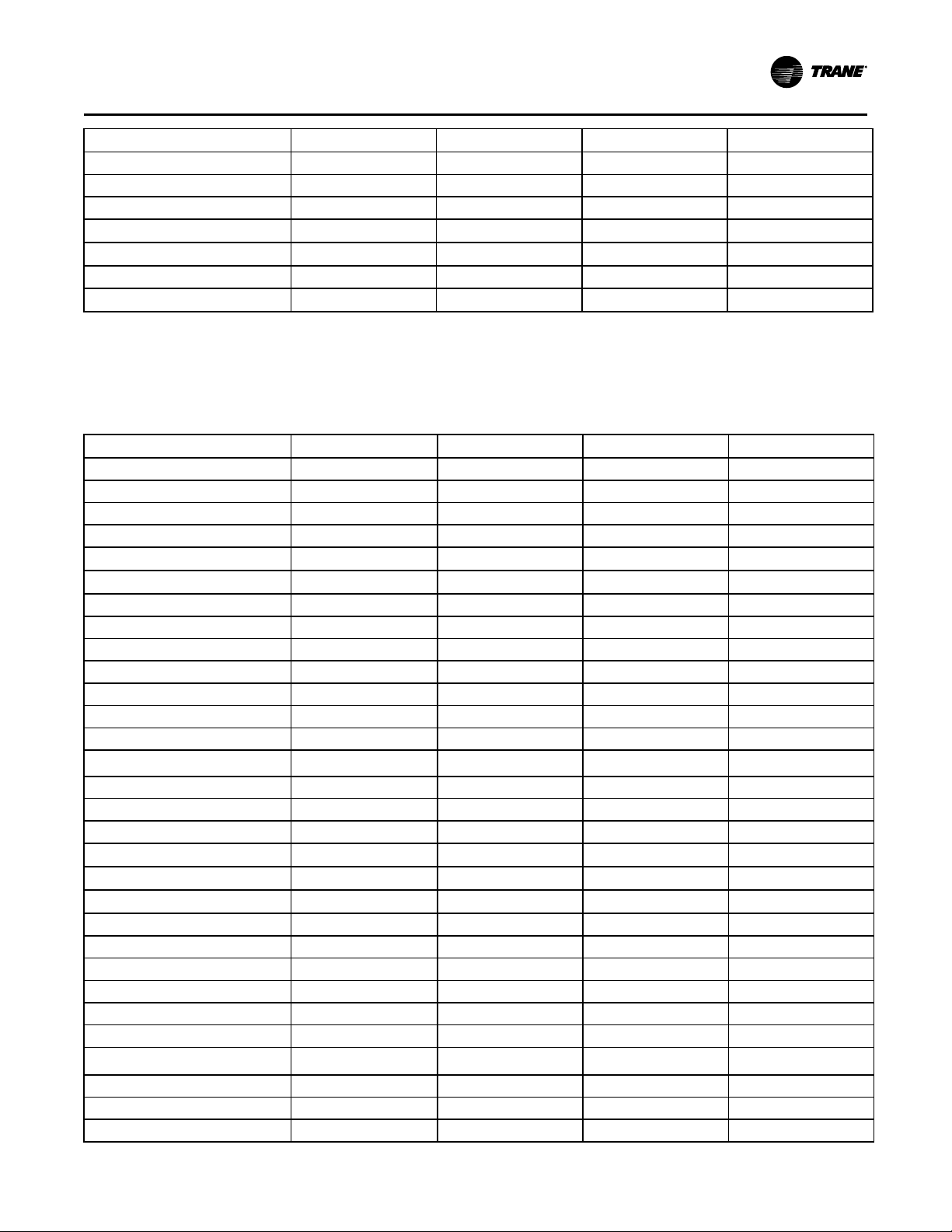

MODEL

TYPE

RATINGS

S9V2B040U3PSBA

(a)

S9V2B060U3PSBA

Upflow/Horizontal Upflow/Horizontal Upflow/Horizontal Upflow / Horizontal

(b)

(a)

S9V2B060U4PSBA

(a)

S9V2B080U3PSBA

1st Stage Input BTUH (ICS) 26,000 39,000 39,000 52,000

1st Stage Capacity BTUH 25,220 37,830 37,830 50,440

2nd Stage Input BTUH 40,000 60,000 60,000 80,000

2nd Stage Capacity BTUH (ICS)

1st Stage Temp. Rise (Min.-Max.)

2nd Stage Temp. Rise (Min.-Max.)

AFUE (%)

(c)(d)

(c) (d)

38,800 58,200 58,200 77,600

25 - 55 25 - 55 25 - 55 30 - 60

30 - 60 35 - 65 35 - 65 40 - 70

96.0 96.0 96.0 96.0

BLOWER DRIVE DIRECT DIRECT DIRECT DIRECT

Diameter — Width (In.)

11 X 8 11 X 8 11 X 8 11 X 8

No. Used 1 1 1 1

Speeds (No.)

CFM vs. in. w.g.

Motor HP

Variable Variable Variable Variable

See Fan Performance

Table

See Fan Performance

Table

See Fan Performance

Table

1/2 1/2 3/4 1/2

See Fan Performance

Table

RPM Variable Variable Variable Variable

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 5.7 5.7 8.0 5.7

COMBUSTION FAN — Type Centrifugal Centrifugal Centrifugal Centrifugal

Drive — No. Speeds

Motor HP — RPM

Direct - 2 Direct - 2 Direct - 2 Direct - 2

3300/2600 3300/2600 3300/2600 3300/2600

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 0.66 0.66 0.66 0.66

FILTER — Furnished? No No No No

Type recommended High Velocity High Velocity High Velocity High Velocity

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER — Min (in.)

(e) (f)

1 — 16x25 — 1 in. 1 — 16x25 — 1 in. 1 — 16x25 — 1 in. 1 — 16x25 — 1 in.

2 Round 2 Round 2 Round 2 Round

HEAT EXCHANGER

Type — Fired

409 Stainless Steel 409 Stainless Steel 409 Stainless Steel 409 Stainless Steel

— Unfired 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel

Gauge (Fired)

20 20 20 20

ORIFICES — Main

Nat. Gas Qty.— Drill Size

LP Gas Qty. — Drill Size

GAS VALVE

Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage

2- 45 3 - 45 3 - 45 4 - 45

2- 56 3 - 56 3 - 56 4 - 56

PILOT SAFETY DEVICE

Type 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter

BURNERS — Type Multiport Inshot Multiport Inshot Multiport Inshot Multiport Inshot

Number 2 3 3 4

POWER CONN. — V/Ph/Hz

Ampacity (In Amps)

(g)

120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

7.9 7.9 10.8 7.9

(a)

6

22-1921-1C-EN

Page 7

PPrroodduucctt SSppeecciiffiiccaattiioonn

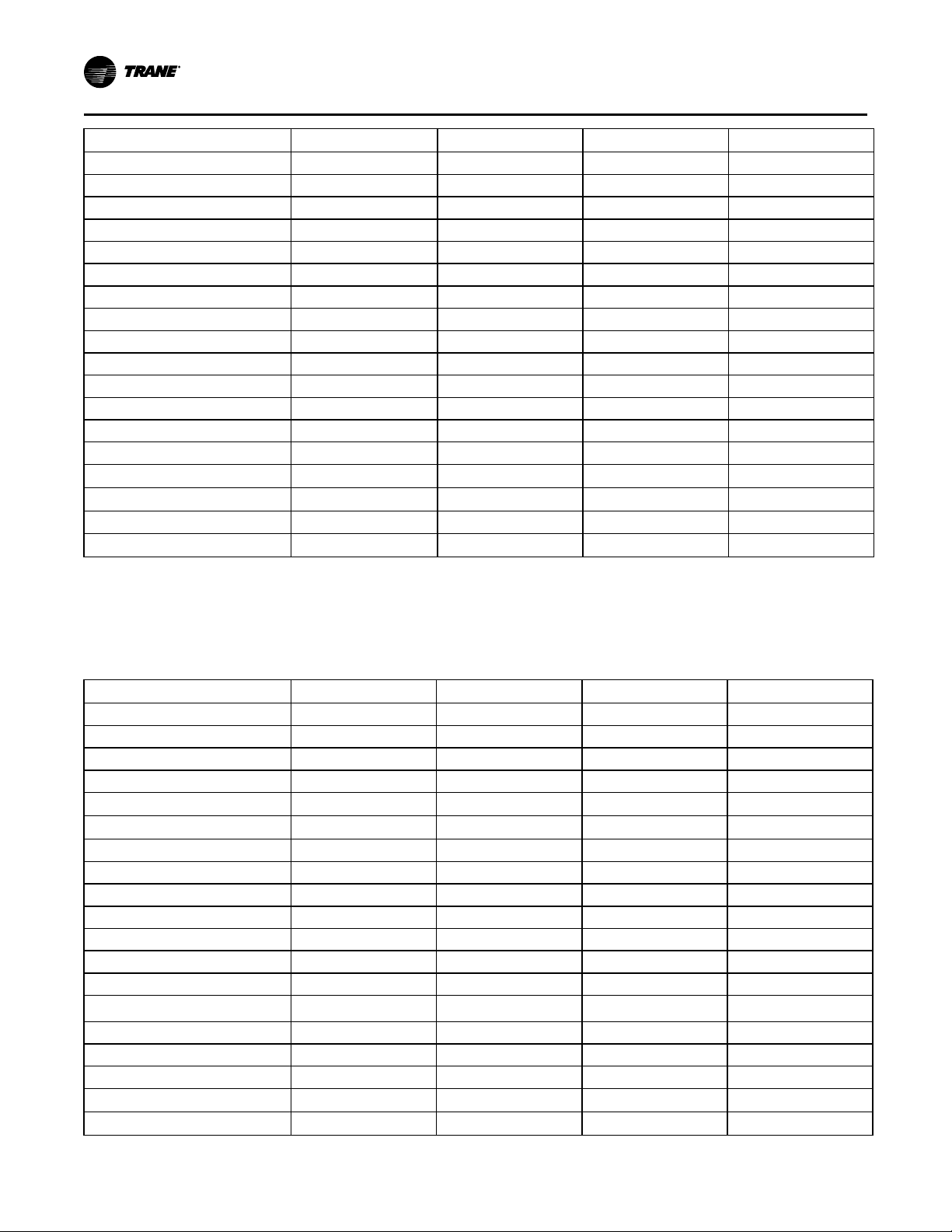

MODEL

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (in.)

