Trane RTWD 60, RTWD 90, RTWD 120, RTWD 150, RTWD 200 Installation and Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Series R®Rotary Liquid Chillers

Water-Cooled and Compressor-Chillers

RTWD 60 RTWD 90 RTWD 120 RTWD 150 RTWD 200

RTWD 70 RTWD 100 RTWD 130 RTWD 160 RTWD 220

RTWD 80 RTWD 1 10 RTWD 140 RTWD 180 RTWD 250

RTUD 80 RTUD 110 RTUD 150 RTUD 200

RTUD 90 RTUD 120 RTUD 160 RTUD 220

RTUD 100 RTUD 130 RTUD 180 RTUD 250

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury.When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

October 2012 RLC-SVX09H-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert

installing contractors to potential hazards that could result

in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Read this manual thoroughly before operating or servicing

this unit.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situationthat could result in

equipment or property-damage only

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Refrigerant under High Pressure!

System contains oil and refrigerant under high

pressure. Recover refrigerant to relieve pressure before

opening the system. See unit nameplate for refrigerant

type. Do not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives. Failure to recover

refrigerant to relieve pressure or the use of nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives could result in an explosion which

could result in death or serious injury or equipment

damage.

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all Personal Protective Equipment (PPE)

recommended for the work being undertaken.

ALWAYSrefer to appropriateMSDS sheets and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit.

Failure to follow recommendations could result in death

or serious injury.

© 2012Trane All rights reserved RLC-SVX09H-EN

Page 3

Warnings, Cautions and Notices

Factory Warranty Information

Compliance with the following is required to preserve the

factory warranty:

All Unit Installations

Startup MUST be performed byTrane, or an authorized

agent ofTrane, to VALIDATE this WARRANTY. Contractor

must provide a two-week startup notification toTrane (or

an agent ofTrane specifically authorized to perform

startup).

Additional Requirements for Units Requiring

Disassembly

When a new fully assembled chiller is shipped and

received from ourTrane manufacturing location, and, for

any reason, it requires disassembly or partialdisassembly

— which could include but is not limited to theevaporator,

condenser, control panel, compressor/motor, factorymounted starter or any other components originally

attached to the fully assembled unit —compliance with the

following is required to preserve the factory warranty:

• Trane, or an agent of Trane specifically authorized to

perform startup and warranty ofTrane

perform or have direct onsite technical supervision of

the disassembly and reassembly work.

• The installing contractor must notifyTrane — or an

agent ofTrane specifically authorized to perform

startup and warrant ofTrane

advance of the scheduled disassembly work to

coordinate the disassembly and reassembly work.

• Startup must be performed byTrane or an agent of

Trane specifically authorized to perform startup and

warranty ofTrane

Trane, or an agent ofTrane specifically authorized to

perform startup and warranty ofTrane

provide qualified personnel and standard hand tools to

perform the disassembly work at a location specified by

the contractor.The contractor shall provide the rigging

equipment such as chain falls, gantries, cranes, forklifts,

etc. necessary for the disassembly and reassembly work

and the required qualified personnel to operate the

necessary rigging equipment.

®

products as noted above.

®

products — two weeks in

®

products, will

®

products, will

• Added Recommended Glycol information.

• Clarified requirements for liquid line service valves on

RTUD units.

• Corrections to electrical data.

• Updated Customer Wire Selection tables.

• Corrected refrigeration circuit graphic in Operating

Principals chapter.

• Updated Compressor Loading Sequence information.

• Updated Diagnostics lists.

• Removed electrical wiring diagrams, and added

reference to new wiring diagram document.

• Miscellaneous minor corrections

Trademarks

Trane, Series R and theTrane logo are trademarks ofTrane

in the United States and other countries. All trademarks

referenced in this document are the trademarks of their

respective owners.

Introduction

This manual covers the installation, operation and

maintenance of RTWD and RTUD units.

Revision Summary

RLC-SVX09H-EN

The following points describe the changes to this revision

of the manual:

• Added factory warranty information.

• Corrections to Model Number descriptions.

• Updated unit dimensions and weights.

RLC-SVX09H-EN 3

Page 4

Table of Contents

Model Number Description ............... 6

Nameplates ........................... 6

Unit Nameplate ..................... 6

Compressor Nameplate ............... 6

Model Number Coding System ......... 6

ASME Nameplate .................... 6

Model Number Descriptions ............ 7

RTWD Model Number ................ 7

Compressor Model Number ........... 8

General Information ..................... 9

Unit Description ....................... 9

Accessory (Options Information ......... 9

General Data .......................... 9

Pre-Installation ......................... 17

Inspection Checklist ................... 17

Unit Storage ......................... 17

Installation requirements and Contractor

responsibilities

....................... 17

Unit Dimensions/Weights ............... 18

Service Clearances and Dimension ..... 18

Weights ............................. 28

Installation - Mechanical ................ 31

Location Requirements ................ 31

Noise Considerations ................ 31

Foundation ........................ 31

Clearances ......................... 31

Rigging .............................. 31

Lifting Procedure ................... 31

Unit Isolation and Leveling ........... 32

Center of Gravity ................... 38

Evaporator Piping .................... 40

Low Evap Refrigerant Cutout/Percent

Glycol Recommendations ............ 55

Condenser Water Piping (RTWD Only) ... 56

Refrigerant Relief Valve Venting ........ 57

RTUD Installation ..................... 58

Application examples ............... 58

Remote Air-Cooled Condenser

Interconnection Refrigerant Piping ..... 60

Condenser by Others

Requirement for Stable fan operation

at low ambient temperatures ..........61

System Configuration ..................62

Equivalent Line Length ...............62

Liquid Line Sizing ....................62

Discharge (Hot Gas) Line Sizing ........67

Example ...........................70

Refrigerant Charge Determination ......71

RTUD Chilled Water Flow Control ......72

Oil Charge Determination .............72

Outdoor Air Temperature Sensor

Installation Requirements .............72

Fan Control for the Remote Air Cooled Con-

denser .............................72

RTUD Condenser Elevation Setting .....73

Shipping Spacers ......................74

Installation - Electrical ....................75

General Recommendations .............75

Installer-Supplied Components .........105

Power Supply Wiring ................106

Interconnecting Wiring ................107

Outdoor Air Temperature Sensor

Installation Requirements ............112

Remote Air Cooled Condenser ........112

Fan Control for the Remote Air Cooled

Condenser .........................112

Communications Interface .............112

RTWD/RTUD Operating Principles ........125

General .............................125

RTWD ............................125

RTUD .............................125

Refrigeration (Cooling) Cycle ...........126

Overview ..........................126

Cycle Description ...................126

Oil System Operation (RTWD/RTUD) ....129

Overview ..........................129

Compressor Motor ..................129

Compressor Rotors .................129

Oil Filter ...........................130

4 RLC-SVX09H-EN

Page 5

Compressor Rotor Oil Supply ........ 130

Compressor Bearing Oil Supply ...... 130

Oil Separator ...................... 130

Compressor Loading Sequence ...... 130

Controls Interface ...................... 131

CH530 Communications Overview ..... 131

Controls Interface .................... 131

DynaView ........................ 131

Display Screens ................... 132

Main Screen ...................... 133

Chiller Operating Mode ............. 133

Settings Screen ................... 138

Lockout Screen ...................... 143

Power Up and Self Tests .............. 144

TechView ........................... 145

Fan Configurations ................. 163

A/C Fan Controls ................... 163

Low Ambient Fan Control Type ...... 164

Fan Deck Arrangement Circuit 1 ...... 165

Fan Deck Arrangement Circuit 2 ...... 166

Example for Fan Configurations ...... 166

A/C Fan Controls (ACFC) ............ 166

Maintenance .........................181

Weekly Maintenance and Checks ......181

Monthly Maintenance and Checks .....181

Annual Maintenance ................181

Scheduling Other Maintenance .......182

Operating Log ........................182

Service Procedures ...................185

Cleaning the Condense (RTWD Only) . .185

RTUD Air Cooled Condenser Applications High Condenser Pressure Limit and High

Pressure Cutout Diagnostics ..........188

Cleaning the Evaporator .............189

Compressor Oil ....................189

Refrigerant Charge ..................191

Freeze Protection .....................192

Diagnostics ............................193

Starter Diagnostics ...................194

Main Processor Diagnostics ............197

Communication Diagnostics ...........208

Limit Conditions ......................214

Wiring Schematics ......................215

Unit Electrical Data ...................215

Pre-Start Checkout ..................... 168

Unit Voltage Power Supply ........... 169

Unit Voltage Imbalance ............. 169

Unit Voltage Phasing ............... 169

Water System Flow Rates ........... 170

Water System Pressure Drop ........ 170

Unit Start-Up Procedures ............... 171

Sequence of Operation ............... 171

PowerUp ........................ 171

Stopped to Starting: ................ 173

Start-up ............................ 177

Seasonal Unit Start-Up Procedure ..... 177

Unit Shutdown ........................ 179

Normal Shutdown to Stopped ......... 179

Seasonal Unit Shutdown ............. 180

Service and Maintenance ............... 181

Overview ........................... 181

RLC-SVX09H-EN 5

Page 6

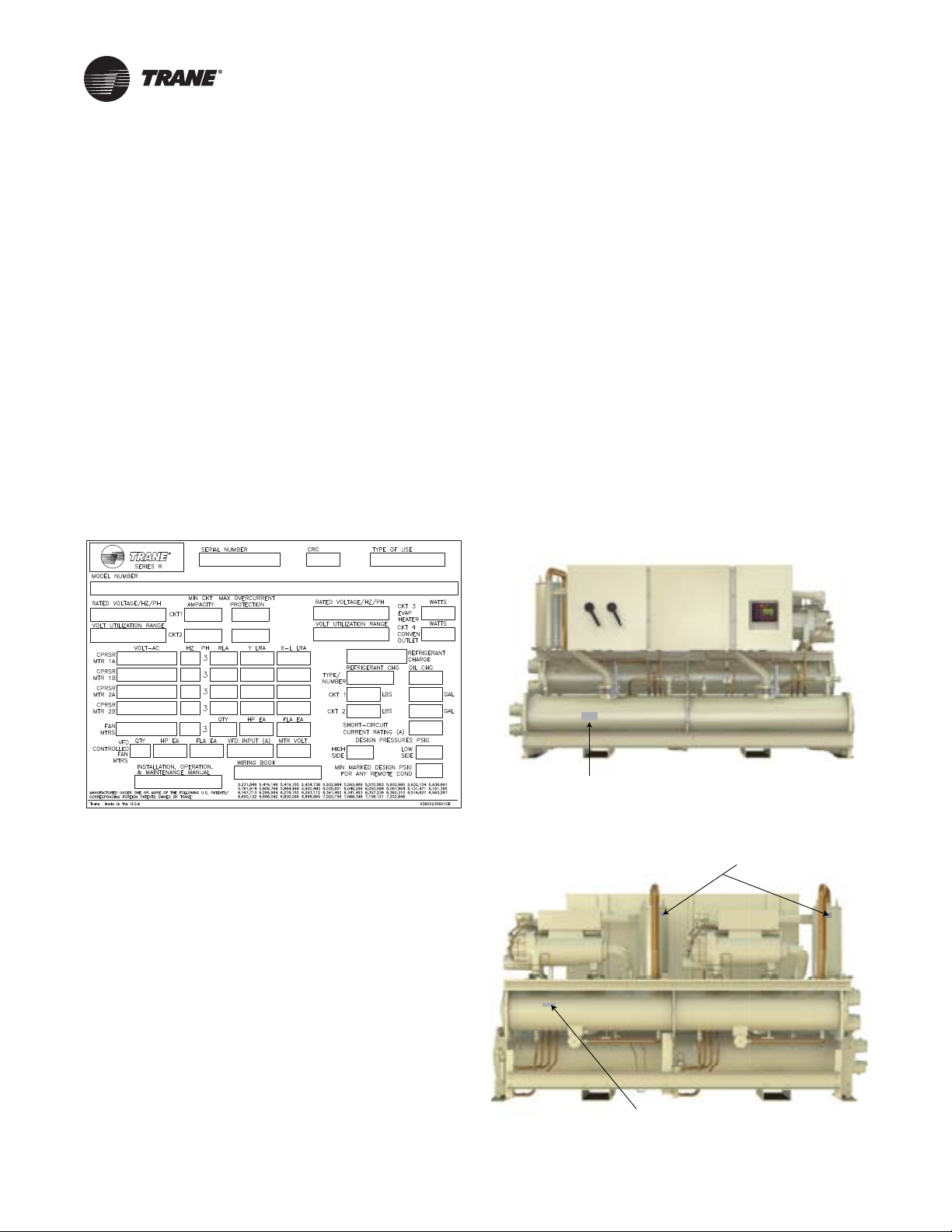

Model Number Description

Nameplates

The RTWD/RTUD unit nameplates are applied to the

exterior surface of the control panel door.

A compressor nameplate is located on each compressor.

Unit Nameplate

See Figure 1. Unit nameplate includes the following:

• Unit model and size descriptor.

• Unit serial number.

• Identifies unit electrical requirements.

• Lists correct operating charges of R-134a and Oil 48.

• Lists unit test pressures

• Identifies installation, operation and maintenance and

service data literature.

• Lists drawing numbers for unit wiring diagrams.

Figure 1. Unit nameplate

Model Number Coding System

Model numbers for unit and compressors are comprised

of numbers and letter which represent equipment

features.

See “RTWD Model Number,” p. 7and “Compressor Model

Number,” p. 8 for details.

Each position, or group of positions, in a number or letter

is used to represent a feature.For example, from the chart,

we can determine that “F” in digit 8 of unit model number

indicates unit voltage is 460/60/3.

ASME Nameplate

The ASME nameplate is different for the evaporators,

condensers (RTWD only) and oil separators.The

evaporator nameplate is located on the left portion of the

shell.The insulation over the nameplate is intentionally

left unglued, for ease in viewing the nameplate.

The condenser nameplate is on the backside of the

condenser below circuit 2 compressor.

Figure 2. Location of ASME unit nameplate - front

Evaporator ASME Nameplate

%VAPORATOR

Figure 3. Location of ASME unit nameplates - back

Compressor Nameplate

Compressor nameplate includes the following:

Oil Separator

SME Nameplates

/IL3EPARATOR

!3-%NAMEPLATES

• Compressor model number.

• Compressor serial number.

• Compressor electrical characteristics.

• Utilization Range.

• Recommended refrigerant.