S9V2B040U3PSBA

15 15 15 15

1/2 1/2 1/2 1/2

(a)

S9V2B060U3PSBA

(a)

S9V2B060U4PSBA

(a)

S9V2B080U3PSBA

DIMENSIONS H x W x D H x W x D H x W x D H x W x D

Uncrated (In.)

Crated (In.)

34 x 17-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4

35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8

WEIGHT

Shipping (Lbs.)/Net (Lbs.)

(a)

Meets Energy Star

(b)

For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level. For

Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

(c)

Central Furnace heating designs are certified to ANSI Z21.47 / CSA 2.3 — latest edition.

(d)

Based on U.S. government standard tests.

(e)

Refer to the Vent Length Table in the Installer's Guide.

(f)

All S9V2 furnace models have a vent outlet diameter that equals 2 in.

(g)

The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

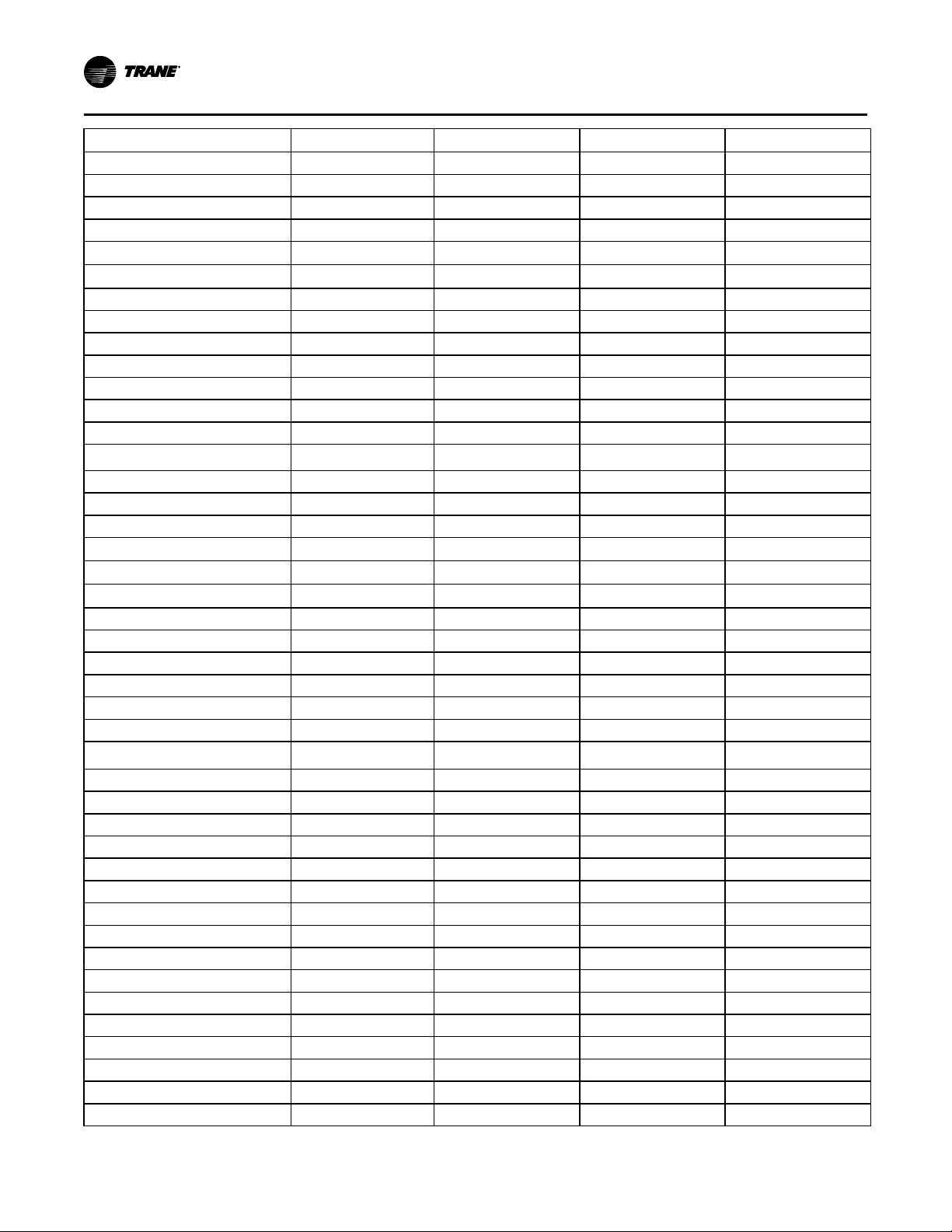

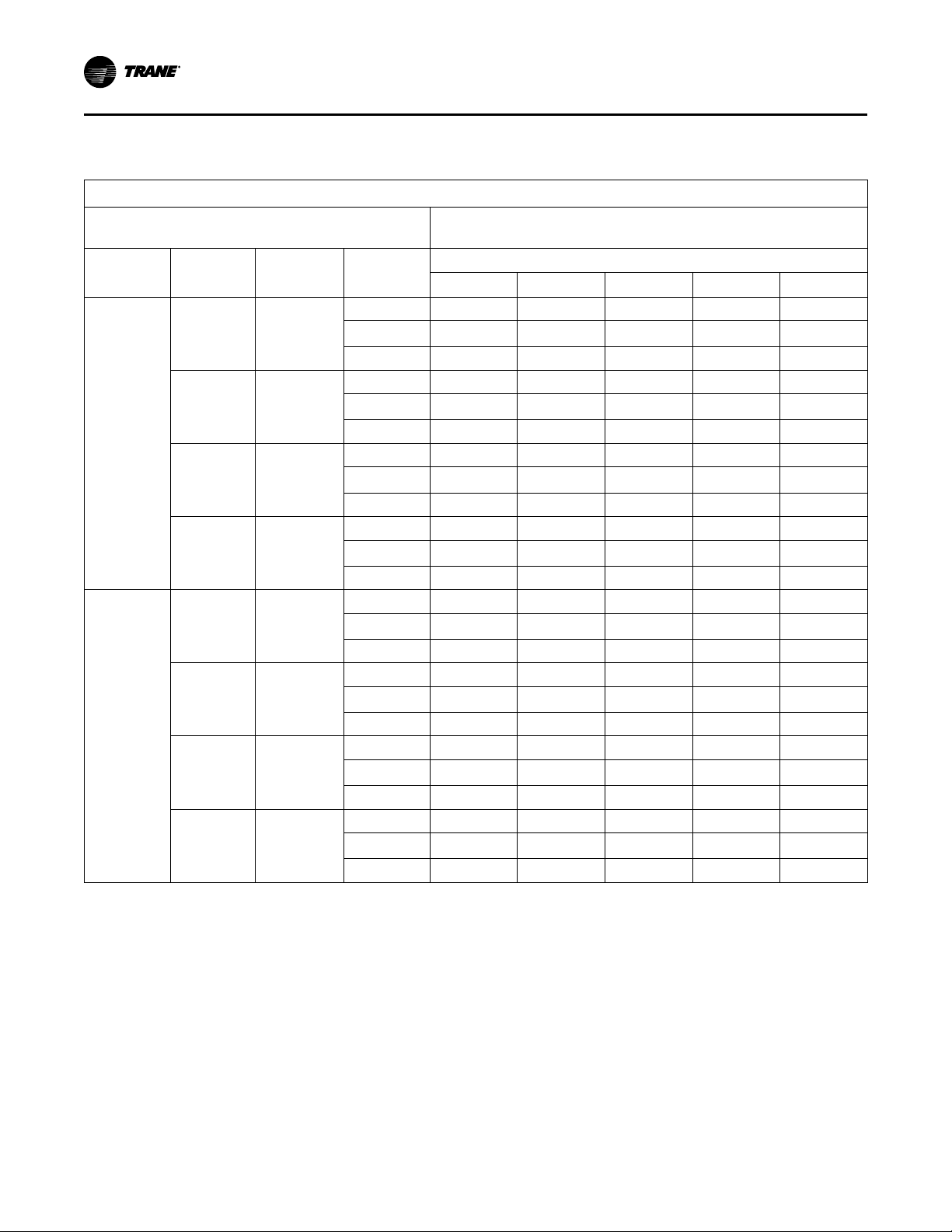

MODEL

TYPE

RATINGS

(b)

122/114 127/119 130/122 132/124

S9V2B080U4PSBA

(a)

S9V2C080U5PSBA

(a)

S9V2C100U4PSBA

(a)

S9V2C100U5PSBA

Upflow/Horizontal Upflow/Horizontal Upflow/Horizontal Upflow / Horizontal

1st Stage Input BTUH (ICS) 52,000 52,000 65,000 65,000

1st Stage Capacity BTUH 50,440 50,440 63,050 63,050

2nd Stage Input BTUH 80,000 80,000 100,000 100,000

2nd Stage Capacity BTUH (ICS)

1st Stage Temp. Rise (Min.-Max.)

2nd Stage Temp. Rise (Min.-Max.)

AFUE (%)

(c)(d)

(c) (d)

77,600 77,600 97,000 97,000

30 - 60 30 - 60 25 - 55 25 - 55

35 - 65 35 - 65 35 - 65 30 - 60

96.0 96.0 96.0 96.0

BLOWER DRIVE DIRECT DIRECT DIRECT DIRECT

Diameter — Width (In.)

11 X 8 11 X 10 11 X 10 11 X 10

No. Used 1 1 1 1

Speeds (No.)

CFM vs. in. w.g.

Motor HP

Variable Variable Variable Variable

See Fan Performance

Table

3/4

See Fan Performance

Table

1

See Fan Performance

Table

3/4

See Fan Performance

Table

1

RPM Variable Variable Variable Variable

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 8.0 10.5 8.0 10.5

COMBUSTION FAN — Type Centrifugal Centrifugal Centrifugal Centrifugal

Drive — No. Speeds

Motor HP — RPM

Direct - 2 Direct - 2 Direct - 2 Direct - 2

3300/2600 3300/2600 3300/2600 3300/2600

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 0.66 0.66 0.66 0.66

FILTER — Furnished? No No No No

Type recommended High Velocity High Velocity High Velocity High Velocity

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER — Min (in.)

(e) (f)

1 — 16x25 — 1 in. 1 — 20x25 — 1 in. 1 — 20x25 — 1 in. 1 — 20x25 — 1 in.