#ONDENSER

Condenser

!3-%NAMEPLATES

ASME nameplates (RTWD only)

Condenser ASME Nameplate

(RTWD only)

6 RLC-SVX09H-EN

Page 7

Model Number Descriptions

RTWD Model Number

Digits 1-4— Chiller Model

RTWD= Water Cooled Chiller - Series R

RTUD= Compressor Series R®Chiller

Digits 5-7— Unit Nominal

Tonnage

060 = 60 NominalTons

070 = 70 NominalTons

080 = 80 NominalTons

090 = 90 NominalTons

100 = 100 NominalTons

110 = 110 Nominal Tons

120 = 120 NominalTons

130 = 130 NominalTons

140 = 140 NominalTons

150 = 150 NominalTons

160 = 160 NominalTons

180 = 180 NominalTons

200 = 200 Nominal Tons

220 = 220 NominalTons

250 = 250 NominalTons

Digit 8— Unit Voltage

A = 200/60/3

B = 230/60/3

D = 380/60/3

E = 400/50/3

F = 460/60/3

G = 575/60/3

Digit 9— Manufacturing Plant

2 = Pueblo, USA

Digits 10, 11— Design Sequence

XX = Factory Assigned

Digit 12— UnitType

1 = Standard efficiency/performance

2 = High efficiency/performance

3 = Premium efficiency/performance

Digit 13— Agency Listing

0 = No agency listing

A = UL listed to US and Canadian

safety standards

D = IBC Seismically Rated Unit

E = UL/Canadian and IBC

F = OSHPD Seismically Rated Unit

G = UL/Canadian and OSHPD

Digit 14— Pressure Vessel Code

1 = ASME pressure vessel code

3 = Chinese code-imported pressure

vessel

S = Special

Digit 15— Unit Application

A = Standard condenser

(< 95°F/35°C entering water)

B = High temperature condenser

(>95°F/35°C entering water)

C = Water-to-water heat pump

D = Remote condenser byTrane

E = Remote condenser by others

Digit 16— Pressure ReliefValve

1 = Single relief valve

2 = Dual relief valve with 3-way

isolation valve

Digit 17— Water Connection

®

Type

A = Grooved pipe connection

Digit 18— EvaporatorTubes

A = Internal and External enhanced

Digit 19— Number of

Evaporator Passes

2 = 2-pass evaporator

3 = 3-pass evaporator

Digit 20— Evaporator Water

Side Pressure

A = 150 psi/10.5 bar evaporator

Digit 21— Evaporator

Application

1 = Standard cooling

2 = Low temperature

3 = Ice-making

Digit 22— CondenserTubes

X = Remote condenser

A = Enhanced fin - copper

B = Internally enhanced 90/10 CuNi

Digit 23— Condenser Water

Side Pressure

0 = Remote condenser

1 = 150 psi/10.5 bar condenser water

Digit 24— Compressor Starter

Type

Y = Wye-delta closed transition

X = Across-the-line starter

Digit 25— Incoming Power Line

Connection

1 = Single point power connection

2 = Double point power connection

Digit 26— Power Line

ConnectionType

A = Terminal block

B = Mechanical disconnect switch

D = Circuit breaker

E = High fault rated panel with circuit

Digit 27— Under/Over Voltage

Protection

0 = No under/over voltage

1 = Under/over voltage protection

water pressure

fin

pressure

starter

breaker

protection

Digit 28— Unit Operator

Interface

A = Dyna-View/English

B = Dyna-View/Spanish

C = Dyna-View/Spanish-Mexico

D = Dyna-View/French

E = Dyna-View/German

F = Dyna-View/Dutch

G = Dyna-View/Italian

H = Dyna-View/Japanese

J = Dyna-View/Portuguese-Portugal

K = Dyna-View/Portuguese-Brazil

L = Dyna-View/Korean

M = Dyna-View/Thai

N = Dyna-View/Simplified Chinese

P = Dyna-View/Traditional Chinese

R = Dyna-View/Russian

T = Dyna-View/Polish

U = Dyna-View/Czech

V = Dyna-View/Hungarian

W = Dyna-View/Greek

X = Dyna-View/Romanian

Y = Dyna-View/Swedish

Digit 29— Remote Interface

(Digital Comm)

0 = No remote digital

communication

A = LonTalk/Tracer Summit™

interface

B = Time of day scheduling

4 = Unit Level BACnet

Digit 30— External Water and

Current Limit Setpoint

0 = No external water and current

limit setpoint

A = External water and current limit

setpoint 4-20 mA

B = External water and current limit

setpoint 2-10 Vdc

Digit 31— Ice Making

0 = No ice making

A = Ice making with relay

B = Ice making without relay

Digit 32— Programmable Relays

0 = No programmable relays

A = Programmable relays

Digit 33— Condenser

Refrigerant Pressure Output

Option

0 = No condenser refrigerant output

1 = Condenser water control output

2 = Condenser pressure (%HPC)

output

3 = Differential pressure output

Digit 34— Outdoor AirTemp

Sensor

0 = No outdoor air temp sensor

A = Outdoor air temp sensor - CWR

(low ambient

RLC-SVX09H-EN 7

Page 8

Digit 35— Condenser Leaving

Hot WaterTemp Control

0 = No condenser leaving hot water

temperature control

1 = Condenser leaving hot water

temperature control

Digit 36— Power Meter

0 = No power meter

P = Power meter

Digit 37— Motor Current Analog

Output (%RLA)

0 = No motor current analog output

1 = Motor current analog output

Digit 38— A/C Fan Control

0 = No fan controls (RTWD)

A = Fan control by others

B = Integral fan controls

Digit 39— Low Ambient Fan

ControlType

0 = No low ambient fan control type

(RTWD)

1 = Two speed fan

2 = Variable speed fan with analog

interface

3 = Variable speed fan with PWM

interface

Digit 40— Installation

Accessories

0 = No installation accessories

(shipped with elastomeric pad)

A = Elastomeric (neoprene) isolators

B = Flanged water connection kit

C = Isolators and flanged water

connection kit

Digit 41— Flow Switch

0 = No flow switch

1 = 150 psi NEMA 1; flow switch x 1

2 = 150 psi NEMA 1; flow switch x 2

3 = 150 psi NEMA 4; flow switch x 1

4 = 150 psi NEMA 4; flow switch x 2

7 = Factory installed proof of

evaporator and condenser

8 = Factory installed proof of

evaporator

9 = Factory installed proof of

condenser

Digit 42— 2-Way Water

Regulating Valve

0 = No 2-way water regulating valve

A = 3” 150psi/88.9mm 10.5 bar 115V

B = 3” 150psi/88.9mm 10.5 bar 220V

C = 3” 150psi/114.3mm 10.5bar 115V

D = 3” 150psi/114.3mm 10.5bar 220V

Digit 43— Sound Reduction

Package

0 = No sound reduction package

A = Sound reduction - factory

installed

Digit 44— Insulation

0 = No insulation

1 = Factory insulation, all cold parts

2 = Insulation for high humidity

Digit 45— Factory Charge

0 = Full factory refrigerant charge

(R-134a)

1 = Nitrogen charge

Digit 46— Base Rail Forklifting

0 = No base rail forklifting

B = Base rail forklifting

Digit 47— Label and Literature

Language

B = Spanish

D = English

E = French

G = Chinese - traditional

Digit 48— Special

0 = None

A = Special

Digits 49-55

0 = None (not used)

Digit 56— Shipping Package

0 = No skid (standard)

1 = Skid

2 = Shrink wrap

3 = Skid and shrink wrap

Digits 57-58

x = Factory assigned

Digit 59— PerformanceTest

Options

0 = No performance test

C = 1 point test with report

D = 2 point test with report

E = 3 point test with report

F = 4 point test with report

G = Witness 1 point test with report

H = Witness 2 point test with report

J = Witness 3 point test with report

K = Witness 4 point test with report

Digit 60— Evaporator FluidType

0 = Water

1 = Calcium chloride

2 = Ethylene glycol

3 = Propylene glycol

4 = Methanol

Compressor Model Number

Digits 1-4— Compressor Model

CHHN= Positive displacement,

helical rotary (twin screw)

hermetic compressor

Digits 5-7— Size

0N2= 120 Tons

0N1= 100 Tons

0M2= 85Tons

0M1= 70Tons

0L2 = 60Tons

0L1 = 50Tons

0K2= 40 Tons

0K1= 35 Tons

Digit 8— Unit Voltage

A = 200/60/3

R = 220/50/3

C = 230/60/3

D = 380/60/3

H = 575/60/3

T = 460/60/3 or 400/50/3

Digit 9— Internal Relief

K = 450 psid

Digits 10, 11— Design Sequence

XX = Factory Assigned

Digit 12— Capacity Limit

N = Standard capacity controls

(no capacity limit

Digits 13-15— Motor kW Rating

134 = 134 kW (N2/60Hz)

112 = 112 kW (N2/50Hz)

092 = 092 kW (M2/60Hz)

077 = 077 kW (M2/50Hz)

069 = 069 kW (L2/60Hz)

058 = 058 kW (L2/50Hz)

050 = 050 kW (K2/60Hz)

041 = 041 kW (K2/50Hz)

112 = 112 kW (N1/60Hz)

093 = 093 kW (N1/50Hz)

077 = 077 kW (M1/60Hz)

065 = 065 kW (M1/50Hz)

057 = 057 kW (L1/60Hz)

048 = 048 kW (L1/60Hz)

043 = 043 kW (K1/60Hz)

036 = 036 kW (K1/60Hz)

Digit 16— Volume Ratio

A = High volume ratio

N = Low volume ratio

8 RLC-SVX09H-EN

Page 9

General Information

Unit Description

The RTWD units are helical-rotary type, water-cooled,

liquid chillers, designed for installation indoors.The units

have 2 independent refrigerant circuits, with one

compressor per circuit.The RTWD units are packaged with

an evaporator and condenser.

Note: Each RTWD unit is a completely assembled,

hermetic package that is factory-piped, wired, leak-

tested, dehydrated, charged and tested for proper

control operations prior to shipment.The chilled

water inlet and outlet openings are covered for

shipment.

The RTWD series featuresTrane's exclusive Adaptive

Control logic with CH530 controls. It monitors the control

variables that govern the operation of the chiller unit.

Adaptive Control logic can correct these variables, when

necessary, to optimize operational efficiencies, avoid

chiller shutdown, and keep producing chilled water.

Compressor unloaders are solenoid actuated. Each

refrigerant circuit is provided with filter, sight glass,

electronic expansion valve, and charging valves on the

RTWD.

The evaporator and condenser are manufactured in

accordance with ASME standards.The evaporator is fully

insulated. Both evaporator and condenser are equipped

with water drain and vent connections.

The RTUD units are helical-rotary type compressor

chillers, designed to be most effective when used with the

Levitor II air-cooled condenser.The RTUD unit consists of

an evaporator, two helical rotary compressors (one per

circuit), oil separators, oil coolers, liquid line service

valves, sightglasses, electronic expansion valves and

filter.The discharge line leaving the oil separator and

liquid line entering the filters are capped and brazed. The

unit ships with a full charge of oil and a nitrogen holding

charge.

Accessory/Options Information

Check all the accessories and loose parts which are

shipped with the unit against the original order. Included

in these items will be water vessel drain plugs, rigging

diagrams, electrical diagrams, and service literature,

which are placed inside the control panel and/or starter

panel for shipment. Also check for optional components,

such as flow switches and isolators.

General Data

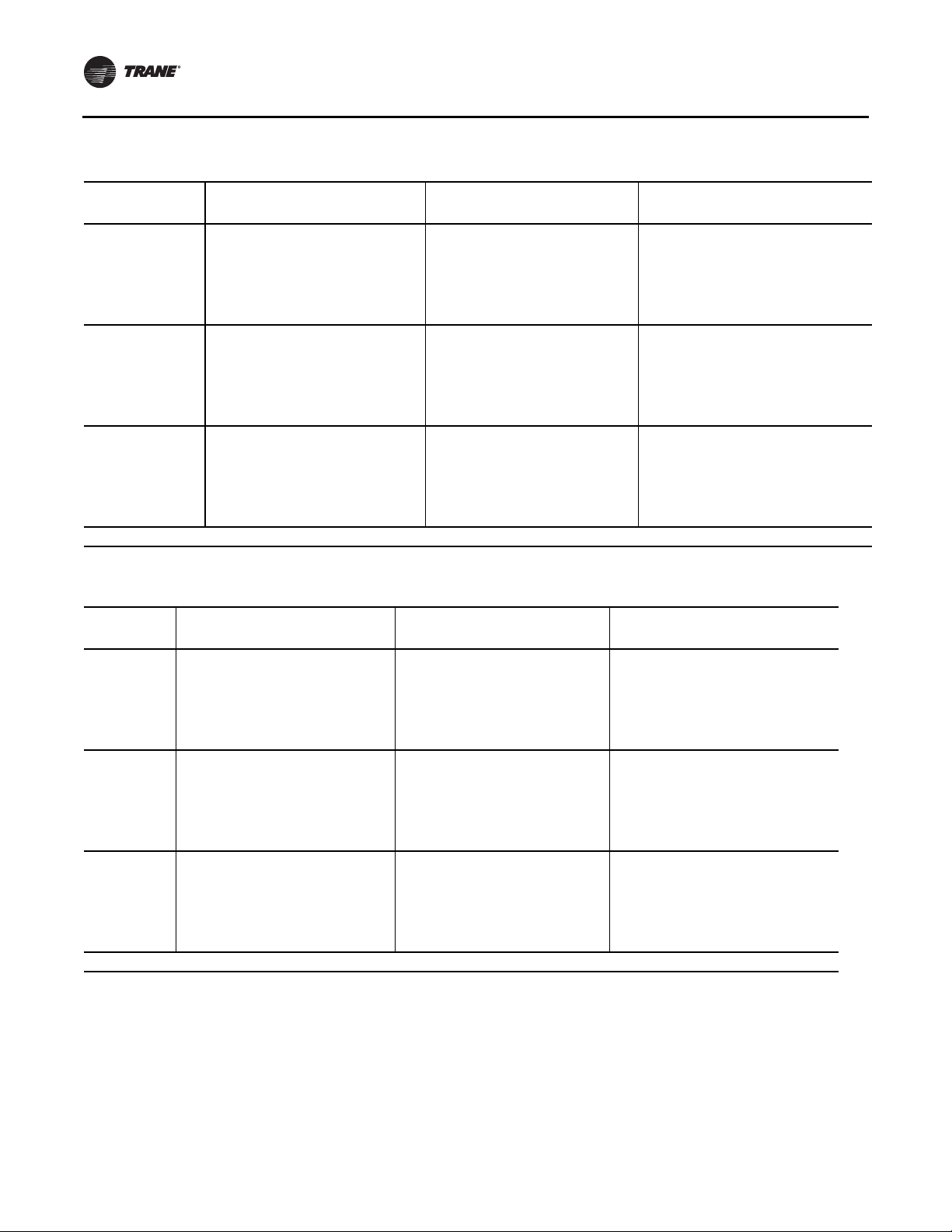

Table 1. General Data - RTWD - 60 Hz - premium

Compressor L2/M1 M1/M1 M1/M2 M2/M2

Nominal Size 65/70 70/70 70/85 85/85

Evaporator

Water Conn.

Water Storage

Minimum Flow

Water Conn.

Water Storage

Minimum Flow

Condenser

Water Conn.

Water Storage

Minimum Flow

General Unit

Refrig Type R-134a R-134a R-134a R-134a

Refrigerant

Oil Charge

Notes:

1. Data containing information on two circuits is shown as circuit 1/

circuit 2.

2. Flow limits are for water only.

efficiency

Size 150 160 180 200

Quantity 2 2 2 2

2 Pass Arrangement

NPS 6 6 6 6

Size

Maximum

Flow

Size

Maximum

Flow

Size

Maximum

Flow

# Refrig

Circuits

Charge

mm 150 150 150 150

(gal) 27.8 27.8 29.3 31.3

(L) 105.1 105.1 110.9 118.3

(gpm) 174 174 186 202

(L/s) 11.0 11.0 11.8 12.7

(gpm) 639 639 683 739

(L/s) 40.3 40.3 43.1 46.7

3 Pass Arrangement

NPS 4 4 4 4

mm 100 100 100 100

(gal) 27.1 27.1 28.6 30.6

(L) 102.4 102.4 108.3 115.7

(gpm) 116 116 124 134

(L/s) 7.3 7.3 7.8 8.5

(gpm) 426 426 456 493

(L/s) 26.9 26.9 28.7 31.1

NPS 6 6 6 6

mm 150 150 150 150

(gal) 30.0 30.0 32.9 32.9

(L) 113.4 113.4 124.4 124.4

(gpm) 206 206 231 231

(L/s) 13 13 14.6 14.6

(gpm) 755 755 845 845

(L/s) 47.6 47.6 53.3 53.3

2222

174.2/

(lb)

(kg) 79/83 83/83 82/82 81/81

(qts) 10.5/12.4 12.4/12.4 12.4/12.4 12.4/12.4

183.0

(L) 9.9/11.7 11.7/11.7 11.7/11.7 11.7/11.7

183.0/

183.0

180.8/

180.8

178.6/

178.6

RLC-SVX09H-EN 9

Page 10

General Information

Table 2. General Data - RTWD - 60 Hz - standard efficiency

Size 80 90 100 110 120 130 140

Compressor K1/K1 K2/K2 K2/L1 L1/L1 L1/L2 L2/L2 L2/M1

Quantity 2 2 2 2222

Nominal Size 40/40 45/45 45/55 55/55 55/65 65/65 65/70

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 4 4 4 4555

mm 100 100 100 100 125 125 125

Water Storage (gal) 11.2 11.2 12.6 14 15.2 16.2 17.7

(L) 42.2 42.2 47.6 53.0 57.4 61.5 66.8

Minimum Flow (gpm) 77 77 89 101 101 110 122

(L/s) 4.9 4.9 5.6 6.4 6.4 6.9 7.7

Maximum Flow (gpm) 281 281 325 368 368 400 444

(L/s) 17.7 17.7 20.5 23.2 23.2 25.2 28

3 Pass Arrangement

Water Conn. Size NPS 3 3 3 3444

mm 80 80 80 80 100 100 100

Water Storage (gal) 11.2 11.2 12.6 14 15.2 16.2 17.7

(L) 42.2 42.2 47.6 53.0 57.4 61.5 66.8

Minimum Flow (gpm) 52 52 59 67 67 73 81

(L/s) 3.3 3.3 3.8 4.3 4.3 4.6 5.1

Maximum Flow (gpm) 187 187 216 244 244 266 295

(L/s) 11.8 11.8 13.6 15.4 15.4 16.8 18.6

Condenser

Water Conn. Size NPS 5 5 5 5555

mm 125 125 125 125 125 125 125

Water Storage (gal) 12.4 14.2 16.0 16.9 18.5 18.5 20.9

(L) 46.8 53.6 60.4 63.8 70.1 70.1 79.2

Minimum Flow (gpm) 83 99 115 124 135 135 156

(L/s) 5.2 6.3 7.3 7.8 8.5 8.5 9.9

Maximum Flow (gpm) 301 361 421 451 491 491 572

(L/s) 18.9 22.7 26.5 28.4 31.0 31.0 36.0

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 2 2 2 2222

Refrigerant Charge (lb) 114.6/114.6 114.6/114.6 112.4/114.6 112.4/112.4 132.3/132.3 130.1/130.1 127.9/132.3

(kg) 52/52 52/52 51/52 51/51 60/60 59/59 58/60

Oil Charge (quarts) 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9

Notes:

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

10 RLC-SVX09H-EN

Page 11

General Information

Table 3. General Data - RTWD - 60 Hz - high efficiency

Size 80 90 100 110 120 130 150 160 180 200 220 250

Compressor K1/K1 K2/K2 K2/L1 L1/L1 L1/L2 L2/L2 L2/M1 M1/M1 M1/M2 M2/M2 M2/N1 N1/N1

Quantity 222222222222

Nominal Size 40/40 45/45 45/55 55/55 55/65 65/65 65/70 70/70 70/85 85/85 85/100 100/100

Evaporator

2 Pass Arrangement

Water Conn.

Water Storage (gal) 9.8 11.9 12.8 15.3 16.4 17.3 19.2 20.3 22.3 24.2 28.6 31.8

Minimum Flow (gpm) 72 92 100 112 123 130 141 151 170 186 211 240

Maximum Flow (gpm) 263 336 364 409 448 476 515 555 622 683 773 879

Water Conn.

Water Storage (gal) 9.8 11.9 12.8 15.3 16.4 17.3 18.8 20.0 22.0 23.8 27.9 31.0

Minimum Flow (gpm) 48 61 67 75 82 87 94 101 113 124 141 160

Maximum Flow (gpm) 175 223 242 271 298 316

Condenser

Water Conn.

Water Storage (gal) 11.9 12.7 14.9 16.6 17.2 18.0 21.6 22.9 24.6 26.2 31.1 39.2

Minimum Flow (gpm) 87 95 117 130 136 145 159 173 189 206 244 325

Maximum Flow (gpm) 317 347 427 473 498 528 584 634 695 755 896 1193

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222222222

Refrigerant

Charge

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/10.5

Notes:

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. 2. Flow limits are for water only.

NPS445555555566

Size

mm 100 100 100 125 125 125 125 125 125 125 150 150

(L) 37.0 45.2 48.3 57.9 62.3 65.4 72.6 77.0 84.5 91. 108.3 120.3

(L/s) 4.6 5.8 6.3 7.1 7.8 8.2 8.9 9.5 10.7 11.8 13.3 15.1

(L/s) 16.6 21.2 22.9 25.8 28.2 30.0 32.5 35.0 39.2 43.1 48.8 55.5

3 Pass Arrangement

NPS334444444444

Size

mm 80 80 80 100 100 100 100 100 100 100 100 100

(L) 37.0 45.2 48.3 57.9 62.3 65.4 71.2 75.6 83.2 90.1 105.5 117.5

(L/s) 3.1 3.9 4.2 4.7 5.2 5.5 5.9 6.4 7.1 7.8 8.9 10.1

344 370 415 456 515 586

(L/s) 11.0 14.1 15.2 17.1 18.8 19.9

NPS555555666666

Size

mm 125 125 125 125 125 125 150 150 150 150 150 150

(L) 45.1 48.1 56.3 62.7 65.2 68.3 81.7 86.8 93.0 99.2 117.8 148.3

(L/s) 5.5 6.0 7.4 8.2 8.6 9.1 10.1 10.9 12.0 13.0 15.4 20.5

(L/s) 20.0 21.9 26.9 29.8 31.4 33.3 36.8 40.0 43.8 47.6 56.5 75.3

(lb)

(kg) 45/45 44/44 56/57 56/56 55/55 54/54 61/65 64/64 63/63 62/62 81/84 82/82

99.2/

99.2

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/11.7

97/97

123.5/

125.7

123.5/

123.5

10.5/

10.5

121.3/

121.3

10.5/

10.5

119/

119

10.5/

10.5

21.7 23.3 26.2 28.7 32.5 37.0

134.5/

143.3

10.5/

12.4

141.1/

141.1

12.4/

12.4

11.7/

11.7

138.9/

138.9

12.4/

12.4

11.7/

11.7

136.7/

136.7

12.4/

12.4

11.7/

11.7

178.6/

185.2

12.4/

12.4

11.7/

11.7

180.8/

180.8

12.4/

12.4

11.7/

11.7

RLC-SVX09H-EN 11

Page 12

General Information

Table 4. General Data – RTUD – 60 Hz

Size 80 90 100 110 120 130 150 160 180 200 220 250

Compressor K1/K1 K2/K2 K2/L1 L1/L1 L1/L2 L2/L2 L2/M1 M1/M1 M1/M2 M2/M2 M2/N1 N1/N1

Quantity 222222222222

Nominal Size 40/40 45/45 45/55 55/55 55/65 65/65 65/70 70/70 70/85 85/85 85/100 100/100

Evaporator

2 Pass Arrangement

Water Conn.

Water Storage (gal) 9.8 10.6 12.0 14.0 15.3 15.3 16.5 19.2 19.2 20.3 22.3 24.2

Minimum Flow (gpm) 77 79 91 99 111 111 122 140 140 151 169 186

Maximum Flow (gpm) 281 291 335 363 408 408 447 514 514 553 620 681

Water Conn.

Water Storage (gal) 9.5 10.3 11.6 13.7 15.1 15.1 16.1 18.8 18.8 20.0 22.0 23.8

Minimum Flow (gpm) 51 53 61 66 74 74 81 94 94 100 112 124

Maximum Flow (gpm) 187 194 224 242 272 272 298 343 343 368 413 454

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222222222

Refrigerant

Charge

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/10.5

Discharge

Connection

Diameter

Connection

Diameter

Notes:

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. 2. Flow limits are for water only.

NPS444555555555

Size

mm 100 100 100 125 125 125 125 125 125 125 125 125

(L) 37.1 40.2 45.3 53.0 58.0 58.0 62.4 72.6 72.6 77.0 84.5 91.5

(L/s) 4.9 5.0 5.7 6.2 7.0 7.0 7.7 8.8 8.8 9.5 10.7 11.7

(L/s) 17.7 21.2 23.0 25.8 28.3 30.0 28.2 32.4 32.4 34.9 39.1 43.0

3 Pass Arrangement

NPS333444444444

Size

mm 80 80 80 100 100 100 100 100 100 100 100 100

(L) 36.0 39.0 44.0 52.0 57.0 57.0 61.0 71.2 71.2 75.6 83.2 90.1

(L/s) 3.2 3.3 3.8 4.2 4.7 4.7 5.1 5.9 5.9 6.3 7.1 7.8

(L/s) 11.8 12.2 14.1 15.3 17.2 17.2 18.8 21.6 21.6 23.2 26.1 28.6

(lb) 50/50 49/49 47/47 65/65 64/64 64/64 62/62 66/66 66/66 66/66 63/63 61/61

(kg)

(inch) 2.1 2.1 2.1 2.6 2.6 2.6 2.6 3.1 3.1 3.1 3.1 3.1

Liquid

(inch) 1.1 1.1 1.1 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.6

22.7/

22.7

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/11.7

22.2/

22.2

21.3/

21.3

29.5/

29.5

10.5/

10.5

29.0/

29.0

10.5/

10.5

29.0/

29.0

10.5/

10.5

28.1/

28.1

10.5/

10.5

29.9/

29.9

10.5/

10.5

29.9/

29.9

10.5/

12.4

29.9/

29.9

12.4/

12.4

11.7/

11.7

28.6/

28.6

12.4/

12.4

11.7/

11.7

27.7/

27.7

12.4/

12.4

11.7/

11.7

12 RLC-SVX09H-EN

Page 13

General Information

Table 5. General Data – Condenser byTrane – 60 Hz

Size 80 90 100 110 120 130 150 160 180 200 220 250

Condenser

Condenser

Quantity

Fins/Inch 12 10 10 12 8 10 8/12 12/12 12/8 8/8 8/10 10/10

Coil Length (in) 162 216 216 216 270 270 162/162 162/162 162/216 216/216 216/216 216/216

(mm) 4115 5486 5486 5486 6858 6858

Coil Width (in) 85 85 85 85 85 85 85/85 85/85 85/85 85/85 85/85 85/85

(mm) 2159 2159 2159 2159 2159 2159

Number of Rows 3 3 4 4 4 4 3/3 3/3 3/3 3/3 3/4 4/4

Condenser Fans

Fan Quantity 6 8 8 8 10 10 6/6 6/6 6/8 8/8 8/8 8/8

Diameter (in) 30 30 30 30 30 30 30 30 30 30 30 30

(mm) 762 762 762 762 762 762 762 762 762 762 762 762

Nominal RPM (rpm) 850 850 850 850 850 850 850 850 850 850 850 850

Air Flow (cfm) 56,646 78,280 72,248 69,280 94,490 90,310

Tip Speed (fpm) 6676 6676 6676 6676 6676 6676 6676 6676 6676 6676 6676 6676

Motor HP (hp) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

General

Recommended

Refrigerant

Charge¹

Discharge/Liquid

Connection

Diameters

Notes:

1. Data containing information on two condensers is shown as cond 1/cond 2.

2. Data containing information on two circuits is shown as circuit 1/circuit 2.

3. Condenser is not factory charged, the refrigerant must be purchased and charged in

the field.

(lbs) 55/55 92/92 97/97 97/97 98/98 122/122 109/109 109/109 109/146 146/146 146/195 195/195

(kg)

(in) 2.1 2.1 2.1 2.1 2.1 2.1 2.125 2.125 2.125 2.125 2.125 2.125

(mm) 54 54 54 54 54 54 54 54 54 54 54 54

111111222222

24.9/

24.9

41.7/

41.7

44.0/

44.0

44.0/

44.0

44.5/

44.5

55.3/

55.3

4115/

4115

2159/

2159

60,954/

56,646

49.4/

49.4

4115/

4115

2159/

2159

56,646/

56,646

49.4/

49.4

4115/

5486

2159/

2159

56,646/

81,272

49.4/

66.2

5486/

5486

2159/

2159

81,272/

81,272

66.2/

66.2

5486/

5486

2159/

2159

81,272/

72,248

66.2/

88.5

72,248/

72,248

5486/

5486

2159/

2159

88.5/

88.5

RLC-SVX09H-EN 13

Page 14

General Information

Table 6. General Data - RTWD 50 Hz - standard efficiency

Size 70 80 90 100 110 120 130 140 150

Compressor K2/K2 K2/L1 L1/L1 L1/L2 L2/L2 L2/M1 M1/M1 M1/M2 M2/M2

Quantity 2 2 2 222222

Nominal Size 45/45 45/55 55/55 55/65 65/65 65/70 70/70 70/85 85/85

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 4 4 4 445555

mm 100 100 100 100 100 125 125 125 125

Water Storage (gal) 11.2 12.6 14.0 14.0 14.0 16.2 17.7 17.7 19.1

(L) 42.2 47.6 53.0 53.0 53.0 61.5 66.8 66.8 72.2

Minimum Flow (gpm) 77 89 101 101 101 110 122 122 133

(L/s) 4.9 5.6 6.3 6.3 6.3 6.9 7.7 7.7 8.4

Maximum Flow (gpm) 281 324 368 368 368 400 444 444 487

(L/s) 17.7 20.5 23.2 23.2 23.2 25.2 28.0 28.0 30.7

3 Pass Arrangement

Water Conn. Size NPS 3 3 3 334444

mm 80 80 80 80 80 100 100 100 100

Water Storage (gal) 11.2 12.6 14.0 14.0 14.0 16.2 17.7 17.7 19.1

(L) 42.2 47.6 53.0 53.0 53.0 61.5 66.8 66.8 72.2

Minimum Flow (gpm) 52 59 67 67 67 73 81 81 89

(L/s) 3.3 3.8 4.3 4.3 4.3 4.6 5.1 5.1 5.6

Maximum Flow (gpm) 187 216 244 244 244 266 295 295 324

(L/s) 11.8 13.6 15.4 15.4 15.4 16.8 18.6 18.6 20.4

Condenser

Water Conn. Size NPS 5 5 5 555555

mm 125 125 125 125 125 125 125 125 125

Water Storage (gal) 12.4 14.2 16.0 16.9 16.9 18.5 20.9 20.9 22.4

(L) 46.8 53.6 60.4 63.8 63.8 70.1 79.2 79.2 84.8

Minimum Flow (gpm) 83 99 115 124 124 135 156 156 170

(L/s) 5.2 6.3 7.3 7.8 7.8 8.5 9.9 9.9 10.8

Maximum Flow (gpm) 301 361 421 451 451 491 571 571 622

(L/s) 18.9 22.7 26.5 28.4 28.4 31.0 36.0 36.0 39.2

General Unit

Refrigerant Type R134a R134a R134a R134a R134a R134a R134a R134a R134a

# Refrig Circuits 2 2 2 222222

Refrigerant Charge (lb)