2 Round 2 Round 2 Round 2 Round

HEAT EXCHANGER

Type — Fired

409 Stainless Steel 409 Stainless Steel 409 Stainless Steel 409 Stainless Steel

— Unfired 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel

(a)

(a)

22-1921-1C-EN

7

Page 8

PPrroodduucctt SSppeecciiffiiccaattiioonn

MODEL

Gauge (Fired)

S9V2B080U4PSBA

20 20 20 20

(a)

S9V2C080U5PSBA

(a)

S9V2C100U4PSBA

(a)

S9V2C100U5PSBA

ORIFICES — Main

Nat. Gas Qty.— Drill Size

LP Gas Qty. — Drill Size

GAS VALVE

Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage

4 - 45 4 - 45 5 - 45 5 - 45

4- 56 4- 56 5- 56 5- 56

PILOT SAFETY DEVICE

Type 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter

BURNERS — Type Multiport Inshot Multiport Inshot Multiport Inshot Multiport Inshot

Number 4 4 5 5

POWER CONN. — V/Ph/Hz

Ampacity (In Amps)

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (in.)

(g)

120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

10.8 13.9 10.8 13.9

15 15 15 15

1/2 1/2 1/2 1/2

DIMENSIONS H x W x D H x W x D H x W x D H x W x D

Uncrated (In.)

Crated (In.)

34 x 17-1/2 x 28–3/4 34 x 21 x 28–3/4 34 x 21 x 28–3/4 34 x 21 x 28–3/4

35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 23 x 30-7/8 35-1/2 x 23 x 30-7/8 35-1/2 x 23 x 30-7/8

WEIGHT

Shipping (Lbs.)/Net (Lbs.)

(a)

Meets Energy Star

(b)

For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level. For

Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

(c)

Central Furnace heating designs are certified to ANSI Z21.47 / CSA 2.3 — latest edition.

(d)

Based on U.S. government standard tests.

(e)

Refer to the Vent Length Table in the Installer's Guide.

(f)

All S9V2 furnace models have a vent outlet diameter that equals 2 in.

(g)

The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

135/127 149/139 154/144 155/145

(a)

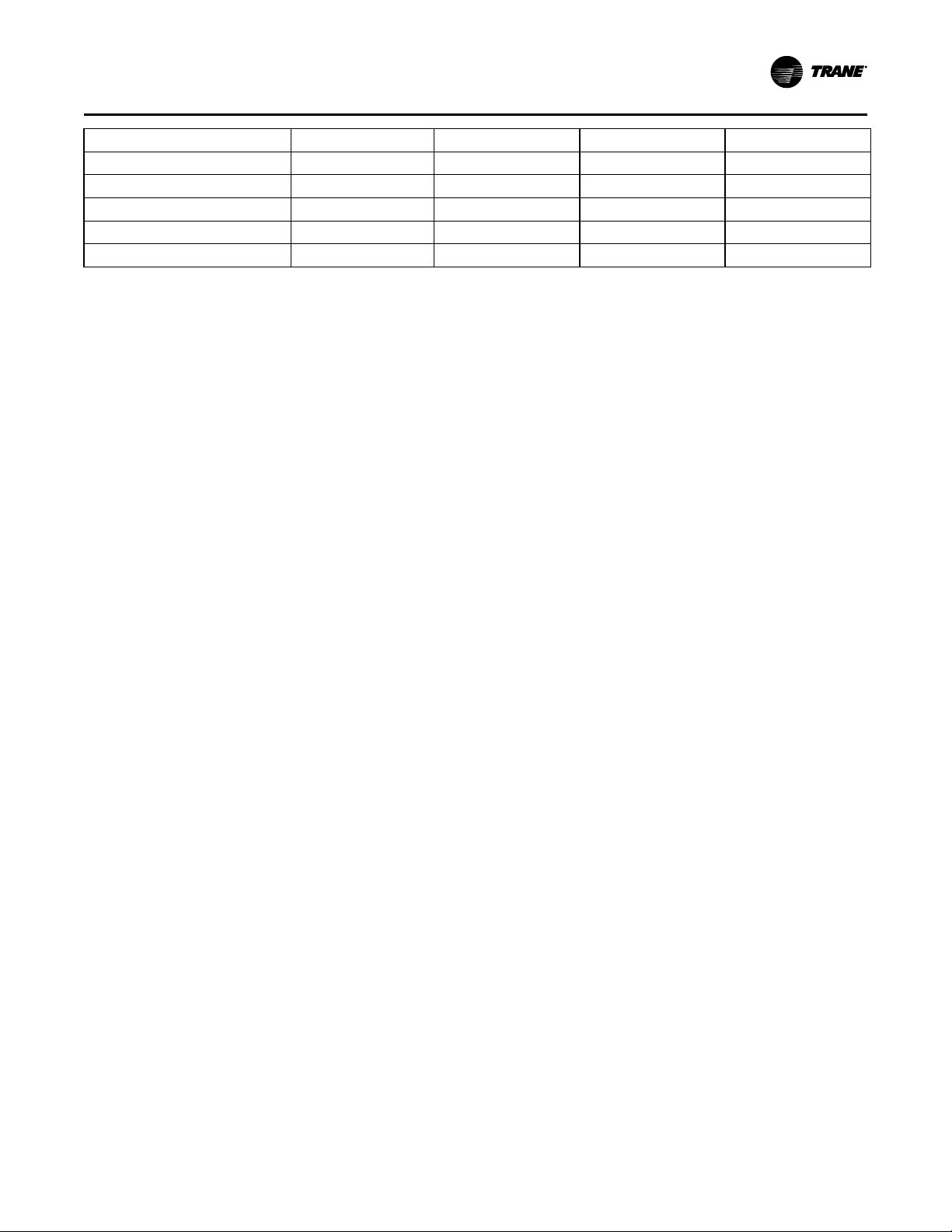

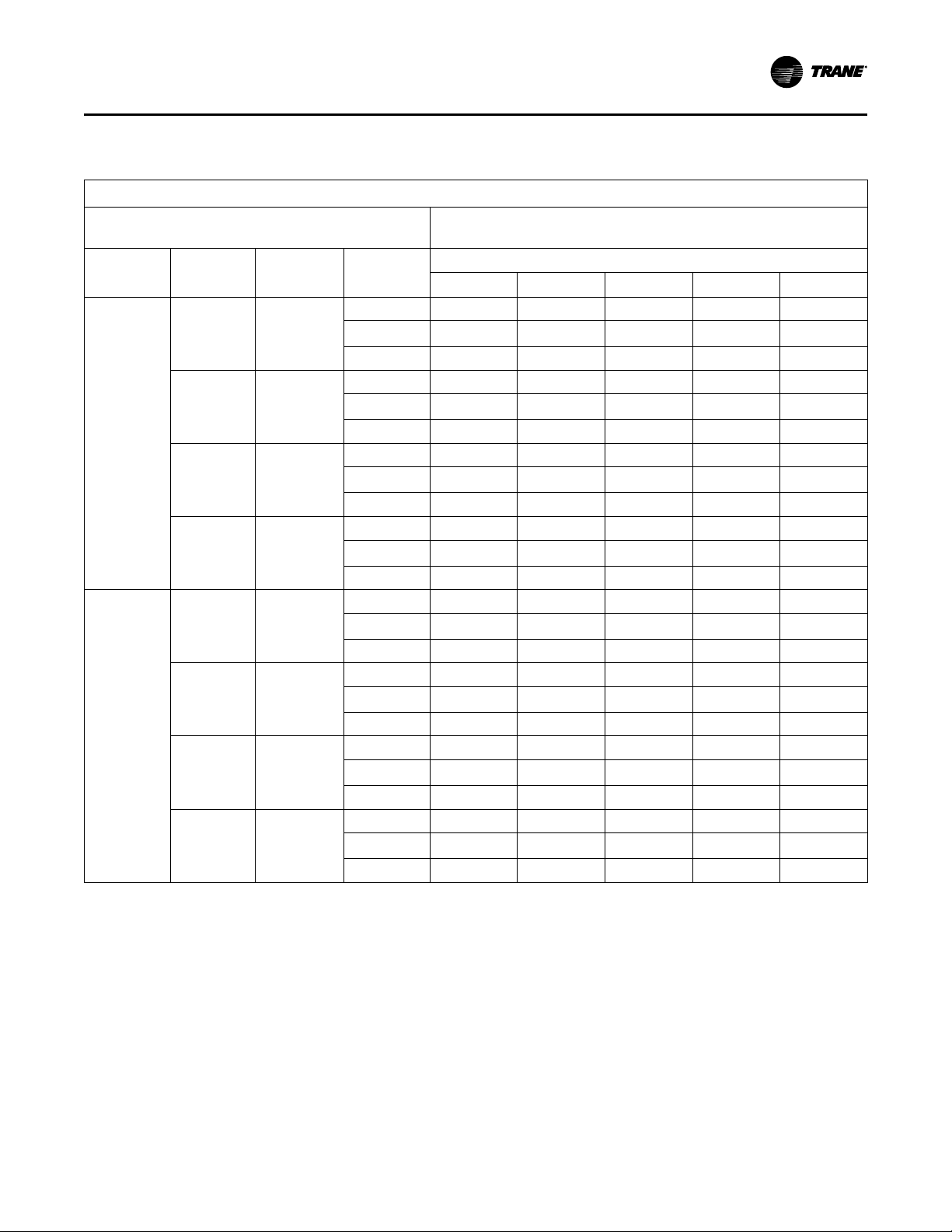

MODEL

TYPE

RATINGS

(a)

S9V2D120U5PSBA

Upflow/Horizontal

(b)

S9V2B040D3PSBA

Downflow Downflow Downflow

(a)

S9V2B060D3PSBA

(a)

S9V2B080D3PSBA

1st Stage Input BTUH (ICS) 78,000 26,000 39,000 52,000

1st Stage Capacity BTUH 75,660 25,220 37,830 50,440

2nd Stage Input BTUH 120,000 40,000 60,000 80,000

2nd Stage Capacity BTUH (ICS)

1st Stage Temp. Rise (Min.-Max.)

2nd Stage Temp. Rise (Min.-Max.)

AFUE (%)

(c)(d)

(c) (d)

116,400 38,800 58,200 77,600

35-65 25 - 55 25 - 55 30 - 60

40-70 30 - 60 35 - 65 40 - 70

96.0 96.0 96.0 96.0

BLOWER DRIVE DIRECT DIRECT DIRECT DIRECT

Diameter — Width (In.)

11 X 10 11 X 8 11 X 8 11 X 8

No. Used 1 1 1 1

Speeds (No.)

CFM vs. in. w.g.