(kg) 52/52 51/51 50/50 50/51 51/51 59/59 58/58 58/60 59/59

Oil Charge (quarts) 7.2/7.2 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9

Notes:

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

114.6/

114.6

112.4/

112.4

110.2/

110.2

110.2/

112.4

112.4/

112.4

130.1/

130.1

127.9/

127.9

127.9/

132.3

130.1/

130.1

14 RLC-SVX09H-EN

Page 15

General Information

Table 7. General Data - RTWD 50 Hz - high efficiency

Size 60 70 80 90 100 110 120 130 140 160 180 200 220 250

Compressor K1/K1 K2/K2 K2/L1 L1/L1 L1/L2 L2/L2 L2/M1 M1/M1 M1/M2 M2/M2 M2/N1 N1/N1 N1/N2 N2/N2

Quantity 22222222222222

Nominal Size 40/40 45/45 45/55 55/55 55/65 65/65 65/70 70/70 70/85 85/85 85/100

Evaporator

2 Pass Arrangement

NPS44455555555666

Water

Conn. Size

Storage

Minimum

Maximum

Conn. Size

Storage

Minimum

Maximum

Condenser

Conn. Size

Storage

Minimum

Maximum

General Unit

Refrig Type R-134a R-134a R-134a R-134a R-134a R-134a R134a R-134a R-134a R-134a R134a R-134a R-134a R-134a

# Refrig

Circuits

Refrigerant

Charge

Oil Charge

Notes:

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

mm 100 100 100 125 125 125 125 125 125 125 125 150 150 150

(gal) 9.8 10.6 11.9 15.3 15.3 16.4 17.3 19.2 20.3 22.3 24.2 28.6 29.9 31.8

Water

(L) 37.0 40.2 45.2 57.9 57.9 62.3 65.4 72.6 77.0 84.5 91.5 108.3 113.3 120.3

(gpm) 72 80 92 112 112 123 130 141 151 170 186 211 223 240

Flow

(L/s) 4.6 5.1 5.8 7.1 7.1 7.8 8.2 8.9 9.5 10.7 11.8 13.3 14.1 15.1

(gpm) 263 291 336 408 408 448 476 515 555 622 683 773 818 879

Flow

(L/s) 16.6 18.3 21.2 25.8 25.8 28.2 30.0 32.5 35.0 39.2 43.1 48.8 51.6 55.5

3 Pass Arrangement

NPS33344444444444

Water

mm 80 80 80 100 100 100 100 100 100 100 100 100 100 100

(gal) 9.8 10.6 11.9 15.3 15.3 16.4 17.3 18.8 20.0 22.0 23.8 27.9 29.2 31.0

Water

(L) 37.0 40.2 45.2 57.9 57.9 62.3 65.4 71.2 75.6 83.2 90.1 105.5 110.5 117.5

(gpm) 48 53 61 75 75 82 86 94 101 113 124 141 149 160

Flow

(L/s) 3.1 3.4 3.9 4.7 4.7 5.2 5.5 5.9 6.4 7.1 7.8 8.9 9.4 10.1

(gpm) 175 193 223 271 271 298 316 344 370 415 456 515 545 586

Flow

(L/s) 11.0 12.2 14.1 17.1 17.1 18.8 19.9 21.7 23.3 26.2 28.7 32.5 34.4 37.0

NPS55555556666666

Water

mm 125 125 125 125 125 125 125 150 150 150 150 150 150 150

(gal) 11.9 11.9 13.8 15.3 16.6 16.6 18.0 21.6 22.9 24.6 26.2 31.1 31.1 35.2

Water

(L) 45.1 45.1 52.2 58.1 62.7 62.7 68.3 81.7 86.8 93.0 99.2 117.8 117.8 133.3

(gpm) 87 87 106 117 130 130 145 159 173 189 206 244 244 286

Flow

(L/s) 5.5 5.5 6.7 7.4 8.2 8.2 9.1 10.0 10.9 11.9 13.0 15.4 15.4 18.0

(gpm) 317 317 387 427 473 473 528 584 634 695 755 896 896 1047

Flow

(L/s) 20.0 20.0 24.4 26.9 29.8 29.8 33.3 36.8 40.0 43.8 47.6 56.5 56.5 66.1

22222222222222

99.2/

(lb)

99.2

(kg) 45/45 45/45 44/44 55/55 55/56 55/55 54/54 61/61 60/62 61/61 60/62 81/81 80/83 82/82

7.2/

(qts)

6.8/

(L)

7.2

6.8

99.2/

99.2

7.2/

7.2

6.8/

6.8

97/97

7.2/

7.2

6.8/

6.8

121.3/

121.3

7.2/

7.2

6.8/

6.8

121.3/

123.5

7.2/

10.5

6.8/

9.9

121.3/

121.3

10.5/

10.5

9.9/

9.9

119/

119

10.5/

10.5

9.9/

9.9

134.5/

134.5

10.5/

10.5

9.9/

9.9

132.3/

136.7

10.5/

10.5

9.9/

9.9

134.5/

134.5

10.5/

10.5

9.9/

9.9

132.3/

136.7

10.5/

12.4

9.9/

11.7

100/

100

178.6/

178.6

12.4/

12.4

11.7/

11.7

100/

120

176.4/

183.0

12.4/

12.4

11.7/

11.7

120/

120

180.8/

180.8

12.4/

12.4

11.7/

11.7

RLC-SVX09H-EN 15

Page 16

General Information

Table 8. General Data - RTWD 50 Hz - premium efficiency

Size 160 180 200

Compressor M2/M2 M2/N1 N1/N1

Quantity 2 2 2

Nominal Size 85/85 85/100 100/100

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 6 6 6

mm 150 150 150

Water Storage (gal) 29.3 31.3 31.8

(L) 110.9 118.3 120.3

Minimum Flow (gpm) 186 202 240

(L/s) 11.8 12.7 15.1

Maximum Flow (gpm) 683 739 879

(L/s) 43.1 46.7 55.5

3 Pass Arrangement

Water Conn. Size NPS 4 4 4

mm 100 100 100

Water Storage (gal) 28.6 30.6 31.0

(L) 108.3 115.7 117.5

Minimum Flow (gpm) 124 134 160

(L/s) 7.8 8.5 10.1

Maximum Flow (gpm) 456 493 586

(L/s) 28.7 31.1 37.0

Condenser

Water Conn. Size NPS 6 6 6

mm 150 150 150

Water Storage (gal) 30.0 34.5 39.2

(L) 113.4 130.6 148.3

Minimum Flow (gpm) 206 244 325

(L/s) 13.0 15.4 20.5

Maximum Flow (gpm) 755 896 1193

(L/s) 47.6 56.5 75.3

General Unit

Refrigerant Type R-134a R-134a R-134a

# Refrig Circuits 2 2 2

Refrigerant Charge (lb) 176.4/176.4 176.6/178.6 176.4/174.2

(kg) 80/80 79/81 80/79

Oil Charge (qts) 10.5/10.5 10.5/12.4 12.4/12.4

(L) 9.9/9.9 9.9/11.7 11.7/11.7

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

16 RLC-SVX09H-EN

Page 17

Pre-Installation

Inspection Checklist

When the unit is delivered, verify that it is the correct unit

and that it is properly equipped. Compare the information

which appears on the unit nameplate with the ordering

and submittal information. See “Model Number

Descriptions,” p. 7.

Inspect all exteriorcomponents for visibledamage. Report

any apparent damage or material shortage to the carrier

and make a “unit damage” notation on the carrier's

delivery receipt. Specify the extent and type of damage

found and notify the appropriateTrane Sales Office.

Important: Do not proceed with installation of a

damaged unit without sales office approval.

To protect against loss due to damage incurred in transit,

complete the following checklist upon receipt of the unit.

• Inspect the individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

• Inspect the unit for concealed damage as soon as

possible after delivery and before it is stored.

Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the

shipment. Do not remove damaged material from the

receiving location.Take photos of the damage, if

possible.The owner must provide reasonable

evidence that the damage did not occur after delivery.

• Notify the carrier's terminal of the damage

immediately, by phone and by mail. Request an

immediate, joint inspection of the damage with the

carrier and the consignee.

• Notify theTrane sales representative and arrange for

repair. Do not repair the unit, however, until damage is

inspected by the carrier's representative.

Unit Storage

If the chiller is to be stored for more than one month prior

to installation, observe the following precautions:

• Do not remove the protective coverings from the

electrical panel.

• Store the chiller in a dry, vibration-free, secure area.

• At least every three months, attach a gauge and

manually check the pressure in the refrigerant circuit.

If the refrigerant pressure is below 71 psigat 70 F (or 46

psig at 50 F), call a qualified service organization and

the appropriateTrane sales office.

Note: Pressure will be approximately 20 psig if shipped

with the optional nitrogen charge.

Installation requirements and Contractor responsibilities

A list of the contractor responsibilities typically associated

with the unit installation process is provided in Table 9.

Note: Unit Start-up must be completed by a qualified

Trane service technician.

Table 9. Installation requirements

Type of

Rqmt

Foundation • Meet foundation

Rigging • Safety chains

Isolation • Isolation

Electrical • Circuit

Water

piping

Relief • Single relief

Insulation • Insulation

Water

Piping

Connection

Componen

ts

Other

Materials

Trane Supplied

breakers or

fusible

disconnects

(optional)

• Unit mounted

starter

• Flow

switches

(optional)

valve

• Dual relief

valves (opt)

• High humidity

insulation (opt)

• Grooved pipe

• Grooved pipe

to flanged

connection

(opt)

Field

Installed

pads or

neoprene

isolators

(opt)

• Flow

switches

(may be

field

supplied)

• Water

regulating

valve

(optional)

• Flow

switches

(may be

field

supplied)

• Water

regulating

valve

(optional)

Field Supplied

Field InstalledTrane Installed

requirements

Clevis connectors

Lifting beam

• Isolation pads or neoprene

isolators (optional)

• Circuit breakers or fusible

disconnects (opt)

• Electrical connections to unit

mounted starter (opt)

• Electrical connections to

remote mounted starter

(opt)

• Wiring sizes per submittal

and NEC

• Terminal lugs

• Ground connection(s)

• BAS wiring (opt)

• Control voltage wiring

• Chilled water pump

contactor and wiring

including interlock

• Condenser water pump

contactor and wiring

including interlock

• Option relays and wiring

• Taps for thermometers and

gauges

• Thermometers

• Strainers (as required)

• Water flow pressure gauges

• Isolation and balancing

valves in water piping

• Vents and drain on waterbox

valves

• Pressure relief valves (for

waterboxes as required)

• Vent line and flexible

connector and vent line from

relief valve to atmosphere

• Insulation

• R-134a refrigerant (1 lb.

max per machine as needed)

• Dry nitrogen (20 psig max

per machine as needed)

RLC-SVX09H-EN 17

Page 18

Unit Dimensions/Weights

Service Clearances and Dimension

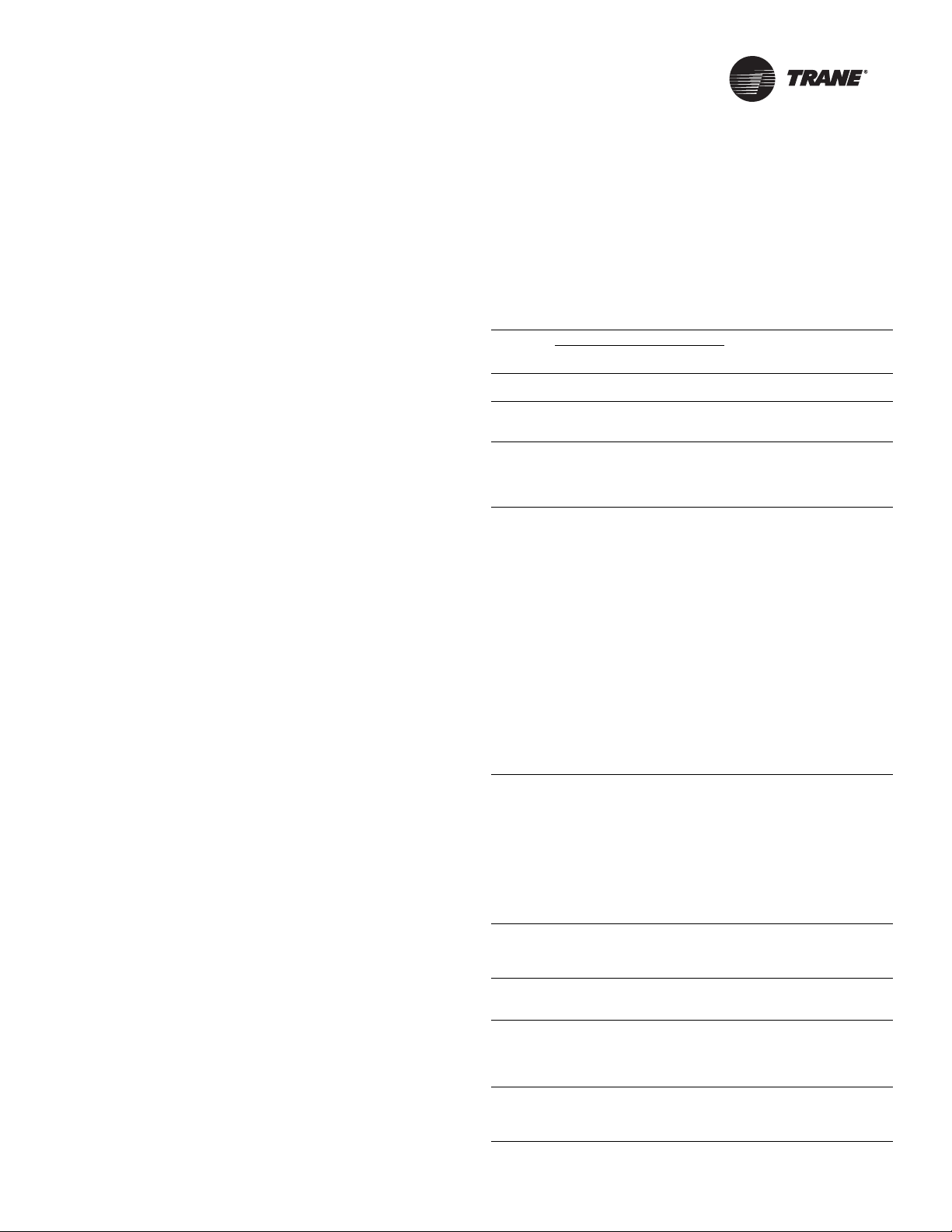

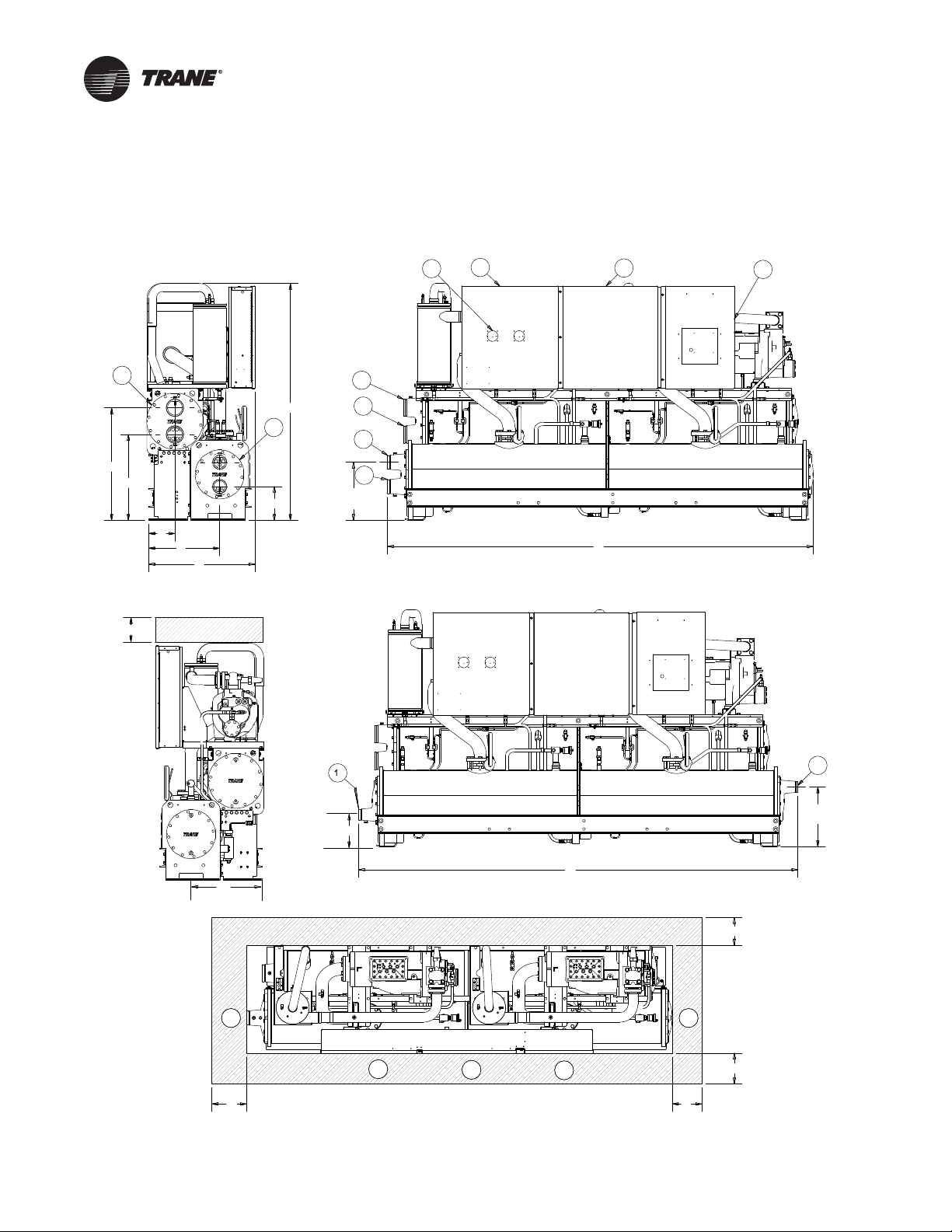

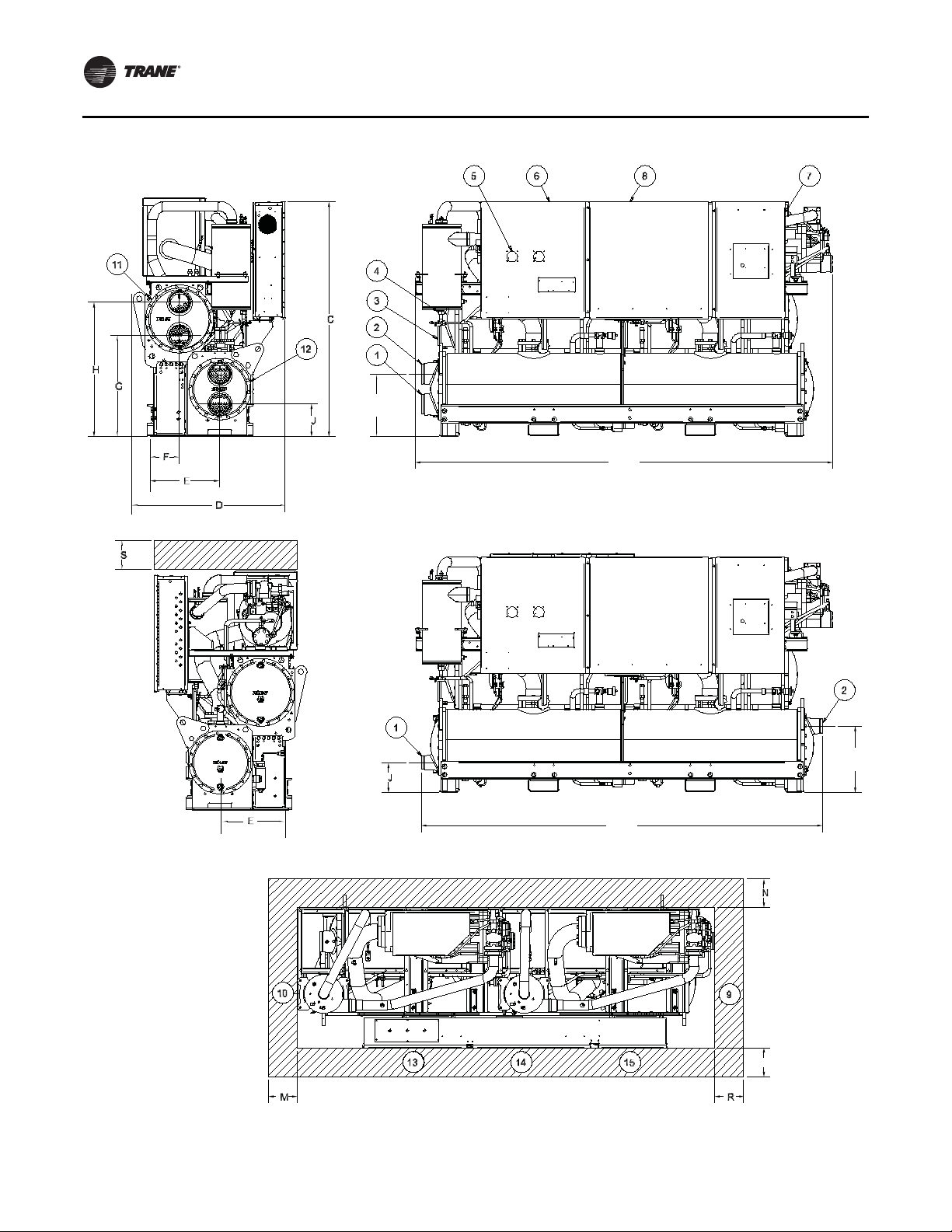

Figure 4. RTWD/RTUD – 60 Hz dimensions – 80-140 ton

5

11

C

12

H

G

J

F

E

D

4

3

2

1

K

(2 pass evap)

2 pass evap

6

8

( 2 pass evap )

A

7

3 pass evap

S

2

L

(3 pass evap)

E

( 3 pass evap )

10

M

1

J

( 3 pass evap )

B

N

9

13

14

15

R

N

18 RLC-SVX09H-EN

Page 19

Unit Dimensions/Weights

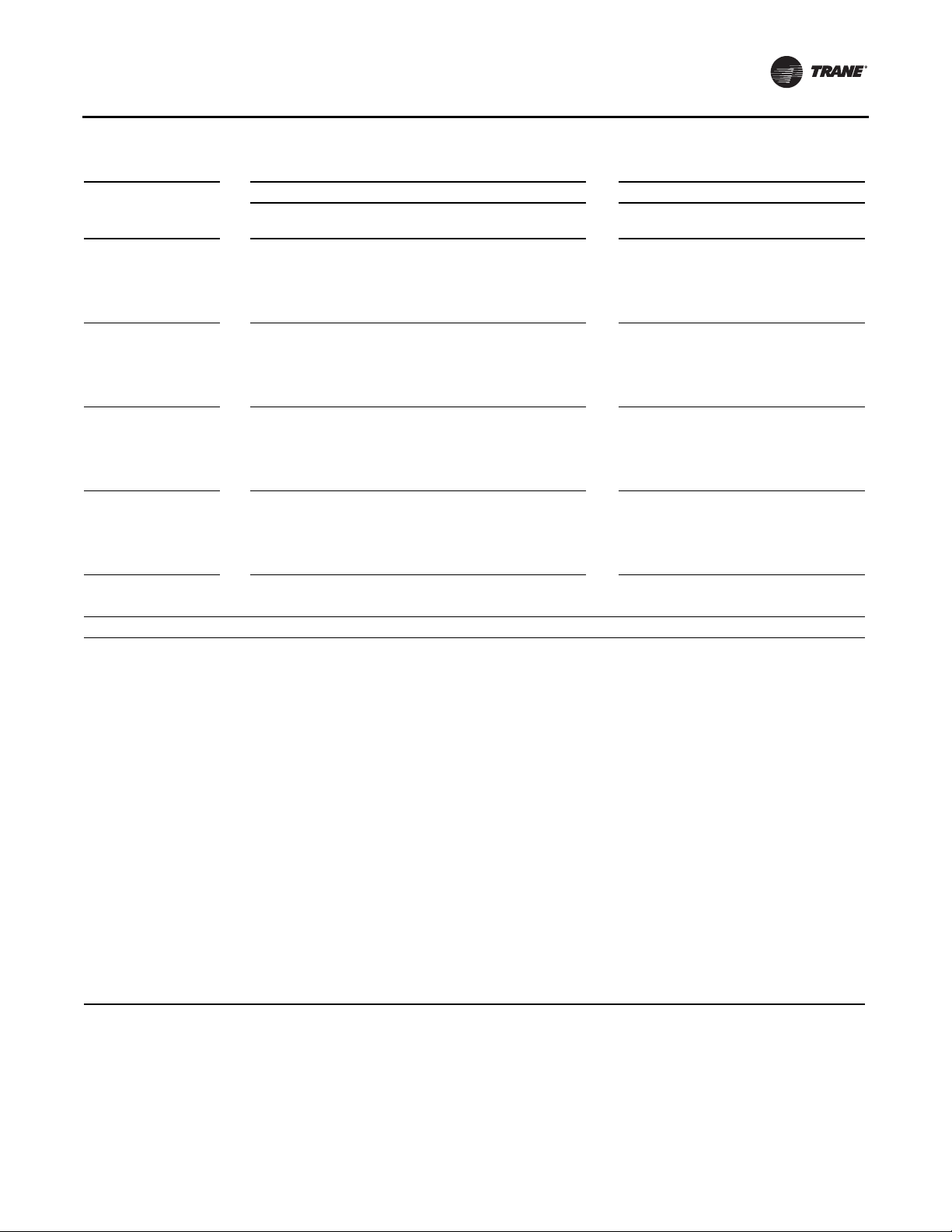

Table 10. RTWD/RTUD – 60 Hz dimensions – 80-140 ton

Standard Efficiency RTWD/RTUD - High Efficiency

A (2 pass evap)

B (3 pass evap)

C

D

E

F

G

H

J (2 pass evap)

J (3 pass evap)

K (2 pass evap)

L (3 pass evap)

M

N*

R

S

80,90

inch (mm)

138.2 (3510) 138.2 (3510) 138.8 (3525) 126.4 (3210) 126.9 (3225)

142.6 (3621) 142.6 (3621) 142.6 (3621) 130.8 (3321) 130.7 (3320)

75.9 (1929) 76.9 (1955) 76.9 (1955) 76.1 (1933) 76.9 (1955)

34.3 (871) 34.3 (871) 34.8 (884) 35.1 (890) 35.1 (890)

23.6 (600) 23.6 (600) 23.6 (600) 23.6 (600) 23.6 (600)

9.1 (231) 9.1 (231) 9.1 (231) 9.1 (231) 9.1 (231)

27.9 (709) 27.9 (709) 27.9 (709) 27.9 (709) 27.9 (709)

36.6 (929) 36.6 (929) 36.6 (929) 36.6 (929) 36.6 (929)

11.0 (280) 11.0 (280) 10.6 (268) 10.8 (273) 11.8 (299)

10.4 (265) 10.4 (265) 10.1 (256) 10.2 (258) 11.3 (287)

18.9 (479) 18.9 (479) 19.2 (487) 18.6 (472) 20.4 (519)

19.5 (495) 19.5 (495) 19.5 (496) 19.2 (488) 19.2 (487)

36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

36 (914)* 36 (914)* 36 (914)* 36 (914)* 36 (914)*

127 (3226) 127 (3226) 127 (3226) 115 (2921) 115 (2921)

36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

100,110

inch (mm)

120,130,140

inch (mm)

80,90

inch (mm)

100,110,120,130

inch (mm)

Reference

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

*

**

Evaporator Water Inlet

Evaporator Water Outlet

Condenser Water Inlet (RTWD only)

Condenser Water Outlet (RTWD only)

Power Disconnect

Power Wire

Control Wire

Control Panel

Condenser Return Waterbox End (RTWD only) - minimum clearance (for tube removal)

Condenser Supply Waterbox End (RTWD only) - minimum clearance (for maintenance)

Condenser (RTWD only)

Evaporator

Panel Power Section - door swing 31.3 inch (796.9 mm)

Panel Power Section - door swing 31.1 inch (790.1 mm)

Panel Control Section - door swing 22.4 inch (568.14 mm)

42 inch (1067 mm) clearance required to other ground parts, two units with panels facing each other or other live parts

require a clearance of 48 inch (1220 mm)

Sound attenuator may increase the footprint - submittal should be used.