Motor HP 1

Variable Variable Variable Variable

See Fan Performance

Table

See Fan Performance

Table

See Fan Performance

Table

1/2 1/2 1/2

See Fan Performance

Table

RPM Variable Variable Variable Variable

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 10.5 5.7 5.7 5.7

COMBUSTION FAN — Type Centrifugal Centrifugal Centrifugal Centrifugal

(a)

8

22-1921-1C-EN

Page 9

PPrroodduucctt SSppeecciiffiiccaattiioonn

MODEL

Drive — No. Speeds

Motor HP — RPM

S9V2D120U5PSBA

(a)

S9V2B040D3PSBA

Direct - 2 Direct - 2 Direct - 2 Direct - 2

3300/2600 3300/2600 3300/2600 3300/2600

(a)

S9V2B060D3PSBA

(a)

S9V2B080D3PSBA

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 0.66 0.66 0.66 0.66

FILTER — Furnished? No No No No

Type recommended High Velocity High Velocity High Velocity High Velocity

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER — Min (in.)

(e) (f)

1 — 24x25 — 1 in. 2 — 14x20 — 1 in. 2 — 14x20 — 1 in. 2 — 14x20 — 1 in.

3 Round 2 Round 2 Round 2 Round

HEAT EXCHANGER

Type — Fired

409 Stainless Steel 409 Stainless Steel 409 Stainless Steel 409 Stainless Steel

— Unfired 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel

Gauge (Fired)

20 20 20 20

ORIFICES — Main

Nat. Gas Qty.— Drill Size

LP Gas Qty. — Drill Size

GAS VALVE

6 - 45 2- 45 3 - 45 4 - 45

6- 56 2- 56 3 - 56 4 - 56

Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage

PILOT SAFETY DEVICE

Type 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter

BURNERS — Type Multiport Inshot Multiport Inshot Multiport Inshot Multiport Inshot

Number 6 2 3 4

POWER CONN. — V/Ph/Hz

Ampacity (In Amps)

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (in.)

(g)

120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

13.9 7.9 7.9 7.9

15 15 15 15

1/2 1/2 1/2 1/2

DIMENSIONS H x W x D H x W x D H x W x D H x W x D

Uncrated (In.)

Crated (In.)

34 x 24-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4 34 x 17-1/2 x 28–3/4

35-1/2 x 26-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 19-1/2 x 30-7/8

WEIGHT

Shipping (Lbs.)/Net (Lbs.)

(a)

Meets Energy Star

(b)

For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level. For

Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

(c)

Central Furnace heating designs are certified to ANSI Z21.47 / CSA 2.3.

(d)

Based on U.S. government standard tests.

(e)

Refer to the Vent Length Table in the Installer's Guide.

(f)

All S9V2 furnace models have a vent outlet diameter that equals 2 in.

(g)

The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

167/156 122/114 127/119 132/124

(a)

22-1921-1C-EN

9

Page 10

PPrroodduucctt SSppeecciiffiiccaattiioonn

MODEL

S9V2B080D4PSBA

(a)

S9V2C100D4PSBA

(a)

S9V2C100D5PSBA

(a)

S9V2D120D5PSBA

TYPE Downflow Downflow Downflow Downflow

RATINGS

(b)

1st Stage Input BTUH (ICS) 52,000 65,000 65,000 78,000

1st Stage Capacity BTUH 50,440 63,050 63,050 75,660

2nd Stage Input BTUH 80,000 100,000 100,000 120,000

2nd Stage Capacity BTUH (ICS)

1st Stage Temp. Rise (Min.-Max.)

2nd Stage Temp. Rise (Min.-Max.)

AFUE (%)

(c)(d)

(c) (d)

77,600 97,000 97,000 116,400

30 - 60 25 - 55 25 - 55 35-65

35 - 65 35 - 65 30 - 60 40-70

96.0 96.0 96.0 96.0

BLOWER DRIVE DIRECT DIRECT DIRECT DIRECT

Diameter — Width (In.)

11 X 8 11 X 10 11 X 10 11 X 10

No. Used 1 1 1 1

Speeds (No.)

CFM vs. in. w.g.

Motor HP

Variable Variable Variable Variable

See Fan Performance

Table

3/4 3/4

See Fan Performance

Table

See Fan Performance

Table

1 1

See Fan Performance

Table

RPM Variable Variable Variable Variable

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 8.0 8.0 10.5 10.5

COMBUSTION FAN — Type Centrifugal Centrifugal Centrifugal Centrifugal

Drive — No. Speeds

Motor HP — RPM

Direct - 2 Direct - 2 Direct - 2 Direct - 2

3300/2600 3300/2600 3300/2600 3300/2600

Volts/Ph/Hz 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

FLA 0.66 0.66 0.66 0.66

FILTER — Furnished? No No No No

Type recommended High Velocity High Velocity High Velocity High Velocity

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER — Min (in.)

(e) (f)

2 — 14x20 — 1 in. 2 — 16x20 — 1 in. 2 — 16x20 — 1 in. 2 — 16x20 — 1 in.

2 Round 2 Round 2 Round 3 Round

HEAT EXCHANGER

Type — Fired

409 Stainless Steel 409 Stainless Steel 409 Stainless Steel 409 Stainless Steel

— Unfired 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel 29–4C Stainless Steel

Gauge (Fired)

20 20 20 20

ORIFICES — Main

Nat. Gas Qty.— Drill Size

LP Gas Qty. — Drill Size

GAS VALVE

4 - 45 5 - 45 5 - 45 6 - 45

4- 56 5- 56 5- 56 6- 56

Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage Redundant - Two Stage

PILOT SAFETY DEVICE

Type 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter 120 V SiNi Igniter

BURNERS — Type Multiport Inshot Multiport Inshot Multiport Inshot Multiport Inshot

Number 4 5 5 6

POWER CONN. — V/Ph/Hz

Ampacity (In Amps)

Max. Overcurrent Protection (Amps)

PIPE CONN. SIZE (in.)

(g)

120 / 1 / 60 120 / 1 / 60 120 / 1 / 60 120 / 1 / 60

10.8 10.8 13.9 13.9

15 15 15 15

1/2 1/2 1/2 1/2

(a)

10

22-1921-1C-EN

Page 11

PPrroodduucctt SSppeecciiffiiccaattiioonn

MODEL

S9V2B080D4PSBA

(a)

S9V2C100D4PSBA

(a)

S9V2C100D5PSBA

(a)

S9V2D120D5PSBA

DIMENSIONS H x W x D H x W x D H x W x D H x W x D

Uncrated (In.)

Crated (In.)

34 x 17-1/2 x 28–3/4 34 x 21 x 28–3/4 34 x 21 x 28–3/4 34 x 24-1/2 x 28–3/4

35-1/2 x 19-1/2 x 30-7/8 35-1/2 x 23 x 30-7/8 35-1/2 x 23 x 30-7/8 35-1/2 x 26-1/2 x 30-7/8

WEIGHT

Shipping (Lbs.)/Net (Lbs.)

(a)

Meets Energy Star

(b)

For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level. For

Canadian applications, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

(c)

Central Furnace heating designs are certified to ANSI Z21.47 / CSA 2.3.

(d)

Based on U.S. government standard tests.

(e)

Refer to the Vent Length Table in the Installer's Guide.

(f)

All S9V2 furnace models have a vent outlet diameter that equals 2 in.

(g)

The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

135/127 154/144 155/145 167/156

(a)

22-1921-1C-EN

11

Page 12

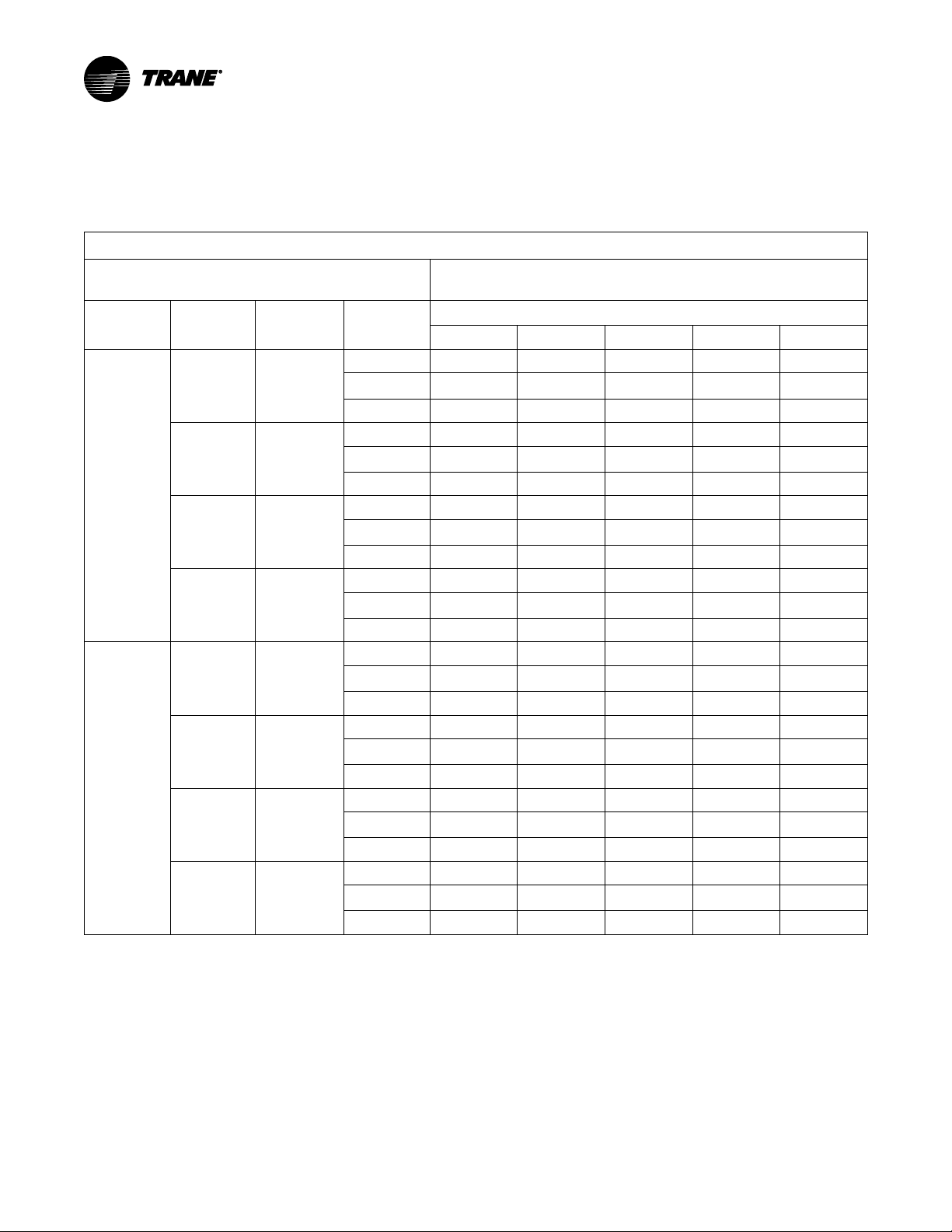

Heating and Cooling Airflow Tables

SS99VV22BB004400UU33PPSSBBAA

Table 2. S9V2B040U3PSBA Heating Airflow

S9V2B040U3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 25,220

2nd Stage Capacity = 38,800

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 468

Medium Low 598

(a)

Medium

High

Low 650

Medium Low 830

(a)

Medium

High

Target

Airflow

634

1008

880

1400

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 468 452 437 421 406

Temp. Rise 49 51 54 56 58

Watts 27 58 90 121 152

CFM 552 600 647 694 741

Temp. Rise 43 39 36 32 28

Watts 41 76 112 147 183

CFM 583 635 687 739 791

Temp. Rise 39 36 33 30 27

Watts 48 83 118 153 189

CFM 930 905 879 853 828

Temp. Rise 25 25 26 27 27

Watts 125 178 232 285 339

CFM 633 636 639 643 646

Temp. Rise 57 57 57 56 56

Watts 48 92 135 179 223

CFM 760 786 813 840 866

Temp. Rise 48 46 45 43 41

Watts 82 132 182 232 282

CFM 792 817 842 867 892

Temp. Rise 44 44 43 43 42

Watts 94 142 189 237 284

CFM 1337 1269 1200 1132 1063

Temp. Rise 27 29 31 32 34

Watts 335 376 417 458 499

12

22-1921-1C-EN

Page 13

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB004400DD33PPSSBBAA

Table 3. S9V2B040D3PSBA Heating Airflow

S9V2B040D3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 25,220

2nd Stage Capacity = 38,800

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 468

Medium Low 598

(a)

Medium

High

Low 650

Medium Low 830

(a)

Medium

High

Target

Airflow

634

1008

880

1400

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 426 430 435 439 444

Temp. Rise 54 54 53 53 52

Watts 38 79 120 161 202

CFM 543 569 595 621 647

Temp. Rise 43 41 39 37 35

Watts 66 125 184 243 303

CFM 611 612 614 616 618

Temp. Rise 38 38 38 37 37

Watts 81 139 198 256 314

CFM 923 918 914 909 904

Temp. Rise 25 25 25 25 26

Watts 198 284 369 455 540

CFM 607 612 617 622 626

Temp. Rise 60 60 59 59 59

Watts 78 124 170 216 261

CFM 807 807 808 808 809

Temp. Rise 45 45 45 45 45

Watts 146 218 290 362 434

CFM 871 874 878 881 885

Temp. Rise 42 42 42 41 41

Watts 182 259 336 413 489

CFM 1307 1237 1167 1097 1028

Temp. Rise 28 30 32 33 35

Watts 492 526 560 593 627

22-1921-1C-EN

13

Page 14

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB004400UU33PPSSBBAA // SS99VV22BB004400DD33PPSSBBAA

Table 4. S9V2B040U3PSBA / S9V2B040D3PSBA Cooling Airflow

S9V2B040U3PSBA / S9V2B040D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

1.5 Ton

2.0 Ton

2.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 675 675 675 675 675

Watts 47 81 121 166 215

CFM 630 630 630 630 630

Watts 40 72 111 154 202

CFM 600 600 600 600 600

Watts 36 67 105 147 193

CFM 555 555 555 555 555

Watts 30 60 96 136 181

CFM 525 525 525 525 525

Watts 27 56 90 130 174

CFM 495 495 495 495 495

Watts 24 51 85 124 167

CFM 465 465 465 465 465

Watts 21 48 80 118 161

CFM 435 435 435 435 435

Watts 19 44 76 113 155

CFM 900 900 900 900 900

Watts 94 137 186 240 298

CFM 840 840 840 840 840

Watts 79 120 166 218 273

CFM 800 800 800 800 800

Watts 70 109 154 204 258

CFM 740 740 740 740 740

Watts 58 95 138 185 236

CFM 700 700 700 700 700

Watts 51 86 127 173 223

CFM 660 660 660 660 660

Watts 44 78 118 162 211

CFM 620 620 620 620 620

Watts 38 71 109 152 199

CFM 580 580 580 580 580

Watts 33 64 101 142 188

CFM 1125 1125 1125 1125 1125

Watts 167 219 278 341 408

CFM

1050 1050 1050 1050 1050

14

22-1921-1C-EN

Page 15

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 4. S9V2B040U3PSBA / S9V2B040D3PSBA Cooling Airflow (continued)

S9V2B040U3PSBA / S9V2B040D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

3.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

0.1 0.3 0.5 0.7 0.9

Watts 139 188 244 304 368

CFM 1000 1000 1000 1000 1000

Watts 123 170 223 281 343

CFM 925 925 925 925 925

Watts 100 145 195 250 308

CFM 875 875 875 875 875

Watts 87 129 178 230 287

CFM 825 825 825 825 825

Watts 121 160 205 254 308

CFM 775 775 775 775 775

Watts 101 139 182 229 281

CFM 725 725 725 725 725

Watts 88 123 164 210 260

CFM 1350 1350 1350 1298 1198

Watts 272 334 402 440 450

CFM 1260 1260 1260 1260 1198

Watts 226 284 348 417 450

CFM 1200 1200 1200 1200 1198

Watts 198 254 315 381 450

CFM 1110 1110 1110 1110 1110

Watts 161 213 271 333 399

CFM 1050 1050 1050 1050 1050

Watts 139 188 244 304 368

CFM 990 990 990 990 990

Watts 119 166 219 277 338

CFM 930 930 930 930 930

Watts 102 146 197 252 311

CFM 870 870 870 870 870

Watts 86 128 176 229 285

External Static Pressure

22-1921-1C-EN

15

Page 16

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB006600UU33PPSSBBAA

Table 5. S9V2B060U3PSBA Heating Airflow

S9V2B060U3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 37,830

2nd Stage Capacity = 58,200

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 632

Medium Low

(a)

Medium 893

High

Low 800

Medium Low

(a)

Medium 1130

High

Airflow

Target

814

1153

1030

1460

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 673 675 677 679 681

Temp. Rise 52 52 52 52 52

Watts 47 83 120 156 193

CFM 850 827 804 780 757

Temp. Rise 41 42 43 44 45

Watts 82 120 157 195 232

CFM 901 903 905 907 909

Temp. Rise 39 39 39 39 39

Watts 106 144 181 219 256

CFM 1131 1121 1112 1102 1093

Temp. Rise 32 31 31 31 31

Watts 209 250 291 332 373

CFM 850 844 838 833 827

Temp. Rise 63 63 64 64 65

Watts 75 120 165 210 255

CFM 1072 1061 1049 1038 1027

Temp. Rise 50 50 51 52 52

Watts 147 196 244 293 341

CFM 1115 1127 1138 1149 1160

Temp. Rise 48 48 48 47 47

Watts 193 246 300 354 408

CFM 1382 1336 1289 1243 1196

Temp. Rise 39 40 42 43 45

Watts 382 400 418 435 453

16

22-1921-1C-EN

Page 17

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB006600DD33PPSSBBAA

Table 6. S9V2B060D3PSBA Heating Airflow

S9V2B060D3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 37,830

2nd Stage Capacity = 58,200

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 632

Medium Low

(a)

Medium 893

High

Low 800

Medium Low

(a)

Medium 1130

High

Airflow

Target

814

1153

1030

1460

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 701 683 664 646 627

Temp. Rise 51 52 54 55 57

Watts 33 79 125 171 217

CFM 799 812 825 838 851

Temp. Rise 45 44 43 42 42

Watts 56 109 163 217 270

CFM 887 895 903 910 918

Temp. Rise 40 40 40 39 39

Watts 77 128 180 231 283

CFM 1075 1087 1099 1111 1122

Temp. Rise 33 33 33 32 32

Watts 163 227 291 355 419

CFM 833 825 816 808 800

Temp. Rise 64 65 66 67 67

Watts 48 109 170 231 292

CFM 987 991 995 1000 1004

Temp. Rise 55 55 55 54 54

Watts 117 109 237 298 358

CFM 1054 1071 1088 1105 1122

Temp. Rise 51 50 49 48 48

Watts 165 211 256 302 348

CFM 1336 1337 1338 1339 1340

Temp. Rise 40 40 40 40 40

Watts 375 402 429 456 483

22-1921-1C-EN

17

Page 18

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB006600UU33PPSSBBAA // SS99VV22BB006600DD33PPSSBBAA

Table 7. S9V2B060U3PSBA / S9V2B060D3PSBA Cooling Airflow

S9V2B060U3PSBA / S9V2B060D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

1.5 Ton

2.0 Ton

2.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 675 675 675 675 675

Watts 46 81 121 165 212

CFM 630 630 630 630 630

Watts 40 72 111 153 200

CFM 600 600 600 600 600

Watts 36 67 105 146 192

CFM 555 555 555 555 555

Watts 30 60 96 137 182

CFM 525 525 525 525 525

Watts 27 56 91 131 175

CFM 495 495 495 495 495

Watts 24 52 86 126 170

CFM 465 465 465 465 465

Watts 21 48 82 121 164

CFM 435 435 435 435 435

Watts 19 45 78 116 160

CFM 900 900 900 900 900

Watts 92 135 184 236 291

CFM 840 840 840 840 840

Watts 78 118 164 214 267

CFM 800 800 800 800 800

Watts 69 108 153 201 253

CFM 740 740 740 740 740

Watts 57 94 136 183 232

CFM 700 700 700 700 700

Watts 50 86 126 171 220

CFM 660 660 660 660 660

Watts 44 78 117 161 208

CFM 620 620 620 620 620

Watts 38 71 109 151 197

CFM 580 580 580 580 580

Watts 33 64 101 142 187

CFM 1125 1125 1125 1125 1125

Watts 164 216 273 334 399

CFM

1050 1050 1050 1050 1050

18

22-1921-1C-EN

Page 19

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 7. S9V2B060U3PSBA / S9V2B060D3PSBA Cooling Airflow (continued)