RLC-SVX09H-EN 19

Page 20

Unit Dimensions/Weights

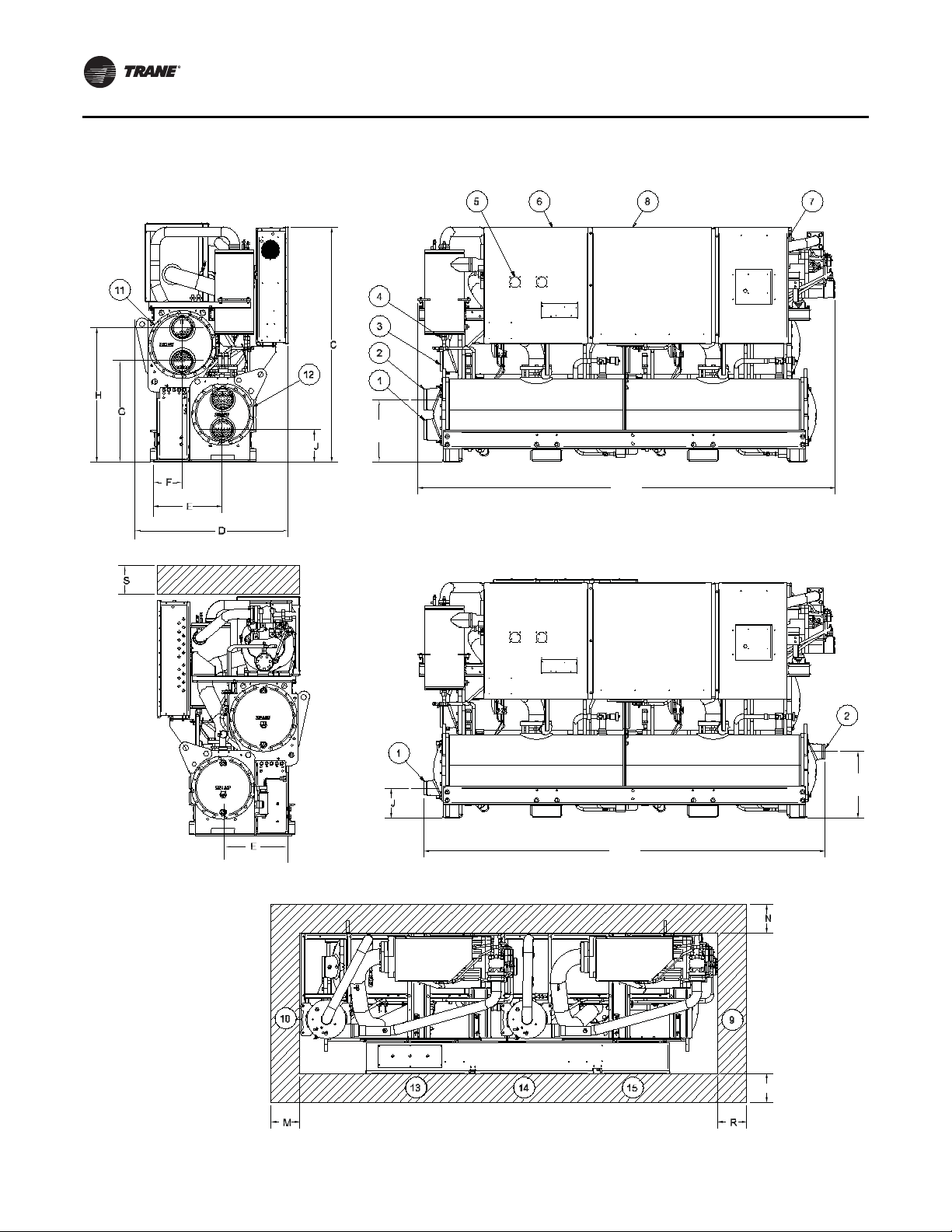

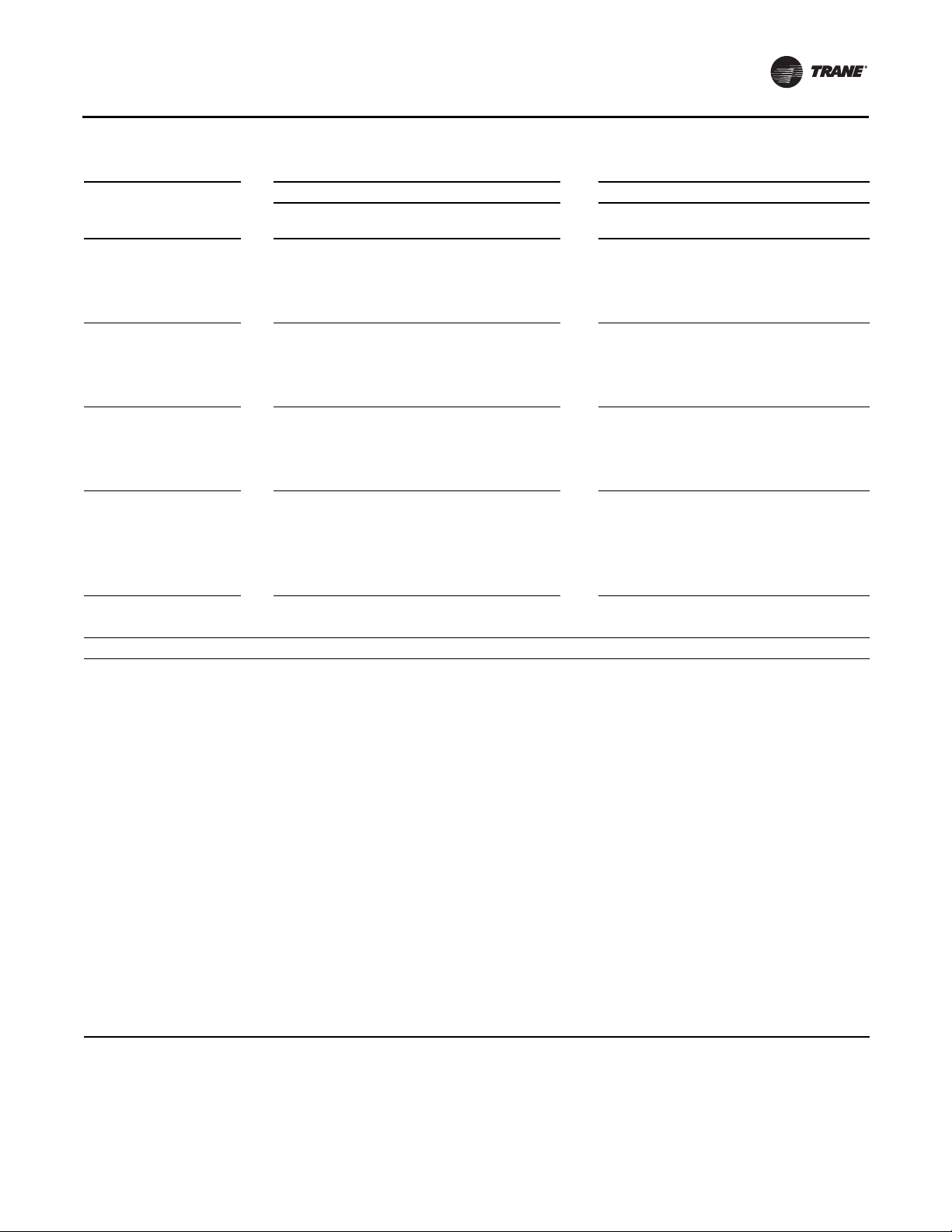

Figure 5. RTWD/RTUD – 60 Hz dimensions – 150-250 tons

K

(2 pass evap)

( 2 pass evap )

A

2 pass evap

(3 pass evap)

( 3 pass evap )

B

3 pass evap

L

(3 pass evap)

P

20 RLC-SVX09H-EN

Page 21

Unit Dimensions/Weights

Table 11. RTWD/RTUD – 60 Hz dimensions – 150-250 tons

A (2 pass evap)

B (3 pass evap)

C

D

E

F

G

H

J (2 pass evap)

J (3 pass evap)

K (2 pass evap)

L (3 pass evap)

M

N

P*

R

S

RTWD

High Efficiency Prem Efficiency

150-200

inch (mm)

132.3 (3360) 136.1 (3456) 147.9 (3755) 126.9 (3225) 132.3 (3360) 132.3 (3360)

132.8 (3371) 136.1 (3456) 150.9 (3831) 130.8 (3321) 132.8 (3371) 132.9 (3376)

75.6 (1920) 76.9 (1955) 76.8 (1950) 76.9 (1955) 75.6 (1920) 76.7 (1949)

47.3 (1202) 47.8 (1213) 47.3 (1202) 37.9 (962) 47.4 (1203) 47.4 (1203)

24.6 (624) 24.8 (630) 24.6 (624) 23.5 (599) 24.5 (624) 24.6 (624)

11.1 (282) 11.2 (295) 11.1 (282) - - -

32.7 (830) 33.1 (840) 33.8 (860) - - -

42.4 (1078) 43.9 (1115) 43.6 (1108) - - -

10.1 (256) 10.6 (270) 10.6 (270) 10.2/259 10.1 (256) 11.3 (263)

9.5 (241) 9.7 (247) 9.7 (247) 9.8/247 9.5 (241) 8.8 (223)

19.3 (490) 20.6 (524) 20.6 (524) 18.9/479 19.3 (490) 19.9 (483)

19.9 (505) 21.6 (549) 21.6 (549) 19.8/501 19.9 (505) 20.7 (526)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

40 (1016)* 40 (1016)* 40 (1016)* 40 (1016)* 40 (1016)* 40 (1016)*

114.8 (2916) 114.8 (2916) 134.5 (3416) 114.8 (2916) 114.8 (2916) 114.8 (2916)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

220, 250

inch (mm)

150-200

inch (mm)

150

inch (mm)

RTUD

160-200

inch (mm)

220,250

inch (mm)

Reference

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

*

**

Evaporator Water Inlet

Evaporator Water Outlet

Condenser Water Inlet (RTWD only)

Condenser Water Outlet (RTWD only)

Power Disconnect

Power Wire

Control Wire

Control Panel

Condenser Return Waterbox End (RTWD only) - minimum clearance (for tube removal)

Condenser Supply Waterbox End (RTWD only) - minimum clearance (for maintenance)

Condenser (RTWD only)

Evaporator

Panel Power Section - door swing 31.3 inch (796.9 mm)

Panel Power Section - door swing 31.1 inch (790.1 mm)

Panel Control Section - door swing 22.4 inch (568.14 mm)

Control panel clearance is 36 or 40 inch (914 or 1016 mm) depending on voltages, starter type, unit application

and local code; 42 inch (1067 mm) clearance required to other grounded parts; two units with panels facing

each other or other live parts require a clearance of 48 inch (1220 mm).

Sound attenuator may increase the footprint - submittal should be used.

RLC-SVX09H-EN 21

Page 22

Unit Dimensions/Weights

v

Figure 6. RTWD - 50 Hz dimensions - 70-150 ton SE, 60-120 ton HE

5

11

C

12

H

G

J

F

E

D

4

3

2

1

K

(2 pass evap)

2 pass evap

6

8

( 2 pass evap )

A

7

3 pass evap

S

2

L

(3 pass e

E

( 3 pass evap )

10

M

1

J

( 3 pass evap )

B

N

9

13

14

15

R

N

22 RLC-SVX09H-EN

Page 23

Unit Dimensions/Weights

Table 12. RTWD – 50 Hz – 70-150 ton SE, 60-120 ton HE

RTWD Standard Efficiency High Efficiency

A (2 pass evap)

B (3 pass evap)

C

D

E

F

G

H

J (2 pass evap)

J (3 pass evap)

K (2 pass evap)

L (3 pass evap)

M

N*

R

S

70,80,90,100,110

inch (mm)

138.2 (3510) 138.8 (3525) 126.4 (3210) 127.0 (3225) 127.0 (3225)

142.6 (3621) 145.6 (3621) 130.8 (3321) 130.7 (3320) 130.7 (3320)

75.9 (1929) 76.9 (1955) 76.1 (1933) 76.1 (1933) 76.9 (1955)

34.3 (871) 34.8 (884) 35.1 (890) 35.1 (890) 35.1 (890)

23.6 (600) 23.6 (600) 23.6 (600) 23.6 (600) 23.6 (600)

9.1 (231) 9.1 (231) 9.1 (231) 9.1 (231) 9.1 (231)

27.9 (709) 27.9 (709) 27.9 (709) 27.9 (709) 27.9 (709)

36.6 (929) 36.6 (929) 36.6 (929) 36.6 (929) 36.6 (929)

11.0 (280) 10.6 (268) 10.8 (273) 11.8 (299) 11.8 (299)

10.4 (265) 10.1 (256) 10.2 (258) 11.3 (287) 11.3 (287)

18.9 (479) 19.2 (487) 18.6 (472) 20.4 (519) 20.4 (519)

19.5 (495) 19.5 (496) 19.2 (488) 19.2 (487) 19.2 (487)

36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

36 (914)* 36 (914)* 36 (914)* 36 (914)* 36 (914)*

127 (3226) 127 (3226) 115 (2921) 115 (2921) 115 (2921)

36 (914) 36 (914) 36 (914) 36 (914) 36 (914)

120,130,140,150

inch (mm)

60,70,80

inch (mm)

90

inch (mm)

100,110,120

inch (mm)

Reference

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

*

**

Evaporator Water Inlet

Evaporator Water Outlet

Condenser Water Inlet

Condenser Water Outlet

Power Disconnect

Power Wire

Control Wire

Control Panel

Condenser Return Waterbox End - minimum clearance (for tube removal)

Condenser Supply Waterbox End - minimum clearance (for maintenance)

Condenser

Evaporator

Panel Power Section - door swing 31.3 inch (796.9 mm)

Panel Power Section - door swing 31.1 inch (790.1 mm)

Panel Control Section - door swing 22.4 inch (568.14 mm)

42 inch (1067 mm) clearance required to other ground parts, two units with panels facing each other or other live parts

require a clearance of 48 inch (1220 mm)

Sound attenuator may increase the footprint - submittal should be used.