S9V2B060U3PSBA / S9V2B060D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

3.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

0.1 0.3 0.5 0.7 0.9

Watts 137 186 240 298 359

CFM 1000 1000 1000 1000 1000

Watts 121 168 220 276 335

CFM 925 925 925 925 925

Watts 99 143 192 245 302

CFM 875 875 875 875 875

Watts 86 128 175 227 281

CFM 825 825 825 825 825

Watts 74 115 160 209 262

CFM 775 775 775 775 775

Watts 64 102 146 193 244

CFM 725 725 725 725 725

Watts 54 91 133 178 228

CFM 1350 1350 1350 1296 1218

Watts 267 329 395 431 452

CFM 1260 1260 1260 1260 1218

Watts 222 279 342 409 452

CFM 1200 1200 1200 1200 1200

Watts 195 250 310 374 441

CFM 1110 1110 1110 1110 1110

Watts 158 210 266 327 390

CFM 1050 1050 1050 1050 1050

Watts 137 186 240 298 359

CFM 990 990 990 990 990

Watts 118 164 216 272 330

CFM 930 930 930 930 930

Watts 100 145 194 247 304

CFM 870 870 870 870 870

Watts 85 127 174 225 279

External Static Pressure

22-1921-1C-EN

19

Page 20

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB006600UU44PPSSBBAA

Table 8. S9V2B060U4PSBA Heating Airflow

S9V2B060U4PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 37,830

2nd Stage Capacity = 58,200

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 782

Medium Low 861

(a)

Medium

High

Low 990

Medium Low 1090

(a)

Medium

High

Target

Airflow

916

1256

1160

1590

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 765 755 745 736 726

Temp. Rise 46 47 47 48 49

Watts 75 120 166 212 258

CFM 817 812 807 802 797

Temp. Rise 43 43 44 44 44

Watts 91 140 188 237 286

CFM 860 856 852 848 844

Temp. Rise 41 41 41 41 42

Watts 102 153 204 256 307

CFM 1111 1109 1107 1105 1103

Temp. Rise 32 32 32 32 32

Watts 227 291 355 419 484

CFM 950 945 941 936 932

Temp. Rise 56 56 57 57 58

Watts 119 171 224 277 330

CFM 1022 1021 1020 1018 1017

Temp. Rise 52 52 52 53 53

Watts 147 202 257 312 367

CFM 1086 1084 1081 1079 1077

Temp. Rise 49 49 49 50 50

Watts 181 239 297 356 414

CFM 1478 1459 1441 1422 1404

Temp. Rise 36 37 37 38 38

Watts 434 496 558 620 682

20

22-1921-1C-EN

Page 21

SS99VV22BB006600UU44PPSSBBAA

Table 9. S9V2B060U4PSBA Cooling Airflow

S9V2B060U4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

2.5 Ton

3.0 Ton

3.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1125 1125 1125 1125 1125

Watts 154 205 261 319 381

CFM 1050 1050 1050 1050 1050

Watts 128 177 229 285 343

CFM 1000 1000 1000 1000 1000

Watts 113 159 210 264 320

CFM 925 925 925 925 925

Watts 93 136 184 234 288

CFM 875 875 875 875 875

Watts 81 122 168 217 269

CFM 825 825 825 825 825

Watts 70 109 153 200 251

CFM 775 775 775 775 775

Watts 60 97 139 185 234

CFM 725 725 725 725 725

Watts 51 87 127 171 219

CFM 1350 1350 1350 1350 1350

Watts 250 312 377 445 515

CFM 1260 1260 1260 1260 1260

Watts 208 265 326 390 457

CFM 1200 1200 1200 1200 1200

Watts 182 237 296 357 422

CFM 1110 1110 1110 1110 1110

Watts 148 199 254 312 373

CFM 1050 1050 1050 1050 1050

Watts 128 177 229 285 343

CFM 990 990 990 990 990

Watts 110 156 206 260 316

CFM 930 930 930 930 930

Watts 94 138 185 236 290

CFM 870 870 870 870 870

Watts 80 121 166 215 267

CFM 1575 1575 1575 1575 1575

Watts 382 453 528 606 686

CFM 1470 1470 1470 1470 1470

Watts 316 382 453 526 602

22-1921-1C-EN

21

Page 22

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 9. S9V2B060U4PSBA Cooling Airflow (continued)

S9V2B060U4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

4.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1400 1400 1400 1400 1400

Watts 276 340 407 477 550

CFM 1295 1295 1295 1295 1295

Watts 224 283 345 411 479

CFM 1225 1225 1225 1225 1225

Watts 193 249 308 371 436

CFM 1155 1155 1155 1155 1155

Watts 165 218 274 334 397

CFM 1085 1085 1085 1085 1085

Watts 140 190 243 301 360

CFM 1015 1015 1015 1015 1015

Watts 118 165 216 270 327

CFM 1800 1800 1730 1670 1600

Watts 554 636 656 686 708

CFM 1680 1680 1680 1670 1600

Watts 457 533 613 686 708

CFM 1600 1600 1600 1600 1600

Watts 399 472 548 626 708

CFM 1480 1480 1480 1480 1480

Watts 322 389 459 533 609

CFM 1400 1400 1400 1400 1400

Watts 276 340 407 477 550

CFM 1320 1320 1320 1320 1320

Watts 236 296 359 426 495

CFM 1240 1240 1240 1240 1240

Watts 199 256 316 379 445

CFM 1160 1160 1160 1160 1160

Watts 167 220 277 337 399

22

22-1921-1C-EN

Page 23

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB008800UU33PPSSBBAA

Table 10. S9V2B080U3PSBA Heating Airflow

S9V2B080U3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 50,440

2nd Stage Capacity = 77,600

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 948

Medium Low 1051

(a)

Medium

High

Low 1200

Medium Low 1330

(a)

Medium

High

Target

Airflow

1090

1168

1380

1480

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1070 1030 990 950 910

Temp. Rise 45 45 46 46 46

Watts 120 162 203 245 286

CFM 1109 1061 1013 965 917

Temp. Rise 42 44 46 47 49

Watts 143 197 252 307 361

CFM 1188 1125 1062 998 935

Temp. Rise 40 42 43 45 47

Watts 154 215 276 336 397

CFM 1230 1212 1193 1174 1156

Temp. Rise 38 39 39 40 41

Watts 194 246 297 349 401

CFM 1331 1293 1256 1218 1172

Temp. Rise 55 56 57 58 61

Watts 221 277 333 388 436

CFM 1436 1388 1340 1263 1172

Temp. Rise 50 52 54 56 61

Watts 287 347 407 421 436

CFM 1380 1380 1338 1263 1172

Temp. Rise 52 52 53 56 61

Watts 283 351 396 421 436

CFM 1460 1400 1338 1263 1172

Temp. Rise 49 51 53 56 61

Watts 329 363 396 421 436

22-1921-1C-EN

23

Page 24

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB008800DD33PPSSBBAA

Table 11. S9V2B080D3PSBA Heating Airflow

S9V2B080D3PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 50,440

2nd Stage Capacity = 77,600

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 948

Medium Low 1051

(a)

Medium

High

Low 1200

Medium Low 1330

(a)

Medium

High

Target

Airflow

1090

1168

1380

1480

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 843 836 830 823 816

Temp. Rise 56 56 57 57 58

Watts 106 158 209 260 312

CFM 949 936 924 911 898

Temp. Rise 50 51 51 52 53

Watts 138 195 252 309 366

CFM 981 952 922 893 864

Temp. Rise 48 49 51 52 54

Watts 151 210 269 328 387

CFM 1043 1031 1018 1006 993

Temp. Rise 45 45 46 47 47

Watts 181 244 307 371 434

CFM 1087 1076 1065 1055 1044

Temp. Rise 66 67 68 68 68

Watts 195 255 315 376 367

CFM 1211 1168 1124 1080 1036

Temp. Rise 59 61 64 66 69

Watts 268 310 352 322 363

CFM 1242 1242 1204 1137 1055

Temp. Rise 57 57 59 63 67

Watts 214 276 321 351 373

CFM 1314 1260 1204 1137 1055

Temp. Rise 54 56 59 63 67

Watts 249 285 321 351 373

24

22-1921-1C-EN

Page 25

SS99VV22BB008800UU33PPSSBBAA // SS99VV22BB008800DD33PPSSBBAA

Table 12. S9V2B080U3PSBA / S9V2B080D3PSBA Cooling Airflow

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

S9V2B080U3PSBA / S9V2B080D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

2.0 Ton

2.5 Ton

3.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 900 900 900 900 900

Watts 95 141 191 245 301

CFM 840 840 840 840 840

Watts 80 124 172 223 277

CFM 800 800 800 800 800

Watts 71 114 160 210 262

CFM 740 740 740 740 740

Watts 59 99 143 191 242

CFM 700 700 700 700 700

Watts 52 91 133 180 229

CFM 660 660 660 660 660

Watts 46 83 124 169 218

CFM 620 620 620 620 620

Watts 40 75 115 159 207

CFM 580 580 580 580 580

Watts 35 68 107 150 197

CFM 1125 1125 1125 1125 1125

Watts 166 222 282 345 410

CFM 1050 1050 1050 1050 1050

Watts 139 192 248 308 370

CFM 1000 1000 1000 1000 1000

Watts 123 173 228 286 346

CFM 925 925 925 925 925

Watts 101 149 200 255 312

CFM 875 875 875 875 875

Watts 88 134 183 236 291

CFM 825 825 825 825 825

Watts 77 120 167 218 272

CFM 775 775 775 775 775

Watts 66 107 153 202 254

CFM 725 725 725 725 725

Watts 57 96 139 187 237

CFM 1350 1350 1338 1263 1172

Watts 267 333 396 421 436

CFM

1260 1260 1260 1260 1172

22-1921-1C-EN

25

Page 26

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 12. S9V2B080U3PSBA / S9V2B080D3PSBA Cooling Airflow (continued)

S9V2B080U3PSBA / S9V2B080D3PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

3.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

Cooling 450

Cooling 420

Cooling 400

Cooling 370

Cooling 350

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

CFM/Ton

0.1 0.3 0.5 0.7 0.9

Watts 223 285 350 419 436

CFM 1200 1200 1200 1200 1172

Watts 196 255 318 385 436

CFM 1110 1110 1110 1110 1110

Watts 160 216 275 337 402

CFM 1050 1050 1050 1050 1050

Watts 139 192 248 308 370

CFM 990 990 990 990 990

Watts 120 170 224 281 341

CFM 930 930 930 930 930

Watts 103 150 202 257 314

CFM 870 870 870 870 870

Watts 87 132 181 234 289

CFM 1460 1400 1338 1263 1172

Watts 329 363 396 421 436

CFM 1460 1400 1338 1263 1172

Watts 329 363 396 421 436

CFM 1400 1400 1338 1263 1172

Watts 294 363 396 421 436

CFM 1295 1295 1295 1263 1172

Watts 239 303 370 421 436

CFM 1225 1225 1225 1225 1172

Watts 207 267 332 399 436

CFM 1155 1155 1155 1155 1155

Watts 177 235 296 360 427

CFM 1085 1085 1085 1085 1085

Watts 151 205 264 325 388

CFM 1015 1015 1015 1015 1015

Watts 128 179 234 292 353

External Static Pressure

26

22-1921-1C-EN

Page 27

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB008800UU44PPSSBBAA

Table 13. S9V2B080U4PSBA Heating Airflow

S9V2B080U4PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 50,440

2nd Stage Capacity = 77,600

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 864

Medium Low

(a)