RLC-SVX09H-EN 23

Page 24

Unit Dimensions/Weights

Figure 7. RTWD - 50 Hz dimensions - 130-250 ton HE, 160-200 ton PE

K

(2 pass evap)

( 2 pass evap )

A

2 pass evap

3 pass evap

L

(3 pass evap)

( 3 pass evap )

(3 pass evap)

B

P

24 RLC-SVX09H-EN

Page 25

Unit Dimensions/Weights

Table 13. RTWD – 50 Hz dimensions – 130-250 ton HE, 160-200 ton PE

RTWD High Efficiency Premium Efficiency

A (2 pass evap)

B (3 pass evap)

C

D

E

F

G

H

J (2 pass evap)

J (3 pass evap)

K (2 pass evap)

L (3 pass evap)

M

N

P*

R

S

130, 140, 160, 180

inch (mm)

132.3 (3360) 136.1 (3456) 147.9 (3755) 136.1 (3456)

132.8 (3371) 136.1 (3456) 150.8 (3831) 136.1 (3456)

75.6 (1920) 76.8 (1949) 76.8 (1950) 76.9 (1955)

47.3 (1202) 47.8 (1213) 47.3 (1202) 47.8 (1213)

24.6 (624) 24.8 (630) 24.6 (624) 24.8 (630)

11.1 (282) 11.6 (295) 11.1 (282) 11.6 (295)

32.7 (830) 33.1 (840) 33.8 (860) 33.1 (840)

42.4 (1078) 43.9 (1115) 43.6 (1108) 43.9 (1115)

10.1 (256) 10.6 (270) 10.6 (270) 10.6 (270)

9.5 (241) 9.7 (247) 9.7 (247) 9.7 (247)

19.3 (490) 20.6 (524) 20.6 (524) 20.6 (524)

19.9 (505) 21.6 (549) 21.6 (550) 21.6 (549)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

40 (1016)* 40 (1016)* 40 (1016)* 40 (1016)*

114.8 (2916) 114.8 (2916) 134.5 (3416) 134.5 (3416)

36.0 (914) 36.0 (914) 36.0 (914) 36.0 (914)

200, 220, 250

inch (mm)

160, 180

inch (mm)

200

inch (mm)

Reference

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

*

**

Evaporator Water Inlet

Evaporator Water Outlet

Condenser Water Inlet

Condenser Water Outlet

Power Disconnect

Power Wire

Control Wire

Control Panel

Condenser Return Waterbox End - minimum clearance (for tube removal)

Condenser Supply Waterbox End - minimum clearance (for maintenance)

Condenser

Evaporator

Panel Power Section - door swing 31.3 inch (796.9 mm)

Panel Power Section - door swing 31.1 inch (790.1 mm)

Panel Control Section - door swing 22.4 inch (568.14 mm)

Control panel clearance is 36 or 40 inch (914 or 1016 mm) depending on voltages, starter type, unit application and

local code; 42 inch (1067 mm) clearance required to other grounded parts; two units with panels facing each other

or other live parts require a clearance of 48 inch (1220 mm).

Sound attenuator may increase the footprint - submittal should be used.

RLC-SVX09H-EN 25

Page 26

Unit Dimensions/Weights

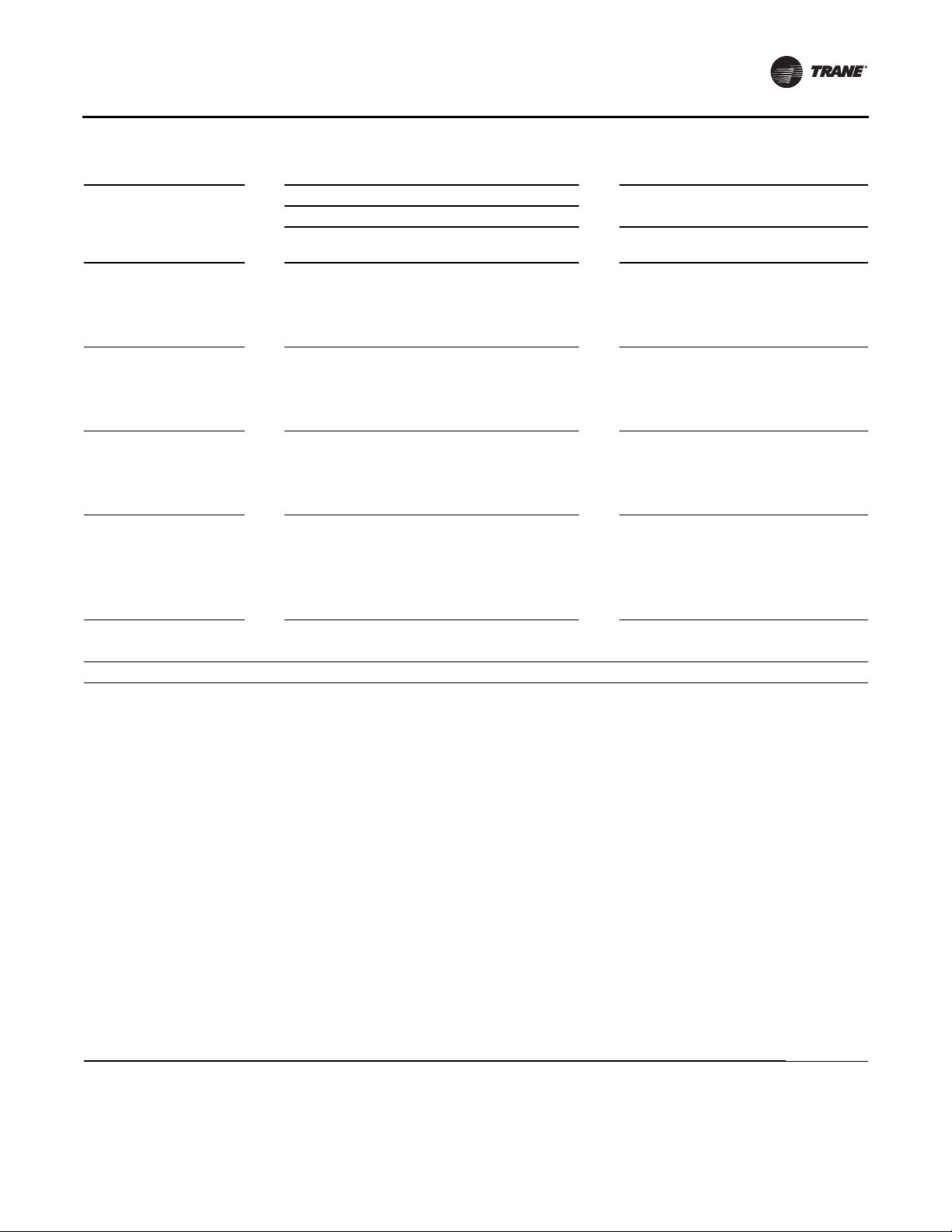

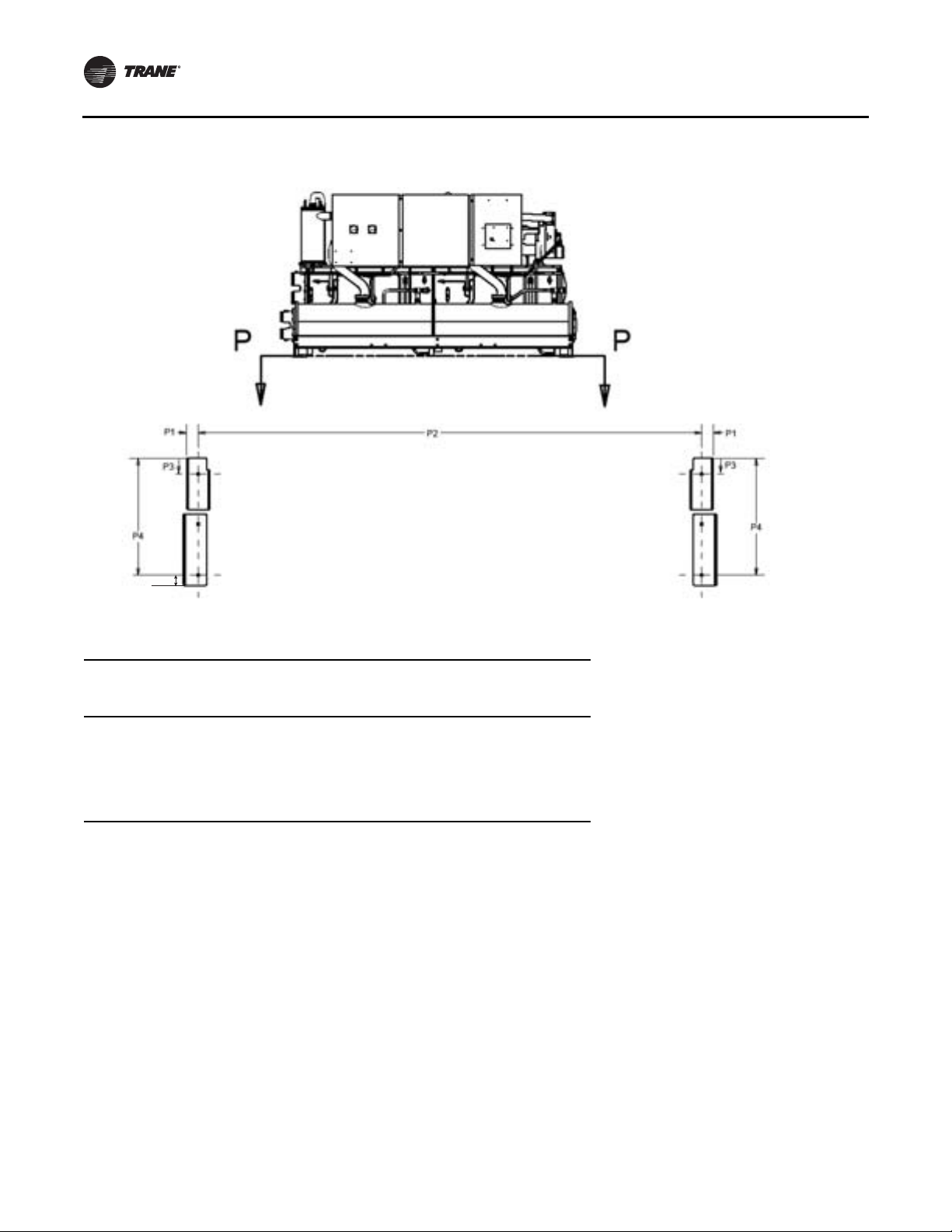

Figure 8. RTWD/RTUD Unit footprint

P5

Table 14. RTWD/RTUD – unit footprint – all sizes

Standard Efficiency

inch (mm) inch (mm) inch (mm)

P1

P2

P3

P4

P5

Note: Base hole diameters all 0.63 inch (16 mm).

3.68 (93.5) 3.68 (93.5) 3.68 (93.5)

123.78 (3144) 111.97 (2844) 131.65 (3344)

2.43 (61.8) 4.30 (109.3) 4.30 (109.3)

24.93 (633.2) 24.93 (633.2) 24.93 (633.2)

2.5 (64) 2.5 (64) 2.5 (64)

High Efficiency

200 PE (50 Hz)

Premium Efficiency

26 RLC-SVX09H-EN

Page 27

Unit Dimensions/Weights

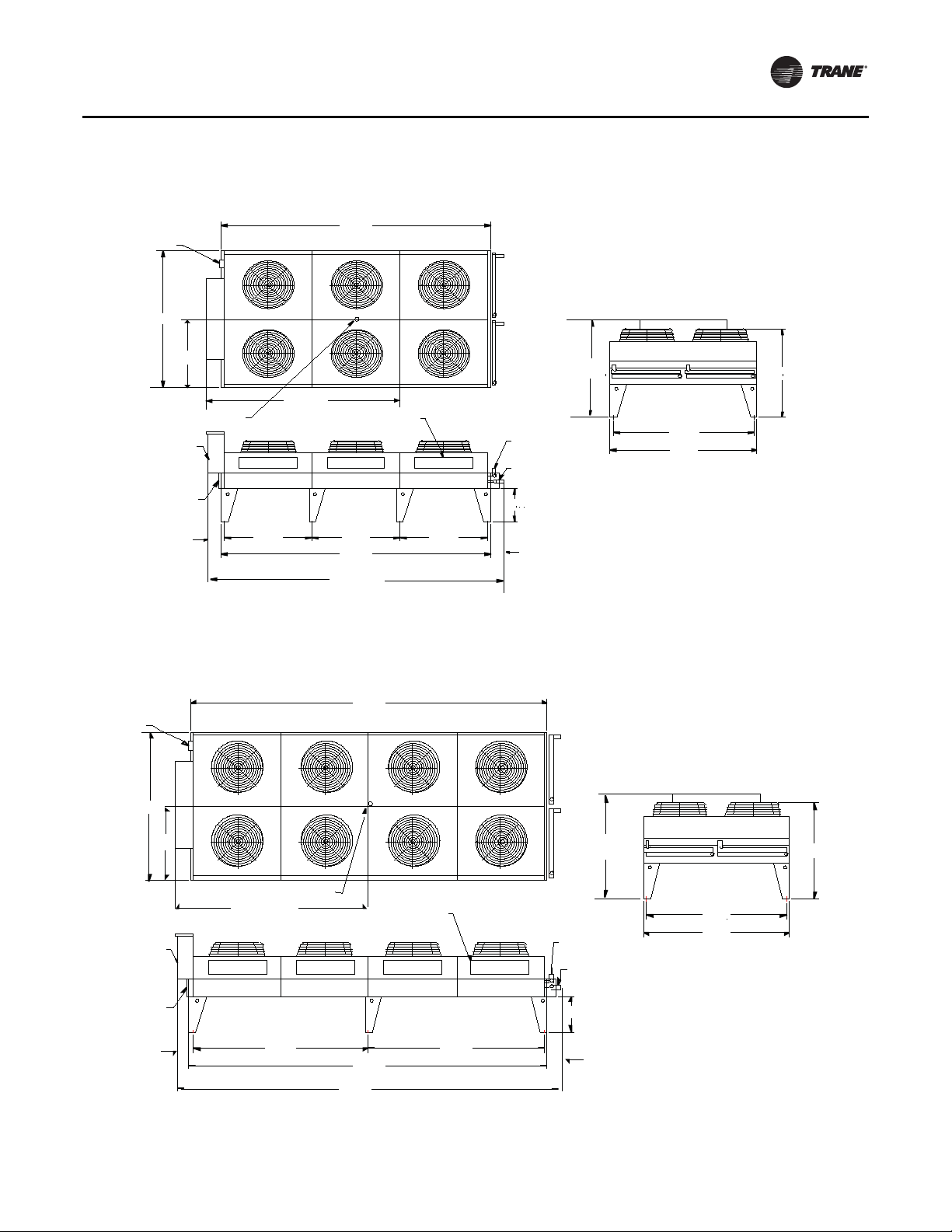

Figure 9. Trane air-cooled condenser -

80T, 150T (cond 1 & 2), 160T (cond 1 & 2), 180T (cond 1)

Disconnect

Approx. center of gravity

Electrical box

split controls

Return bend cover

90.5‚

switch

45.25‚

10.0‚

93.0‚

54.0‚ 54.0‚

Figure 10. Trane air-cooled condenser -

90T, 100T, 110T, 180T (cond 2), 200T (cond 1 & 2), 220T (cond 1 & 2), 250T (cond1&2)