Medium 958

High

Low 1200

Medium Low

(a)

Medium 1330

High

Airflow

Target

907

1051

1260

1460

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 914 882 849 816 783

Temp. Rise 51 53 55 57 59

Watts 90 131 172 213 255

CFM 940 912 885 858 831

Temp. Rise 50 51 53 54 56

Watts 104 141 178 215 253

CFM 983 932 881 830 779

Temp. Rise 47 50 53 55 58

Watts 118 151 184 218 251

CFM 1029 1068 1107 1146 1185

Temp. Rise 45 44 42 40 39

Watts 155 195 235 275 314

CFM 1207 1206 1205 1204 1203

Temp. Rise 60 60 60 60 60

Watts 206 258 309 361 412

CFM 1260 1261 1262 1263 1264

Temp. Rise 57 57 57 57 57

Watts 232 287 342 397 452

CFM 1360 1347 1333 1320 1306

Temp. Rise 53 53 54 54 55

Watts 263 322 380 439 497

CFM 1420 1439 1458 1477 1496

Temp. Rise 51 50 49 49 48

Watts 377 433 489 546 602

22-1921-1C-EN

27

Page 28

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22BB008800DD44PPSSBBAA

Table 14. S9V2B080D4PSBA Heating Airflow

S9V2B080D4PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 50,440

2nd Stage Capacity = 77,600

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 864

Medium Low

(a)

Medium 958

High

Low 1200

Medium Low

(a)

Medium 1330

High

Airflow

Target

907

1051

1260

1460

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 770 770 770 770 770

Temp. Rise 61 61 61 61 61

Watts 72 118 164 210 256

CFM 809 809 809 809 809

Temp. Rise 58 58 58 58 58

Watts 88 134 180 227 273

CFM 854 854 854 854 854

Temp. Rise 54 54 54 54 54

Watts 101 150 198 247 296

CFM 993 993 993 993 993

Temp. Rise 47 47 47 47 47

Watts 133 186 239 292 346

CFM 1082 1082 1082 1082 1082

Temp. Rise 66 66 66 66 66

Watts 181 239 298 357 416

CFM 1190 1190 1190 1190 1190

Temp. Rise 59 59 59 59 59

Watts 206 268 329 390 451

CFM 1225 1225 1225 1225 1225

Temp. Rise 58 58 58 58 58

Watts 239 303 367 431 495

CFM 1227 1227 1227 1227 1227

Temp. Rise 57 57 57 57 57

Watts 320 390 460 530 600

28

22-1921-1C-EN

Page 29

SS99VV22BB008800UU44PPSSBBAA // SS99VV22BB008800DD44PPSSBBAA

Table 15. S9V2B080U4PSBA / S9V2B080D4PSBA Cooling Airflow

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

S9V2B080U4PSBA / S9V2B080D4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

2.5 Ton

3.0 Ton

3.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 1125 1125 1125 1125 1125

Watts 155 205 259 316 376

CFM 1050 1050 1050 1050 1050

Watts 130 177 228 282 340

CFM 1000 1000 1000 1000 1000

Watts 115 160 209 262 317

CFM 925 925 925 925 925

Watts 94 136 183 233 286

CFM 875 875 875 875 875

Watts 82 122 167 216 267

CFM 825 825 825 825 825

Watts 71 110 153 199 249

CFM 775 775 775 775 775

Watts 61 98 139 184 233

CFM 725 725 725 725 725

Watts 52 87 127 171 218

CFM 1350 1350 1350 1350 1350

Watts 252 311 374 440 508

CFM 1260 1260 1260 1260 1260

Watts 209 265 324 386 451

CFM 1200 1200 1200 1200 1200

Watts 184 237 294 354 416

CFM 1110 1110 1110 1110 1110

Watts 150 199 253 309 369

CFM 1050 1050 1050 1050 1050

Watts 130 177 228 282 340

CFM 990 990 990 990 990

Watts 112 156 205 258 313

CFM 930 930 930 930 930

Watts 95 138 185 235 288

CFM 870 870 870 870 870

Watts 81 121 166 214 265

CFM 1575 1575 1575 1575 1575

Watts 383 452 524 599 676

CFM

1470 1470 1470 1470 1470

22-1921-1C-EN

29

Page 30

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 15. S9V2B080U4PSBA / S9V2B080D4PSBA Cooling Airflow (continued)

S9V2B080U4PSBA / S9V2B080D4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

4.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

0.1 0.3 0.5 0.7 0.9

Watts 317 382 449 520 593

CFM 1400 1400 1400 1400 1400

Watts 278 339 404 472 542

CFM 1295 1295 1295 1295 1295

Watts 225 282 343 407 473

CFM 1225 1225 1225 1225 1225

Watts 194 248 306 367 431

CFM 1155 1155 1155 1155 1155

Watts 166 218 273 331 392

CFM 1085 1085 1085 1085 1085

Watts 141 190 242 298 356

CFM 1015 1015 1015 1015 1015

Watts 119 165 215 268 324

CFM 1800 1784 1746 1665 1581

Watts 555 619 665 674 681

CFM 1680 1680 1680 1665 1581

Watts 458 531 608 674 681

CFM 1600 1600 1600 1600 1600

Watts 400 470 543 619 697

CFM 1480 1480 1480 1480 1480

Watts 323 388 456 527 600

CFM 1400 1400 1400 1400 1400

Watts 278 339 404 472 542

CFM 1320 1320 1320 1320 1320

Watts 237 295 357 421 488

CFM 1240 1240 1240 1240 1240

Watts 201 255 314 375 439

CFM 1160 1160 1160 1160 1160

Watts 168 220 275 334 395

External Static Pressure

30

22-1921-1C-EN

Page 31

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC008800UU55PPSSBBAA

Table 16. S9V2C080U5PSBA Heating Airflow

S9V2C080U5PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 50,440

2nd Stage Capacity = 77,600

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 857

Medium Low

(a)

Medium 1123

High

Low 1190

Medium Low

(a)

Medium 1560

High

Airflow

Target

1044

1498

1450

2080

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 837 870 902 934 967

Temp. Rise 55 53 51 50 48

Watts 65 112 160 208 256

CFM 997 1015 1033 1050 1068

Temp. Rise 46 45 45 44 43

Watts 102 155 209 263 316

CFM 1067 1094 1121 1148 1175

Temp. Rise 43 42 41 40 39

Watts 123 180 236 293 350

CFM 1420 1416 1411 1407 1402

Temp. Rise 32 33 33 33 34

Watts 238 320 402 485 567

CFM 1129 1148 1168 1188 1208

Temp. Rise 63 62 61 60 59

Watts 127 195 263 331 399

CFM 1387 1395 1404 1412 1420

Temp. Rise 52 51 51 51 51

Watts 248 310 372 434 496

CFM 1484 1498 1512 1525 1539

Temp. Rise 48 48 47 47 47

Watts 281 358 435 512 589

CFM 1954 1956 1959 1961 1964

Temp. Rise 37 37 37 37 37

Watts 597 732 866 1001 1135

22-1921-1C-EN

31

Page 32

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC008800UU55PPSSBBAA

Table 17. S9V2C080U5PSBA Cooling Airflow

S9V2C080U5PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

3.5 Ton

4.0 Ton

4.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1575 1575 1575 1575 1575

Watts 279 351 426 504 584

CFM 1470 1470 1470 1470 1470

Watts 233 300 370 443 519

CFM 1400 1400 1400 1400 1400

Watts 205 269 336 406 478

CFM 1295 1295 1295 1295 1295

Watts 168 227 289 355 423

CFM 1225 1225 1225 1225 1225

Watts 145 201 261 324 389

CFM 1155 1155 1155 1155 1155

Watts 125 178 235 295 358

CFM 1085 1085 1085 1085 1085

Watts 107 157 211 269 329

CFM 1015 1015 1015 1015 1015

Watts 91 138 189 244 302

CFM 1800 1800 1800 1800 1800

Watts 399 482 567 655 745

CFM 1680 1680 1680 1680 1680

Watts 332 409 488 571 655

CFM 1600 1600 1600 1600 1600

Watts 291 364 441 519 600

CFM 1480 1480 1480 1480 1480

Watts 237 305 375 449 524

CFM 1400 1400 1400 1400 1400

Watts 205 269 336 406 478

CFM 1320 1320 1320 1320 1320

Watts 176 236 300 367 436

CFM 1240 1240 1240 1240 1240

Watts 150 207 267 330 396

CFM 1160 1160 1160 1160 1160

Watts 127 180 237 297 360

CFM 2025 2025 2025 2025 2020

Watts 550 643 740 838 934

CFM 1890 1890 1890 1890 1890

Watts 456 543 632 725 819

32

22-1921-1C-EN

Page 33

Table 17. S9V2C080U5PSBA Cooling Airflow (continued)

S9V2C080U5PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

5.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1800 1800 1800 1800 1800

Watts 399 482 567 655 745

CFM 1665 1665 1665 1665 1665

Watts 324 400 479 561 645

CFM 1575 1575 1575 1575 1575

Watts 279 351 426 504 584

CFM 1485 1485 1485 1485 1485

Watts 239 307 378 451 527

CFM 1395 1395 1395 1395 1395

Watts 203 267 334 403 476

CFM 1305 1305 1305 1305 1305

Watts 171 231 294 360 428

CFM 2250 2250 2250 2150 2020

Watts 734 839 947 955 934

CFM 2100 2100 2100 2100 2020

Watts 607 705 805 907 934

CFM 2000 2000 2000 2000 2000

Watts 531 624 719 816 916

CFM 1850 1850 1850 1850 1850

Watts 430 515 603 693 785

CFM 1750 1750 1750 1750 1750

Watts 370 450 533 619 707

CFM 1650 1650 1650 1650 1650

Watts 316 392 470 551 634

CFM 1550 1550 1550 1550 1550

Watts 268 339 412 489 568

CFM 1450 1450 1450 1450 1450

Watts 225 291 360 432 507

22-1921-1C-EN

33

Page 34

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000UU44PPSSBBAA

Table 18. S9V2C100U4PSBA Heating Airflow

S9V2C100U4PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 63,050

2nd Stage Capacity = 97,000

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 1146

Medium Low 1280

(a)

Medium

High

Low 1450

Medium Low 1620

(a)

Medium

High

Target

Airflow

1446

1493

1830

1890

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1191 1199 1208 1216 1224

Temp. Rise 50 49 49 49 49

Watts 133 192 251 310 369

CFM 1314 1304 1294 1284 1274

Temp. Rise 45 45 45 46 46

Watts 173 235 297 359 421

CFM 1478 1466 1453 1441 1428

Temp. Rise 40 40 40 40 40

Watts 243 304 364 425 485

CFM 1498 1511 1524 1537 1550

Temp. Rise 39 39 39 39 38

Watts 264 330 397 464 531

CFM 1480 1488 1496 1503 1511

Temp. Rise 60 60 60 60 60

Watts 244 312 380 449 517

CFM 1658 1656 1654 1652 1650

Temp. Rise 54 54 54 54 55

Watts 330 408 486 564 642

CFM 1869 1857 1846 1811 1714

Temp. Rise 48 48 49 49 52

Watts 471 549 628 677 695

CFM 1959 1919 1879 1811 1714

Temp. Rise 46 47 48 49 52

Watts 540 600 660 677 695

34

22-1921-1C-EN

Page 35

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000DD44PPSSBBAA

Table 19. S9V2C100D4PSBA Heating Airflow

S9V2C100D4PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 63,050

2nd Stage Capacity = 97,000

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 1080

Medium Low 1166

(a)

Medium

High

Low 1500

Medium Low 1620

(a)

Medium

High

Target

Airflow

1318

1361

1830

1890

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1068 1048 1029 1009 989

Temp. Rise 55 57 60 63 66

Watts 101 151 201 251 301

CFM 1158 1113 1068 1023 978

Temp. Rise 51 53 55 57 59

Watts 115 172 229 285 342

CFM 1326 1272 1218 1164 1111

Temp. Rise 46 48 50 51 53

Watts 153 206 259 312 365

CFM 1312 1270 1229 1188 1147

Temp. Rise 46 47 47 48 49

Watts 166 221 276 331 387

CFM 1514 1478 1441 1404 1367

Temp. Rise 58 60 61 63 64

Watts 223 297 370 443 516

CFM 1620 1588 1556 1523 1491

Temp. Rise 55 56 57 58 59

Watts 276 345 415 484 553

CFM 1768 1746 1724 1702 1620

Temp. Rise 50 51 52 53 53

Watts 372 446 520 594 668

CFM 1810 1783 1756 1729 1702

Temp. Rise 49 50 51 52 52

Watts 405 476 548 677 695

22-1921-1C-EN

35

Page 36

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000UU44PPSSBBAA // SS99VV22CC110000DD44PPSSBBAA

Table 20. S9V2C100U4PSBA / S9V2C100D4PSBA Cooling Airflow

S9V2C100U4PSBA / S9V2C100D4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

2.5 Ton

3.0 Ton

3.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 1125 1125 1125 1125 1125

Watts 123 178 236 296 360

CFM 1050 1050 1050 1050 1050

Watts 104 156 210 268 329

CFM 1000 1000 1000 1000 1000

Watts 93 142 195 251 309

CFM 925 925 925 925 925

Watts 77 123 173 226 282

CFM 875 875 875 875 875

Watts 68 112 160 211 265

CFM 825 825 825 825 825

Watts 60 102 147 196 249

CFM 775 775 775 775 775

Watts 52 92 135 183 234

CFM 725 725 725 725 725

Watts 45 83 125 170 220

CFM 1350 1350 1350 1350 1350

Watts 194 259 326 396 468

CFM 1260 1260 1260 1260 1260

Watts 163 224 287 353 422

CFM 1200 1200 1200 1200 1200

Watts 144 202 263 327 393

CFM 1110 1110 1110 1110 1110

Watts 119 173 231 291 354

CFM 1050 1050 1050 1050 1050

Watts 104 156 210 268 329

CFM 990 990 990 990 990

Watts 91 140 192 247 306

CFM 930 930 930 930 930

Watts 78 125 174 228 284

CFM 870 870 870 870 870

Watts 67 111 158 209 264

CFM 1575 1575 1575 1575 1575

Watts 289 363 440 519 600

CFM

1470 1470 1470 1470 1470

36

22-1921-1C-EN

Page 37

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

Table 20. S9V2C100U4PSBA / S9V2C100D4PSBA Cooling Airflow (continued)

S9V2C100U4PSBA / S9V2C100D4PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

Cooling

Cooling

(a)

Factory Setting

Unit

Outdoor

4.0 Ton

(a)

Airflow

Setting

(CFM/

ton)

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

Cooling 310

Cooling 290

(a)

CFM/Ton

CFM/Ton

CFM/Ton

0.1 0.3 0.5 0.7 0.9

Watts 241 311 383 458 535

CFM 1400 1400 1400 1400 1400

Watts 213 280 349 421 495

CFM 1295 1295 1295 1295 1295

Watts 175 237 302 369 439

CFM 1225 1225 1225 1225 1225

Watts 152 211 273 338 405

CFM 1155 1155 1155 1155 1155

Watts 131 187 247 308 373

CFM 1085 1085 1085 1085 1085

Watts 113 166 222 281 343

CFM 1015 1015 1015 1015 1015

Watts 96 146 199 256 315

CFM 1800 1800 1800 1800 1714

Watts 410 494 580 669 695

CFM 1680 1680 1680 1680 1680

Watts 342 420 502 585 671

CFM 1600 1600 1600 1600 1600

Watts 301 376 454 534 617

CFM 1480 1480 1480 1480 1480

Watts 246 316 388 464 541

CFM 1400 1400 1400 1400 1400

Watts 213 280 349 421 495

CFM 1320 1320 1320 1320 1320

Watts 183 247 313 381 452

CFM 1240 1240 1240 1240 1240

Watts 157 216 279 344 412

CFM 1160 1160 1160 1160 1160

Watts 133 189 248 310 375

External Static Pressure

22-1921-1C-EN

37

Page 38

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000UU55PPSSBBAA

Table 21. S9V2C100U5PSBA Heating Airflow

S9V2C100U5PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 63,050

2nd Stage Capacity = 97,000

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 1145

Medium Low

(a)

Medium 1548

High

Low 1590

Medium Low

(a)

Medium 2150

High

Airflow

Target

1426

1620

1980

2250

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1129 1097 1065 1033 1000

Temp. Rise 52 53 54 56 57

Watts 116 169 222 275 328

CFM 1373 1376 1378 1381 1384

Temp. Rise 43 42 42 42 42

Watts 195 264 332 400 468

CFM 1475 1460 1445 1430 1415

Temp. Rise 40 40 39 39 39

Watts 248 311 374 436 499

CFM 1540 1545 1551 1556 1561

Temp. Rise 38 38 38 38 38

Watts 301 347 393 440 486

CFM 1570 1548 1526 1503 1481

Temp. Rise 57 58 59 60 61

Watts 270 342 413 485 557

CFM 1968 1936 1903 1871 1839

Temp. Rise 45 46 47 48 49

Watts 526 613 700 787 875

CFM 2092 2071 2051 2030 2010

Temp. Rise 43 43 44 44 45

Watts 672 752 831 910 990

CFM 2150 2130 2110 2090 2029

Temp. Rise 42 42 42 43 44

Watts 743 814 886 957 905

38

22-1921-1C-EN

Page 39

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000DD55PPSSBBAA

Table 22. S9V2C100D5PSBA Heating Airflow

S9V2C100D5PSBA Furnace Heating Airflow (CFM) and Power (Watts) vs. External Static Pressure with Filter

1st Stage Capacity = 63,050

2nd Stage Capacity = 97,000

Heating

Heating 1st

Stage

Heating 2nd

Stage

(a)

Factory Setting.

Airflow

Setting

Low 1094

Medium Low 1296

(a)

Medium

High

Low 1520

Medium Low 1800

(a)

Medium

High

Target

Airflow

1346

1620

1870

2250

External Static Pressure

0.1 0.3 0.5 0.7 0.9

CFM 1094 1023 952 881 809

Temp. Rise 53 57 61 65 69

Watts 100 153 206 258 311

CFM 1296 1212 1127 1043 958

Temp. Rise 45 48 51 55 58

Watts 156 216 276 337 397

CFM 1346 1259 1171 1083 996

Temp. Rise 43 46 49 53 56

Watts 172 234 297 359 421

CFM 1620 1515 1409 1304 1198

Temp. Rise 36 38 41 44 46

Watts 284 358 431 504 578

CFM 1437 1420 1403 1385 1368

Temp. Rise 62 63 63 64 65

Watts 236 308 380 453 525

CFM 1744 1712 1680 1649 1617

Temp. Rise 51 52 53 54 55

Watts 378 462 545 629 713

CFM 1811 1779 1747 1715 1683

Temp. Rise 49 50 51 52 53

Watts 421 508 594 681 768

CFM 2211 2109 2006 1903 1800

Temp. Rise 40 42 45 47 49

Watts 714 817 920 1023 905

22-1921-1C-EN

39

Page 40

HHeeaattiinngg aanndd CCoooolliinngg AAiirrffllooww TTaabblleess

SS99VV22CC110000UU55PPSSBBAA // SS99VV22CC110000DD55PPSSBBAA

Table 23. S9V2C100U5PSBA / S9V2C100D5PSBA Cooling Airflow

S9V2C100U5PSBA / S9V2C100D5PSBA Furnace Cooling Airflow (CFM) and Power (Watts) vs. External Static Pressure

with Filter

External Static Pressure

Cooling

Cooling

Cooling

Cooling

Unit

Outdoor

3.5 Ton

4.0 Ton

4.5 Ton

Airflow

Setting

(CFM/

ton)

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

Cooling 400

CFM/Ton

Cooling 370

CFM/Ton

Cooling 350

CFM/Ton

Cooling 330

CFM/Ton

Cooling 310

CFM/Ton

Cooling 290

CFM/Ton

Cooling 450

CFM/Ton

Cooling 420

CFM/Ton

0.1 0.3 0.5 0.7 0.9

CFM 1575 1575 1575 1575 1575

Watts 263 333 406 481 558

CFM 1470 1470 1470 1470 1470

Watts 218 283 352 423 496

CFM 1400 1400 1400 1400 1400

Watts 191 254 319 388 458

CFM 1295 1295 1295 1295 1295

Watts 155 214 275 340 406

CFM 1225 1225 1225 1225 1225