166.0‚

Service panel

166.0‚

184.0‚

54.0‚

64.0‚

Inlet connection

Outlet connection

22.0‚

8.0‚

58.5‚

86.5‚

90.5‚

0.75 inch anchor holes

Disconnect switch

90.5‚

45.25‚

Electrical box

split controls

Return bend cover

10.0‚

Approx. center of gravity

120.0‚

108.0‚

220.0‚

Service panel

220.0‚

238.0‚

108.0‚

64.0‚

Inlet connection

Outlet connection

22.0‚

8.0‚

0.75 inch anchor holes

58.5‚

86.5‚

90.5‚

RLC-SVX09H-EN 27

Page 28

Unit Dimensions/Weights

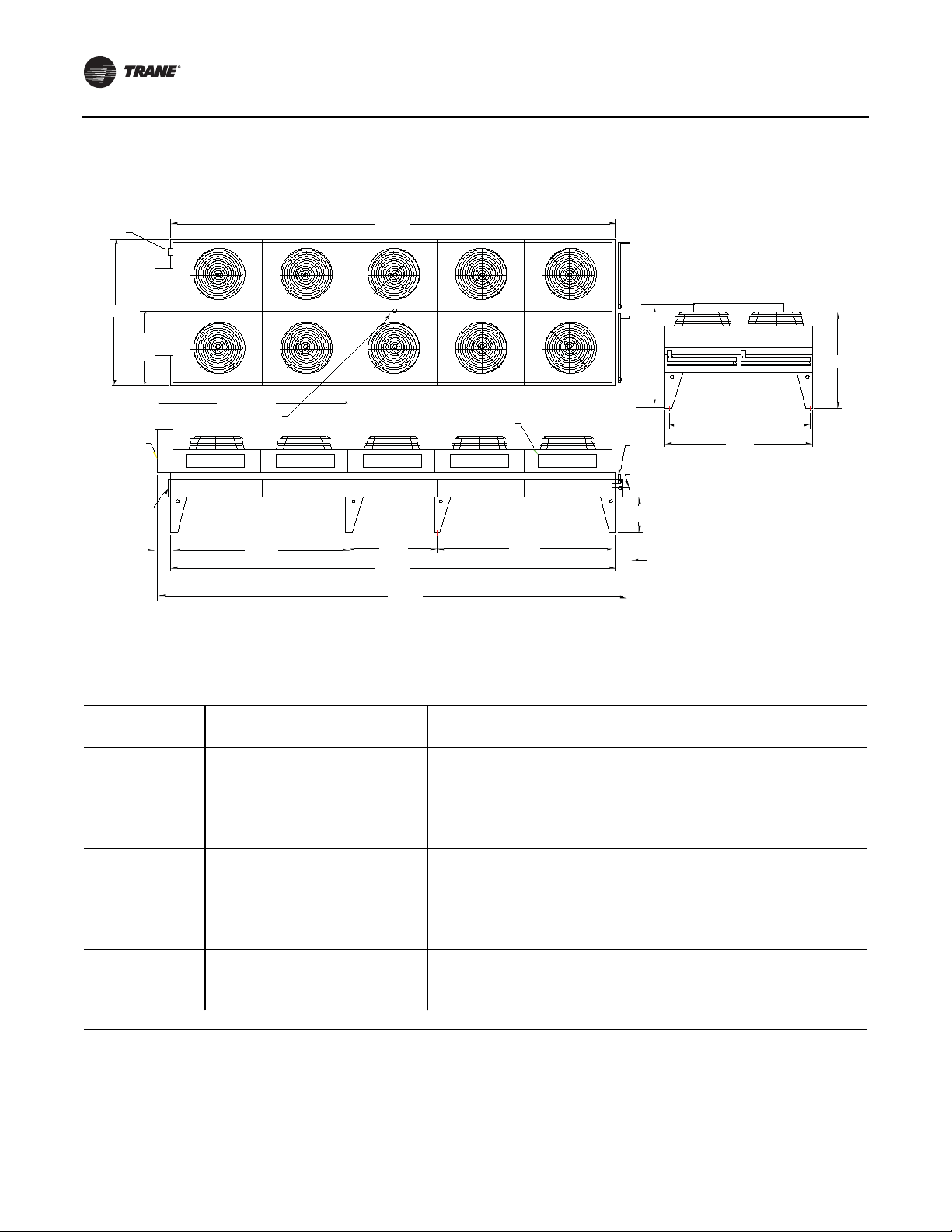

Figure 11. Trane air-cooled condenser - 120T, 130T

Disconnect

switch

90.5‚

45.25‚

Electrical box

split controls

Return

bend cover

10.0‚

Weights

Approx. center of gravity

145.0‚

108.0‚

274.0‚

54.0‚

274.0‚

292.0‚

108.0‚

64.0‚

Inlet connection

Outlet connection

22.0‚

8.0‚

58.5‚

86.5‚

90.5‚

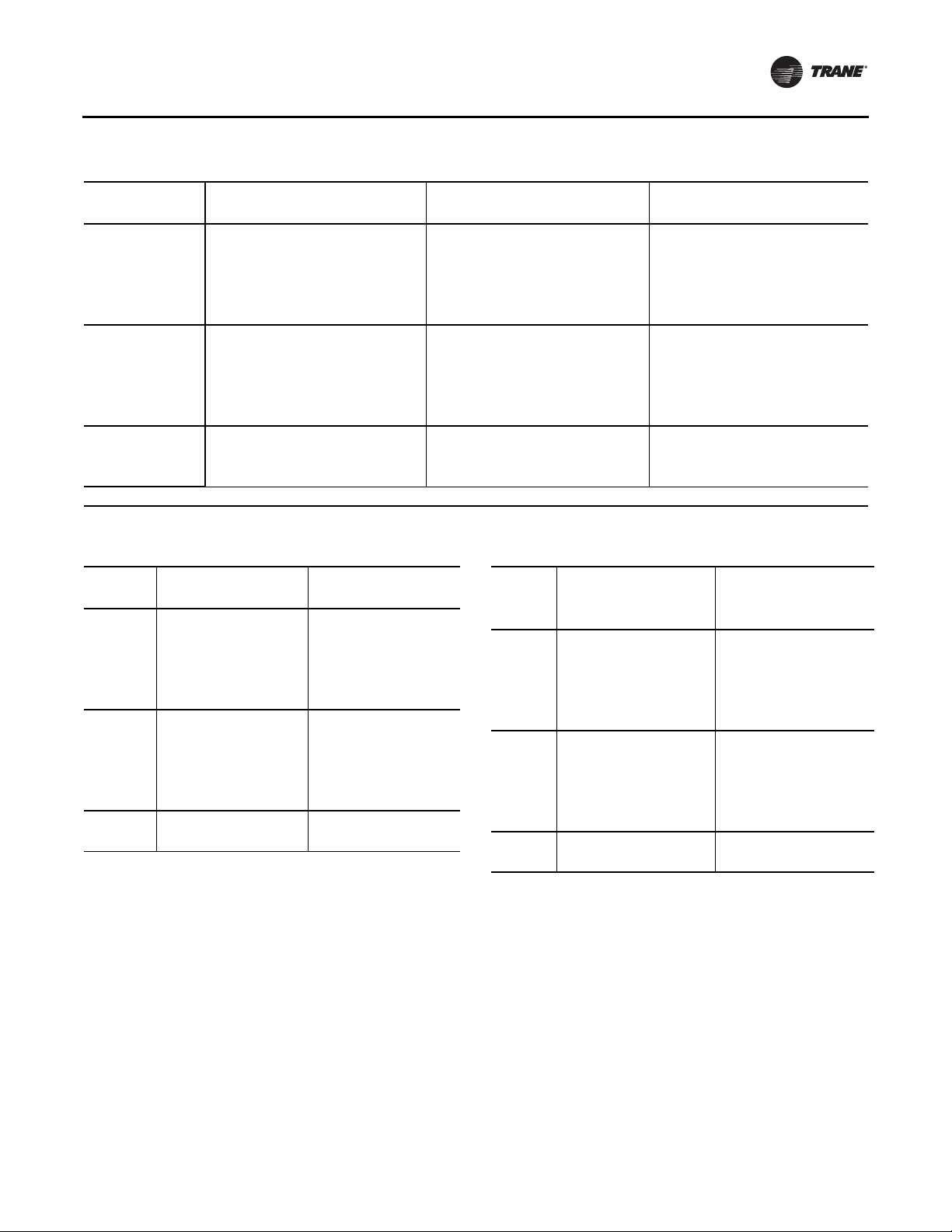

Table 15. Weights - RTWD 60 Hz - IP units

Standard Efficiency High Efficiency Premium Efficiency

Model Operating (lb) Shipping (lb) Operating (lb) Shipping (lb) Operating (lb) Shipping (lb)

80 5900 5703 5732 5551 - -

90 5933 5721 5792 5587 - -

100 6140 5902 6255 6025 - -

110 6332 6074 6475 6208 - -

120 6530 6248 6510 6230 - -

130 6535 6244 6543 6248 - -

140 6971 6649 - - - -

150 - - 7884 7544 8724 8243

160 - - 8395 8036 9171 8691

180 - - 8490 8098 9290 8772

200 - - 8578 8157 9337 8803

220 - - 9493 8995 - -

250 - - 10071 9478 - -

Note: Weights include optional base rail forklifting. Subtract 300 lbs if this option is not selected.

28 RLC-SVX09H-EN

Page 29

Unit Dimensions/Weights

Table 16. Weights - RTWD 60 Hz - SI units

Standard Efficiency High Efficiency Premium Efficiency

Model Operating (kg) Shipping (kg) Operating (kg) Shipping (kg) Operating (kg) Shipping (kg)

80 2676 2587 2600 2518 - -

90 2691 2595 2627 2534 - -

100 2785 2677 2837 2733 - -

110 2872 2755 2937 2816 - -

120 2962 2834 2953 2826 - -

130 2964 2832 2968 2834 - -

140 3162 3016 - - - -

150 - - 3576 3422 3957 3739

160 - - 3808 3645 4160 3942

180 - - 3851 3673 4214 3979

200 - - 3891 3700 4235 3993

220 - - 4306 4080 - -

250 - - 4568 4299 - -

Note: Weights include optional base rail forklifting. Subtract 136.1 kg if this option is not selected.

Table 17. Weights - RTUD - 60 Hz

IP units (lbs) SI units (kg)

Model Operating Shipping Operating Shipping

80 4874 4793 2211 2174

90 4892 4804 2219 2179

100 5073 4974 2301 2256

110 5326 5221 2416 2368

120 5322 5194 2414 2356

130 5322 5194 2414 2356

150 5917 5781 2684 2622

160 6804 6643 3086 3013

180 6876 6715 3119 3046

200 6980 6810 3166 3089

220 7300 7112 3311 3226

250 7602 7401 3448 3357

Note: Weights include optional base rail fork lifting. Subtract 300 lbs if this

option is not selected.

Table 18. Air-Cooled Condenser Weights

RTUD

Tonnage

80 2100 - 953 -

90 2651 - 1202 -

100 2884 - 1308 -

110 2950 - 1338 -

120 4005 - 1817 -

130 4046 - 1835 -

150 2044 2100 927 953

160 2100 2100 953 953

180 2100 2526 953 1146

200 2526 2526 1146 1146

220 2526 2884 1146 1308

250 2884 2884 1308 1308

I-P Units (lbs) SI Units (kg)

Shipping Weight Shipping Weight

Cond 1 Cond 2 Cond 1 Cond 2

RLC-SVX09H-EN 29

Page 30

Unit Dimensions/Weights

Table 19. Weights - RTWD 50 Hz - IP units

Standard Efficiency High Efficiency Premium Efficiency

Model Operating (lb) Shipping (lb) Operating (lb) Shipping (lb) Operating (lb) Shipping (lb)

60 - - 5706 5525 - -

70 5874 5677 5724 5534 - -

80 6030 5807 5893 5680 - -

90 6187 5938 6319 6063 - -

100 6268 6010 6412 6145 - -

110 6332 6014 6495 6220 - -

120 6903 6614 6914 6619 - -

130 7337 7016 8177 7837 - -

140 7342 7020 8245 7884 - -

150 7395 7049 N/A N/A - -

160 - - 8342 7950 9061 8565

180 - - 8770 8351 9579 9030

200 - - 9758 9259 10060 9467

220 - - 9793 9284 - -

250 - - 9958 9398 - -

Note: All weights +/-3%. Weights include optional base rail forklifting. Subtract 300 lbs if this option is not selected.

Table 20. Weights - RTWD 50 Hz - SI units

Standard Efficiency High Efficiency Premium Efficiency

Model Operating (kg) Shipping (kg) Operating (kg) Shipping (kg) Operating (kg) Shipping (kg)

60 - - 2588 2506 - -

70 2664 2575 2596 2510 - -

80 2735 2634 2673 2576 - -

90 2806 2693 2866 2750 - -

100 2843 2726 2908 2787 - -

110 2872 2755 2946 2821 - -

120 3131 3000 3136 3002 - -

130 3328 3182 3709 3555 - -

140 3330 3184 3740 3576 - -

150 3354 3197 - - - -

160 - - 3784 3606 4110 3885

180 - - 3979 3788 4345 4096

200 - - 4426 4200 4563 4294

220 - - 4442 4211 - -

250 - - 4517 4263 - -

Note: Weights include optional base rail forklifting. Subtract 136.1 kg if this option is not selected.

30 RLC-SVX09H-EN

Page 31

Installation - Mechanical

Location Requirements

Noise Considerations

• Refer toTrane Engineering Bulletin -Series R

Sound Ratings and Installation Guide for sound

consideration applications.

• Locate the unit away from sound-sensitive areas.

• Install the isolation pads under the unit. Refer to“Unit

Isolation.”

• Install rubber vibration isolators in all water piping.

• Seal all wall penetrations.

Note: Consult an acoustical engineer for critical

applications.

Foundation

Provide rigid, non-warping mounting pads or a concrete

foundation of sufficient strength and mass to support the

applicable operating weight (i.e., including completed

piping, and full operating charges of refrigerant, oil and

water). See “Unit Dimensions/Weights” chapter for unit

operating weights. Once in place, the unit must be level

within 1/4” (6.4 mm) over its length and width.TheTrane

Company is not responsible for equipment problems

resulting from an improperly designed or constructed

foundation.

Clearances

Provide enough space around the unit to allow the

installation and maintenance personnel unrestricted

access to allservice points. Refer to submittal drawings for

the unit dimensions, to provide sufficient clearance for the

opening of control panel doors and unit service. Refer to

the chapter on “Unit Dimensions/Weights” for minimum

clearances. In all cases, local codes which require

additional clearances will take precedence over these

recommendations.

Note: Required vertical clearance above the unit is 36”

(914.4 mm).There should be no piping or conduit

located over the compressor motor. If the unit

configuration requires a variance to the clearance

dimensions, contact yourTrane Sales Office

Representative. Also refer toTrane Engineering

Bulletins for application information on RTWD/

RTUD chillers.

Chiller

center of gravity dimensions. Refer to the rigging label

attached to the unit for further details.\

WARNING

Heavy Objects!

• Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of

the cables (chains or slings), hooks, and shackles

used to lift the unit must be capable of supporting the

entire weight of the unit.

• Lifting cables (chains or slings) may not be of the

same length. Adjust as necessary for even unit lift.

• The high center of gravity on this unit requires the use

of an anti-rolling cable (chain or sling).To prevent unit

from rolling, attach cable (chain or sling) with no

tension and minimal slack around compressor

suction pipe as shown.

• Do not use fork lift to move or lift unit unless unit has

lifting base with locations marked by caution labels

installed.

Other lifting arrangements could cause equipment or

property damage. Failure to follow instructions above

or properly lift unit could result in unit dropping and

possibly crushing operator/technician which could

result in death or serious injury.

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in unit dropping and

possibly crushing operator/technician which could

result in death or serious injury and possible equipment

or property-only damage.

Lifting Procedure

Attach chains or cables to lifting beam, as shown in

Figure .Lifting beam crossbars MUST be positioned so